Analysis of Influential Parameters in the Dynamic Loading and Stability of the Swing Drive in Hydraulic Excavators

Abstract

1. Introduction

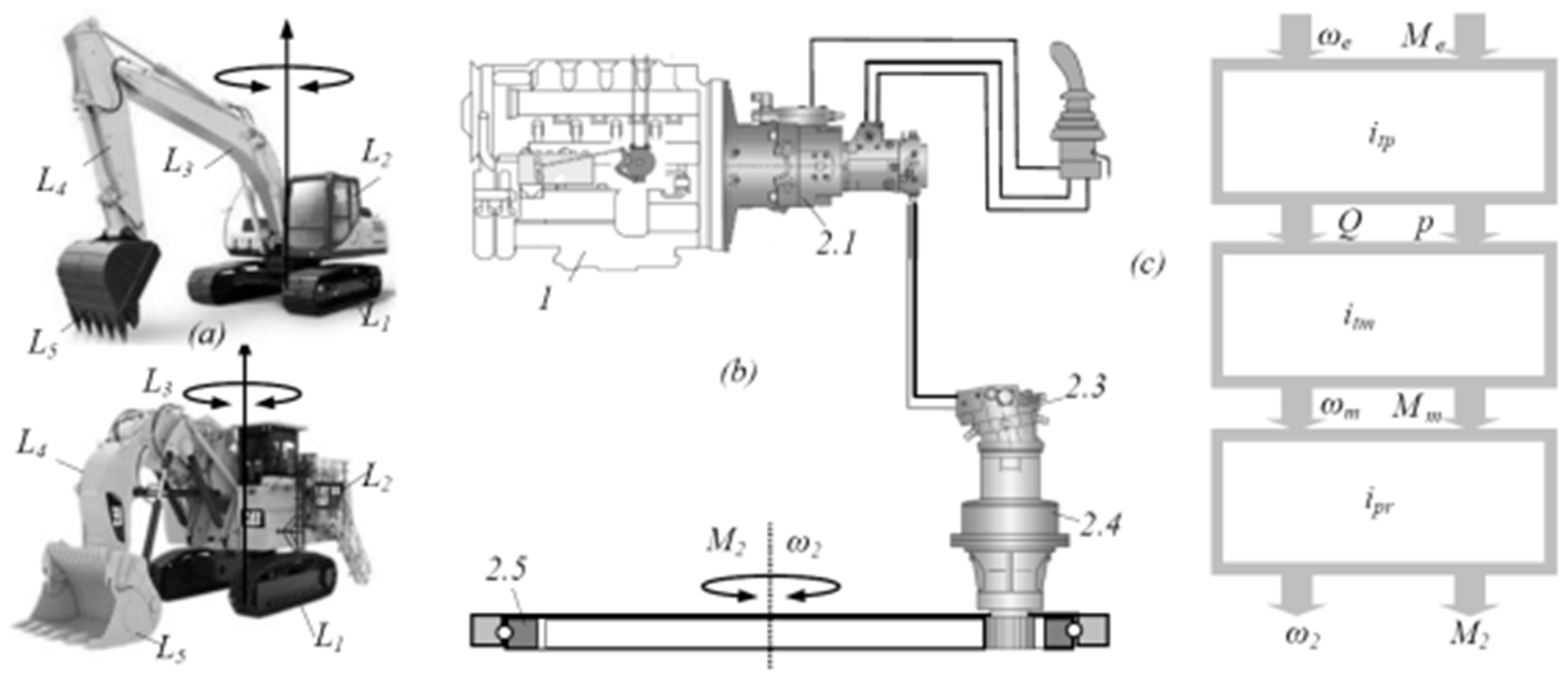

2. Swing Drive Parameters

- For the number of rotary upper structure revolutions:

- For the rotary upper structure drive moment:where: qpmax, qmmax—the maximum specific flow of the hydraulic pump and the hydraulic motor, p, po—the pressure in the extension and retraction duct of the hydraulic motor, np—the number of the hydraulic pump revolutions, ir, ηr—the transmission ratio and the degree of efficiency of the reducer, ηpv, ηpm, ηmv, ηmm—the volumetric and mechanical degrees of efficiency of the hydraulic pump and the hydraulic motor, εp = qp/qpmax—the hydraulic pump regulation range, εm = qm/qmmax—the hydraulic motor regulation range, and ηl—the degree of efficiency between the reducer and the axial bearing. The above transmission functions show that the same output parameters of the swing drive, the number of revolutions n2, and moment M2 can be achieved with a lower specific flow of the hydraulic motor qm and a higher transmission ratio ir of the reducer (and vice versa) for the selected axial bearing and given pressure p, specific flow qp, and number of revolutions np of the hydraulic pump.

