3. Methodology

3.1. Research Gap and Aim

The issue of artificial intelligence and digitization in the sustainable design and manufacturing of products in all industries represents a challenge from several perspectives. First, there is the general phenomenon of artificial intelligence in the last period. This topic is gaining popularity, but the unfamiliarity of the technology also brings opposing views and a lot of skepticism among the public, who could be more enthusiastic about innovation and new technologies. This is also the reason to carry out research in this area. On the other hand, relevant research results, developments, and innovations can contribute positively to the understanding of this issue, the implementation of solutions, and the pursuit of the possibility of increasing efficiency and productivity in industries.

Another challenge is the sector’s position within the industry and economy of the countries. The construction industry has several specifics that must be considered in the manufacturing of products in civil engineering. The specificity of products also creates specific conditions for the implementation and use of artificial intelligence in the industry.

The civil engineering industry is undergoing a digital transformation, and the rapid growth of available technologies is driving this change. Artificial intelligence, with its immense potential, can significantly accelerate this process, increasing the degree of digitization in the construction industry.

The introduction of these challenges, the review of case studies, and the research carried out so far have yet to find an answer or a guide to overcome these challenges and analyze these topics. Since production in the construction industry is specific, the potential of artificial intelligence in manufacturing civil engineering products needs to be given due attention based on a thorough theoretical analysis [

5,

6,

13,

14,

15,

17,

22,

24,

25,

26] and knowledge of the current state, some studies [

13,

22,

24,

26], and scientific considerations, which are, however, supported by a large consensus in the cited literature, the following research questions were set to find answers:

What is the potential of AI in the manufacturing of products in civil engineering?

What is the current use rate of AI in civil engineering manufacturing products?

What is the impact of artificial intelligence on performance in manufacturing products in civil engineering?

The aim of the research is to analyze the relationships between digitization in the industry, artificial intelligence, and performance in the design, production, and use of construction products in the context of Industry 4.0 principles.

