Effect of Oil Film Radial Clearances on Dynamic Characteristics of Variable Speed Rotor with Non-Concentric SFD

Abstract

1. Introduction

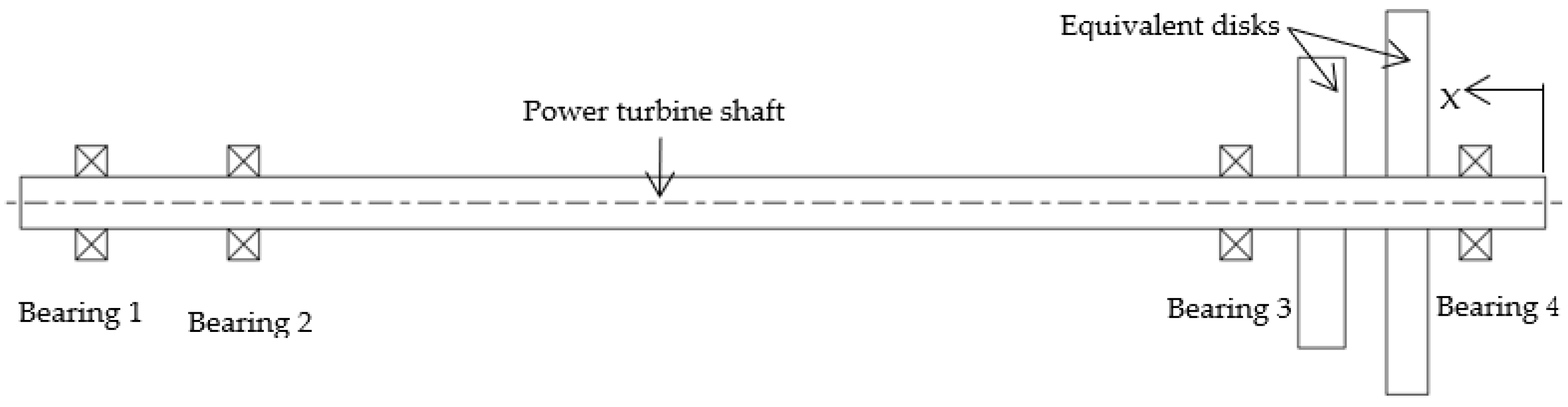

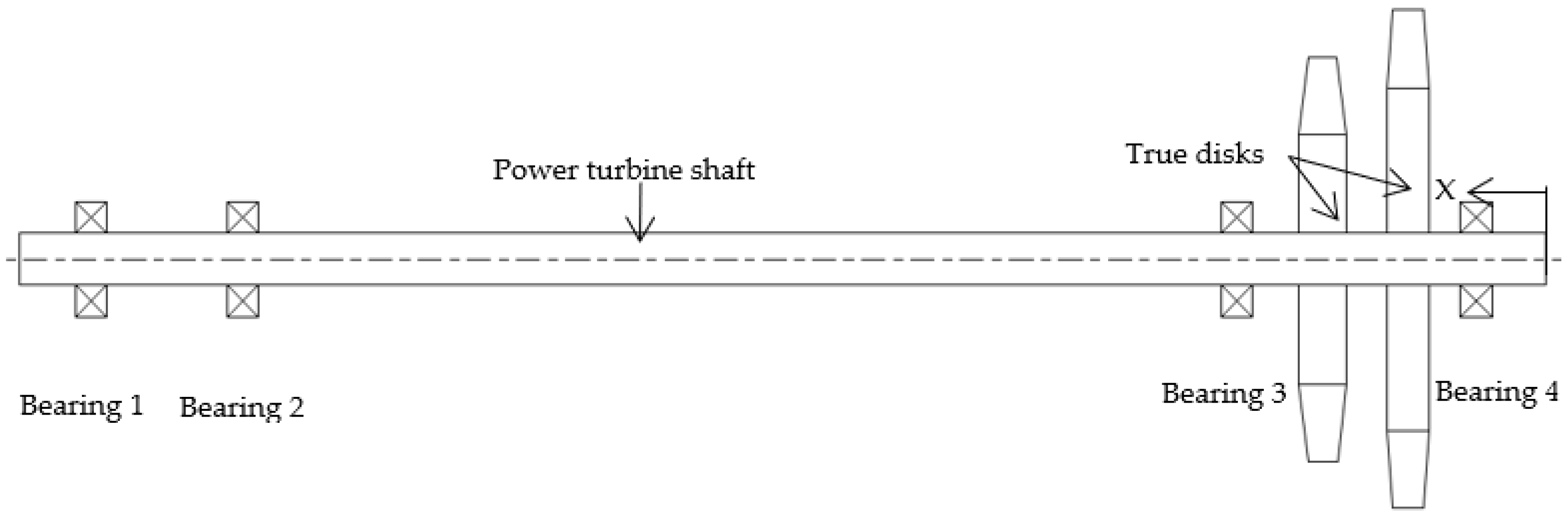

2. Equivalent Rotor Design

2.1. Design of the Equivalent Rotor

- (1)

- The main structures, such as the fitting relationship between the inner ring of the bearing and the shaft, turbine disk and shaft, connection method, axial preloading method, support span, support method, support stiffness, and bearing lubrication method, were consistent with the real rotor.

