A Conceptual Framework Based on Current Directives to Design Lithium-Ion Battery Industrial Repurposing Models

Abstract

1. Introduction

2. How to Add Sustainability to the Lithium-Ion Batteries’ Life Cycle: The State of the Art

3. Framework for LIB Repurposing

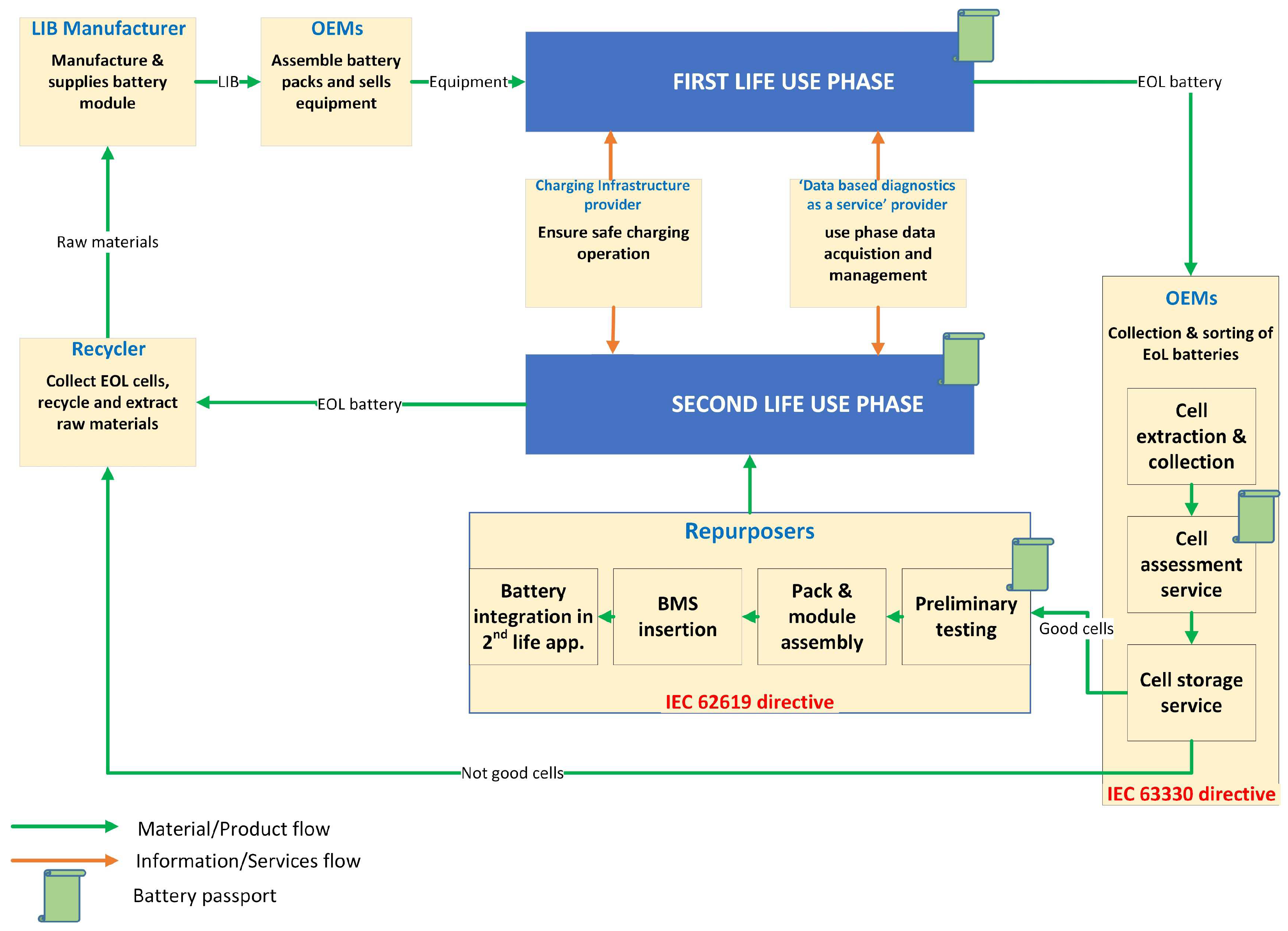

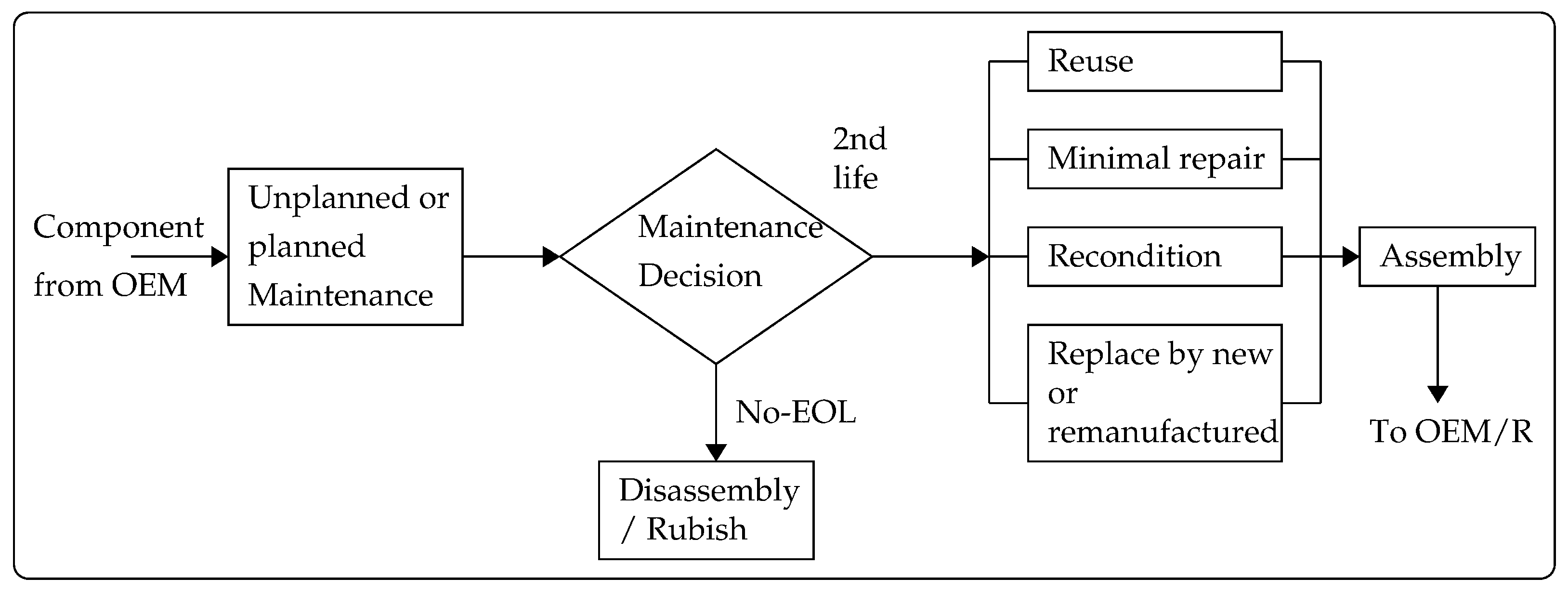

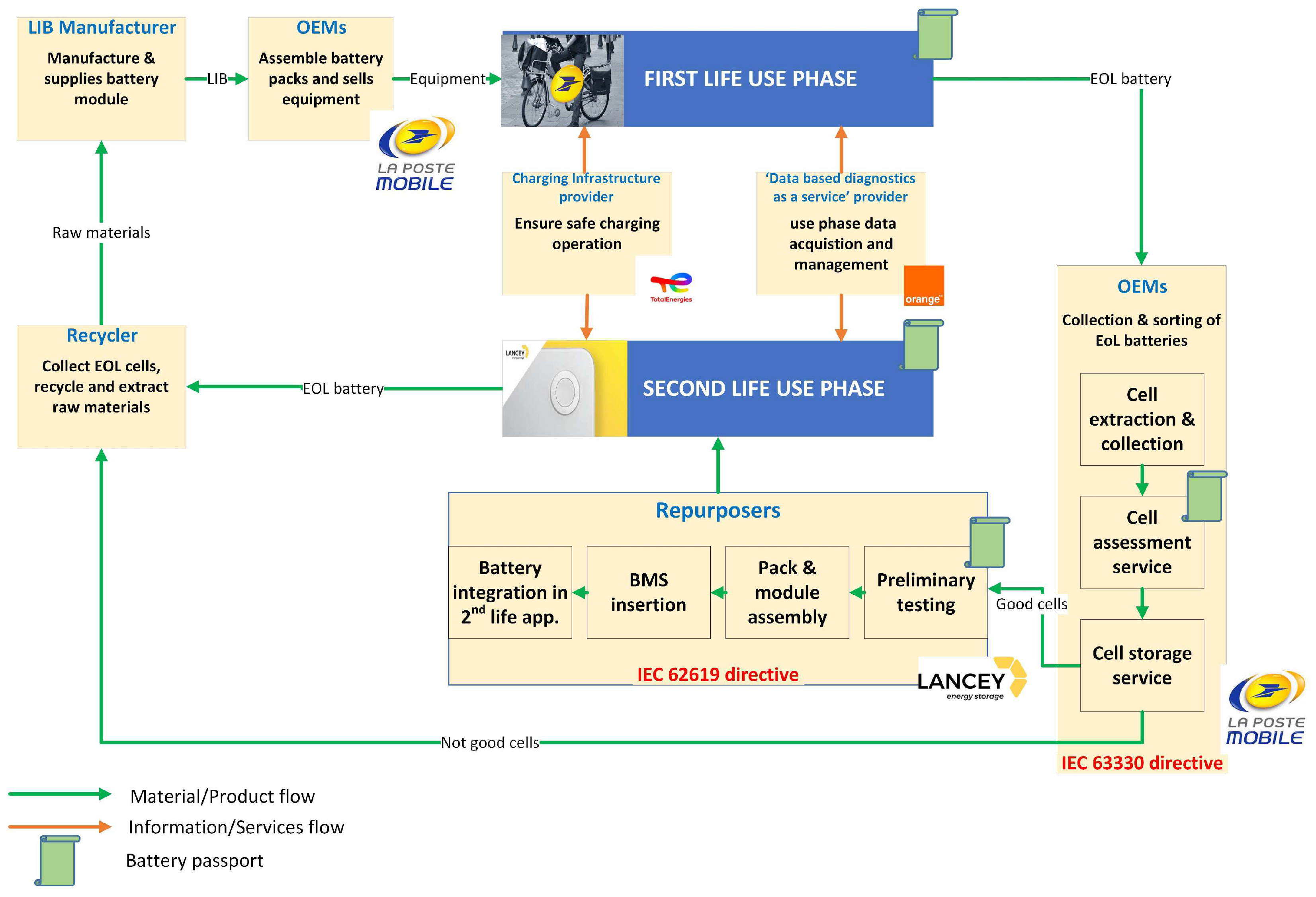

3.1. Stakeholder Interaction

3.2. Policies Related to Battery Repurposing

4. Influence of LIB Regulations on Industrial Organizations

- The right of repurposers to access the BMS data of EV batteries and industrial batteries.

- Repurposers are obliged to ensure adequate quality control and safety during performance testing, packing and shipment of batteries and their components.

- Repurposers shall ensure that the repurposed/remanufactured battery complies with these regulations related to environmental and human health protection requirements in other legislation and technical requirements for its specific purpose of use when placed on the market.

- An electronic exchange system would be set up, storing characteristic information and data for each Electric Vehicle Battery (EVB) type and model, “shall be sortable and searchable, respecting open standards for third party use”.

- IEC 62619:2022 [33]: This standard specifies requirements and tests for the safe operation of secondary lithium cells and batteries for use in industrial applications. The standards also include a detailed list of LIB second-life applications such as telecoms, uninterruptible power supplies, utility switching, emergency power and similar applications.

