1. Introduction

The joint mechanism of a robot is an important carrier for realizing robot functions, having a direct effect on robot performance. Research on novel high-performance joint configurations in robots has always been a focus of academic and industrial research and has important significance.

Scholars have conducted extensive research on the humanoid robot shoulder joint configuration, and the resulting configurations can be roughly divided into three categories: series, parallel, and hybrid configurations. The serial configuration often uses three rotating joints connected in sequence [

1,

2,

3], which has the advantages of a large motion range, easy modular design, convenient maintenance, and a mature control model. The disadvantage is that the next-level driving device is the previous-level load, resulting in torque loss.

Spherical parallel mechanisms (SPMs) are characterized by a compact structure, high stiffness, and high precision and have been actively investigated in configuration research on shoulder joint mechanisms. Gosselin first conducted kinematic optimization analysis on a 3-RRR SPM and applied it to a spatial pointing mechanism [

4,

5]. Hou et al. [

6] proposed an offset-designed 3-PSS/S spherical parallel shoulder joint configuration and optimized the mechanism workspace. In addition, they proposed a 3-P

cSS/S spherical parallel shoulder joint configuration [

7], which had the ability to rotate the entire circumference around the normal direction of the moving platform. Yang et al. [

8] proposed a 3-RRR+(S-P) spherical parallel shoulder joint configuration. This configuration achieved static unloading and stiffness balance by placing a spherical passive limb in the 3-RRR SPM central region. Abe et al. [

9] proposed an active ball joint mechanism driven by spherical gear meshing, which could be used for shoulder joint mechanisms and had a small volume and compact structure. Stanišić et al. [

10] proposed a shoulder joint configuration based on a spherical six-bar mechanism, which theoretically had a flexible workspace of half a sphere. Wu et al. [

11] achieved the working space superposition of two parallel mechanisms by sharing the components of a 3-RRR SPM and a 5R SPM and establishing an associative motion relationship between the motion pairs of the two mechanisms, resulting in a shoulder joint configuration that satisfied the human shoulder motion space.

Owing to interference and motion coupling between the limbs, the normal spin range of an SPM around a platform is smaller than that of a series configuration, which limits the shoulder joint movement space obtained by the configuration. Spherical hybrid mechanisms (SHMs) adopt the compact structure, high stiffness, and high precision of SPMs while also possessing complete cycle rotation capabilities that general SPMs do not have, which can improve the above shortcomings to a certain extent. Mghames et al. [

12] proposed a spherical hybrid shoulder joint configuration with a 5R SPM+R which had good workspace coverage. Wang et al. [

13] proposed a hybrid shoulder joint configuration consisting of a two-degree-of-freedom (DOF) two anti-parallelogram mechanism and a rotating pair in series, which offered a large workspace, lightweight structure, modularity, and fast assembly.

The above configurations were obtained by adding a series mechanism to a parallel mechanism, but the parallel part still needed to bear the weight of the series joint driver, resulting in some torque loss. Therefore, several scholars proposed an integrated hybrid joint configuration; specifically, Okada and Nakamura proposed a 3SU-UPRR hybrid shoulder joint configuration [

14]. Guan et al. [

15] proposed a 4RRRR-RUUR spherical hybrid shoulder joint configuration. Hess-Coelho proposed a 3RRR-RUR hybrid wrist joint configuration [

16]. Bajaj and Dollar proposed a PRU-PSS-RUR hybrid wrist joint configuration [

17]. The driving sources of the above configurations all started from the base, and each driver did not have to bear the weight of each other’s driving devices, which improved the utilization rate of the driving torque.

In addition, other scholars developed shoulder joint mechanism configurations driven by steel ropes and pneumatic muscles from a lighter weight perspective [

18,

19]. Unlike engineering applications, several scholars have proposed several musculoskeletal shoulder joint configurations that used elastic ropes or pneumatic muscle drives to mimic the compliance and dynamic characteristics of the human shoulder joint [

20,

21,

22,

23].

The optimization design of parallel mechanisms can be based on various criteria, including the workspace, dexterity, dynamics, transmission capability, and stiffness. Gosselin et al. [

4] optimized the structural parameters of a 3-RRR SPM with the goal of maximizing the workspace. Tao and An used the minimum interference design method to optimize the workspace of a 3-RRR SPM [

24]. Gosselin and Angeles defined a global motion evaluation index on the basis of the condition number of the Jacobian matrix and performed size synthesis on a 3-RRR SPM to improve the global motion performance of the mechanism [

25]. Khoshnoodi et al. [

26] used a genetic algorithm to solve the structural parameter optimization problem of an SPM with GCI as the objective function. Bai optimized the spherical mechanism dexterity by transforming numerical optimization problems into nonlinear least squares problems [

27]. Wu et al. [

28] proposed a dynamic optimization method that improves the dynamic performance of a mechanism by minimizing the mass. Mirshekari et al. [

29] optimized the dynamic structural parameters of a fast grasping parallel mechanism based on the global dynamic dexterity index. Brinker et al. [

30] considered the transmission and constraint characteristics of parallel mechanisms and conducted a kinematic performance evaluation of high-speed Delta parallel robots. Liu et al. [

31] considered motion/force transmission characteristics and optimized the design of a spherical 5R SPM. Wu et al. [

32] defined a transmission index on the basis of the virtual coefficient between a transmission wrench and twist screws, achieving the optimization design of asymmetric SPM transmission. Liu et al. [

33] studied the optimization problem of a 3-DOF SPM considering both dexterity and stiffness as evaluation criteria. Chen et al. [

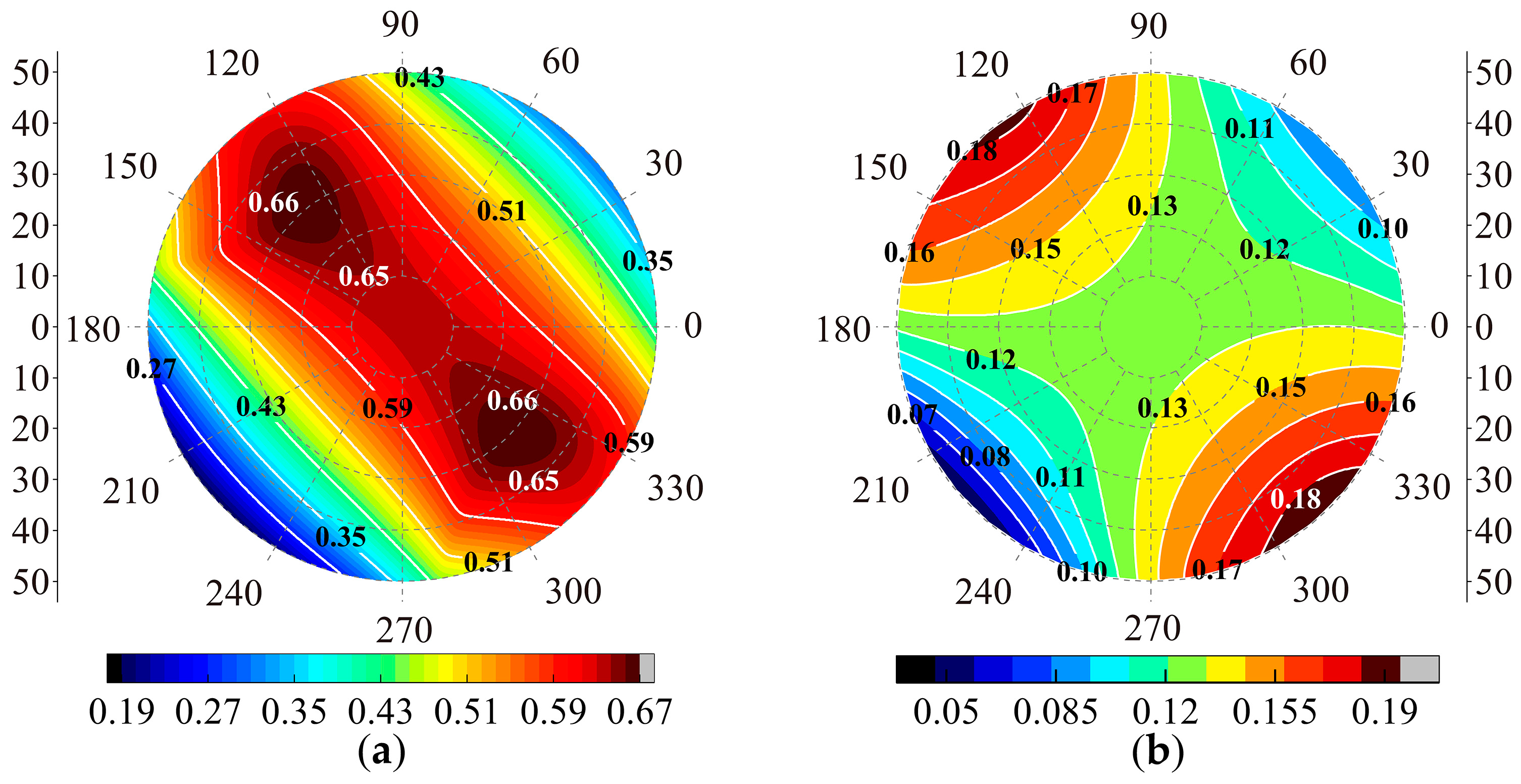

34] constructed a multiobjective optimization function that included workspace, dexterity, and joint torque indicators and combined a multiobjective genetic algorithm and fuzzy analytic hierarchy process methods to optimize the 3-RRR spherical parallel mechanism. In this work, the optimization design aims to find the optimal design parameters in terms of dexterity within a specified workspace and therefore uses the GCI and GDCI as the objective function for optimization.

In order to increase the workspace, linear displacement stiffness, and driving torque utilization of existing humanoid robot shoulder joint mechanisms, this paper conducts research on the mechanism configuration and structural parameters optimization of a novel spherical hybrid bionic shoulder joint. This paper is organized as follows: a prototype mechanism of biomimetic joints is proposed, and the improved linear displacement stiffness of the spherical mechanism is verified in

Section 2. The forward and inverse kinematics and Jacobian matrix of the mechanism are solved in

Section 3. Structural parameter optimization analysis is conducted, and recommended and adopted values for structural parameters are obtained in

Section 4. The final bionic shoulder joint mechanism is described in

Section 5. This work is concluded in

Section 6.

