Aero-Engine Fault Detection with an LSTM Auto-Encoder Combined with a Self-Attention Mechanism

Abstract

:1. Introduction

2. Self-Attention-Based LSTM Auto-Encoder Fault Detection Modeling

2.1. Auto-Encoder

2.2. LSTM Network

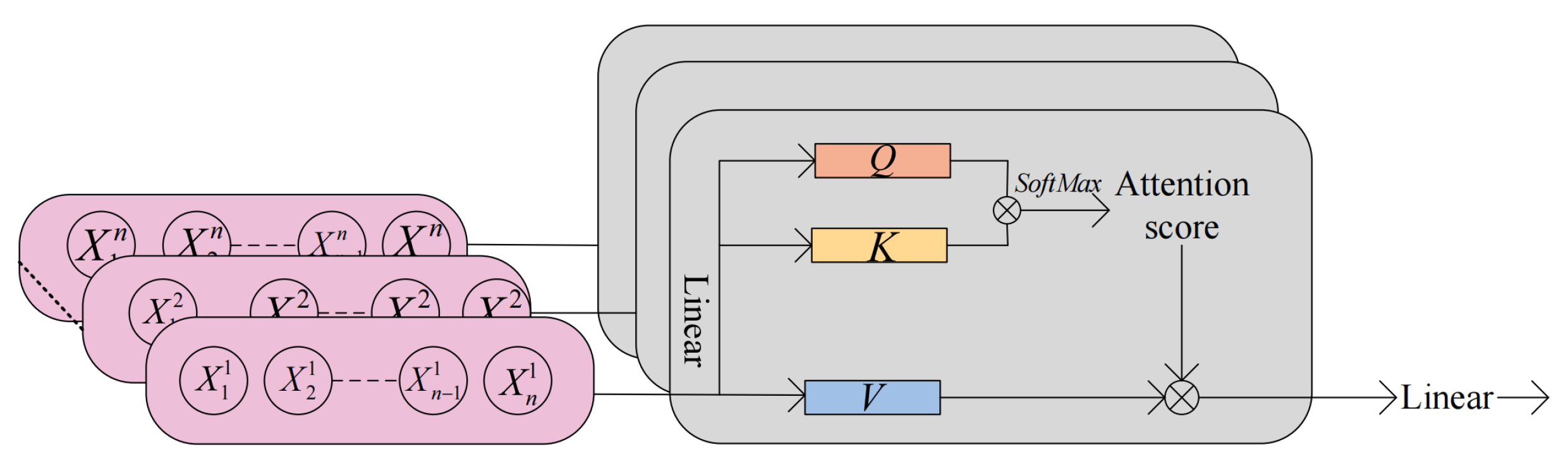

2.3. Self-Attention Mechanisms

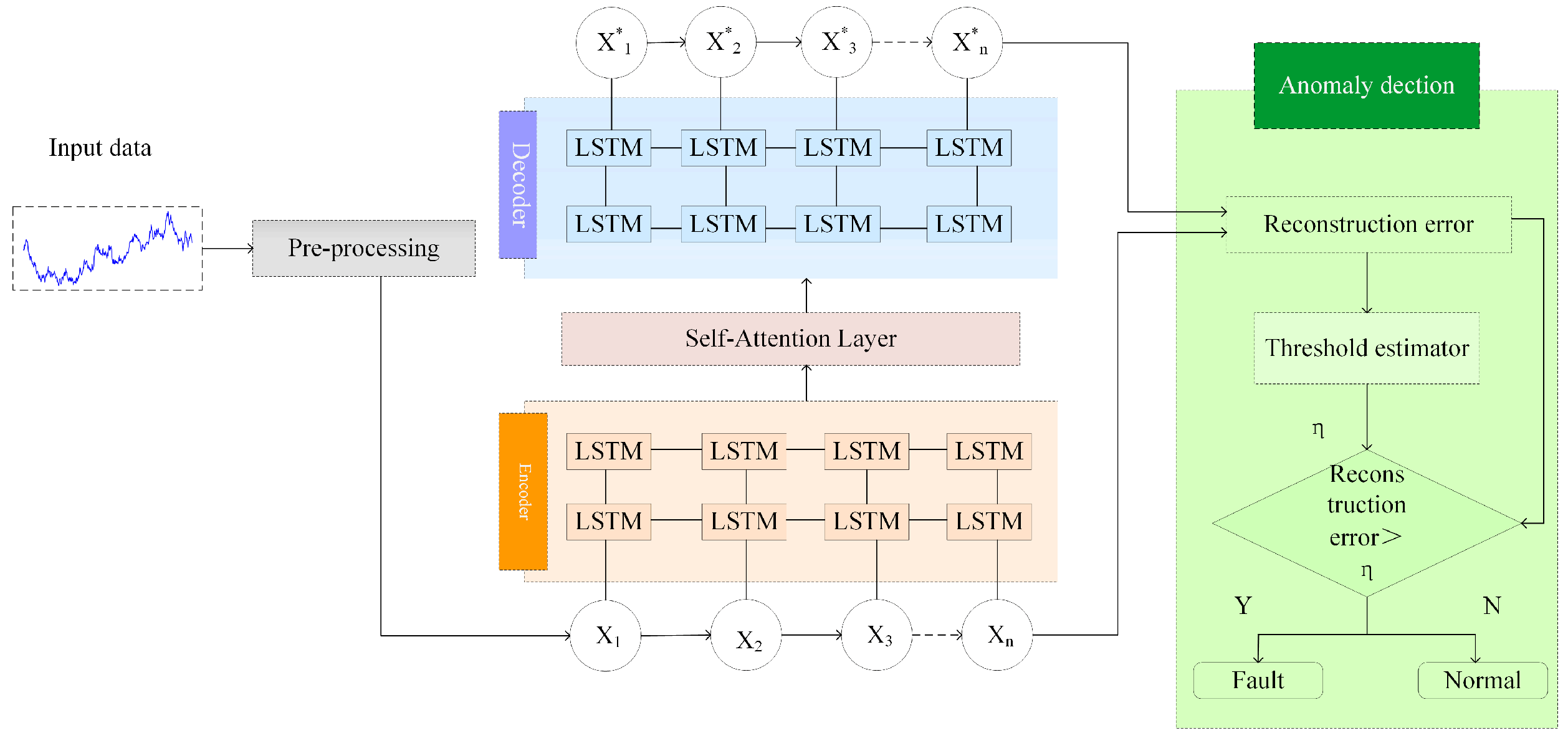

2.4. Fault Detection Model

3. Aero-Engine Fault Detection

3.1. Introduction to the Dataset

3.2. Fault Data Analysis

3.3. Experimental Indicators

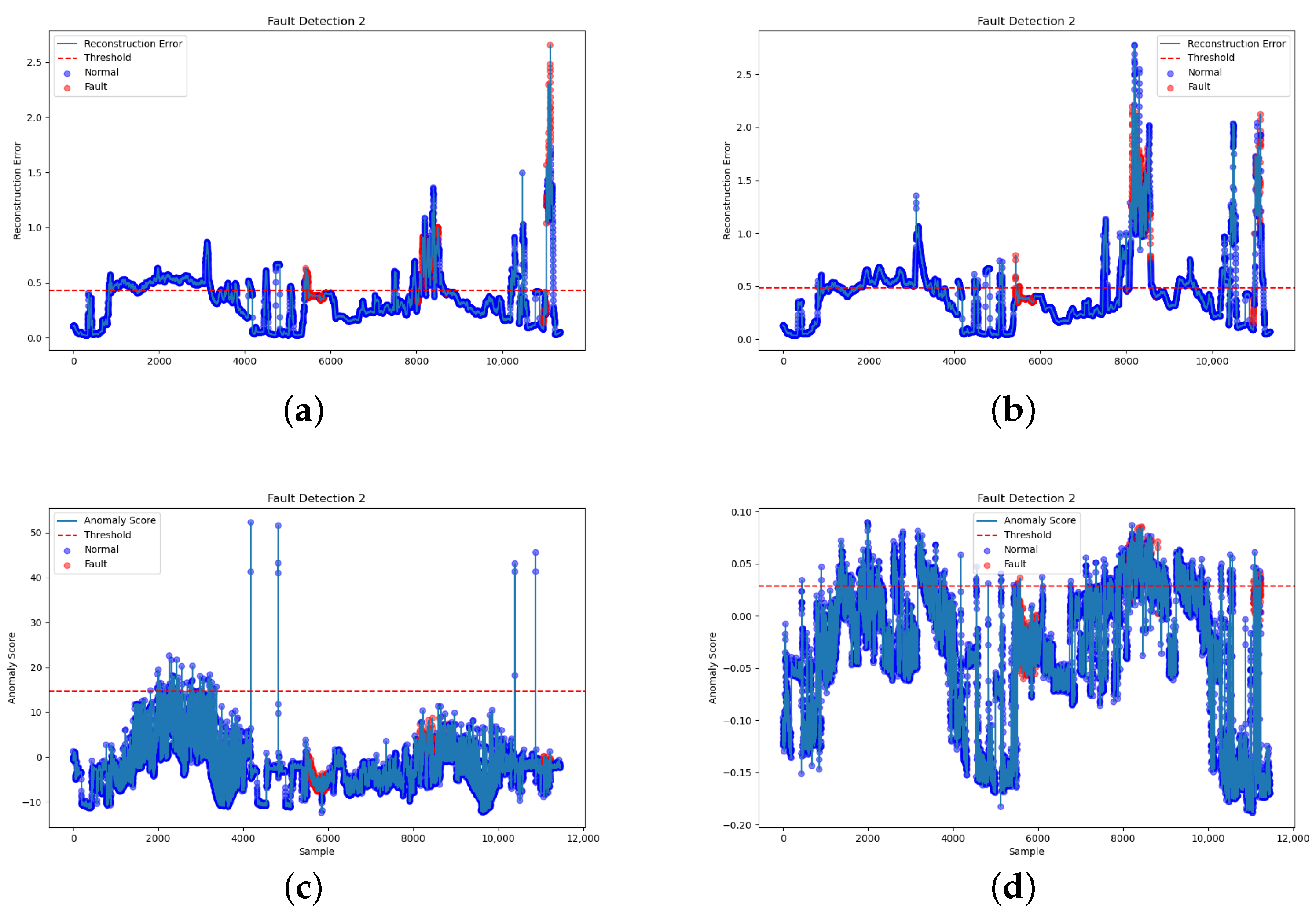

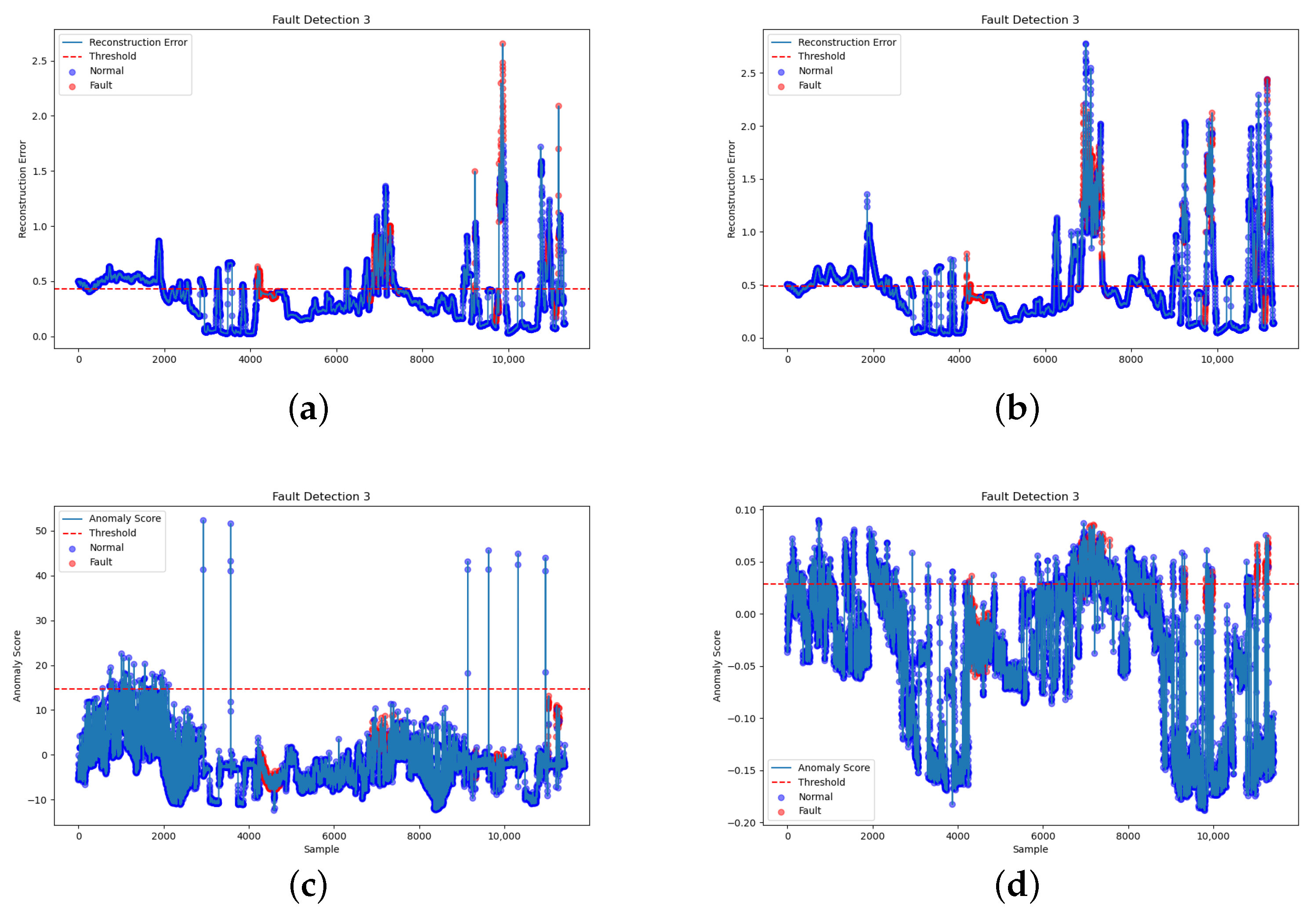

3.4. Analysis of Experimental Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Auto-encoder | |