- IEC 63330-1 ED1:2024 [34]: This standard specifies the requirements for the repurposing of secondary cells, modules, battery packs and battery systems. It also specifies the procedure to evaluate the performance and safety of used batteries for repurposing. The Energy Storage and Stationary Battery Committee under the management of the society of IEEE power and energy has developed a standard called P2993 (PE/ESSB) - Recommended Practices for Energy Storage System Design using Second-life Electric Vehicle Batteries. This standard describes the selection and repurposing (including design, operation and maintenance) of second-life Electric Vehicle batteries in Energy Storage Systems with voltage levels of 10 kV and below. Thus, there are well-defined standards set by different governing organizations to facilitate the repurposing of EV batteries. In relation to those regulations, the major inputs in Figure 1 are the elements included in the battery passport, which is designed to support second-life EVB operators to make better used EVB classification decisions and to support recyclers in planning their operations more effectively. The IEC directives of IEC 62619:2022 [33] and IEC 63330-1 ED1:2024 [34] give a broader idea of how to handle EOL batteries during battery sorting, diagnosis and integration into second-life applications. Once the battery reaches its second End Of Life, the recyclers can handle the batteries to close the loop.

5. Role of an Efficient SoH Estimation Methodology in the Context of Repurposing

6. End-of-Life Electric Bike Batteries Repurposed for Use in Electric Heater Batteries

7. Conclusions and Perspectives

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ARIMA | Autoregressive Integrated Moving Average |

| BMS | Battery Management System |

| EMS | Energy Management System |

| EOL | End of Life |

| ESS | Energy Storage System |

| EU | European Union |

| EV | Electric Vehicle |

| EVB | Electric Vehicle Battery |

| IC | Incremental Capacity |

| IEC | International Electrotechnical Commission |

| IEEE | Institute of Electrical and Electronics Engineers |

| LIB | Lithium-Ion Battery |

| OEM | Original Equipment Manufacturer |

| OEM_R | Original Equipment Re-manufacturer |

| PV | PhotoVoltaic |

| SBM | Sustainable Business Model |

| SoH | State of Health |

| SVM | Support Vector Regression |

| UPS | Uninterruptible Power Supply |

References

- Melin, H.E. The Lithium-Ion Battery End-of-Life Market 2018–2025-Analysis of Volumes, Players, Technologies and Trends; Technical Report; Circular Energy Storage: London, UK, 2018. [Google Scholar]

- Tolio, T.; Bernard, A.; Colledani, M.; Kara, S.; Seliger, G.; Duflou, J.; Battaia, O.; Takata, S. Design, management and control of demanufacturing and remanufacturing systems. CIRP Ann. 2017, 66, 585–609. [Google Scholar] [CrossRef]

- Fazeli, A.; Stadie, M.; Kerner, M.; Burger, A.; Nagaoka, H.; Kramis, M.; Ortloff, J.; Jomrich, F. A proof of concept for the application of second-life electric vehicle batteries as a stationary energy storage system. In Proceedings of the IEEE Electrical Power and Energy Conference (EPEC), Toronto, ON, Canada, 22–31 October 2021. [Google Scholar]

- EN 52020PC0798; Proposal for a Regulation of the European Parliament and of the Council Concerning Batteries and Waste Batteries, Repealing Directive 2006/66/EC and Amending Regulation (EU) No 2019/1020. European Union Commission: Brussels, Belgium, 2020.

- Schroeder, P.; Anggraeni, K.; Weber, U. The relevance of circular economy practices to the sustainable development goals. J. Ind. Ecol. 2019, 23, 77–95. [Google Scholar] [CrossRef]

- Slater-Thompson, N. Almost All U.S. Nuclear Plants Require Life Extension Past 60 Years to Operate beyond 2050; Technical Report; U.S. Energy Information Administration (EIA): Washington, DC, USA, 2014.