2. RBR-2RRR Spherical Hybrid Bionic Shoulder Joint Prototype Mechanism

2.1. Physiological Structure and Movement Description of the Shoulder Joint

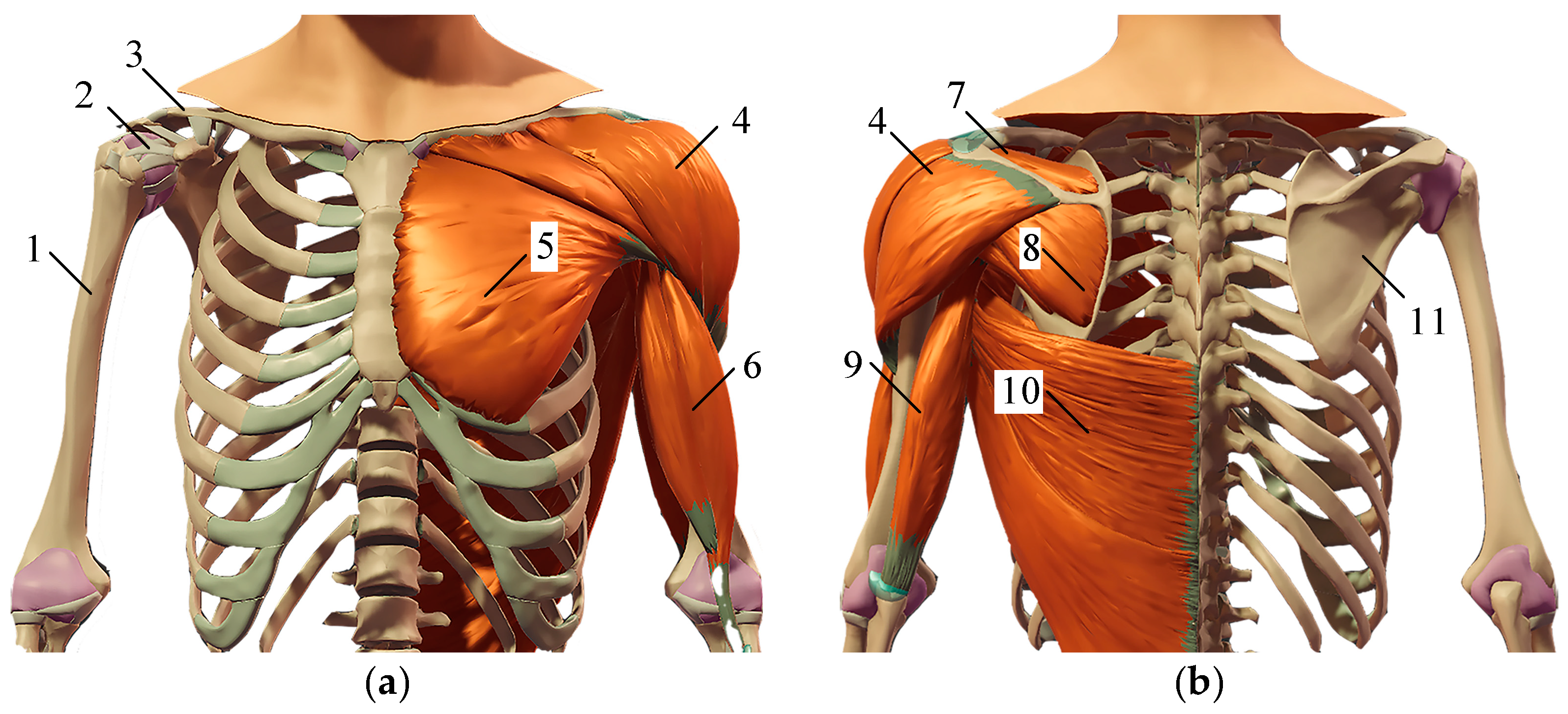

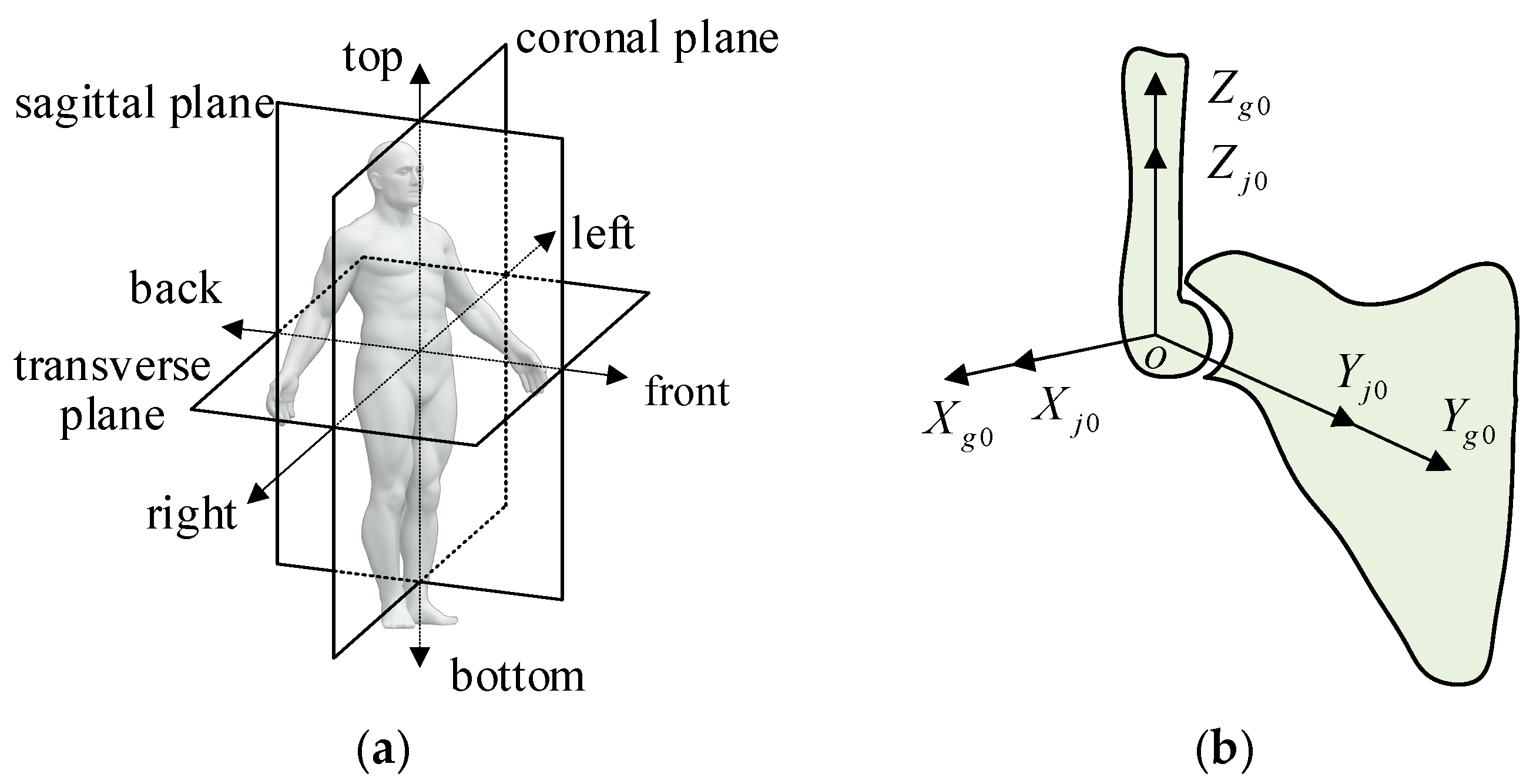

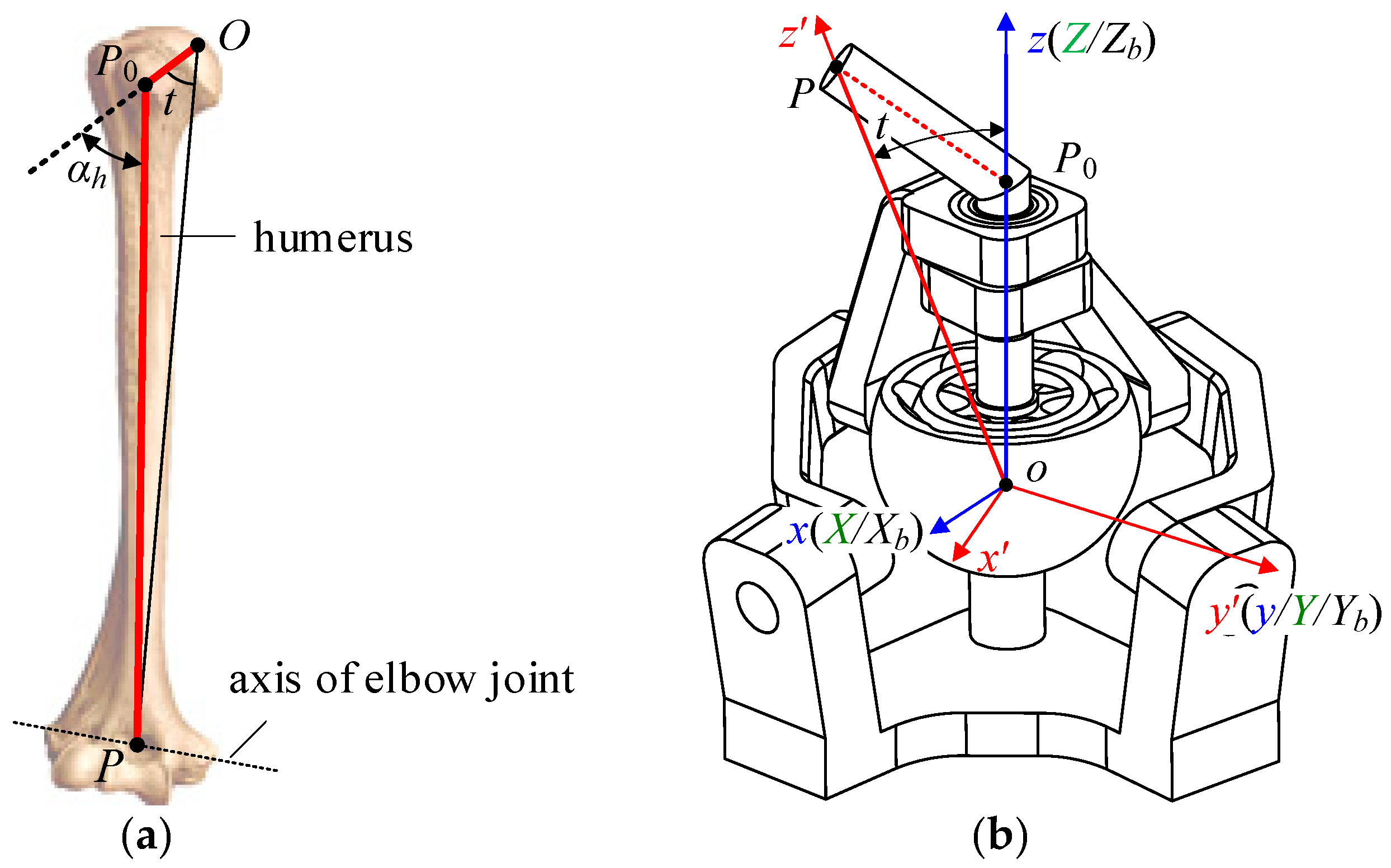

As shown in

Figure 1, the human shoulder joint is composed of the humerus, clavicle, and scapula and is a typical ball-and-socket joint. As the joint with the largest range of human motion, the shoulder joint has three degrees of rotational freedom, namely flexion and extension, abduction and adduction, and internal rotation and external rotation.

The three reference planes in human anatomy are shown in

Figure 2a, and their names and features are as follows: sagittal plane—cutting the human body into the left and right parts; coronal plane—cutting the human body into the front and back parts; and transverse plane—cutting the human body into the upper and lower parts. A fixed coordinate system

connected to the scapula and a moving coordinate system

connected to the humerus on the shoulder are established, as shown in

Figure 2b. Among them, the

axis perpendicular to the transverse plane points upward, and the

axis perpendicular to the coronal plane points forward.

