Design and Comparison of Two Maize Seeders Coupled with an Agricultural Robot

Abstract

1. Introduction

2. Materials and Methods

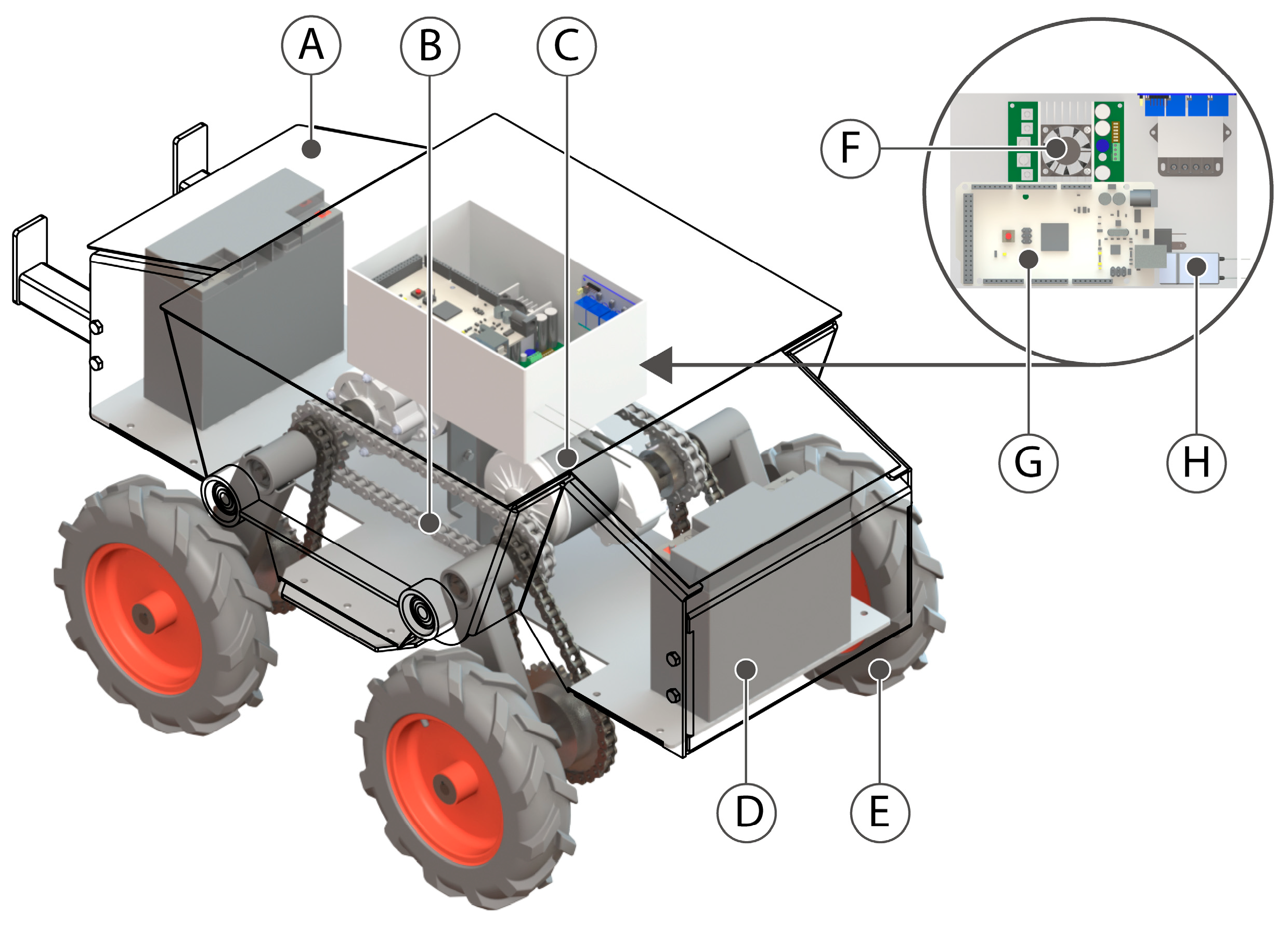

2.1. The Agricultural Robot as Operating Platform

2.2. QFD Analysis

2.3. Agrotechnical Evaluation of Seeder Prototypes

2.3.1. Effective Field Capacity

2.3.2. Plant Spacing, Sowing Depth and Seed Singulation

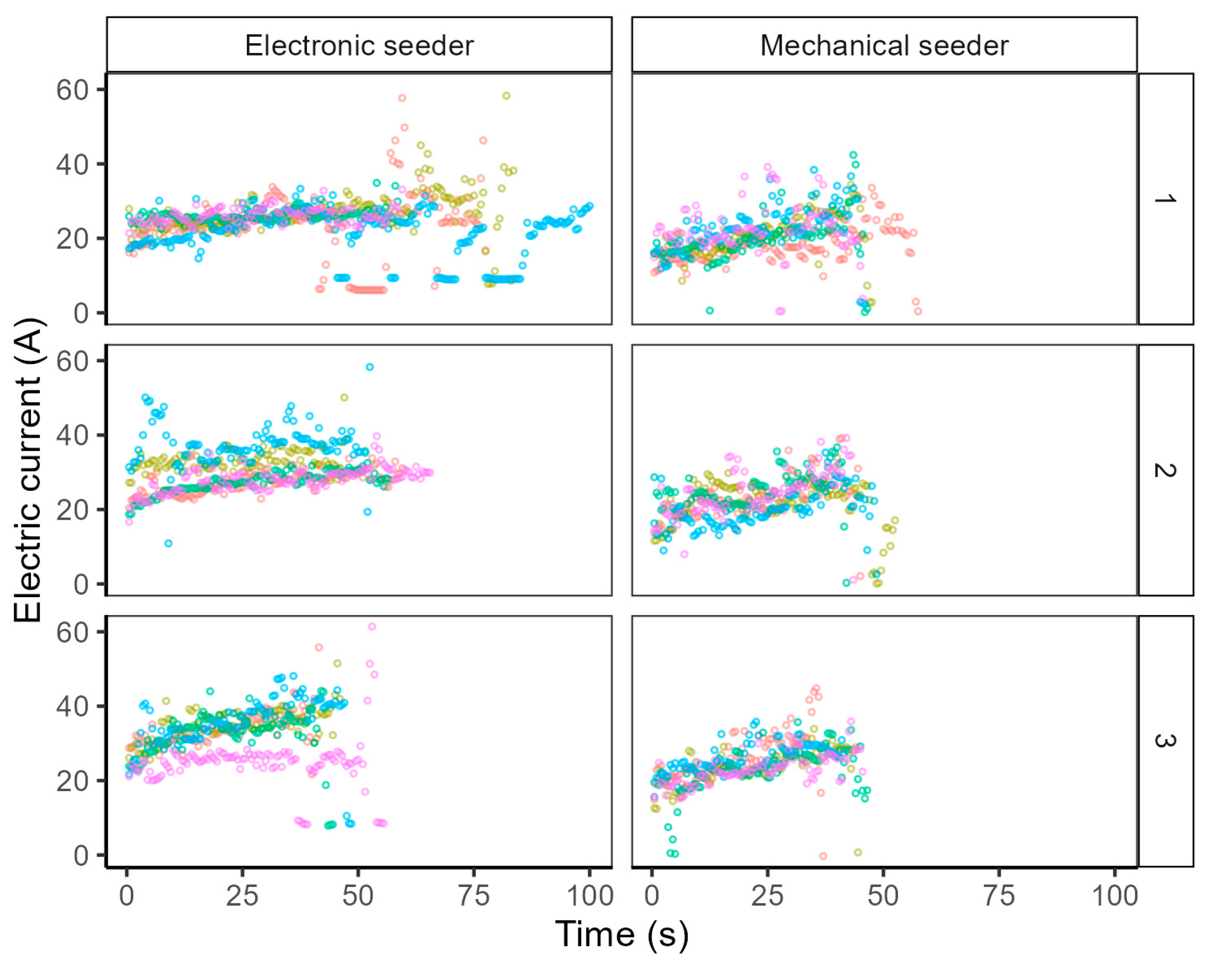

2.3.3. Electric Current Consumption and Battery Range

3. Results

3.1. QFD Analysis

3.1.1. Extraction and Prioritization of User Requirements

3.1.2. House of Quality

= 9) represents a strong relationship, the empty circle (○ = 3) represents a moderate relationship, and the triangle (▲ = 1) represents a weak relationship. This level of correlation was defined by each of the groups according to the previously established levels of importance.