- Reinhardt, R.; Christodoulou, I.; Gassó-Domingo, S.; García, B.A. Towards sustainable business models for electric vehicle battery second use: A critical review. J. Environ. Manag. 2019, 245, 432–446. [Google Scholar] [CrossRef] [PubMed]

- Klör, B.; Beverungen, D.; Bräuer, S.; Plenter, F.; Monhof, M. A Market for Trading Used Electric Vehicle Batteries-Theoretical Foundations and Information Systems. In Proceedings of the 23rd European Conference on Information System (ECIS), Münster, Germany, 26–29 May 2015. [Google Scholar]

- Rehme, M.; Richter, S.; Temmler, A.; Götze, U. Second-Life Battery Applications—Market Potentials and Contribution to the Cost Effectiveness of Electric Vehicles. In Proceedings of the Conference on Future Automotive Technology (CoFAT), München, Germany, 4 May 2016. [Google Scholar]

- Basia, A. Evaluation of the State of the Health of Li-Ion Batteries in the Context of Circular Economy. Ph.D. Thesis, Université Grenoble Alpes, Saint-Martin-d’Hères, France, 2021. [Google Scholar]

- Canals Casals, L.; Amante García, B.; González Benítez, M.M. Aging model for re-used electric vehicle batteries in second life stationary applications. In Proceedings of the Project Management and Engineering Research: AEIPRO, Cartagena, Spain, 13–15 July 2016; pp. 139–151. [Google Scholar]

- Bonges, H.A.; Lusk, A.C. Addressing electric vehicle (EV) sales and range anxiety through parking layout, policy and regulation. Transp. Res. Part A Policy Pract. 2016, 83, 63–73. [Google Scholar] [CrossRef]

- Jiao, N.; Evans, S. Secondary use of Electric Vehicle Batteries and Potential Impacts on Business Models. J. Ind. Prod. Eng. 2016, 33, 348–354. [Google Scholar] [CrossRef]

- Törkler, A. Batteries Refurbishing & Reuse. ELIBAMA Projet: European Li-Ion Battery Advanced Manufacturing for Electric Vehicles. 2014. Available online: https://elibama.files.wordpress.com/2014/10/v-c-batteries-reuse.pdf (accessed on 19 May 2024).

- Mitali, J.; Dhinakaran, S.; Mohamad, A. Energy storage systems: A review. Energy Storage Sav. 2022, 1, 166–216. [Google Scholar] [CrossRef]

- Committee on Energy; Natural Resources. The Refinery Permit Process Schedule Act; Technical Report; United States Congress Senate: Washington, DC, USA, 2006. [Google Scholar]

- Antikainen, M.; Valkokari, K. A Framework for Sustainable Circular Business Model Innovation. Technol. Innov. Manag. Rev. 2016, 6, 5–12. [Google Scholar] [CrossRef]

- Mezafack, R.A.D.; Simeu-Abazi, Z.; Di Mascolo, M. An approach for mastering Carbon Footprint in the context of Distributed Maintenance. In Proceedings of the 6th International Conference on Control, Automation and Diagnosis (ICCAD), Lisbon, Portugal, 13–15 July 2022. [Google Scholar]

- Boons, F.; Lüdeke-Freund, F. Business Models for Sustainable Innovation: State of the Art and Steps Towards a Research Agenda. J. Clean. Prod. 2013, 45, 9–19. [Google Scholar] [CrossRef]

- Jiao, N.; Evans, S. Business Models for Sustainability: The Case of Repurposing a Second-Life for Electric Vehicle Batteries. In Proceedings of the Sustainable Design and Manufacturing, Bologna, Italy, 26–28 April 2017; pp. 537–545. [Google Scholar]

- Neubauer, J.S.; Wood, E.; Pesaran, A. A Second Life for Electric Vehicle Batteries: Answering Questions on Battery Degradation and Value. SAE Int. J. Mater. Manuf. 2015, 8, 544–553. [Google Scholar] [CrossRef]

- Neubauer, J.; Pesaran, A. The ability of battery second use strategies to impact plug-in electric vehicle prices and serve utility energy storage applications. J. Power Sources 2011, 196, 10351–10358. [Google Scholar] [CrossRef]

- Ahmadi, L.; Young, S.B.; Fowler, M.; Fraser, R.A.; Achachlouei, M.A. A cascaded life cycle: Reuse of electric vehicle lithium-ion battery packs in energy storage systems. Int. J. Life Cycle Assess. 2017, 22, 111–124. [Google Scholar] [CrossRef]

- Cready, E.; Lippert, J.; Pihl, J.; Weinstock, I.; Symons, P. Technical and Economic Feasibility of Applying Used EV Batteries in Stationary Applications; Technical Report; Sandia National Lab., United States Department of Energy: Albuquerque, NM, USA, 2003.