| Recurrent neural network | |

| Long short-term memory | |

| b | Bias term |

| W | Weight |

| h | Encoder output |

| Forget gate | |

| output gate | |

| Input gate | |

| Crankshaft revolution speed | |

| Power target value | |

| Input gate | |

| Manifold intake air pressure | |

| Atmospheric pressure | |

| Direct current power supply voltage | |

| Measured power | |

| Target intake air pressure | |

| Target fuel pressure | |

| Exhaust valve opening position | |

| Engine control unit |

References

- Xu, J.; Wang, Y.; Wang, Z.; Wang, X.; Zhao, Y. Transient gas path fault diagnosis of aero-engine based on domain adaptive offline reinforcement learning. Aerosp. Sci. Technol. 2024, 155, 109701. [Google Scholar] [CrossRef]

- Huang, Y.; Tao, J.; Zhao, J.; Sun, G.; Yin, K.; Zhai, J. Graph structure embedded with physical constraints-based information fusion network for interpretable fault diagnosis of aero-engine. Energy 2023, 283, 129120. [Google Scholar] [CrossRef]

- Liao, Z.; Zhan, K.; Zhao, H.; Deng, Y.; Geng, J.; Chen, X.; Song, Z. Addressing class-imbalanced learning in real-time aero-engine gas-path fault diagnosis via feature filtering and mapping. Reliab. Eng. Syst. Saf. 2024, 249, 110189. [Google Scholar] [CrossRef]

- Chen, J.; Yan, Z.; Lin, C.; Yao, B.; Ge, H. Aero-engine high speed bearing fault diagnosis for data imbalance: A sample enhanced diagnostic method based on pre-training WGAN-GP. Measurement 2023, 213, 112709. [Google Scholar] [CrossRef]

- Li, B.; Xue, S.K.; Fu, Y.H.; Tang, Y.D.; Zhao, Y.P. Kernel adapted extreme learning machine for cross-domain fault diagnosis of aero-engines. Aerosp. Sci. Technol. 2024, 146, 108970. [Google Scholar] [CrossRef]

- Chi, J.; Liu, Y.; Luo, D.; Cao, L. Fault Diagnosis of Aero-engine Gas Path Base on PSO-SVM. In Proceedings of the 2019 CAA Symposium on Fault Detection, Supervision and Safety for Technical Processes (SAFEPROCESS), Xiamen, China, 5–7 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 82–86. [Google Scholar]