- (2)

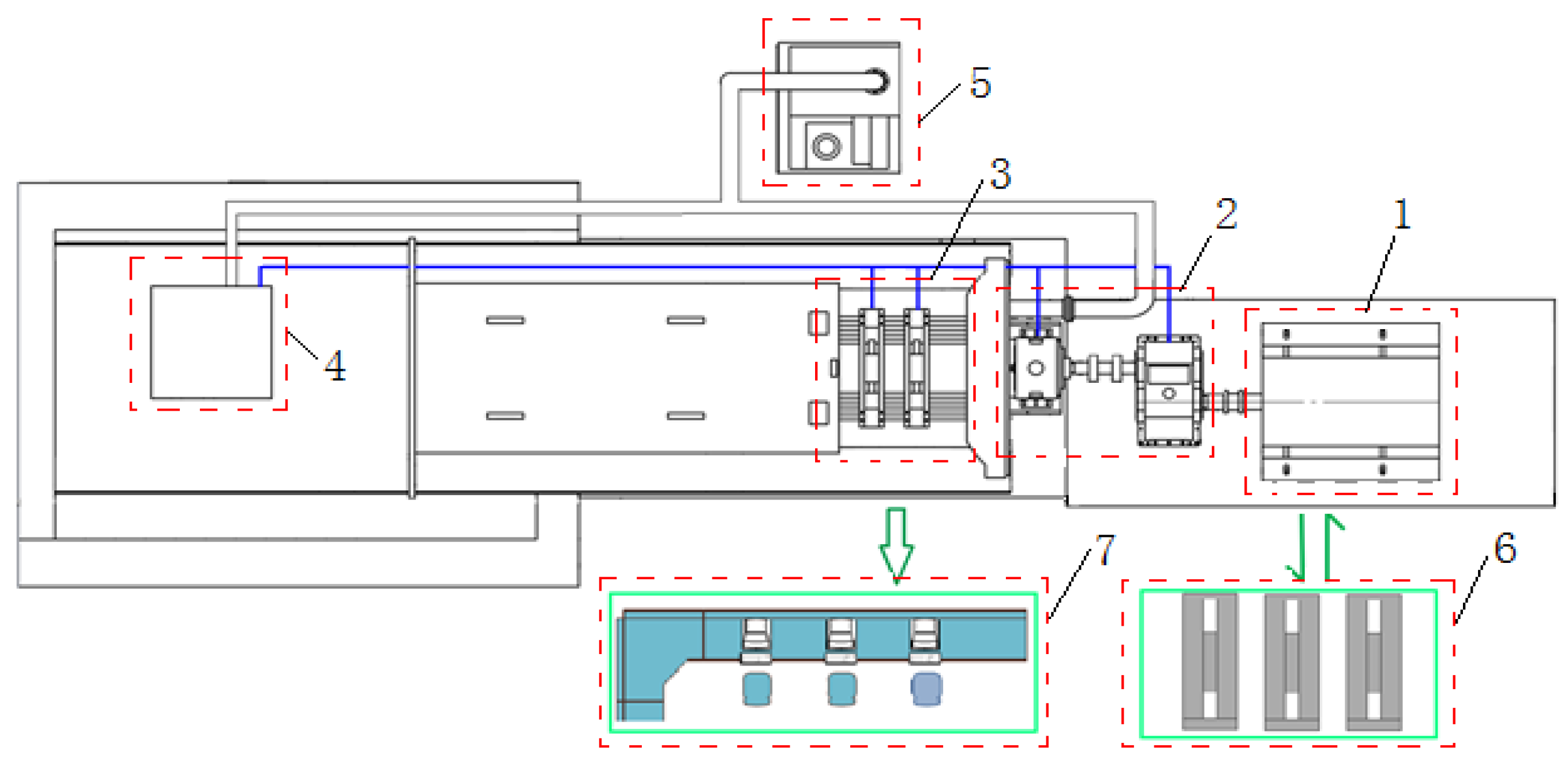

- The equivalent power turbine disks adopt an equivalent disk structure, and its inertia parameters, such as mass, center of mass, and moment of inertia, are consistent with those of the real power turbine disks. At the same time, while ensuring that the strength of the power turbine equivalent disk meets the requirements, the structure was simplified, and the blade, mortise, and groove structures of the real wheel disk were removed. The rotor structure shown in Figure 1 was mainly composed of a power turbine shaft with a hollow structure, two-stage turbine disks, and four bearings. The Bearing 1 is a ball bearing, and the others are all roller bearings. Moreover, the Bearing 2 adopts an NCSFD structure, as shown in Figure 2.

