Concurrent AI Tuning of a Double-Loop Controller for Multi-Phase Drives

Abstract

1. Introduction

Novelty and Contributions

- An automatic and on-line method for the adjustment of all controller parameters is proposed.

- All parts of the drive (electro-magnetic and mechanical) are considered in a holistic way.

- The weighting factors of FSMPC are retained as degrees of freedom for the consideration of different objectives (figures of merit).

- The whole sinusoidal steady-state operation space of the drive is considered to include combinations of speed and load.

- Flexibility to adapt to different applications is achieved through the use of a customizable optimization problem.

- An assessment in a real five-phase IM is presented considering computational and experimental issues.

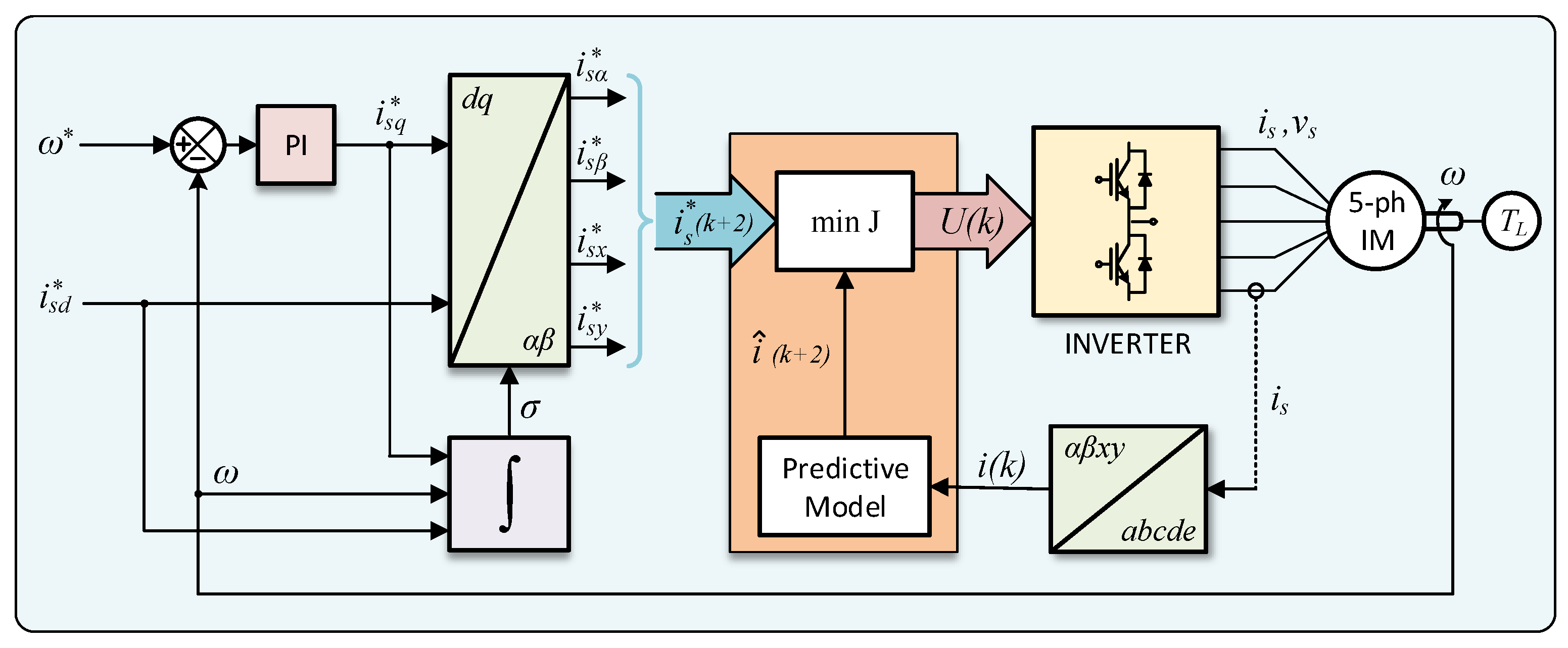

2. FSMPC Control of IM

2.1. Figures of Merit

- Overshoot in mechanical speed (). This is defined as per (9), and is something to avoid.

- Mechanical speed rise time (). This is defined as per (10), and should be low enough to provide a fast dynamic response of the drive. It is usually in conflict with , so in most cases, a compromise solution must be found.

- The absolute error of the integral time () penalizes the duration of the tracking error. This is defined as per (11) and is applied to the mechanical speed.

- Torque ripple (). This is defined as per (12) and is actually an electro-magnetic quantity directly generated by stator currents. It is a cause for mechanical stress, so it has to be avoided.