- Liao, Z.; Zhang, R.; Zhao, H.; Gao, F.; Geng, J.; Chen, X.; Song, Z. Towards domain shifts: Stream fine-tuning via feed-forward fault data generation for on-board aero-engine gas-path diagnosis. Measurement 2024, 237, 115207. [Google Scholar] [CrossRef]

- Lu, Z.; Li, B.; Fu, C.; Wu, J.; Xu, L.; Jia, S.; Zhang, H. Remaining Useful Life Prediction Method Based on Dual-Path Interaction Network with Multiscale Feature Fusion and Dynamic Weight Adaptation. Actuators 2024, 13, 413. [Google Scholar] [CrossRef]

- Yang, T.; Han, S.; Han, Q.; Zhu, Q.; Yu, X. A Fault Diagnosis Study of Aero-engine Hydraulic Piping Clamp Based on Deep Learning. In Proceedings of the 2021 Global Reliability and Prognostics and Health Management (PHM-Nanjing), Nanjing, China, 15–17 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–5. [Google Scholar]

- Yang, T.; Li, G.; Yuan, S.; Qi, Y.; Yu, X.; Han, Q. The LST-SATM-net: A new deep feature learning framework for aero-engine hydraulic pipeline systems intelligent faults diagnosis. Appl. Acoust. 2023, 210, 109436. [Google Scholar] [CrossRef]

- Nie, L.; Xu, S.; Zhang, L.; Yin, Y.; Dong, Z.; Zhou, X. Remaining Useful Life Prediction of Aeroengines Based on Multi-Head Attention Mechanism. Machines 2022, 10, 552. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhou, R.; Dong, Z. Aero-engine faults diagnosis based on K-means improved Wasserstein GAN and relevant vector machine. In Proceedings of the 2019 Chinese Control Conference (CCC), Guangzhou, China, 27–30 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 4795–4800. [Google Scholar]

- Liu, F.Z.; Shi, Y.; Sun, C.Y.; Sun, X.M. Improved real-time H∞ control for aero-engines based on the equilibrium manifold expansion model. J. Frankl. Inst. 2024, 361, 107342. [Google Scholar] [CrossRef]

- Gan, C.; Ding, S.; Qiu, T.; Liu, P.; Ma, Q. Model-based safety analysis with time resolution (MBSA-TR) method for complex aerothermal–mechanical systems of aero-engines. Reliab. Eng. Syst. Saf. 2024, 243, 109864. [Google Scholar] [CrossRef]

- Wang, B.; Xuan, Y. Heuristic deepening of aero engine performance analysis model based on thermodynamic principle of variable mass system. Energy 2024, 306, 132481. [Google Scholar] [CrossRef]

- Xiang, F.; Zhang, Y.; Zhang, S.; Wang, Z.; Qiu, L.; Choi, J.H. Bayesian gated-transformer model for risk-aware prediction of aero-engine remaining useful life. Expert Syst. Appl. 2024, 238, 121859. [Google Scholar] [CrossRef]

- Sun, A.; Guo, D.; Wang, R. A data-based expert system for aero-engine gas path fault diagnosis. In Proceedings of the 2021 33rd Chinese Control and Decision Conference (CCDC), Kunming, China, 22–24 May 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 2917–2922. [Google Scholar]

- Chen, M.; Qu, R.; Fang, W. Case-based reasoning system for fault diagnosis of aero-engines. Expert Syst. Appl. 2022, 202, 117350. [Google Scholar] [CrossRef]

- Ma, S.; Yu, X.M.; Sun, T.; Zhao, G.; Guo, M. Research on Data-Driven Fault Diagnosis of Aero-Engine Transmission Systems. In Proceedings of the 2023 42nd Chinese Control Conference (CCC), Tianjin, China, 24–26 July 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 4922–4927. [Google Scholar]

- Wang, Y.Q.; Zhao, Y.P. A novel inter-domain attention-based adversarial network for aero-engine partial unsupervised cross-domain fault diagnosis. Eng. Appl. Artif. Intell. 2023, 123, 106486. [Google Scholar] [CrossRef]

- Liu, K.; Wang, P.; Li, Q. The research of aero-engine digital twin model based on model-driven and data-driven fusion method. In Proceedings of the 2021 IEEE 10th Data Driven Control and Learning Systems Conference (DDCLS), Suzhou, China, 14–16 May 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 322–327. [Google Scholar]

