Experimental Evaluation of Flexible Fixture Stiffness for Steering Knuckles When Loading a Milling Machine Tool

Abstract

1. Introduction

State of the Art

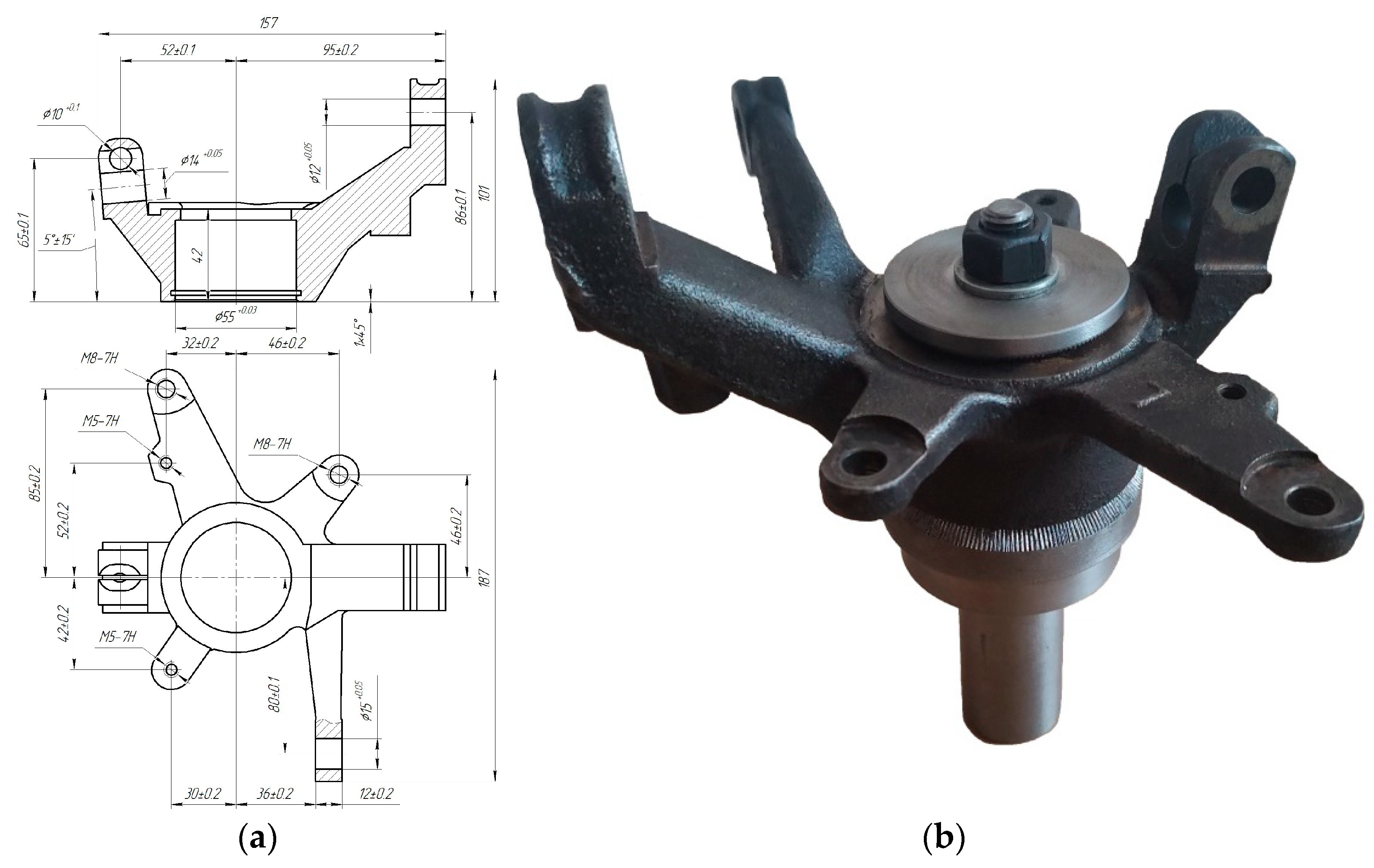

2. Materials and Methods

- (1)

- To develop the design of the flexible fixture based on the principles of incomplete locating for machining the maximum number of surfaces of the steering knuckle in one setup.

- (2)

- To conduct a study of the stress–strain state of the proposed construction using FEM methods.

- (3)

- Perform experimental studies of the developed design of the flexible fixture and compare them with the results of FEM.

- -

- Overall dimensions: l × b × h = 120 × 80 × 70–180 × 105 × 100 mm.

- -

- Mass, m = 1.1–2.5 kg.

- -

- Accuracy of the central holes—IT 7.

- -

- Accuracy of the auxiliary holes—IT 7–IT9.

- -

- Roughness of the auxiliary hole walls and flat surfaces, Ra 1.6–3.2 µm.

