Analysis of Vibration Characteristics and Influencing Factors of Complex Tread Pattern Tires Based on Finite Element Method

Abstract

1. Introduction

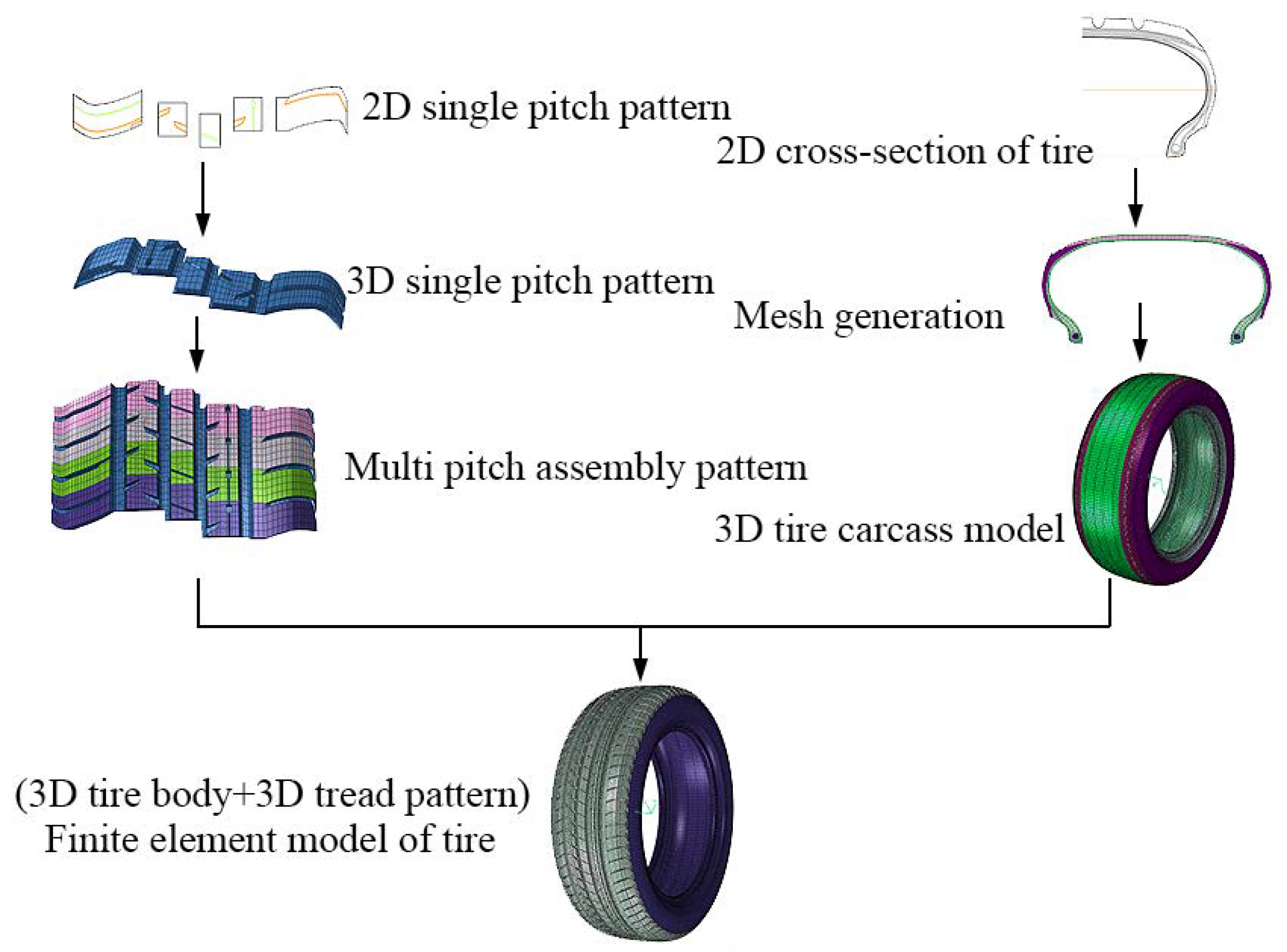

2. Establishment of Tire Simulation Model

2.1. Complex Pattern Tire Model

2.2. Material Settings

3. Experimental Validation

3.1. Tire Vibration Modal Testing

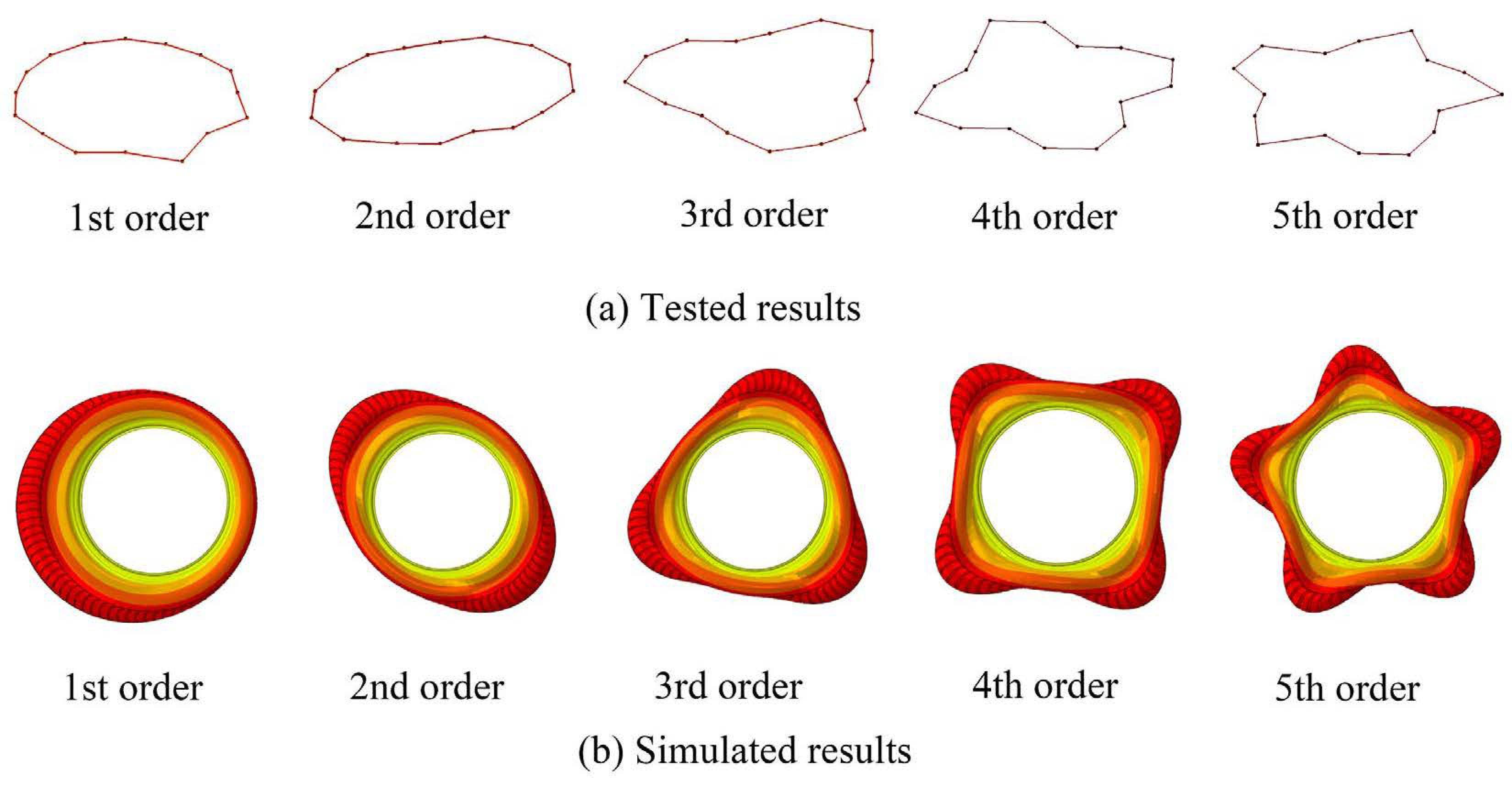