- Kiakojouri, A.; Lu, Z.; Mirring, P.; Powrie, H.; Wang, L. A Generalised Intelligent Bearing Fault Diagnosis Model Based on a Two-Stage Approach. Machines 2024, 12, 77. [Google Scholar] [CrossRef]

- Huang, Y.; Tao, J.; Sun, G.; Wu, T.; Yu, L.; Zhao, X. A novel digital twin approach based on deep multimodal information fusion for aero-engine fault diagnosis. Energy 2023, 270, 126894. [Google Scholar] [CrossRef]

- Song, Y.; Gou, L.; Zhang, M.; Huang, Y.; Chen, Y. Data-Driven Equivalent Space Aero-Engine Sensor Robust Fault Diagnosis. In Proceedings of the 2023 14th International Conference on Mechanical and Aerospace Engineering (ICMAE), Porto, Portugal, 18–21 July 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 237–242. [Google Scholar]

- Chen, Y.; Wang, X.; Wang, Y.; Gao, Y.; Qu, J.; Dai, H.; Xu, C. Multi-combination fault data augmentation method of aero-engine gas path based on Extraction TimeGAN. Measurement 2025, 242, 115778. [Google Scholar] [CrossRef]

- Wang, C.; Peng, Z.; Liu, R. Prediction of Aero-Engine Remaining Useful Life Combined with Fault Information. Machines 2022, 10, 927. [Google Scholar] [CrossRef]

- Hu, J.; Li, W.; Zhang, Y.; Tian, Z. Cross-domain few-shot fault diagnosis based on meta-learning and domain adversarial graph convolutional network. Eng. Appl. Artif. Intell. 2024, 136, 108970. [Google Scholar] [CrossRef]

- Liu, D.; Zhong, S.; Lin, L.; Zhao, M.; Fu, X.; Liu, X. HOOST: A novel hyperplane-oriented over-sampling technique for imbalanced fault detection of aero-engines. Knowl.-Based Syst. 2024, 300, 112142. [Google Scholar] [CrossRef]

- Kang, Y.; Chen, G.; Wang, H.; Sheng, J.; Wei, X. Fault anomaly detection method of aero-engine rolling bearing based on distillation learning. ISA Trans. 2024, 145, 387–398. [Google Scholar] [CrossRef] [PubMed]

- Lin, X.; Li, B.; Yang, X.; Wang, J. Fault diagnosis of aero-engine bearing using a stacked auto-encoder network. In Proceedings of the 2018 IEEE 4th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 14–16 December 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 545–548. [Google Scholar]

- Shi, H.; Cao, S.; Zuo, H.; Ma, J.; Lin, C. Deep subdomain adversarial network with self-supervised learning for aero-engine high speed bearing fault diagnosis with unknown working conditions. Measurement 2025, 241, 115668. [Google Scholar] [CrossRef]

- Pengyu, L.; Wenkui, H.; Kun, Y.; Qiuying, Y.; Yong, Y. Fault diagnosis based on multi-sensor information fusion using LSTM and DS evidence theory. In Proceedings of the 2020 7th International Conference on Information Science and Control Engineering (ICISCE), Changsha, China, 18–20 December 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 617–621. [Google Scholar]

- Guo, P.; Wei, C.; Yin, Z. Anomaly detection of spacecraft reconstructed signals based on attention mechanism. In Proceedings of the 2023 6th International Symposium on Autonomous Systems (ISAS), Nanjing, China, 23–25 June 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–5. [Google Scholar]

- Zhao, Y.; Suo, C.; Wang, Y. Remaining Useful Life Estimation Using a Variational Autoencoder-Regression Framework. In Proceedings of the 2023 IEEE 6th International Conference on Pattern Recognition and Artificial Intelligence (PRAI), Haikou, China, 18–20 August 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1267–1272. [Google Scholar]

- Zhai, J.; Zhang, S.; Chen, J.; He, Q. Autoencoder and its various variants. In Proceedings of the 2018 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Miyazaki, Japan, 7–10 October 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 415–419. [Google Scholar]

- Tan, Z.; Pan, P. Network fault prediction based on CNN-LSTM hybrid neural network. In Proceedings of the 2019 International Conference on Communications, Information System and Computer Engineering (CISCE), Haikou, China, 5–7 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 486–490. [Google Scholar]