2.2. Comparison Between Equivalent and Real Rotor

3. Dynamic Characteristic Analysis

3.1. Rotor Motion Equation

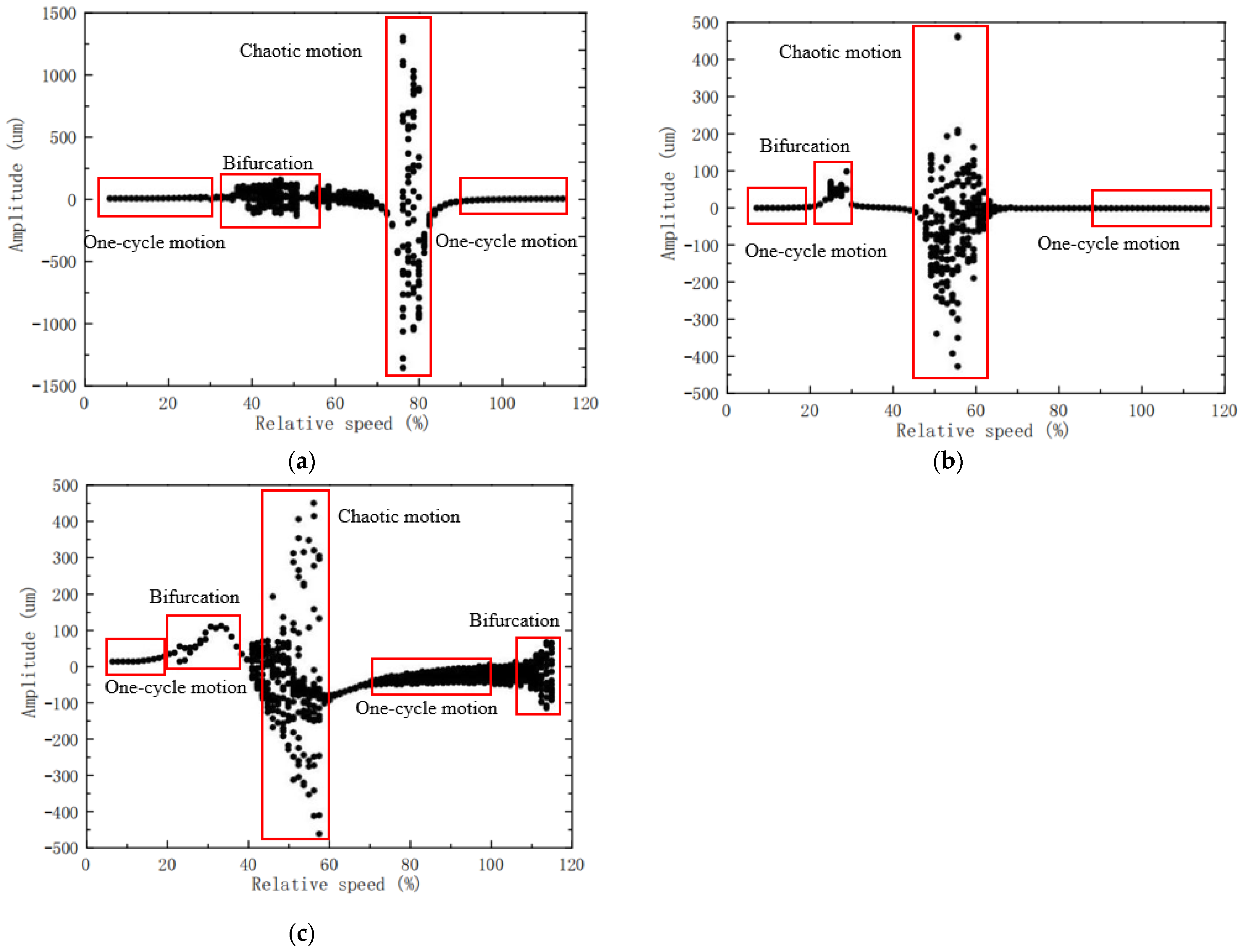

3.2. Nonlinear Analysis

3.3. Critical Speeds and Vibration Shapes

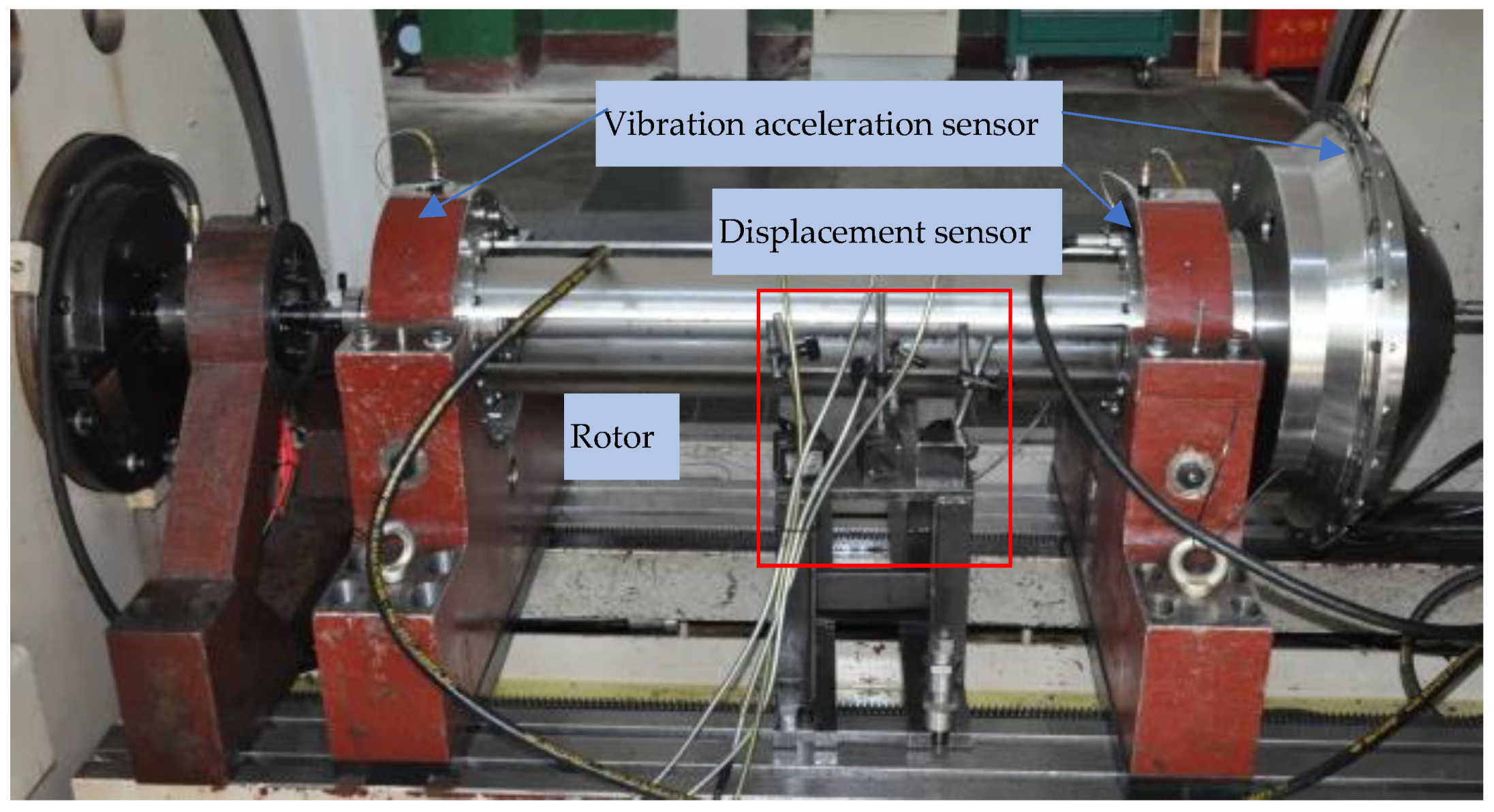

4. Experimental Research

4.1. Equipment and Test Rig

4.2. Experimental Results and Analysis

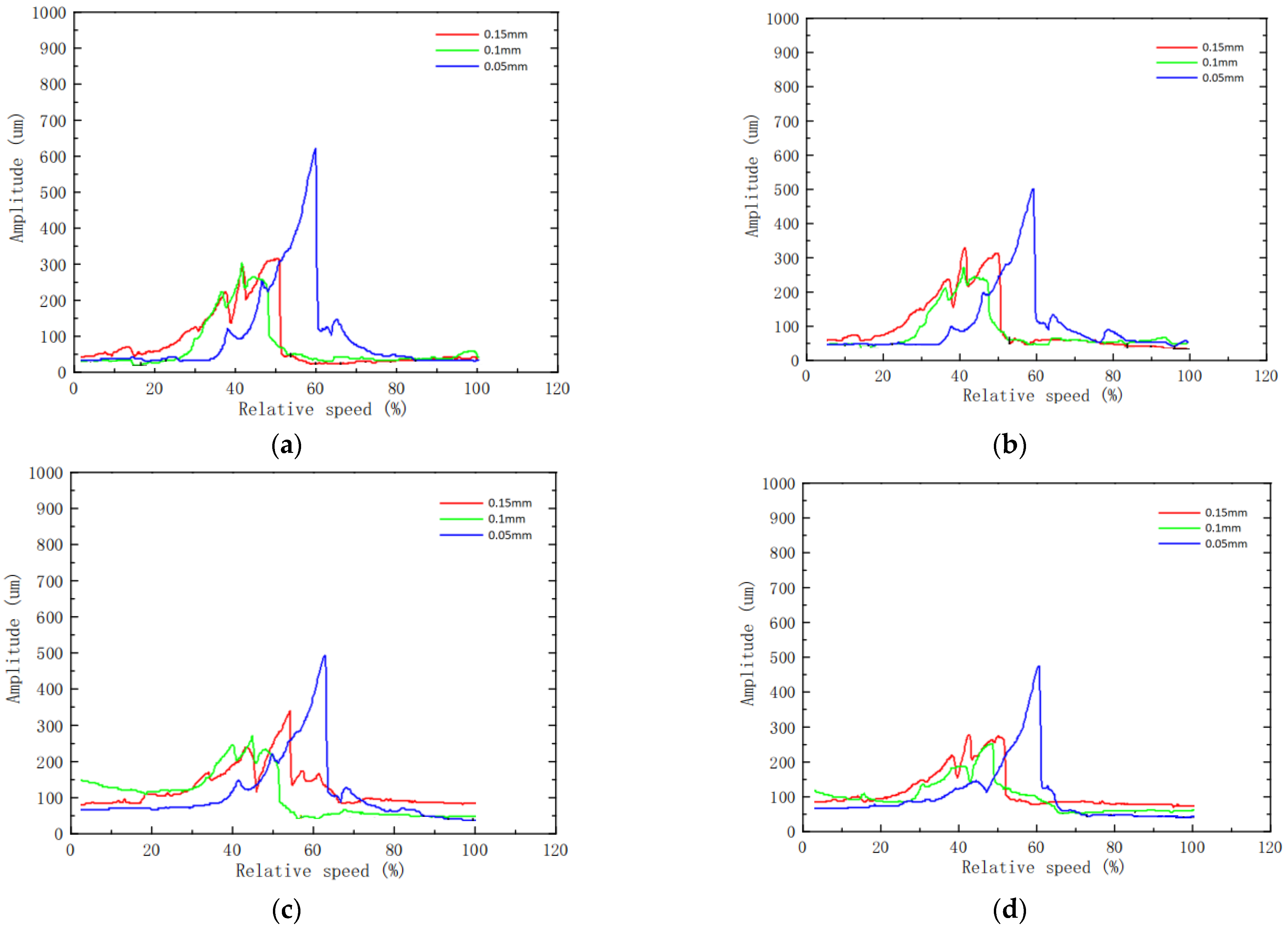

- (1)

- As the oil film clearance increases, the critical speed gets smaller, and the amplitude at the critical speed decreases, indicating that NCSFD has a good vibration reduction effect when the rotor reaches the critical speed. However, when the oil film clearance is greater than 0.10 mm, the reduction in amplitude tends to be less significant.

- (2)

- When the oil film clearance is 0.05 mm, the rotor response amplitude and corresponding critical speed are both large.

- (3)

- When the oil film clearance is 0.15 mm, the response amplitude of the rotor at high speed after crossing the critical point is larger.

- (4)

- When the oil film clearance is 0.10 mm, the response amplitude of the rotor is small at critical speed and supercritical speed, and the operating speed range is wider. Therefore, it is more reasonable to take 0.10 mm as the oil film clearance.

5. Wide Speed Domain Stability Test of the Rotor System

6. Conclusions

- (1)

- The equivalent rotor dynamic characteristics designed have good consistency with the actual rotor, verifying the practical efficacy of the proposed dynamic similarity design method.

- (2)

- The rotor system with NCSFD exhibits obvious nonlinear characteristics, with the rotor exhibiting “single period motion” at low speeds, then gradually entering “chaotic motion” through bifurcation, and finally returning to “single period motion.” Different oil film radial clearances can lead to differences in the specific speed range of bifurcation points, “single period motion,” and “chaotic motion” regions.

- (3)

- Theoretical analysis and experimental verification have shown that selecting 0.10 mm as the oil film clearance is optimal. To expand the rotor’s operating speed range, increasing the oil film clearance is feasible, although attention should be paid to the rotor’s response amplitude at high speeds.