When the

Euler angle with

,

, and

as the attitude angle parameters is used, the corresponding rotation matrix is as follows:

If the length of the humerus is 1, the coordinates of the end point

of the humerus in

are as follows:

Yang et al. used the Xsens MVN motion capture system to measure the motion range of the human shoulder joint and obtained the following relationship [

35]:

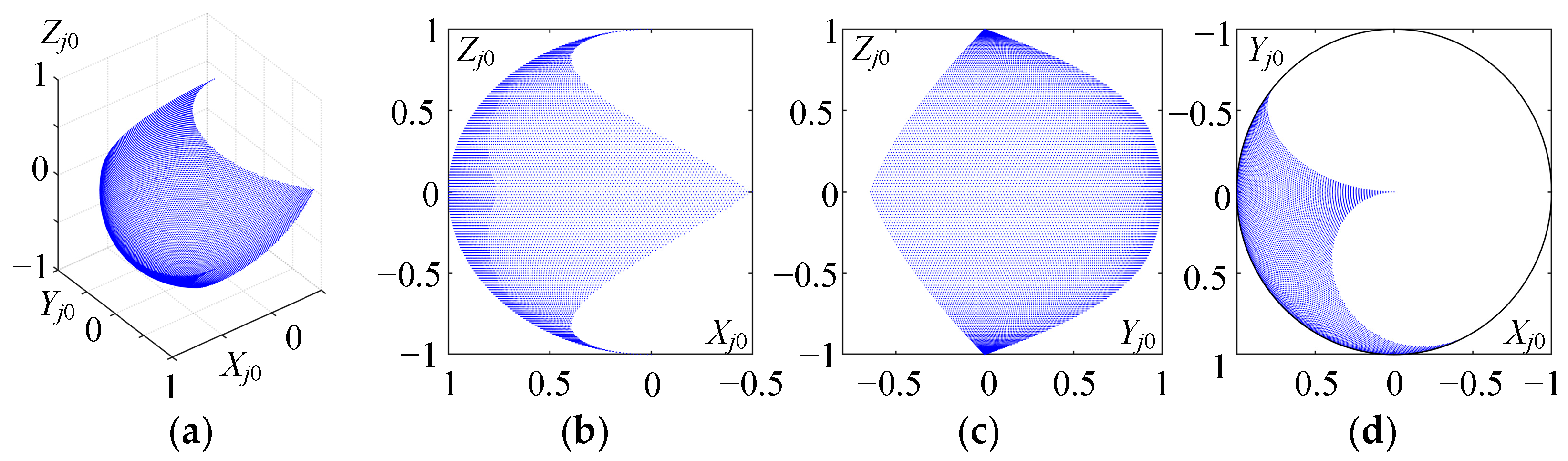

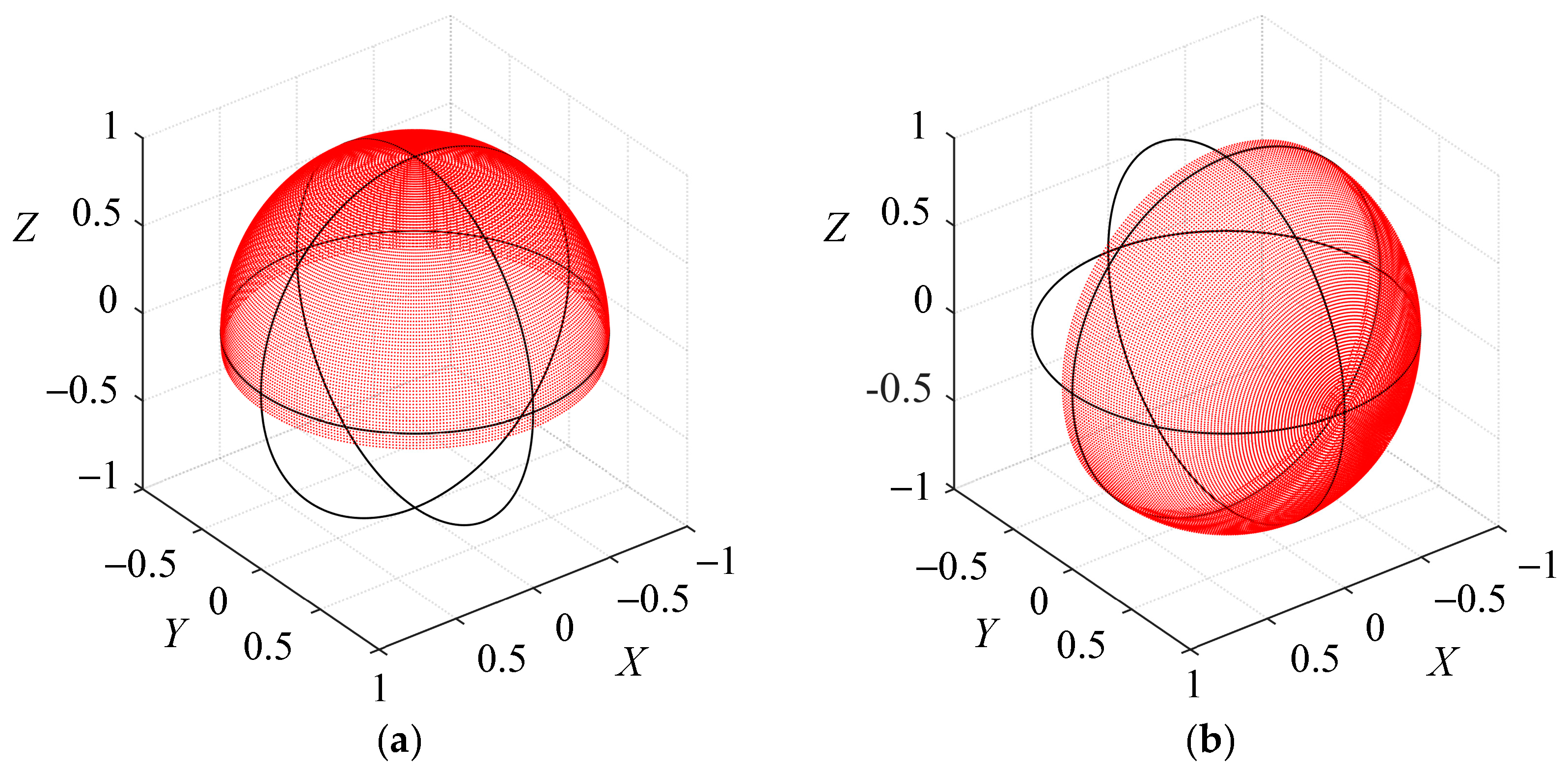

The motion space of the human shoulder joint is obtained from Equations (2) and (3), as shown in

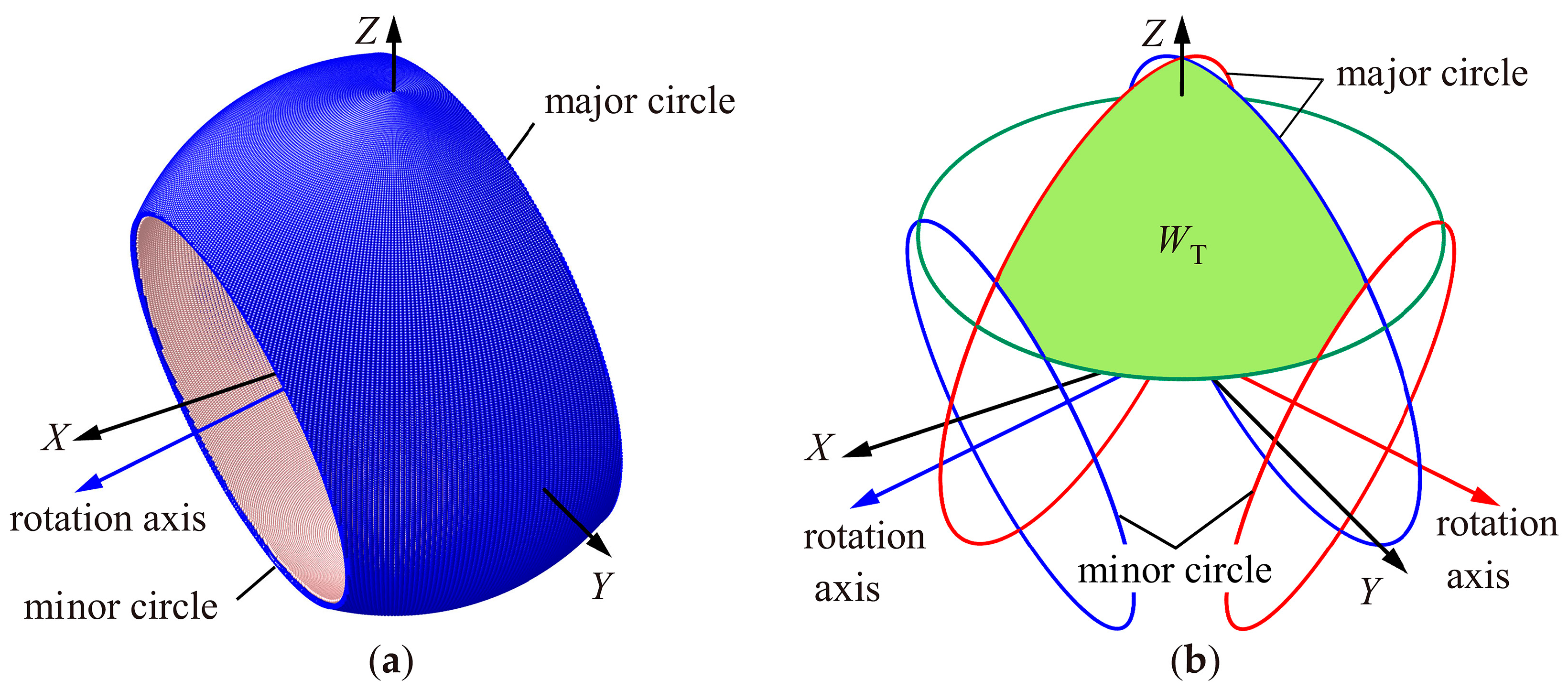

Figure 3.

2.2. Prototype Mechanism of the Spherical Hybrid Shoulder Joint

According to the physiological structure of the human body, the humerus and scapula form the rigid skeleton of the shoulder joint, and the ligament tissue is distributed between the humerus, clavicle, and scapula to connect and limit them. The various muscle groups work together to drive and complete the task movements of the shoulder joint.