- Xu, C.; Wang, Z. Fault Detection for Satellite Gyroscope Using LSTM Networks. In Proceedings of the 2023 IEEE 12th Data Driven Control and Learning Systems Conference (DDCLS), Xiangtan, China, 12–14 May 2023; pp. 633–638. [Google Scholar]

- Mnih, V.; Heess, N.; Graves, A.; Kavukcuoglu, K. Recurrent models of visual attention. In Proceedings of the 27th International Conference on Neural Information Processing Systems, NIPS’14—Volume 2, Cambridge, MA, USA, 8–13 December 2014; pp. 2204–2212. [Google Scholar]

- Shi, X.; Lu, R. Attention-based bidirectional hierarchical LSTM networks for text semantic classification. In Proceedings of the 2019 10th International Conference on Information Technology in Medicine and Education (ITME), Qingdao, China, 23–25 August 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 618–622. [Google Scholar]

- Yang, Q.; Li, H.; Hua, C.; Wu, D. Fault Diagnosis of Multimodal Chemical Process Based on Attention Mechanism and Deep Subdomain Countermeasure Adaptive Network. In Proceedings of the 2022 2nd International Conference on Algorithms, High Performance Computing and Artificial Intelligence (AHPCAI), Guangzhou, China, 21–23 October 2022; pp. 686–690. [Google Scholar]

| Serial Number | Parameterisation | Abridge |

|---|---|---|

| 1 | Crankshaft Revolution Speed | CREV |

| 2 | Power Target Value | TP |

| 3 | Manifold Intake Air Pressure | MIAP |

| 4 | Measured Fuel Pressure | MFP |

| 5 | Atmospheric Pressure | AP |

| 6 | Direct Current Power Supply Voltage | DCPSV |

| 7 | Measured Power | MP |

| 8 | Target Intake Air Pressure | TIAP |

| 9 | Target Fuel Pressure | TFP |

| 10 | Exhaust Valve Opening Position | EVOP |

| Time Step | AE-LSTM (s) | SLAE (s) |

|---|---|---|

| 10 | 300 | 443 |

| 20 | 408 | 686 |

| 30 | 512 | 911 |

| 40 | 608 | 1178 |

| 50 | 705 | 1502 |

| 60 | 793 | 1768 |

| 70 | 873 | 2082 |

| 80 | 980 | 2372 |

| 90 | 1079 | 2833 |

| 100 | 1175 | 3262 |

| Fault Number | SLAE | AE-LSTM | OC-SVM | IF | ||||

|---|---|---|---|---|---|---|---|---|

| FPR | FNR | FPR | FNR | FPR | FNR | FPR | FNR | |

| 1 | 0.0732 | 0.5974 | 0.2463 | 0.8033 | 0.0003 | 1 | 0.0725 | 0.9781 |

| 2 | 0.3244 | 0.5691 | 0.3462 | 0.6289 | 0.0062 | 1 | 0.1320 | 0.6600 |

| 3 | 0.3188 | 0.5339 | 0.3749 | 0.5818 | 0.0067 | 1 | 0.1336 | 0.6073 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, W.; Zhang, J.; Meng, G.; Zhang, H. Aero-Engine Fault Detection with an LSTM Auto-Encoder Combined with a Self-Attention Mechanism. Machines 2024, 12, 879. https://doi.org/10.3390/machines12120879

Du W, Zhang J, Meng G, Zhang H. Aero-Engine Fault Detection with an LSTM Auto-Encoder Combined with a Self-Attention Mechanism. Machines. 2024; 12(12):879. https://doi.org/10.3390/machines12120879

Chicago/Turabian StyleDu, Wenyou, Jingyi Zhang, Guanglei Meng, and Haoran Zhang. 2024. "Aero-Engine Fault Detection with an LSTM Auto-Encoder Combined with a Self-Attention Mechanism" Machines 12, no. 12: 879. https://doi.org/10.3390/machines12120879

APA StyleDu, W., Zhang, J., Meng, G., & Zhang, H. (2024). Aero-Engine Fault Detection with an LSTM Auto-Encoder Combined with a Self-Attention Mechanism. Machines, 12(12), 879. https://doi.org/10.3390/machines12120879