3.2. Analysis of Vibration Mode Results

4. Results and Discussion

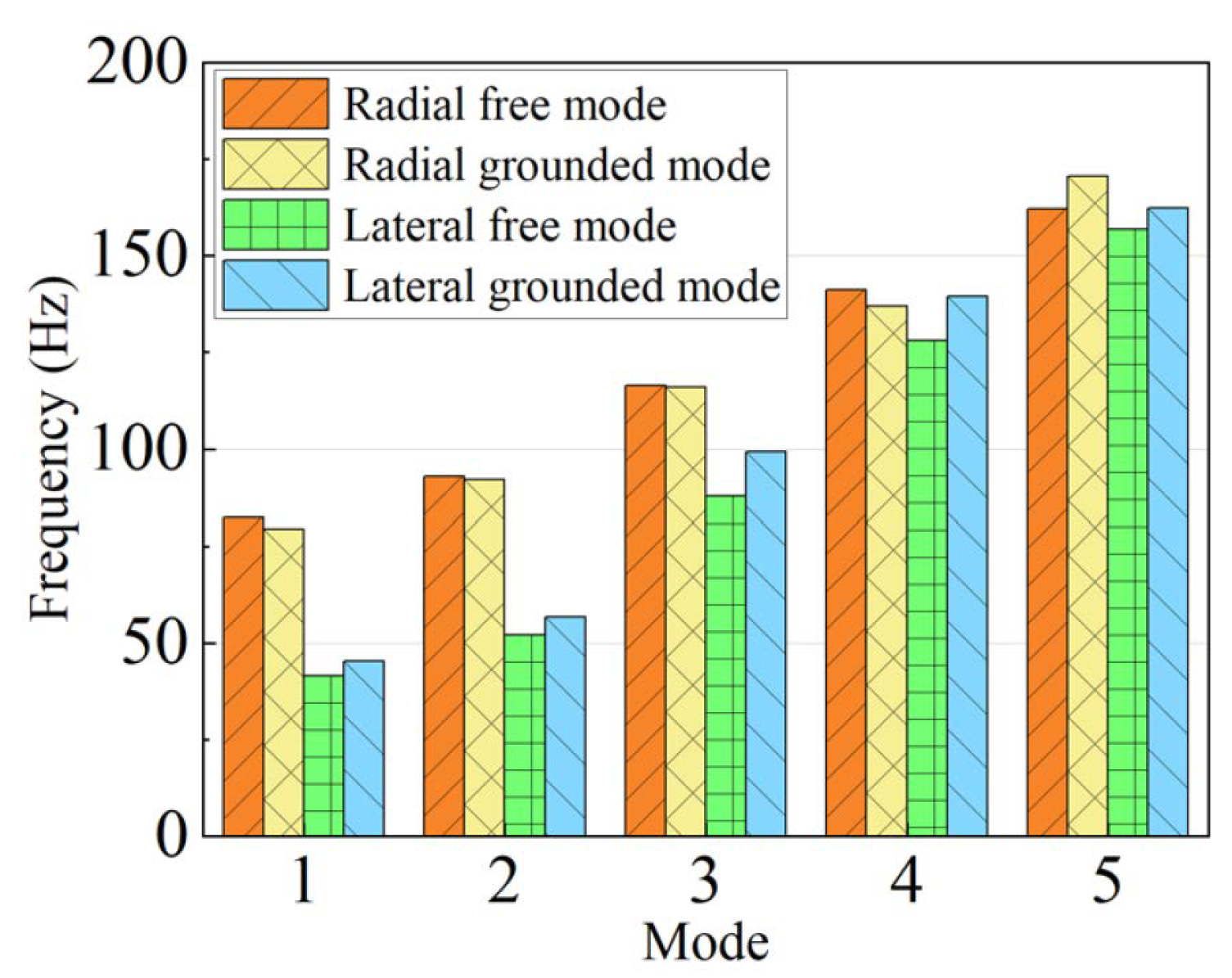

4.1. Finite Element Analysis of Vibration Characteristics

4.1.1. Vibration Modal Theory

4.1.2. Shape and Modal Frequency Analysis

4.2. The Influencing Factors of Vibration Characteristics

4.2.1. Inflation Pressure

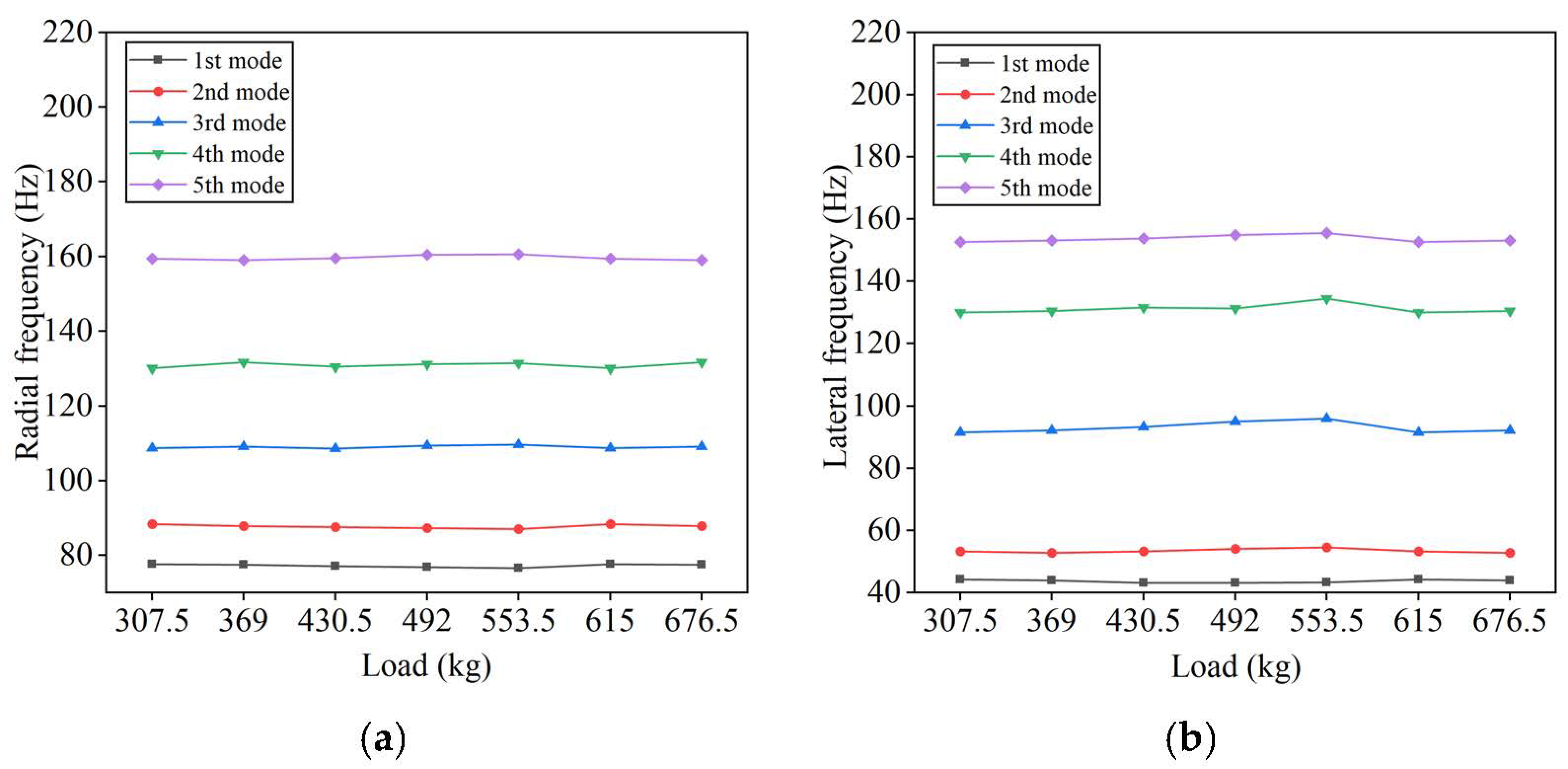