= 9) represents a strong relationship, the empty circle (○ = 3) represents a moderate relationship, and the triangle (▲ = 1) represents a weak relationship. This level of correlation was defined by each of the groups according to the previously established levels of importance.3.1.3. Morphological Analysis and Selection of Components

3.2. Computer-Aided Design of the Seeders

3.3. Hardware and Software Description for the Seeder with Electronic Metering System

3.4. Agrotechnical Evaluation of the Seeders

3.5. Electric Current Consumption and Battery Range

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Oliveira, L.F.P.; Moreira, A.P.; Silva, M.F. Advances in Agriculture Robotics: A State-of-the-Art Review and Challenges Ahead. Robotics 2021, 10, 52. [Google Scholar] [CrossRef]

- De Clercq, M.; Vats, A.; Biel, A. Agriculture 4.0: The Future of Farming Technology. Proc. World Gov. Summit Dubai 2018, 11–13. Available online: https://www.oliverwyman.com/our-expertise/insights/2018/feb/agriculture-4-0--the-future-of-farming-technology.html (accessed on 13 August 2024).

- Arora, N.K. Impact of Climate Change on Agriculture Production and Its Sustainable Solutions. Environ. Sustain. 2019, 2, 95–96. [Google Scholar] [CrossRef]

- Chandra, R.; Collis, S. Digital Agriculture for Small-Scale Producers: Challenges and Opportunities. Commun. AMC 2021, 64, 75–84. [Google Scholar] [CrossRef]

- Cheng, C.; Fu, J.; Su, H.; Ren, L. Recent Advancements in Agriculture Robots: Benefits and Challenges. Machines 2023, 11, 48. [Google Scholar] [CrossRef]

- Marinoudi, V.; Sørensen, C.G.; Pearson, S.; Bochtis, D. Robotics and Labour in Agriculture. A Context Consideration. Biosyst. Eng. 2019, 184, 111–121. [Google Scholar] [CrossRef]

- Giller, K.E.; Delaune, T.; Silva, J.V.; van Wijk, M.; Hammond, J.; Descheemaeker, K.; van de Ven, G.; Schut, A.G.T.; Taulya, G.; Chikowo, R.; et al. Small Farms and Development in Sub-Saharan Africa: Farming for Food, for Income or for Lack of Better Options? Food Secur. 2021, 13, 1431–1454. [Google Scholar] [CrossRef]

- Samberg, L.H.; Gerber, J.S.; Ramankutty, N.; Herrero, M.; West, P.C. Subnational Distribution of Average Farm Size and Smallholder Contributions to Global Food Production. Environ. Res. Lett. 2016, 11, 124010. [Google Scholar] [CrossRef]

- Dhillon, R.; Moncur, Q. Small-Scale Farming: A Review of Challenges and Potential Opportunities Offered by Technological Advancements. Sustainability 2023, 15, 15478. [Google Scholar] [CrossRef]

- Finan, T.J.; Langworthy, M.W.; Fox, R.W. Institutional Change and Smallholder Innovation: An Example from the Portuguese Dairy Sector. Econ. Dev. Cult. Chang. 1990, 38, 699–712. [Google Scholar] [CrossRef]

- Van Loon, J.; Woltering, L.; Krupnik, T.J.; Baudron, F.; Boa, M.; Govaerts, B. Scaling Agricultural Mechanization Services in Smallholder Farming Systems: Case Studies from Sub-Saharan Africa, South Asia, and Latin America. Agric. Syst. 2020, 180, 102792. [Google Scholar] [CrossRef]