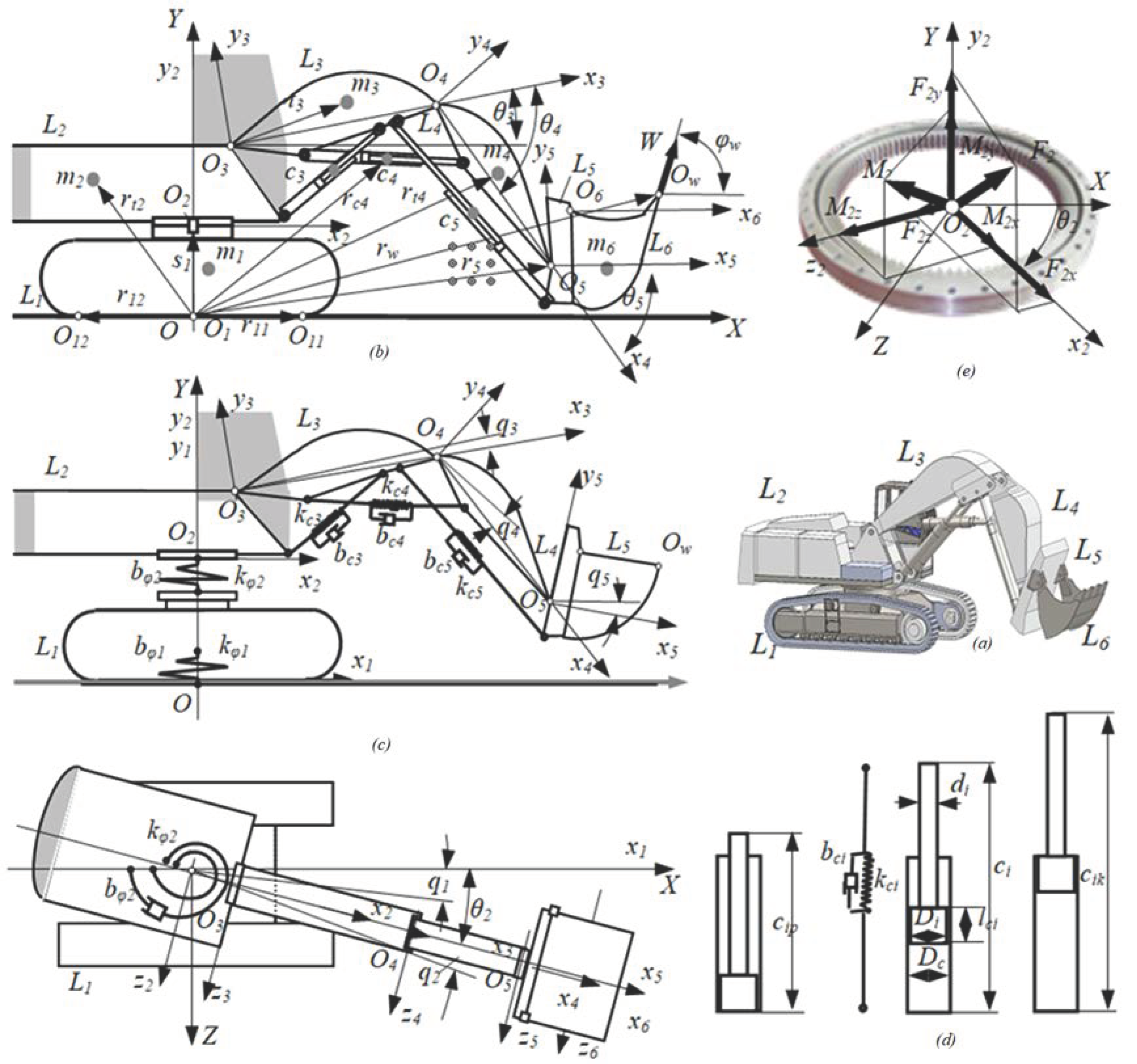

Dynamic Mathematical Models of the Excavator

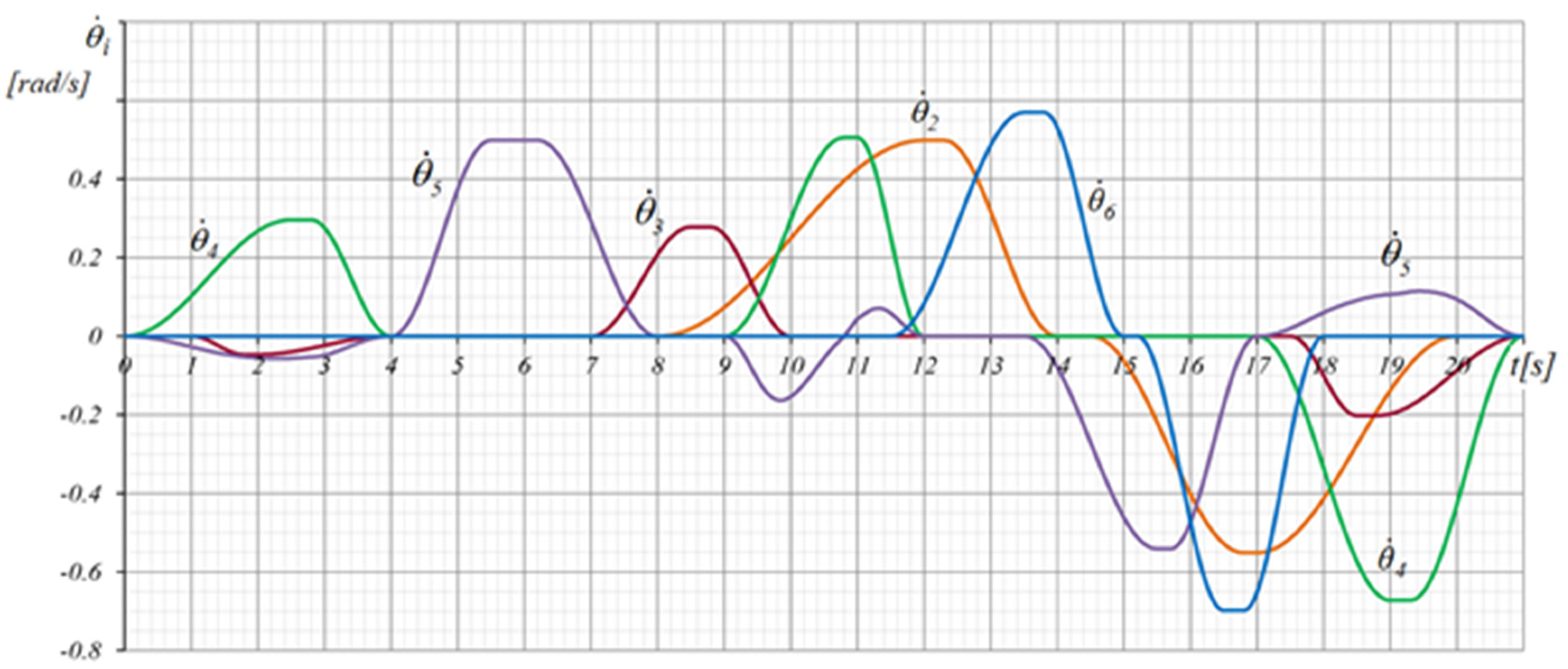