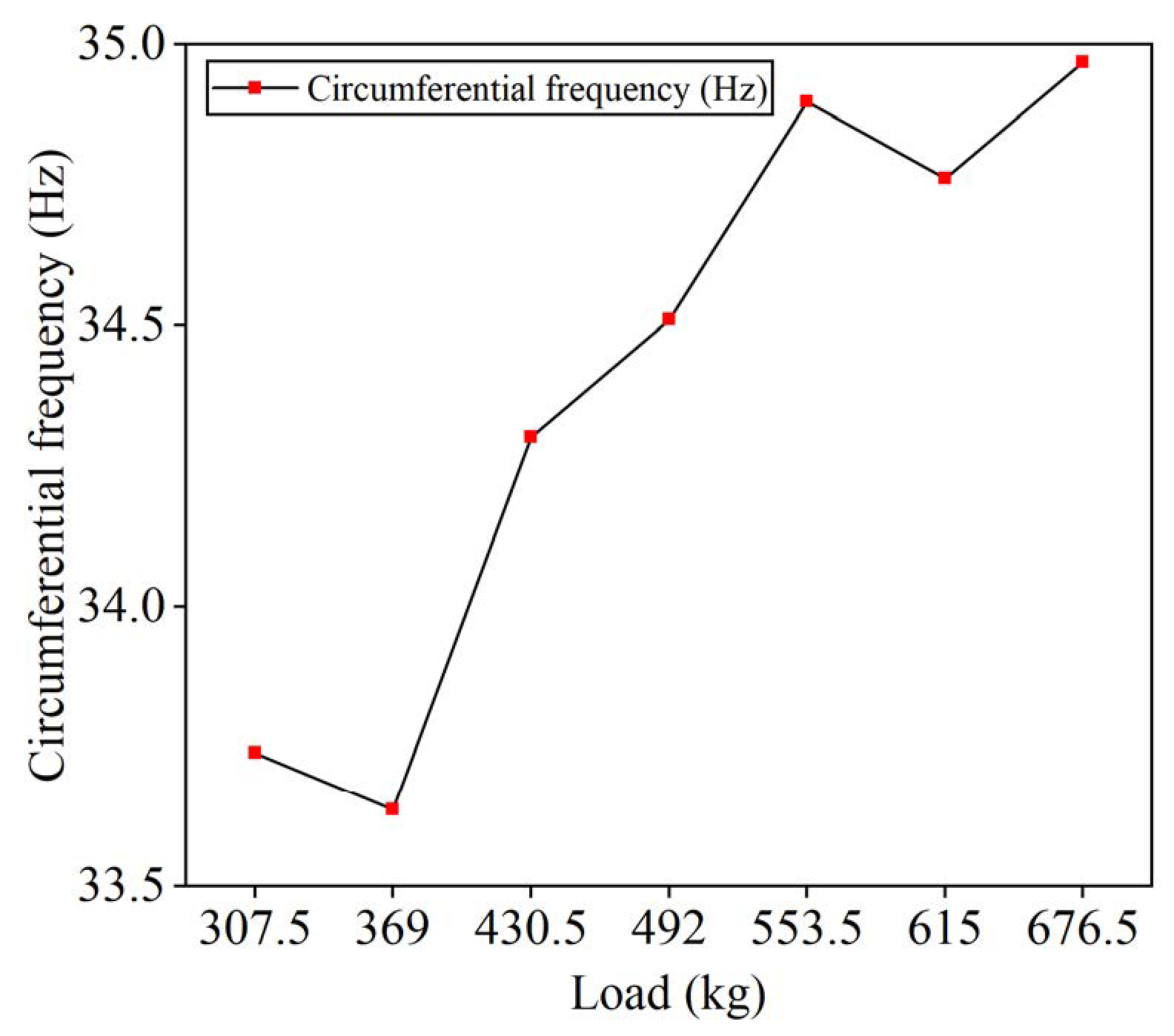

4.2.2. Tire Load

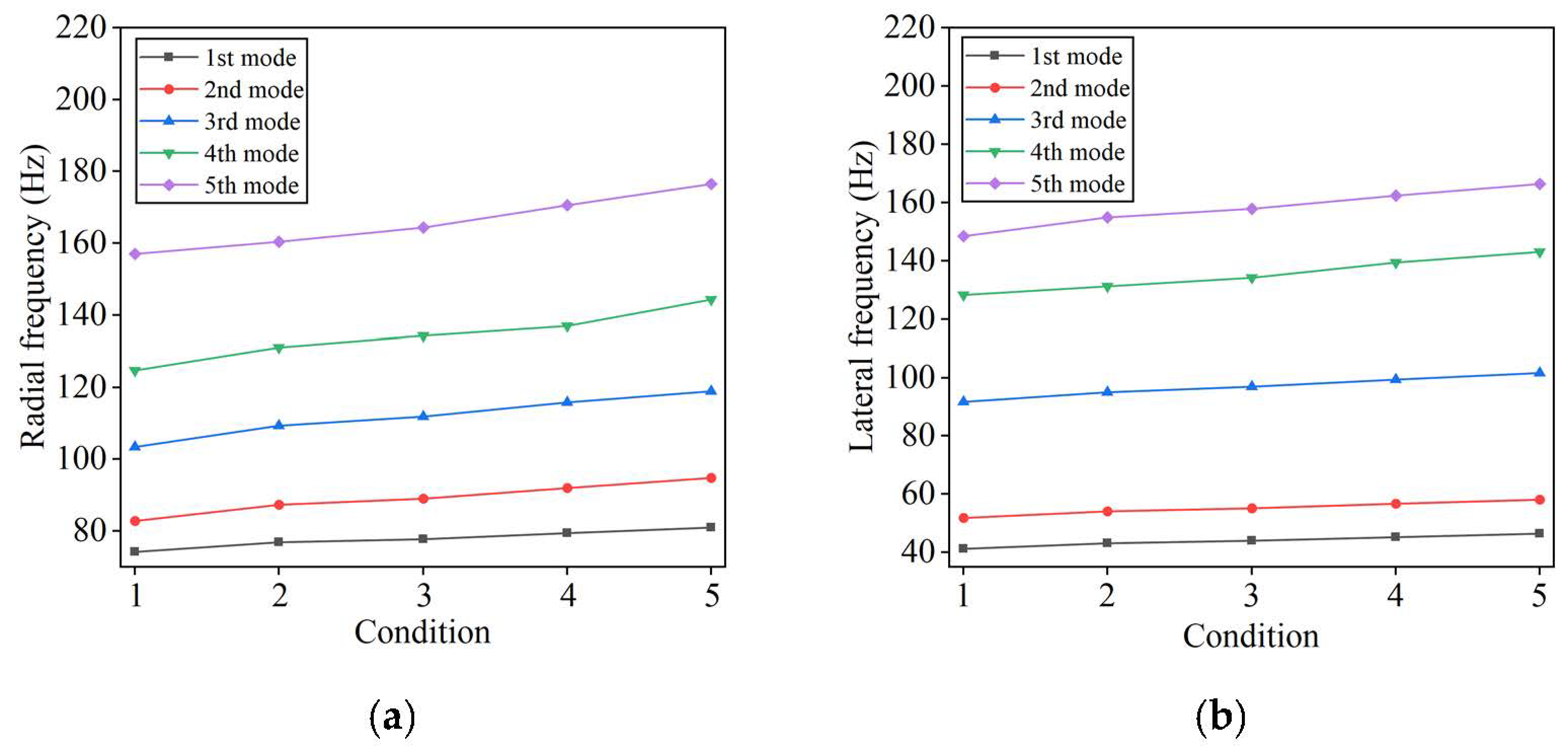

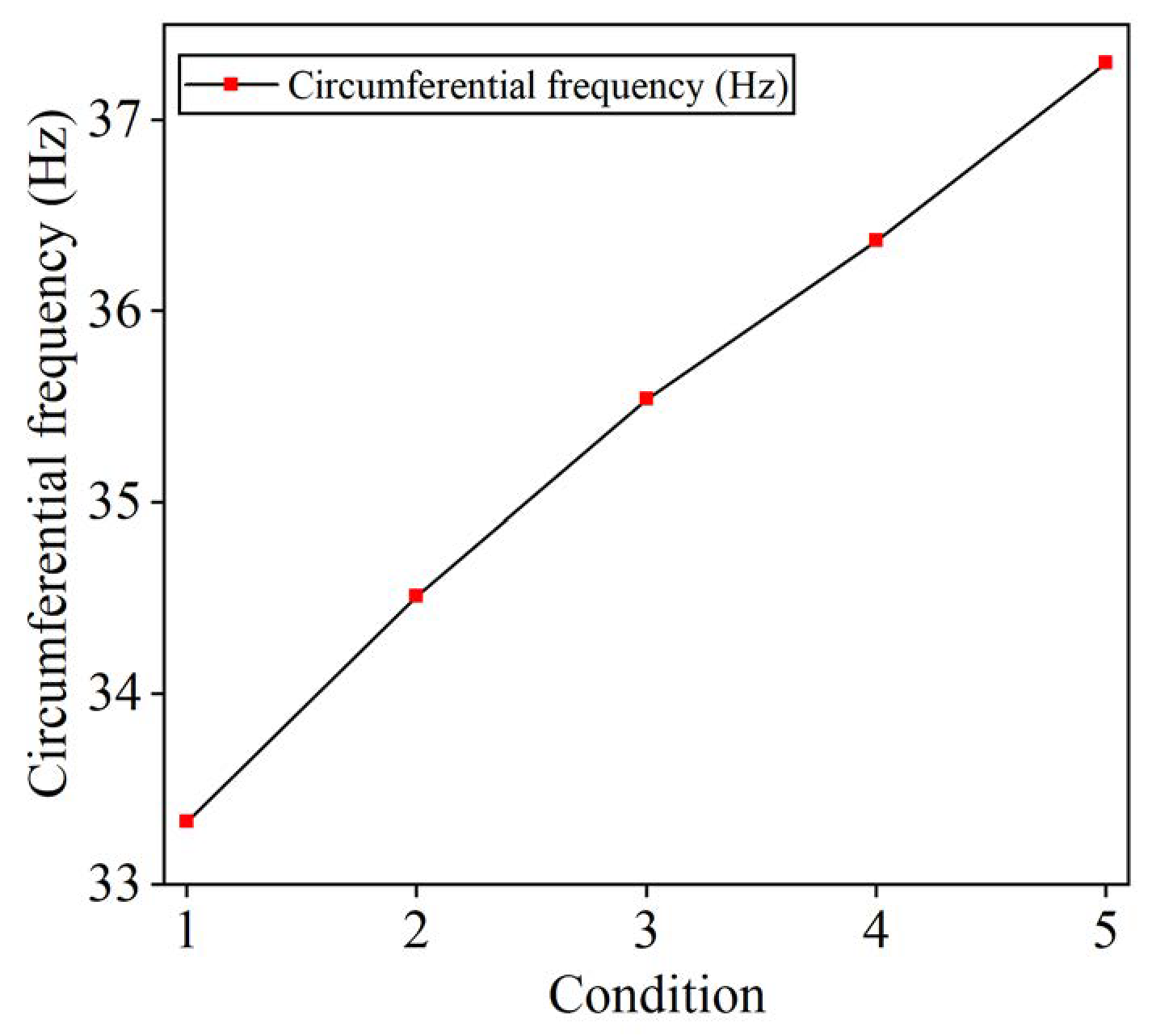

4.2.3. Operating Condition

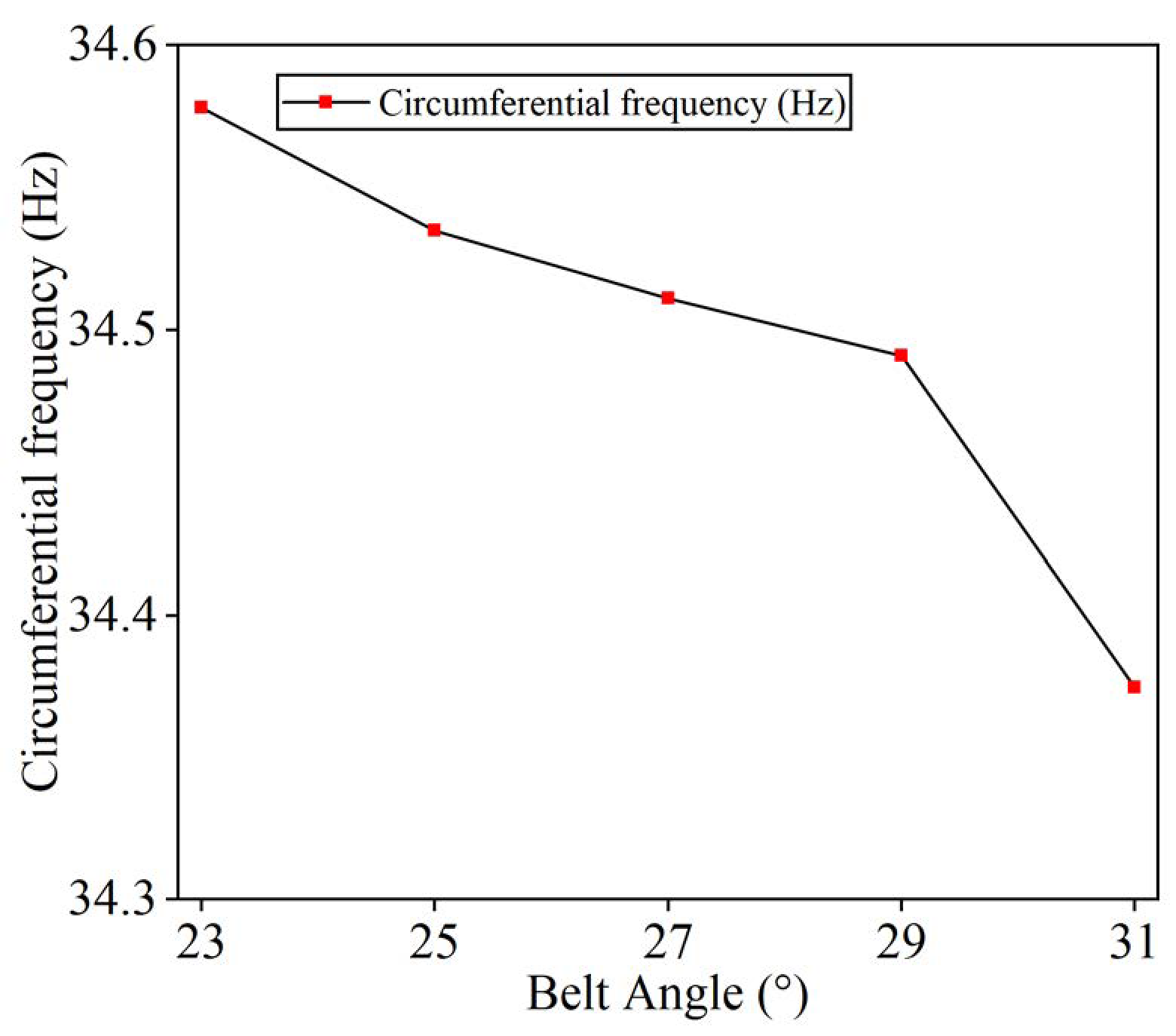

4.2.4. Belt Angle

5. Conclusions

- (1)

- Through experimental comparisons, it was verified that the combination modeling technique used to establish the simulation model of a tire with complex tread patterns is reliable. Compared to the free vibration mode, the radial vibration of the tire with complex patterns shows a suppressed effect under the constraint state of the ground. For the lateral vibration mode, the grounding effect increases the internal air pressure and tire rigidity, which enhances the vibration frequency of the lateral mode.

- (2)

- In both free mode and grounded mode, the change in inflation pressure will directly affect the stiffness of the tire, thereby changing the natural frequency of the tire, and the higher the vibration mode order, the greater the impact of inflation pressure.

- (3)

- The overall stiffness of tires with complex patterns increases as the load and air pressure rise under different operating conditions. The change in load exerts minimal impact on the radial grounding mode of the tire, but the rise in load has a suppressive effect on the first two vibration frequencies. The lateral low order frequency of the tire is unstable, and when subjected to lower loads, the lateral 1st and 2nd order vibration frequencies fluctuate with load changes, making the tire prone to misalignment at the lateral low order frequency.