- Benos, L.; Tsaopoulos, D.; Bochtis, D. A Review on Ergonomics in Agriculture. Part I: Manual Operations. Appl. Sci. 2020, 10, 1905. [Google Scholar] [CrossRef]

- Fountas, S.; Mylonas, N.; Malounas, I.; Rodias, E.; Santos, C.H.; Pekkeriet, E. Agricultural Robotics for Field Operations. Sensors 2020, 20, 2672. [Google Scholar] [CrossRef]

- Van Loon, J.; Krupnik, T.J.; López-Gómez, J.A.; Timsina, J.; Govaerts, B. A Standard Methodology for Evaluation of Mechanical Maize Seed Meters for Smallholder Farmers Comparing Devices from Latin America, Sub-Saharan Africa, and Asia. Agronomy 2020, 10, 1091. [Google Scholar] [CrossRef]

- Yang, S.; Zhai, C.; Gao, Y.; Dou, H.; Zhao, X.; He, Y.; Wang, X. Planting Uniformity Performance of Motor-Driven Maize Precision Seeding Systems. Int. J. Agric. Biol. Eng. 2022, 15, 101–108. [Google Scholar] [CrossRef]

- Ling, L.; Xiao, Y.; Huang, X.; Wu, G.; Li, L.; Yan, B.; Geng, D. Design and Testing of Electric Drive System for Maize Precision Seeder. Agriculture 2024, 14, 1778. [Google Scholar] [CrossRef]

- Azmi, H.N.; Hajjaj, S.S.H.; Gsangaya, K.R.; Sultan, M.T.H.; Mail, M.F.; Hua, L.S. Design and Fabrication of an Agricultural Robot for Crop Seeding. Mater. Today Proc. 2021, 81, 283–289. [Google Scholar] [CrossRef]

- Sneha, A.; Abirami, E.; Ankita, A.; Srimeena, R. Agricultural Robot for Automatic Ploughing and Seeding. In Proceedings of the International Conference on Technological Innovations in ICT for Agriculture and Rural Development, Chennai, India, 10–12 July 2015; pp. 17–23. [Google Scholar]

- Soyoye, B.O.; Ademosun, O.C.; Olu-Ojo, E.O. Development of a Manually Operated Vertical Seed-Plate Maize Planter. Agric. Eng. Int. CIGR J. 2016, 18, 70–80. [Google Scholar]

- Swapnil, T.; Kasturi, M.L.; Girish, P.; Rajkumar, P. Design and Fabrication of Seed Sowing Machine. Int. Res. J. Eng. Technol. 2017, 4, 704–707. [Google Scholar] [CrossRef]

- Kumar, P.; Ashok, G. Design and Fabrication of Smart Seed Sowing Robot. Mater. Today Proc. 2020, 39, 354–358. [Google Scholar] [CrossRef]

- FAO. FAO Strategy on Climate Change 2022–2031; FAO: Rome, Italy, 2022. [Google Scholar]

- Lowenberg-DeBoer, J.; Huang, I.Y.; Grigoriadis, V.; Blackmore, S. Economics of Robots and Automation in Field Crop Production. Precis. Agric. 2020, 21, 278–299. [Google Scholar] [CrossRef]

- Daum, T.; Adegbola, P.Y.; Adegbola, C.; Daudu, C.; Issa, F.; Kamau, G.; Kergna, A.O.; Mose, L.; Ndirpaya, Y.; Fatunbi, O.; et al. Mechanization, Digitalization, and Rural Youth—Stakeholder Perceptions on Three Mega-Topics for Agricultural Transformation in Four African Countries. Glob. Food Secur. 2022, 32, 100616. [Google Scholar] [CrossRef]

- Geza, W.; Ngidi, M.; Ojo, T.; Adetoro, A.A.; Slotow, R.; Mabhaudhi, T. Youth Participation in Agriculture: A Scoping Review. Sustainability 2021, 13, 9120. [Google Scholar] [CrossRef]

- Velázquez López, N.; Reyes Amador, A. Sistema de Suspensión Para Vehículos Terrestres Autónomos o No Autónomos (Titulo de modelo de utilidad N. 4369). Instituto Mexicano de la Propiedad Industrial (IMPI). 2018. Documento MX/W/2020/077113. Available online: https://vidoc.impi.gob.mx/visor?usr=SIGA&texp=SI&tdoc=E&id=MX/u/2018/000639 (accessed on 18 June 2024).