- (4)

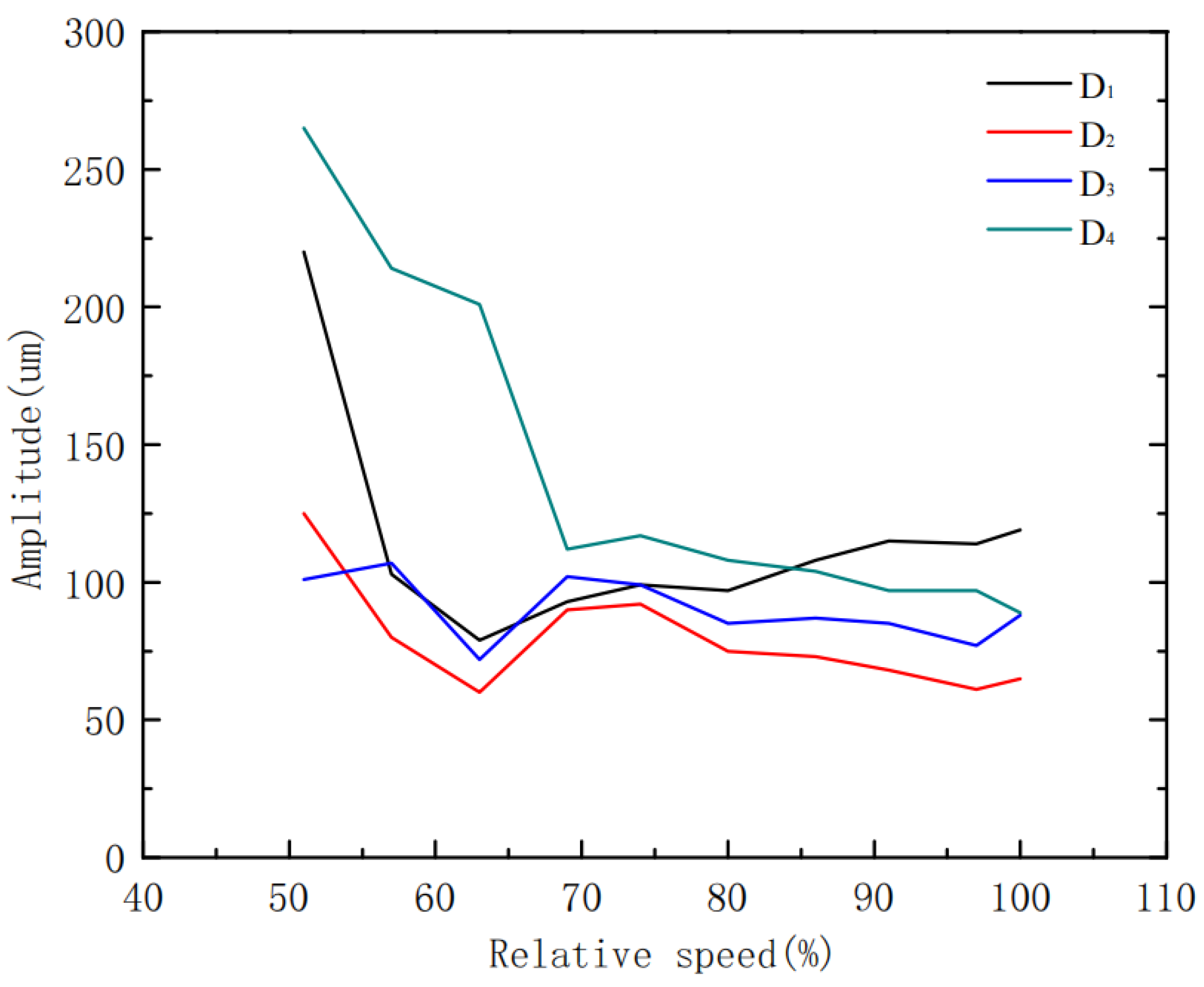

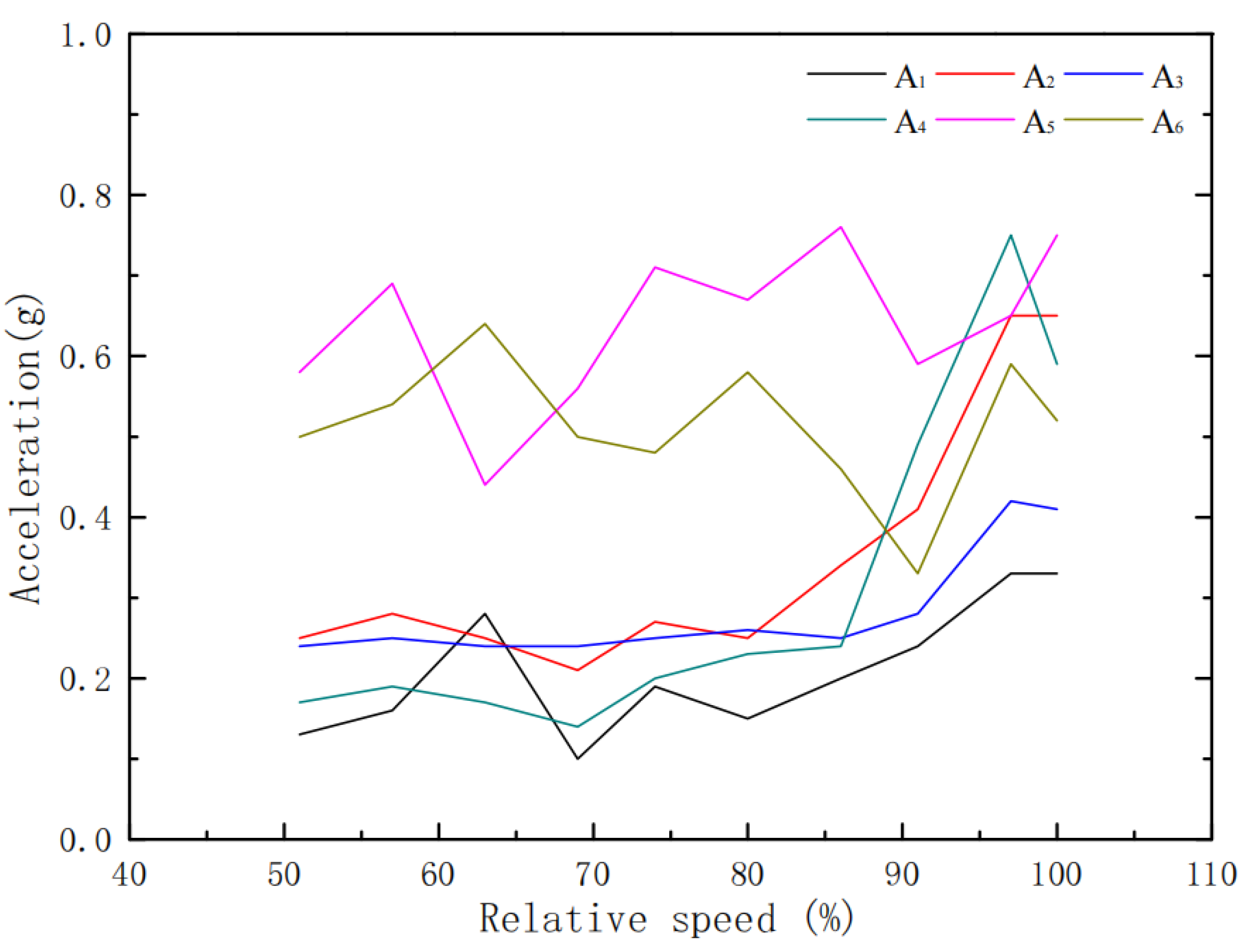

- The rotor system has a deflection variation of no more than 4 μm and a vibration acceleration variation of no more than 0.04 g within the rotating speed range of 0.51 n to 1.0 n. This indicates that it has a wide working speed range.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tai, X.Y.; Li, K.H. Rotor dynamics analysis of centrifugal compressor considering elastic foundation characteristics. CHN. J. Turbo. 2020, 62, 57–63. [Google Scholar]

- Jiang, L.J.; Yuan, J.B. Dynamic analysis of cantilever rotor considering impeller coupling. CHN. J. Turbo. 2020, 62, 16–21. [Google Scholar]

- Barra, F.; Capone, P.; Monstein, R. Implementation of a comprehensive mathematical model for tilt-rotor real time flight simulation. In Proceedings of the 45th European Rotorcraft Forum, Warsaw, Poland, 17–20 September 2019. [Google Scholar]

- Song, M.B.; Yan, P.; Wang, X.; Xiang, Y.Z.; Yang, Y.; Xie, R.H. Exploration of maximum unbalance of a turboshaft engine based on airworthiness requirements. J. Aerosp. Power 2023, 38, 1467–1473. [Google Scholar]

- Gerard, E.W. Overview of variable speed power turbine research. In Proceedings of the NASA Fundamental Aeronautics Conference, Cleveland, OH, USA, 15–17 March 2011. [Google Scholar]

- Hendricks, E.S.; Jones, S.M.; Gray, J.S. Design optimization of a variable speed power turbine. In Proceedings of the 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Cleveland, OH, USA, 28–30 July 2014. [Google Scholar]

- Zhang, G.H.; Huang, Y.Z.; Chen, Y.L.; Wang, Z.L.; Xu, K.F.; Feng, L. Experiment on vibration reduction performance of elastic ring squeeze film damper under sudden unbalance. J. Aerosp. Power 2023, 38, 32–40. [Google Scholar]

