Simulation and Analysis of Double Compound CAM Pusher Tool Changing Mechanism for NC Machine Tool

Abstract

1. Introduction

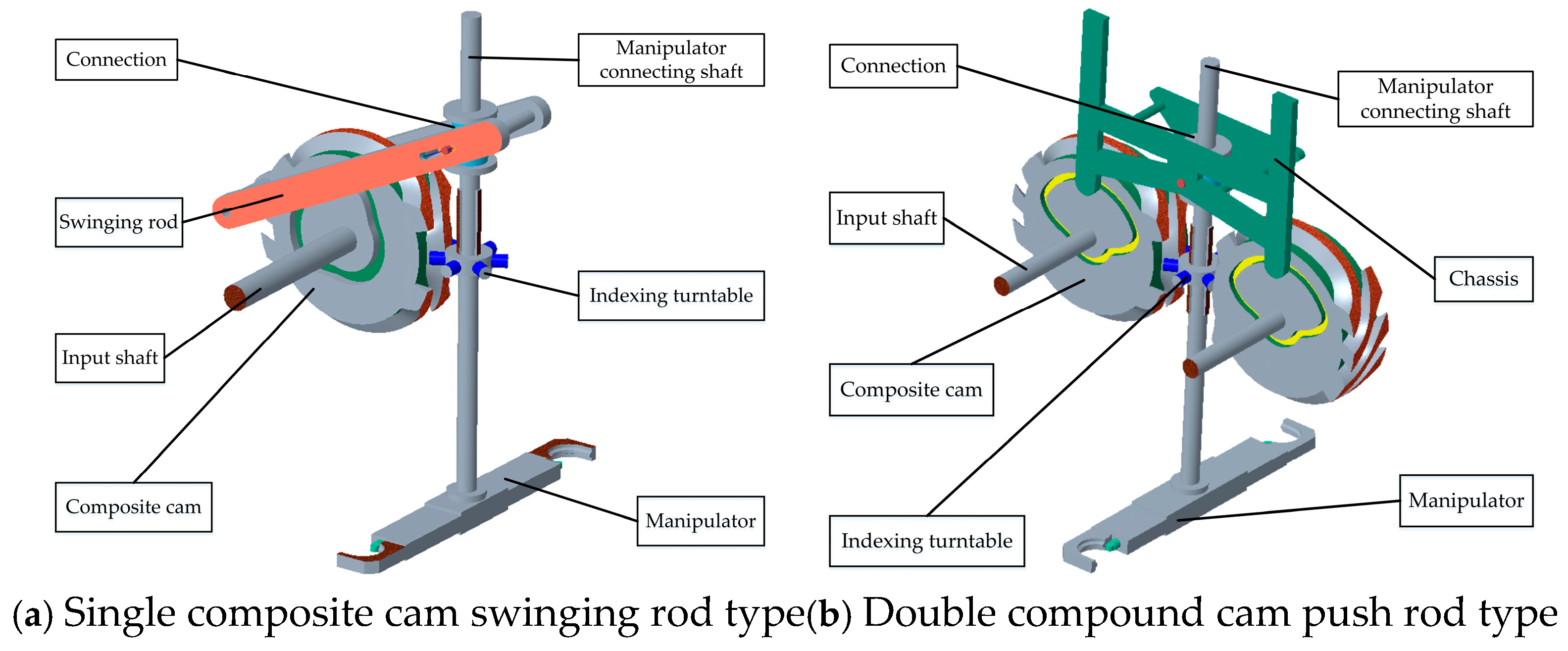

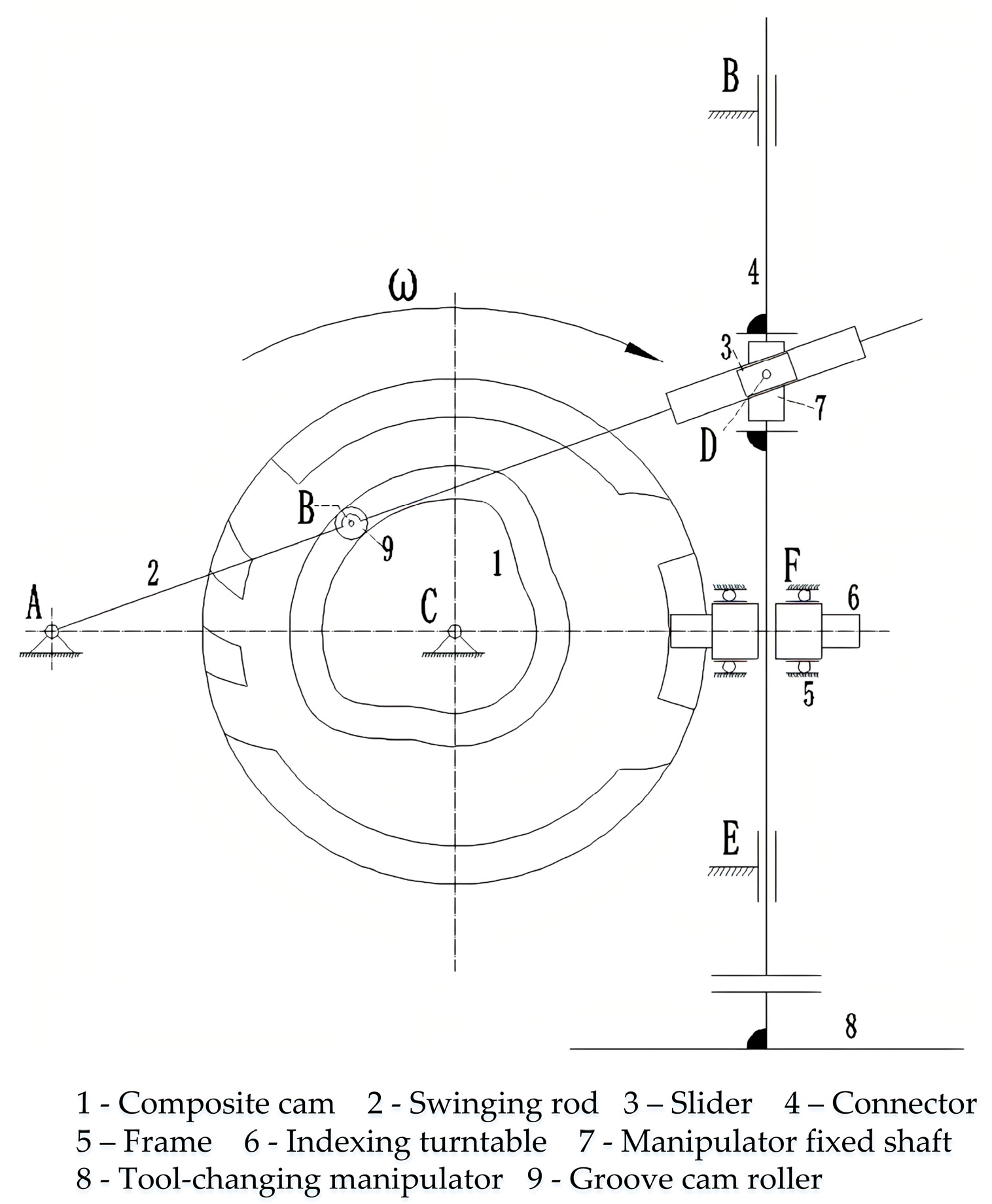

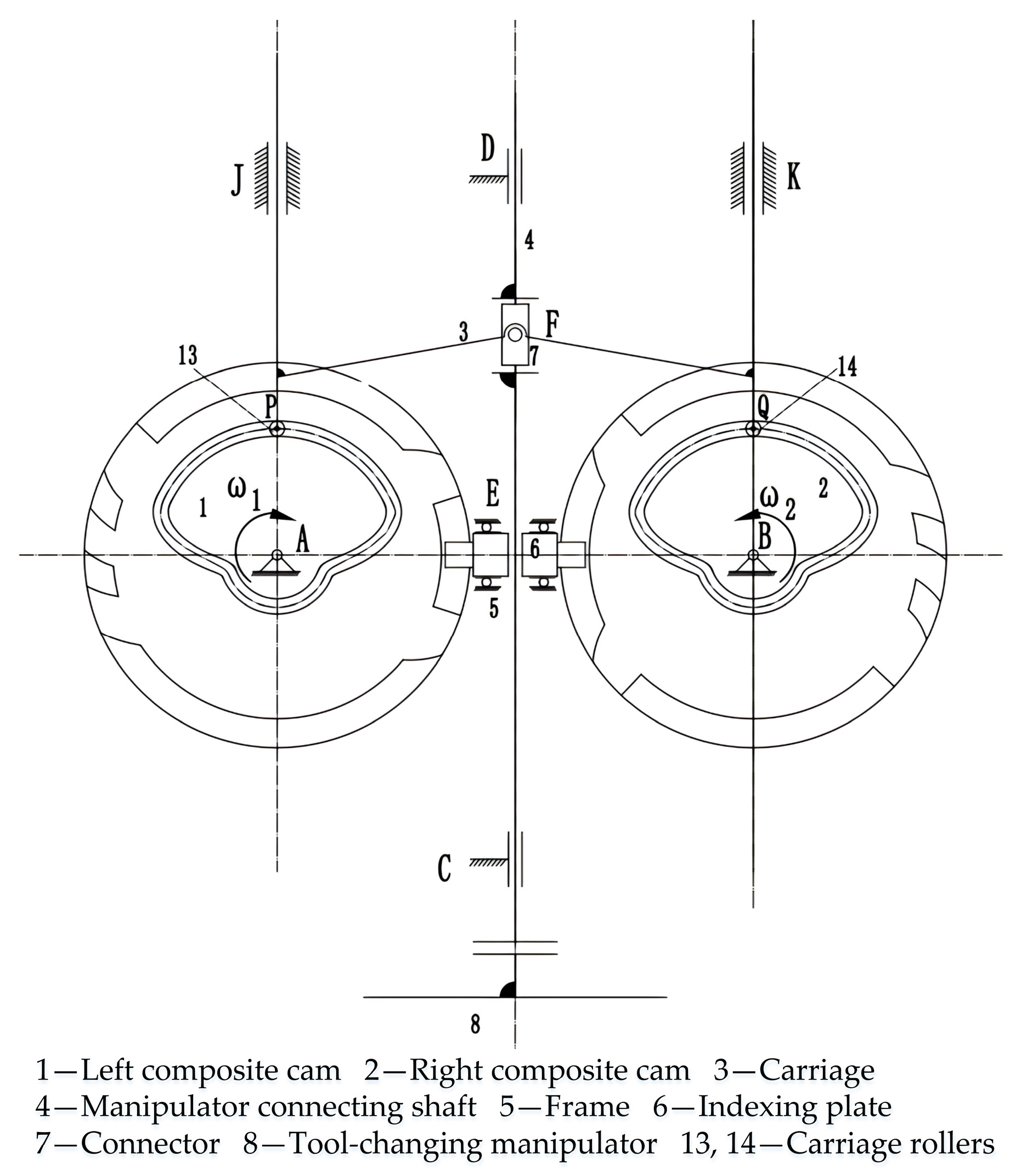

2. Solid Modeling of Two Types of Cam Tool Changers

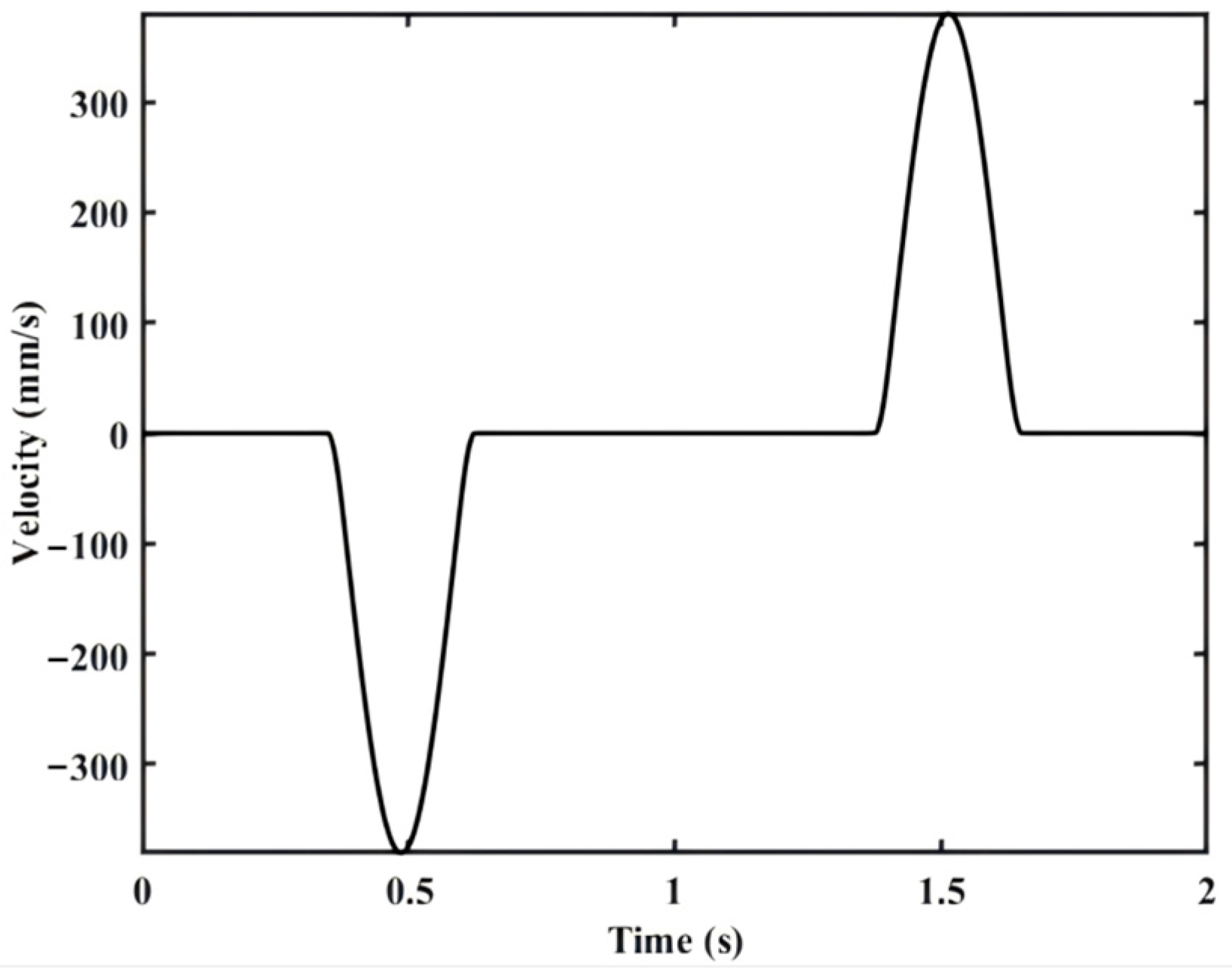

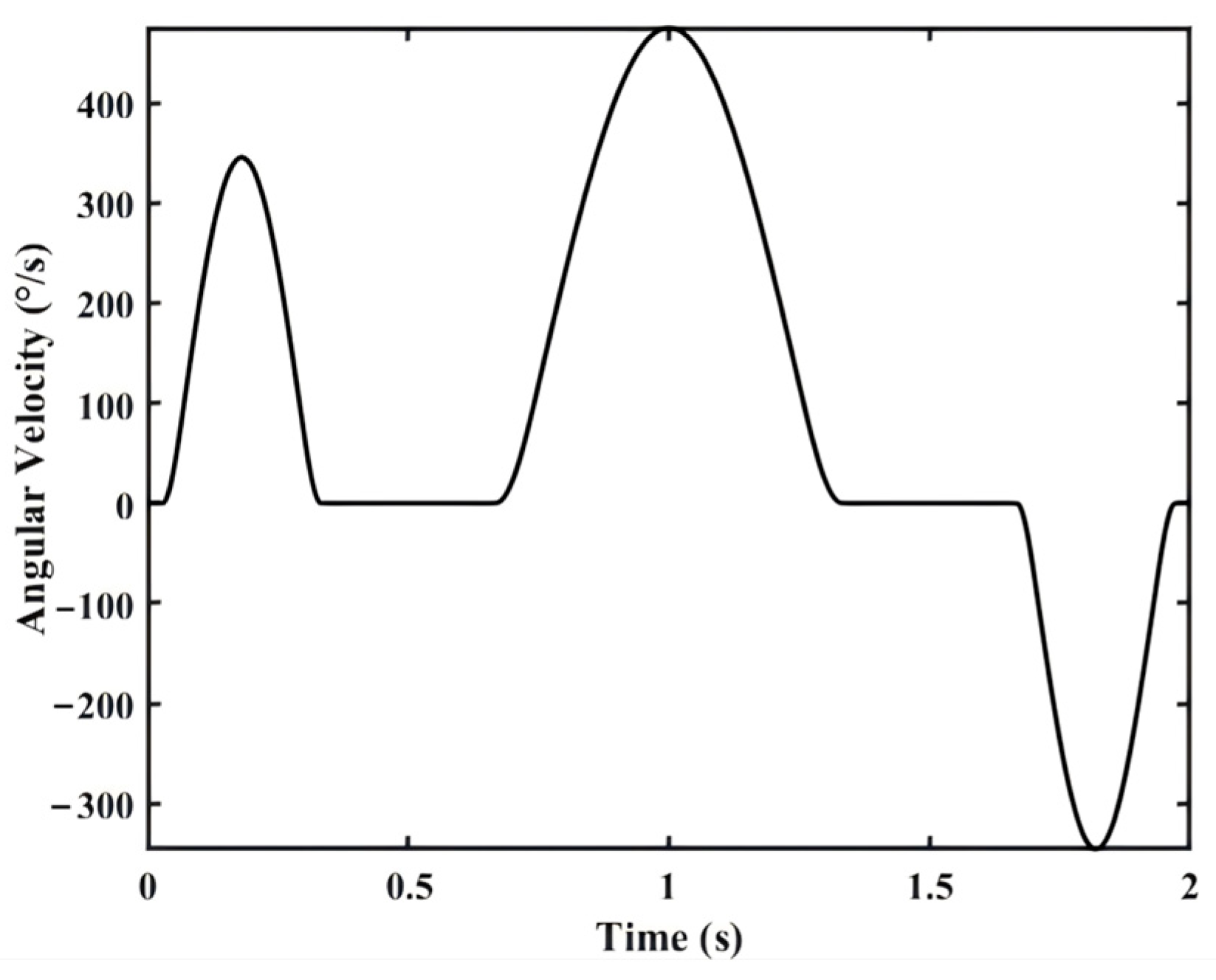

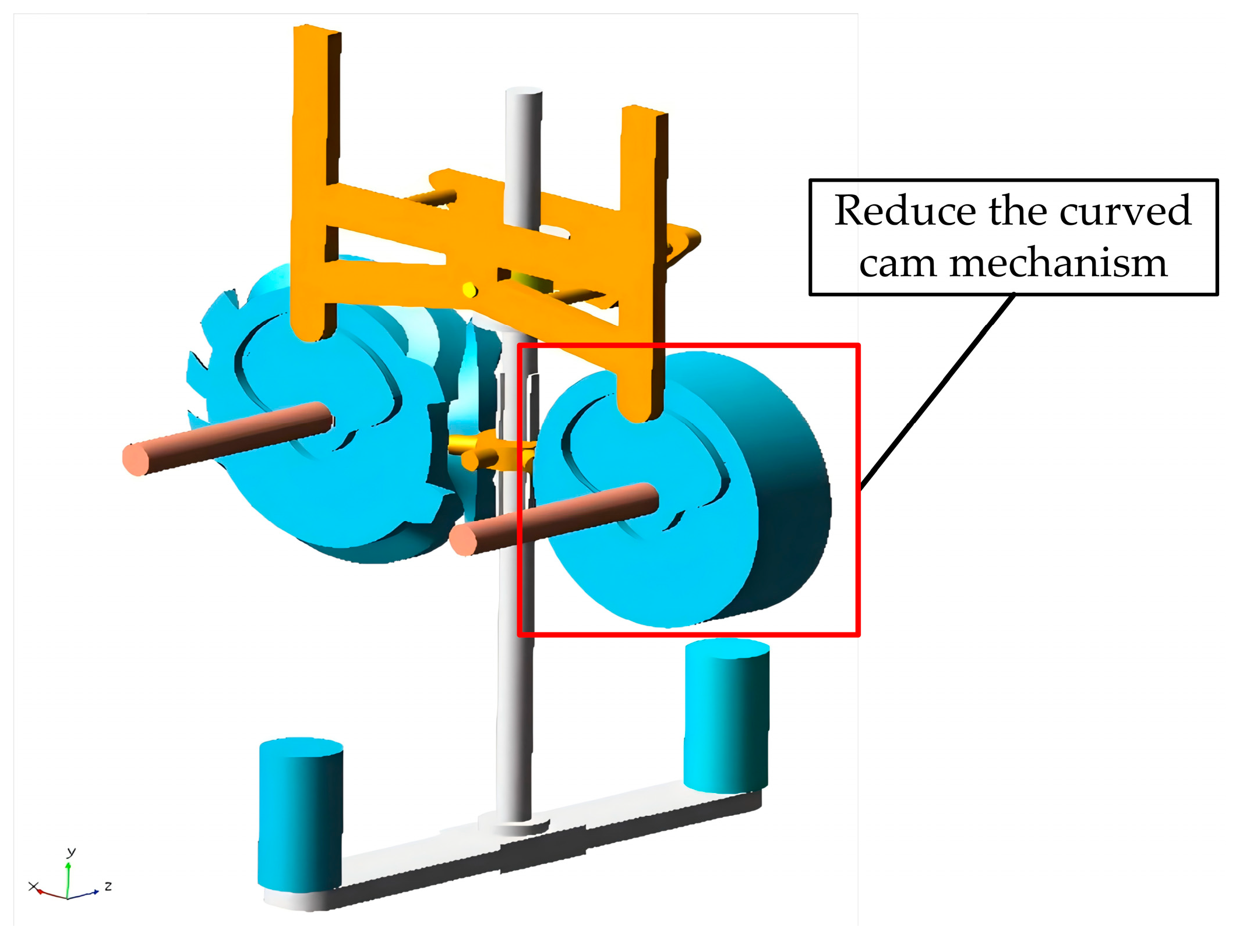

2.1. Theoretical Linear and Angular Velocities of the Manipulator

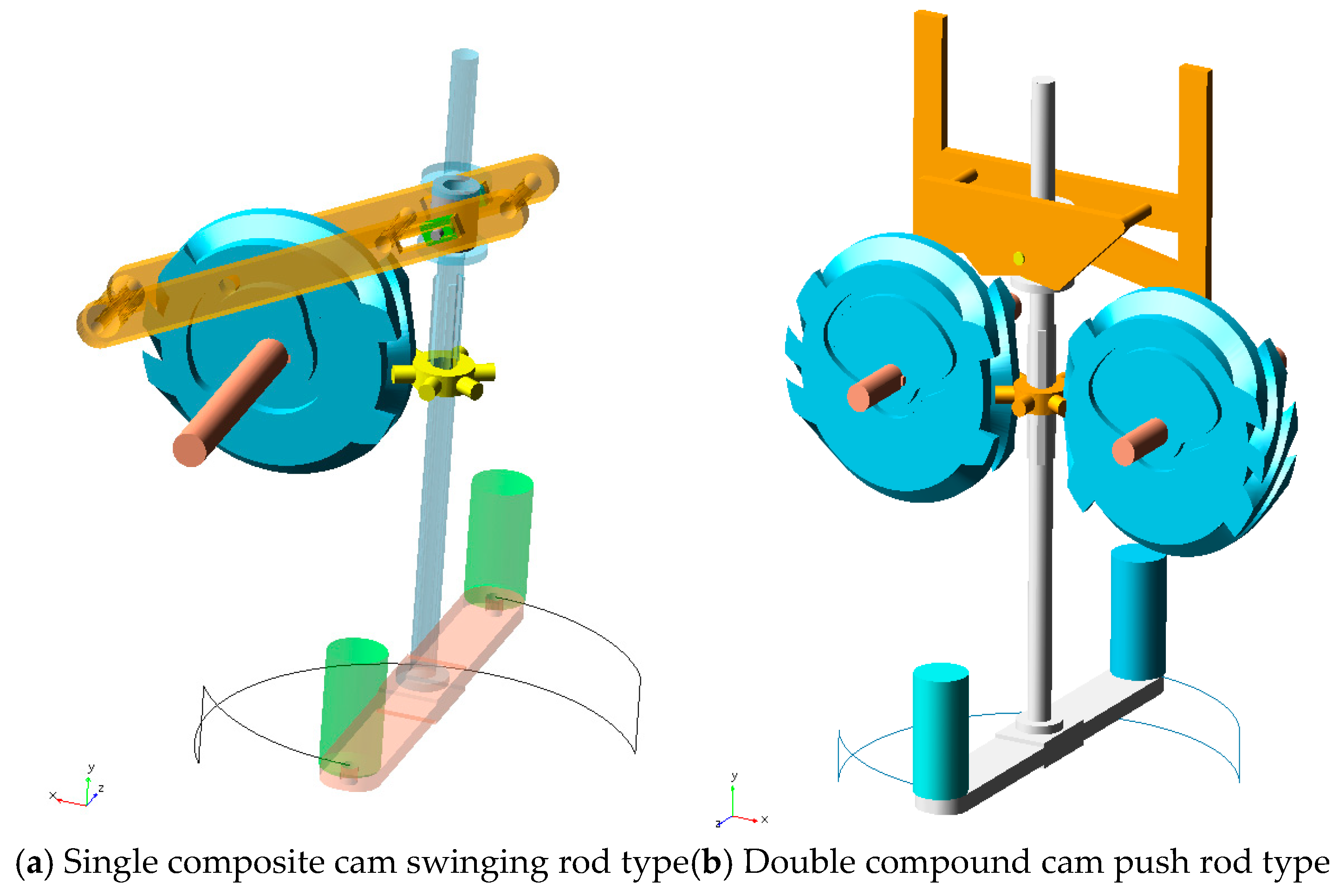

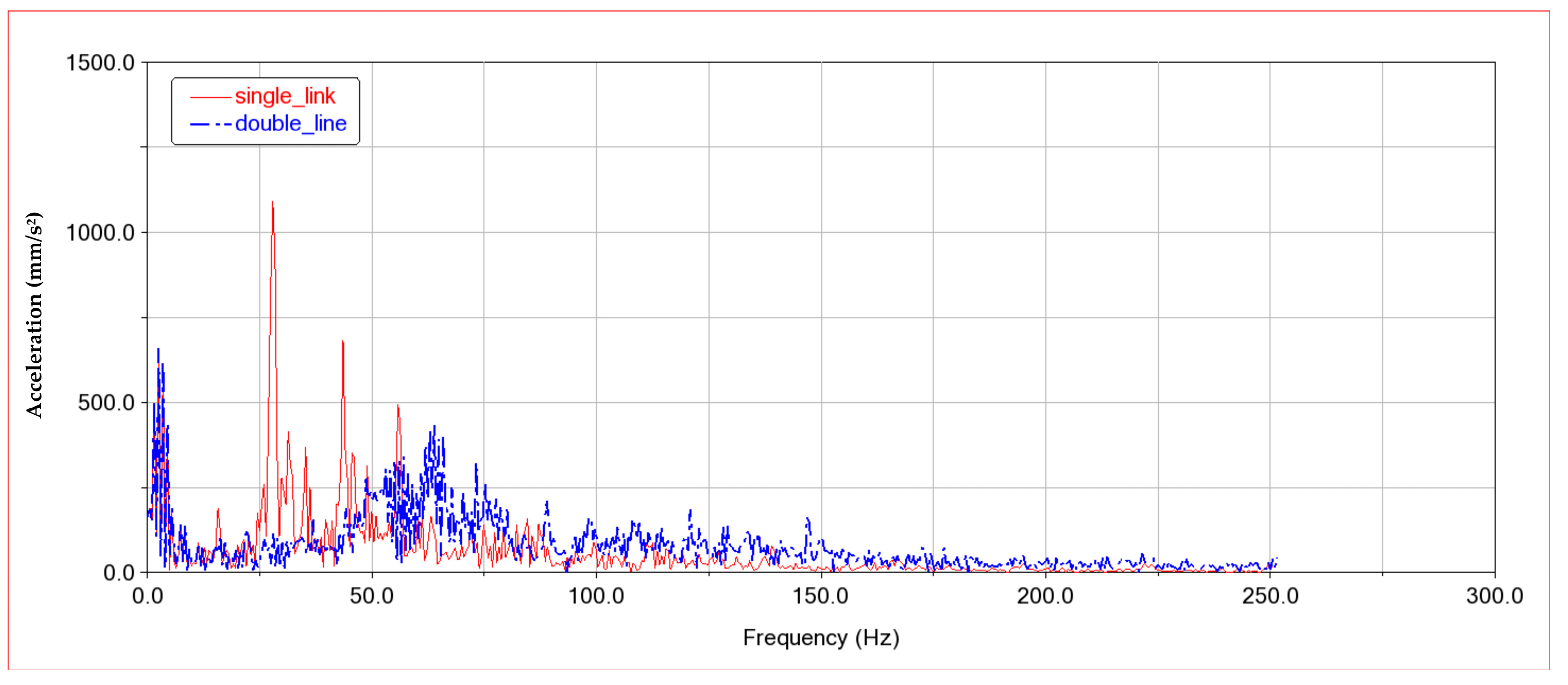

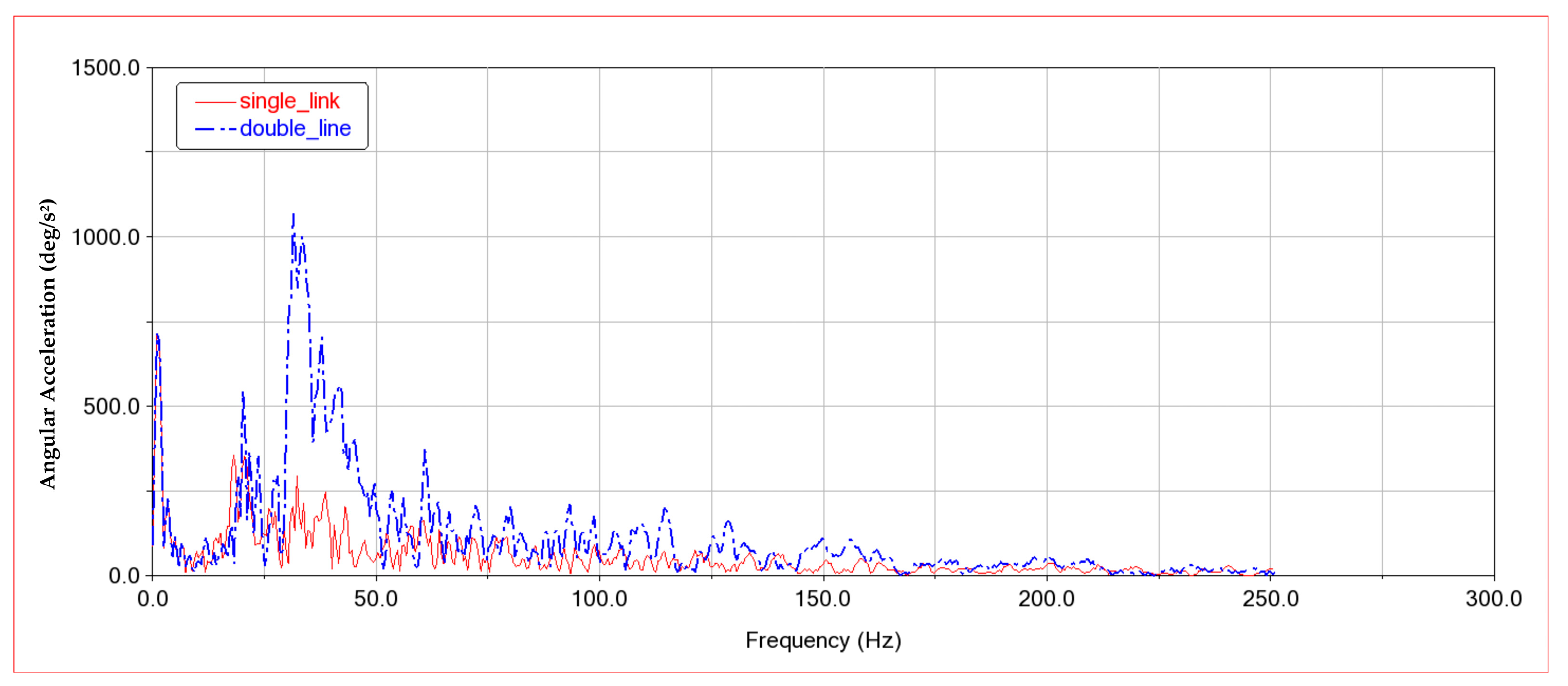

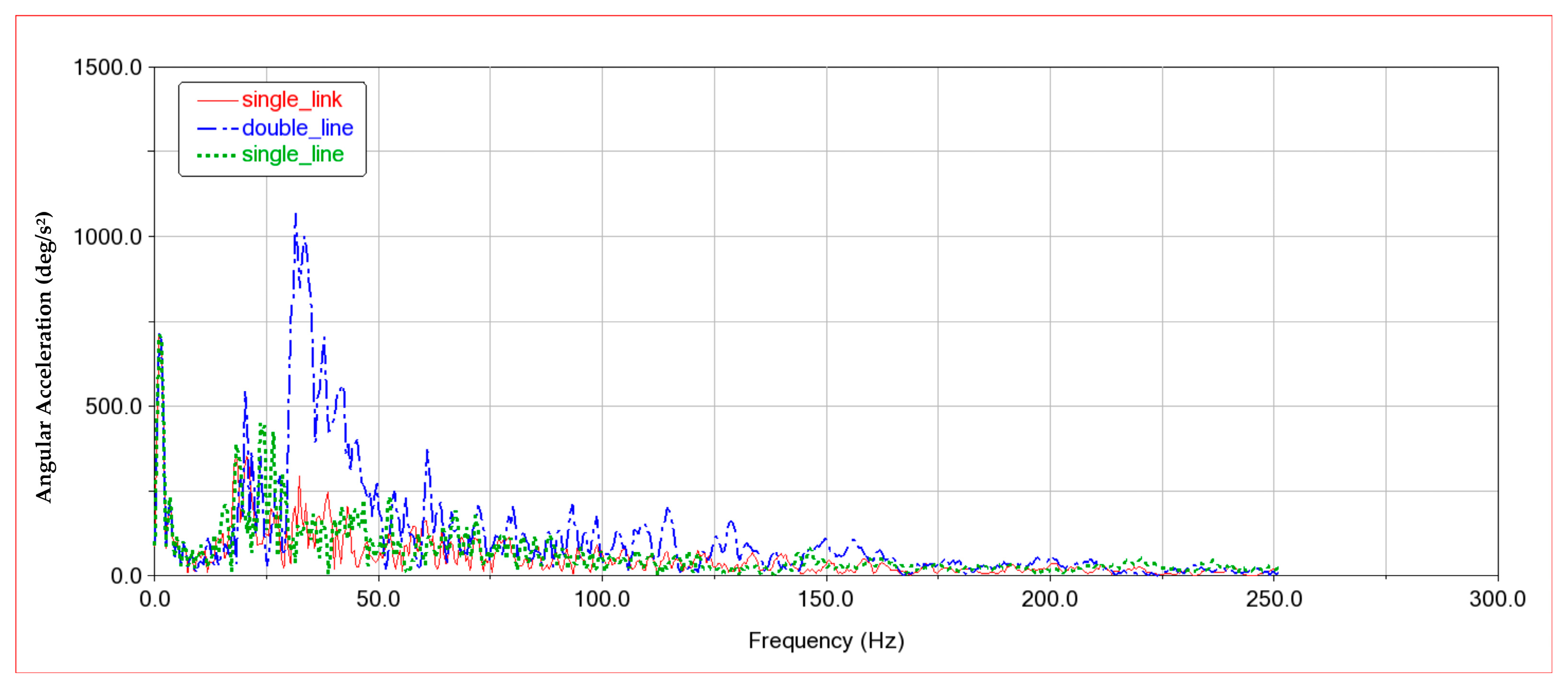

2.2. Solid Modeling

3. Contact Force Analysis of the Swinging Rod and Push Rod

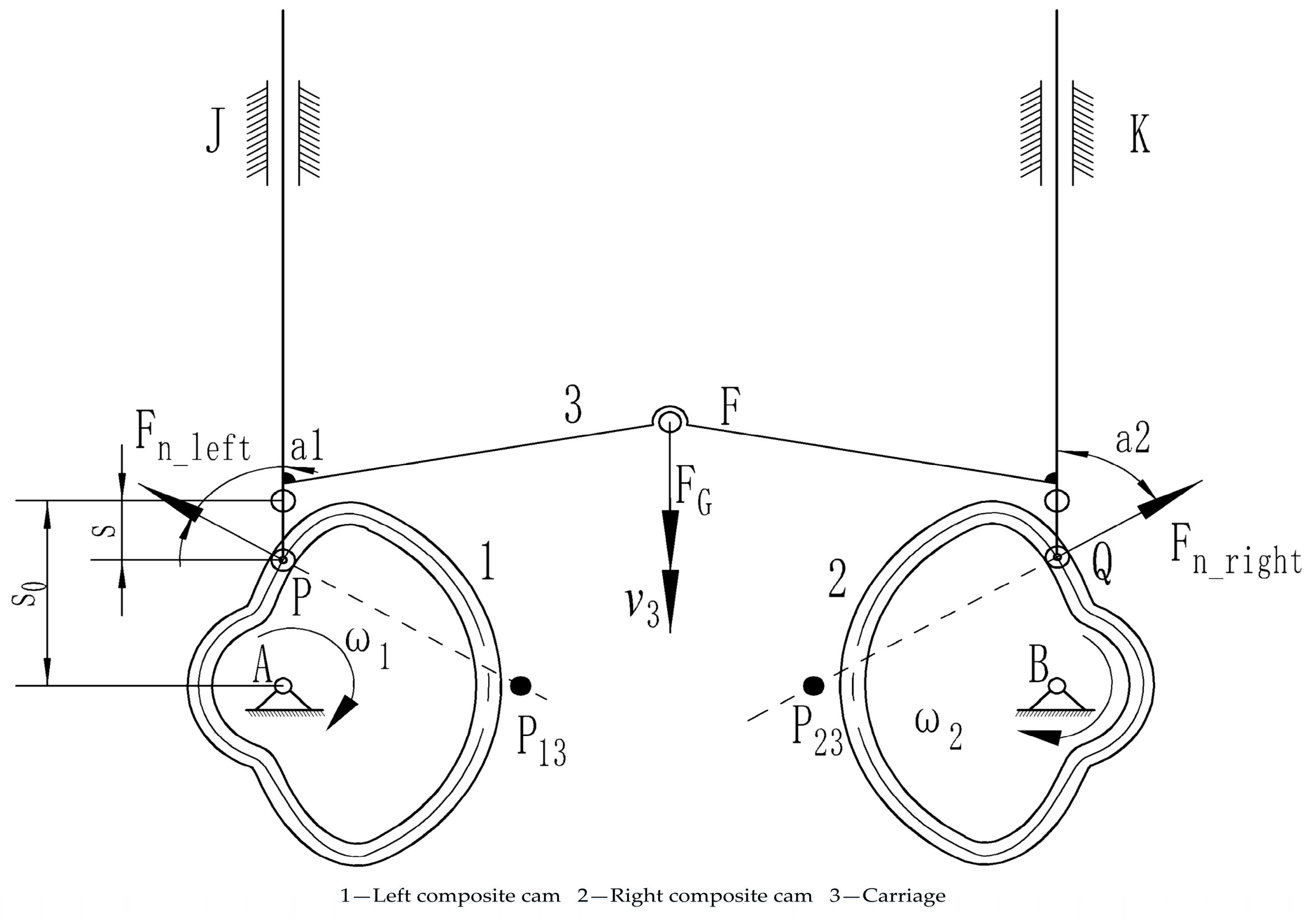

3.1. Pressure Angle of Cam Mechanism

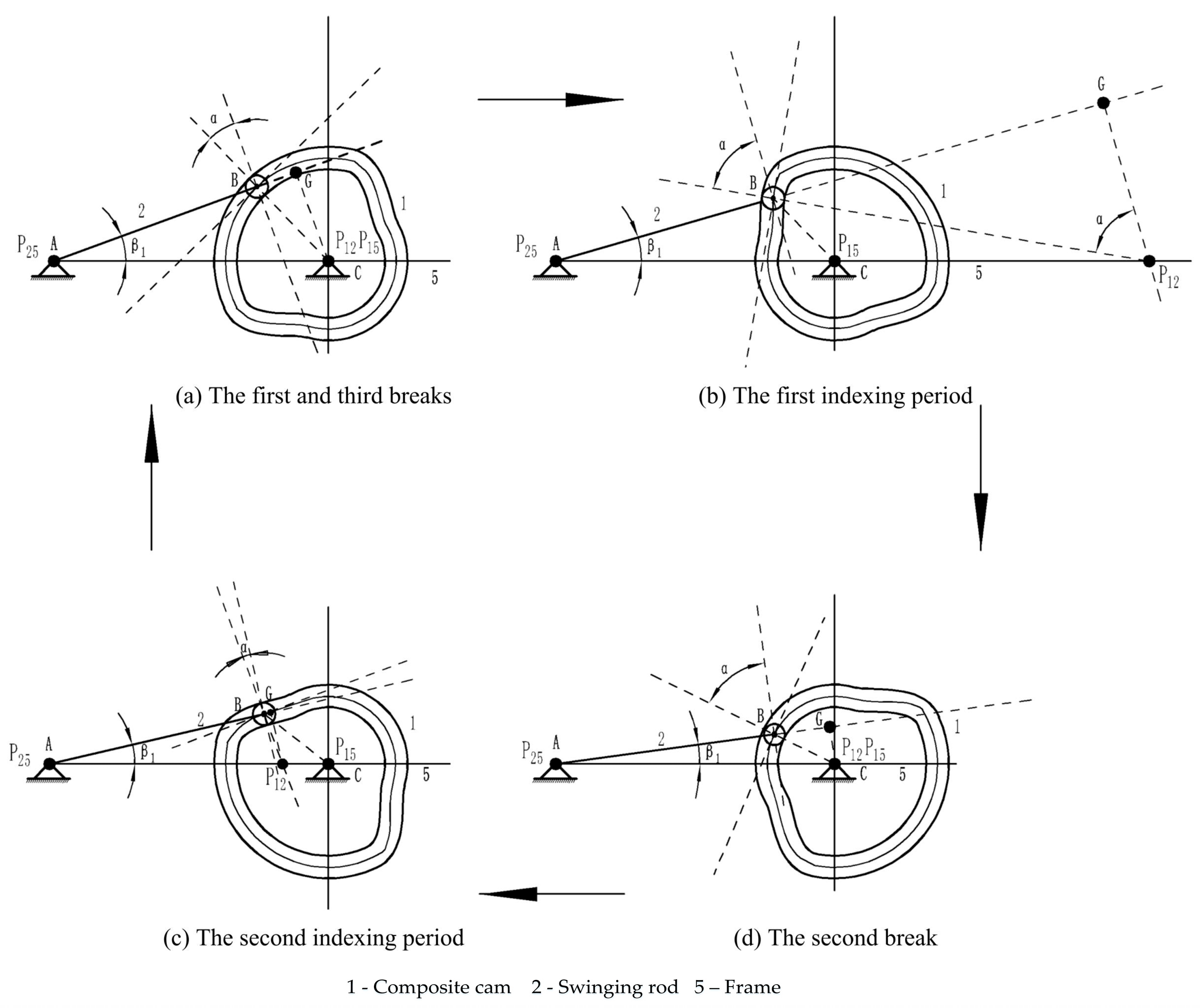

3.1.1. Analysis of Pressure Angle in Swinging Rod Groove Cam Mechanism

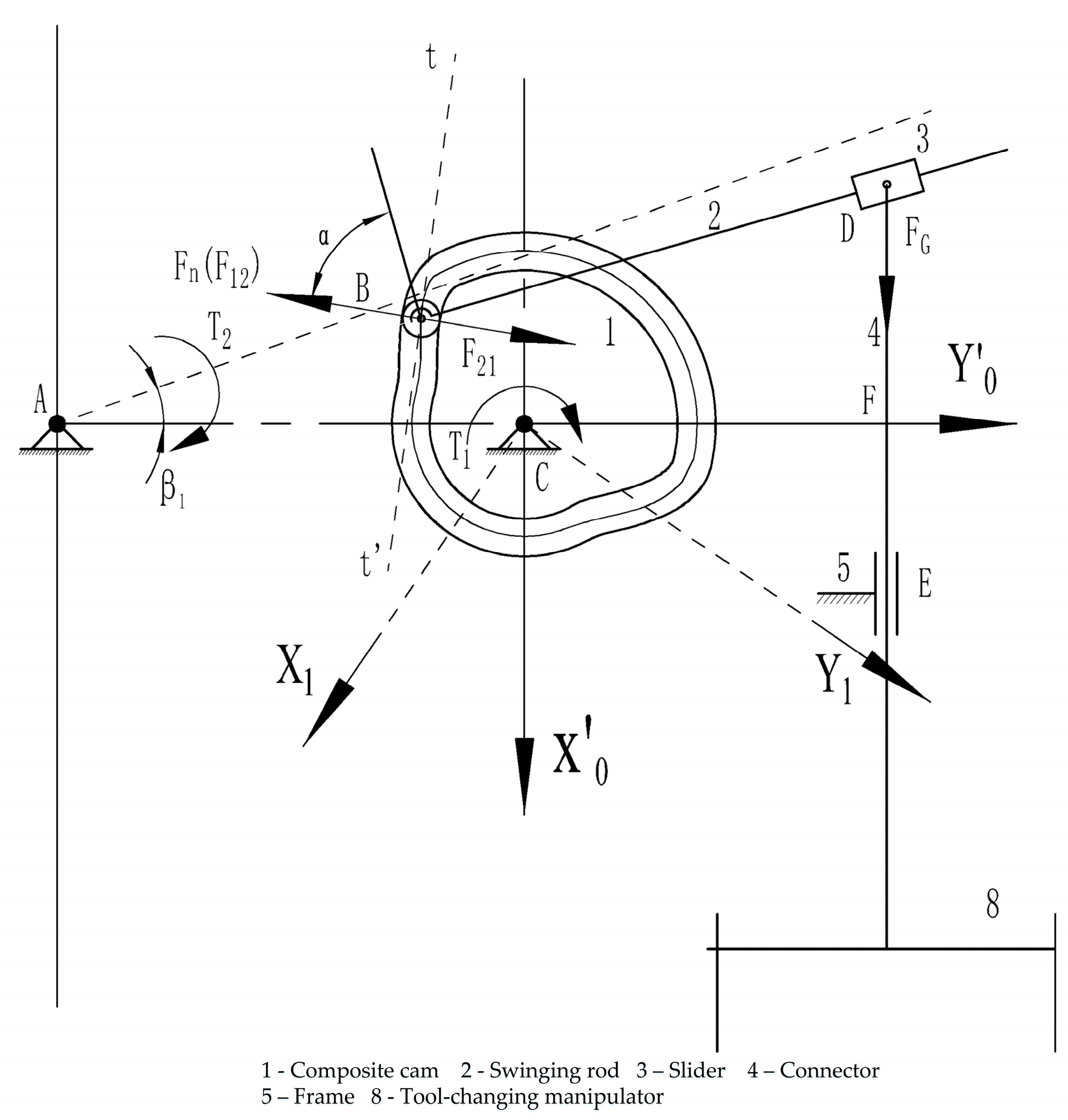

3.1.2. Analysis of Pressure Angle in Push Rod Groove Cam Mechanism

3.2. Contact Forces of Followers

3.2.1. Contact Forces of Swinging Rod

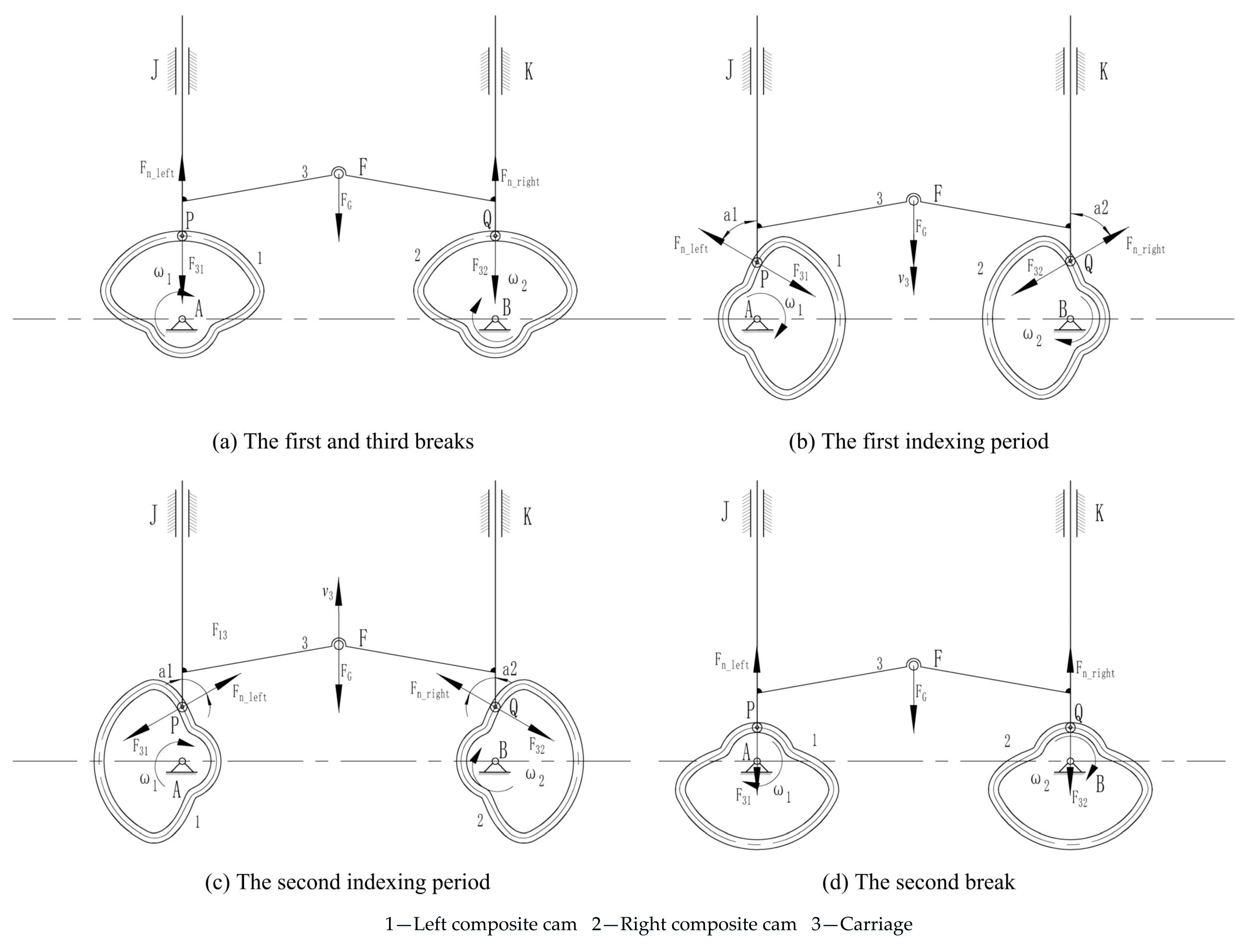

3.2.2. Contact Forces of Push Rod

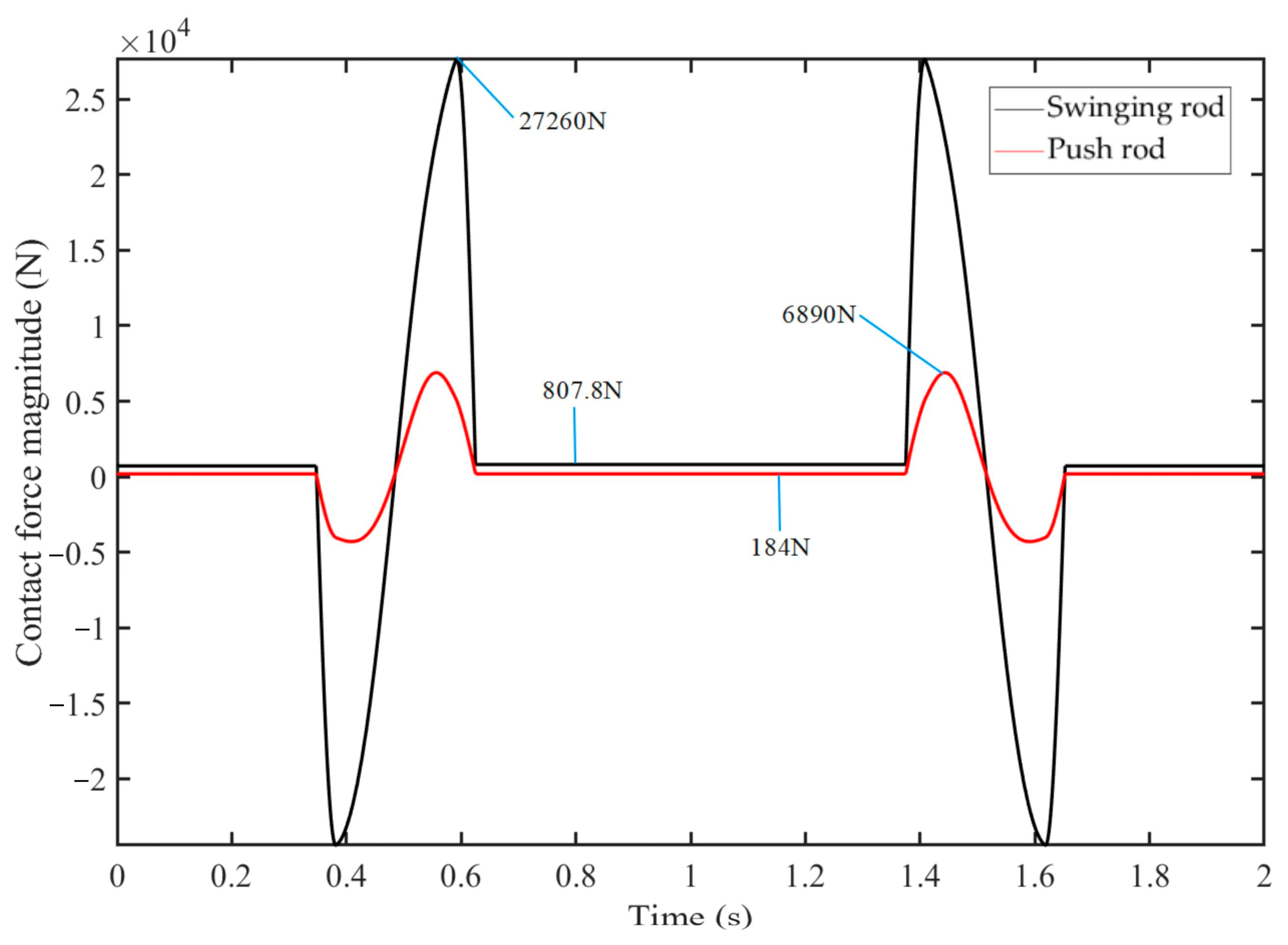

3.3. Quantitative Comparative Analysis