- Sánchez-Chávez, D.I.; Velázquez-López, N.; García-Sánchez, G.; Hernández-Mercado, A.; Avendaño-Lopez, O.A.; Berrocal-Aguilar, E. Robot for Navigation in Maize Crops for the Field Robot Event 2023. Agric. Sci. 2024, 21, 35–45. [Google Scholar]

- Dimension Engineering LLC “Sabertooth Dual 60A Motor Driver”. Available online: https://www.dimensionengineering.com/products/sabertooth2x60 (accessed on 27 September 2024).

- Kumar, A.A.; Tewari, V.K.; Maiti, J.; Nare, B. Design and Selection of Agricultural Machinery Using a Quality Function Deployment Technique. Agric. Eng. Int. CIGR J. 2015, 17, 91–99. [Google Scholar]

- Tiewtoy, S.; Moocharoen, W.; Kuptasthien, N. User-Centred Machinery Design for a Small Scale Agricultural-Based Community Using Quality Function Deployment. Int. J. Sustain. Eng. 2024, 17, 2295854. [Google Scholar] [CrossRef]

- Shrivastava, P. House of Quality: An Effective Approach to Achieve Customer Satisfaction & Business Growth in Industries. Int. J. Sci. Res. 2016, 5, 1365–1371. [Google Scholar]

- Belhe, U.; Kusiak, A. The House of Quality in a Design Process. Int. J. Prod. Res. 1996, 34, 2119–2131. [Google Scholar] [CrossRef]

- 7256-1:1984; International Organization for Standardization (ISO). Sowing Equipment—Test Methods. Part 1: Single Seed Drills (Precision Drills). International Organization for Standardization: Geneva, Switzerland, 1984. [Google Scholar]

- Terradonis “Sembradoras Para Sus Cultivos Hortícolas”. Available online: https://www.terradonis.com/home-es.html (accessed on 27 September 2024).

- Zhao, H.; Zhang, D.; Yang, L.; Cui, T.; Song, W.; He, X.; Wu, H.; Dong, J. Optimal Design and Experiment of Critical Components of Hand-Pushing Corn Plot Precision Planter. Agriculture 2022, 12, 2103. [Google Scholar] [CrossRef]

- Trentin, R.G.; Modolo, A.J.; de Oliveira Vargas, T.; da Rocha Campos, J.R.; Baesso, M.M.; Trogello, E.; Madaloz, J.C.C. Traction Force Demand of Soybean Planting in Compacted Oxisol. Aust. J. Crop Sci. 2018, 12, 374–379. [Google Scholar] [CrossRef]

- Bertonha, R.S.; Furlani, C.E.A.; Silva Vicente, F.A.; Wright, D.L. Tractor Performance and Corn Crop Development as a Function of Furrow Opener and Working Depth in a Red Latosol. Artic. Aust. J. Crop Sci. 2015, 9, 812–818. [Google Scholar]

), moderate relationship is represented by the empty circle (○) and weak relationship is represented by the triangle (▲). The symbols +/− above indicate the presence of absence of a relationship between different quality characteristics, respectively.

), moderate relationship is represented by the empty circle (○) and weak relationship is represented by the triangle (▲). The symbols +/− above indicate the presence of absence of a relationship between different quality characteristics, respectively.

), moderate relationship is represented by the empty circle (○) and weak relationship is represented by the triangle (▲). The symbols +/− above indicate the presence of absence of a relationship between different quality characteristics, respectively.

