Abstract

The manufacturing industry continues to suffer from inefficiency, excessively high prices, and uncertainty over product quality. This statement remains accurate despite the increasing use of automation and the significant influence of Industry 4.0 and AI on industrial operations. This review details an extensive analysis of a substantial body of literature on artificial intelligence (AI) and Industry 4.0 to improve the efficiency of material processing in manufacturing. This document includes a summary of key information (i.e., various input tools, contributions, and application domains) on the current production system, as well as an in-depth study of relevant achievements made thus far. The major areas of attention were adaptive manufacturing, predictive maintenance, AI-driven process optimization, and quality control. This paper summarizes how Industry 4.0 technologies like Cyber-Physical Systems (CPS), the Internet of Things (IoT), and big data analytics have been utilized to enhance, supervise, and monitor industrial activities in real-time. These techniques help to increase the efficiency of material processing in the manufacturing process, based on empirical research conducted across different industrial sectors. The results indicate that Industry 4.0 and AI both significantly help to raise manufacturing sector efficiency and productivity. The fourth industrial revolution was formed by AI, technology, industry, and convergence across different engineering domains. Based on the systematic study, this article critically explores the primary limitations and identifies potential prospects that are promising for greatly expanding the efficiency of smart factories of the future by merging Industry 4.0 and AI technology.

1. Introduction

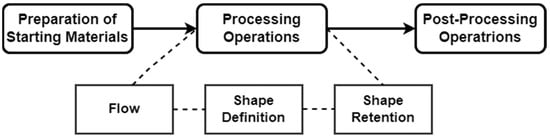

Industry 4.0, which is sometimes referred to as the fourth industrial revolution, is a term that describes the transformation of traditional manufacturing processes into a cyber-physical production system (CPPS) through the utilization of digital technology integrated with physical manufacturing. Through the utilization of real-time data monitoring and the promotion of collaborative efforts within the production team, this system can make assessments and even propose corrective actions [1]. A significant number of small and medium-sized firms, and even many major corporations, are implementing several of the technologies that are part of Industry 4.0 to maintain their position in global competition in terms of cost, quality, productivity, and reliability [2]. Companies integrating Industry 4.0 technologies—the Internet of Things (IoT), cloud computing, and computerized production systems into current facilities are thus turning them into smart factories. The physical systems of a factory are helping us to complete this metamorphosis. Driven by its use of automation and mechanization, a smart factory is an upgraded form of the conventional factory model. It can control a broad spectrum of product manufacture and show agility in reaction to demand fluctuations. This may be accomplished by combining the technology of cyber systems with the manufacture of physical goods [3]. This type of manufacturing, which is connected by real-time data monitoring and continuous data streaming, not only reduces the amount of time needed for production and rework but also enhances the reputation of the company because of its ability to precisely sort materials, anticipate machine failure at an early stage, and recognize and evaluate significant events [4,5,6]. In addition, the deployment of IoT in industrial systems may assist in the early identification of problems, the flexibility to handle design modifications in products, the detection of data anomalies during maintenance, and the implementation of various production processes [7,8,9]. In addition, the use of Industry 4.0 techniques, such as big data analysis and cloud computing, contributes to the development of a distributed production system in which all data and information are centralized and can be employed according to the requirements of the customer [10,11]. These technologies enable the producer to make decisions based on a wide variety of data sources via the means of the identification of major patterns and trends [12]. In addition, the current advancement in the production system known as additive manufacturing has made it possible for producers and customers to have a more intimate relationship with one another through the utilization of these contemporary technologies [12,13]. By establishing a common method of communication using websites and the internet, additive manufacturing (AM) has the potential to enhance the efficiency of the supply chain and facilitate the rapid prototyping of materials [13]. Other new technologies that are part of Industry 4.0 contribute to increased productivity in this way. The combination of lean technologies with Industry 4.0 will also make it possible to create production systems that are both flexible and very cost-effective [14]. Optimizing the processing of materials is another significant emphasis that should be made to increase production efficiency. It is possible to enhance overall efficiency by reducing the amount of time spent on production, improving product quality, and saving a significant amount of money. The processing of additive materials comprises several processes, all of which ought to be better controlled to achieve the goal that is depicted in Figure 1 [15]. Usually, in conjunction with additive processes, the method starts with first preparing the components, wherein materials undergo refinement to increase the general quality of the final print. Using methods like powder-based or wire-based additive manufacturing—in the processing phase—the material is deposited in layers to gradually form the desired geometry. Reaching the intended object dimensions depends on precisely controlling the material deposition. To guarantee that the component has the necessary strength and durability, postprocessing steps like curing, surface finishing and heat treatment are employed. This procedure is crucial to guarantee that the resulting part is accurate, long-lasting, and suitable for use [15].

Figure 1.

Material processing steps during the additive process based on the data in Ref. [15].

Producing a finished product that satisfies the client’s requirements includes a broad range of processes such as casting, forming, machining, and fabrication [15]. Applying Industry 4.0 technologies helps us better control quality and limits the expenditure on such processes; ultimately, it will lead to profitability. To accomplish this objective, the use of manufacturing processes that make use of data analytics and AI is critical to improve product quality and expedite production. All the input variables are guaranteed to be accurate and consistent if a method that is both consistent and rigorous is put into practice [16]. In addition, the deployment of predictive maintenance and the increased utilization of available and pre-deployed resources are two other factors that lead to cost reductions in the industrial sector [17]. An example of these factors is the reduction in expenses related to breakdowns, maintenance, rework, and overhauls. Resilience and flexibility are two qualities that material processing must exhibit if it is to continue to be competitive in the global market. Thanks to the fourth industrial revolution, we can now create a manufacturing line that is adjustable and versatile [18,19]. The development of robots and additive manufacturing has further facilitated collaboration between customers and manufacturing enterprises. This advancement has enabled the rapid creation of initial models and large-scale item customization, eliminating the need for costly equipment modifications.

Role of AI in Enhancing Manufacturing Efficiency

AI is a computer-enabled interactive group of algorithm systems that can execute tasks using its own intellect, like how a human utilizes their brain to fulfill a task or complete an action targeting a desirable outcome within the constraints of a problem. The tasks encompassed by this category [20] comprise the understanding of natural languages, the identification of patterns, and the assessment of independent and unique circumstances, all to propose immediate action as necessary. Among the technologies that are included in the category of AI are machine learning (ML) [21], deep learning [22], computer vision [23], and natural language processing (NLP) [24]. A few examples of these technologies are included in the forthcoming sections. The use of these technologies is being pursued by a wide range of firms to enhance the effectiveness of their internal procedures. A variety of industries make use of these technologies to improve the effectiveness of systems that are deployed inside their own businesses. When it comes to improving the efficiency of production in a variety of industries, AI, just like other types of organizations or businesses, plays a significant role. There are several AI systems that improve the control of processes, the planning of production, and the early identification of faults [25]. Predictive maintenance like condition-based monitoring, advanced data processing methods, and better process control approaches are some of the technologies that should be considered to belong under this category. The use of AI makes it possible to analyze past data and identify trends, abnormalities, etc., which in turn provides direction for the development of recommendations about the upkeep of material manufacturing processes. Several ML techniques have been applied to improve material process parameters, find flaws and defects, and project equipment failure. Using these fixes lowers downtime and helps to reduce manufacturing costs [26]. AI-powered statistical quality control during material processing has allowed companies to significantly reduce rework costs while preserving high accuracy. Improving the efficiency of the industrial sector is one of the several objectives of looking at the combined effects of Industry 4.0 and AI on material handling. By means of the integration of several technologies included in Industry 4.0, industry partners may better grasp the intricacy of the production process. This will help them optimize the efficiency of machinery, tools, and other resources at hand, as well as manage raw materials and monitor their processing across the workflow.