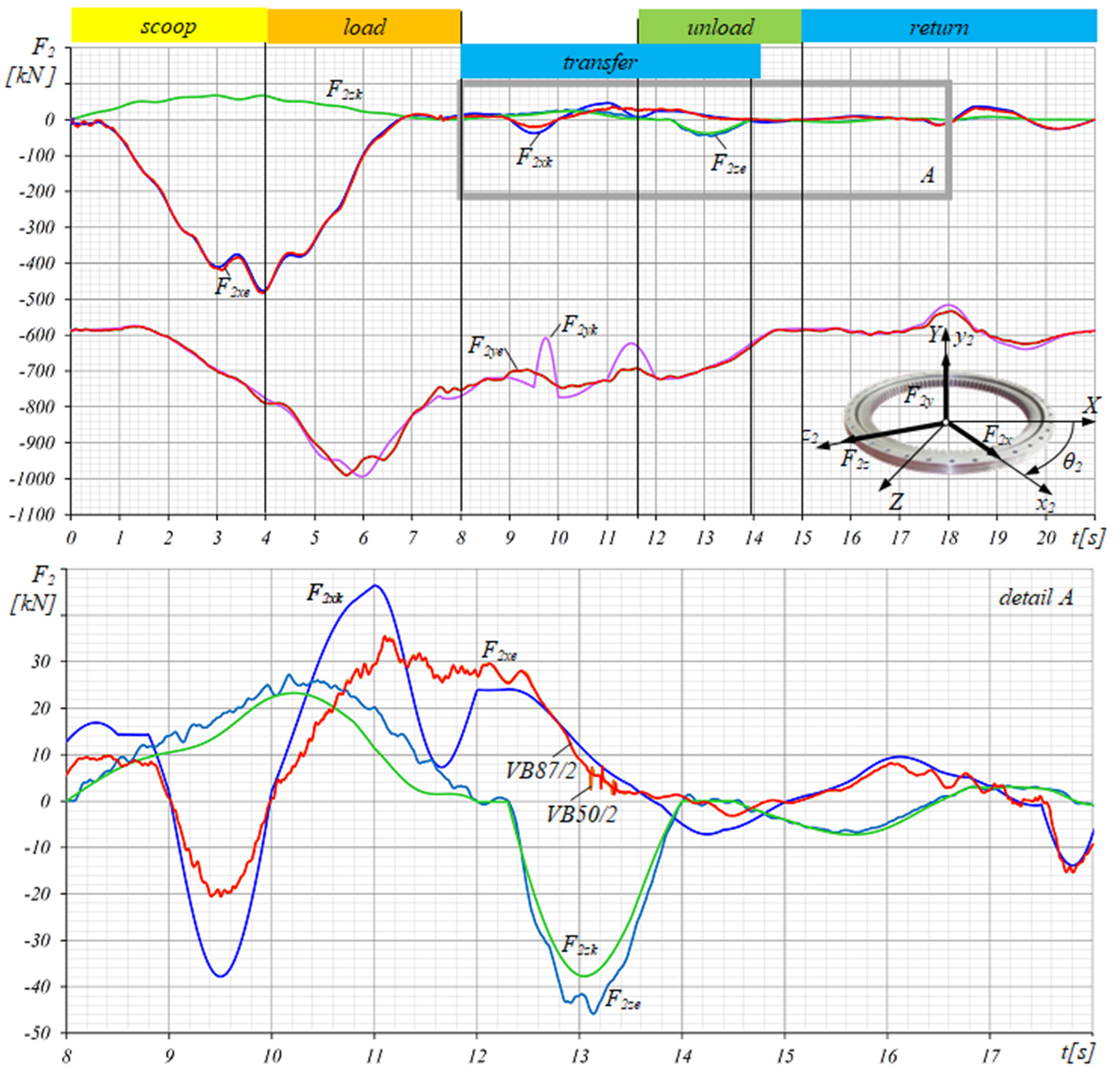

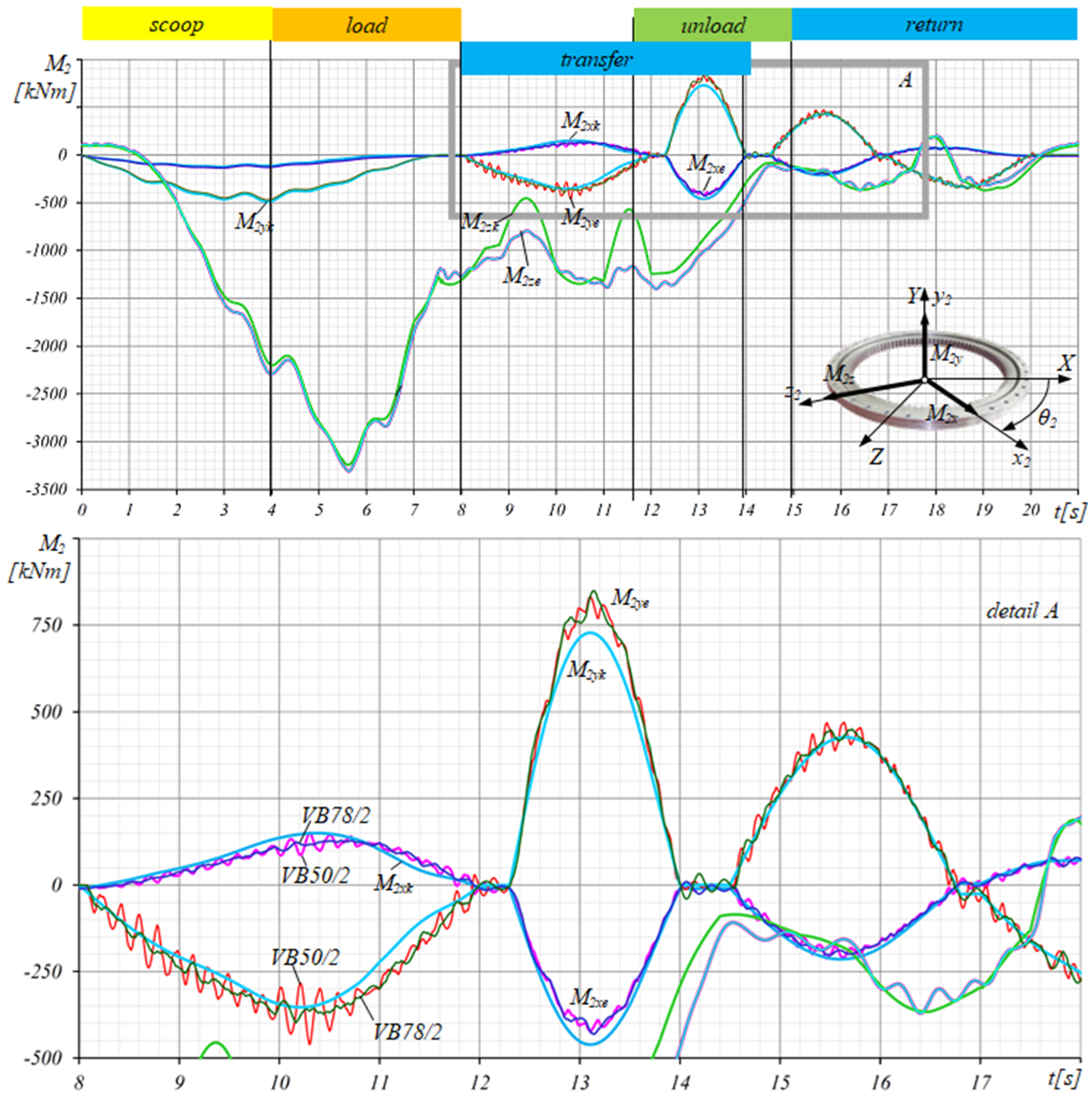

3. Dynamic Loading of the Swing Drive

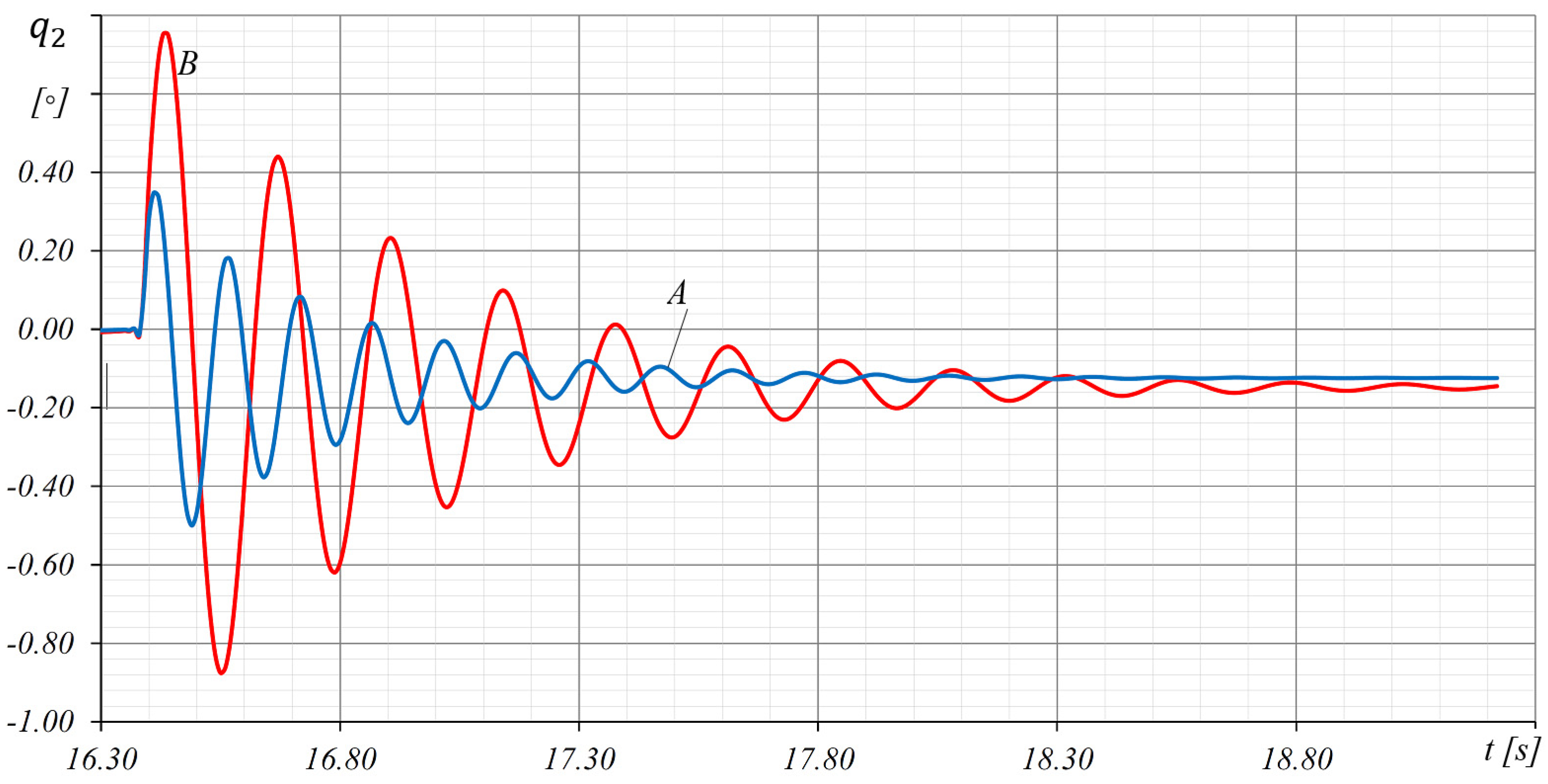

4. Dynamic Stability of the Swing Drive

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Geralda, L.N.; Muhammad, A.; Himmawan, S.A.; Diky, Z. Performance Improvement of Hydraulic Excavator Efficiency. J. Mechatron. Artif. Intell. 2024, 1, 27–44. [Google Scholar]

