1. Introduction

Passenger cars have emerged as the primary means of family transportation, with an estimated 1.4 billion in operation worldwide. Thus, the car is an integral part of our everyday routines. To capitalize on their proprietary technological advances, manufacturers introduce new designs ever more frequently [

1].

In this regard, one of the challenges is concerned with the seat, whose main functions are providing a seating space, safety, and comfort. The car seat is one of the most important components in a vehicle. Proposing an innovative design is a pretext for companies to assert their creativity, personality, safety, functionality, and differentiation [

2]. Moreover, ergonomic and comfortable seats play a key role in minimizing physical strain and fatigue, thereby supporting sustained attention and concentration [

3]. Comfort is considered a higher priority, especially during long journeys.

Designing a comfortable seat is complicated [

4,

5,

6] because there are a lot of factors to consider in human–seat interactions. Some factors depend on the passenger (anatomical features and characteristics of the passenger’s buttocks) and others on the seat characteristics (seat hardness, seat shape, and contour) [

7]. In fact, human–seat interactions are affected by human anthropometry [

8], body shape [

4], posture [

9], the seat’s design, body sensitivity [

10], comfort [

11,

12,

13,

14,

15], and seating duration [

16]. In the literature, several studies have been carried out to improve comfort by changing the seat pan tilt angle and the friction coefficient of the seat surface [

17], as well as work on the pressure distribution at the body–seat interface [

14,

18,

19,

20].

Thus, the contact area is the best factor for objectively assessing the perceived (dis)comfort. Improving this contact area can potentially increase the positive experience of a car journey. Furthermore, some pressure mapping systems are low-cost and easy to use [

21,

22].

All of these aspects must already be considered in the early stages of the design process. To do this, the virtual prototype plays a fundamental role. In the automotive sector, prototypes are supported, i.e., for rapid visualization of car parameters and car exterior body proportions [

23], or for designing a shaped seat pan pad [

24].