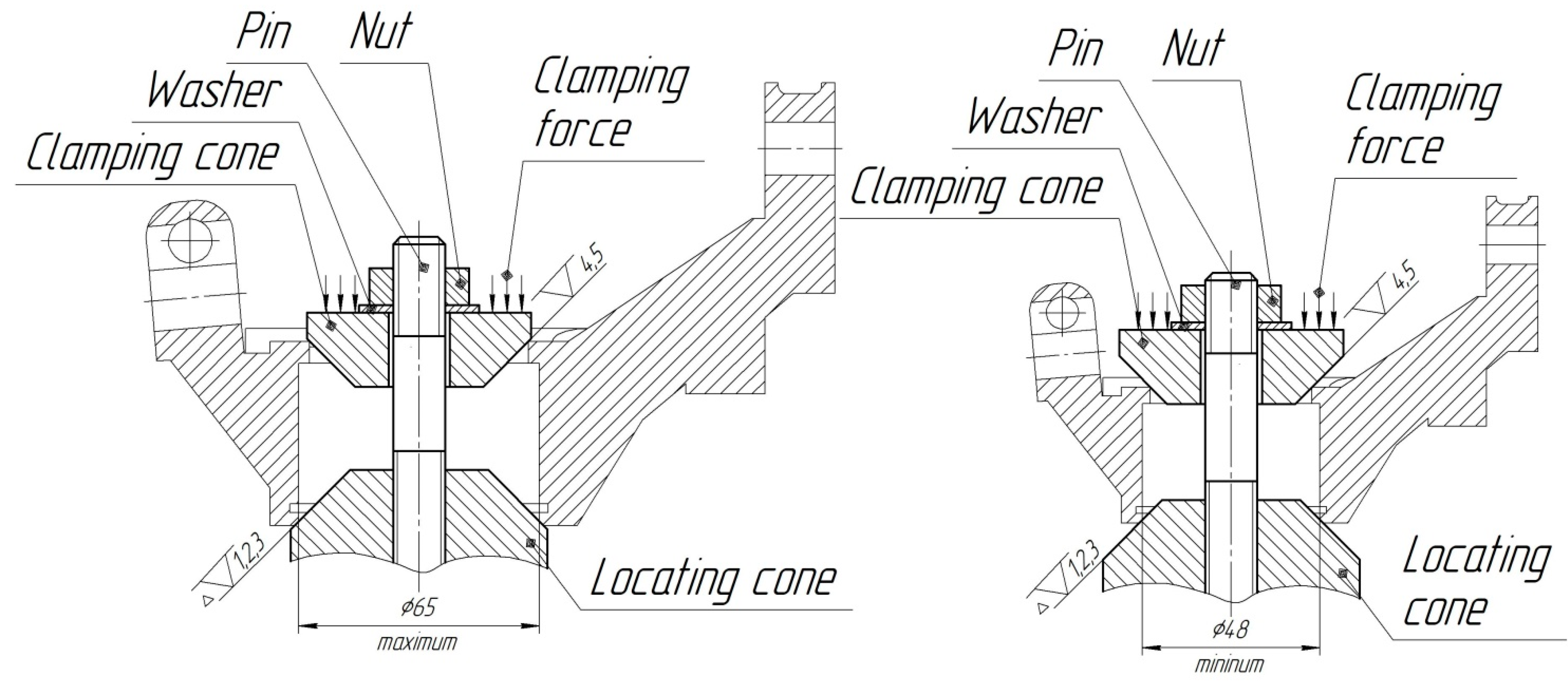

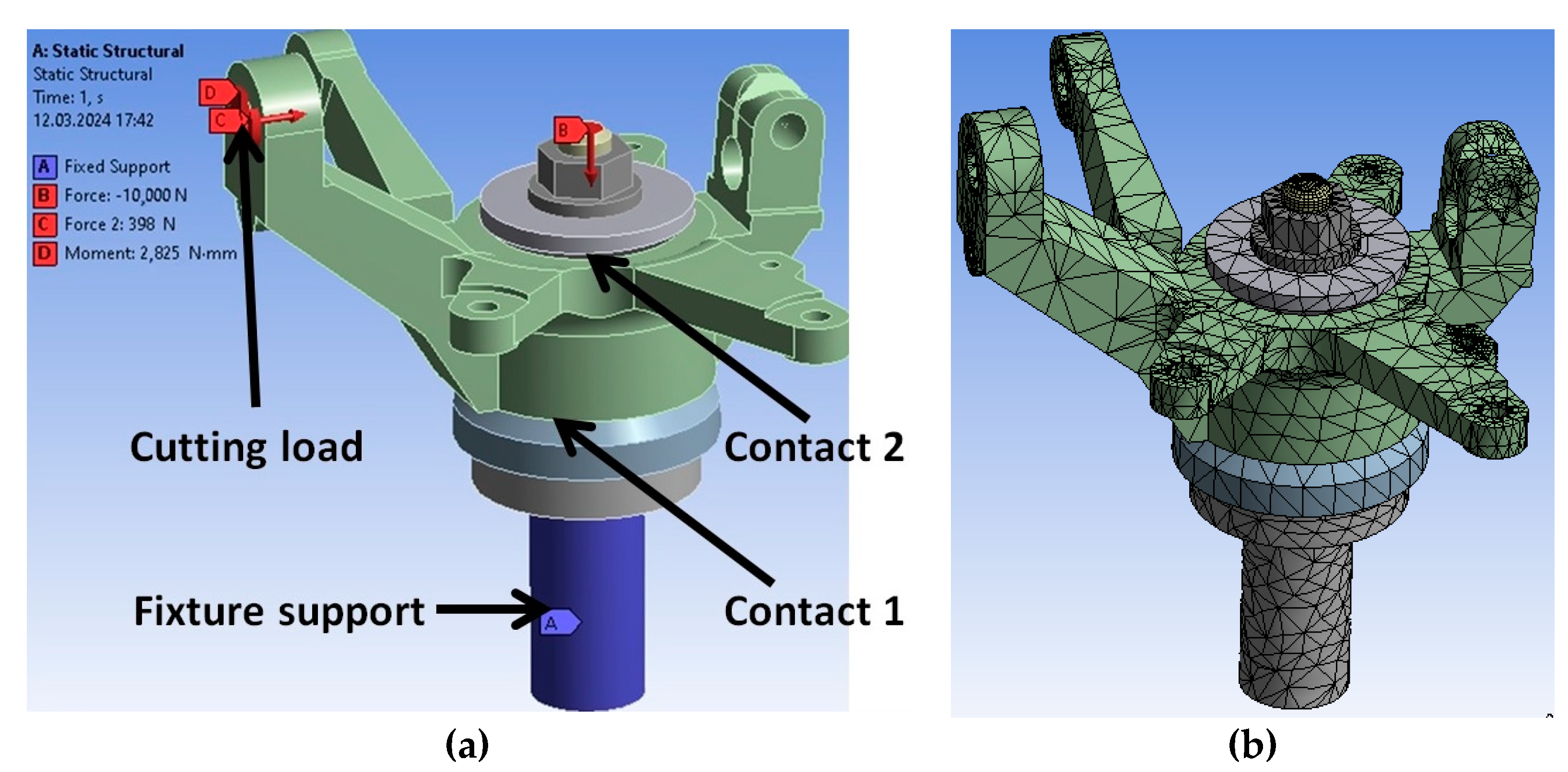

2.1. Set Up of the Finite-Element Method Calculations

2.2. Physical Measurement of Steering Knuckle Deflections

3. Results

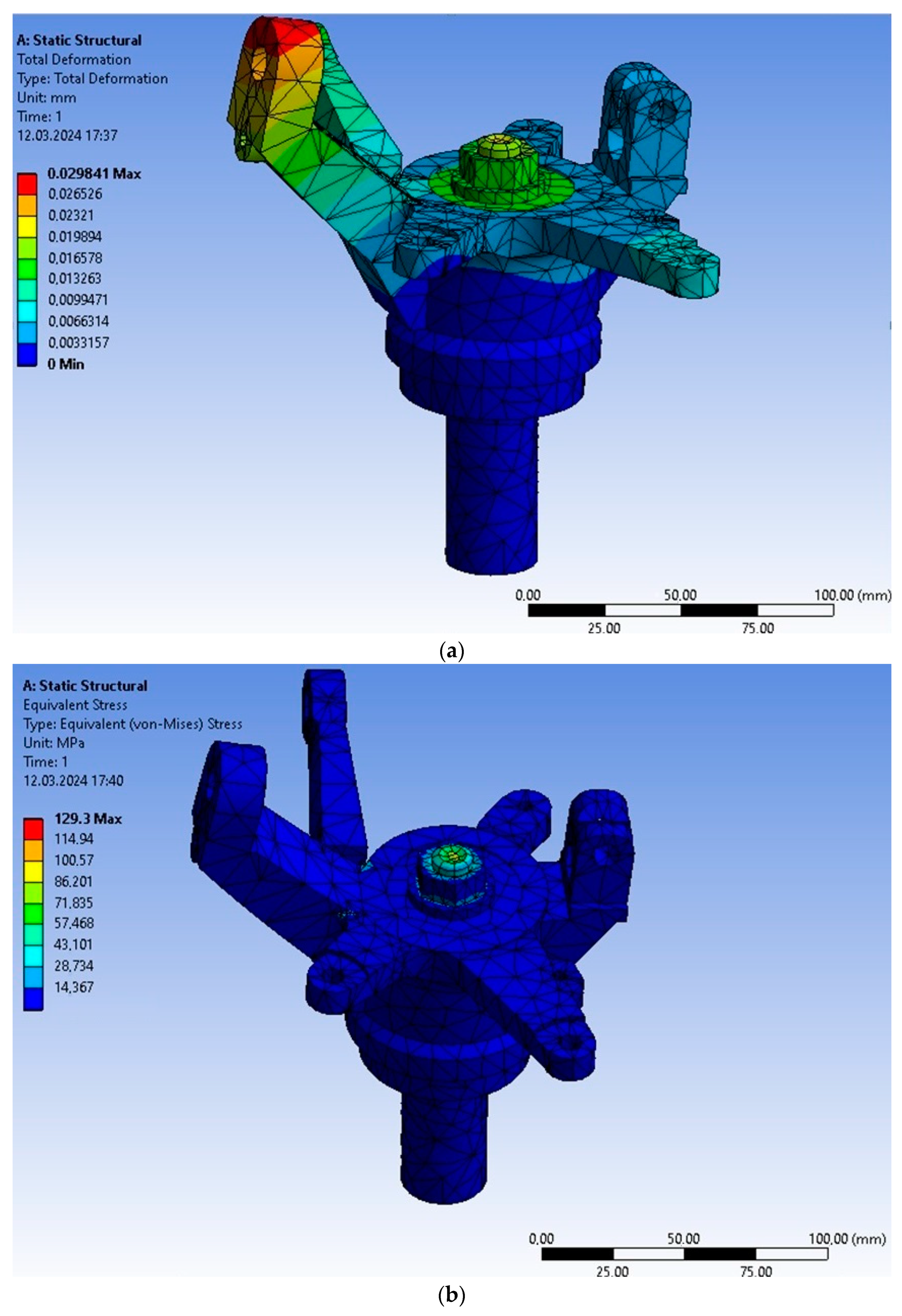

Analysis of the Finite Element Modeling

4. Discussion

5. Conclusions

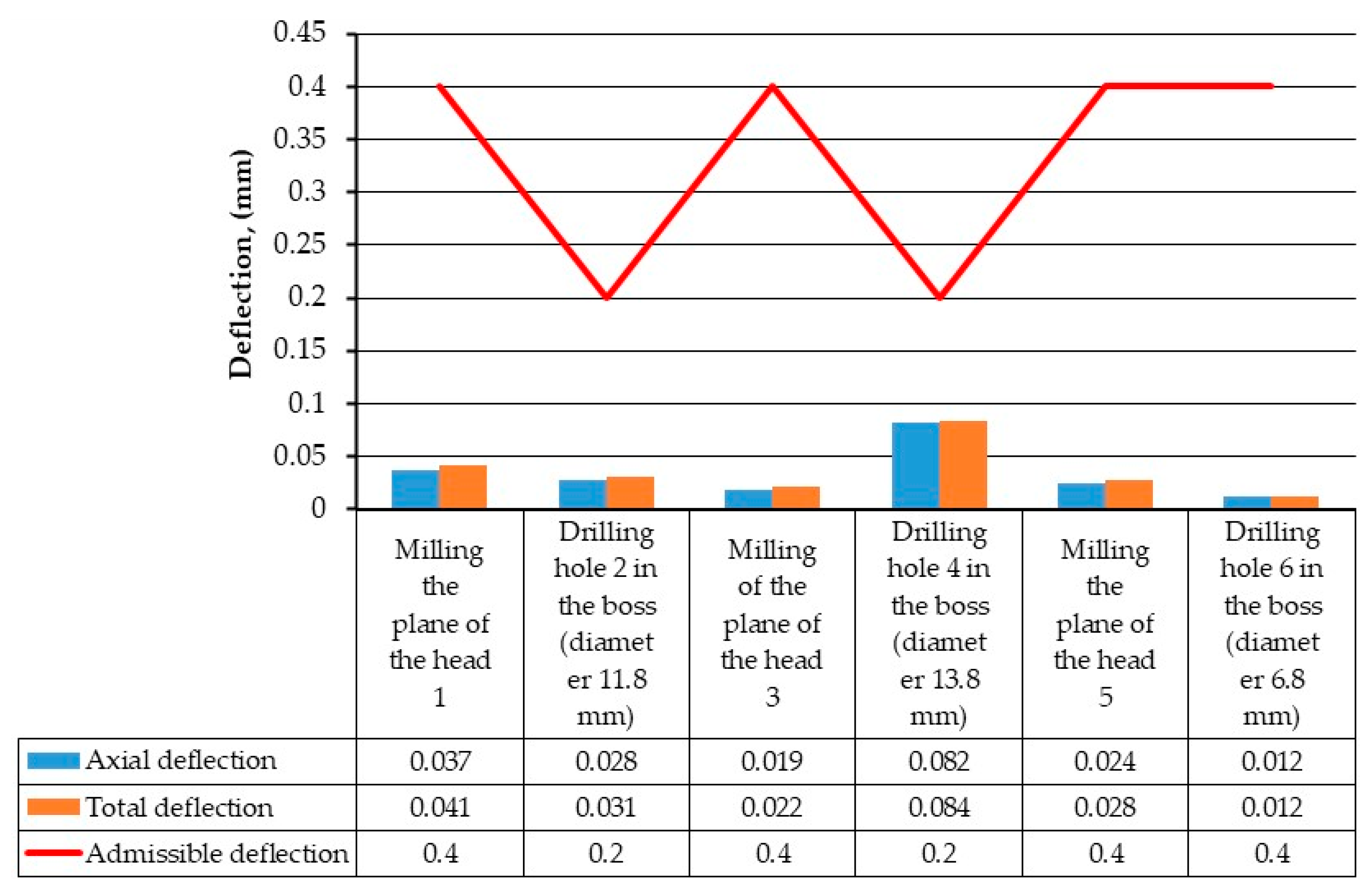

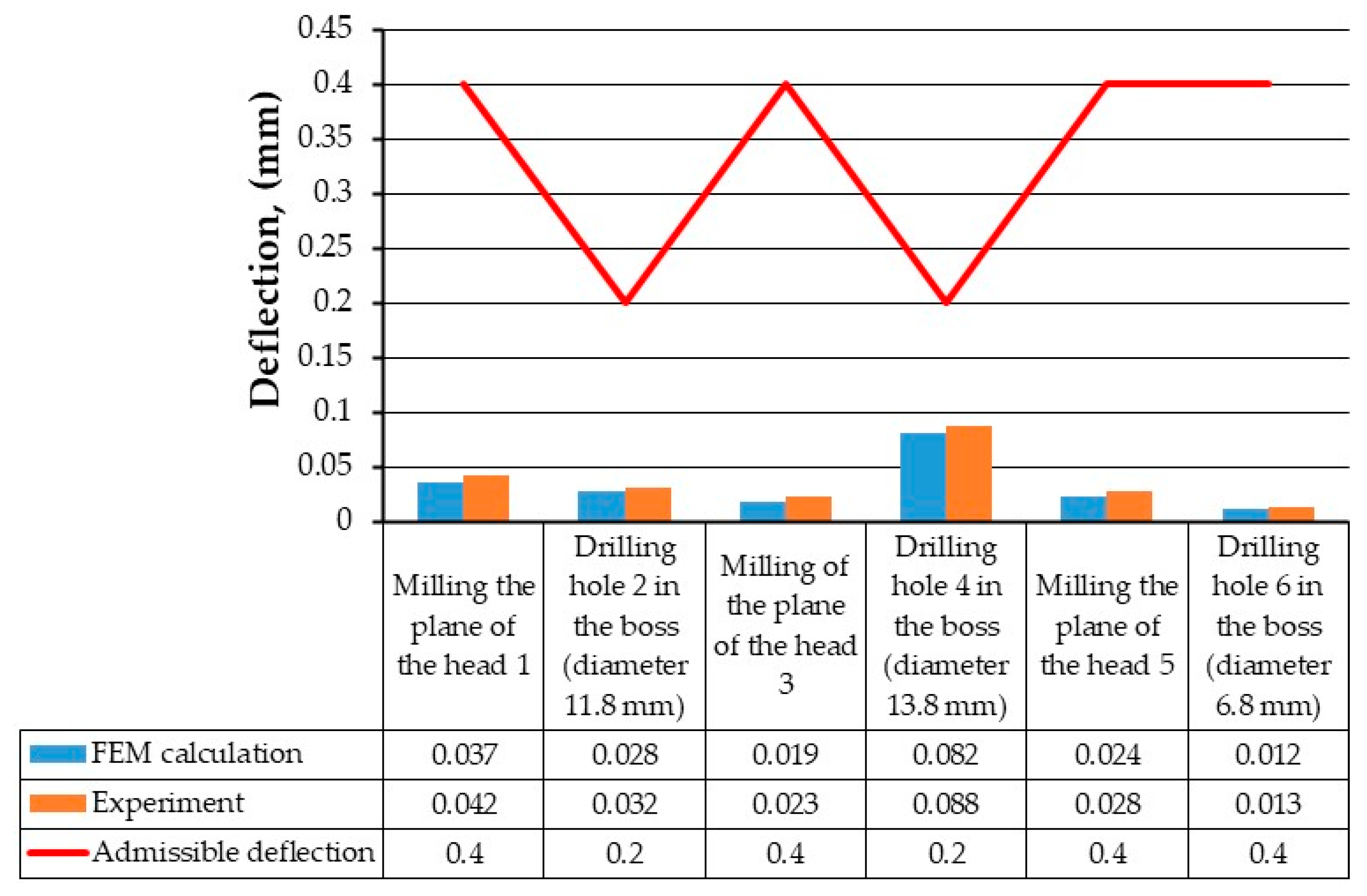

- A flexible fixture with an incomplete location for steering knuckles provides sufficient accuracy at all transitions of a multi-purpose operation. Using FEM methods, it was evaluated that the maximum stresses of 238 MPa at the most loaded transition and the smallest part of the workpiece do not exceed the tensile strength, and at the same time, a margin of 2.5 times is preserved.