3.2. Data Collection and Processing

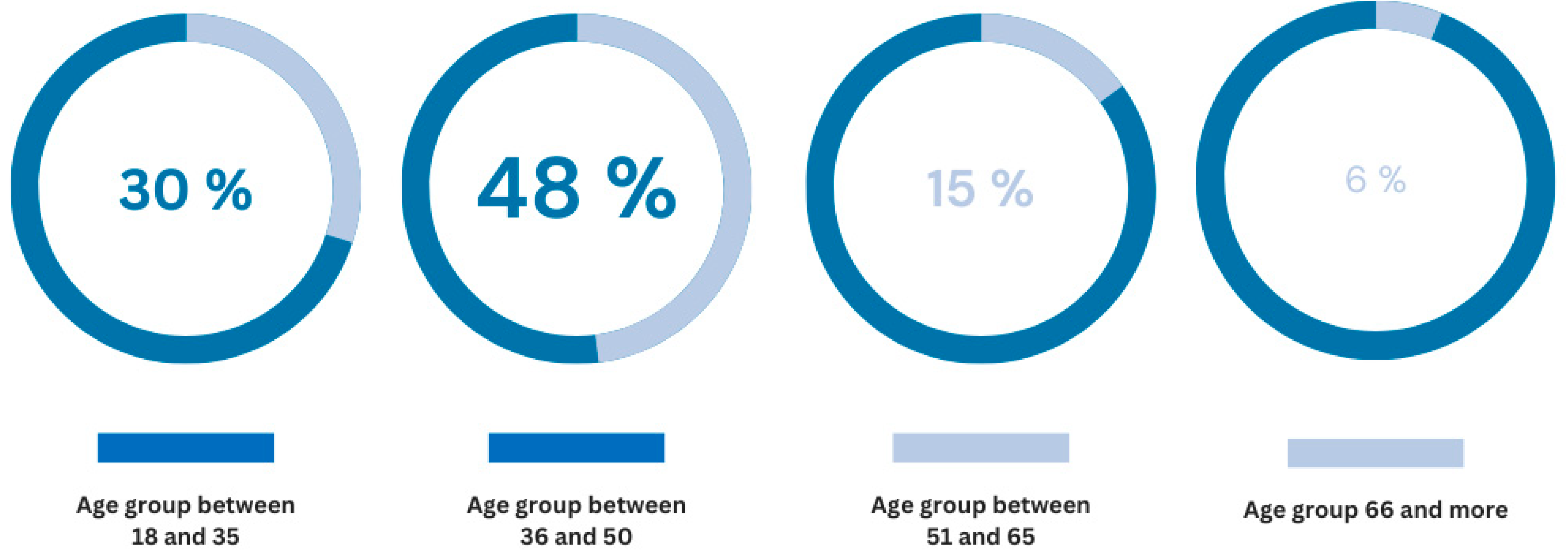

Data collection was ensured through an online questionnaire addressed to product managers. The research sample was selected by random selection from the database of contacts in the construction industry, whose activity was the design and production of construction products. The representation of the addressed research sample was proportionally divided according to the structure of the sub-sector for the year 2023, and thus, representation according to the structure of the economy was ensured. In total, more than 900 respondents were contacted, of which the return was almost 3.5%. A total of 33 respondents representing the design and manufacturing of civil engineering products went through construction projects. This represents a significant number of construction products, which is crucial for the smaller construction market. Companies representing the construction market in Slovakia participated in the research, including designers, investors, and developers. In the context of digital technologies, the representation of respondents based on age structure is important. The research sample according to the age category of respondents is described in more detail in

Figure 1.

The largest group of respondents was between 36 and 50 years old. In total, this was around 48% of the respondents. The next largest group of respondents was between 18 and 35 years old. On the contrary, the group aged 51 to 65 comprised only 15% of the research sample, and the group over 66% comprised only 6%. This age structure of the respondents also correlates with the age structure of employees in construction companies who deal with the planning and design of construction products and are often managers.

Data processing was based on data sorting, followed by a rigorous evaluation using a variety of statistical methods. While descriptive statistics played a role, the primary focus was on the use of powerful analytical tools. MS Excel tools were instrumental in this evaluation.

The data analysis was based on Spearman’s correlation and regression analysis, which analyzed the relationships between individual activity performance and AI influence. Regression analysis determined the statistical significance of correlation relations.

The interpretation of the correlation coefficient according to Cohen [

34] is as follows:

0–0.1 (trivial);

0.1–0.3 (small);

0.3–0.5 (medium);

0.5–0.7 (strong);

0.7–0.9 (very strong).