), moderate relationship is represented by the empty circle (○) and weak relationship is represented by the triangle (▲). The symbols +/− above indicate the presence of absence of a relationship between different quality characteristics, respectively.

| General Category | Specific Requirement |

|---|---|

| Seeding precision | Homogeneous seed placement Adequate sowing depth Seed singulation |

| Automated | Programmable seeding parameters Remote adjustment of seeding parameters Variable input dosing |

| Low cost | Construction with economical materials Economical maintenance Spare parts readily available |

| Robot compatibility | Communication between robot and seeder Continuous feedback to the user |

| Ease of use | No need for advanced technical knowledge Quick and easy attachment to the agricultural robot Simple steps to start the system |

| Robustness | Materials resistant to field conditions Operability on uneven terrain |

| Weight | Constructed of lightweight materials Hoppers with adequate capacity Maximum battery life |

| Requirements | Relevance for IAUIA | Relevance for CIMMYT |

|---|---|---|

| Seeding precision | 4.7 | 4.8 |

| Automated | 4.5 | 1.8 |

| Low cost | 3.6 | 4.4 |

| Robot compatibility | 5.0 | 4.5 |

| Ease of use | 2.4 | 4.3 |

| Robustness | 4.2 | 5.0 |

| Weight | 4.5 | 3.2 |

| Component | Possible Solutions | ||||

|---|---|---|---|---|---|

| Chassis material | Steel | Aluminum | Steel + Aluminum | Plastic | Carbon fiber |

| Agricultural robot attachment | 1-point hitch | 2-point hitch | 3-point hitch | >3-point hitch | |

| Type of seed metering system | Spoon-wheel metering device | Vertical plate with cups metering system | Hole seed-metering wheel | Horizontal plate | Pneumatic |

| Actuating mechanism of the seed metering system | Sprocket and roller chain mechanical mechanism | Shaft-driven mechanical mechanism | Belt-driven mechanical mechanism | Stepper motor electronic mechanism | Servo-driven electronic mechanism |

| Furrow opener | Tine type | Disc coulter type | Runner type | Punch type | Concave disc type |

| Seed hopper material | Plastic | Galvanized steel | Stainless steel | ||

| Seed covering and firming device | Single wheel type | Slide type | Finger wheel type | ||

| Seeder lifting mechanism | Articulated parallelogram type | Frame bar pivot type | Rigid frame type | ||

| Parameter | Mechanical-Driven Metering System Seeder (CIMMYT) | Electronic-Driven Metering System Seeder (IAUIA) |

|---|---|---|

| Working speed (km/h) | 2.0 ± 0.2 (n = 15) | 1.6 ± 0.4 (n = 15) |

| Effective working capacity (ha/h) | 0.15 ± 0.02 (n = 15) | 0.12 ± 0.03 (n = 15) |

| Plant spacing (cm) | 17.1 ± 8.8 (n = 305) | 12.4 ± 9.2 (n = 417) |

| Sowing depth (mm) | 34.8 ± 5.0 (n = 45) | 53.6 ± 9.4 (n = 45) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Gómez, J.A.; Patiño-Espejel, J.E.; Velázquez-López, N.; Sánchez-Chávez, D.I.; Van Loon, J. Design and Comparison of Two Maize Seeders Coupled with an Agricultural Robot. Machines 2024, 12, 935. https://doi.org/10.3390/machines12120935

López-Gómez JA, Patiño-Espejel JE, Velázquez-López N, Sánchez-Chávez DI, Van Loon J. Design and Comparison of Two Maize Seeders Coupled with an Agricultural Robot. Machines. 2024; 12(12):935. https://doi.org/10.3390/machines12120935

Chicago/Turabian StyleLópez-Gómez, Jesús A., Joshua E. Patiño-Espejel, Noé Velázquez-López, David I. Sánchez-Chávez, and Jelle Van Loon. 2024. "Design and Comparison of Two Maize Seeders Coupled with an Agricultural Robot" Machines 12, no. 12: 935. https://doi.org/10.3390/machines12120935

APA StyleLópez-Gómez, J. A., Patiño-Espejel, J. E., Velázquez-López, N., Sánchez-Chávez, D. I., & Van Loon, J. (2024). Design and Comparison of Two Maize Seeders Coupled with an Agricultural Robot. Machines, 12(12), 935. https://doi.org/10.3390/machines12120935