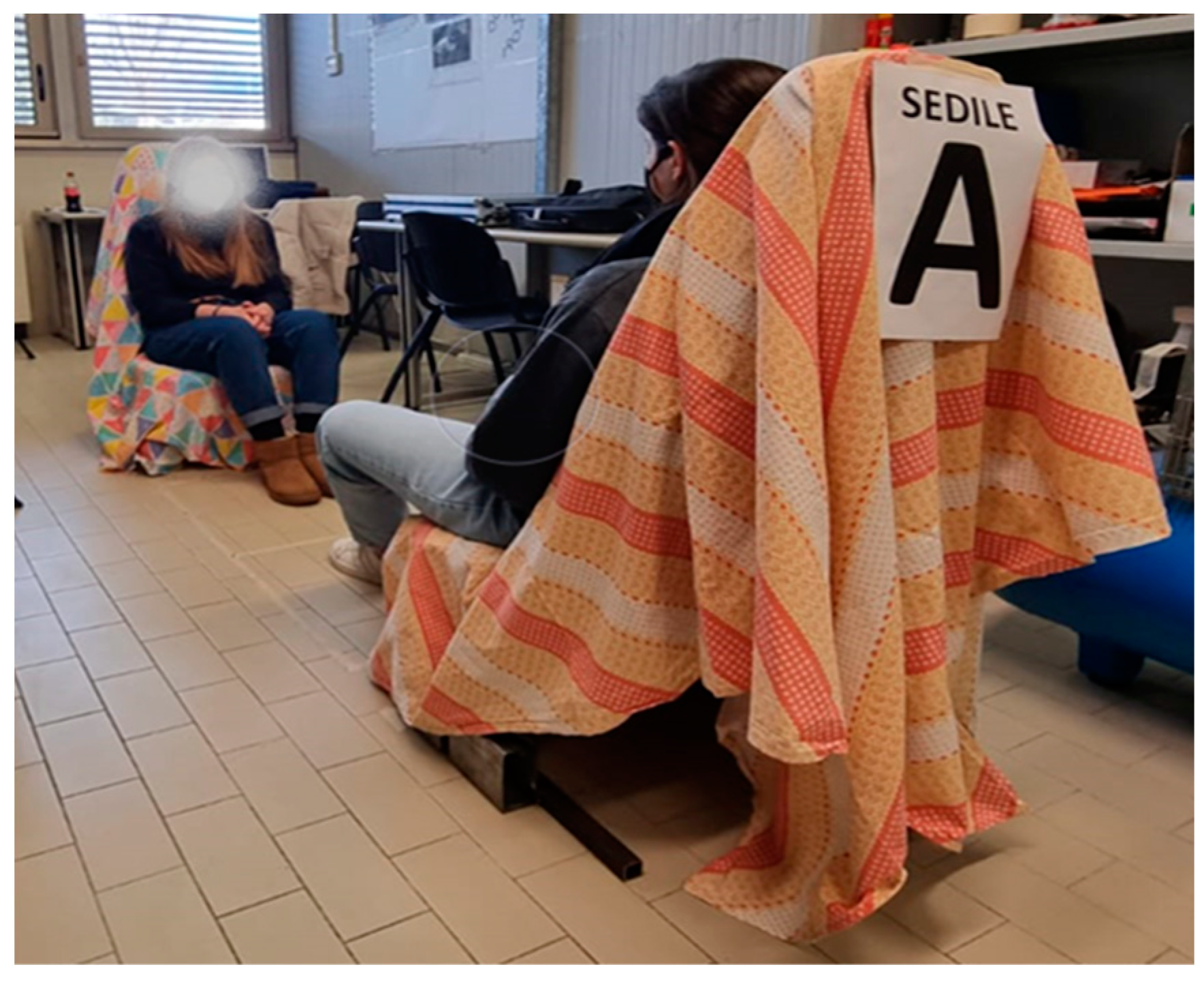

Therefore, the assumption is that developing a shaped seat pad based on human contours could improve pressure distribution and, consequently, increase comfort and decrease discomfort perception. Starting from this hypothesis, two different car seats were compared: a standard seat, and another with a shaped seat pan.

The experiment was divided into two parts.

