Trial Manufacture and Performance Research of Hydraulic Oil Tank for Three Kinds of Non-Metallic Materials

Abstract

1. Introduction

- (1)

- Low Density: Non-metal materials have a density of approximately 1/8 that of metal materials, resulting in significant reductions in weight and emissions for engineering machinery. This is conducive to the “dual carbon” strategy.

- (2)

- Corrosion Resistance: Engineering machinery often operates in harsh conditions. Compared to metal materials prone to rust and corrosion, non-metal materials exhibit highly corrosion-resistant properties, reducing the risk of component damage caused by corrosion [3].

- (3)

- Diversification: The integrated development of engineering machinery emphasizes high space utilization. Metal HOTs typically have rectangular shapes, reflecting the difficulty of shaping metal materials into diverse forms. Non-metal materials can easily be manufactured into containers of various shapes, greatly enhancing the spatial utilization of engineering machinery [4].

- (4)

- Simplified Process: Metal materials require multiple processes, such as stamping, welding, and rust prevention during the forming process, which can be complex. Non-metal materials, on the other hand, utilize simpler forming methods such as injection molding, rolling molding, and additive manufacturing, resulting in a much simpler process that is beneficial for cost reduction.

- (1)

- Materials should be conducive to process molding. Powder materials must be used for rotational molding, among which polyethylene (PE) is the most studied and widely used material, accounting for 84 % of rotational molding materials. It is also the main material for making non-metallic fuel tanks. In addition, thermoplastic materials such as polypropylene (PP), nylon (PA), and polyvinyl chloride (PVC) also have many applications, accounting for 15% [12].

- (2)

- The material should meet the requirements of working conditions. The HOT is significantly different from the fuel tank. The internal medium of the HOT is constantly circulating, and the pressure loss of the hydraulic system during the working process is converted into heat energy and then brought back to the HOT through the circulating oil, resulting in a higher working temperature of the HOT, exceeding 80 °C [13]. At the same time, the HOT will also work under pressure; that is, it needs to bear a certain pressure, such as the closed HOT [14]. In addition, construction machinery also faces significant acceleration loads, such as sudden braking and vibration, which will affect the HOT.