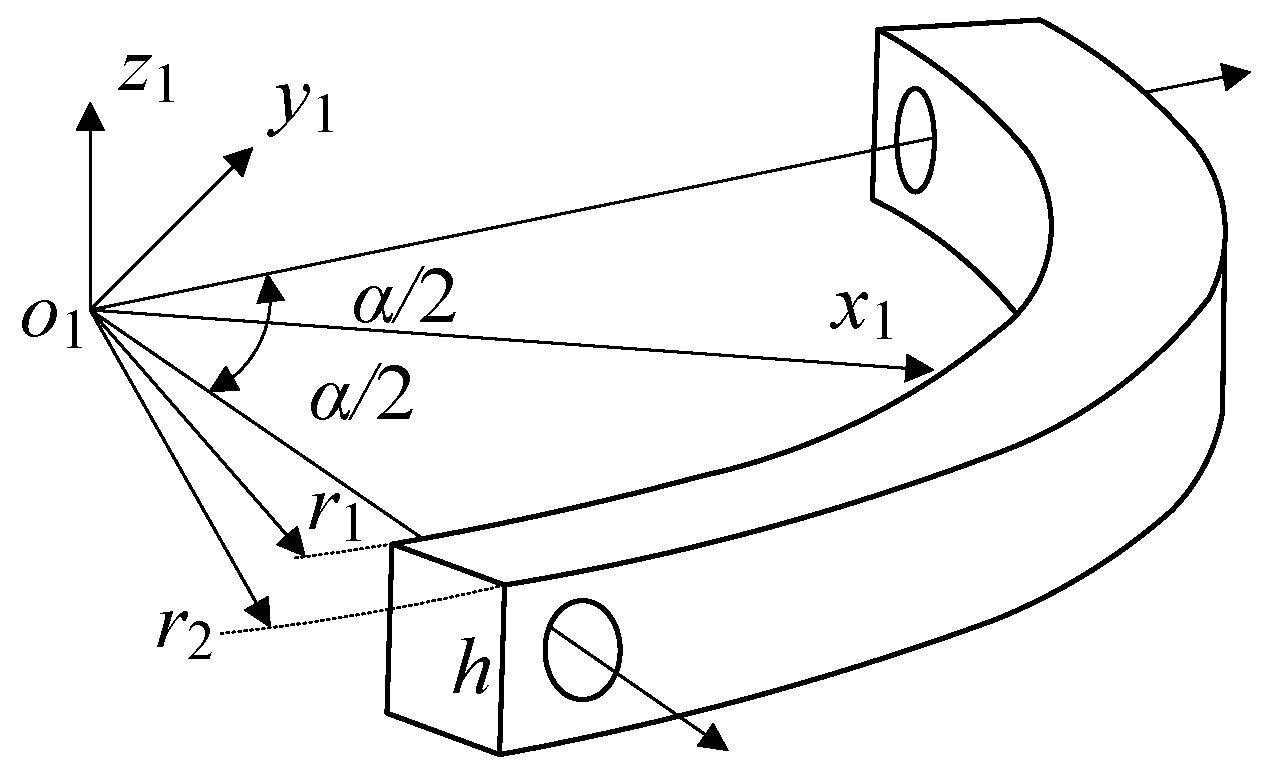

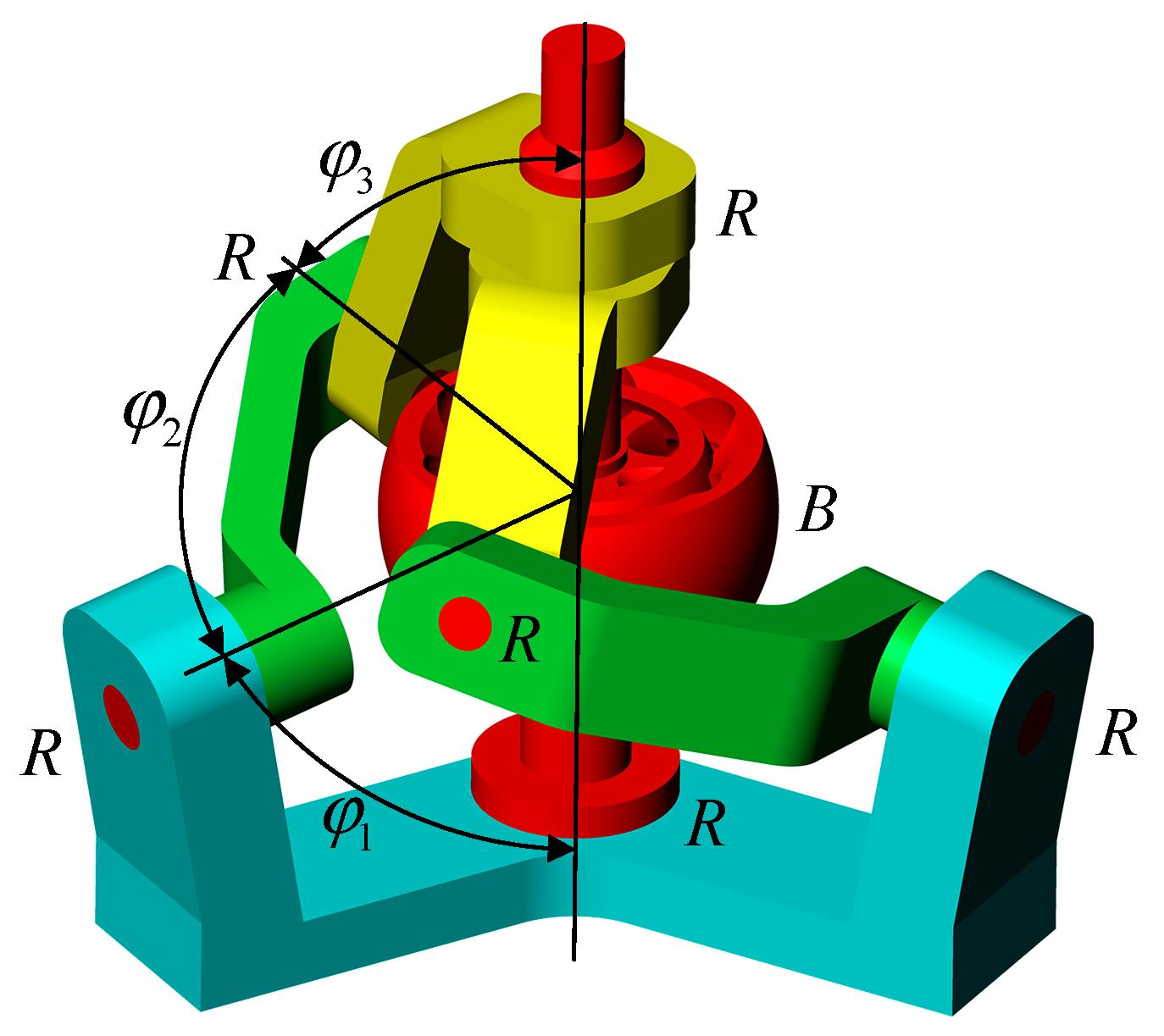

On the basis of the physiological structural characteristics of the human shoulder joint, an RBR-2RRR spherical hybrid shoulder joint prototype mechanism is proposed (R represents the revolute pair and B represents the ball cage joint [