4. Dynamic Simulation Analysis of Two Types of Tool Changers

4.1. Establishing the Simulation Model

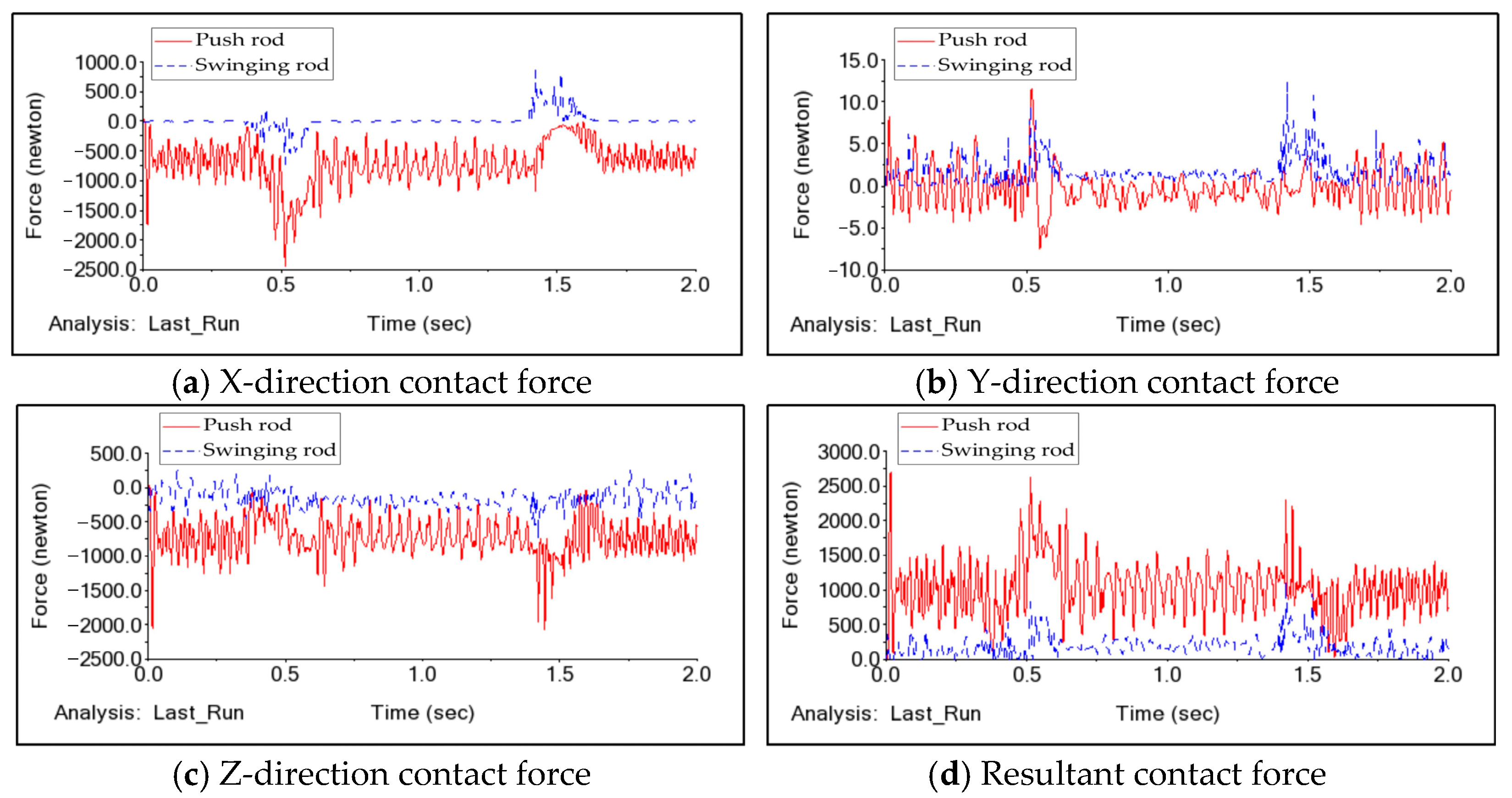

4.2. Comparative Analysis of Contact Forces Between Swinging Rod and Push Rod

4.3. Comparative Analysis of Manipulator Motion Smoothness

4.4. Model Optimization

5. Experiments

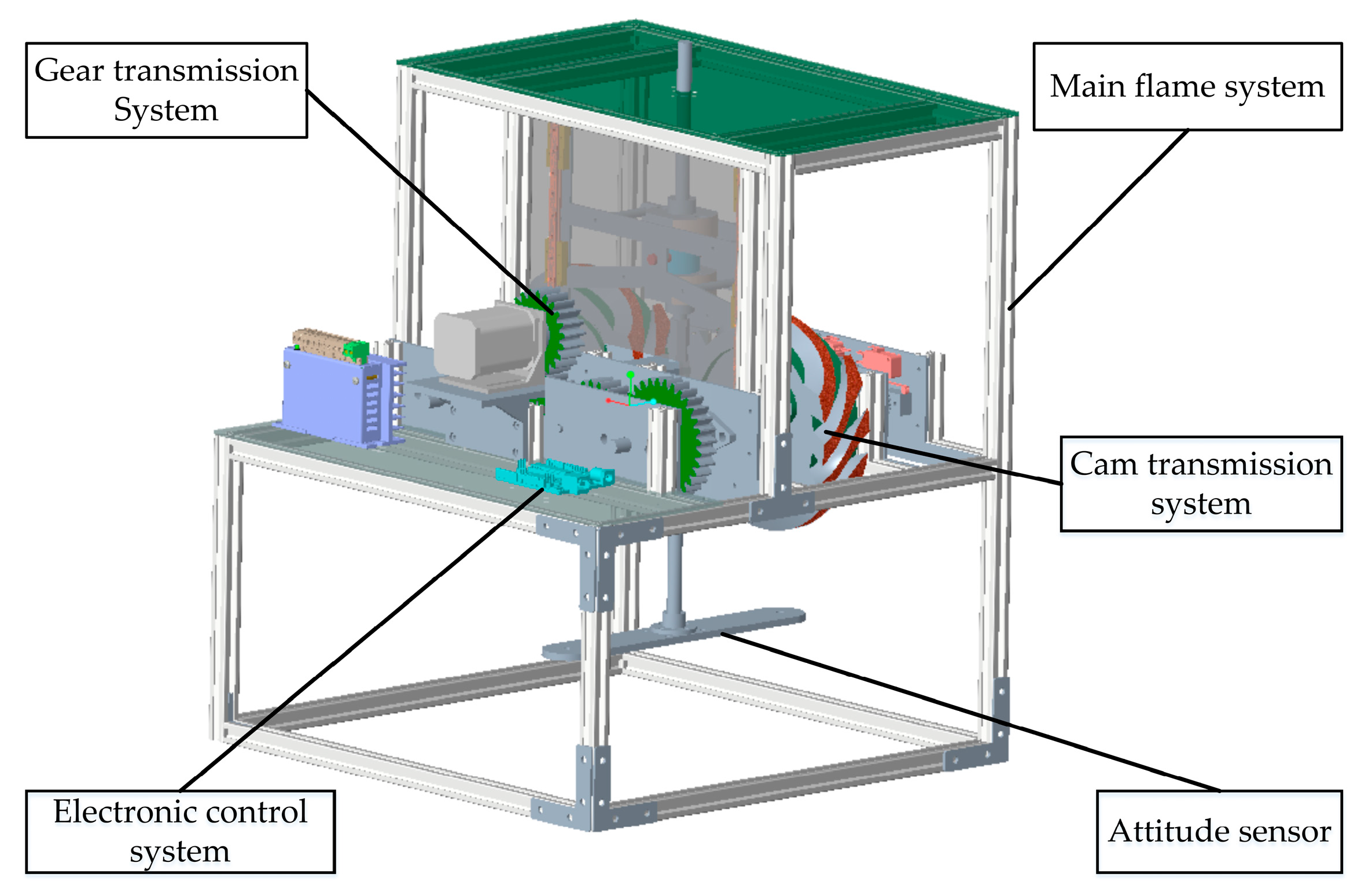

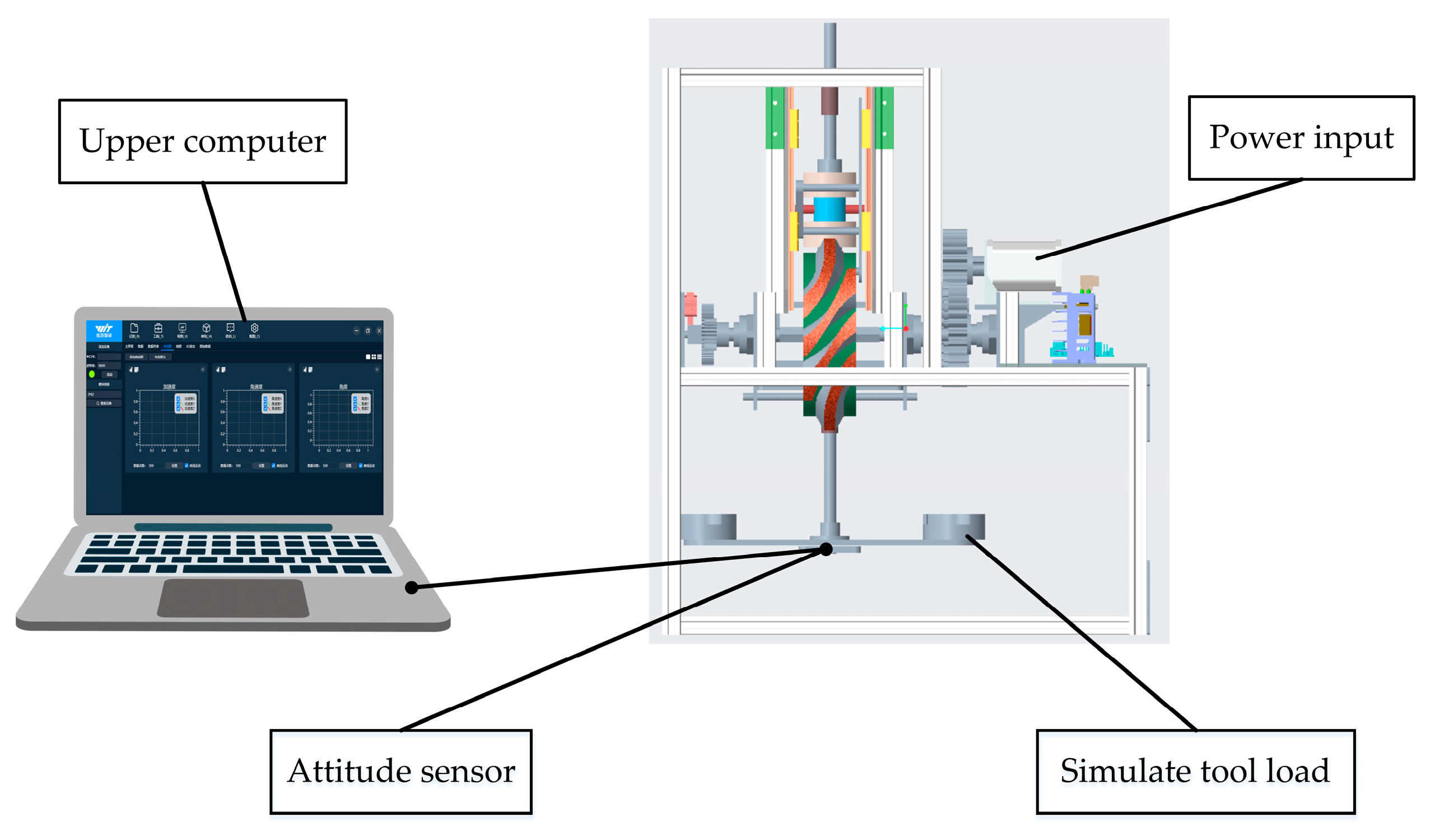

5.1. Design of Experimental Platform

5.2. Data Acquisition

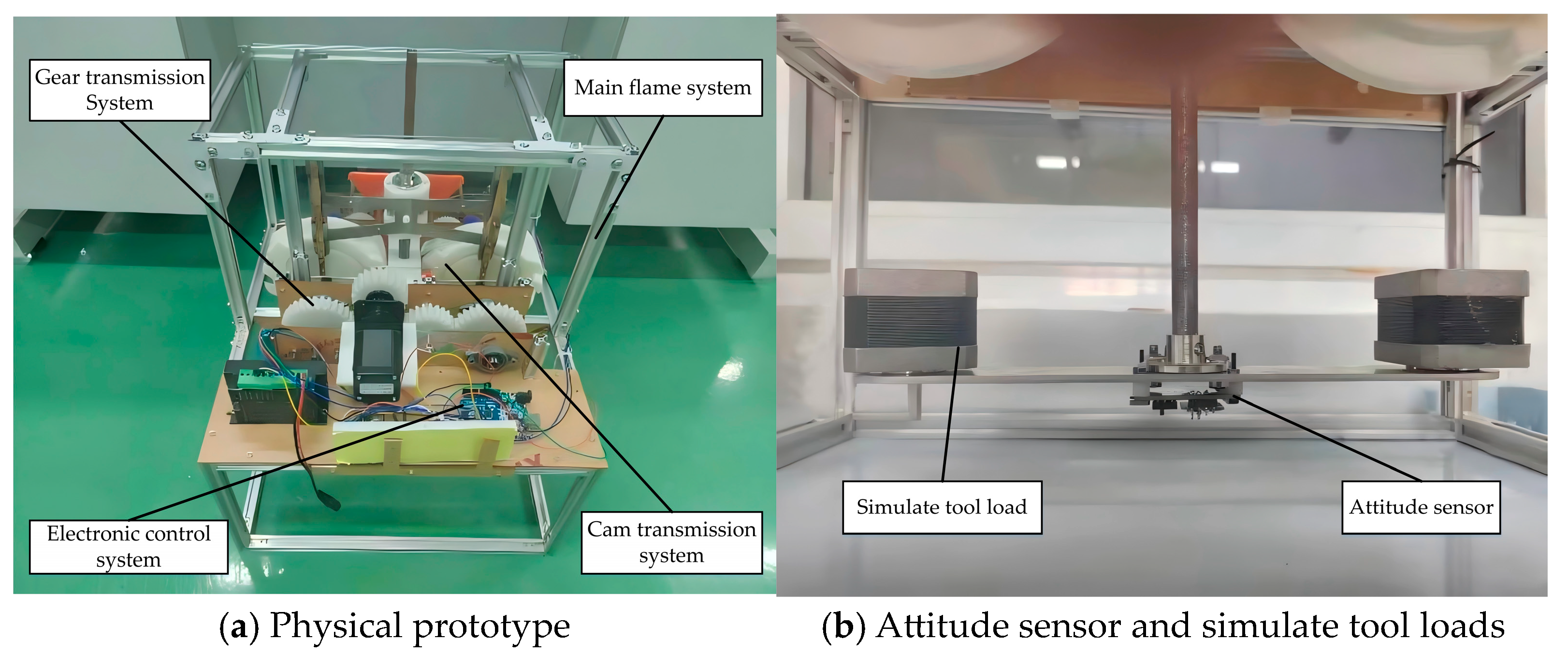

5.3. Physical Assembly

5.4. Data Comparison

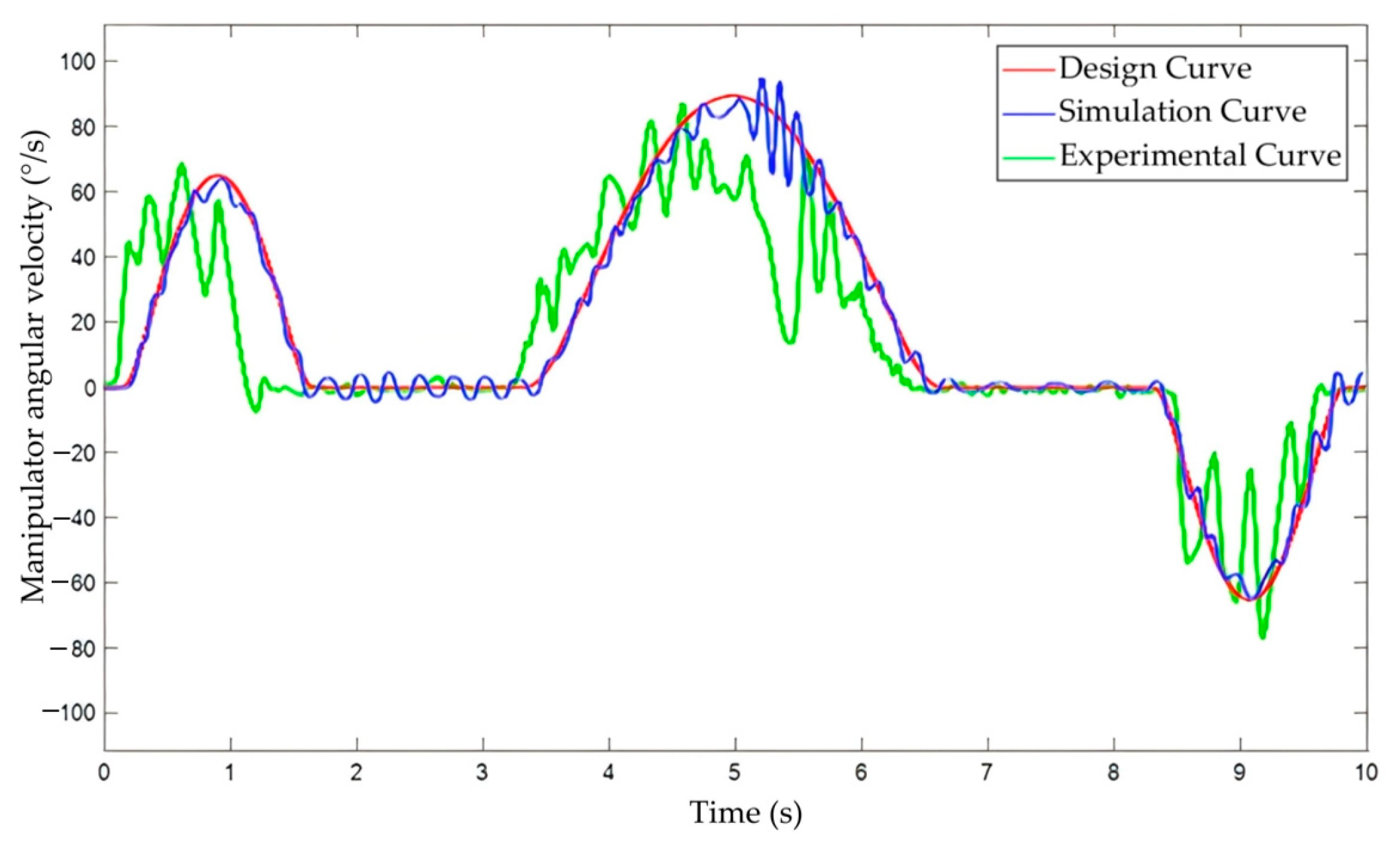

6. Conclusions

- To solve the problems of amplified vibration errors and large impact forces in the single composite cam swinging rod type tool changer mechanism, a double composite cam push rod type tool changer was proposed.

- Based on the meshing process between the push rod, swinging rod, and cam, a pressure angle model and contact force equation under load conditions were derived. Quantitative analysis using Matlab showed that the contact force between the push rod and cam is less than that of the swinging rod, reducing system impacts during tool changes.