- The proposed flexible fixture for machining parts steering knuckles can ensure the necessary accuracy under static loading since the movements do not exceed the permissible values on the corresponding surfaces according to the drawing. Although they are more significant than the results of FEM, in the worst case, by 17.4%, this allows to discuss the prospects of introducing fixtures with incomplete basing for machining other types of complexly shaped parts such as brackets, rockers, etc.

- Validation of FEM and experimental results evaluated that a scientific approach to designing fixtures with incomplete locations allows obtaining the specified processing accuracy while ensuring the necessary stable position exclusively by clamping forces.

- Further research will focus on the experimental determination of fixtures’ accuracy and stiffness characteristics of steering knuckles in dynamic mode during machining.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Beno, M.; Zvoncan, M.; Kovác, M.; Peterka, J. Circular interpolation and positioning accuracy deviation measurement on five axis machine tools with different structures. Teh. Vjesn. 2013, 20, 479–484. [Google Scholar]

- Liu, C.H.; Wang, J.; Zhou, B.H.; Yu, J.B.; Zheng, Y.; Liu, J.F. Development of Fixture Layout Optimization for Thin-Walled Parts: A Review. Chin. J. Mech. Eng. 2024, 37, 17. [Google Scholar] [CrossRef]

- Gameros, A.A.; Axinte, D.; Siller, H.R.; Lowth, S.; Winton, P. Experimental and Numerical Study of a Fixturing System for Complex Geometry and Low Stiffness Components. J. Manuf. Sci. Eng.-Trans. ASME 2017, 139, 045001. [Google Scholar] [CrossRef]

- Zhang, G.Q.; Dai, Y.Q.; Lai, Z.H. A novel force-based two-dimensional tool centre error identification method in single-point diamond turning. Precis. Eng.-J. Int. Soc. Precis. Eng. Nanotechnol. 2021, 70, 92–109. [Google Scholar] [CrossRef]

- Yamnikov, A.S.; Danilenko, E.A. Influence of the Shape Error of Measuring Base on the Accuracy of Manufacturing Parts from Stamped Blanks. Meas. Tech. 2022, 65, 174–179. [Google Scholar] [CrossRef]