2. Quality Analysis of Rotational Molding of the Non-Metallic HOT

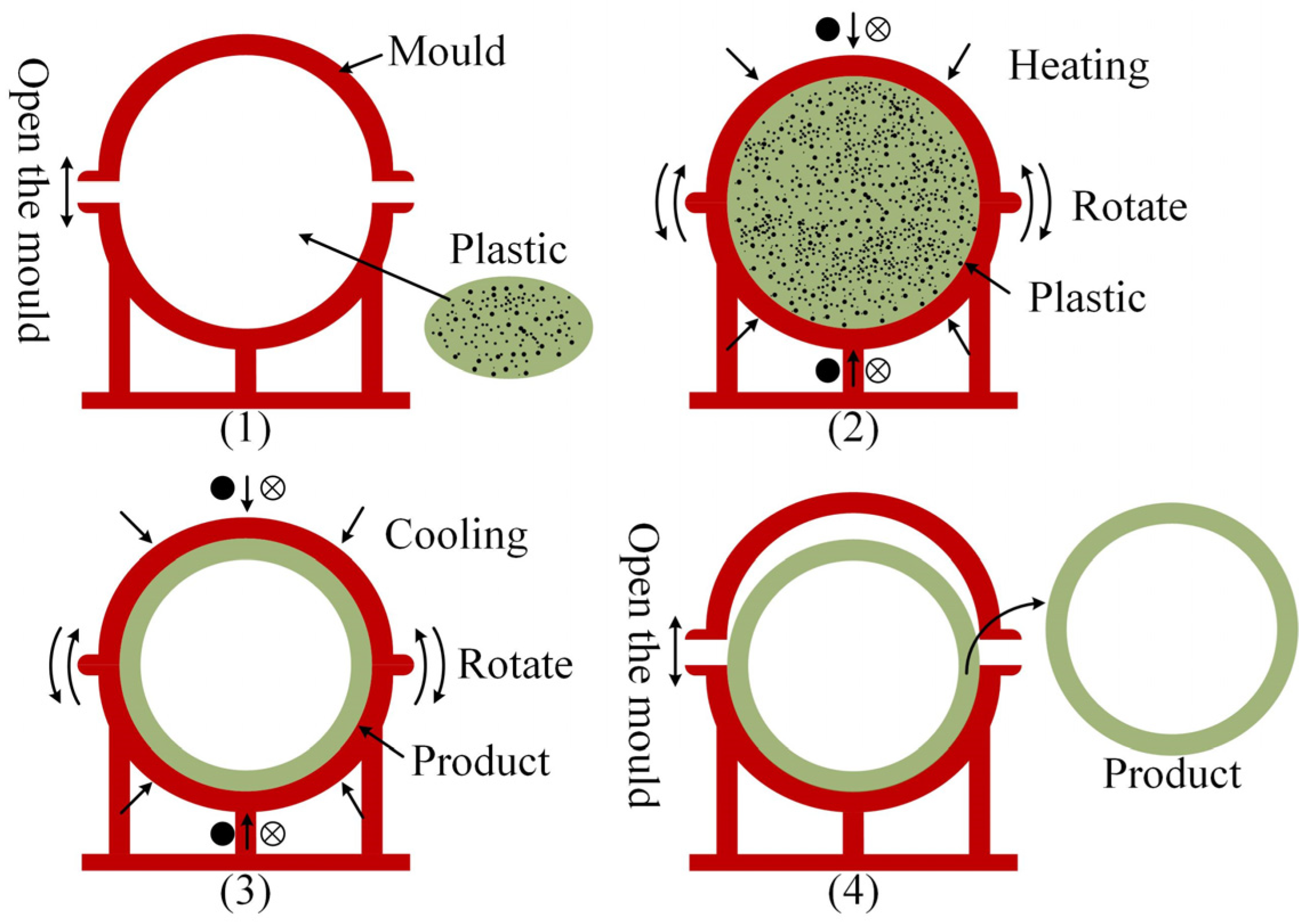

2.1. Analysis of the Rotational Molding Process and Its Key Parameters

2.2. Analysis of the Rotational Molding Process and Its Key Parameters

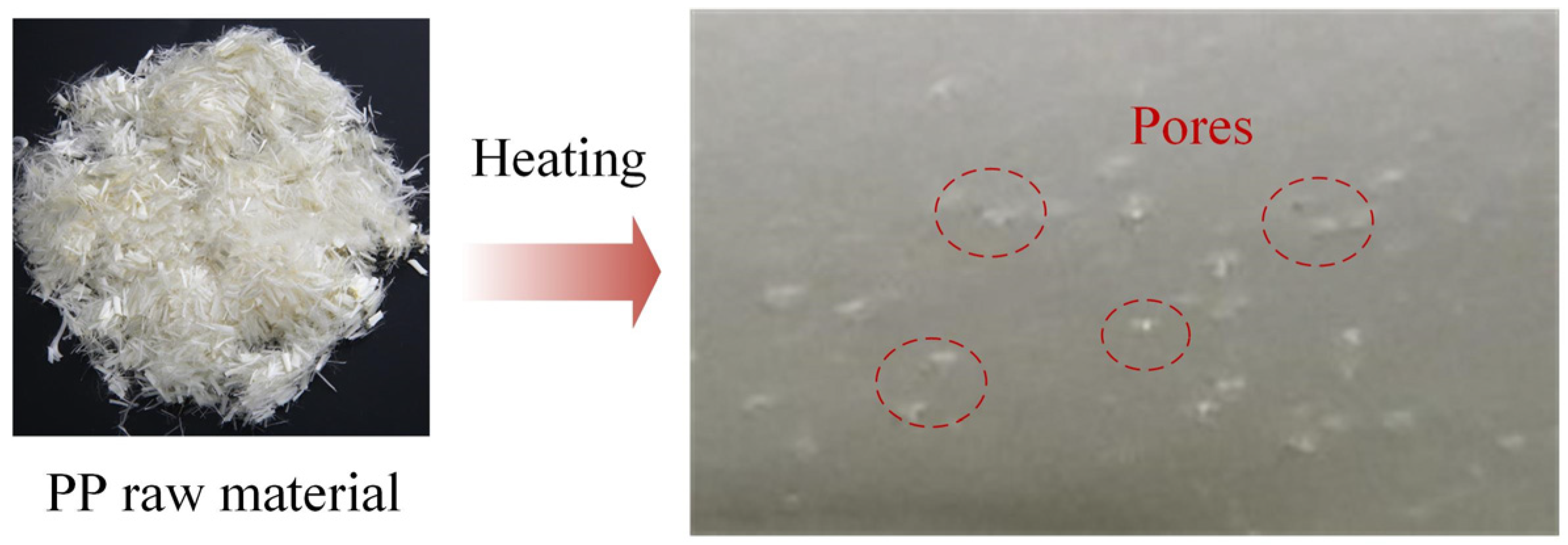

- (1)

- Incomplete heating of plastic powder;

- (2)

- Poor fluidity of plastic powder melt;

- (3)

- Plastic powder has a slender tail or hairy shape, and more air will be retained in the process of rotational molding [20].