AM processes are developing swiftly to meet client expectations and provide improved product quality as industry needs arise with new data processing technologies. Ashima et al. have postulated that introducing the latest IoT developments into additive manufacturing will help three-dimensional (3D) printing overcome its limitations. This article researched improvements targeting automated 3D printing accuracy for improved surface finish and tolerances, which is currently a problem for most AM processes. Automatic 3D printing systems are a new research challenge, and there is little research on this topic [27]. By introducing machine learning in AM apparatus aimed at implementing AI at an industrial scale, the goal was to boost local manufacturing efficiency. The authors suggested that further integration of AI-equipped AM equipment with Industry 4.0 cloud data would improve production accuracy and rates. According to this research, AI implementation at the local level provided many benefits to the factory, including the rapid identification of process parameters, the choice of application-suitable materials, initial product testing, and improved safety throughout production [28]. AM’s speed, accuracy, reproducibility, and cost may prevent it from being used in industrial facilities for the mass manufacture of standard components. AM has extensive production possibilities because of its material (polymers to metals), size (nanoscale to macroscale), and functionality (self-assembling to excellent heat transfer) [29]. Even with the advanced method and material intended to improve the internal structure and design, there is still a chance that these changes will have a negative effect on the strength of the material. Combining AM and subtractive processes, also called hybrid manufacturing, addresses some of these challenges and allows for part repair and restructuring and product surface quality improvements. Decentralization can also be adopted by using cloud services to distribute production across factories or equipment, thereby allowing SMEs to participate in a global supply chain [30]. Digital manufacturing and 3D printing will also impact society through innovative product design, sustainability, and material efficiency [31]. Another study demonstrated that an AI model monitored Wire + arc additive manufacturing (WAAM) welding processes can identify defects and control feed rate, voltage, current, and process parameters in real time. The ensemble model used here allows for the investigation of process parameter combinations to provide improved fault identification. Generalized WAAM anomaly detection and diversification models are needed for further study. Soon, strong AI models will combine form and high-quality or reliable data [32].

Turning industrial operations into ever more intelligent, flexible, and efficient systems naturally connects AI with Industry 4.0. Industry 4.0 combines digital technology—digital twins, for example—with physical processes to create CPPS, which uses real-time data to improve industrial processes. In this changing paradigm, AI is very crucial, as it makes advanced data analysis possible, data anomaly detection practical, predictive maintenance doable, process optimization possible, and other related uses conceivable. Computer vision and machine learning technologies allow the development of well-informed choices leading to decisions by way of thorough analysis of the enormous data produced by Industry 4.0 systems. Industry 4.0’s synergy with AI drives real-time monitoring, anomaly identification, and adaptive reactions, thereby boosting production. Furthermore, this combination system may increase production, reduce operational interruptions, and attain accuracy, thus enabling the development of intelligent factories.

The primary goal of this review article is to examine the potential methods by which material processing might be improved by combining the capabilities of Industry 4.0 and AI. Another goal is to provide a strategy for leveraging these advantages in current industrial environments. This article assesses the practicality of incorporating some technologies from Industry 4.0 into material processing methods. The main objective of this activity is to ensure that participants have a comprehensive understanding of how Industry 4.0 technologies facilitate the real-time monitoring, control, and optimization of industrial processes. Furthermore, this study will discuss how AI influences the efficiency of many industrial facilities. This work aims to evaluate the use of AI in improving logistics management, thereby providing quality assurance and optimizing processes. The article also considers the different ways in which the integration of AI and technology linked within Industry 4.0 can increase industrial productivity. In addition, there will be an analysis of the problems brought about by the combination of AI and Industry 4.0 and suggestions for how these problems may be overcome. Some emerging concepts, such as cyber security and edge computing etc., will be covered in the latter section of this article.

2. Materials and Methods

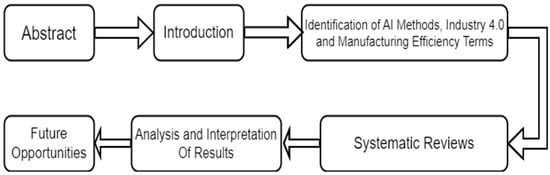

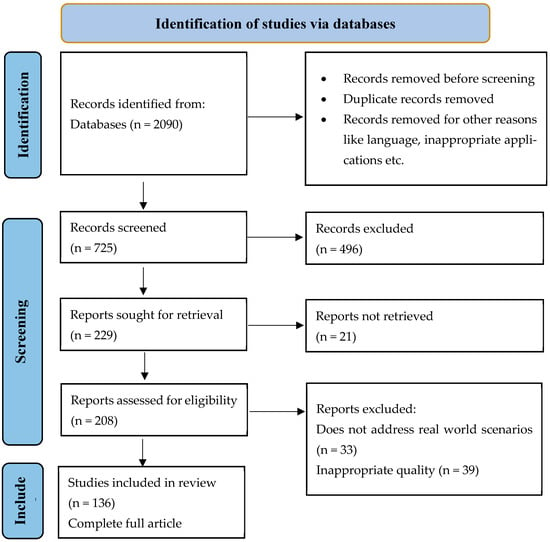

The study’s methodology followed the recommendations provided by PRISMA, which stands for Preferred Reporting Items for Systematic Reviews and Meta-Analyses. Figure 2 depicts the research methodologies used in writing the paper. A literature review search string was generated using the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) criteria. The papers were assessed using a framework developed by identifying the key ideas associated with resource efficiency, business divisions, and AI approaches and important aspects defining current research trends in these areas. Figure 3 illustrates the sequential process of the literature review study.

Figure 2.

Research process.

Figure 3.

Flow diagram of research methodology and literature selection process.

2.1. Research Questions

A total of three research questions (RQ) were formulated in the present study as follows:

- RQ1: What are the Industry 4.0 and AI technologies for improving material processing efficiency?

- RQ2: How can integrating Industry 4.0 with AI technologies optimize manufacturing efficiency?

- RQ3: What are the main challenges in adopting Industry 4.0 and AI technologies for manufacturing, and what future trends and emerging technologies have been proposed to overcome these challenges?

2.2. Search Strategy

Firstly, we performed a keyword search using the logical operators AND/OR in Scopus. Subsequently, we conducted a search by employing relevant keywords in esteemed publications such as Google Scholar, Emerald, MDPI, Sage, Research Gate, Wiley, Taylor & Francis, and other credible sources. We subsequently assessed the titles and abstracts of all the citations retrieved from our search to ascertain their potential significance. Subsequently, we collected the pertinent citations to conduct a comprehensive analysis. A meticulous examination of the bibliographies of all pertinent publications was conducted to conduct a comprehensive literature search. Table 1 provides a comprehensive overview of the search method, encompassing all pertinent facts and websites. In addition, we intended to reach out to authors in cases where research appeared to meet the criteria but did not provide the necessary data. This was performed to obtain supplemental information and, thus, increase the number of studies included in our analysis.

Table 1.

Study selection and databases.

2.3. Study Selection (Inclusion and Exclusion Criteria)

We included all articles focusing on the utilization of AI and Industry 4.0 technologies which were used in various manufacturing or production systems. Ethical approval was not required because this study retrieved and synthesized data from already published studies. Table 2. Illustrates the inclusion and exclusion process of the literature review for the study.

Table 2.

Study selection.