- Gan, J.; Zhou, Z.; Yu, A.; Ellis, D.; Attwood, R.; Chen, W. Co-simulation of multibody dynamics and discrete element method for hydraulic excavators. Powder Technol. 2023, 414, 118001. [Google Scholar] [CrossRef]

- Mitrev, R.; Janošević, D.; Marinković, D. Dynamical modelling of hydraulic excavator considered as a multibody system. Tech. Gaz. 2017, 24, 327–338. [Google Scholar]

- Xiang, Q.; Wang, P.; Li, Y. An algorithm of eliminating spike of the measured excavator load spectrum signal based on peak-valley extraction. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2020; Volume 1633, p. 012013. [Google Scholar]

- Fragassa, C.; Minak, G.; Pavlovic, A. Measuring deformations in the telescopic boom under static and dynamic load conditions. Facta Univ. Ser. Mech. Eng. 2020, 18, 315–328. [Google Scholar] [CrossRef]

- Wang, P.; Xiang, Q.; Królczyk, G.; Lu, P.; Wang, B.; Li, Z. Dynamic Modeling of a Hydraulic Excavator Stick by Introducing Multi-Case Synthesized Load Spectrum for Bench Fatigue Test. Machines 2022, 10, 741. [Google Scholar] [CrossRef]

- Arsić, D.; Gnjatović, N.; Sedmak, S.; Arsić, A.; Uhričik, M. Integrity assessment and determination of residual fatigue life of vital parts of bucket-wheel excavator operating under dynamic loads. Eng. Fail. Anal. 2019, 105, 182–195. [Google Scholar] [CrossRef]

- Yu, C.; Bao, Y.; Li, Q. Finite element analysis of excavator mechanical behavior and boom structure optimization. Meas. J. Int. Meas. Confed. 2021, 173, 108637. [Google Scholar] [CrossRef]

- Peng, J.; Cheng, X.; Wang, J.; Xiao, L. Contact analysis of heavy-duty apron feeder with clearance. Eng. Rev. 2023, 43, 91–105. [Google Scholar] [CrossRef]

- Edwards, D.; Parn, E.A.; Sing, M.C.P.; Thwala, W.D. Risk of excavators overturning: Determining horizontal centrifugal force when slewing freely suspended loads. Eng. Constr. Archit. Manag. 2019, 26, 479–498. [Google Scholar] [CrossRef]

- Mitrev, R.; Marinković, D. Numerical study of the hydraulic excavator overturning stability during performing lifting operations. Adv. Mech. Eng. 2019, 11, 1687814019841779. [Google Scholar] [CrossRef]

- Jovanovic, V.; Janošević, D.; Marinković, D.; Petrović, N.; Pavlović, J. Railway Load Analysis During the Operation of an Excavator Resting on the Railway Track. Acta Polytech. Hung. 2023, 20, 79–93. [Google Scholar] [CrossRef]

- Yuan, Y.; Ren, J.; Wang, Z.; Mu, X. Dynamic analysis of the rigid-flexible excavator mechanism based on virtual prototype. Facta Univ. Ser. Mech. Eng. 2022, 20, 341–361. [Google Scholar] [CrossRef]

- Liang, G.; Liu, L.; Meng, Y.; Chen, Y.; Bai, G.; Fang, H. Dynamic Modeling and Analysis of Loader Working Mechanism Considering Cooperative Motion with the Vehicle Body. Machines 2023, 11, 9. [Google Scholar] [CrossRef]

- Petrović, G.; Pavlović, J.; Madić, M.; Marinković, D. Optimal Synthesis of Loader Drive Mechanisms: A Group Robust Decision-Making Rule Generation Approach. Machines 2022, 10, 329. [Google Scholar] [CrossRef]

- Lee, J.S.; Ham, Y.; Park, H.; Kim, J. Challenges, tasks, and opportunities in teleoperation of excavator toward human-in-the-loop construction automation. Autom. Constr. 2022, 135, 104119. [Google Scholar] [CrossRef]