- Liu, S.L.; Afazov, S.; Becker, A.; Ratchev, S. Machining error prediction scheme aided smart fixture development in machining of a Ti6Al4V slender part. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2023, 237, 1509–1517. [Google Scholar] [CrossRef]

- Fazil, A.; Ahmad, Z.; Hayat, K.; Sultan, T.; Ijaz, M.A.; Sohail, S.; Asad, M.; Djavanroodi, F. An experimental and numerical study on optimization of number and position of the clamps in sheet metals fixture. Mech. Adv. Mater. Struct. 2023, 1–11. [Google Scholar] [CrossRef]

- Parvaz, H.; Hosseini, S.V. Analysis of reaction forces in fixture locating points: An Analytical, numerical, and experimental study. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2024, 238, 809–822. [Google Scholar] [CrossRef]

- Sohrabifard, M.; Nategh, M.; Ghazavi, M. Evaluation, calibration, and modal analysis for determination of contact stiffness between workpiece and components of milling fixture. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2023, 237, 1819–1835. [Google Scholar] [CrossRef]

- Zhu, Z.J.; Zhao, C.Y. Angular error measurement of workpiece repositioning using a full-scale rotation detection method. Opt. Express 2023, 31, 4812–4825. [Google Scholar] [CrossRef]

- da Silva, W.T.A.; Peterka, J.; Vopat, T. Experimental Research on the Dynamic Stability of Internal Turning Tools for Long Overhangs. J. Manuf. Mater. Process. 2023, 7, 61. [Google Scholar] [CrossRef]

- Peterka, J.; Kuruc, M.; Kolesnyk, V.; Dehtiarov, I.; Moravcikova, J.; Vopat, T.; Pokorny, P.; Jurina, F.; Simna, V. Selected Aspects of Precision Machining on CNC Machine Tools. Machines 2023, 11, 946. [Google Scholar] [CrossRef]

- Ivanov, V.; Botko, F.; Dehtiarov, I.; Kocisko, M.; Evtuhov, A.; Pavlenko, I.; Trojanowska, J. Development of Flexible Fixtures with Incomplete Locating: Connecting Rods Machining Case Study. Machines 2022, 10, 493. [Google Scholar] [CrossRef]

- Fiedler, F.; Ehrenstein, J.; Höltgen, C.; Blondrath, A.; Schäper, L.; Göppert, A.; Schmitt, R. Jigs and fixtures in production: A systematic literature review. J. Manuf. Syst. 2024, 72, 373–405. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, K.; Wu, D.; Yu, T.; Yu, J.; Liao, Y. Analysis and optimization of the machining fixture system stiffness for near-net-shaped aero-engine blade. Int. J. Adv. Manuf. Technol. 2021, 113, 3509–3523. [Google Scholar] [CrossRef]

- Shirinzadeh, B. Flexible fixturing for workpiece positioning and constraining. Assem. Autom. 2002, 22, 112–120. [Google Scholar] [CrossRef]

- Feng, Q.; Maier, W.; Stehle, T.; Möhring, H.C. Optimization of a clamping concept based on machine learning. Prod. Eng.-Res. Dev. 2022, 16, 9–22. [Google Scholar] [CrossRef]

- Park, J.W.; Park, J.; Kim, H.; Kim, N.; Kim, D.Y. Assembly Part Positioning on Transformable Pin Array Fixture by Active Pin Maximization and Joining Point Alignment. IEEE Trans. Autom. Sci. Eng. 2022, 19, 1047–1057. [Google Scholar] [CrossRef]

- Hao, Q.L.; Yang, Q. A self-adaptive auxiliary fixture for deformation control in blade machining. Int. J. Adv. Manuf. Technol. 2020, 111, 1415–1423. [Google Scholar] [CrossRef]

- Arslane, M.; Slamani, M.; Chatelain, J.F. Development and validation of a machining fixture for complex-shaped components based on Pluckerian matrix approach and SDT concept. Int. J. Adv. Manuf. Technol. 2021, 114, 1697–1716. [Google Scholar] [CrossRef]

- Zheng, Y.; Hou, Z.; Rong, Y. The study of fixture stiffness—Part II: Contact stiffness identification between fixture components. Int. J. Adv. Manuf. Technol. 2008, 38, 19–31. [Google Scholar] [CrossRef]

- Sohrabifard, M.; Nategh, M.J. Investigation of the stability and contact stiffness of workpiece inside fixture in different machining conditions. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 4739–4758. [Google Scholar] [CrossRef]

- Zheng, Y.; Rong, Y.; Hou, Z. The study of fixture stiffness part I: A Finite element analysis for stiffness of fixture units. Int. J. Adv. Manuf. Technol. 2008, 36, 865–876. [Google Scholar] [CrossRef]

- Ivanov, V.; Dehtiarov, I.; Pavlenko, I.; Liaposhchenko, O.; Zaloga, V. Parametric Optimization of Fixtures for Multiaxis Machining of Parts. In Advances in Manufacturing Ii, Vol 2—Production Engineering and Management; Springer: Berlin/Heidelberg, Germany, 2019; pp. 335–347. [Google Scholar] [CrossRef]

- Liu, J.F.; Du, X.M.; Zhou, H.G.; Liu, X.J.; Li, L.; Feng, F. A digital twin-based approach for dynamic clamping and positioning of the flexible tooling system. Procedia CIRP 2019, 80, 746–749. [Google Scholar] [CrossRef]