3. Results

3.1. Year-Wise Publication Progress

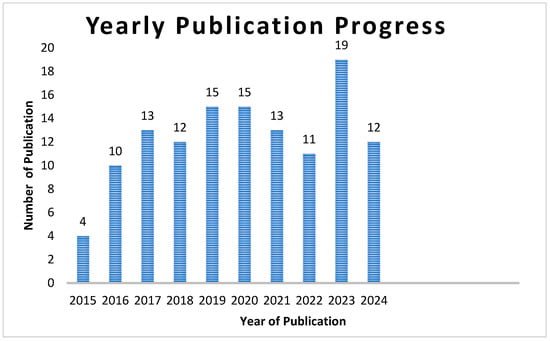

Figure 4 illustrates the yearly publication progress of this topic, revealing a trending nature from 2015 to 2020, followed by a slight decline until 2023. While the reduction in publications is not significant, it is noteworthy that a significant number of researchers are actively engaged in this field.

Figure 4.

Publication progress.

3.2. Highly Cited Papers (Global Citations)

Table 3 presents a summary and the primary contribution of each highly cited paper under consideration for review. From this table, it is clear that many authors from all over the world are working to tackle new challenges and create new opportunities in this area to improve manufacturing efficiency.

Table 3.

Most cited papers.

3.3. Most Productive Journals

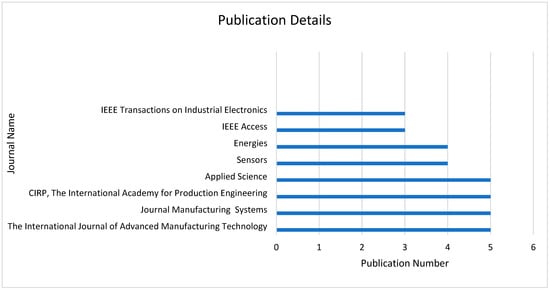

Figure 5 shows the journal's name with their publishing article number which has been published covering this topic.

Figure 5.

Journal-wise publication number.

4. Discussion

- RQ1: What are the Industry 4.0 and AI technologies for improving material processing efficiency?

4.1. Industry 4.0 Technologies in Material Processing

Industry 4.0 has emerged as a new industrial paradigm, where the implementation of various technologies provides a digital capability to network, monitor, and control factory environments. It offers a complex technological structure that transforms traditional material processing techniques into smart manufacturing systems. Figure 6 provides an overview of various Industry 4.0 technologies [33,34]. It combines technologies to provide a digitally managed solution for real-world material processing. It can gather real-time data, monitor the process from a distance, and adjust the process parameters involved in the process correctly. Application of such technologies in various manufacturing processes helps producers improve product quality, reduce waste, respond quickly, save energy, and so on. Table 4 illustrates the various Industry 4.0 technologies and their impact on enhancing manufacturing efficiency in the material processing fields. Reducing material waste, allowing for mass customization, and allowing more complex geometries—which so reduces lead times and production costs—AM helps to improve efficiency [35,36]. This is quite beneficial in sectors like aerospace and automotive, where precision and material economy are vital. Robotics, when tied into AM, offer manufacturing flexibility by reducing uncertainty, reducing human error, and facilitating autonomous task execution. In high-volume companies, this is vital as it results in faster reaction times and high degrees of accuracy and repeatability. Big data analytics, cloud computing, IoT, etc., serve to allow condition monitoring, energy-efficient optimization, and better decision-making all through the production lifecycle by means of a deeper understanding of manufacturing processes. Improved process control, real-time monitoring, and predictive analytics, all of which are strategies spanning major Industry 4.0 technologies, ultimately raise manufacturing efficiency.

Figure 6.

Overview of Industry 4.0 technologies.

Table 4.

Industry 4.0 technologies and their related contributions.

4.1.1. IoT in Material Processing

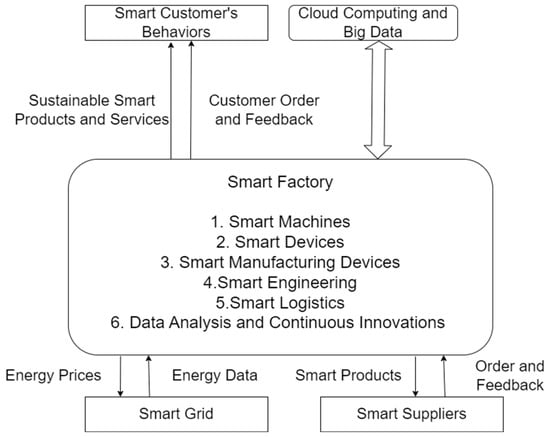

IoT enables electronics included in or subsequently added to physical machines or systems to gather real-time data and network them within cyberspace. It facilitates the connection of multiple manufacturing resources and promotes horizontal integration. This opens a new opportunity for conventional or new manufacturing services to improve manufacturing efficiency [60]. The framework of an IoT-based smart manufacturing system is shown in Figure 7. It provides a system where IoT can network with different facilities and customers to meet the customer specifications.

Figure 7.

IoT based smart factory based on the data in Ref. [60].

4.1.2. Leveraging Big Data Analytics for Material Processing Optimization

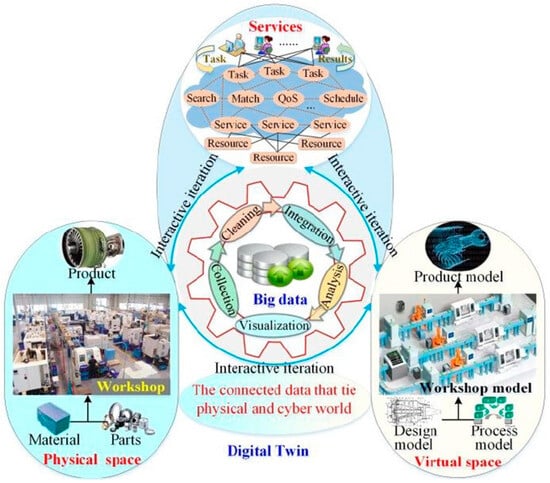

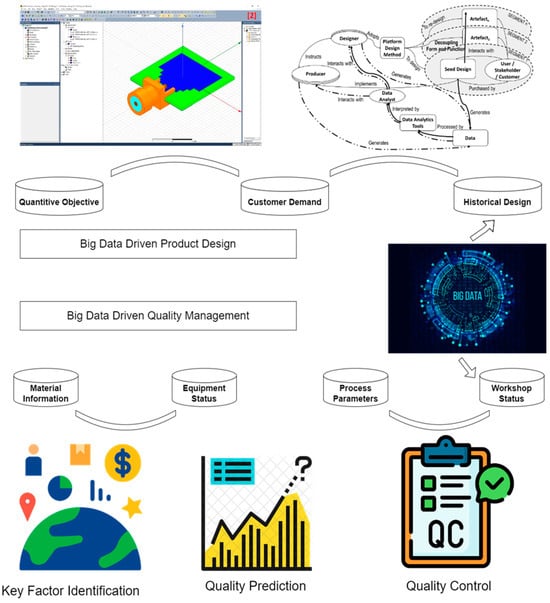

Big data analytics for material processing optimization consists of multiple phases, including data collecting via IoT devices and sensors. To enable accessibility and analysis, several data streams, for example, temperature, pressure, and material qualities, are gathered and combined with a central system. The fusion of DT and big data, as illustrated in Figure 8, was utilized to expedite the product life cycle during the design stage, a goal central to the concept of manufacturing as a service and service-oriented smart manufacturing. This data fusion resulted in the promotion of smart manufacturing, which was beneficial to all aspects of production, like quick product design, production planning, and predictive maintenance [61].