- Wolfs, P. An economic assessment of “second use” lithium-ion batteries for grid support. In Proceedings of the 20th Australasian Universities Power Engineering Conference, Christchurch, New Zealand, 5–8 December 2011. [Google Scholar]

- Gaines, L.; Sullivan, J.; Burnham, A. Life-Cycle Analysis for Lithium-Ion Battery Production and Recycling. In Proceedings of the 90th Annual Meeting of Transportation Research Board, Washington, DC, USA, 23–27 January 2011. [Google Scholar]

- Ramoni, M.O.; Zhang, H.C. End-of-life (EOL) issues and options for electric vehicle batteries. Clean Technol. Environ. Policy 2013, 15, 881–891. [Google Scholar] [CrossRef]

- Manzetti, S.; Mariasiu, F. Electric vehicle battery technologies: From present state to future systems. Renew. Sustain. Energy Rev. 2015, 51, 1004–1012. [Google Scholar] [CrossRef]

- Standridge, C.R.; Hasan, M.M. Post-vehicle-application lithium-ion battery remanufacturing, repurposing and recycling capacity: Modeling and analysis. J. Ind. Eng. Manag. (JIEM) 2015, 8, 823–839. [Google Scholar] [CrossRef]

- Burke, A.; Miller, M.; Zhao, H. Lithium batteries and ultracapacitors alone and in combination in hybrid vehicles: Fuel economy and battery stress reduction advantages. In Proceedings of the 25th World Battery, Hybrid and Fuel Cell Electric Vehicle Symposium & Exhibition, Shenzhen, China, 5–9 November 2010. [Google Scholar]

- Williams, B.; Lipman, T. Strategy for Overcoming Cost Hurdles of Plug-In-Hybrid Battery in California: Integrating Post-Vehicle Secondary Use Values. Transp. Res. Rec. J. Transp. Res. Board 2010, 2191, 59–66. [Google Scholar] [CrossRef]

- Neubauer, J.; Pesaran, A. PHEV/EV Li-Ion Battery Second-Use Project; Technical Report; National Renewable Energy Laboratory: Golden, CO, USA, 2010.

- IEC 62619; Secondary Cells and Batteries Containing Alkaline or Other Non-Acid Electrolytes—Safety Requirements for Secondary Lithium Cells and Batteries, for Use in Industrial Applications. International Electrical Commission: Geneva, Switzerland, 2022.

- IEC 63330-1 ED1; Repurposing of Secondary Batteries—Part 1: General Requirements. International Electrical Commission: Geneva, Switzerland, 2024.

- Basia, A.; Gascard, E.; Simeu-Abazi, Z.; Zwolinski, P. Overcoming the barriers in diagnostics and prognostics of the circular industrial system by hidden markov model. In Proceedings of the 3rd International Conference on Control, Automation and Diagnosis (ICCAD), Grenoble, France, 2–4 July 2019. [Google Scholar]

- Den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product design in a circular economy: Development of a typology of key concepts and terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- European Union. Promoting Remanufacturing, Refurbishment, Repair, and Direct Reuse; European Union: Brussels, Belgium, 2017. [Google Scholar]

- ISO 14224:2016(E); Petroleum, Petrochemical and Natural Gas Industries—Collection and Exchange of Reliability and Maintenance Data for Equipment. International Standard Organisation: Geneva, Switzerland, 2016.