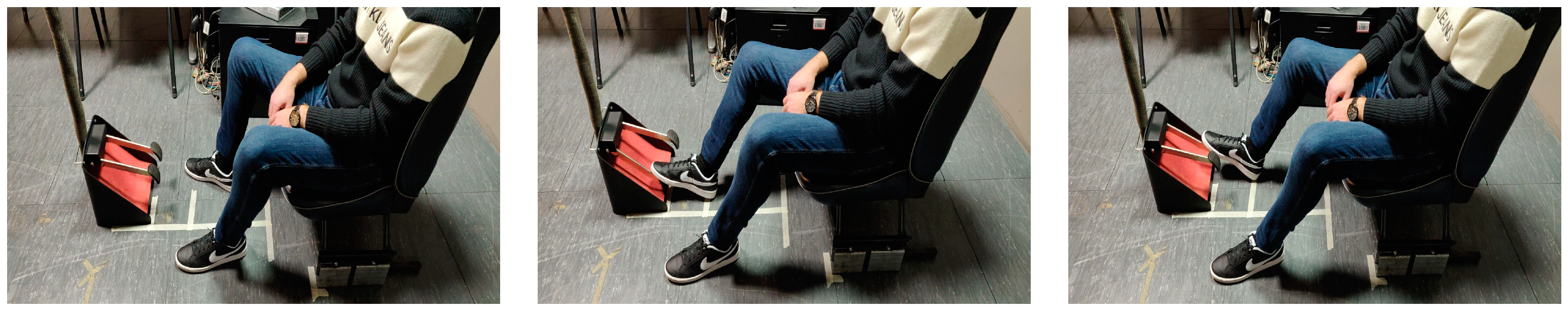

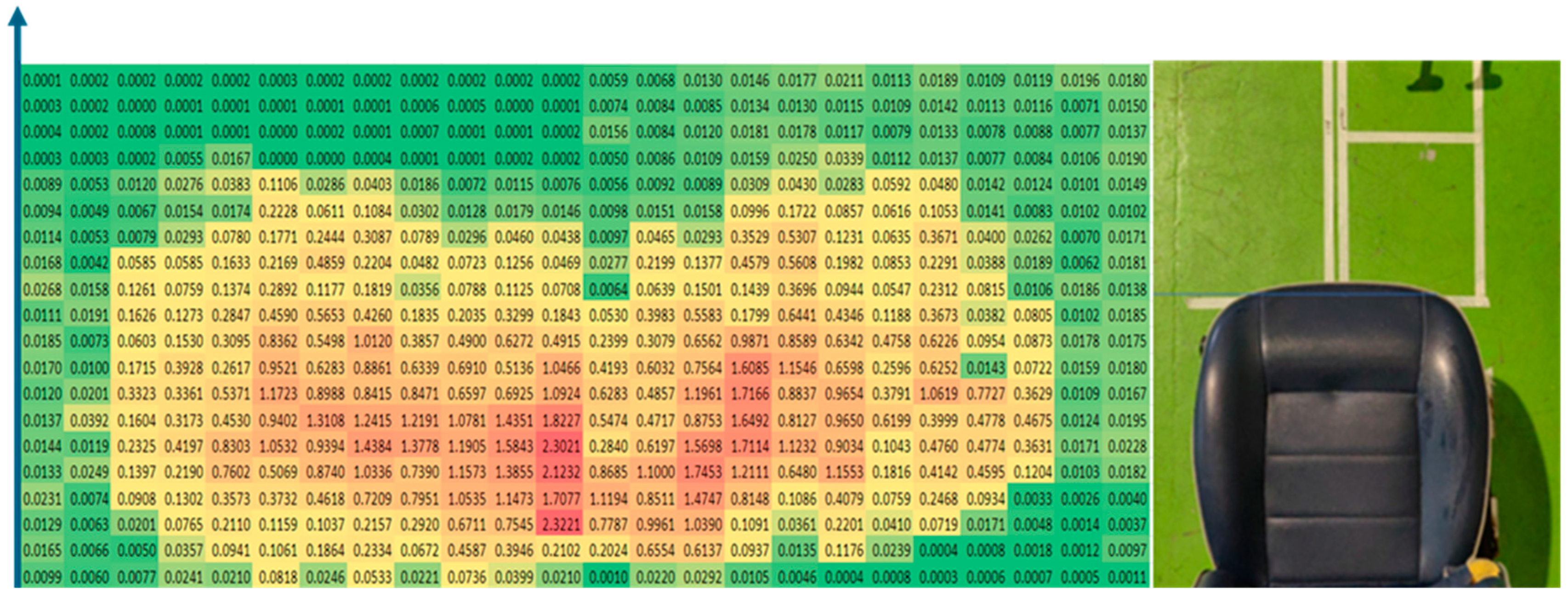

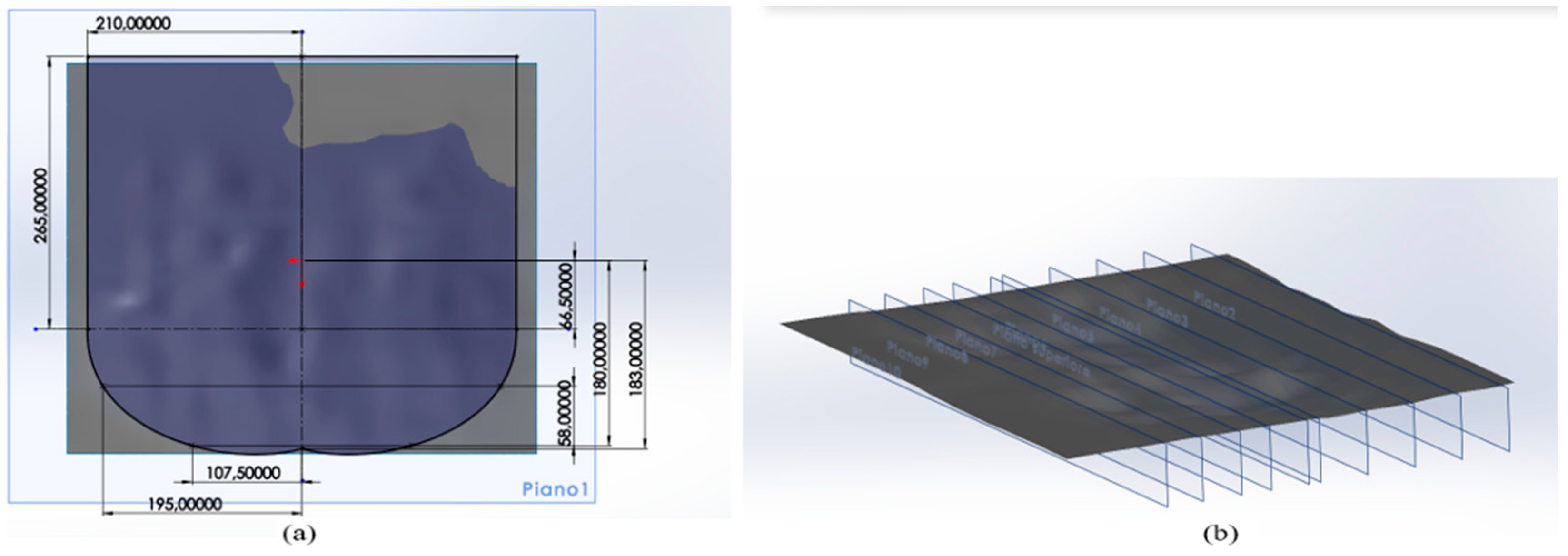

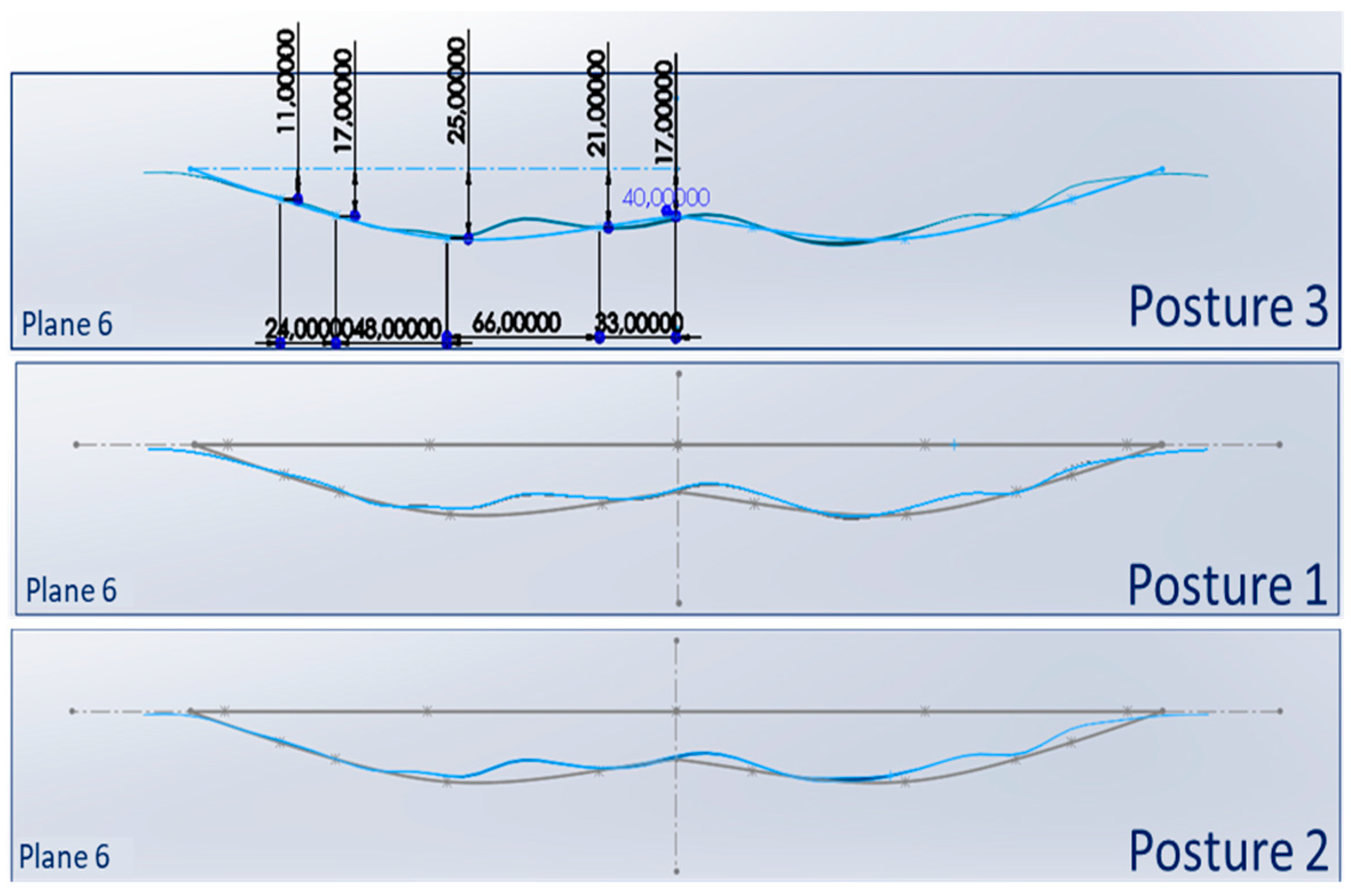

The first part focused on the shaped seat pad design. Forty-one people were asked to sit on a standard seat, and interface pressure maps were acquired; three different postures were investigated, in order to represent different passengers’ conditions: non-driving passengers in a relaxed posture, driving passengers pressing the brake pedal, and driving passengers pressing the accelerator pedal. The averaged pressure maps were merged to obtain a geometric model that conformed throughout the sample for the different postures.

The second part aimed to validate the shaped seat pad. Sitting comfort and discomfort are independent entities associated with different factors; discomfort is related to biomechanics and fatigue factors (long periods), and comfort is a sense of well-being and aesthetics (short periods) [