Figure 8.

Fusion among big data, digital twin, and services in manufacturing based on the data in Ref. [61].

Big data can be used to sample information from various engineering areas like design, manufacturing, quality, testing, etc. Design plays an important role in manufacturing processes. Using big data, the design stage is currently transitioning from a subjective conceptual scope to a data-driven one. Big data provides the ability to refine the design, prompt customer response, and promote innovation. Quality plays a crucial role in reducing rework, which in turn boosts productivity. Raw material quality and process parameters are the most important parameters in measuring product quality. Figure 9 [62] discusses the use of big data to measure product quality and improve design stages during material processing. Through its implementation, it can easily be understood that the time involved in the design stage has been decreased, and it allowed more adaptability in the design stages through the assimilation of inputs from customer demand and historical design.

Figure 9.

Big data application in quality measurement based on the data in Ref. [62].

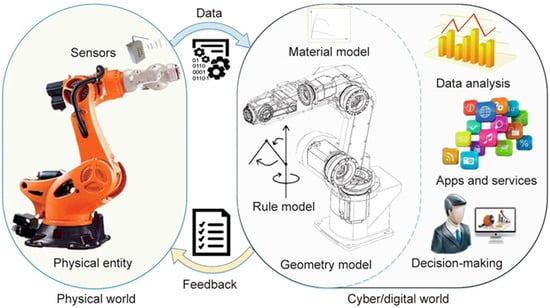

4.1.3. CPS’s Role in Material Processing

CPS is the paradigm of turning a group of physical material processing machines into a flexible production environment by combining data from sensors and actuators installed into and in the immediate surroundings of machines. Analyzing this data helps to optimize process parameters, therefore enhancing the process efficiency and quality. Modern algorithms and embedded sensing enable the widespread implementation of these technologies. The integration of predictive analytics and ML with CPS further improves the ability to forecast productivity and functionality. Furthermore, researchers in the field have expressed significant concerns about the preferred integration method of DTs and CPS. There are two major aspects of manufacturing using CPS and DTs: physical machines and the virtual or digital environment [63]. CPS and DTs can improve manufacturing systems’ resilience, intelligence, and efficiency by creating feedback loops that allow physical processes to influence cyber parts and vice versa [64]. In addition to a variety of widely accessible services and applications, the cyber or digital realm encompasses the intelligent management of information, analysis, and computational capabilities. Figure 10 illustrates the connection between physical entities and the cyber world through sensors and data management.

Figure 10.

Cyber–Physical System based on the data in Ref. [63].

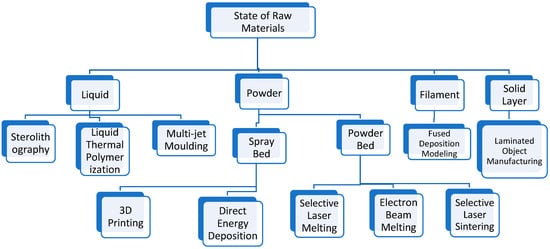

4.1.4. AM and Robotics Integration in Industry 4.0

The integration of AM and robotics in manufacturing processes has enabled the process to be more effective. Several types of AM are available to optimize production efficiency [35], which has been shown in Figure 11.

Figure 11.

Classification of AM based on the data in Ref. [35].

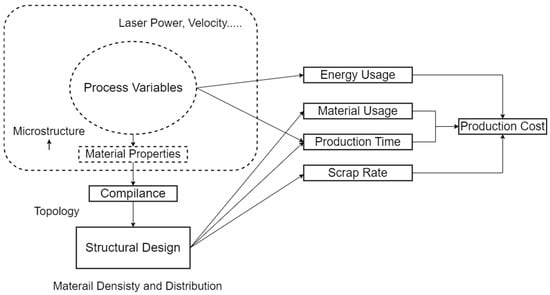

AM allows the creation of complex geometries that are impossible and, at other times, significantly time-consuming in traditional manufacturing [65]. It enables the production of the final product through the layer-by-layer deposition of material using either wire or powder [66]. With robots handling repetitive tasks, a modern factory combining AM, SM and robots runs smoothly and reduces labor cost and time, increasing productivity. More importantly, additive manufacturing (AM) can optimize the material usage rate, leading to waste reduction. The use of robots in these steps aids in precision and safety and reduces errors [67,68], as illustrated in Figure 12. Using concurrent structure and process optimization leads to a 21% reduction in manufacturing costs and a 21% percent faster build time by adopting the cost minimization framework, as shown in Figure 12 [69].

Figure 12.

Cost Optimization framework based on the data in Ref. [69].

4.2. Enhancing Manufacturing Efficiency with AI

Many disciplines have been touched by the AI revolution and its many enabling technologies. Among other advantages, AI has greatly helped to lower waste, boost production efficiency, and lower downtime in the manufacturing sector. Figure 13 shows the main AI technologies that are helping to shape future smart manufacturing systems. Table 5 lists the main AI technologies together with how they affect the pertinent sector.

Figure 13.

Key components of AI.

Table 5.

Mostly used AI tools and their contributions.

These technologies influence smart systems significantly. Two machine learning models that can maximize productivity and reduce industrial waste by parameter adjustment are dynamic programming and regression. Identification of faults in real-time and prevention of significant production problems before they cause catastrophic failure to depend on CNNs and unsupervised learning models. By means of their impact, deep learning models assist in foreseeing material behavior at different production phases, thereby reducing failures and increasing product quality. Robotic and material handling automation of challenging activities also helps to boost production by using reinforcement learning methods [75,76,77]. For the benefit of future manufacturing environments, AI technology is vital for achieving predictive maintenance, real-time monitoring, and complete automation—all essential components of smart industrial systems.

4.2.1. ML Algorithms for Process Optimization

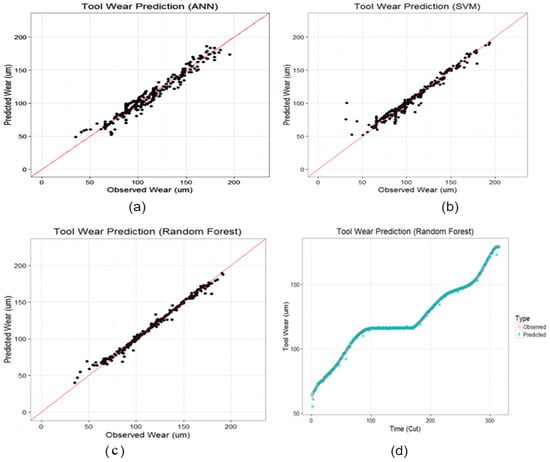

The application of ML algorithms to manufacturing processes has been rapidly gaining popularity in the recent past. The development of ML algorithms such as linear regression [83], random forest (RF) [84], decision trees [85], SVM [86], neural networks [87], clustering algorithms [88], etc. provides the opportunity to establish a relationship between input process parameters and output results [89]. Each of these algorithms has its own characteristics best suited to dealing with different kinds of manufacturing problems. The major applications of ML algorithms are fault analysis [90], process monitoring, condition monitoring, and tool wear [91]. SVM is used to identify faulty products on a manufacturing line. Figure 14 illustrates how several models, such as artificial neural networks (ANN), support vector machines (SVM), and radio frequency (RF), are utilized in numerous production sectors to monitor the quality of components from their product range [89,90,91,92,93,94,95,96]. This information is used to predict tool wear based on historical data, ultimately preventing catastrophic failures and improving efficiency.

Figure 14.