The intensity of correlation relationships of regression analysis values is in the interval between −1 and 1. When interpreting the results, we consider the values that indicate the strength of correlation and regression expressed by a number from an interval from −1 to 1.

Following this, a comprehensive regression analysis was carried out to thoroughly examine the statistical significance of the measured correlations. The p-value was set at 0.05, further reinforcing the reliability of the research process.

3.3. Limitation of Research

The research limits are primarily related to initial problems in implementing new technologies. Despite the trend and publicity of the AI issue, still, few potential users know about this technology. Therefore, the interpretation of some activities associated with AI could be wrong for the respondents, and they did not have to give the correct answer due to a misunderstanding of the issue. However, this was eliminated by the description and explanation of the questionnaire, which was supposed to minimize this possibility to a minimum. After a thorough description and explanation of what AI is, the condition for participating in the research was to recognize technologies that work based on artificial intelligence or have a penchant for machine learning. These criteria were explained through examples of individual software solutions and their functions, which, although only in the initial phase, solve the problem through these technological options. If the respondent needed to understand the fundamental essence of how AI and machine learning work even after a thorough description and explanation, the results should not be considered, as they would not be relevant to the research. Therefore, the research also had an educational character to encourage respondents to the relevant results from the market.

The second group of research limits are specific industries. In the construction field, several specifics are associated with production itself. This leads to different situations and perceptions of the issue, such as confusing the term with robotization. Likewise, the production of construction products is unique in some cases. While the extensive use of AI makes sense for repetitive activities, some of these uses may need to be revised in the design and production of construction products. Likewise, the uniqueness of construction products can essentially bring about different results in terms of use and impact than other industries.