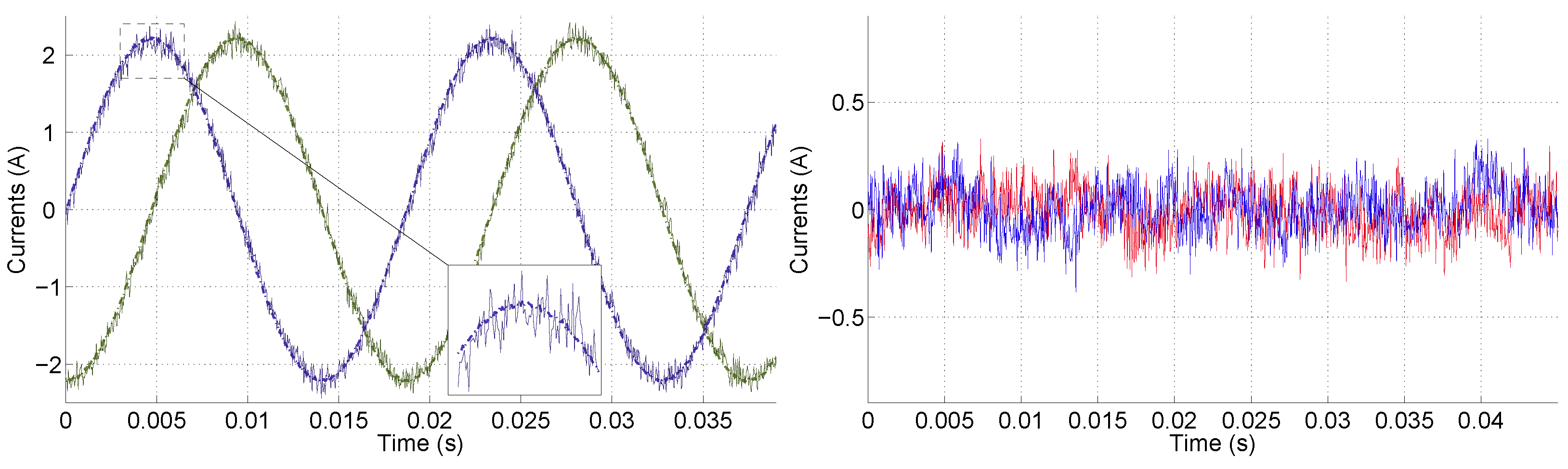

- Harmonic content (). This is defined as per (13) and must be kept as low as possible as it contributes to losses.

- Average value for the switching frequency (). This is defined as per (14) and must be maintained within suitable limits to avoid losses and damages to the VSI.