- Dynamic simulations of the single composite cam swinging rod type and double composite cam push rod type tool changer mechanisms were conducted using the ADAMS simulation platform. Results indicated that the additional arc cams in the double composite cam structure reduced the stability of the manipulator’s movement and increased impacts on the indexing plate. The right-side arc cam was, therefore, removed, resulting in the optimized single composite cam push rod type mechanism, which improved tool change smoothness and reduced follower impact.

- During experimental validation, a scaled experimental platform with a factor of 0.5 was built to collect data on angular position, angular velocity, and linear acceleration under load conditions. These data were processed using Matlab, validating the accuracy of the simulation and theoretical models and confirming the feasibility of the push rod type cam tool changer.

- Compared to existing single composite cam swinging rod and double composite push rod mechanisms, the optimized single composite cam push rod type tool changer proposed in this study offers several advantages. The push rod type mechanism showed improved stability during both linear and rotary movements, significantly reducing acceleration fluctuations and minimizing system impacts. Additionally, due to structural improvements, the push rod-type mechanism is suitable for high load conditions, providing better load-bearing capacity and impact resistance than the swinging rod structure. While the optimized push rod structure compromises on compactness and takes up more space, it provides unique advantages in applications requiring high stability and load-bearing capacity.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, J.; Tao, W.; Feng, T. Development Status and Key Technologies of Automatic Tool Changer. Mach. Tool Hydraul. 2013, 5, 174–176+160. [Google Scholar]

- Cai, X.; Che, W.; Chen, W. Research on parametric design technology of highspeed cam mechanism with oscillating follower. J. Graph. 2021, 42, 664–669. [Google Scholar]

- Chen, T. Modeling and Motion Simulation of the Globoidal Indexing CAM on Feeding, echanism Based on Conjugate Surface Theory. J. Sanmenxia Polytech. 2023, 22, 127–134. [Google Scholar]

- Li, J.; Rao, X.; Tang, M. Research of the Profile Surface Equation of Globoidal Indexing Cam Based on Unified Mathematical Expression. J. Mech. Transm. 2018, 42, 23–28. [Google Scholar]

- Chang, Z.; Zhang, C.; Yang, Y. Using envelop theory to generate meshing curved surface of spatial indexing cam. J. Mach. Des. 2000, 17, 10–11. [Google Scholar]