Since this is a new issue, it would be appropriate in the future, as described in later research, to implement it in more markets and obtain results from a more extensive research sample. This leads to better results and stability, which can be applied across the entire industry.

The design phase represents the space where AI can be implemented to the greatest extent. However, the consequences of this can be perceived and manifested only in the production phase, which can lead to a distorted perception of the results. On the contrary, there are fewer cases in the maintenance phase, so some results may point to incorrectness and bad interpretation, where the effect may not appear at first glance.

Other research limitations include the pitfalls of statistics and data crunching, which are common in any statistical evaluation. Even though proven methods are used in the research, statistical deviations and error rates are always possible. Despite all the tests and proven methods and procedures used, this fact cannot be 100% eliminated. However, due to the implementation of proven procedures, this risk is minimal and can be considered acceptable.

4. Results and Discussion

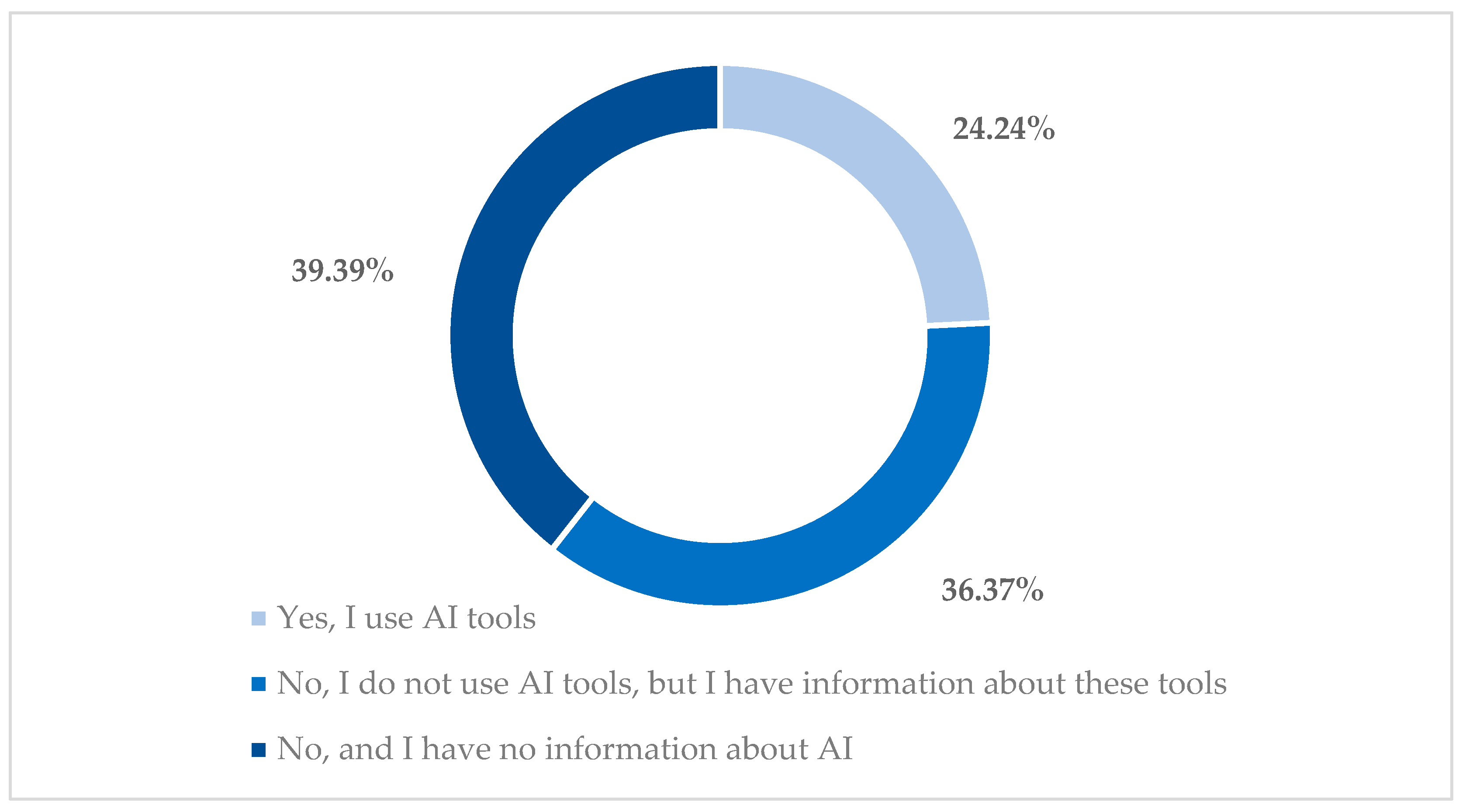

The rate of use of artificial intelligence in the sustainable design and production of construction products is relatively low. Almost 40% of the respondents in the sample stated that they do not use any AI tool or even have information about AI (

Figure 2). The civil engineering industry differs from industries with high innovation adoption. This is consistent with a study from Australia [

26,

27]. This also applies to digital technologies and the so-called intelligent solutions within the Industry 4.0 concept (in this case, the equivalent of the industry, Construction 4.0). Despite the great effort towards digitization and automation in the industry as a tool for enabling a higher degree of sustainability, the construction industry is not among the most innovative branches of the industry.

Highlighting the low adoption of AI tools in the construction industry, as evidenced by the fact that more than 76% of respondents do not use any AI tool in sustainable design and production, is a key step in raising awareness and encouraging change.

On the contrary, based on the research sample, only a quarter of the respondents use AI tools in the construction industry. These results indicate a low use of AI in the sustainable design and production of construction products. Discussing the drivers of using AI tools in the construction industry is appropriate. Future research in this area should also be directed there. However, now based on the facts, it is necessary to mention that more than 75% of the industry is not using AI tools, even though, based on the study mentioned above, the performance of the industry is increasing by only 1% in the last decades [

8].