25]. Therefore, in this study two different tests were conducted: a 1-min test (comfort assessment) and a 15-min test (discomfort assessment).

The virtual prototype of the shaped pad was designed with 3D-CAD (Computer Aided Design) software (Grasshopper® for Rhino 5.0 software) starting from the set of pressure maps output from the first part of the experiment. Then, a physical prototype was manufactured and compared with the standard pad.

The main research questions of the study are as follows:

What is the preferred seat pan of the subjects, among standard and shaped ones?

Comparing the two-seat pans, how does the comfort/discomfort perception change?

Is the shaped seat pan better than the standard one, considering the contact area and the pressure distribution?

Does the new shaped seat pad have a positive effect on costs (materials)?

Based on these research questions, our aim is to expand knowledge on the design of seat pans that can increase comfort and reduce discomfort during their use. Similar studies have been carried out in the aeronautical sector [

24] and in the office chair sector [

22]. The authors’ goals are to demonstrate the validity of these assumptions for car seats also, defining a design roadmap that can be easily replicated to create commercial seat pads that follow human contours without changing the materials.

4. Experimental Results and Discussion

4.1. (Dis)comfort Data

After processing the acquired data, it was noted that 26 of 33 participants after the “1 min” test and 10 of 19 participants after the “15 min” test preferred the shaped pan instead of the standard one. This means that, as an average of all performed tests, 78.8% of the participants chose the shaped seat pan. Furthermore, the results show that the preference for the shaped seat pan was immediately evident during the “1 min” test; this also justifies the choices of the authors in preparing two different tests for evaluating comfort and perceived discomfort as two separate entities [

25].