Comparison of observed and predicted values of tool wear using (a) ANN, (b) SVM, (c) RF, (d) Tool wear prediction using SVM based on the data in Ref. [97].

4.2.2. Deep Learning Applications in Material Processing

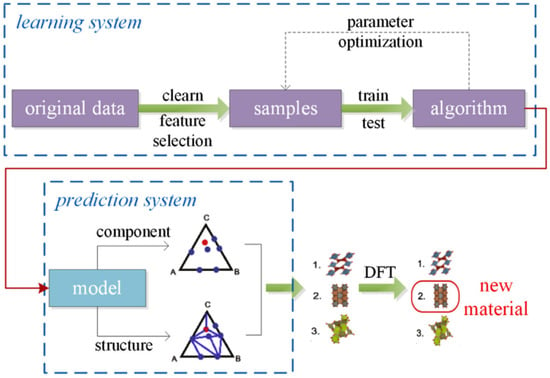

Modern AI methods like deep learning have the potential to be applied for predictive modeling and quality control. Based on their material composition, metallurgical information can be leveraged to estimate the mechanical characteristics of certain alloys. Studies [98] have shown the great degree of accuracy and precision that deep learning displays in classifying products, spotting defects, and identifying defect mechanisms. Deep learning models like CNN and RNN may help in diagnosing machinery problems and prognostic defects [99,100,101,102,103]. Furthermore, a deep learning model can teach itself and forecast target output with great accuracy and dependability by using sensor information. As a result, a deep learning model optimizes process parameters as it builds the relationship between process parameters and output results. These models can predict noble materials like metals with better accuracy and make an impact on new material design [104]. Figure 15. shows the general procedure of material discovery using an ML algorithm, where the model optimizes the process parameters considering material components and structural properties.

Figure 15.

Overview of material discovery by ML based on the data in Ref. [104].

4.2.3. Reinforcement Learning (RL) for Adaptive Manufacturing Systems

RL is a subset of ML models used for high levels of flexibility and responsiveness to changing conditions in adaptable manufacturing systems [105]. Today’s world revolves around increased demand uncertainty, customization, agility, and the use of RL to adapt to changing conditions and minimize waste in production systems. One of the key advantages of RL in manufacturing systems is that it can handle scheduling problems and improve manufacturing systems [106,107,108]. Previously, various heuristic models and mathematical models were employed to enhance their efficiency. The current advancement of RL dramatically changes the scheduling environment by considering the continuous interaction between variables such as machine setup time, job priorities, processing time, and so on [109,110,111]. Eventually, the RL model “reinforced” itself to track sensor data and modify process parameters, hence minimizing faulty products. Furthermore, RL helps robots perform assembly duties in a product assembly line so they may adapt the actuation of their robotic arms in real-time using a feedback control system as part of a sophisticated manufacturing system [112,113].

- RQ2: How integrating Industry 4.0 with AI technologies can optimize manufacturing efficiency in material processing?

5. Integration and Synergies between Industry 4.0 and AI

The incorporation of Industry 4.0 with AI has the potential to significantly enhance industrial efficiency in several areas of material handling. Industry 4.0 uses a variety of technologies to collect data from multiple manufacturing lines within a manufacturing organization. By using AI, these data might be used to spot aberrant trends and faulty components and detect machine breakdowns pre-emptively. Table 6 shows how Industry 4.0 and AI technologies could be used in industrial operations together. For a computer numerical control system, for example, the spindle’s state is vital. The use of AI with Industry 4.0 offers a complete solution for real-time performance prediction and monitoring of a machine tool’s spindle condition. This has moderately increased production efficiency and helped to reduce notable failures [114]. Integration of Industry 4.0 with AI will also help spot anomalies in predictive maintenance in a timely manner. Different modern AI techniques enable early and accurate anomaly identification, therefore lowering the frequency of catastrophic failures that can compromise the reliability of the system and improve output [115]. Big data-based predictive maintenance has been proposed for structuring multi-source data and heterogeneous information to handle machine failure while keeping the system's operability stable. This integration’s effectiveness has been verified, and it can predict the remaining life of several parts of that system [116]. Furthermore, in a production company, data-driven management can improve productivity. The data management model applied in three different case studies and measured data productivity ranged between 30% and 45%, and the overall equipment efficiency is near 85%, which indicates that a suitable method can improve the measurement process of data in the industry 4.0 context [117].

Table 6.

Impact of integration of Industry 4.0 and AI technologies.

The adoption of technologies, including AM, big data analytics, and IoT, has the capacity not only to improve efficiency but also to support more sustainable industrial practices as Industry 4.0 technologies and AI-driven processes continue to transform manufacturing [133]. Emerging AM is intrinsically more economical than conventional manufacturing since it can maximize the deposition of raw materials to create a final shape that directly contributes to environmental sustainability by conserving raw materials and minimizing industrial waste [134]. It also reduces the amount of postprocess work needed, which reduces the waste of raw materials, addressing resource utilization and economic concerns [134]. Using AI for predictive maintenance and process optimization helps manufacturers greatly lower energy usage by adjusting their process parameters. This helps manufacturing sites lower their carbon impact in line with world sustainability targets. Big data analytics, circular economy, and AI combined in supply chain management lower greenhouse gas emissions associated with manufacturing and transportation. Furthermore, the synergy effect of several technologies can decrease resource depletion and lower the environmental impact of product life cycles, therefore supporting a more sustainable manufacturing ecosystem [135,136].

- RQ3: What are the main challenges adopting Industry 4.0 and AI technologies for manufacturing in material processing and what future trends and emerging technologies have been proposed to overcome these challenges?

6. Challenges, Opportunities, and Future Directions

6.1. Addressing Challenges of Adoption of Industry 4.0 and AI

- Integration and compatibility of technology

Most of the industrial manufacturing processes will involve many linked systems, including enterprise resource planning, programming logic controllers, supervisory control from remote areas and data acquisition, DTs, IoT devices, and AI-driven platforms. Thus, the integration of technologies can be challenging. Given the different communication protocols, data formats, and operating standards across such platforms, seamless communication among them would be a major obstacle. In real-time data management and decision-making, consistency, quality, and accuracy will be challenging as every system produces unique data.

- Cybersecurity risks and data privacy

Industry 4.0 connects large numbers of devices, coupled with AI-driven analytics, cloud computing, and other technologies that greatly expand the attack points for cyber-attacks. Moreover, many industrial organizations depend on legacy systems and equipment not intended with contemporary cyber security in mind, so replacing existing systems with new ones presents both logistical and economic problems.

- Skills deficit and workforce development

Constant technological developments call for staff to be always learning and evolving. Managing complicated algorithms, data analytics, and operational process integration will be needed for either knowledge in one sector or competence in another. The most difficult features of implementation of these systems might be fear of job displacement, opposition to change, and inexperience with tools.

- Feasibility study of finance

Implementation of the system will necessitate an assessment of upfront technological expenses, including initial investment in hardware, software, infrastructure updates, and training. For a manufacturing firm, cost-benefit analysis, net present value study, and internal rate of return can determine if such a system is practical or not.

- Scalability and adaptability

There is a significant need to evaluate the increasing demand and ambiguity of the procedures involved in this system. In an atmosphere of uncertainty, how will this future system manage several procedures, machines, and stakeholders? The key will be maintaining operational agility, promoting sustainable development, and grabbing possibilities in an increasingly competitive world.

- Real-time data processing and analysis

In an Industry 4.0 environment, the volume of data generated will be exceptionally large, so handling it can be challenging, potentially creating bottlenecks in various manufacturing processes. Furthermore, data integration and data transformation capabilities will be difficult because the data will come from a variety of sources, such as machines, products, IoT sensors, and so on.