36]), as shown in

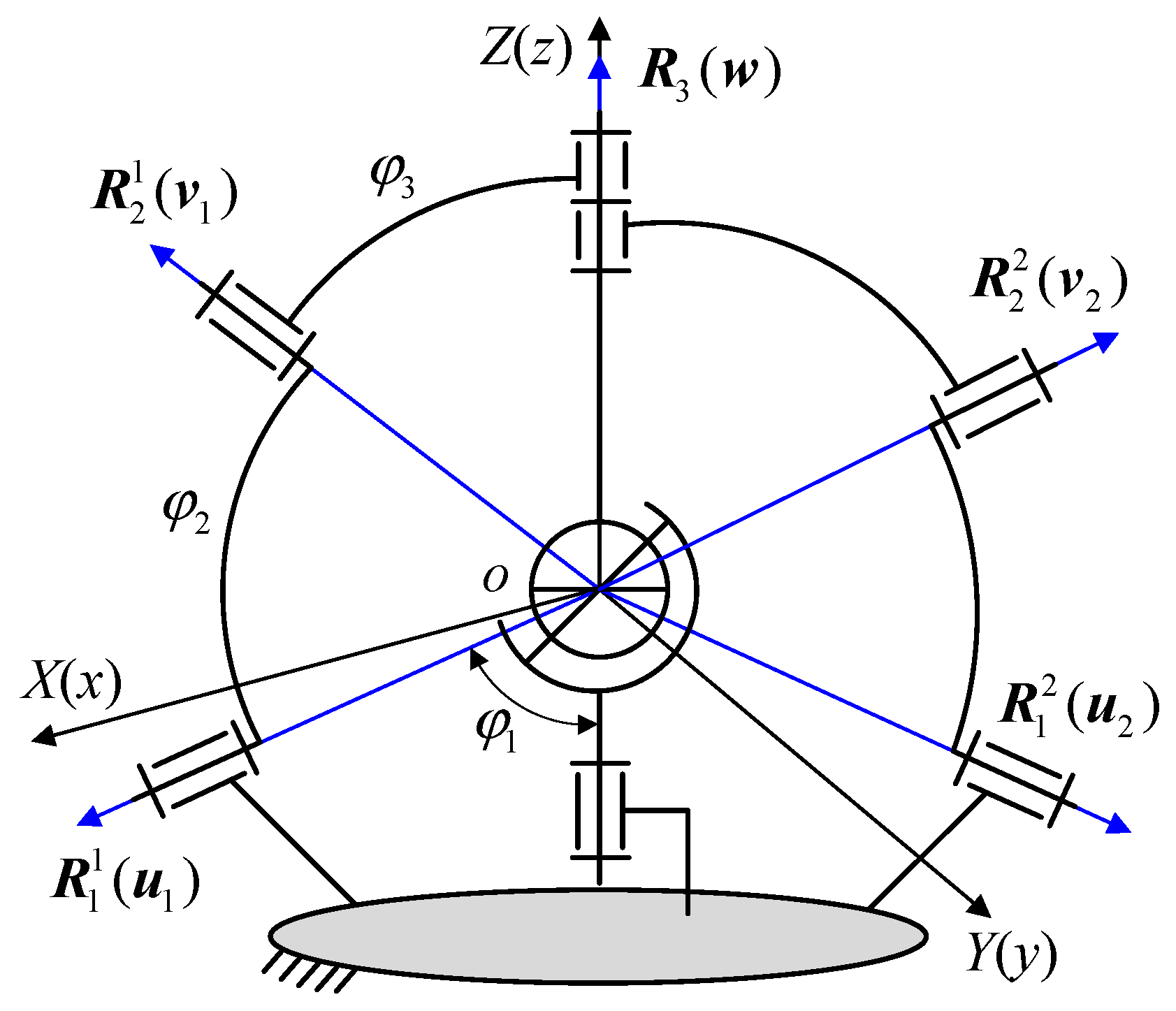

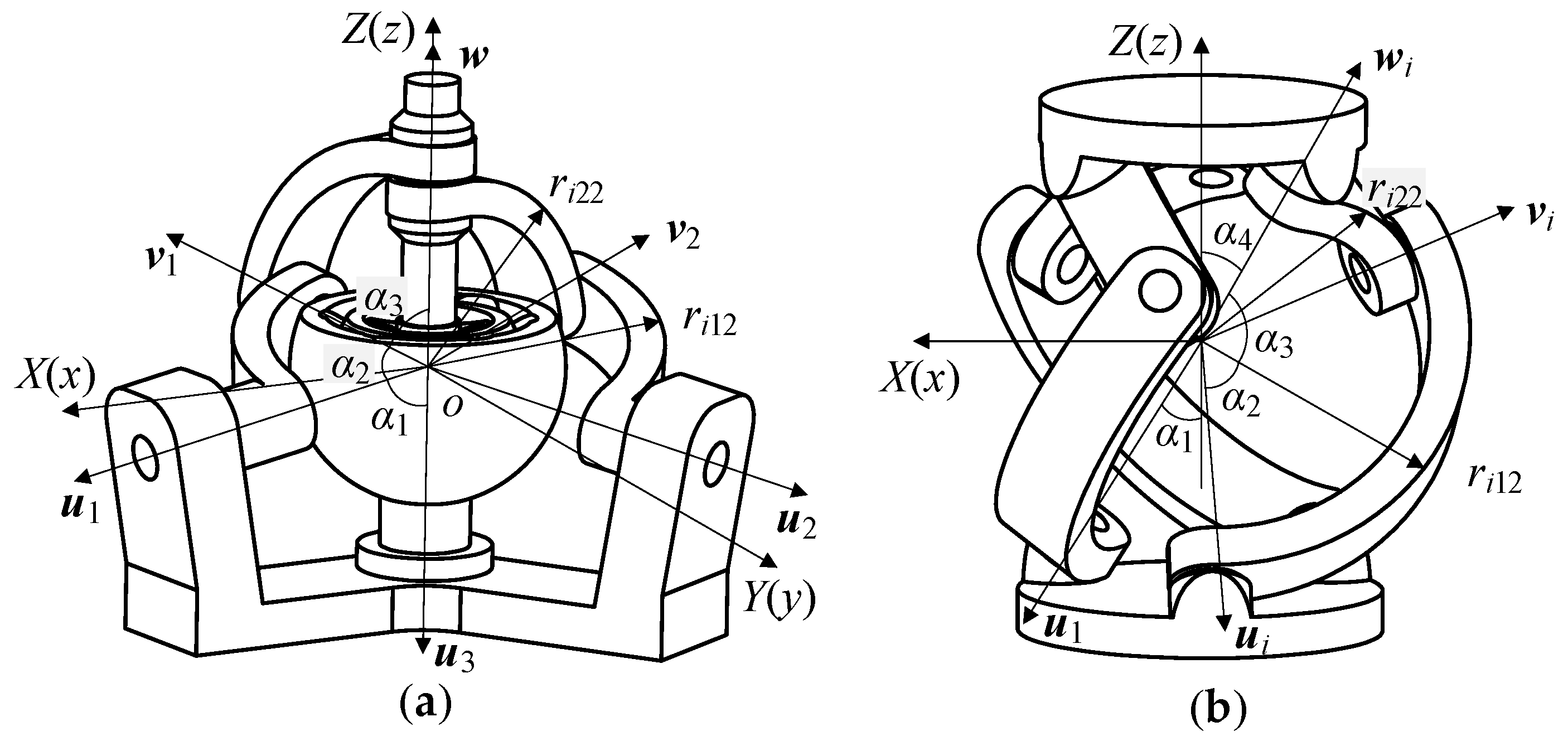

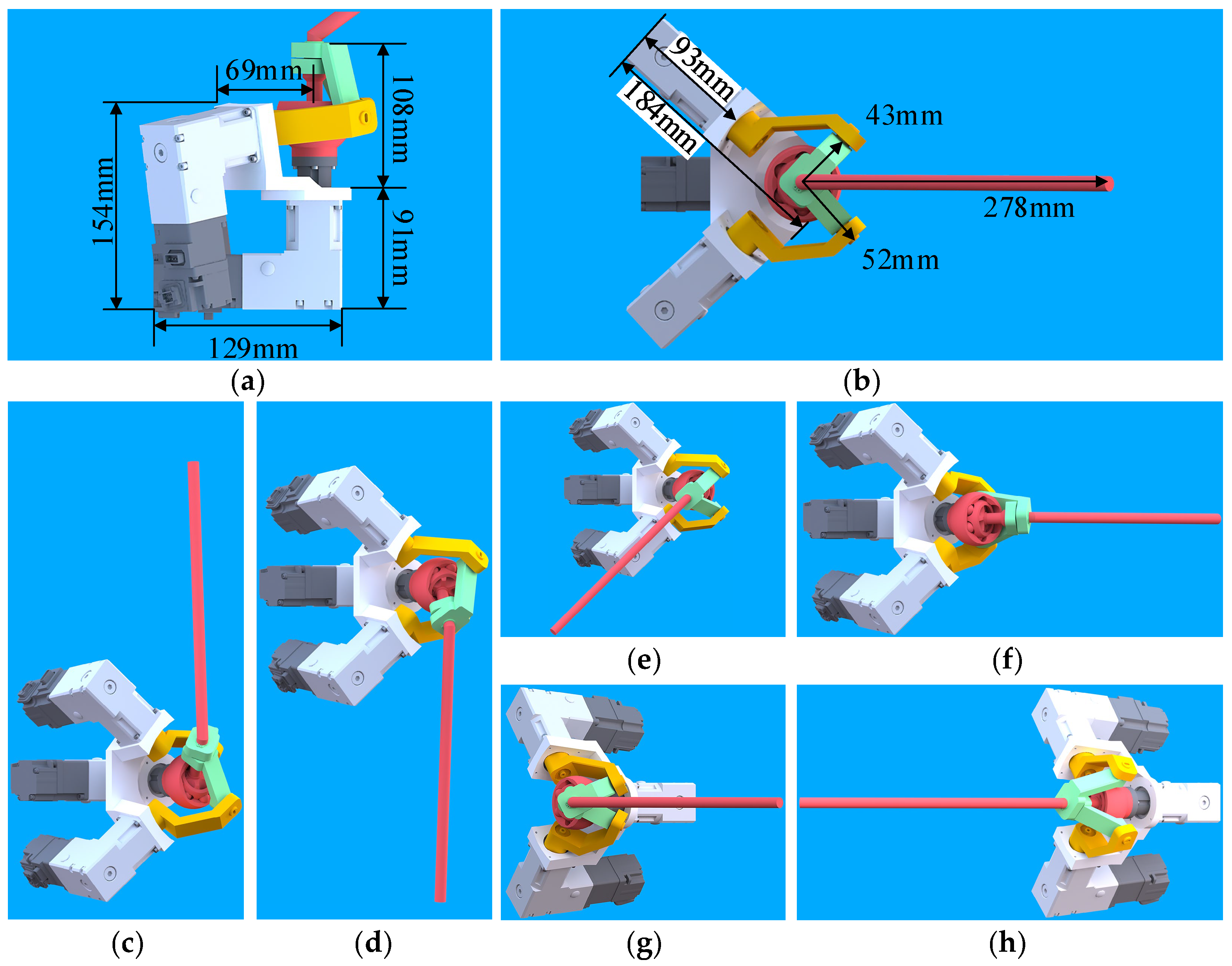

Figure 4. The rigid skeleton of the shoulder joint is equivalent to the rigid components in the mechanism, the connection effect of ligaments is equivalent to the connection relationship between the kinematic pairs, and the collaborative driving of muscle groups is equivalent to the hybrid driving layout between the various limbs of the mechanism. The DOF of this mechanism is three rotational DOFs, where the spin motion of the output rod is driven by the RBR central limb and the spatial two-dimensional swing of the output rod is driven by two RRR side limbs.

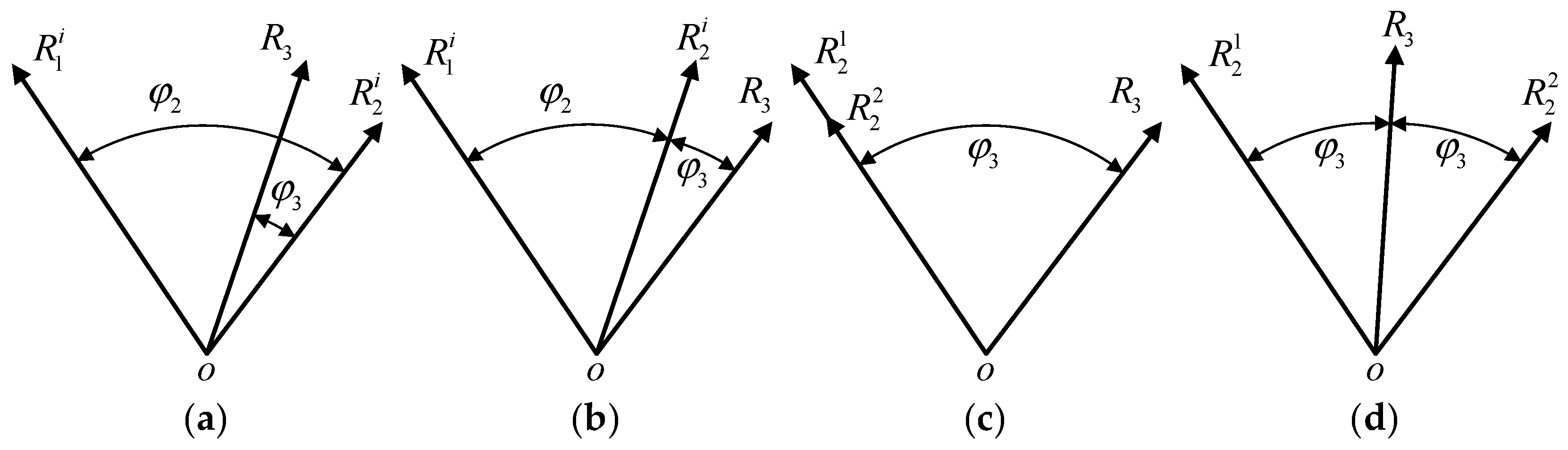

The structural parameters of the mechanism are , , , and , where is the angle between the first axis of the limb and the normal of the fixed platform; is the angle between the first and second axes of the same limb; is the angle between the second and third axes of the same limb; and is the angle between the projections of the first axes of the two limbs on the fixed platform. During assembly, it is necessary to ensure that the axes of the six revolute pairs intersect at one point and coincide with the rotation center of the ball cage joint.

The advantages of the proposed RBR-2RRR spherical hybrid bionic shoulder joint prototype mechanism are as follows: (1) Each driving input directly acts on the output end, and each driving device does not have to bear the weight of the other driving devices, resulting in a higher utilization rate of the driving torque. (2) Each driving device can be arranged close to the fixed platform to reduce the end load and improve the dynamic performance. (3) The central transmission limb is a constant-speed transmission chain with simple motion control. In addition, the central transmission limb can also support the moving platform for external force unloading and improve the linear displacement stiffness of the mechanism. (4) The normal rotation of the mechanism around the platform is not restricted, which can further improve the normal rotation range of the shoulder joint mechanism around the platform. (5) The added central transmission limb improves the spatial utilization of the central area of the mechanism and reduces the spatial volume of the mechanism (compared with the 3-RRR configuration).

2.3. Verification of Linear Displacement Stiffness Improvement

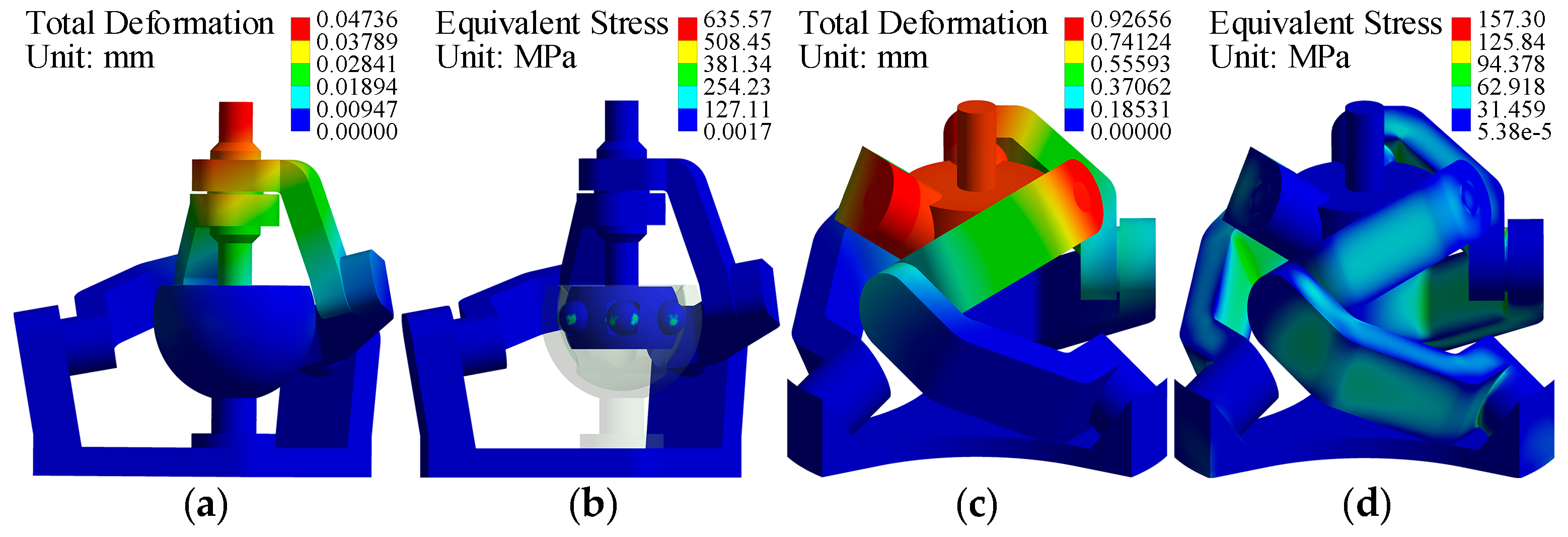

On the basis of the ANSYS static analysis module, the deformation response of the RBR-2RRR mechanism and the 3-RRR mechanism to the same load is compared to verify that the proposed RBR-2RRR mechanism can improve the linear displacement stiffness of the spherical mechanism.

In the modeling stage, the structural parameters

,

,

, and

of the RBR-2RRR mechanism are

,

,

, and

, respectively. The 3-RRR mechanism adopts the second set of structural parameters optimized for stiffness in Table 1 of [

33]. Specifically, the angle between adjacent revolute pairs is 90°, and the angle between the revolute pairs’ axes on the moving platform and the fixed platform and the normal of the platform is 60°. The width and thickness of the limbs and the rotation shaft radius of the revolute pair are the same in the two mechanisms.