- Zhao, L.; Liao, M.F.; Wang, S.J.; Liu, Q.Y.; Hou, L.Z. Experimental study on vibration reducing effect of elastic ring squeeze film damper. J. Propuls. Technol. 2021, 42, 1129–1137. [Google Scholar]

- Zhang, L.H.; He, L.D.; Chen, Z.; Wan, F.T.; Ding, J.C. Structure design of an integral elastic ring squeeze film damper and experiments on the rotor passing through critical speed. J. Vib. Shock 2019, 38, 72–78, 108. [Google Scholar]

- Yang, X.M.; Jiang, B.Z.; Li, Y.; Zhao, Q.; Deng, S.E.; Zhang, W.H.; Cui, Y.C. Dynamic characteristics of elastic ring squeeze film damper coupled high-speed ball bearings. J. Sound Vib. 2022, 537, 117186. [Google Scholar] [CrossRef]

- Han, Z.F.; Ding, Q.; Wang, W. Dynamical analysis of an elastic ring squeeze film damper-rotor system. Mech. Mach. Theory 2019, 131, 406–419. [Google Scholar] [CrossRef]

- Gheller, E.; Chatterton, S.; Vania, A.; Pennacchi, P. Squeeze Film Damper Modeling: A Comprehensive Approach. Machines 2022, 10, 781. [Google Scholar] [CrossRef]

- Xu, Y.; Cao, H.R.; Shi, J.H.; Pei, S.Y.; Zhang, B.; She, K.L. A comprehensive multi-parameter optimization method of squeeze film damper-rotor system using hunter-prey optimization algorithm. Tribol. Int. 2024, 194, 109538. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, Y.; Luo, Z.; Han, Q. Analysis on influences of squeeze film damper on vibrations of rotor system in aeroengine. Appl. Sci. 2022, 12, 615. [Google Scholar] [CrossRef]

- Luo, Z.; Sun, K.; Ge, X.D.; Zhou, G.Z.; Cui, Z.W. Dynamic analysis of the rotor system with elastic ring squeeze film damper considering oil film temperature. Nonlinear Dyn. 2023, 111, 15981–16002. [Google Scholar] [CrossRef]

- Chen, X.; Ren, G.M.; Gan, X.H. Dynamic behavior of a flexible rotor system with squeeze film damper considering oil-film inertia under base motions. Nonlinear Dyn. 2021, 106, 3117–3145. [Google Scholar] [CrossRef]