2.3. Analysis of the Rotational Molding Process and Its Key Parameters

3. Performance Test Scheme of the Non-Metallic HOT

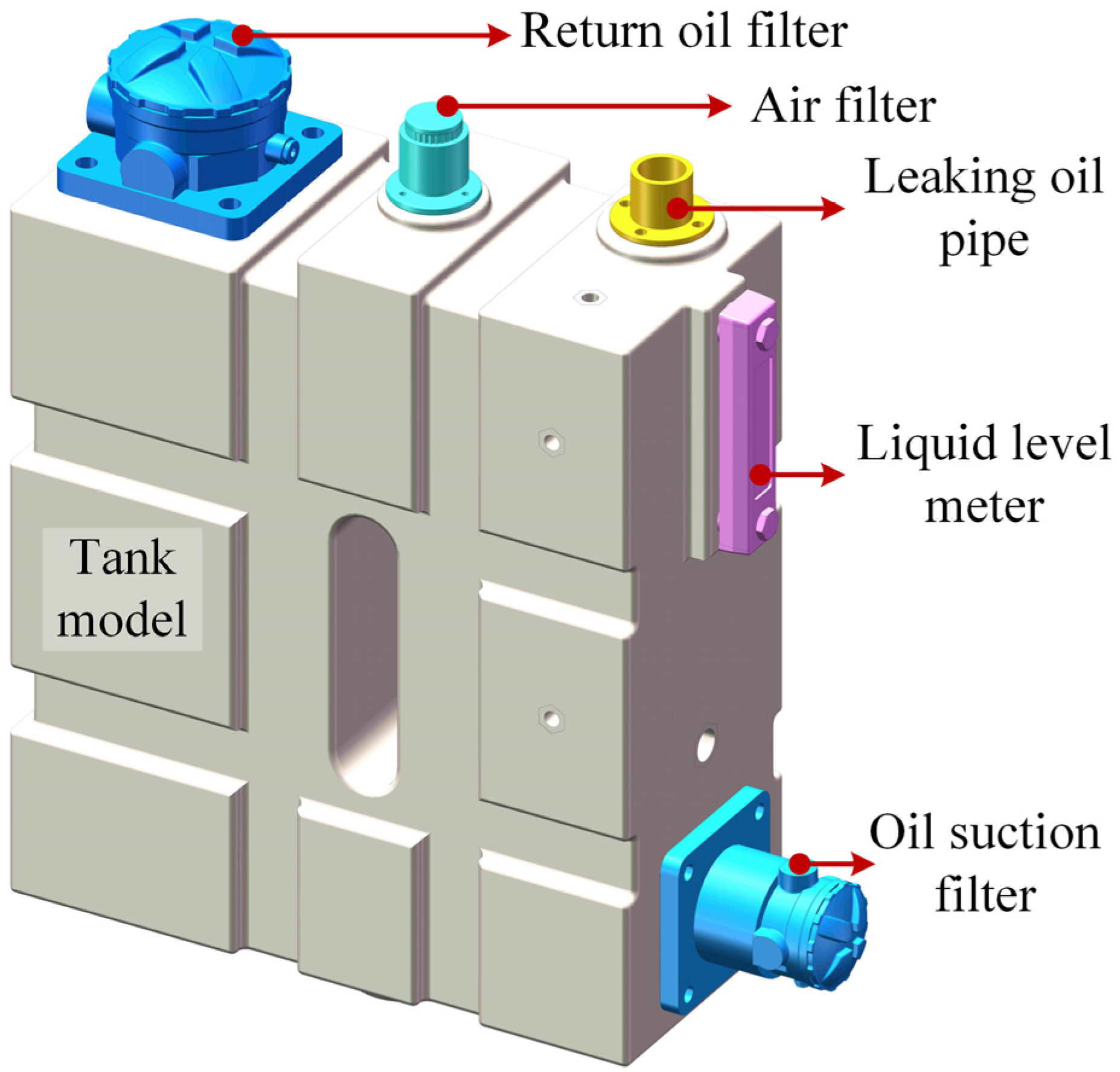

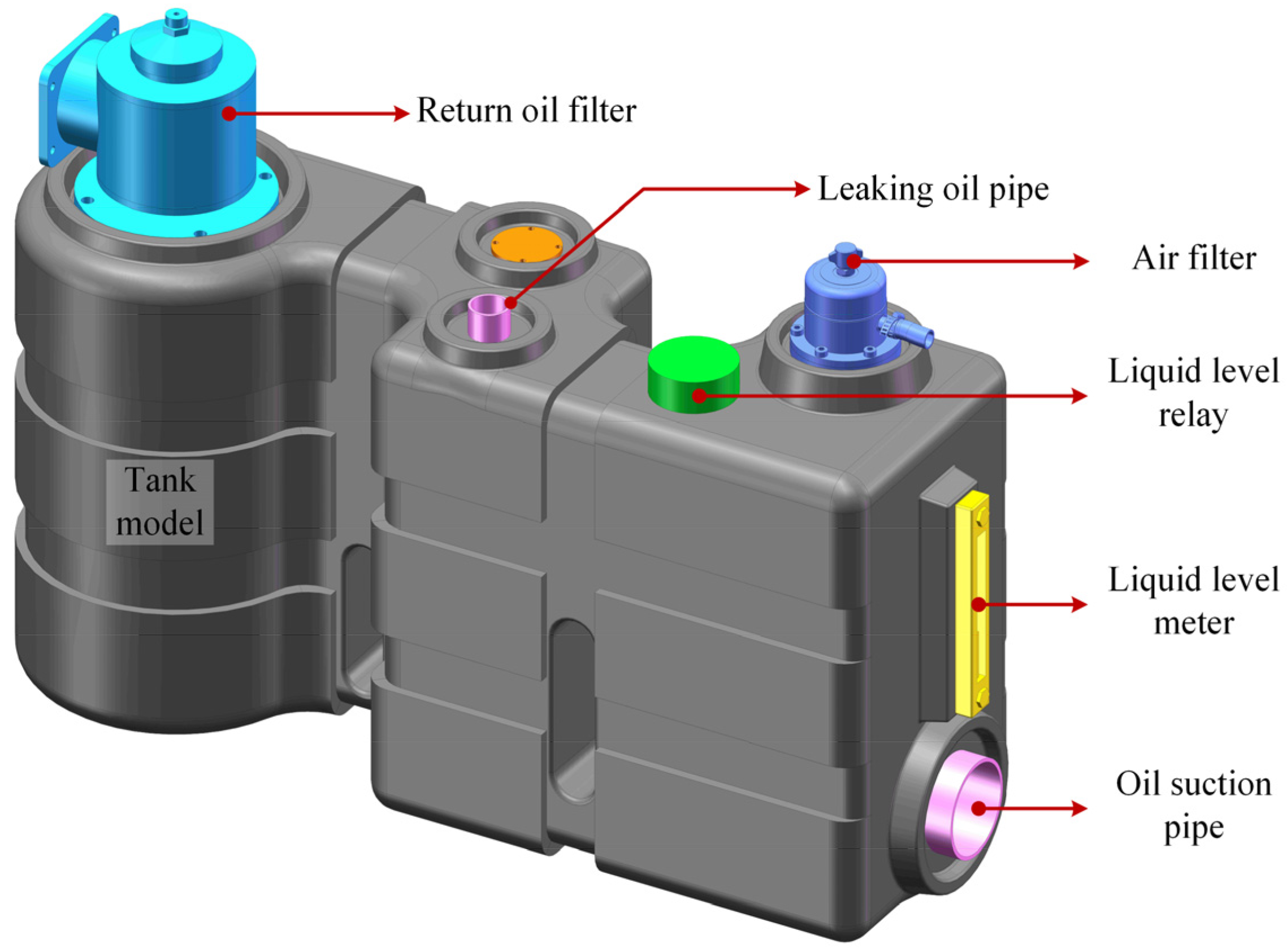