- Li, J.; Wang, X. Design of Cylindrical Indexing Cam and Circular Cone Rollers by MATLAB. Mech. Eng. Autom. 2015, 4, 78–79+82. [Google Scholar]

- Fang, Z.; Xu, J.; Cui, P. Simulation Design of Cam Mechanism Based on ADAMS and MATLAB. Coal Mine Mach. 2018, 39, 141–143. [Google Scholar]

- Zhao, S.; Fu, Y.; Lu, Q.; Zheng, L. Research on the Modeling and Kinematics Simulation of Globoidal Indexing Cam Mechanism Based on Creo and ADAMS. Mach. Des. Manuf. 2020, 2020, 111–114. [Google Scholar]

- Cao, P.; Luo, K.; He, X. Parametric Design of Globoidal Indexing CAM Mechanism and Secondary Development of NX. Int. J. Ind. Syst. Eng. 2021, 40, 1031–1036. [Google Scholar]

- Liu, P. Influence of Tapered Roller Bearing Clearance on Its Dynamic Characteristics. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2020. [Google Scholar]

- Sun, D. Dynamic Characteristics Analysis and Elastohydro-Dynamic Lubrication Simulation of Arc Cam Reduction Mechanism. Master’s Thesis, Hubei Automotive Industrial Institute, Shiyan, China, 2023. [Google Scholar]

- Cui, Y.; Zhang, H.; Huan, Y. Dynamic Characteristics Analysis of Circumferential Rod Fastening Rotor-Bearing System Considering Contact Stiffness. Power Gener. Technol. 2021, 42, 447–453. [Google Scholar]