- Zhang, L.; Fu, W.; Yuan, X.; Meng, Z. Research on Optimal Control of Excavator Negative Control Swing System. Processes 2020, 8, 1096. [Google Scholar] [CrossRef]

- Cheng, M.; Zhang, J.; Xu, B.; Ding, R. Electrohydraulic Load Sensing System via Compound Control of Flow Feedforward and Pressure Feedback. J. Mech. Eng. 2018, 54, 262–270. [Google Scholar] [CrossRef]

- Qin, T.; Ma, Y.; Li, Y.; Quan, L. Torque equilibrium position closed-loop control of dual electric motors swing system for large mining excavator. Mechatronics 2023, 95, 103035. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, X.; Ge, L.; Quan, L. Dual Source Integrated Driving for Hydraulic Excavator Swing System. IEEE Access 2021, 9, 120755–120764. [Google Scholar] [CrossRef]

- Huang, W.; Quan, L.; Ge, L.; Xia, L. Combined velocity and position control of large inertial hydraulic swing mechanism considering energy balance of supply and demand. Autom. Constr. 2019, 106, 102899. [Google Scholar] [CrossRef]

- Göncz, P.; Drobne, M.; Glodez, S. Computational model for determination of dynamic load capacity of large three-row roller slewing bearings. Mech. Mach. Theory 2013, 32, 44–53. [Google Scholar] [CrossRef]

- Šalinić, S.; Nikolić, M.; Bošković, G. Contribution of the Determination of the Load on Suspension Ring of the Underframe of the Hydraulic Excavator. IMK-14 Res. Dev. Heavy Mach. 2014, 20, 129–133. [Google Scholar]

- Smolnicki, T.; Stańco, M.; Derlukiewicz, D. Distribution of loads in the large size bearing—Problems of identification. Tech. Gaz. 2013, 20, 831–836. [Google Scholar]

- Jovanovic, V.; Marinković, D.; Petrović, N.; Stojanović, D. The Load Spectrum of Axial Bearing of Hydraulics Excavator with Shovel Attachment. J. Eng. Manag. Syst. Eng. 2024, 3, 175–182. [Google Scholar] [CrossRef]

- Xiao, J.; Wu, Y.; Long, W.; Xu, C. Failure Analysis of Gantry Crane Slewing Bearing Based on Gear Position Accuracy Error. Appl. Sci. 2022, 12, 11907. [Google Scholar] [CrossRef]

- Skyba, R.; Hrček, S.; Smetánka, L.; Majchrá, M. Contact pressure analysis of slewing rings. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 659. [Google Scholar]

- He, P.; Wang, Y.; Liu, H.; Guo, E.; Wang, H. Influence of the elastic and elastic-plastic material parameters on the mechanical properties of slewing bearings. Adv. Mech. Eng. 2021, 13, 1687814021992151. [Google Scholar] [CrossRef]

- Marek, K.; Piotr, S. The fem application in numerical analysis of slewing rings roller/ball combination bearing. Commun. Sci. Lett. Univ. Zilina 2017, 19, 3–9. [Google Scholar] [CrossRef]

- He, P.; Ding, Y.; Wang, Y.; Li, F.; Liu, W.; Wang, H. A New Analysis Method for the Carrying Capacity of Three-Row Roller Slewing Bearing. Mechanika 2022, 28, 266–272. [Google Scholar]

- Potočnik, R.; Göncz, P.; Glodež, S. Static capacity of a large double row slewing ball bearing with predefined irregular geometry. Mech. Mach. Theory 2013, 64, 67–79. [Google Scholar] [CrossRef]

- Jovanovic, V.; Marinković, D.; Janošević, D.; Petrović, N. Influential Factors in the Loading of the Axial Bearing of the Slewing Platform Drive in Hydraulic Excavators. Tech. Gaz. 2023, 30, 158–168. [Google Scholar]

- Marek, K.; Robert, U. Analysis of the influence of slewing bearing mounting on their static load capacity. Transp. Res. Procedia 2019, 40, 745–750. [Google Scholar]

- Piotr, R.; Kania, L.; Pytlarz, R. Numerical analysis of the screw connection with preload tension used in the mounting of slewing bearings. J. KONES 2015, 19, 465–472. [Google Scholar]

- Mascenik, J.; Coranic, T. Experimental Determination of the Coefficient of Friction on a Screw Joint. Appl. Sci. 2022, 12, 11987. [Google Scholar] [CrossRef]

- Yu, Y.; Do, T.C.; Park, Y.; Ahn, K.K. Energy saving of hybrid hydraulic excavator with innovative powertrain. Energy Convers. Manag. 2021, 244, 114447. [Google Scholar] [CrossRef]

- Rexroth A Bosch Company. Available online: https://www.boschrexroth.com/web/161ed0d4-cb8d-408b-9def-9fd158670577 (accessed on 9 June 2024).