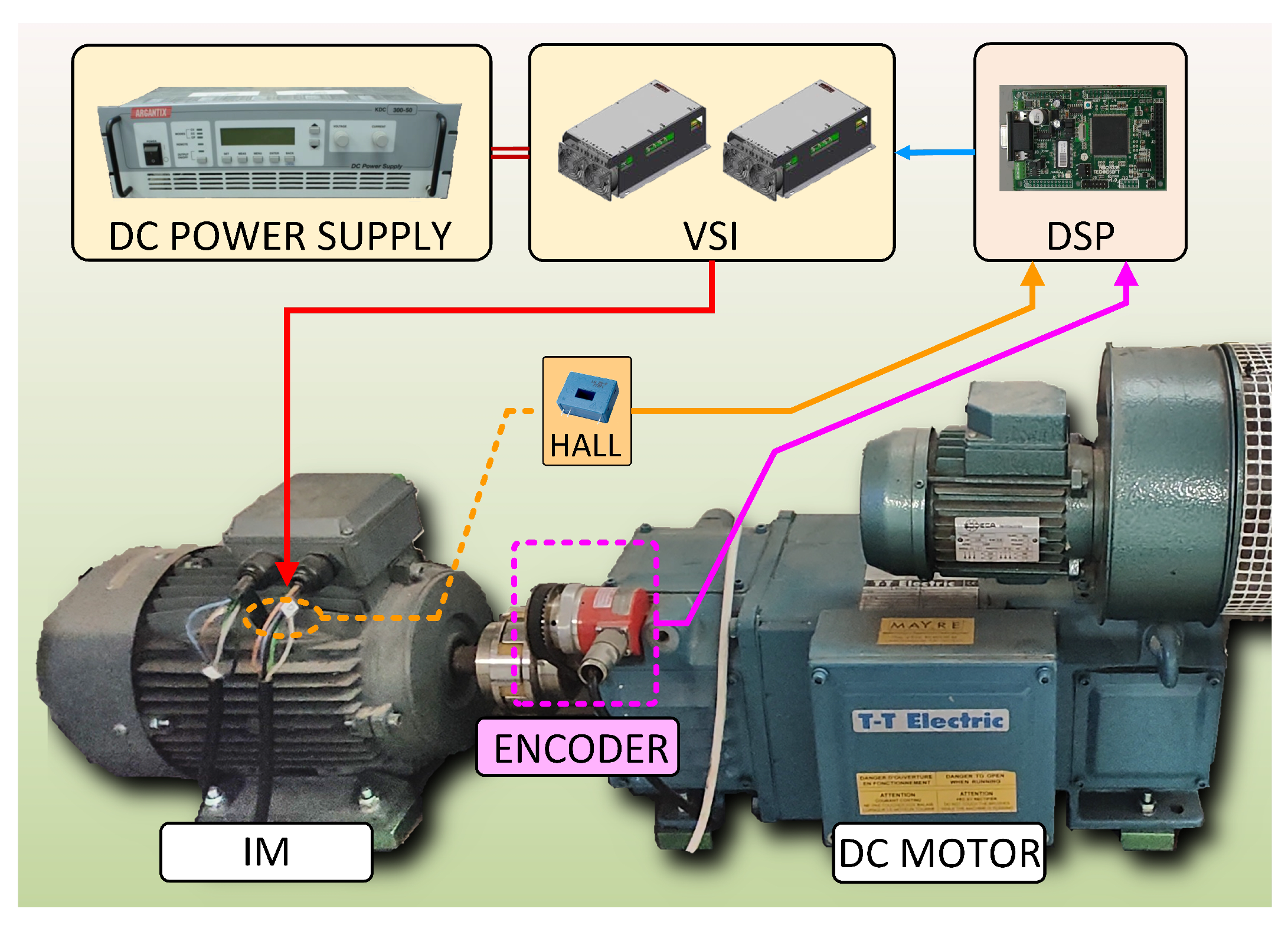

2.2. Experimental Setup

3. Proposed ANN Tuning Method

3.1. Objectives and Restrictions

3.2. Data Gathering and Training

- The outer PI loop can be roughly tuned using a simplified dynamical model corresponding to a second-order transfer function. This provides a set of initial guesses for and that are later refined.

- Similarly, an initial guess for the WF parameters of the CF can be obtained from previous works on IMs, as shown in [13]. This provides a set of initial guesses for and .

- Finally, instead of the extensive exploration of space featured in previous works, gradient descent is used to produce new combinations from existing ones. In this way, the experimental setup can drive itself in the data-gathering task. This is similar to the strategy for real-time WF selection proposed in [13] for a six-phase IM.