- Toro, J.V.; Wiberg, A.; Tarkian, M. Application of optimized convolutional neural network to fixture layout in automotive parts. Int. J. Adv. Manuf. Technol. 2023, 126, 339–353. [Google Scholar] [CrossRef]

- Alshameri, T.; Ding, H.; Dong, Y.D.; Yiheng, Z.; Hui, J.; Maqram, A. Multi-Objective Approach to Automated Fixture Synthesis Incorporating Deep Neural Network for Deformation Evaluation. Robot. Comput.-Integr. Manuf. 2023, 84, 102579. [Google Scholar] [CrossRef]

- Guo, H.N.; Li, Y.G.; Liu, C.Q.; Ni, Y.; Tang, K. A Deformation Force Monitoring Method for Aero-Engine Casing Machining Based on Deep Autoregressive Network and Kalman Filter. Appl. Sci. 2022, 12, 7014. [Google Scholar] [CrossRef]

- Li, E.M.; Zhou, J.T.; Yang, C.S.; Wang, M.W.; Zhang, S.S. Clamping force prediction based on deep spatio-temporal network for machining process of deformable parts. Sci. Rep. 2023, 13, 7012. [Google Scholar] [CrossRef]

- Mirzendehdel, A.M.; Behandish, M.; Nelaturi, S. Topology optimization with accessibility constraint for multi-axis machining. Comput.-Aided Des. 2020, 122, 102825. [Google Scholar] [CrossRef]

- Mirzendehdel, A.M.; Behandish, M.; Nelaturi, S. Topology Optimization for Manufacturing with Accessible Support Structures. Comput.-Aided Des. 2022, 142, 103117. [Google Scholar] [CrossRef]

- Han, X.B.; Feng, W.D. Error model of a precision two-dimensional fixture. Int. J. Adv. Manuf. Technol. 2023, 124, 4033–4043. [Google Scholar] [CrossRef]

- Cheng, S.; Tan, G.Q. Intelligent vehicle inspection tool design based on freeman chain code for automatic annotation of 3D models. Scalable Comput.-Pract. Exp. 2023, 24, 769–782. [Google Scholar] [CrossRef]

- Li, E.M.; Zhou, J.T.; Yang, C.S.; Zhao, J.H.; Li, Z.Y.; Zhang, S.S.; Wang, M.W. Part machining deformation prediction based on spatial-temporal correlation learning of geometry and cutting loads. J. Manuf. Process. 2023, 92, 397–411. [Google Scholar] [CrossRef]

- Dovhopolov, A.; Nekrasov, S.; Zhyhylii, D.; Savchenko, Y.; Stupin, B. Modeling of a Stress-Strain State of Detachable Connection in Details of Reinforced Composite Materials with CEA Method. Stroj. Časopis-J. Mech. Eng. 2020, 70, 17–28. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.H.; Ma, X.P.; Zhang, X.H.; Fu, D.Y.; Yan, Q.T. Study on Welding Deformation and Optimization of Fixture Scheme for Thin-Walled Flame Cylinder. Materials 2022, 15, 6418. [Google Scholar] [CrossRef] [PubMed]

- Meng, S.; Zheng, L.Y.; Fan, W.; Wang, X.; Zhou, J. Intelligent layout optimization of reconfigurable flexible fixture for assembling multiple aircraft panels. Int. J. Adv. Manuf. Technol. 2023, 126, 1261–1278. [Google Scholar] [CrossRef]

- Du, X.M.; Liu, S.; Jin, S. Distribution analysis of deterministic clamping and positioning error for machining of ring-shaped workpieces considering alignment uncertainty. Int. J. Adv. Manuf. Technol. 2024, 131, 3921–3936. [Google Scholar] [CrossRef]

- Qazani, M.R.C.; Parvaz, H.; Pedrammehr, S. Optimization of fixture locating layout design using comprehensive optimized machine learning. Int. J. Adv. Manuf. Technol. 2022, 122, 2701–2717. [Google Scholar] [CrossRef]

- Rex, F.M.T.; Hariharasakthisudhan, P.; Andrews, A.; Abraham, B.P. Optimization of flexible fixture layout to improve form quality using parametric finite element model and mixed discrete-integer genetic algorithm. Proc. Inst. Mech. Eng. Part C-J. Eng. Mech. Eng. Sci. 2022, 236, 16–29. [Google Scholar] [CrossRef]

- Weicheng, G.; Yong, Z.; Xiaohui, J.; Ning, Y.; Kun, W.; Xiao, L. Improvement of stiffness during milling thin-walled workpiece based on mechanical/magnetorheological composite clamping. J. Manuf. Process. 2021, 68, 1047–1059. [Google Scholar] [CrossRef]

- Nekrasov, S.; Zhyhylii, D.; Dovhopolov, A.; Karatas, M.A. Research on the manufacture and strength of the innovative joint of FRP machine parts. J. Manuf. Process. 2021, 72, 338–349. [Google Scholar] [CrossRef]

- Buransky, I.; Bracik, M.; Simna, V.; Vopat, T. Influence of end millvariable pitch on surface quality of aluminium thin-walled parts. MM Sci. J. 2018, 2018, 2552–2557. [Google Scholar] [CrossRef]

- Pawar, U.; Chavan, S.G.; Bhole, K.S.; Rathod, M.; Bhole, D. Computer aided approach for case specific design of fixture for slot milling process. Int. J. Interact. Des. Manuf.-IJIDeM 2023, 1–11. [Google Scholar] [CrossRef]

- Byun, S.H.; Seo, J.H.; Cho, R.Y.; Yi, S.M.; Kim, L.K.; Han, H.S.; On, S.W.; Kim, W.H.; An, H.W.; Yang, B.E. Finite Element Analysis of a New Non-Engaging Abutment System for Three-Unit Implant-Supported Fixed Dental Prostheses. Bioengineering 2022, 9, 483. [Google Scholar] [CrossRef] [PubMed]

- Technical Card Steel 41Cr4; Quenching and Tempering Steel; Ovako AB: Stockholm, Sweden.