- Guan, J. Research on Automatic Tool Changer and Fault Diagnosis of Machining Center Based on PMC. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2019. [Google Scholar]

- Liang, C. Dynamic Study of Rigid-Flexible Coupling for Cam-Type Automatic Tool Changer. Master’s Thesis, Shaanxi University of Science & Technology, Xi’an, China, 2017. [Google Scholar]

- Wang, G. Design of High-Speed and High-Reliability Disc Tool Change System. Master’s Thesis, Ningxia University, Ningxia, China, 2022. [Google Scholar]

- Wang, G. Research on High-Speed Machining Center Automatic Tool Changer. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2015. [Google Scholar]

- Wang, S. Research on Motion Characteristics of Automatic Tool Changer. Master’s Thesis, Dalian University of Technology, Dalian, China, 2018. [Google Scholar]

- Yu, J.; Luo, L.; Shu, X.; Wu, Y.; Wen, C.; Hu, Q. Modeling and Profile Analysis of Globoidal Cam in Automatic Tool Changer. J. Mech. Transm. 2017, 41, 88–92. [Google Scholar]

- Stephen, S.; Cao, J.; Liang, J.; Zhang, C. Design of Offset Type Redundant Globoidal Cam. J. Mech. Transm. 2017, 41, 187–190, 202. [Google Scholar]

- Qin, X. Design of a Reversible Tool Storage Mechanism and Rotation Direction Recognition Device. Guangdong Polytech. Water Resour. Electr. Eng. 2024, 22, 48–51. [Google Scholar]