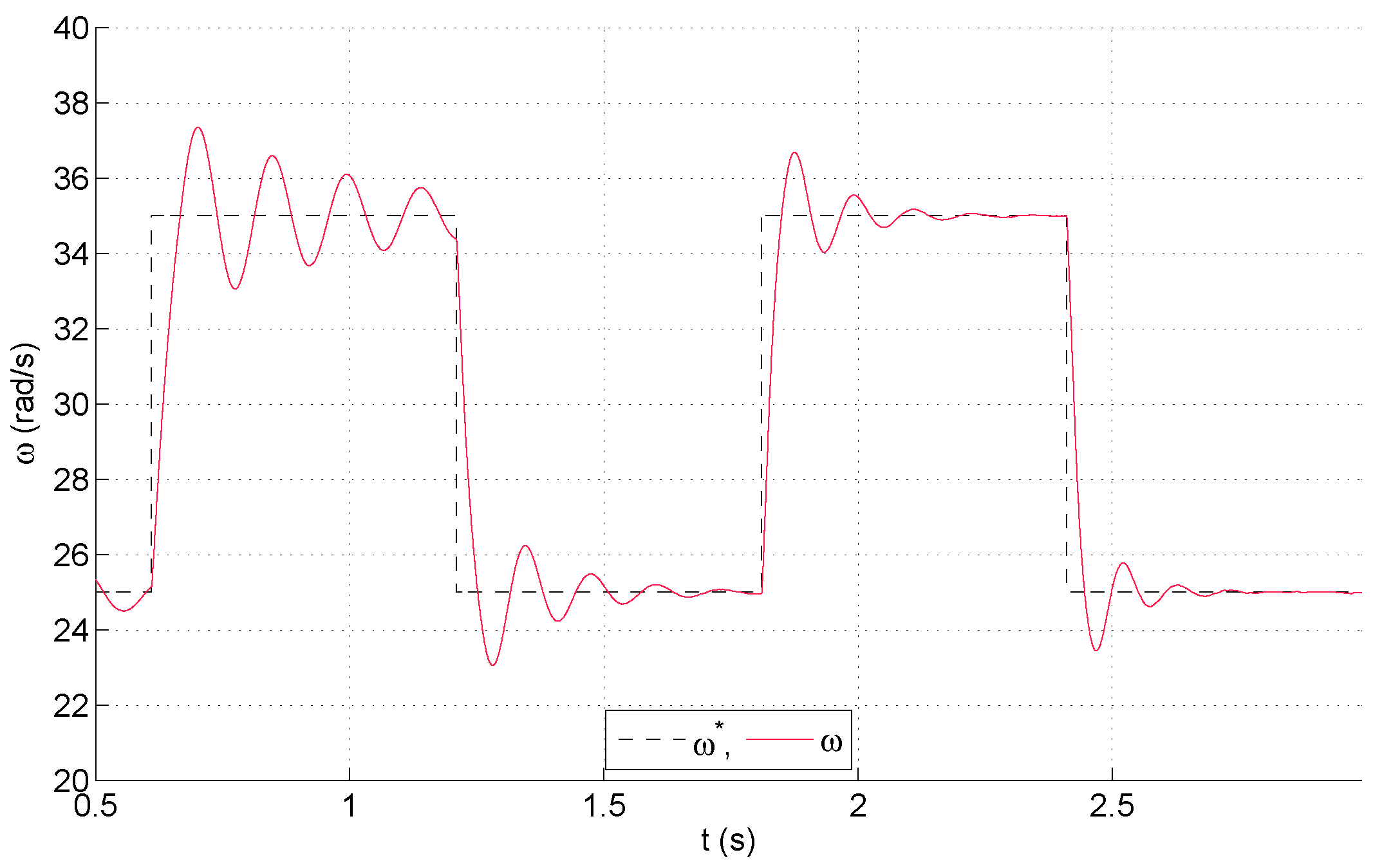

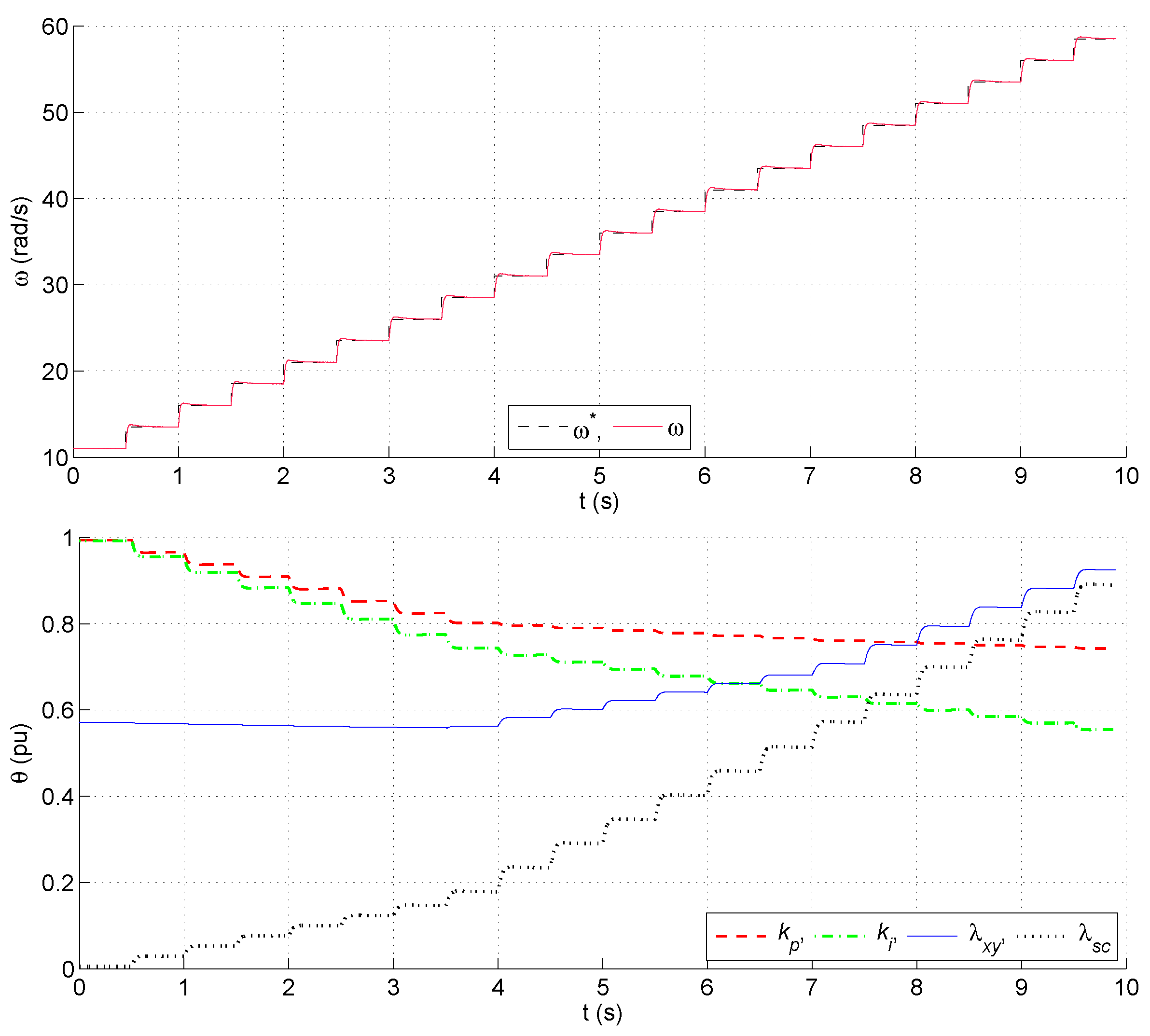

4. Experimental Results

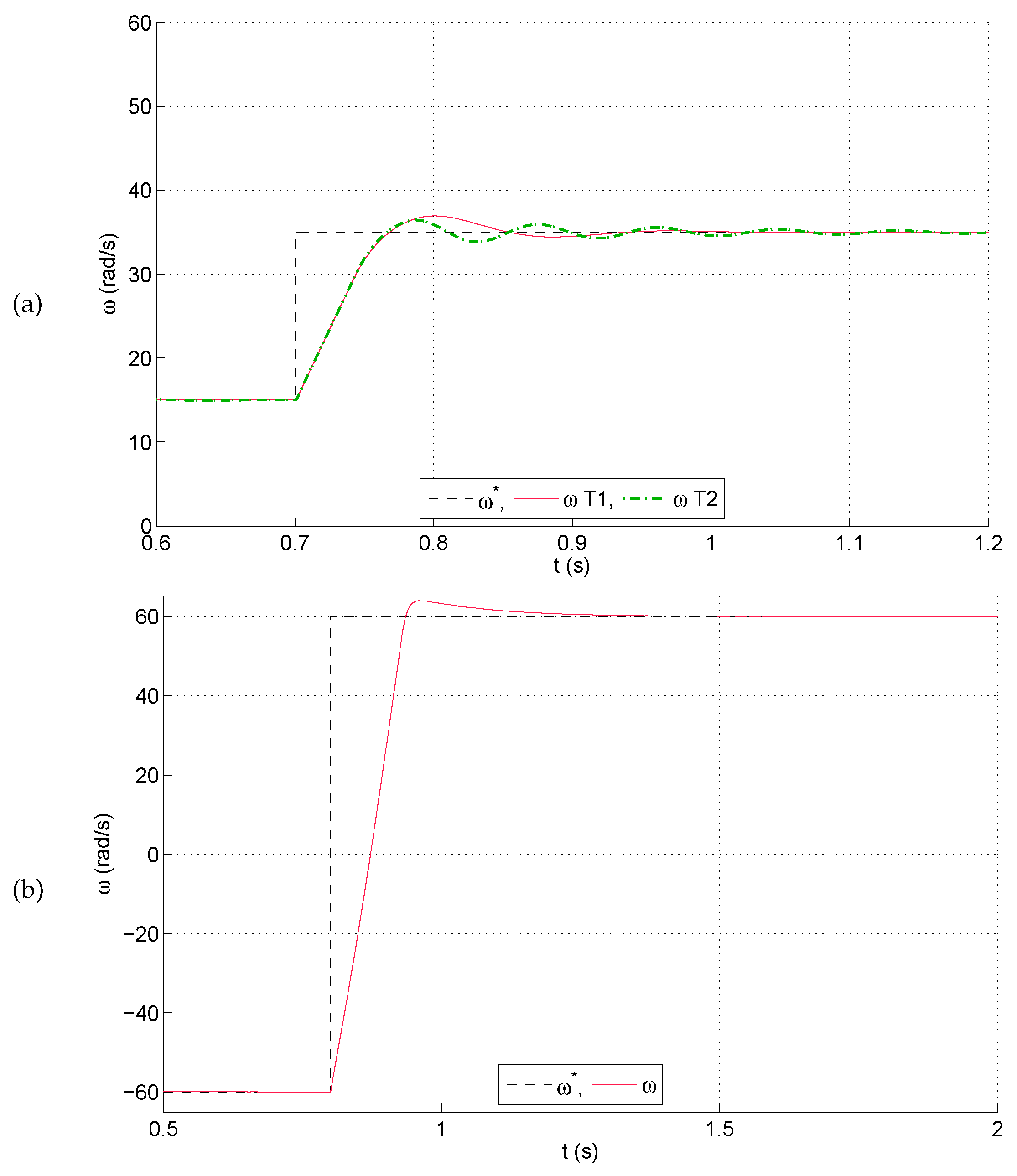

- Tuning (A) is a commonly found tuning in which the non-linearities produced by changes in the operating point are not realized. In particular and are set to low enough values to obtain acceptable values of and on average. A fast response is sought with this tuning, achieving low values of . This type of tuning is found in many published works.