3.1. Equipment and Instruments

3.2. Preparation of Test Plan

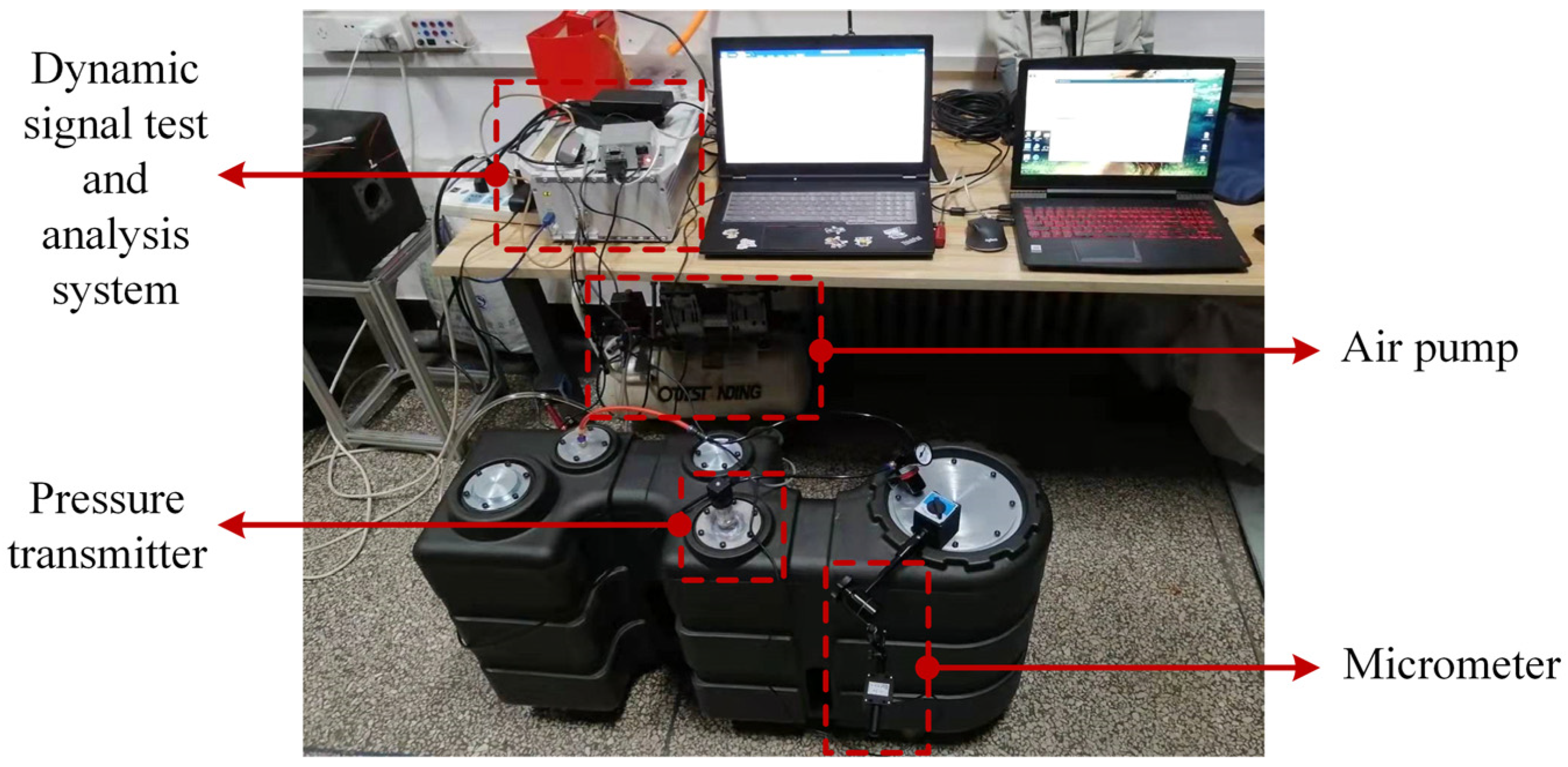

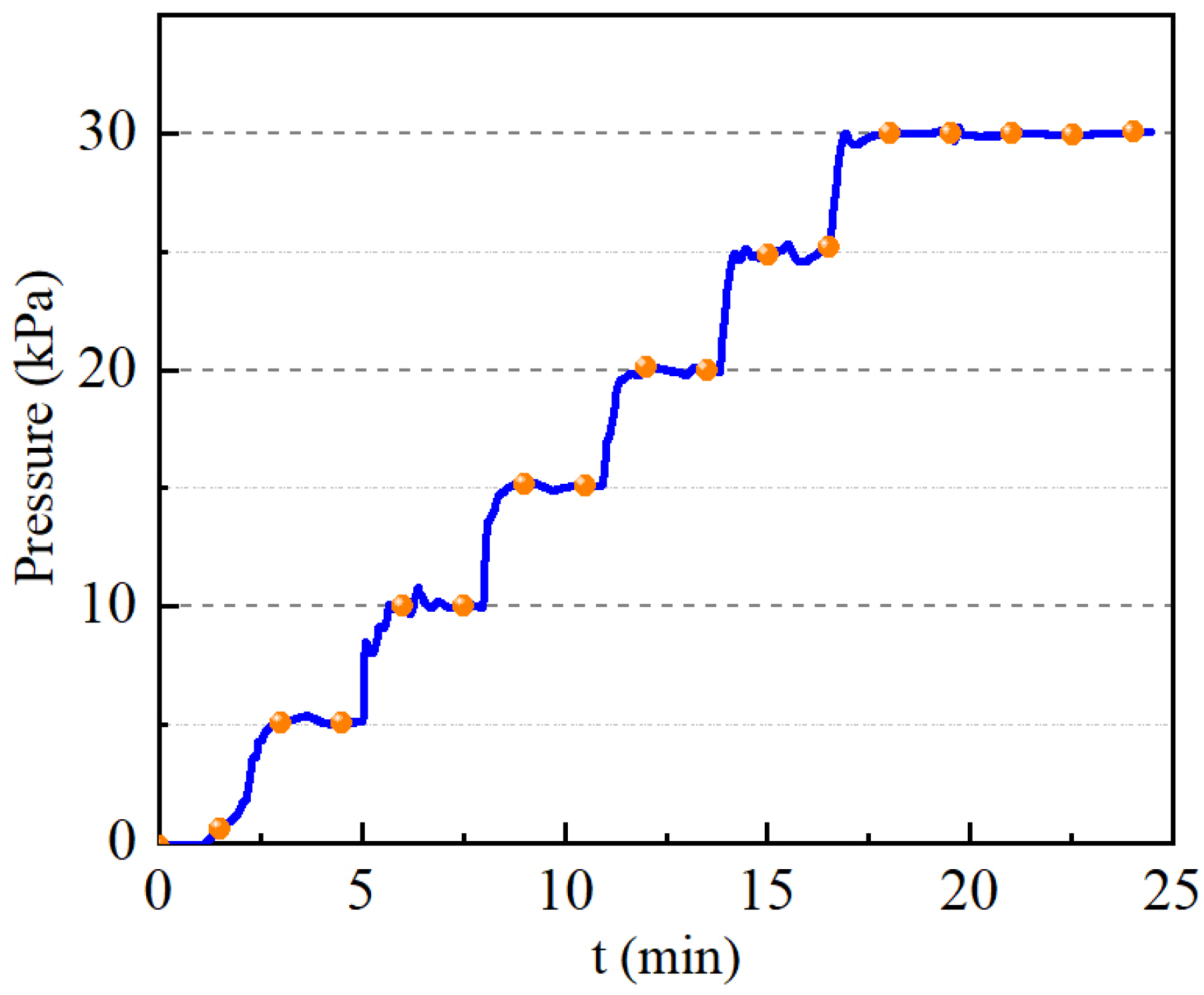

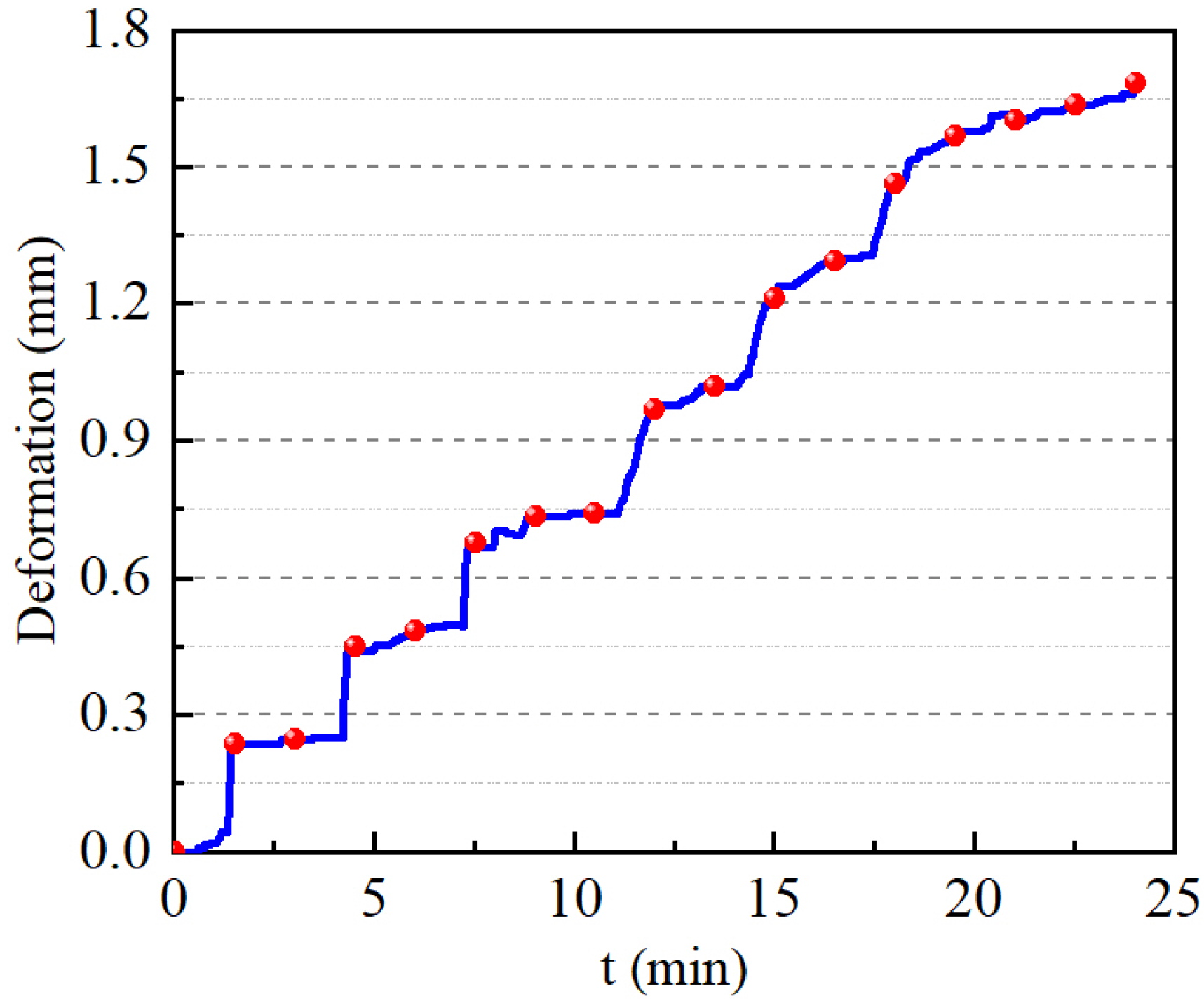

- (1)