- Shames, I. Engineering Mechanics: Statics and Dynamics; PWS-Kent Pub. Co.: Boston, MA, USA, 2010. [Google Scholar]

- Sun, H.; Chen, Z.; Ge, W. Mechanics of Machinery, 8th ed.; Tsinghua University Press: Beijing, China, 2013; pp. 167–188. [Google Scholar]

- Cardona, S.; Zayas, E.; Jordi, L.; Catala, P. Synthesis of displacement functions by Bezier curves in constant-breadth cams with parallel flat-faced double translating and oscillating followers. Mech. Mach. Theory 2013, 62, 5–62. [Google Scholar] [CrossRef]

- Lu, X.; Wang, S.; Lu, Y.; Li, N.; Wen, C. Research on TBF distribution model of circular tool magazine and ATC. Int. J. Ind. Syst. Eng. 2019, 32, 382–404. [Google Scholar]

- Hou, J.; Feng, S. Research on Modeling and Processing Simulation of Ball Type Single Head of Globoidal Indexing Cam Entity. Modul. Mach. Tool Autom. Manuf. Tech. 2016, 2, 129–133. [Google Scholar]

- Gao, Y. Research of Mechanism of ADAMS Contact and Contact Friction. Automob. Appl. Technol. 2017, 6, 64–66+75. [Google Scholar]

- Gong, Z.; Jin, J. Design of the Cam in the Tool Changing Manipulator. Mach. Tool Hydraul. 2015, 14, 61–63+66. [Google Scholar]

- Li, J.; Feng, D. Contour Surface Design of Globoidal Indexing Cam. Mech. Eng. Autom. 2019, 3, 39–41. [Google Scholar]