- (4)

- At the same pressure and load, except for the radial and lateral first-order vibration frequencies that undergo a turning point at a belt angle of 29°, all other frequencies decrease with increasing belt angle. Meanwhile, the increase in belt angle leads to a decrease in the circumferential grounding frequency, but the variation is small between 25° and 29°. Therefore, in the tire design and production process, the belt angle is often set in the range of 25° to 29°.

- (5)

- The analysis of tire vibration characteristics in this paper takes into account the influences of inflation pressure, load, working conditions, and belt layer angle. Further research can be conducted to explore the impacts of environmental temperature, rubber compound, and belt layer cord density and width on tire vibration characteristics.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, H.; Al-Qadi, I.L.; Stanciulescu, I. Simulation of tyre–pavement interaction for predicting contact stresses at static and various rolling conditions. Int. J. Pavement Eng. 2012, 13, 310–321. [Google Scholar] [CrossRef]

- Yu, X.; Huang, H.; Zhang, T. A Theoretical three-dimensional ring based model for tire high-order bending vibration. J. Sound Vib. 2019, 459, 114820. [Google Scholar] [CrossRef]

- Heo, H.; Sofield, M.; Ju, J.; Neogi, A. Acoustic metasurface-aided broadband noise reduction in automobile induced by tire-pavement interaction. Materials 2021, 14, 4262. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Song, W.; Karimi, M.; Chi, C.-H.; Kudreyko, A. Fractional autoregressive integrated moving average and finite-element modal: The forecast of tire vibration trend. IEEE Access 2018, 6, 40137–40142. [Google Scholar] [CrossRef]

- Radhika, B.; Pannala, V. Study of dynamic characteristics of air cavity resonances from tyre-pavement interaction noise using single frequency filtering. J. Acoust. Soc. Am. 2023, 153, 2985. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Yan, S.; Zhao, Y. Numerical and experimental studies of a radial truck tire with tread pattern. Simulation 2015, 91, 970–979. [Google Scholar] [CrossRef]

- Wu, J.; Wang, Y.; Su, B.; Dong, J.; Cui, Z.; Gond, B.K. Prediction of tread pattern block deformation in contact with road. Polym. Test 2017, 58, 208–218. [Google Scholar] [CrossRef]

- Zhou, H.; Jiang, Z.; Wang, G.; Zhang, S. Aerodynamic characteristics of isolated loaded tires with different tread patterns: Experiment and simulation. Chin. J. Mech. Eng. 2021, 34, 6. [Google Scholar] [CrossRef]

- Pinay, J.; Saito, Y.; Mignot, C.; Gauterin, F. Understanding the contribution of groove resonance to tire-road noise on different surfaces under various operating conditions. Acta Acust. 2020, 4, 6. [Google Scholar] [CrossRef]

- Guzzomi, A.L.; Sharman, A.; Stone, B.J. Some torsional stiffness and damping characteristics of a small pneumatic tyre and the implications for powertrain dynamics. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2010, 224, 229–244. [Google Scholar] [CrossRef]

- Wu, X.; Shuguang, Z.; Tianxin, N. Bifurcation and factors influence analysis on self-excited vibration of tire tread. J. Vib. Control 2017, 23, 930–947. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, Q. In-plane vibration modal analysis of heavy-loaded radial tire with a larger flat ratio. J. Vibroeng. 2017, 19, 5327–5345. [Google Scholar] [CrossRef]

- Matsubara, M.; Tajiri, D.; Ise, T.; Kawamura, S. Vibrational response analysis of tires using a three-dimensional flexible ring-based model. J. Sound Vib. 2017, 408, 368–382. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, W.; Sepahvand, K.K.; Wei, Y.; Marburg, S. A three-dimensional ring model for uncertainty quantification in natural frequencies and sound radiation characteristics of tires. J. Theor. Comp. Acout. 2020, 28, 2050016. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, Q.; Niu, H. Development of the flexible ring on an elastic continuous foundation tire model for planar vibration of the heavy load radial tire. Appl. Sci. 2018, 8, 2064. [Google Scholar] [CrossRef]

- Li, Y.; Zuo, S.; Lei, L.; Yang, X.; Wu, X. Characteristics’ analysis of lateral vibration of tire tread. J. Vib. Control 2011, 17, 2095–2102. [Google Scholar] [CrossRef]

- Bari, P.; Kanchwala, H. An analytical tire model using thin shell theory. Int. J. Mech. Sci. 2023, 248, 108227. [Google Scholar] [CrossRef]

- Zhou, S.; Chen, L.; Li, Y.; Sun, P.; Su, G.; Meng, J. Study on the influence of different tire cord structures on tire grounding characteristics. J. Eng. Fiber Fabr. 2022, 17, 155892502211385. [Google Scholar] [CrossRef]

- Guan, Y.; Cheng, G.; Zhao, G.; Zhang, H. Investigation of the vibration characteristics of radial tires using experimental and numerical techniques. J. Reinf. Plast. Compos. 2011, 30, 2035–2050. [Google Scholar] [CrossRef]

- Cheng, H.; Gao, L.; Liu, Z.; Gao, Q.; Liu, X. The planar wide-frequency vibration characteristics of heavy-load radial tires. Math. Probl. Eng. 2021, 2021, 5805292. [Google Scholar] [CrossRef]

- Swami, A.; Pandey, A.K. Vibration analysis of a tire under static loading using flexible ring-based model. J. Vib. Acoust. 2021, 143, 011007. [Google Scholar] [CrossRef]