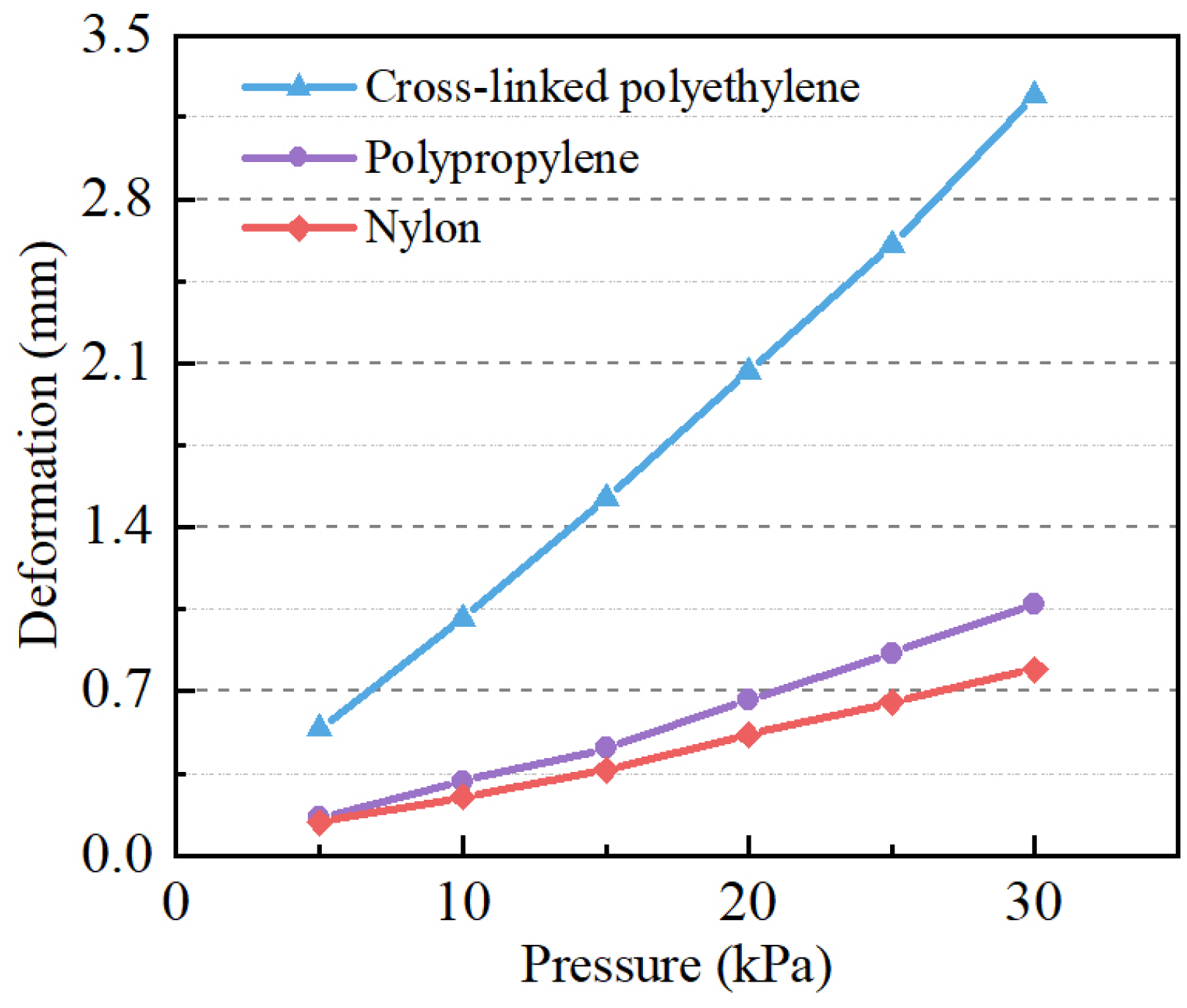

- Normal temperature pressure test method: The ambient temperature pressure test involves injecting water at 20 °C to 80% of the HOT’s volume. Once all inlets and outlets of the HOT are sealed, the HOT is filled with gas. The test device is depicted in Figure 8. The pressure is maintained in the range of 0–30 kPa, with a 2-min duration for each 5 kPa increment. Once the pressure reaches 30 kPa, it is held until the deformation stabilizes. The internal pressure gradient of the HOT is illustrated in Figure 9, with a pressure error of less than 0.3 kPa. Then, proceed to check and record any leakage as well as the maximum deformation of the HOT.

- (2)