The settings in the ANSYS static analysis module are as follows: the materials for all components are aluminum alloy, except for the outer race, inner race, steel ball, cage, and output rod in the ball cage joint, which are 42CrMo, 42CrMo, GCr15, 20CrMnTi, and structural steel, respectively. The starting revolute pair of each limb chain in the two mechanisms is bound to the fixed platform, and the contact between the other rotating pairs is set to not be separated. The contact between the inner and outer surfaces of the cage is set to be frictionless, and the contact between the steel ball and the inner and outer raceways of the ball cage joint is set to be friction contact with a friction coefficient of 0.1. The unit size is 2 mm, and automatic mesh generation is performed. During the simulation process, it was found that the 3-RRR mechanism first reached the maximum allowable stress value (160 MPa) of the aluminum alloy under a vertical load of 1500 N. Therefore, based on a vertical load of 1500N, the deformation response of the two mechanisms to the same load is compared.

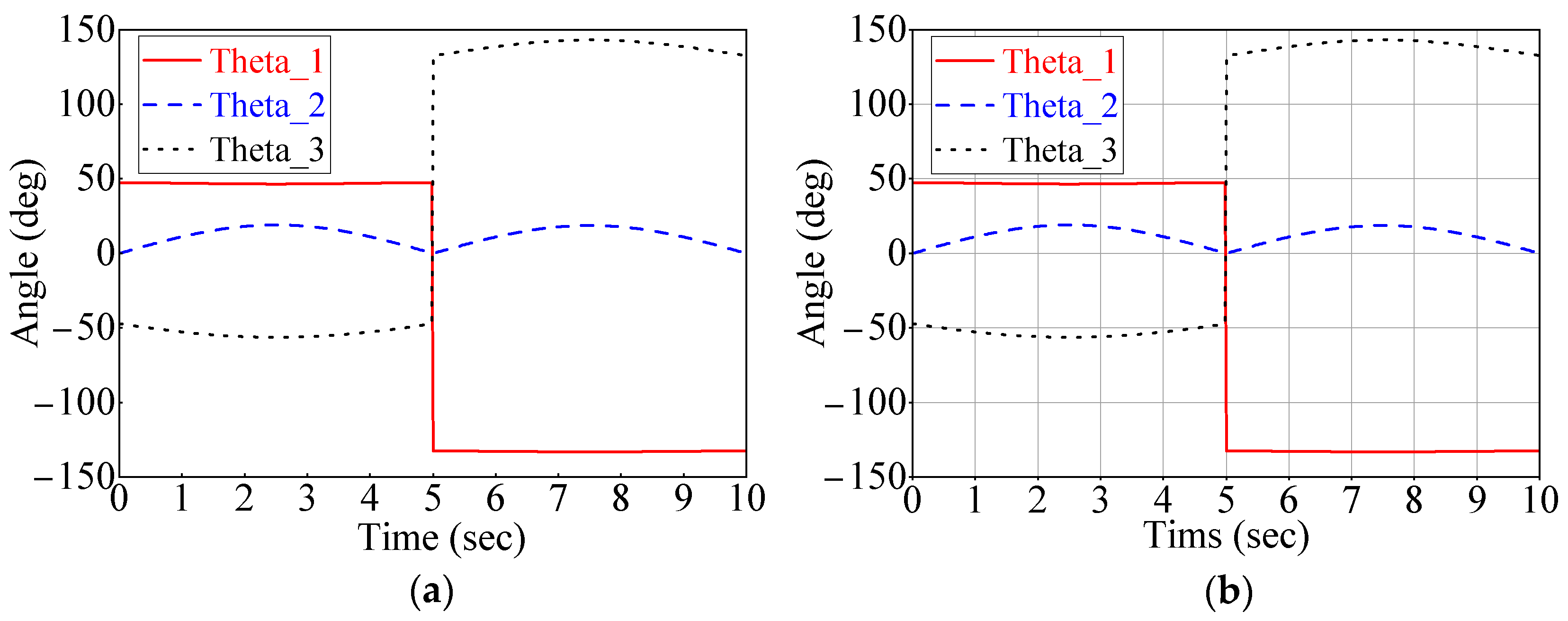

The simulation results show that under a vertical load of 1500 N, the maximum stress value of the RBR-2RRR mechanism (

Figure 5b) is 635.57 MPa, which occurs at the position where the steel ball contacts the raceway. The maximum stress value of the 3-RRR mechanism (

Figure 5d) is 157.30 MPa, which occurs on the contact plane between the two links. In the ball cage joint, the allowable contact stress between the steel ball and the raceway can reach 3000 MPa [

37]. Therefore, although the maximum stress value of the RBR-2RRR mechanism is greater than that of the 3-RRR mechanism, it is much smaller than the allowable contact stress value between the steel ball and the raceway. Therefore, the stress state of the RBR-2RRR mechanism is safe. On the other hand, although the maximum stress value of the 3-RRR mechanism is small, it is close to the maximum allowable stress value of the material, so the stress state of the 3-RRR mechanism is now dangerous. Meanwhile, compared to the 3-RRR mechanism, the force transmission of the RBR-2RRR mechanism mainly occurs on the central limb, and the load force on the side limb of the mechanism is very small, achieving external force unloading. Overall, the RBR-2RRR mechanism exhibits better stress performance.

Comparing the deformation diagrams of the RBR-2RRR mechanism (

Figure 5a) and the 3-RRR mechanism (

Figure 5c), it can be seen that under approximately the same geometric parameters of the components, for the same vertical load, the deformation of the RBR-2RRR mechanism (0.047 mm) is much smaller than that of the 3-RRR mechanism (0.927 mm). This indicates that the RBR-2RRR mechanism can reduce the deformation displacement of the motion platform under external loads and improve the linear displacement stiffness of the spherical mechanism, consistent with the configuration expectation.

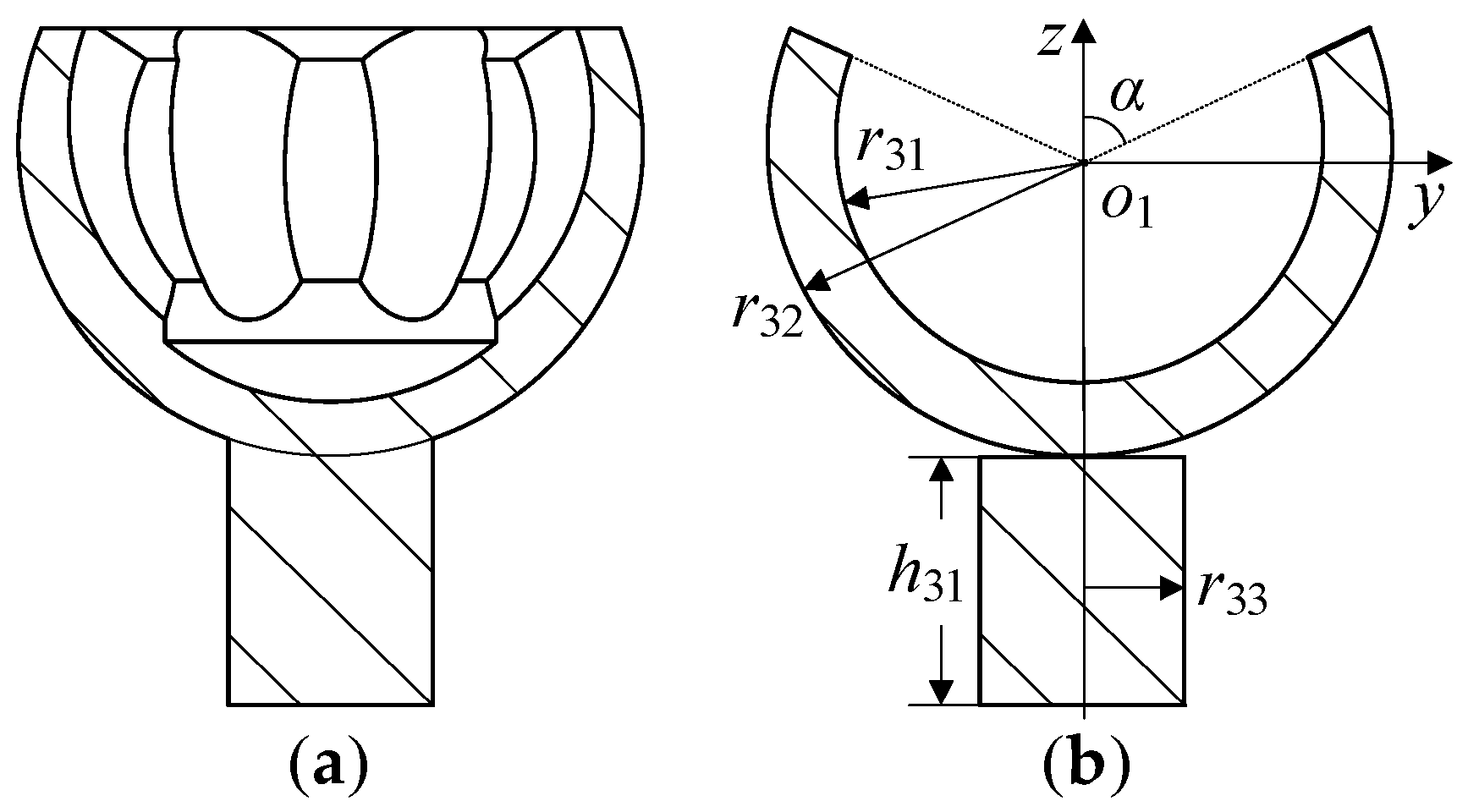

5. Hybrid Bionic Shoulder Joint Mechanism with an Offset Design

The workspace of the bionic shoulder joint prototype mechanism is a spherical crown with a central angle of

, which still has a certain gap compared with the motion range of the human shoulder joint (

Figure 3). To increase the workspace of the proposed bionic shoulder joint mechanism and match its motion range with the human shoulder joint, further improvements will be made to its structure.

5.1. Offset Design of the Spherical Hybrid Bionic Shoulder Joint Mechanism

Although the output rod of the RBR-2RRR SHM method proposed earlier is not restricted in the normal rotation around the moving platform, it is not reflected in the workspace of the mechanism output rod; that is, the contribution of the spin motion of the output rod to the workspace of the mechanism is to some extent masked.

The human shoulder joint is a ball-and-socket joint, but its motion space is significantly larger than that of traditional ball-and-socket joints.

Figure 14a shows the structure of the human humerus. The output rod of the human humerus is significantly different from that of the traditional spherical pair: the humeral neck

and humeral body

have a certain angle, which is an offset layout.

Compared with the structure of the human humerus, the fundamental reason why the contribution of the spin motion of the RBR-2RRR SHM output rod to the workspace is partially obscured is that the axis of the output rod is always coaxial with the normal of the moving platform. Therefore, Zhou et al. proposed a biomimetic design concept of offset output [

8], which involves bending the axis of the output rod in any direction at a certain angle to release the impact of the spin motion of the output rod on the mechanism workspace.

To increase the workspace of the proposed spherical hybrid shoulder joint mechanism, the output rod of the prototype mechanism was bent at a certain angle to deviate its axis from the original output rod axis, resulting in the RBR-2RRR spherical hybrid biomimetic shoulder joint mechanism with an offset design, as shown in

Figure 14b.

The actual angle between the output rod axis

and the straight output rod axis

is set as the offset angle

, which can be obtained from the trigonometric relationship:

According to human anatomy, the approximate dimensions of the humerus in adult males are mm, mm, and . By substituting the above parameters into Equation (50), is obtained. The final output bias angle of the hybrid bionic shoulder joint is determined to be .

5.2. Installation Posture Angle and Spatial Mapping Relationship

The workspace of the obtained spherical hybrid bionic shoulder joint mechanism does not coincide with the workspace of the human shoulder joint in spatial orientation. To match the workspace of the shoulder joint mechanism with that of the human shoulder joint, it is necessary to further determine the installation posture angle of the shoulder joint mechanism’s fixed platform relative to the robot body and establish a parameter mapping relationship between the human workspace and the spherical hybrid shoulder joint prototype mechanism.