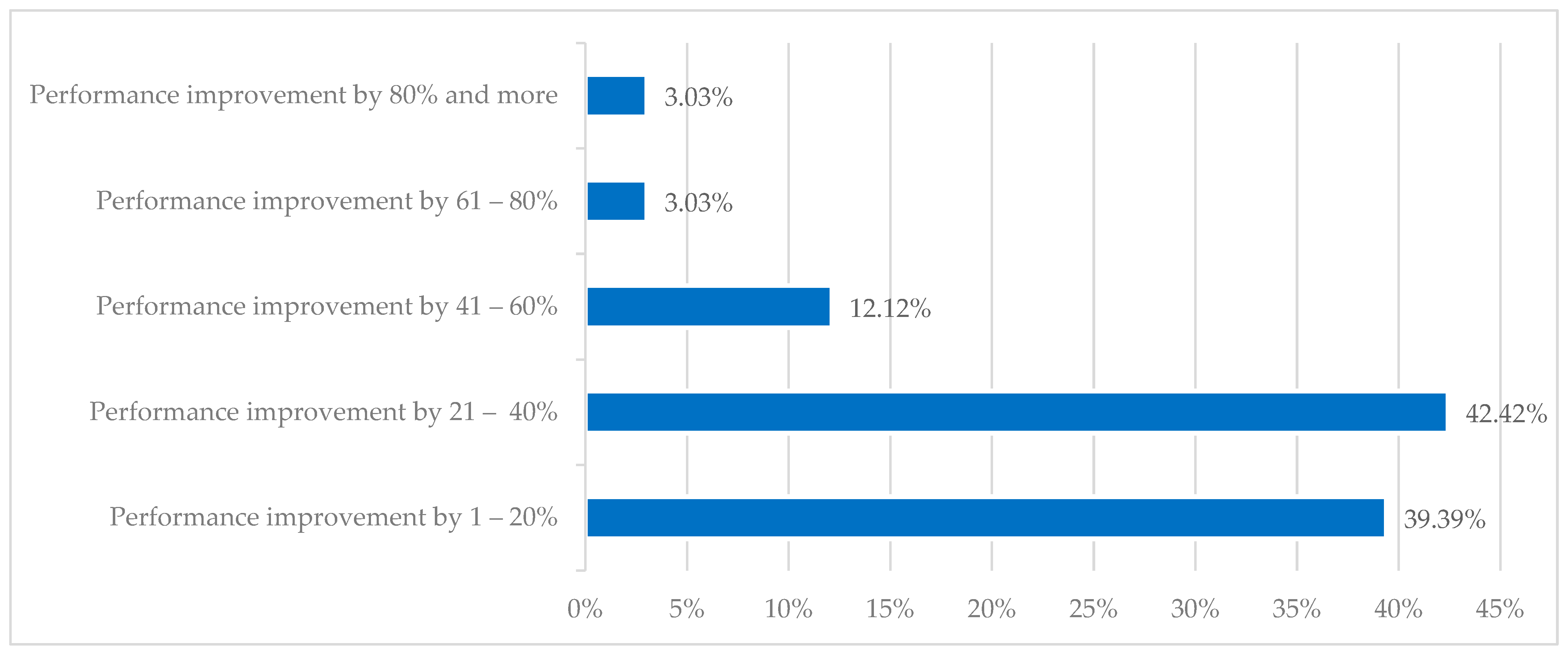

The results of the research also brought expectations arising from the implementation of AI in increasing performance. Based on the research sample, the greatest increase in performance is predicted at the level of 21 to 40% (

Figure 3). Almost two-thirds of respondents expect an increase in performance in the range from 1 to 40%. In contrast, just over 6% expect AI to increase efficiency in the design and manufacture of building products by more than 60%. A significant finding from the research data was that no one, on the contrary, expects performance due to the use of AI. This is also reflected in studies focused on the benefits brought by AI in the construction industry, including increasing performance [

23].

Correlation analysis of the data pointed to strong relationships between the use of AI in designing and manufacturing civil engineering products (

Table 1). Especially, in the design phase, there is a strong relationship with the positive results of increasing performance using generative design, 3D modeling with AI, and material planning. These results also support the information from the study regarding the contribution of AI in the construction industry [

3] since there is a strong correlation between the use of AI and the increase in performance in terms of planned costs and shortening the delivery time of construction products. The research sample also found a strong correlation between AI and process automation. Conversely, performance gains do not correlate strongly with AI and component production. On the contrary, this relationship was strongly correlated only in the production phase.

Other correlations were observed to be moderate or weak. These results highlight a clear trend towards the importance of AI in the design phase, where it is feasible to generate numerous designs of acceptable quality in a relatively short time. This trend was noted for most of the investigated variables, further emphasizing the potential of AI in the design phase.

Moderate and weak correlations were recorded in the product facility management phase, that is, in the maintenance and service phase. Due to the lower frequency of processes in this phase, the potential of using AI is lower.

The design phase and relationships between performance in individual activities due to the use of AI are also shown in the following figure (

Figure 4). The intensity of correlation relationships is in the interval between −1 and 1. The values in the table indicate the strength of the correlation expressed by a number in an interval from −1 to 1. The strength of the correlation and the scale are specified in more detail in the methodology section. With gratitude to AI, the generative design of construction products in the design phase increases flexibility. Performance is also enhanced by the influence of AI in cost planning and time planning. On the contrary, it was not strongly correlated with the design of components and prefabs in the design phase. It should be noted here that the design phase was not crucial for performance assessment; on the contrary, as can be seen in the following picture (

Figure 4), it was strong in the production phase.

The manufacturing phase and relationship analysis pointed to this strong correlation between AI use and performance manufacturing of components and prefabs. Three-dimensional modeling and the use of AI yielded the second-highest correlation. Also worth mentioning is the relationship between materials and cost planning performance.

The use phase, also in the construction industry often referred to as the facility management phase, is the least significant in the strength of correlations within the correlation analysis. Correlation analysis pointed to moderately strong correlations in this phase, primarily about performance due to the influence of AI on process automation, the delivery of service and product on time, the production of components, and the 3D modeling of civil engineering products (

Figure 4).