- Zhao, H.; Fu, B.; Zhao, X.; Zhao, B. Parameterized design and dynamics simulation of globoidal indexing cam. Manuf. Autom. 2022, 44, 146–152. [Google Scholar]

- Wang, S.; Chen, T. Research of a CNC Machining Center Automatic Tool Changing Manipulator. Mod. Manuf. Technol. Equip. 2022, 58, 81–83. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhang, X.; Wang, X.; Lai, Z.; Zhu, W.; Zhang, Y. Simulation and Analysis of Double Compound CAM Pusher Tool Changing Mechanism for NC Machine Tool. Machines 2024, 12, 898. https://doi.org/10.3390/machines12120898

Zhang X, Zhang X, Wang X, Lai Z, Zhu W, Zhang Y. Simulation and Analysis of Double Compound CAM Pusher Tool Changing Mechanism for NC Machine Tool. Machines. 2024; 12(12):898. https://doi.org/10.3390/machines12120898

Chicago/Turabian StyleZhang, Xinbo, Xiaobing Zhang, Xigui Wang, Zhongping Lai, Wenxue Zhu, and Yujie Zhang. 2024. "Simulation and Analysis of Double Compound CAM Pusher Tool Changing Mechanism for NC Machine Tool" Machines 12, no. 12: 898. https://doi.org/10.3390/machines12120898

APA StyleZhang, X., Zhang, X., Wang, X., Lai, Z., Zhu, W., & Zhang, Y. (2024). Simulation and Analysis of Double Compound CAM Pusher Tool Changing Mechanism for NC Machine Tool. Machines, 12(12), 898. https://doi.org/10.3390/machines12120898