- Tuning (B) corresponds to the proposed method, where is provided by an ANN. The constraints of (16) are set to (%) and (kHz). Function uses the parameters , , and . This tuning aims at ensuring proper working of the VSI, leading to a reduction in overshoot and maintaining a certain trade-off between performance indicators.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| ANN | Artificial neural network |

| CF | Cost function |

| DC | Direct Current |

| FSMPC | Finite-State Model Predictive Control |

| IM | Induction machine |

| IFOC | Indirect Field-Oriented Control |

| PI | Proportional–Integral |

| PWM | Pulse width modulation |

| NN | Neural network |

| VSI | Voltage Source Inverter |

| WF | Weighting factor |

References

- Lim, C.S.; Levi, E.; Jones, M.; Rahim, N.; Hew, W.P. A Comparative Study of Synchronous Current Control Schemes Based on FCS-MPC and PI-PWM for a Two-Motor Three-Phase Drive. Ind. Electron. IEEE Trans. 2014, 61, 3867–3878. [Google Scholar] [CrossRef]

- Hoggui, A.; Benachour, A.; Madaoui, M.C.; Mahmoudi, M.O. Comparative Analysis of Direct Torque Control with Space Vector Modulation (DTC-SVM) and Finite Control Set-Model Predictive Control (FCS-MPC) of Five-Phase Induction Motors. Prog. Electromagn. Res. B 2024, 108, 89–104. [Google Scholar] [CrossRef]

- Aciego, J.J.; Gonzalez-Prieto, I.; Duran, M.J.; Gonzalez-Prieto, A.; Carrillo-Rios, J. Guiding the Selection of Multi-Vector Model Predictive Control Techniques for Multiphase Drives. Machines 2024, 12, 115. [Google Scholar] [CrossRef]

- Alharbi, A.; Odhano, S.; Smith, A.; Deng, X.; Mecrow, B. A Review of Modeling and Control of Multi-Phase Induction Motors Under Machine Faults. In Proceedings of the 2024 International Conference on Electrical Machines (ICEM), Torino, Italy, 1–4 September 2024; IEEE: New York, NY, USA, 2024; pp. 1–9. [Google Scholar]

- Shawier, A.; Habib, A.; Mamdouh, M.; Abdel-Khalik, A.S.; Ahmed, K.H. Assessment of predictive current control of six-phase induction motor with different winding configurations. IEEE Access 2021, 9, 81125–81138. [Google Scholar] [CrossRef]

- Gonzalez-Prieto, A.; González-Prieto, I.; Duran, M.J.; Aciego, J.J. Dynamic response in multiphase electric drives: Control performance and influencing factors. Machines 2022, 10, 866. [Google Scholar] [CrossRef]

- Liu, C.; Luo, Y. Overview of advanced control strategies for electric machines. Chin. J. Electr. Eng. 2017, 3, 53–61. [Google Scholar]

- González, O.; Ayala, M.; Romero, C.; Rodas, J.; Gregor, R.; Delorme, L.; González-Prieto, I.; Durán, M.J.; Rivera, M. Comparative Assessment of Model Predictive Current Control Strategies applied to Six-Phase Induction Machines. In Proceedings of the 2020 IEEE International Conference on Industrial Technology (ICIT), Buenos Aires, Argentina, 26–28 February 2020; IEEE: New York, NY, USA, 2020; pp. 1037–1043. [Google Scholar]

- Fretes, H.; Rodas, J.; Doval-Gandoy, J.; Gomez, V.; Gomez, N.; Novak, M.; Rodriguez, J.; Dragičević, T. Pareto Optimal Weighting Factor Design of Predictive Current Controller of a Six-Phase Induction Machine based on Particle Swarm Optimization Algorithm. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 10, 207–219. [Google Scholar] [CrossRef]

- Arahal, M.R.; Kowal, A.; Barrero, F.; Castilla, M. Cost function optimization for multi-phase induction machines predictive control. Rev. Iberoam. Automática E Informática Ind. 2019, 16, 48–55. [Google Scholar] [CrossRef]