The cross-analysis of the data showed that the preferred seat, chosen after experimenting with both, obtained higher comfort and lower discomfort values in the specific questionnaire for that seat pan pad. Statistical analysis showed a significant correlation between the (dis)comfort ranking and the preferred seat pan pad (Spearman coefficient = 0.615) (

Table A1 in

Appendix A). This demonstrates the consistency in participants’ responses.

The descriptive adjectives data correlated to the two seat pans were analyzed.

Figure 13 and

Figure 14 show the occurrences of participants that chose each adjective to describe the seat pans.

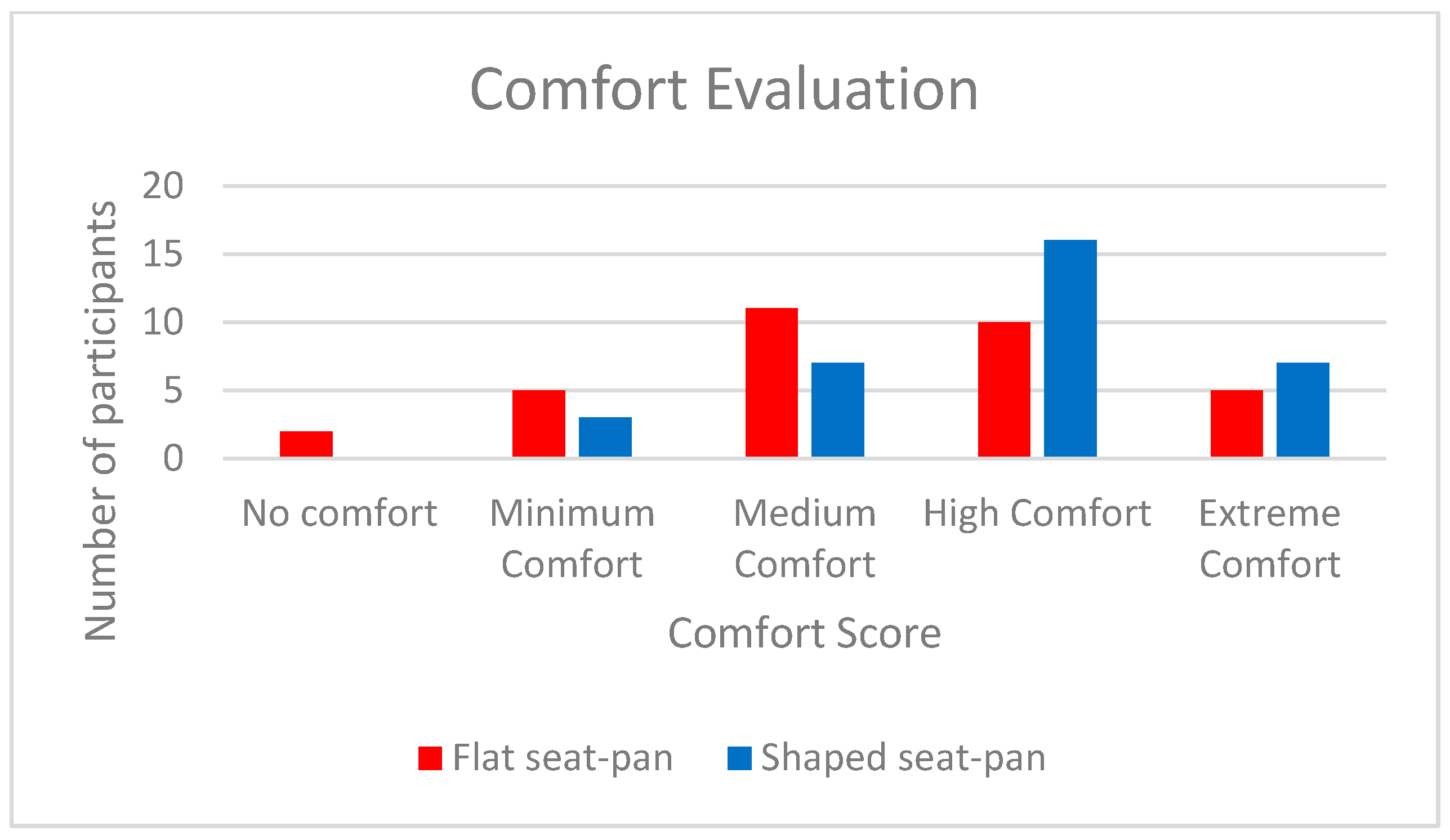

The shaped seat pan appeared softer due to the lower mean pressure distribution and the higher contact area. This seat pan pad was more comfortable and more appropriate to the body shape, confirming the literature studies [

18,

22,

28,

29]. The shaped seat pan was rated as “enveloping” in the comments. The flat seat pan pad seemed to be firmer than the shaped one due to its geometrical characteristics (the material being exactly the same). Participants who preferred it stated that (in open questions) the flat seat pan supported their body weight better.