- Gunter, E.J. Steady State and Transient Analysis of a Squeeze Film Damper Bearing for Rotor Stability; National Technical Information Service: Charlottesville, VA, USA, 1975. [Google Scholar]

- Holmes, R.; Dogan, M. Investigation of a rotor bearing assembly incorporating a squeeze-film damper bearing. J. Mech. Eng. Sci. 1982, 24, 129–137. [Google Scholar] [CrossRef]

- Roberts, J.B.; Ellis, J.; Carraseo, A. An experimental study of the nonlinear behavior of a squeeze film bearing. J. Trib. 1993, 115, 312–318. [Google Scholar] [CrossRef]

- Holmes, R.; Box, S. Study on the use of squeeze film dampers in rotor support structures. Mach. Vibr. 1992, 1, 71–79. [Google Scholar]

- Holmes, R.; Sykes, J.E.H. The vibration of an aero-engine rotor incorporating two squeeze-film dampers. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 1996, 210, 39–51. [Google Scholar] [CrossRef]

- Sykes, J.E.H.; Holmes, R. The effect of bearing misalignment on the nonlinear vibration of aero-engine rotor damper assembles. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 1990, 204, 83–99. [Google Scholar] [CrossRef]

- Bai, J.; Pan, B.; He, W.B. Sudden unbalance response analysis of cantilever rotor system with squeeze film damper. Sci. Technol. Eng. 2018, 18, 299–305. [Google Scholar]

- Xia, N.; Meng, G. Non-synchronous response and bifurcation character of two-disk rotor system with a non-centralized SFD. J. Northw. Polytechn. Univ. 2000, 18, 216–220. [Google Scholar]

- Cui, Y.; Wang, Q.Z.; Wang, Y.L.; Li, T. Numerical simulation on cavitation flow filed characteristics of nonconcentric squeeze film damper. J. Harb. Eng. Univ. 2020, 41, 978–984. [Google Scholar]

- Chen, S.Q.; Wang, G.Y.; Jia, Z.B.; Xu, J.K. Steady-state unbalance response of a rigid rotor in squeeze film damper bearings without centralizing springs. J. Northw. Polytech. Univ. 1985, 3, 117–128. [Google Scholar]

- Andres, L.S.; Seshagiri, S. Damping and inertia coefficients for two end sealed squeeze film dampers with a central groove: Measurements and predictions. J. Eng. Gas Turb. Power 2013, 135, 112503-1-9. [Google Scholar]

- Andres, L.S. Force coefficients for a large clearance open end squeeze film damper with a central feed groove: Experiments and predictions. Tribol. Int. 2014, 71, 17–25. [Google Scholar] [CrossRef]

- Jawaid, I.I. Bifurcations of a flexible rotor response in squeeze-film dampers without centering springs. Chaos Solitons Fractals 2004, 24, 583–596. [Google Scholar]

- Zhu, C.S.; Mao, C.; Li, P.F. Experimental comparison of vibration isolation ability of centralized and uncentralized squeeze film damper. J. Aerosp. Power 2017, 32, 2672–2679. [Google Scholar]

- Feng, Y.; Deng, W.Q.; Liu, W.K.; Yuan, S.; Hu, T.X. Comparative experimental investigation on vibration attenuating characteristics of concentric and non-concentric squeeze film damper. Mech. Sci. Technol. Aerosp. Eng. 2023, 42, 978–984. [Google Scholar]

- Chauhan, S.; Singh, M.; Aggarwal, A.K. Bearing defect identification via evolutionary algorithm with adaptive wavelet mutation strategy. Measurement 2021, 179, 109445. [Google Scholar] [CrossRef]

- Chauhan, S.; Singh, M.; Kumar Aggarwal, A. An effective health indicator for bearing using corrected conditional entropy through diversity-driven multi-parent evolutionary algorithm. Struct. Health Monit. 2021, 20, 2525–2539. [Google Scholar] [CrossRef]

- Chauhan, S.; Singh, M.; Aggarwal, A.K. Cluster head selection in heterogeneous wireless sensor network using a new evolutionary algorithm. Wirel. Pers. Commun. 2021, 119, 585–616. [Google Scholar] [CrossRef]

- Yang, X.G.; Luo, G.H.; Tang, Z.H.; Wang, F. Modeling method and dynamic characteristics of high-dimensional counter-rotating dual rotor system. J. Aerosp. Power 2014, 29, 585–595. [Google Scholar]

- Chiang, H.W.D.; Hsu, C.N.; Tu, S.H. Rotor-bearing analysis for turbo machinery single and dual-rotor systems. J. Propuls. Power 2004, 20, 1096–1104. [Google Scholar] [CrossRef]

- Fu, C.G.; Zheng, T.P.; Ou, Y.X. Rotor Dynamics and Whole Engine Vibration (No.19 Volume of Aeroengine Design Manual), 3rd ed.; Aviation Industry Press: Beijing, China, 2000. [Google Scholar]

| Structural Parameters | Value |

|---|---|

| Length | 1400 mm |

| Shaft diameter | 50 mm |

| Mass | 35 kg |

| Disks | Mass (kg) | Axial Position of Mass Center (mm) | Radius of Gyration (mm) |

|---|---|---|---|

| Equivalent disks | 29.554 | −69.392 | 128.84 |

| True disks | 29.995 | −67.128 | 128.89 |

| Error rate (%) | 1.49 | 3.37 | 0.03 |

| Bearing Number | Support Stiffness (107 N∙m−1) |

|---|---|

| Bearing1 | 5.00 |

| Bearing2 | 1.50 |

| Bearing3 | 3.50 |

| Bearing4 | 0.01 |

| Critical Speed Order | Value of True Rotor | Value of Equivalent Rotor | Error (%) |