- Gonzalez-Prieto, I.; Zoric, I.; Duran, M.J.; Levi, E. Constrained model predictive control in nine-phase induction motor drives. IEEE Trans. Energy Convers. 2019, 34, 1881–1889. [Google Scholar] [CrossRef]

- Makhamreh, H.; Trabelsi, M.; Kükrer, O.; Abu-Rub, H. A lyapunov-based model predictive control design with reduced sensors for a PUC7 rectifier. IEEE Trans. Ind. Electron. 2020, 68, 1139–1147. [Google Scholar] [CrossRef]

- Arahal, M.R.; Satué, M.G.; Barrero, F.; Ortega, M.G. Adaptive Cost Function FCSMPC for 6-Phase IMs. Energies 2021, 14, 5222. [Google Scholar] [CrossRef]

- Lu, C.H.; Liao, P.Y.; Charng, Y.H.; Liu, C.M.; Guo, J.Y. Multivariable self-tuning PID controller based on wavelet fuzzy neural networks. In Proceedings of the 2014 International Conference on Machine Learning and Cybernetics, Lanzhou, China, 13–16 July 2014; IEEE: New York, NY, USA, 2014; Volume 2, pp. 755–759. [Google Scholar]

- Lu, P.; Huang, W.; Xiao, J. Speed tracking of Brushless DC motor based on deep reinforcement learning and PID. In Proceedings of the 2021 7th International Conference on Condition Monitoring of Machinery in Non-Stationary Operations (CMMNO), Guangzhou, China, 20–22 May 2021; IEEE: New York, NY, USA, 2021; pp. 130–134. [Google Scholar]

- Kanungo, A.; Choubey, C.; Gupta, V.; Kumar, P.; Kumar, N. Design of an intelligent wavelet-based fuzzy adaptive PID control for brushless motor. Multimed. Tools Appl. 2023, 82, 33203–33223. [Google Scholar] [CrossRef]

- Mao, H.; Tang, X.; Tang, H. Speed control of PMSM based on neural network model predictive control. Trans. Inst. Meas. Control 2022, 44, 2781–2794. [Google Scholar] [CrossRef]

- Hammoud, I.; Hentzelt, S.; Oehlschlaegel, T.; Kennel, R. Learning-based model predictive current control for synchronous machines: An LSTM approach. Eur. J. Control 2022, 68, 100663. [Google Scholar] [CrossRef]

- Wai, R.J.; Lin, F.J. Adaptive recurrent-neural-network control for linear induction motor. IEEE Trans. Aerosp. Electron. Syst. 2001, 37, 1176–1192. [Google Scholar]

- Satue, M.G.; Arahal, M.R.; Ramirez, D.R. Estimation of rotor currents in polyphase machines for predictive control. Rev. Iberoam. Automática E Informática Ind. 2023, 20, 25–31. [Google Scholar]

- Hanke, S.; Wallscheid, O.; Böcker, J. Comparison of Artificial Neural Network and Least Squares Prediction Models for Finite-Control-Set Model Predictive Control of a Permanent Magnet Synchronous Motor. In Proceedings of the 10th International Conference on Power Electronics, Machines and Drives, Online, 15–17 December 2020; IET: London, UK, 2021; Volume 2, pp. 266–271. [Google Scholar]

- Gao, L.; Chai, F. Model Predictive Direct Speed Control of Permanent-Magnet Synchronous Motors with Voltage Error Compensation. Energies 2023, 16, 5128. [Google Scholar] [CrossRef]

- Tian, M.; Cai, H.; Zhao, W.; Ren, J. Nonlinear Predictive Control of Interior Permanent Magnet Synchronous Machine with Extra Current Constraint. Energies 2023, 16, 716. [Google Scholar] [CrossRef]

- Abu-Ali, M.; Berkel, F.; Manderla, M.; Reimann, S.; Kennel, R.; Abdelrahem, M. Deep learning-based long-horizon MPC: Robust, high performing, and computationally efficient control for PMSM drives. IEEE Trans. Power Electron. 2022, 37, 12486–12501. [Google Scholar] [CrossRef]

- Karimi, M.; Rostami, M.A.; Zamani, H. Continuous control set model predictive control for the optimal current control of permanent magnet synchronous motors. Control Eng. Pract. 2023, 138, 105590. [Google Scholar] [CrossRef]

- Yin, Z.; Zhao, H. Overshoot Reduction Inspired Recurrent RBF Neural Network Controller Design for PMSM. In Proceedings of the 2023 IEEE 32nd International Symposium on Industrial Electronics (ISIE), Helsinki-Espoo, Finland, 19–21 June 2023; IEEE: New York, NY, USA, 2023; pp. 1–6. [Google Scholar]