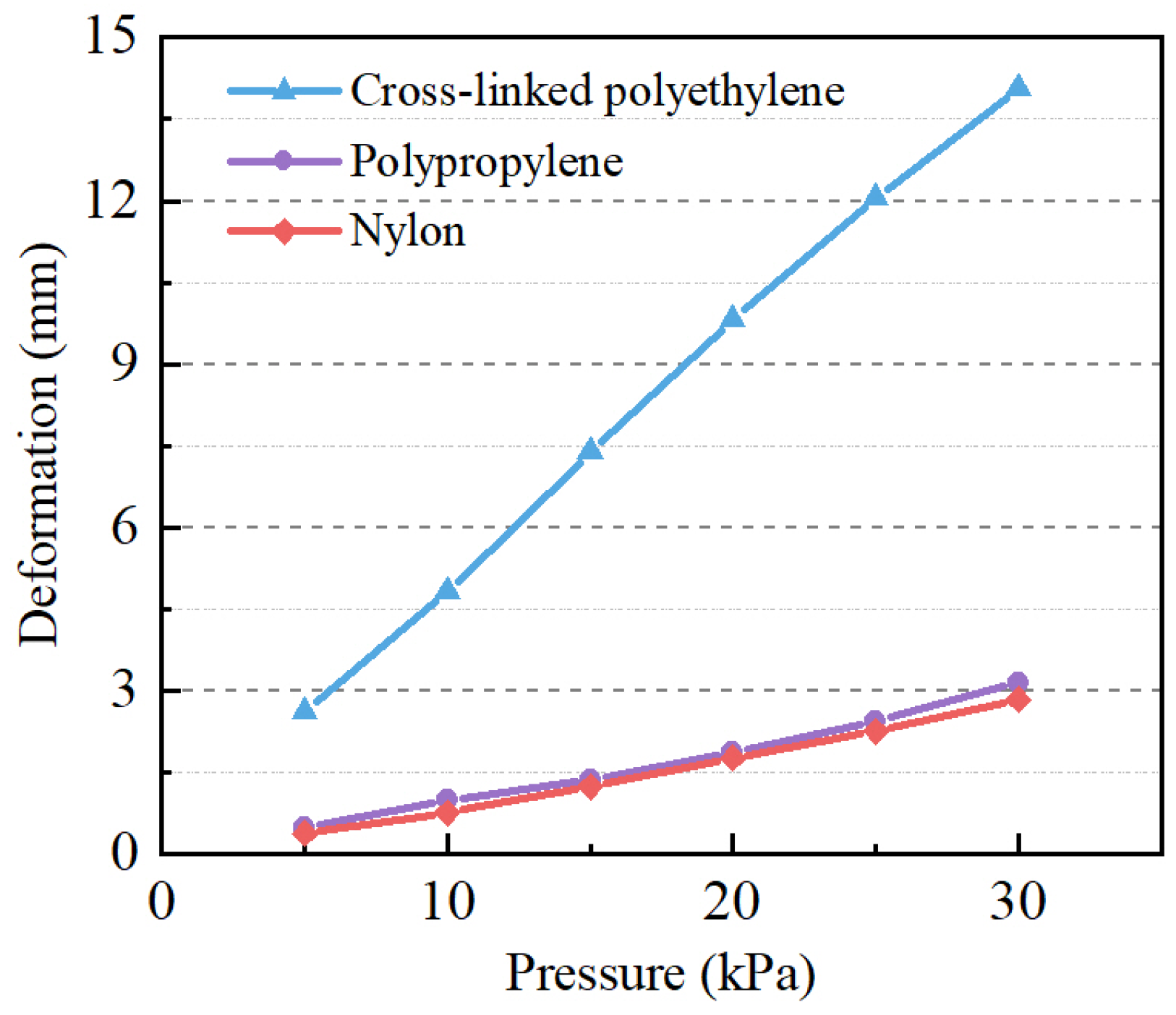

- High-temperature pressure test method: At an ambient temperature of 20 °C, 80 % of the volume of water at 80 °C is injected into the HOT. All inlets and outlets of the HOT are sealed, and gas is then filled into the HOT. The test device is depicted in Figure 8, and the pressure gradient is shown in Figure 9. Proceed to check and record any leakage as well as the maximum deformation of the HOT.

- (3)

- Low-temperature impact test method: The empty HOT is placed in an environment with a temperature of −15 °C for 12 h. Subsequently, it is subjected to free fall, with air resistance ignored. The impact energy of the HOT is controlled to be 90 J. The calculation formula for the height between the impact point of the HOT and the impact plane is shown in Equation (1). Proceed to impact each corner of the HOT and then check and record any damage.