Correlation analysis pointed to the relationships between the potential use of AI and the increase in performance in the individual activities of the design and production of construction products. In data processing, correlation analysis is a statistical method that points to and identifies strong relationships and quantifies their strength. The relationships described above indicate the trend and assumption of the results of the use of AI and its impact on performance. To confirm the results, a regression analysis is necessary, which will point out the significance of the results of the correlation analysis (

Table 2).

The intensity of the regression analysis values is in the interval between −1 and 1 and determines the significance of the correlation terms. When interpreting the results, we consider the values that indicate the strength of the correlation. The methodology section specifies the regression rate and scaling in more detail.

The results of the regression analysis indicate the confirmation of the results of the correlation analysis and, thus, many positive relationships between the increase in performance due to the influence of AI in selected activities, such as design optimization, cost estimation, and project scheduling, in the design and production of construction products. In the design phase of construction products, this is the impact of AI on performance in generative design, 3D modeling, material and cost planning, and time planning. The regression analysis confirmed that the identified correlations are statistically significant, and, therefore, the interpretation of the findings has a substantial weight and indicates a trend for the industry. On the contrary, in the production phase, the regression analysis did not indicate unequivocal results, and only the correlations between the increase in performance due to AI in the 3D modeling of products and the production of components and prefabs can be considered statistically significant.

Here, it is up for debate whether this is not the direction in the production of construction products, increasing performance and implementing AI in the construction industry, which, in the long term, can lead to a sustainable increase in performance in the sector. Considering the repetitive activities in producing prefabs and components, there is a high assumption of the suitability of using AI, which, as research has shown, would lead to an increase in performance. Many researchers have pointed to the contribution of AI only in the design phase of the construction industry. On the contrary, others pointed to the benefit of production as well. The results of this study point to an increase in performance and the justification for using AI in production as well. However, from the point of view of quantifying the impact of AI on performance, the design phase is more significant, which was also shown by the correlation and regression analysis of the data within this research sample.

The research results also pointed out and confirmed the trend that the study below shows, where among the main benefits of AI in the management of construction projects (a construction project as a product of civil engineering manufacturing), productivity and performance are the main reasons for use [

9]. This research pointed out the expectations and the results of this research, and it also agreed with this research sample, leading to very similar conclusions.

The research results point to the trend of using AI in designing and manufacturing civil engineering products. This topic has been discussed a lot lately. Artificial intelligence is often a topic for debate and diverse opinions. It is very important to note that knowledge of this topic is relatively low. The results also pointed this out. Therefore, the expectations of adopting innovations, such as including AI, may be unrealistic. Product managers stated that it is often about specific groups of employees and their digital skills, their way of accepting changes, their interest in innovation, and the opinions of society. However, it is possible to agree with the claims that AI will take people’s jobs. On the contrary, several product managers, as well as experts in the field of IT, point to new positions and tasks of employees connected with the implementation of AI and working with it. This leads to the assumption of transformation in the industry. The concept of Industry 4.0 thus brings space for faster change and transformation in industries. The logical outcome is the concept of Industry 5.0, a future stage where, as mentioned above, the key figure will be the person at the center of the system despite the available digital solutions. Industry 5.0 will be characterized by a harmonious coexistence of humans and AI, with the former retaining their central role in decision making and problem solving. Therefore, information systems and digital transformation bring space for the emergence, creation, and filling of new positions, which will be based on digital skills, sophisticated work, and advanced technology, among which AI can be included. Several product managers pointed to the need to increase digital competencies and skills and implement available technologies and see it as a challenge and an opportunity. It is possible to identify with this statement, and, as the research results show, it is highly likely that such a scenario will occur.

Of course, other summative activities should also be focused on the relationship, the person, and the system. The increase in competencies, whether digital or managerial, can lead to the support of the implementation of AI in the process of the design and selection of construction products. The goal is to achieve better results in terms of quality, cost optimization, and delivery. These factors will be important in every industry. It is working with information and information modeling and linking and automating processes that can support the idea of implementing AI in BIM. This implementation has the potential to revolutionize the performance of designing and manufacturing construction products, a prospect that should excite professionals in the field.