- Saberi, S.; Rezaie, B. Robust adaptive direct speed control of PMSG-based airborne wind energy system using FCS-MPC method. ISA Trans. 2022, 131, 43–60. [Google Scholar] [CrossRef] [PubMed]

- Penthala, T.; Kaliaperumal, S. Predictive control of induction motors using cascaded artificial neural network. Electr. Eng. 2024, 106, 2985–3000. [Google Scholar] [CrossRef]

- Guler, N.; Bayhan, S.; Komurcugil, H. Equal weighted cost function based weighting factor tuning method for model predictive control in power converters. IET Power Electron. 2022, 15, 203–215. [Google Scholar] [CrossRef]

- Zhang, Z.; Wei, H.; Zhang, W.; Jiang, J. Ripple Attenuation for Induction Motor Finite Control Set Model Predictive Torque Control Using Novel Fuzzy Adaptive Techniques. Processes 2021, 9, 710. [Google Scholar] [CrossRef]

- Holakooie, M.H.; Iwanski, G. An Adaptive Identification of Rotor Time Constant for Speed-sensorless Induction Motor Drives: A Case Study for Six-phase Induction Machine. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 9, 5452–5464. [Google Scholar] [CrossRef]

- Yepes, A.G.; Riveros, J.A.; Doval-Gandoy, J.; Barrero, F.; Lopez, Ó.; Bogado, B.; Jones, M.; Levi, E. Parameter identification of multiphase induction machines with distributed windings—Part 1: Sinusoidal excitation methods. IEEE Trans. Energy Convers. 2012, 27, 1056–1066. [Google Scholar] [CrossRef]

- Mehrotra, K.; Mohan, C.K.; Ranka, S. Elements of Artificial Neural Networks; MIT Press: Cambridge, MA, USA, 1997. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| Stator resistance, | 12.85 | |

| Rotor resistance, | 4.80 | |

| Stator leakage inductance, | 79.93 | mH |

| Rotor leakage inductance, | 79.93 | mH |

| Mutual inductance, | 681.7 | mH |

| Rotational inertia, | 0.02 | kg m2 |

| Number of pairs of poles, P | 3 | - |

| Speed | Ctrl | ||||

|---|---|---|---|---|---|

| Low | A | 295 | 8.3 | 0.15 | 1.60 |

| Med | A | 295 | 8.3 | 0.15 | 1.60 |

| High | A | 295 | 8.3 | 0.15 | 1.60 |

| Low | B | 387 | 12.3 | 0.12 | 0.00 |

| Med | B | 295 | 7.8 | 0.15 | 1.58 |

| High | B | 285 | 6.5 | 0.21 | 2.85 |

| Speed | Ctrl | (%) | (ms) | (mNm) | - | (mA) | kHz | - |

|---|---|---|---|---|---|---|---|---|

| Low | A | 9.4 | 834 | 23.3 | 24.2 | 23.9 | 3.85 | 0.99 |

| Med | A | 9.7 | 834 | 19.9 | 7.0 | 24.9 | 9.95 | 0.92 |

| High | A | 9.9 | 839 | 18.6 | 5.1 | 25.7 | 11.2 | 0.92 |

| Low | B | 9.5 | 823 | 24.2 | 15.0 | 24.2 | 6.71 | 0.95 |

| Med | B | 9.1 | 835 | 20.1 | 6.9 | 24.9 | 10.0 | 0.92 |

| High | B | 8.1 | 838 | 19.1 | 6.0 | 24.7 | 10.0 | 0.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Satué, M.G.; Barrero, F.; Martínez-Heredia, J.M.; Colodro, F. Concurrent AI Tuning of a Double-Loop Controller for Multi-Phase Drives. Machines 2024, 12, 899. https://doi.org/10.3390/machines12120899

Satué MG, Barrero F, Martínez-Heredia JM, Colodro F. Concurrent AI Tuning of a Double-Loop Controller for Multi-Phase Drives. Machines. 2024; 12(12):899. https://doi.org/10.3390/machines12120899

Chicago/Turabian StyleSatué, Manuel G., Federico Barrero, Juana María Martínez-Heredia, and Francisco Colodro. 2024. "Concurrent AI Tuning of a Double-Loop Controller for Multi-Phase Drives" Machines 12, no. 12: 899. https://doi.org/10.3390/machines12120899

APA StyleSatué, M. G., Barrero, F., Martínez-Heredia, J. M., & Colodro, F. (2024). Concurrent AI Tuning of a Double-Loop Controller for Multi-Phase Drives. Machines, 12(12), 899. https://doi.org/10.3390/machines12120899