- Ku, L.; Fu, H.; Chen, K.; Zhang, J.; Bi, S.; Zhou, L. Numerical analysis of steady-state mechanical characteristics of the flexible spoke non-pneumatic tire under multiple working conditions. J. Terramech. 2023, 106, 35–45. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, G.; Zhou, H.; Yang, J. Finite element analysis of influential factors on vibration characteristics of rolling tire. China Rubber Ind. 2019, 65, 1306–1312. [Google Scholar]

- Liu, C.; Cao, F.; Song, Z.; Ju, Z.; Wang, Y. Analysis of factors affecting tire vibration mode based on finite element method. Tire Ind. 2019, 39, 652–656. [Google Scholar]

- Lv, T.; Zang, L.; Xue, C.; Li, Y.; Mao, Y.; Wang, X. Study on the effect of different design parameters of sidewall insert rubber on the mechanical characteristics of self-supporting run-flat tires. Lubricants 2023, 11, 458. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, Q. Parametric analysis of in-plane rigid-elastic coupled non-contact tire model for heavily loaded radial tire. Proc. Inst. Mech. Eng. Part C-J. Eng. Mech. Eng. Sci. 2019, 233, 91–107. [Google Scholar] [CrossRef]

- Cho, J.R.; Kim, K.W.; Yoo, W.S.; Hong, S.I. Mesh generation considering detailed tread blocks for reliable 3d tire analysis. Adv. Eng. Softw. 2004, 35, 105–113. [Google Scholar] [CrossRef]

- Cho, J.R.; Lee, H.W.; Jeong, W.B.; Jeong, K.M.; Kim, K.W. Numerical estimation of rolling resistance and temperature distribution of 3-D periodic patterned tire. Int. J. Solids Struct. 2013, 50, 86–96. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, X.; Hu, F.; Ma, C.; Li, X.; Miao, Z.; Song, J.; Ma, L.; Li, W. Study of the effect of carbon black filling on the mechanical behavior of rubber hyper-elasticity. Materials 2023, 16, 6561. [Google Scholar] [CrossRef]

- Hou, C.; Qi, Y.; Wang, Z.; Ning, Y. Stiffness characteristic analysis of rubber resilient wheel based on Mooney-Rivlin model and Yeoh model. Int. Combust. Engine Parts 2018, 11, 38–40. [Google Scholar]

- Jiang, X.; Jiang, F. Operational modal analysis using symbolic regression for a nonlinear vibration system. Int. J. Solids Struct. 2021, 40, 120–134. [Google Scholar] [CrossRef]

- Carson, E.; Demmel, J.W. Accuracy of the $s$-step Lanczos method for the symmetric eigenproblem in finite precision. SIAM J. Matrix Anal. Appl. 2015, 36, 793–819. [Google Scholar] [CrossRef]

- Wang, Z.; Qiu, S.; Ye, Z.; Hu, B. Posteriori selection strategies of regularization parameters for Lanczos’ generalized derivatives. Appl. Math. Lett. 2021, 111, 106645. [Google Scholar] [CrossRef]

| Component | C10 | C20 | C30 |

|---|---|---|---|

| Tread | 7.331 × 10−1 | −2.939 × 10−2 | 2.840 × 10−3 |

| Base | 7.408 × 10−1 | 8.522 × 10−3 | 1.857 × 10−3 |

| Belt | 1.012 × 100 | 3.899 × 10−2 | 3.590 × 10−4 |

| Carcass | 1.142 × 100 | 2.660 × 10−2 | 8.713 × 10−4 |

| Sidewall | 5.279 × 10−1 | −2.698 × 10−2 | 1.027 × 10−3 |

| Triangle | 2.026 × 100 | −1.004 × 10−1 | 5.329 × 10−3 |

| Inner liner | 5.594 × 10−1 | −6.73 × 10−4 | 1.558 × 10−3 |

| Rim cushion | 1.215 × 100 | −4.336 × 10−2 | 3.816 × 10−3 |

| Parameter | Crown Strips | Belt | Carcass | Bead Ring |

|---|---|---|---|---|

| Elastic modulus (GPa) | 9.14 | 110.98 | 9.36 | 210 |

| Poisson’s Ratio | 0.4 | 0.33 | 0.4 | 0.33 |

| Condition | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Pressure (kPa) | 175 | 210 | 225 | 250 | 275 |

| Load (kg) | 430.5 | 492 | 553.5 | 615 | 676.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, M.; Ge, Y.; Du, X.; Meng, Z. Analysis of Vibration Characteristics and Influencing Factors of Complex Tread Pattern Tires Based on Finite Element Method. Machines 2024, 12, 386. https://doi.org/10.3390/machines12060386

Xu M, Ge Y, Du X, Meng Z. Analysis of Vibration Characteristics and Influencing Factors of Complex Tread Pattern Tires Based on Finite Element Method. Machines. 2024; 12(6):386. https://doi.org/10.3390/machines12060386

Chicago/Turabian StyleXu, Mengdi, Yunfei Ge, Xianbin Du, and Zhaohong Meng. 2024. "Analysis of Vibration Characteristics and Influencing Factors of Complex Tread Pattern Tires Based on Finite Element Method" Machines 12, no. 6: 386. https://doi.org/10.3390/machines12060386

APA StyleXu, M., Ge, Y., Du, X., & Meng, Z. (2024). Analysis of Vibration Characteristics and Influencing Factors of Complex Tread Pattern Tires Based on Finite Element Method. Machines, 12(6), 386. https://doi.org/10.3390/machines12060386