The histogram in

Figure 15 shows the distribution of comfort scores given by participants.

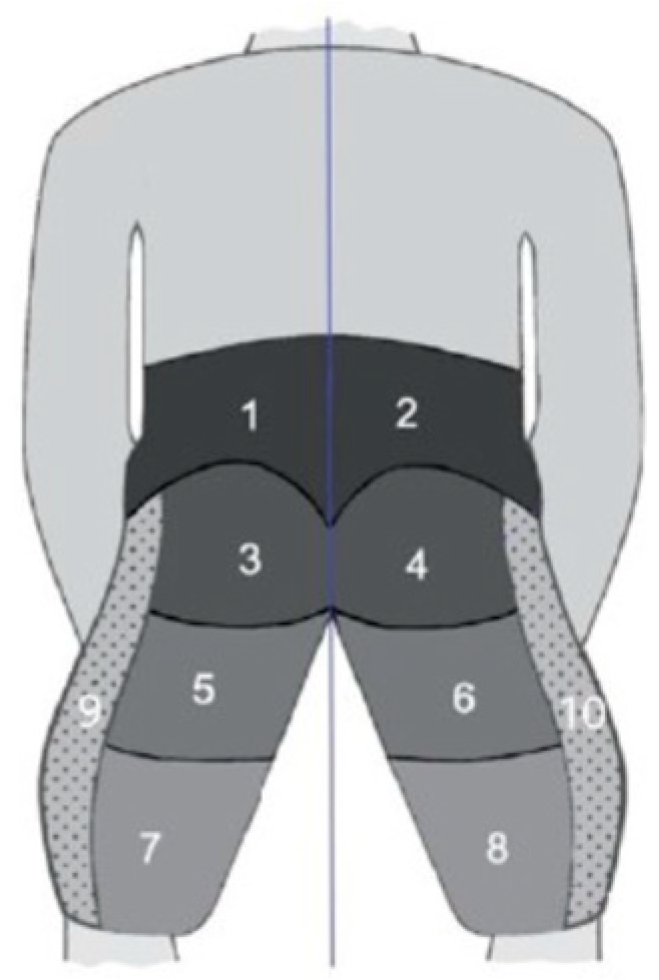

Table 5 shows the discomfort average score for each body part for the seat pans; the highest values are related to the lumbar and buttocks areas (zones 1, 2, 3, and 4). The sensitivity of the human buttocks is different both for the same seat pan pad and between the flat and shaped ones [

10]. For these areas where the sensitivity to discomfort is higher, the shaped seat pan solution brought improvements, exhibiting lower discomfort values.

Table 6 and

Table 7 show the number of participants that answered the questionnaires rating the perceived discomfort score (from no discomfort to extreme discomfort), for each body part.

For the flat seat pan, participants provided ratings ranging from low to high discomfort. One person even rated the discomfort in zone 10, as experiencing extreme discomfort.

In

Table 7, values show that participants provided ratings ranging from no discomfort to extreme discomfort scores to the shaped seat pan.