- Supply chain integration and collaboration

Emerging distributed digital factories enable various factories from all over the world to be brought under one umbrella. Involving multiple suppliers, manufacturers, distributors, and other stakeholders across different geographic regions will make any supply chain more complicated. A lack of integrated data systems and standardized communication channels can lead to inefficiencies, inaccuracies, and delays in information insight into the systems.

6.2. Future Directions: Emerging Trends

- Edge computing

The reduction of latency and the improvement of security will make it feasible for industrial manufacturing processes to perform real-time data processing or decision-making. Currently, technological advancements are continuing to occur at a breakneck speed, which makes this real-time decision-making feasible. As a result of the provision of predictive maintenance, it improves the effectiveness of the production line, optimizes the efficiency of the resources that are available for raw materials, and considerably increases the availability of the machine.

- DTs

DTs create virtual replicas of physical assets, processes, and systems that can be used for real-time process monitoring, predicting, and optimizing performance. If any mismatch or anomalous data are discovered during operations without human intervention, it allows for real-time correction. It will also facilitate the testing of new processes and materials in a virtual environment, which reduces time and resources and eliminates physical prototypes and the need to perform excessive amounts of experimentation.

- AI-driven automation

With contemporary AI technologies, optimizing resource usage, increasing quality assurance, and simplifying supply chain management might be convenient and easier. Organizing and managing large amounts of data from equipment, machinery, retailers, and suppliers enables us to spot abnormalities and investigate data trends. It can also enable the system to be anticipated and changed to lower disruption.

- Blockchain throughout the supply chain

Blockchain technology assures accountability, transparency, traceability, and efficiency by providing a clear and immutable record, reducing paperwork, eliminating fraud, and thereby accelerating transactions. Blockchain offers data security by means of robust encryption and distributed storage, therefore lowering data tempering. It also speeds the process and offers a single source of right information, therefore enabling manufacturers to exactly monitor the source and movement of products and supplies. AI and blockchain, taken together, will enhance demand forecasting, predictive analytics, and real-time decision-making. Blockchain technology allows one to create and manage digital twins, virtual replicas of real-world assets, data integrity assurance, and asset management improvement. Blockchain-as-a-service, asset tokenizing, and distributed manufacturing networks might all give way to smart manufacturing systems.

- Circular economy

By means of Industry 4.0 technology and AI integration with the concepts of circular economy, objects can endure longer, therefore reducing the necessity for frequent replacements. Manufacturers might also maximize resource use, reduce waste, and raise the quality of their goods. Future routes in circular economy application indicated here will be energy efficiency, material traceability, and acceptance of green manufacturing processes.

- Standardization and Development of Interoperability of Industrial Protocols in Industry 4.0

The rapid progress of Industry 4.0 technologies has made it possible to integrate all machines, raw materials, devices, and diverse systems into a single networked system. Most old machines adhere to different protocols, which poses a barrier to their integration and operations. Adhering to standard communication protocols and fostering interoperability can effectively resolve these issues. For real-time data exchange, a real-time feedback system and efficient machine-to-machine communication can be possible through some of the emerging universal protocols and languages, like OPC UA (Open Platform Communications Unified Architecture) and MQTT (Message Queuing Telemetry Transport). Lastly, interoperability helps manufacturers to connect with several vendors or suppliers with various technologies from different parts of the globe, which helps to ensure the more recent technologies and quickly integrated and adopted and benefit the broader ecosystem.

- Preventive Maintenance Using Advanced AI

AI-driven maintenance management has already successfully overcome some of the situations in traditional experience-based preventative or corrective maintenance. The new system allows any user to know the current conditions and potential future failure modes of machines or parts in the manufacturing system, which reduces machine breakdown costs, unplanned downtime, and losses of manufacturing productivity due to accidental failures, etc. The application of digital twin and sensor data can help to analyze data trends in real-time by using AI and can easily detect and propose corrective action for any failure condition before the actual event happens to cause significant disruption to the manufacturing environment.

- Evolution of Cybersecurity from Industry 4.0 to 5.0

Cybersecurity now plays a major and more complicated role as the paradigm moves from Industry 4.0 to Industry 5.0. Under one roof, several machines in Industry 4.0 are linked and instantly share their data from one to another. In these situations, more connections via IoT, cloud services, and digital twin models might pose several hazards targeted at data theft or the insertion of harmful information into the actual system. This calls for strong defenses against industrial espionage, network invasions, and data breaches. Under Industry 5.0, systems combine AI models, AI-driven automation, and human-machine interfaces. Blockchain technology may help by providing immutable records, protecting communication channels, and securely distributing data storage in the current challenging cybersecurity management.

- Adaptation of Industry 4.0 Technologies for Small and Medium-sized Enterprises (SMEs)

Among the several challenges SMEs must overcome to operate effectively in the industrial environment are lack of capital investment and in-house knowledge to implement advanced technology systems such as IoT-based devices, AI-driven automation, and smart manufacturing solutions. One may circumvent these conditions by employing cloud-based solutions by reducing the cost of major upfront hardware/software/know-how purchases. Emerging IoT-based gadgets give real-time data insights that help to improve operational efficiency. Standardized technologies enable the integration of new systems into existing infrastructure, therefore enabling SMEs to adapt. Cooperative networks where SMEs may share operational knowledge, technology resources, and even expertise would help the group’s development and digital transformation thereby enabling SMEs to remain competitive by raising production efficiency. Through their adoption of these synergistic technologies, SMEs should embrace Industry 4.0’s benefits to accelerate material processing, maximize resource efficiency, and increase general industrial efficiency.

7. Conclusions

This study used a systematic literature review (SLR) technique to determine the current research developments in Industry 4.0 and AI. The study included various well-known scientific databases, like IEEE, Web of Science, Scopus, etc., under an SLR. After screening, 143 papers were chosen for review. Generally, Industry 4.0 technologies improve industrial productivity, response times, and production efficiency, among other aspects. It is clear from the research articles discussed in this paper that manufacturing has advanced rapidly as a network-based manufacturing paradigm. Industries are adopting Industry 4.0’s enabling technologies—blockchain, big data, AI, IoT, etc.—to gather and examine data during the many phases of a product’s life. According to this literature study, Industry 4.0 and AI have a significant impact on production efficiency and productivity across all these phases. Still, study in this field is less than what is warranted because of a lack of combined consideration of Industry 4.0 and AI. To help overcome these research constraints, the authors theorized avenues of further research in several fields. This SLR highlights the following significant contributions:

- Firstly, this paper explores the current functions and potential of Industry 4.0 technologies in various production processes across various types of raw material processing companies. Furthermore, this work examines the impact of various Industry 4.0 technologies on all aspects of manufacturing process enhancement, which will benefit future research:

- Secondly, this paper highlights the most significant AI technologies, which, through a thorough application in many manufacturing subsystems, have demonstrated an increase in their performance through data anomaly detection, process parameter and resource optimization, and waste reduction;

- Thirdly, this study adopted the PRISMA method for an SLR and explores several options for manufacturing efficiency improvement through the synergistic influence of Industry 4.0 and AI technologies. The technologies of AI and Industry 4.0 and their impacts are as follows:

- RNN, Logistics Regressor with IoT, Cloud Computing, and Simulation have a significant synergistic effect on early fault detection, quality control, and the identification of anonymous data;

- Various ML algorithms with integration of Industry 4.0 are capable of handling real-time monitoring, prediction, and condition-based monitoring, allowing for the visualization of warnings and errors in any production system.