On the other hand, realizing the requirements for implementing AI in processes in individual industries is essential. IT infrastructure is on the one hand, user skills are on the other, and management attitude is on the third. All of this can increase the success of using AI and the results, including designing and manufacturing construction products.

5. Conclusions

The research on AI’s influence on performance in the design and production of construction products has unearthed key findings. These insights not only shed light on the future potential of AI but also its current impact on enhancing performance in the construction industry.

One of the general views on AI in increasing performance was the automation of processes and activities in the design and production of construction products. From this point of view, it was about generative design and 3D modeling, which can represent a space for increasing performance in the design phase. This achieved a strong correlation of up to 0.68 and 0.597, respectively, representing a significant impact of AI usage and an increase in the design phase.

On the other hand, there is room for increasing performance through effective behavior in the design and production of construction products, such as cost optimization, shortening the delivery time of construction products, and reducing the consumption of materials. In the case of the impact on material planning, there was a strong correlation at the level of 0.544, and in the case of cost planning, the impact of AI was still at the level of 0.641, which is an equally strong correlation. In the production phase, there was a strong correlation and impact precisely in the production of components. AI strongly correlated with increased productivity at the level of 0.619, which is a great influence and a significant effect at work.

These are areas where the use of AI can be very helpful. This research pointed out trends where it is possible to expect an increase in performance due to the use of AI, such as cost optimization, more effective time planning, which is based on historical data, and better predicting time losses, thus increasing efficiency in this area. Likewise, better design leads to lower consumption of materials. Regarding the regression analysis results, which confirmed the statistical significance of the results, it can be stated that the relationship and impact are significant in manufacturing components and prefabs in connection with the use of AI, which for this is only 0.0001 of the result of regression production.

The research pointed to trends in the use of AI and their impact on increasing performance, especially in the design phase of construction products. It is primarily for activities such as 3D modeling and generating proposals, which can be very effective. Other researchers also pointed this out, which was the starting point for this research. One can strongly agree with several conclusions, and above all with the perception of the impact on performance, where it was demonstrated to this research sample that AI has an impact on performance in the design and production of construction products. Likewise, several studies have pointed to the possible scope for optimization and automation of the creation of budgets, time, and delivery plans. These results were recorded on this research sample, and based on statistical tests, they can be considered statistically significant.

On the other hand, not all the expected results were confirmed in the production phase. Prefabrication played a major role as a method of mass production of building components and semi-finished products. This method also reduces costs and improves the delivery of construction products.

The topic of AI in the construction industry, especially in the design and production of construction products, is complex and multifaceted. To further our understanding, future research should delve into the specifics of AI’s impact on different construction markets and conditions. This will help us refine our conclusions and recommendations.

Future research should also focus on the primary motivators and drivers in implementing and using AI in designing and producing construction products. This can lead to a better understanding of the issue and barriers to more significant use. There is also room for a global dimension and a shift in research and recommendation of findings to better outcomes for a larger group of users. Within the Industry 4.0 concept, the application of research is not only for the building products sub-sector but also for other sectors such as engineering, metallurgy, and others that work with product design, and the conditions may be similar.

Future research should also reflect the position of the person in the system and, thus, the continuity of the Industry 4.0 concept with Industry 5.0. As also mentioned in the Discussion section, increasing competencies, especially managerial and digital skills, could lead to accepting new challenges and classes. The interplay between digital technologies and people can bring a synergistic effect. This results in the possibility of innovation, but also, on the other hand, the constantly necessary human contribution, primarily for coordination purposes, but also responsibility for the results and result-oriented management of design and production. The connection of digital technologies, such as AI, and humans is where industries and work are likely to be transformed. The need for research activity on the synergy between AI and humans is extremely urgent, and future research should address this. Topics such as ethics, accountability for results, and performance will play an important role in discussions and research.