Correlation analysis showed a strong correlation between seat preference and buttocks discomfort (left and right sides), with Spearman coefficients equal to −0.728 and −0.654, respectively. In fact, participants that preferred the flat or shaped seat pan pad declared that they perceived less discomfort in the buttocks area. This negative correlation indicates that, in the choice of the preferred pad, buttocks discomfort played an important role.

The data analysis, moreover, showed that 100% of the female participants preferred the shaped pad; this is probably due to the different physical conformation of the pelvis.

Moreover, the Spearman index showed strong positive correlations between the discomfort assessment of two adjacent body parts (

Table A2 and

Table A3 in

Appendix A). This suggests that two body parts, in proximity, influence each other’s discomfort levels or, alternately, that it is difficult to identify the precise area where the discomfort is concentrated. No correlation was found regarding the anthropometric characteristics of the participants. The contoured seat was preferred by about 80% of the sample. Considering that the sample for both tests sufficiently varied in height and weight (

Table 3 and

Table 4), this means that anthropometric characteristics cannot be considered as a “factor of influence” while experiencing the shaped seat.

4.2. Pressure Distribution and Contact Area

The pressure mat data (for both pads), acquired during the validation phases (15 min for each solution), were analyzed. For each solution (flat and shaped seat pans) and each participant, a single average pressure and contact area map was obtained.

Then, the two maps from the two solutions for each participant were compared. In particular, data from the shaped pad were subtracted from standard pad data: negative values of average pressure mean that the mean pressure on the shaped pad is lower than the flat pad. Positive values of contact area mean that the contact area on the shaped pad is larger than the flat pad.

Finally, the mean values (

Table 8) show the trend of the results, demonstrating that the shaped pad allows lower mean pressure and a larger contact area than the flat pad, like the scientific literature confirms [

22,

30,

31]. The subjective data (perceived comfort and discomfort) were statistically validated through the objective data (pressure distribution and contact area).

6. Conclusions

The car seat’s function is to provide comfortable seating posture for occupants. An uncomfortable seat increases the risk of health issues and discomfort perception. Consequently, the seat plays an essential role in the car design process. A shaped seat pan was designed to follow the buttock–thigh contour. A special procedure was applied to create the enveloping shape of the seat pan pad: the pressure distributions of 41 participants were acquired and processed. Participants were asked to assume three different postures on a standard car seat (1—relaxed posture simulating a passenger, no pedal use; 2—pressing the brake pedal; 3—pressing the accelerator pedal) for 60 s each. The pressure data were opportunely processed to generate the geometric characteristics that were obtained using Matlab® and Grasshopper®, then merged to create a final solid model of the shaped pan to be manufactured with a low-pressure foaming machine and integrated into a standard car seat. The proposed design approach is easily replicable and modifiable using virtual prototyping techniques and physical prototyping activities. The aim was to compare the proposed seat pan (shaped pan) and the standard one (flat plan) in terms of comfort and discomfort perceptions, and to validate the comparison using objective data acquired by a pressure mat at the interface between the subject and car seat. To avoid any potential influences on the participants’ perceptions and expectations, two blind tests were conducted: the first one (the comfort assessment), in which 33 participants tested the two solutions, for 1 min each; and the second one (the discomfort assessment), in which 19 participants (not the same as the previous test) tested each solution for 15 min. In both tests, the shaped seat pan pad was preferred by 79% of the participants, and 100% of the female participants preferred the shaped seat pan.

Generally, the shaped seat pan pad was considered more suited and “enveloping”. Comfort and discomfort data confirmed the participants’ preference: the shaped seat pan pad scored higher for comfort level than the flat one, and less for local discomfort level, especially in the buttocks area. Regarding the objective data (pressure mat data), the results showed that the shaped pad was the best solution in terms of better pressure distribution and lower pressure peaks, thanks to its larger contact area than the flat pad. This study confirms the scientific literature about the influence of pressure distribution and contact area on (dis)comfort perception. Furthermore, it shows a new design roadmap that is easy to replicate, in order to create commercial seat pads based on the physical interaction data between human buttocks and the seat itself.