To enable problem analysis, the following coordinate system is established, as shown in

Figure 14b: (a) The coordinate systems

and

, which are fixedly connected to the hybrid bionic shoulder joint fixed platform and the direct output rod

, respectively, have the same coordinate axis settings as

and

in

Figure 6. (b) The fixed coordinate system

, which is fixedly connected to the robot body, is assumed to have its initial pose coinciding with

. The posture angle of

relative to

is the installation posture angle of the hybrid bionic shoulder joint. Let

rotate by

,

, and

around the

axis,

axis, and

axis to reach the installation posture. In addition, on the basis of the principle of consistency between the mechanism workspace and the human workspace, the initial posture of

should coincide with

in

Figure 2b. (c). The offset rod coordinate system

is fixedly connected to the actual output axis

. Without loss of generality, assuming that the deflection direction occurs within the

plane,

can be obtained by rotating

around the

axis by

. The relative attitude relationship between each coordinate system is as follows:

Therefore, if the pose description of a certain point in the coordinate system

or

is known as

,

,

or

,

,

, there is the following spatial mapping relationship:

After , , , and are determined, the transformation relationship of the attitude angle parameters between the human workspace and the spherical hybrid shoulder joint prototype mechanism can be solved according to Equation (52).

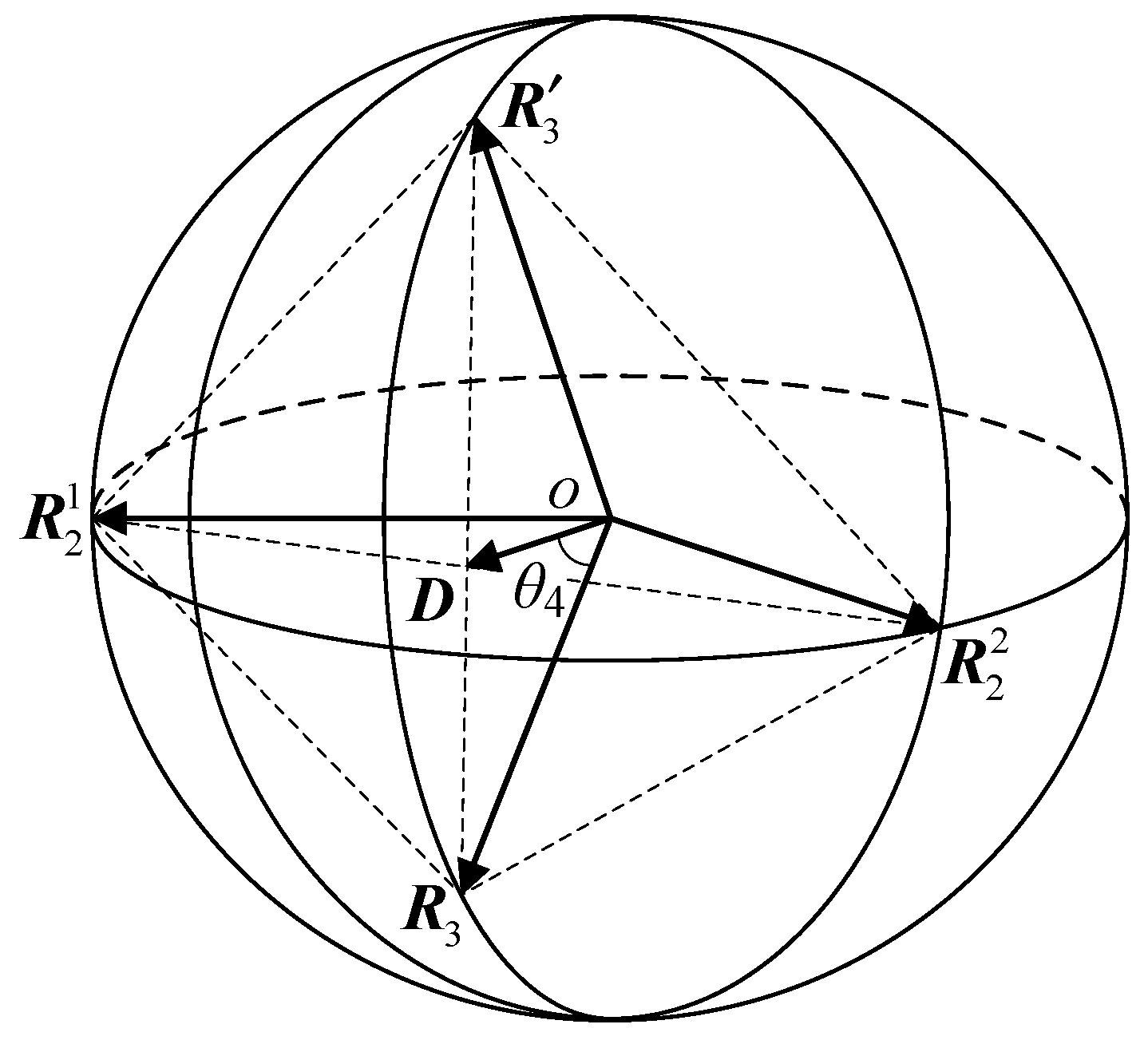

When

,

,

, and

, the workspace of the RBR-2RRR spherical hybrid shoulder joint with an offset design can be obtained from Equation (52), as shown in

Figure 15a, which is shaped like a spherical crown with a central angle of

. The workspace of the prototype mechanism is a spherical crown with a central angle of

. The workspace of the 3-RRR mechanism is a pointed cone with approximately

of opening and

of torsion [

5]. Compared with the prototype mechanism and the 3-RRR mechanism, the working space of the RBR-2RRR SHM with an offset design is significantly increased.

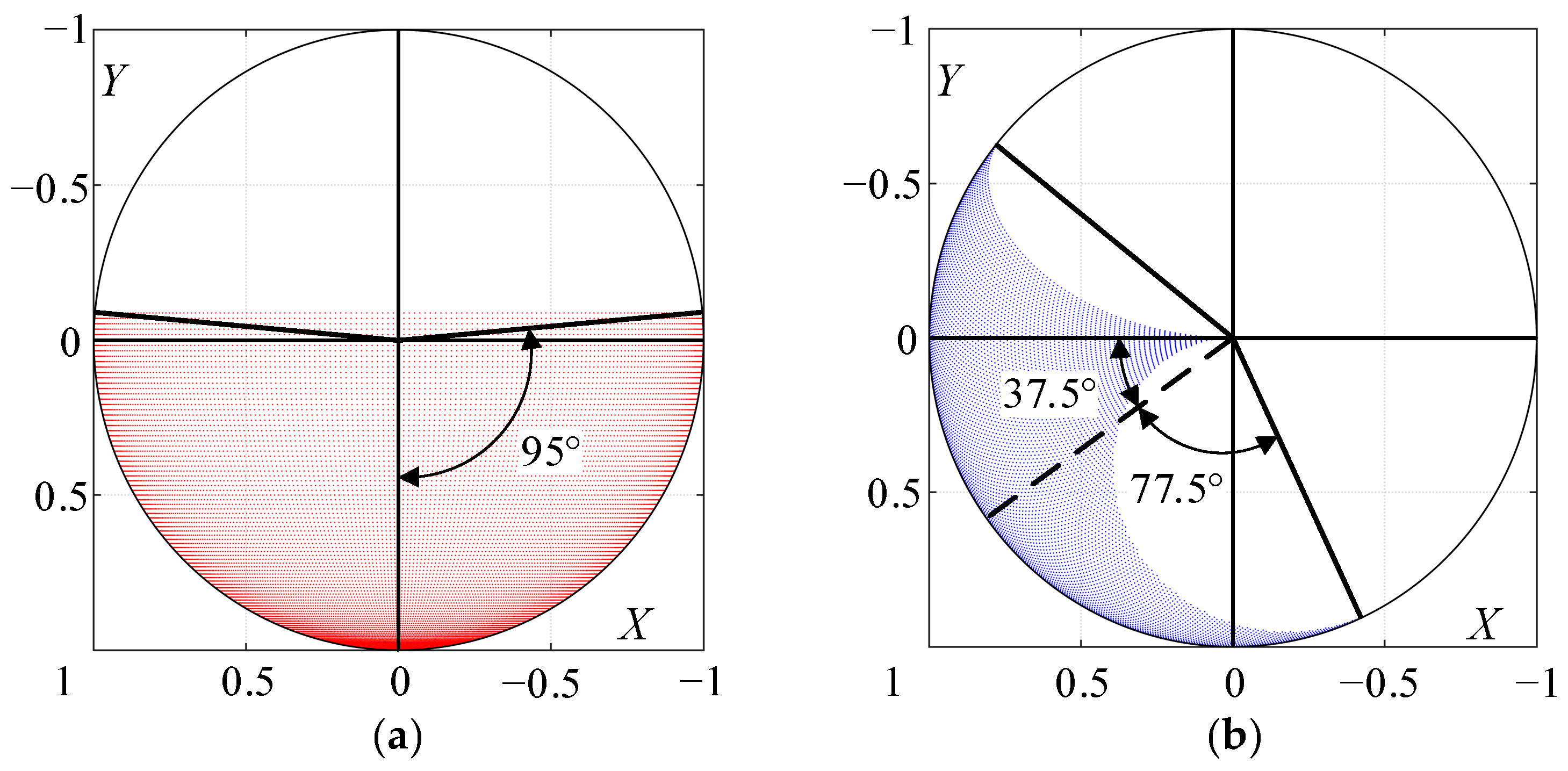

Figure 3 and

Figure 15a show that the workspace of the bionic shoulder joint is symmetrical about the

plane, whereas the active space of the human shoulder joint is symmetrical about the

plane. Therefore, the fixed platform of the bionic shoulder joint can be rotated clockwise around the

axis by

first. At this point, the spatial posture of the bionic shoulder joint workspace relative to the coordinate system

is shown in

Figure 15b. Furthermore, the initial installation pose angle is determined as

After the first rotation, the workspace of the bionic shoulder joint relative to the coordinate system

and the motion space of the human shoulder joint are both symmetrical about the

plane. The projections of the two on the

plane are shown in

Figure 16.