- Takata, S.; Suemasu, K.; Asai, K. Life cycle simulation system as an evaluation platform for multitiered circular manufacturing systems. CIRP Ann. 2019, 68, 21–24. [Google Scholar] [CrossRef]

- Basia, A.; Simeu-Abazi, Z.; Gascard, E.; Zwolinski, P. Review on State of Health estimation methodologies for lithium-ion batteries in the context of circular economy. CIRP J. Manuf. Sci. Technol. 2021, 32, 517–528. [Google Scholar] [CrossRef]

- Basia, A.; Simeu-Abazi, Z.; Gascard, E.; Zwolinski, P. State of Health Estimation for Lithium-ion Battery by Incremental Capacity Based ARIMA–SVR Model. In Proceedings of the 31st European Safety and Reliability Conference (ESREL), Angers, France, 19–23 September 2021. [Google Scholar]

| Stakeholder | Responsibility |

|---|---|

| Battery Manufacturer | 1. Ecodesign of battery 2. Push the repurposing regulations |

| Battery based equipment manufacturer (a) Electric Vehicle (b) Two wheeler E-mobility (c) ESS developer | 1. Ensure efficient operation of battery to increase battery life 2. Timely collection of EOL battery from the equipment 3. Push the repurposing regulations |

| Charging Infrastructure companies | 1. Ensure optimal charging of battery to increase battery life 2. Can also create repurposed charging infrastructure |

| Data based Diagnostics as a Service provider | 1. Provide battery diagnostics insights to facilitate decision making 2. Create second life use models using EOL battery data |

| Repurposing Companies (a) ESS developers (b) Off-grid power generators (c) Small scale consumer electronics manufacturer | 1. Collection of the EOL batteries from OEM 2. Testing and sorting 3. Integration into new system 4. Lifecycle monitoring |

| Recyclers | 1. Collection of batteries after second EOL for recycling |

| R&D labs | 1. Support the repurposers to have state-of-the-art systems for diagnosis & battery sorting |

| Governmental Regulatory bodies | 1. Push the regulations to industrial market for ensuring safety repurposing business landscape 2. Create standards and certification procedures for battery |

| OEM | 2nd Life Actors | Collaboration Objective |

|---|---|---|

| Tier Mobility | Nunam | Turn used batteries into new energy storage systems, which will then power small devices such as smartphones, fans or lamps. |

| SKODA AUTO | IBG Cesko | Develop smart energy storage systems using second-life batteries from Electric Vehicles. |

| Nissan | Beeplanet | Manufacture low, medium and large-scale energy storage equipment from second-life batteries from Electric Vehicles. |

| Irizar e-mobility | Ibil: Designer; Repsol: Commissioner | Develop 50 kW charging stations for Electric Vehicles with an energy storage system from Irizar e-mobility second-life batteries. |

| Nissan (Leaf) | Relectrify | Combine repurposed batteries from Nissan Leaf vehicles with Relectrify BMS and Inverter technology to create a battery system. |

| BMW UK | Off-Grid Energy | BMW Group UK will supply Off-Grid Energy and battery modules to create mobile power units, giving retired BMW and MINI EV batteries a second life. |

| FCA Italy S.p.A. | Engie EPS | First large-scale industrial application of V2G integrated with second-life batteries. |

| Volvo bus | Stena’s Battery loop | Give old batteries a second life in static energy storage projects. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basia, A.; Simeu-Abazi, Z.; Gascard, E.; Zwolinski, P. A Conceptual Framework Based on Current Directives to Design Lithium-Ion Battery Industrial Repurposing Models. Machines 2024, 12, 440. https://doi.org/10.3390/machines12070440

Basia A, Simeu-Abazi Z, Gascard E, Zwolinski P. A Conceptual Framework Based on Current Directives to Design Lithium-Ion Battery Industrial Repurposing Models. Machines. 2024; 12(7):440. https://doi.org/10.3390/machines12070440

Chicago/Turabian StyleBasia, Akash, Zineb Simeu-Abazi, Eric Gascard, and Peggy Zwolinski. 2024. "A Conceptual Framework Based on Current Directives to Design Lithium-Ion Battery Industrial Repurposing Models" Machines 12, no. 7: 440. https://doi.org/10.3390/machines12070440

APA StyleBasia, A., Simeu-Abazi, Z., Gascard, E., & Zwolinski, P. (2024). A Conceptual Framework Based on Current Directives to Design Lithium-Ion Battery Industrial Repurposing Models. Machines, 12(7), 440. https://doi.org/10.3390/machines12070440