- CAT Company. Available online: https://www.cat.com/en_US/products/new/equipment/excavators.html (accessed on 15 September 2024).

- Houman, H. Hydraulic Formulary; Rexroth Bosch Group: Lohr am Main, Germany, 2013; pp. 1–43. [Google Scholar]

- Kizielewicz, B.; Sałabun, W. SITW Method: A New Approach to Re-identifying Multi-criteria Weights in Complex Decision Analysis. Spectr. Mech. Eng. Oper. Res. 2024, 1, 215–226. [Google Scholar] [CrossRef]

| Parameter | Symbol | Dimension | Value |

|---|---|---|---|

| Torsional rigidity of the support surface and undercarriage | kφ1 | Nm/rad | 7.056 × 109 |

| Torsional damping of the support surface and undercarriage | bφ1 | Nms/rad | 7.056 × 107 |

| Parameter | Symbol | Dimension | Transmission Variants | |

|---|---|---|---|---|

| VB50/2 | VB87/2 | |||

| Specific flow of the hydraulic motor | q2m | cm3 | 80.40 | 200.00 |

| Internal diameter of the hydraulic motor ducts | dvm | m | 0.025 | 0.032 |

| Length of the hydraulic motor ducts | lvm | m | 0.320 | 0.320 |

| Hydraulic rigidity of the hydraulic motor | kh2 | Nm/rad | 2327 | 7949 |

| Damping coefficient of the swing drive | bc2 | s−1 | 0.879 | 0.879 |

| Oil modulus of elasticity | Eo | N/m2 | 1.4 × 109 | 1.4 × 109 |

| Reducer transmission ratio | ir | - | 111.86 | 35.13 |

| Transmission ratio between the reducer shaft and the bearing | il | - | 6.93 | 6.93 |

| Parameter | Symbol | Dimension | Hydraulic Cylinders | ||

|---|---|---|---|---|---|

| Boom | Stick | Bucket | |||

| Diameter of the hydraulic cylinder piston | Di | m | 0.280 | 0.250 | 0.220 |

| Diameter of the hydraulic cylinder piston rod | di | m | 0.200 | 0.180 | 0.160 |

| Internal diameter of the hydraulic cylinder | dci | m | 0.2805 | 0.2505 | 0.2205 |

| Initial length of the hydraulic cylinder | cip | m | 2.800 | 2.300 | 3.150 |

| Final length of the hydraulic cylinder | cik | m | 4.500 | 3.500 | 4.100 |

| Number of hydraulic cylinders | nci | - | 2 | 2 | 2 |

| Internal diameter of the hydraulic cylinder ducts | dvi | m | 0.048 | 0.048 | 0.048 |

| Length of the hydraulic cylinder ducts | lvi | m | 6.000 | 6.000 | 7.000 |

| Dynamic viscosity of hydraulic oil | ηo | Ns/m2 | 0.09 | 0.09 | 0.09 |

| Parameters of Initial Conditions | Symbol | Dimension | Values |

|---|---|---|---|

| Manipulation task time | t | s | 16.76 |

| Undercarriage position angle | θ1 | ° | 0.000 |

| Upper structure angle | θ2 | ° | 54.342 |

| Boom position angle | θ3 | ° | 50.526 |

| Stick position angle | θ4 | ° | −42.292 |

| Bucket position angle | θ5 | ° | −37.282 |

| Upper structure angular velocity | rad/s | −0.551 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jovanović, V.; Janošević, D.; Marinković, D.; Petrović, N.; Djokić, R. Analysis of Influential Parameters in the Dynamic Loading and Stability of the Swing Drive in Hydraulic Excavators. Machines 2024, 12, 737. https://doi.org/10.3390/machines12100737

Jovanović V, Janošević D, Marinković D, Petrović N, Djokić R. Analysis of Influential Parameters in the Dynamic Loading and Stability of the Swing Drive in Hydraulic Excavators. Machines. 2024; 12(10):737. https://doi.org/10.3390/machines12100737

Chicago/Turabian StyleJovanović, Vesna, Dragoslav Janošević, Dragan Marinković, Nikola Petrović, and Radomir Djokić. 2024. "Analysis of Influential Parameters in the Dynamic Loading and Stability of the Swing Drive in Hydraulic Excavators" Machines 12, no. 10: 737. https://doi.org/10.3390/machines12100737

APA StyleJovanović, V., Janošević, D., Marinković, D., Petrović, N., & Djokić, R. (2024). Analysis of Influential Parameters in the Dynamic Loading and Stability of the Swing Drive in Hydraulic Excavators. Machines, 12(10), 737. https://doi.org/10.3390/machines12100737