|---|---|---|---|

| First | 0.278 n | 0.264 n | 2.50 |

| Second | 0.515 n | 0.517 n | 0.30 |

| Third | 1.465 n | 1.488 n | 3.98 |

| Mode Shapes Order | True Rotor | Equivalent Rotor |

|---|---|---|

| First |  |  |

| Second |  |  |

| Third |  |  |

| Oil Film Radial Clearance Value (mm) | Support Stiffness (107 N∙m−1) | |||

|---|---|---|---|---|

| Bearing 1 | Bearing 2 | Bearing 3 | Bearing 4 | |

| 0.05 | 5.00 | 2.59 | 3.50 | 0.01 |

| 0.10 | 5.00 | 0.32 | 3.50 | 0.01 |

| 0.15 | 5.00 | 0.10 | 3.50 | 0.01 |

| Oil Film Radial Clearance Value (mm) | First Three Orders Critical Speed And Margins (%) | ||

|---|---|---|---|

| First | Second | Third | |

| 0.05 | 0.283 n, 44.54 | 0.609 n, 5.80 | 1.859 n, 85.93 |

| 0.10 | 0.239 n, 22.06 | 0.443 n, 31.47 | 1.340 n, 33.95 |

| 0.15 | 0.220 n, 12.01 | 0.422 n, 34.73 | 1.305 n, 30.50 |

| Oil Film Radial Clearance Value (mm) | First Three Orders Mode Shapes | ||

|---|---|---|---|

| First | Second | Third | |

| 0.05 |  |  |  |

| 0.10 |  |  |  |

| 0.15 |  |  |  |

| Parameters | Sensors | Unit |

|---|---|---|

| Amplitude | Displacement sensor (D1–D4) | μm |

| Vibration acceleration | Vibration acceleration sensor (A1–A6) | g |

| Oil film Radial Clearance Value (mm) | Experimental Value | Calculated Value | Error (%) |

|---|---|---|---|

| 0.05 | 0.630 n | 0.609 n | 3.21 |

| 0.10 | 0.475 n | 0.443 n | 7.04 |

| 0.15 | 0.457 n | 0.422 n | 7.62 |

| Speeds | 0.51 n | 0.57 n | 0.63 n | 0.69 n | 0.74 n | 0.80 n | 0.86 n | 0.91 n | 0.97 n | 1.0 n | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Variation value (μm) | D1 | 220~224 | 103~105 | 79~81 | 93~96 | 99~102 | 97~99 | 108~110 | 115~117 | 114~116 | 119~121 |

| D2 | 125~126 | 80~82 | 60~62 | 90~92 | 92~94 | 75~77 | 73~75 | 68~69 | 61~63 | 65~67 | |

| D3 | 101~103 | 107~109 | 72~74 | 102~105 | 99~102 | 85~87 | 87~89 | 85~87 | 77~80 | 88~90 | |

| D4 | 265~268 | 214~217 | 201~203 | 112~114 | 117~120 | 108~110 | 104~106 | 97~100 | 97~99 | 89~93 | |

| Speeds | 0.51 n | 0.57 n | 0.63 n | 0.69 n | 0.74 n | 0.80 n | 0.86 n | 0.91 n | 0.97 n | 1.0 n | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Variation value (g) | A1 | 0.13~0.16 | 0.16~0.18 | 0.28~0.30 | 0.10~0.13 | 0.19~0.22 | 0.15~0.18 | 0.20~0.23 | 0.24~0.26 | 0.33~0.35 | 0.33~0.35 |

| A2 | 0.25~0.28 | 0.28~0.30 | 0.25~0.28 | 0.21~0.24 | 0.27~0.30 | 0.25~0.28 | 0.34~0.38 | 0.41~0.44 | 0.65~0.68 | 0.65~0.68 | |

| A3 | 0.24~0.26 | 0.25~0.28 | 0.24~0.28 | 0.24~0.27 | 0.25~0.27 | 0.26~0.28 | 0.25~0.28 | 0.28~0.30 | 0.42~0.45 | 0.41~0.44 | |

| A4 | 0.17~0.19 | 0.19~0.22 | 0.17~0.20 | 0.14~0.17 | 0.20~0.24 | 0.23~0.26 | 0.24~0.26 | 0.49~0.51 | 0.75~0.78 | 0.59~0.61 | |

| A5 | 0.58~0.62 | 0.69~0.72 | 0.44~0.47 | 0.56~0.60 | 0.71~0.74 | 0.67~0.71 | 0.76~0.80 | 0.59~0.62 | 0.65~0.68 | 0.75~0.77 | |

| A6 | 0.50~0.53 | 0.54~0.57 | 0.64~0.66 | 0.50~0.54 | 0.48~0.51 | 0.58~0.60 | 0.46~0.49 | 0.33~0.35 | 0.59~0.62 | 0.52~0.56 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nie, W.; Yang, X.; Tang, G.; Zhang, Q.; Wang, G. Effect of Oil Film Radial Clearances on Dynamic Characteristics of Variable Speed Rotor with Non-Concentric SFD. Machines 2024, 12, 882. https://doi.org/10.3390/machines12120882

Nie W, Yang X, Tang G, Zhang Q, Wang G. Effect of Oil Film Radial Clearances on Dynamic Characteristics of Variable Speed Rotor with Non-Concentric SFD. Machines. 2024; 12(12):882. https://doi.org/10.3390/machines12120882

Chicago/Turabian StyleNie, Weijian, Xiaoguang Yang, Guang Tang, Qicheng Zhang, and Ge Wang. 2024. "Effect of Oil Film Radial Clearances on Dynamic Characteristics of Variable Speed Rotor with Non-Concentric SFD" Machines 12, no. 12: 882. https://doi.org/10.3390/machines12120882

APA StyleNie, W., Yang, X., Tang, G., Zhang, Q., & Wang, G. (2024). Effect of Oil Film Radial Clearances on Dynamic Characteristics of Variable Speed Rotor with Non-Concentric SFD. Machines, 12(12), 882. https://doi.org/10.3390/machines12120882