Finally, this literature study identified some research challenges and concerns, as well as future trending technologies. The study offers valuable insights to both industry leaders and academics. Future research should scale beyond Industry 4.0 and focus on developing a framework that integrates several Industry 5.0 technologies with AI technologies to enhance efficiency, productivity, and sustainability in both large corporations as well as small businesses. Moreover, blockchain and other advanced technologies, when coupled with Industry 5.0 and AI, should greatly raise near-future production efficiency and security.

Author Contributions

Conceptualization, M.S.A. and S.P.I.; methodology, M.S.A. and S.P.I.; software, M.S.A.; validation, M.S.A. and S.P.I.; formal analysis, M.S.A. and S.P.I.; investigation, M.S.A. and S.P.I.; resources, F.L.; data curation, M.S.A. and S.P.I.; writing—original draft preparation, M.S.A. and S.P.I.; writing—review and editing, M.S.A., S.P.I. and F.L.; visualization, M.S.A. and S.P.I.; supervision, S.P.I. and F.L.; project administration, F.L.; funding acquisition, F.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially funded by NSF Grants CMMI 1625736 and EEC 1937128, and the Intelligent Systems Center at Missouri University of Science and Technology.

Data Availability Statement

No new data were created.

Conflicts of Interest

Not applicable.

References

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Masood, T.; Sonntag, P. Industry 4.0: Adoption challenges and benefits for SMEs. Comput. Ind. 2020, 121, 103261. [Google Scholar] [CrossRef]

- Kalsoom, T.; Ramzan, N.; Ahmed, S.; Ur-Rehman, M. Advances in Sensor Technologies in the Era of Smart Factory and Industry 4.0. Sensors 2020, 20, 6783. [Google Scholar] [CrossRef]

- Agrifoglio, R.; Cannavale, C.; Laurenza, E.; Metallo, C. How emerging digital technologies affect operations management through co-creation. Empirical evidence from the maritime industry. Prod. Plan. Control 2017, 28, 1298–1306. [Google Scholar] [CrossRef]

- Radziwon, A.; Bilberg, A.; Bogers, M.; Madsen, E.S. The Smart Factory: Exploring Adaptive and Flexible Manufacturing Solutions. Procedia Eng. 2014, 69, 1184–1190. [Google Scholar] [CrossRef]

- Gattullo, M.; Scurati, G.W.; Fiorentino, M.; Uva, A.E.; Ferrise, F.; Bordegoni, M. Towards augmented reality manuals for industry 4.0: A methodology. Robot. Comput. Integr. Manuf. 2019, 56, 276–286. [Google Scholar] [CrossRef]

- Haji, S.H.; Ameen, S.Y. Attack and Anomaly Detection in IoT Networks using Machine Learning Techniques: A Review. Asian J. Res. Comput. Sci. 2021, 9, 30–46. [Google Scholar] [CrossRef]

- Conway, J. The Industrial Internet of Things: An Evolution to a Smart Manufacturing Enterprise. Schneider Electric Whitepaper. 2015. Available online: https://it-resource.schneider-electric.com/white-papers/the-industrial-internet-of-things-an-evolution-to-a-smart-manufacturing-enterprise (accessed on 5 October 2020).

- Soori, M.; Arezoo, B.; Dastres, R. Internet of things for smart factories in industry 4.0, a review. Internet Things Cyber-Phys. Syst. 2023, 3, 192–204. [Google Scholar] [CrossRef]

- Georgakopoulos, D.; Jayaraman, P.P.; Fazia, M.; Villari, M.; Ranjan, R. Internet of Things and Edge Cloud Computing Roadmap for Manufacturing. IEEE Cloud Comput. 2016, 3, 66–73. [Google Scholar] [CrossRef]

- Abell, J.A.; Chakraborty, D.; Escobar, C.A.; Im, K.H.; Wegner, D.M.; Wincek, M.A. Big Data-Driven Manufacturing—Process-Monitoring-for-Quality Philosophy. J. Manuf. Sci. Eng. 2017, 139, 101009. [Google Scholar] [CrossRef]

- Li, L. Research on the Characteristics of Industrial Talent Demand Depending on Big Data Technology. J. Electr. Syst. 2024, 20, 1259–1271. [Google Scholar] [CrossRef]

- Beidouri, Z.; Naji, A.; Fadile, L. Supply Chain Management for Additive Manufacturing; Springer International Publishing: Cham, Switzerland, 2023. [Google Scholar]

- Ding, B.; Ferràs Hernández, X.; Agell Jané, N. Combining lean and agile manufacturing competitive advantages through Industry 4.0 technologies: An integrative approach. Prod. Plan. Control 2023, 34, 442–458. [Google Scholar] [CrossRef]

- Francis, L.F. Introduction to Materials Processing. In Materials Processing; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–20. [Google Scholar]

- Arinez, J.F.; Chang, Q.; Gao, R.X.; Xu, C.; Zhang, J. Artificial Intelligence in Advanced Manufacturing: Current Status and Future Outlook. J. Manuf. Sci. Eng. 2020, 142, 110804. [Google Scholar] [CrossRef]

- Achouch, M.; Dimitrova, M.; Ziane, K.; Sattarpanah Karganroudi, S.; Dhouib, R.; Ibrahim, H.; Adda, M. On Predictive Maintenance in Industry 4.0: Overview, Models, and Challenges. Appl. Sci. 2022, 12, 8081. [Google Scholar] [CrossRef]

- Azarian, M.; Yu, H.; Solvang, W.D. Correction to: Integrating Additive Manufacturing into a Virtual Industry 4.0 Factory. In Advanced Manufacturing and Automation X 10; Springer: Singapore, 2021. [Google Scholar]

- Bhatt, P.M.; Malhan, R.K.; Shembekar, A.V.; Yoon, Y.J.; Gupta, S.K. Expanding capabilities of additive manufacturing through use of robotics technologies: A survey. Addit. Manuf. 2020, 31, 100933. [Google Scholar] [CrossRef]

- Rao, A.S.S.; Rao, C.R.; Krantz, S. Artificial Intelligence; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Nozari, H.; Ghahremani-Nahr, J.; Szmelter-Jarosz, A. AI and machine learning for real-world problems. In Advances in Computers; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Wang, S.; Zhang, J.; Wang, P.; Law, J.; Calinescu, R.; Mihaylova, L. A deep learning-enhanced Digital Twin framework for improving safety and reliability in human–robot collaborative manufacturing. Robot. Comput. Integr. Manuf. 2024, 85, 102608. [Google Scholar] [CrossRef]

- O’Donovan, C.; Giannetti, C.; Pleydell-Pearce, C. Revolutionising the Sustainability of Steel Manufacturing Using Computer Vision. Procedia Comput. Sci. 2024, 232, 1729–1738. [Google Scholar] [CrossRef]

- Costa, A.P.O.; Seabra, M.R.R.; César de Sá, J.M.A.; Santos, A.D. Manufacturing process encoding through natural language processing for prediction of material properties. Comput. Mater. Sci. 2024, 237, 112896. [Google Scholar] [CrossRef]

- Waltersmann, L.; Kiemel, S.; Stuhlsatz, J.; Sauer, A.; Miehe, R. Artificial Intelligence Applications for Increasing Resource Efficiency in Manufacturing Companies—A Comprehensive Review. Sustainability 2021, 13, 6689. [Google Scholar] [CrossRef]

- Hassani, I.; Mazgualdi, C.E.; Masrour, T. Artificial Intelligence and Machine Learning to Predict and Improve Efficiency in Manufacturing Industry; IEEE: New York, NY, USA, 2019. [Google Scholar]