- Dehtiarov, I.; Neshta, A.; Kosov, I.; Klok, Y. Experimental research of the rigidity of fixtures with incomplete location for connecting rod type parts. Tech. Sci. Technol. 2022, 3, 15–26. [Google Scholar] [CrossRef]

- Ivanov, V.; Dehtiarov, I.; Evtuhov, A.; Pavlenko, I.; Ruban, A. Multiaxis Machining of Fork-Type Parts: Fixture Design and Numerical Simulation. In Lecture Notes in Networks and Systems; Springer: Cham, Germany, 2021; Volume 223, pp. 142–152. [Google Scholar]

- Material Datasheet C45; Murray Steel Products: Middlesbrough, UK.

- ANSYS Mechanical User’s Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2013; p. 1858.

- 80-ENG-D-413; Checking Fixture—Gauge Standard. ABC Technologies: Southfield, MI, USA, 2020.

- Ding, G.Z.; Wang, Y.F.; Yuan, S.M.; Lin, L.; Zhao, Z.C. Research on Rapid and Accurate Fixture Design for Non-Intervention Machining of Complex Parts. Metals 2022, 12, 1174. [Google Scholar] [CrossRef]

| C, % | P, % | S, % | Si, % | Mn, % | Cr, % | Cu, % | Ni, % | Fe, % |

|---|---|---|---|---|---|---|---|---|

| 0.41 | 0.035 | 0.04 | 0.2 | 0.8 | 0.25 | 0.4 | 0.25 | 97.615 |

| Young’s Modulus, GPa | Poisson’s Ratio | Density, kg/m3 | Tensile Strength, MPa | The Ultimate Strength of the Compression, MPa | Yield Strength, MPa | Hardness, (HRC) |

|---|---|---|---|---|---|---|

| 200 | 0.3 | 7850 | 950 | 950 | 726 | 45 |

| Parameters of Implemented Contact Groups | |||

|---|---|---|---|

| Contact | Contact Surface | Type of Contacting Surface | Friction Coefficient |

| 1 | working surface of the bottom cone/cone surface of the steering knuckles | corrugated/machined | 0.7 [13] |

| 2 | the working surface of the top cone/cylindrical surface of the top face of the steering knuckles | corrugated/unmachined | 0.3 [13] |

| C, % | P, % | S, % | Mn, % | Cr, % | Fe, % |

|---|---|---|---|---|---|

| 0.45 | 0.025 | 0.035 | 0.8 | 0.5 | 98.19 |

| Young’s Modulus, GPa | Poisson’s Ratio | Density, kg/m3 | Tensile Strength, MPa | The Ultimate Strength of the Compression, MPa | Yield Strength, MPa | Hardness, (HRC) |

|---|---|---|---|---|---|---|

| 200 | 0.3 | 7850 | 932 | 932 | 784 | 33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolesnyk, V.; Kuruc, M.; Dehtiarov, I.; Neshta, A.; Avramenko, S.; Kononovych, V.; Dynnyk, O.; Dovhopolov, A.; Lemekh, S.; Titskyi, R. Experimental Evaluation of Flexible Fixture Stiffness for Steering Knuckles When Loading a Milling Machine Tool. Machines 2024, 12, 405. https://doi.org/10.3390/machines12060405

Kolesnyk V, Kuruc M, Dehtiarov I, Neshta A, Avramenko S, Kononovych V, Dynnyk O, Dovhopolov A, Lemekh S, Titskyi R. Experimental Evaluation of Flexible Fixture Stiffness for Steering Knuckles When Loading a Milling Machine Tool. Machines. 2024; 12(6):405. https://doi.org/10.3390/machines12060405

Chicago/Turabian StyleKolesnyk, Vitalii, Marcel Kuruc, Ivan Dehtiarov, Anna Neshta, Serhii Avramenko, Vitalii Kononovych, Oksana Dynnyk, Andrii Dovhopolov, Serhii Lemekh, and Roman Titskyi. 2024. "Experimental Evaluation of Flexible Fixture Stiffness for Steering Knuckles When Loading a Milling Machine Tool" Machines 12, no. 6: 405. https://doi.org/10.3390/machines12060405

APA StyleKolesnyk, V., Kuruc, M., Dehtiarov, I., Neshta, A., Avramenko, S., Kononovych, V., Dynnyk, O., Dovhopolov, A., Lemekh, S., & Titskyi, R. (2024). Experimental Evaluation of Flexible Fixture Stiffness for Steering Knuckles When Loading a Milling Machine Tool. Machines, 12(6), 405. https://doi.org/10.3390/machines12060405