On the basis of the

directional views of the two workspaces, the bionic shoulder joint is rotated clockwise around the

axis by

to reach the target pose. Therefore, the final installation pose angle is determined as

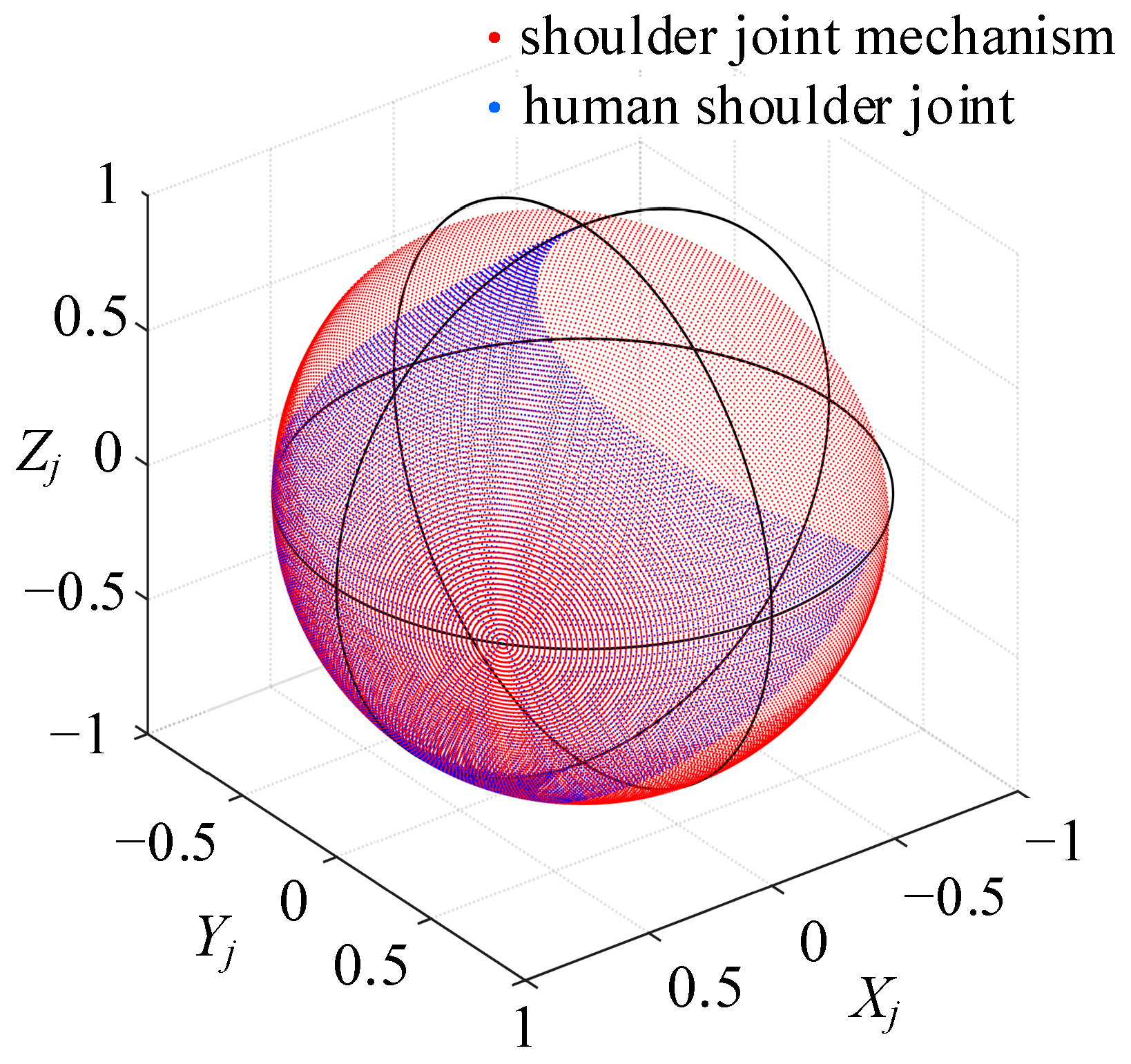

The comparative relationship between the bionic shoulder joint and the human shoulder joint motion space is shown in

Figure 17. The results show that the workspace of the offset-designed spherical hybrid shoulder joint mechanism (red area) can fully cover the motion range of the human shoulder joint (blue area), proving that the proposed offset-designed spherical hybrid shoulder joint mechanism meets the workspace requirements.

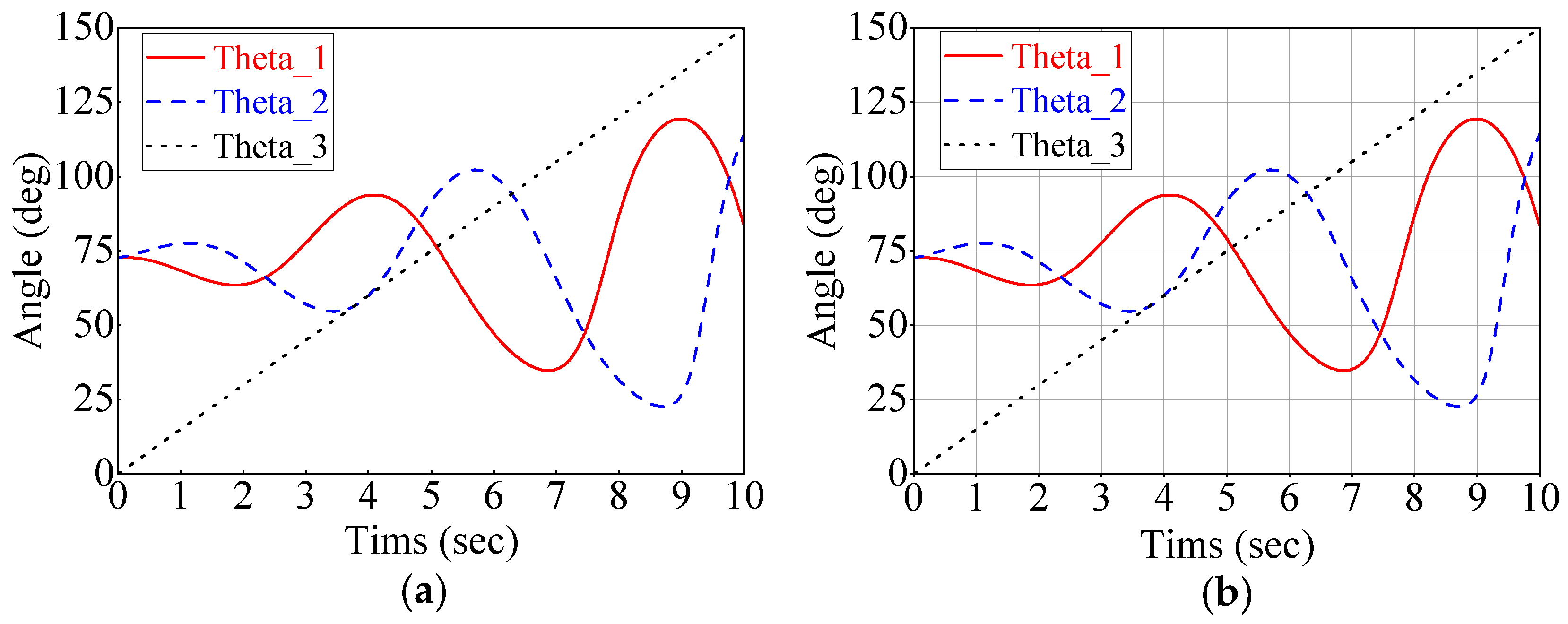

5.3. Shoulder Joint Action Simulation

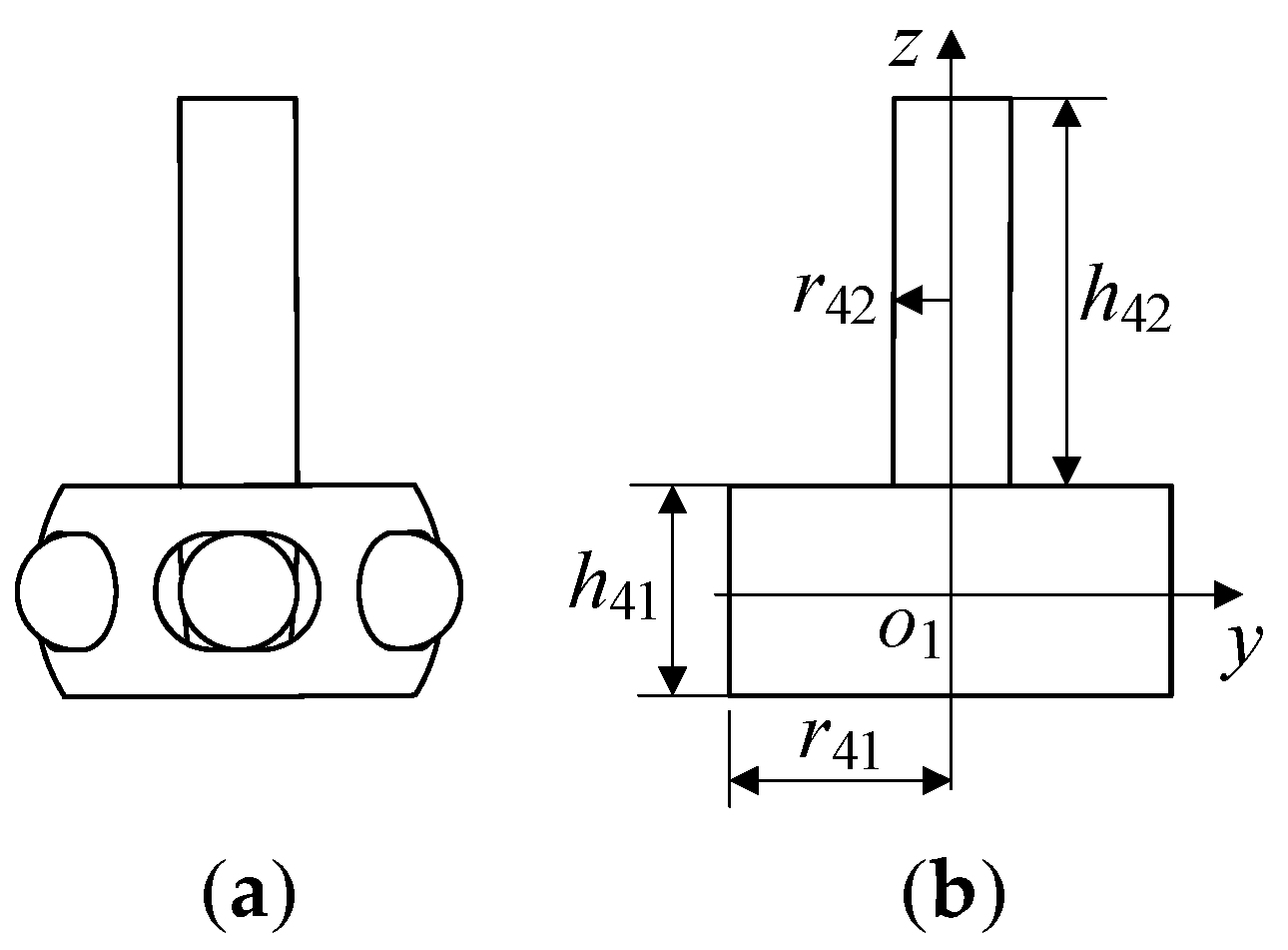

Based on the dimensions of the human glenohumeral joint and the structural parameters and installation posture angle of the spherical hybrid shoulder joint mechanism, a virtual model machine is constructed to simulate human shoulder joint actions. The spatial dimensions and simulated actions of the virtual prototype are shown in

Figure 18. The results show that the spherical hybrid shoulder joint mechanism with an offset design proposed in this paper can complete the relevant task actions of the human shoulder joint and meet the configuration expectations.

6. Conclusions

To improve the workspace, linear displacement stiffness, and driving torque utilization of existing humanoid robot shoulder joint mechanisms, an offset-designed RBR-2RRR spherical hybrid bionic shoulder joint configuration (SHBSJC) is proposed, and its structural parameters are optimized. First, the physiological structure of the shoulder joint is biomimetically designed, a prototype mechanism of the RBR-2RRR SHBSJC is proposed, and its kinematics and velocity Jacobian matrix are solved. Based on finite element static analysis, the deformation response of the RBR-2RRR and 3-RRR under the same load is compared to verify that the proposed mechanism meets the configuration expectation of improving linear displacement stiffness. Considering the workspace and singularity, the constraint conditions that the structural parameters of the prototype mechanism need to satisfy are obtained. Using the GCI and GDCI indicators as optimization functions, we obtain recommended and adopted values for structural parameters. The corresponding diagrams of the LCI and LDCI indicate that mechanism’s motion dexterity and dynamic dexterity meet the configuration expectations. To further increase the prototype mechanism’s workspace and match the human shoulder joint’s motion range, an RBR-2RRR SHBSJC with an offset design is proposed, and the offset angle, installation posture angle, and spatial mapping relationship of the mechanism are determined. The results of the workspace comparison and virtual model machine action simulation indicate that the final configuration meets workspace expectations. This research has enriched the design methods and configuration types of shoulder joints in humanoid robots, providing theoretical guidance and engineering application value for the biomimetic design and development of shoulder joints in humanoid robots.