4. Comparison of Test Performance of the Non-Metallic HOT

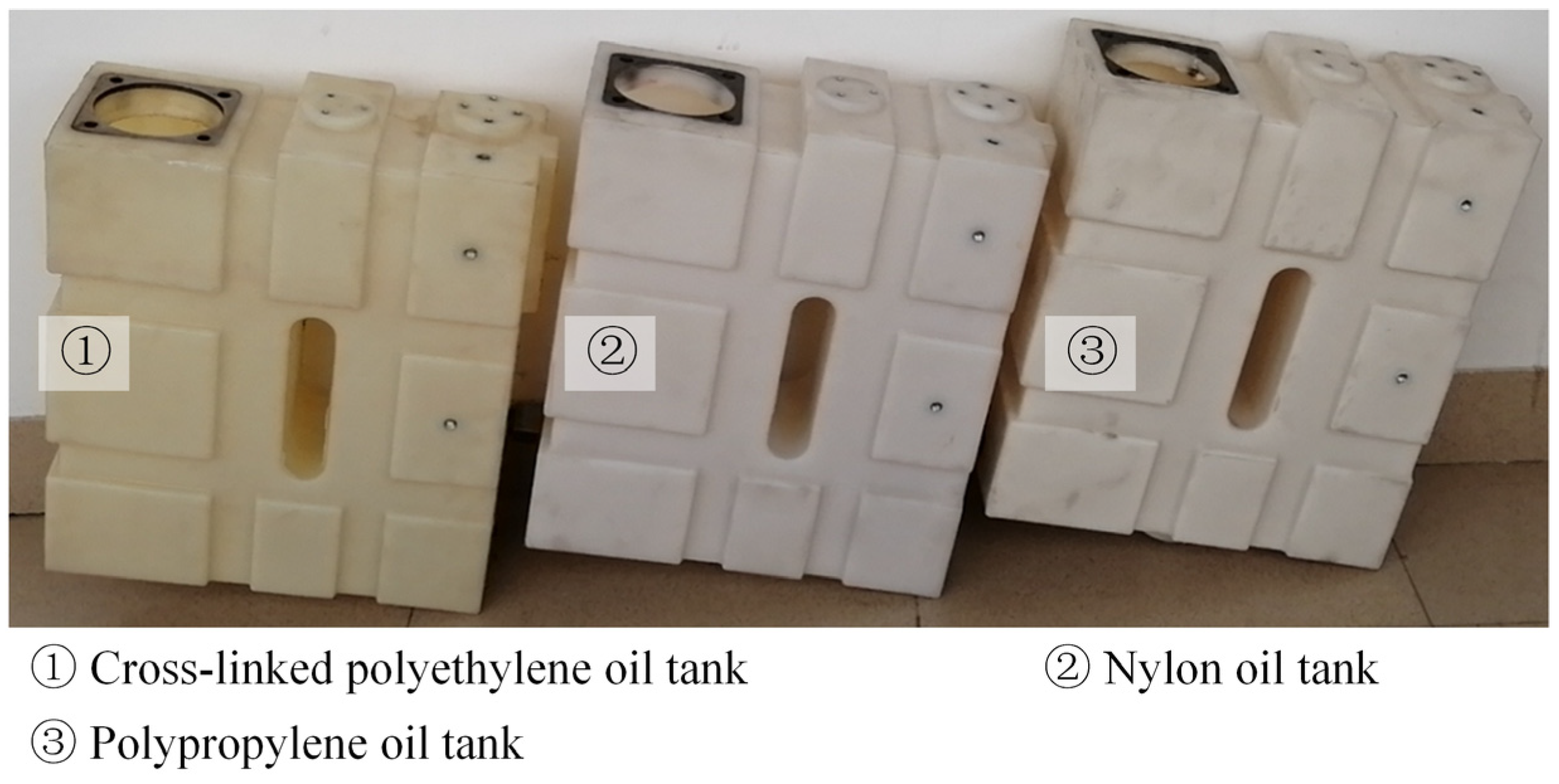

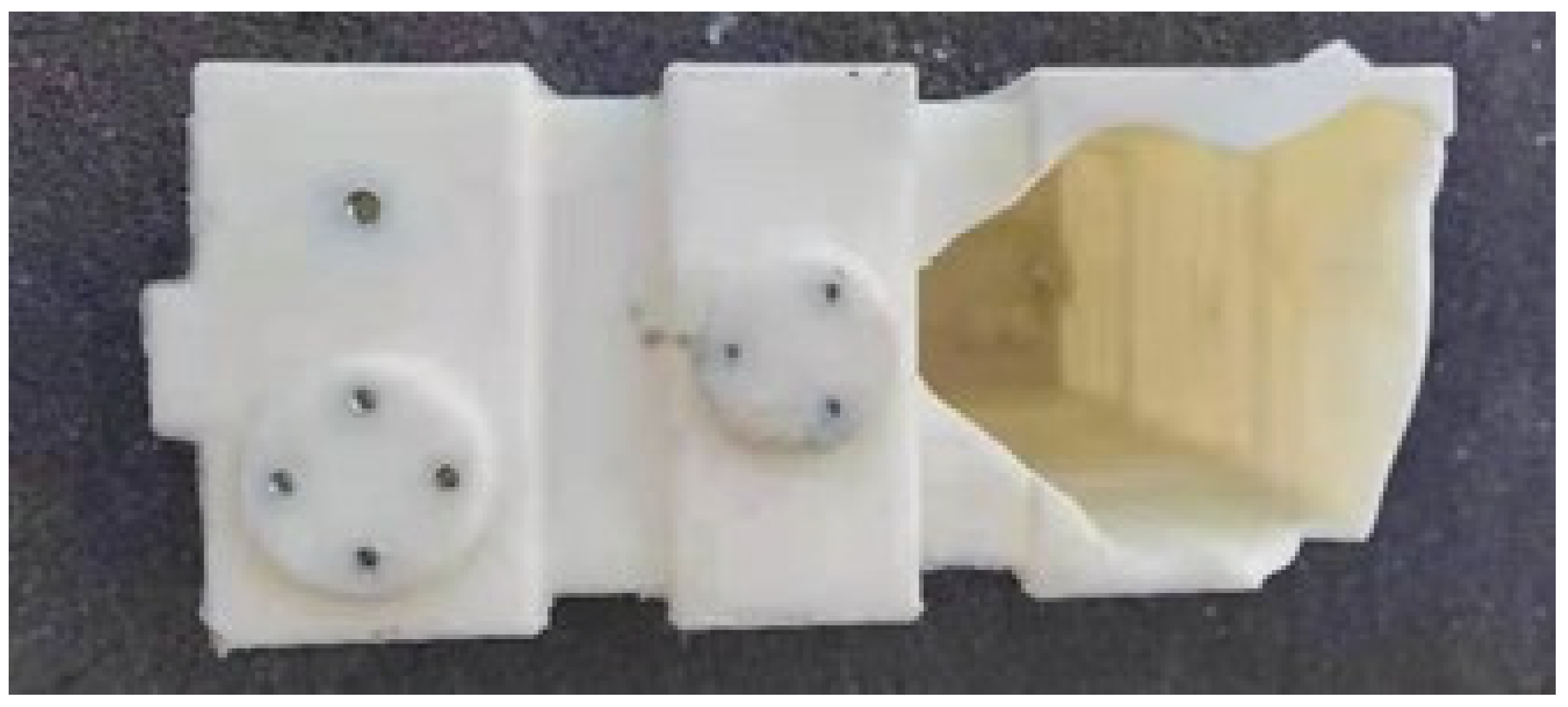

4.1. Test Results of 28 L Non-Metallic HOT

4.2. 115 L XLPE HOT Test

5. Comparison of Test Performance of Non-Metallic HOT

- (1)

- The scheme for molding a non-metallic HOT using the rotational molding process is feasible. The molding quality of a non-metallic HOT is closely related to material properties and process parameters. While XLPE material is easy to mold, its poor mechanical properties necessitate caution to avoid difficulties during demolding or even product damage caused by excessive cooling. The PA material has a narrow forming window and excessively high flowability, making it challenging to mold large products. It is necessary to adjust the heating stage process parameters to reduce the temperature difference between the inner and outer sides of the material. The shape of PP powder makes it difficult to eliminate bubbles during the molding process, resulting in air holes on the inner wall of the molded products.

- (2)

- A test scheme for evaluating the performance of a non-metallic HOT is proposed. The test results indicate that the mechanical properties of PA material are the best, while those of XLPE material are the worst. The deformation of XLPE products in both the ambient temperature pressure test and the high-temperature pressure test is the largest, significantly surpassing that of the other two materials. In addition, comparing the results of the two experiments, it can be proven that the thermal stability of cross-linked polyethylene is also the poorest among the three. Ultimately, the PP products were crushed at a temperature of −15 °C under an impact energy of 90 J, confirming their poor low-temperature resistance and unsuitability for use in low-temperature environments.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kong, X.; Zhu, Q.; Yao, J.; Shang, Y.; Zhu, Y. Basic theory and key technology of “new method for lightweight design and manufacturing of hydraulic components and systems”. Chin. J. Mech. Eng. 2021, 57, 4–12. [Google Scholar]

- Yang, H. Preface. Chin. J. Mech. Eng. 2021, 57, 1–3. [Google Scholar]

- Krawczyka, R.; Słaniaa, J.; Golańskia, G.; Nawrockib, J. Analysis of the reasons for crack in a tank of the hydraulic system. Eng. Fail. Anal. 2020, 116, 104716. [Google Scholar] [CrossRef]

- Yao, J.; Liu, X.; Li, M.; Kong, D.; Hu, J. Design and characteristic analysis of miniaturized labyrinth hydraulic reservoir. Chin. J. Mech. Eng. 2021, 57, 83–92. [Google Scholar]

- ARGO-HYTOS Hydraulic Fluid Solutions Home Page. Available online: https://www.argo-hytos.com/products/tank-solutions.html (accessed on 27 February 2024).

- Zhai, F.; Li, C.; Ye, Z.; Tan, C.; Chen, Y. Influence of built-in filter boundary on flow field in miniaturized hydraulic tank. Chin. J. Mech. Eng. 2021, 57, 114–122. [Google Scholar]

- Yin, J.; Quan, X.; Wu, D. Structure and Heat Dissipation Design of Carbon Fiber Hydraulic Tank. Electro-Mech. Eng. 2023, 39, 32–36. [Google Scholar]

- Bruak, U.; Sena, A.; Gokay, S.; Erdem, A.; Vedat, D.; Zahit, M.; Halti, T.; Serter, A. Static and dynamic analysis of plastic fuel tanks used in buses. Procedia Eng. 2015, 101, 509–517. [Google Scholar]

- Tan, M.; Lin, B.; Sun, P.; Liang, H. Research and development of rotational molding fuel tank for excavators. Constr. Mach. Equip. 2017, 48, 1–7. [Google Scholar]

- Shafigullin, L.; Sotnikov, A.; Romanova, N.; Shabaeva, E.; Sarimov, D. Development of a polymeric fuel tank with high barrier properties. IOP Conf. Ser.-Mater. Sci. Eng. 2019, 570, 1–7. [Google Scholar] [CrossRef]

- Azizeh-Mitra, Y.; Haile, A. Modeling of complex parison formation in extrusion blow molding: Effect of medium to large die heads and fuel tank geometry. Polym. Eng. Sci. 2009, 49, 229–239. [Google Scholar]

- Ogila, Y.; Shao, M.; Yang, W.; Tan, J. Rotational molding: A review of the models and materials. Express Polym. Lett. 2017, 11, 778–798. [Google Scholar] [CrossRef]

- Zhang, K.; Gu, Z.; Feng, K.; Quan, L. Modeling and simulation analysis of thermal balance of excavator hydraulic. Chin. Hydraul. Pneum. 2021, 45, 100–107. [Google Scholar]

- Zhao, D.; Jia, T.; Cui, Y. Design and constant pressure characteristics of a ship-borne pressure tank. J. Tsinghua Univ. (Sci. Technol.) 2019, 59, 306–313. [Google Scholar]

- Gupta, N.; Ramkumar, P.; Sangani, V. An approach toward augmenting materials, additives, process ability and parameterization in rotational molding: A review. Mater. Manuf. Process. 2020, 35, 1539–1556. [Google Scholar] [CrossRef]

- Lumirca Del Valle Espinoza, L.; Viviane Alves, E.; Leila Lea Yuan, V.; Julio Cesar, J.; Elen Beatriz Acordi Vasques, P. Rotomolding and polyethylene composites with rotomolded lignocellulosic materials: A review. J. Reinf. Plast. Compos. 2020, 39, 459–472. [Google Scholar]

- Mahsa, D.; Taher, A.; Mohamad, K.; Milad, M. Investigation of tensile properties of polymeric nanocomposite samples in the rotational molding process. Polym. Bull. 2021, 78, 2465–2481. [Google Scholar]

- Wang, X.; Wang, K.; Sun, X.; Chen, X.; Liang, W. Analyses on equivalence of time-temperature during heating cross-linked polyethylene in rotation molding. Plastics 2017, 32, 50–57. [Google Scholar]

- Chandran, V.G.; Waigaonkar, S.D. Rheological and dynamic mechanical characteristics of rotationally moldable linear low-density polyethylene fumed silica nanocomposites. Polym. Compos. 2016, 37, 2995–3002. [Google Scholar] [CrossRef]

- Xu, H.; Xu, Y.; He, J.; Xiao, D.; Zhao, H.; Wu, J.; Liu, S. Investigation and solution of defects on plastic products by rotational molding processing. Eng. Plast. Appl. 2017, 35, 40–44. [Google Scholar]

- Ali Reza, Z.; Shokoufeh, H.; Hamed, A. Rheological, mechanical and thermal properties of the PA/PVB blends and their nanocomposites: Structure-property relationships. Polym. Test. 2018, 66, 48–63. [Google Scholar]

- Reylina, T.; Mark, M.; Allysa, O. A review of the factors that influence aging and degradation in crosslinked polyethylene (XLPE) polyolefin. Mater. Today Proc. 2023, 10, 95. [Google Scholar]

- Wu, B.; Li, Y.; Yang, J.; Zhou, Y. Mechanism of low-temperature brittle–ductile transition of polypropylene/low-density polyethylene blend foam under compressive stress caused by cell stretching. Adv. Eng. Mater. 2023, 25, 2300533. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Melt Index (g/10 min) | Tensile Yield Strength (MPa) | Flexural Modulus (MPa) | Melting Point (°C) | Vicat Softening Point (°C) |

|---|---|---|---|---|---|---|

| XLPE | 945 | 10 | 17 | 780 | 140 | 130 |

| PP | 905 | 15 | 23 | 1530 | 172 | 145 |

| PA 12 | 1140 | 2 | 55 | 2000 | 220 | 210 |

| The First Stage | The Second Stage | Cooling Mode | Demolding Temperature | Molding Quality | ||

|---|---|---|---|---|---|---|

| Heating Time | Heating Temperature | Heating Time | Heating Temperature | |||

| 24 min | 270 °C | 7 min | 250 °C | Air cooling | 100 °C | Well formed |

| The First Stage | The Second Stage | Cooling Mode | Demolding Temperature | Molding Quality | ||

|---|---|---|---|---|---|---|

| Heating Time | Heating Temperature | Heating Time | Heating Temperature | |||

| 18 min | 300 °C | 20 min | 250 °C | Air cooling | 100 °C | A large amount of powder inside is not melted |

| 38 min | 350 °C | 5 min | 240 °C | Air cooling | 100 °C | The powder can be scraped from the inner wall, overburning |

| 39 min | 300 °C | 5 min | 240 °C | Natural cooling | 90 °C | Well molded, with a few air holes on the inner wall |

| The First Stage | The Second Stage | Cooling Mode | Demolding Temperature | Molding Quality | ||

|---|---|---|---|---|---|---|

| Heating Time | Heating Temperature | Heating Time | Heating Temperature | |||

| 35 min | 300 °C | 5 min | 240 °C | Air cooling | 120 °C | Incomplete melting; excessive cooling, difficult mold work removal |

| 37 min | 300 °C | 5 min | 240 °C | Air cooling | 150 °C | The mold removal temperature is too high, and the raw materials are not cooled for molding. |

| 37 min | 300 °C | 5 min | 240 °C | Natural cooling | 100 °C | Well molded |

| The First Stage | The Second Stage | The Third Stage | Cooling Mode | Demolding Temperature | Molding Quality | |||

|---|---|---|---|---|---|---|---|---|

| Heating Time | Heating Temperature | Heating Time | Heating Temperature | Heating Time | Heating Temperature | |||

| 12 min | 240 °C | 25 min | 300 °C | 5 min | 240 °C | Air cooling | 90 °C | Well molded |

| The First Stage | The Second Stage | The Third Stage | Cooling Mode | Demolding Temperature | Molding Quality | |||

|---|---|---|---|---|---|---|---|---|

| Heating Time | Heating Temperature | Heating Time | Heating Temperature | Heating Time | Heating Temperature | |||

| 15 min | 240 °C | 25 min | 330 °C | 5 min | 250 °C | Air cooling+ Natural cooling | 90 °C | The product is not shaped, and most of the raw materials are not melted |

| 30 min | 240 °C | 45 min | 360 °C | 5 min | 250 °C | Air cooling and Natural cooling | 90 °C | The product is molded, the embedded parts are poorly covered and partially cracked, and the inner wall has white stripes. |

| 30 min | 220 °C | 35 min | 350 °C | 5 min | 250 °C | Air cooling and Natural cooling | 100 °C | The product is molded, and the embedded parts are well-covered. There is no material near the mold-closing surface, and there are still a few white stripes on the inner wall. |

| 28 min | 230 °C | 30 min | 340 °C | 2 min | 250 °C | Air cooling and Natural cooling | 110 °C | The product is molded with hollow through holes in some parts, pits on the sealing surface, and raw material stacking and turbulence on the inner wall. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Z.; Zhai, F.; Tan, C.; Chen, X.; Chen, T.; Ma, P. Trial Manufacture and Performance Research of Hydraulic Oil Tank for Three Kinds of Non-Metallic Materials. Machines 2024, 12, 176. https://doi.org/10.3390/machines12030176

He Z, Zhai F, Tan C, Chen X, Chen T, Ma P. Trial Manufacture and Performance Research of Hydraulic Oil Tank for Three Kinds of Non-Metallic Materials. Machines. 2024; 12(3):176. https://doi.org/10.3390/machines12030176

Chicago/Turabian StyleHe, Zhiqiang, Fugang Zhai, Changyu Tan, Xiaojun Chen, Tianshuo Chen, and Pengpeng Ma. 2024. "Trial Manufacture and Performance Research of Hydraulic Oil Tank for Three Kinds of Non-Metallic Materials" Machines 12, no. 3: 176. https://doi.org/10.3390/machines12030176

APA StyleHe, Z., Zhai, F., Tan, C., Chen, X., Chen, T., & Ma, P. (2024). Trial Manufacture and Performance Research of Hydraulic Oil Tank for Three Kinds of Non-Metallic Materials. Machines, 12(3), 176. https://doi.org/10.3390/machines12030176