- Ashima, R.; Haleem, A.; Bahl, S.; Javaid, M.; Kumar Mahla, S.; Singh, S. Automation and manufacturing of smart materials in additive manufacturing technologies using Internet of Things towards the adoption of industry 4.0. Mater. Today Proc. 2021, 45, 5081–5088. [Google Scholar] [CrossRef]

- Kaleem, M.A.; Khan, M. Significance of Additive Manufacturingfor Industry 4.0 with Introduction of Artificial Intelligence in Additive Manufacturing Regimes. In Proceedings of the 2020 17th International Bhurban Conference on Applied Sciences and Technology (IBCAST), Islamabad, Pakistan, 14–18 January 2020; IEEE: New York, NY, USA, 2020; pp. 152–156. [Google Scholar]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations. J. Manuf. Sci. Eng. 2015, 137, 014001. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput.-Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Lee, C.; Seo, G.; Kim, D.B.; Kim, M.; Shin, J.-H. Development of Defect Detection AI Model for Wire + Arc Additive Manufacturing Using High Dynamic Range Images. Appl. Sci. 2021, 11, 7541. [Google Scholar] [CrossRef]

- Hernandez Korner, M.E.; Lambán, M.P.; Albajez, J.A.; Santolaria, J.; Ng Corrales, L.d.C.; Royo, J. Systematic Literature Review: Integration of Additive Manufacturing and Industry 4.0. Metals 2020, 10, 1061. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Despeisse, M.; Ford, S. The Role of Additive Manufacturing in Improving Resource Efficiency and Sustainability. In Proceedings of the Advances in Production Management Systems: Innovative Production Management Towards Sustainable Growth: IFIP WG 5.7 International Conference, APMS 2015, Tokyo, Japan, 7–9 September 2015. [Google Scholar]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Lakshmanan, R.; Nyamekye, P.; Virolainen, V.-M.; Piili, H. The convergence of lean management and additive manufacturing: Case of manufacturing industries. Clean. Eng. Technol. 2023, 13, 100620. [Google Scholar] [CrossRef]

- Li, M.; Milojević, A.; Handroos, H. Robotics in Manufacturing—The Past and the Present. In Technical, Economic and Societal Effects of Manufacturing 4.0; Springer International Publishing: Cham, Switzerland, 2020; pp. 85–95. [Google Scholar]

- Parmar, H.; Khan, T.; Tucci, F.; Umer, R.; Carlone, P. Advanced robotics and additive manufacturing of composites: Towards a new era in Industry 4.0. Mater. Manuf. Process 2022, 37, 483–517. [Google Scholar] [CrossRef]

- Gavin Lai, N.Y.; Jayasekara, D.; Wong, K.H.; Yu, L.J.; Kang, H.S.; Pawar, K.; Zhu, Y. Advanced Automation and Robotics for High Volume Labour-Intensive Manufacturing. In Proceedings of the 2020 International Congress on Human-Computer Interaction, Optimization and Robotic Applications (HORA), Ankara, Turkey, 26–27 June 2020; IEEE: New York, NY, USA, 2020; pp. 1–9. [Google Scholar]

- Huang, Z.; Shen, Y.; Li, J.; Fey, M.; Brecher, C. A Survey on AI-Driven Digital Twins in Industry 4.0: Smart Manufacturing and Advanced Robotics. Sensors 2021, 21, 6340. [Google Scholar] [CrossRef]

- Ramírez, H.; Mendoza, E.; Mendoza, M.; González, E. Application of Augmented Reality in Statistical Process Control, to Increment the Productivity in Manufacture. Procedia Comput. Sci. 2015, 75, 213–220. [Google Scholar] [CrossRef]

- Novak-Marcincin, J.; Barna, J.; Janak, M.; Novakova-Marcincinova, L. Augmented Reality Aided Manufacturing. Procedia Comput. Sci. 2013, 25, 23–31. [Google Scholar] [CrossRef]

- Nee, A.Y.C.; Ong, S.K. Virtual and Augmented Reality Applications in Manufacturing. IFAC Proc. Vol. 2013, 46, 15–26. [Google Scholar] [CrossRef]

- Bello, S.A.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Davila Delgado, J.M.; Akanbi, L.A.; Ajayi, A.O.; Owolabi, H.A. Cloud computing in construction industry: Use cases, benefits and challenges. Autom. Constr. 2021, 122, 103441. [Google Scholar] [CrossRef]

- Gangadhara, B. Optimizing Cloud–Based Manufacturing: A Study on Service and Development Models. Int. J. Sci. Res. 2023, 12, 2487–2491. [Google Scholar] [CrossRef]

- Haghnegahdar, L.; Joshi, S.S.; Dahotre, N.B. From IoT-based cloud manufacturing approach to intelligent additive manufacturing: Industrial Internet of Things—An overview. Int. J. Adv. Manuf. Technol. 2022, 119, 1461–1478. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, Y.; Da Xu, L.; Zhang, L.; Li, B.H. CCIoT-CMfg: Cloud Computing and Internet of Things-Based Cloud Manufacturing Service System. IEEE Trans. Ind. Inform. 2014, 10, 1435–1442. [Google Scholar] [CrossRef]

- Caputo, A.; Marzi, G.; Pellegrini, M.M. The Internet of Things in manufacturing innovation processes. Bus. Process Manag. J. 2016, 22, 383–402. [Google Scholar] [CrossRef]

- Saravanan, G.; Parkhe, S.S.; Thakar, C.M.; Kulkarni, V.V.; Mishra, H.G.; Gulothungan, G. Implementation of IoT in production and manufacturing: An Industry 4.0 approach. Mater. Today Proc. 2022, 51, 2427–2430. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Wang, S.; Liang, Y.C.; Li, W.D.; Cai, X.T. Big Data enabled Intelligent Immune System for energy efficient manufacturing management. J. Clean. Prod. 2018, 195, 507–520. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, S.; Liu, Y.; Si, S. A big data analytics architecture for cleaner manufacturing and maintenance processes of complex products. J. Clean. Prod. 2017, 142, 626–641. [Google Scholar] [CrossRef]

- He, Q.P.; Wang, J. Statistical process monitoring as a big data analytics tool for smart manufacturing. J. Process Control 2018, 67, 35–43. [Google Scholar] [CrossRef]

- Shang, C.; You, F. Data Analytics and Machine Learning for Smart Process Manufacturing: Recent Advances and Perspectives in the Big Data Era. Engineering 2019, 5, 1010–1016. [Google Scholar] [CrossRef]

- Teti, R.; Jemielniak, K.; O’Donnell, G.; Dornfeld, D. Advanced monitoring of machining operations. CIRP Ann. 2010, 59, 717–739. [Google Scholar] [CrossRef]

- Tapia, G.; Elwany, A. A Review on Process Monitoring and Control in Metal-Based Additive Manufacturing. J. Manuf. Sci. Eng. 2014, 136, 060801. [Google Scholar] [CrossRef]

- Mourtzis, D. Simulation in the design and operation of manufacturing systems: State of the art and new trends. Int. J. Prod. Res. 2020, 58, 1927–1949. [Google Scholar] [CrossRef]

- Negahban, A.; Smith, J.S. Simulation for manufacturing system design and operation: Literature review and analysis. J. Manuf. Syst. 2014, 33, 241–261. [Google Scholar] [CrossRef]

- Yang, C.; Shen, W.; Wang, X. Applications of Internet of Things in manufacturing. In Proceedings of the 2016 IEEE 20th International Conference on Computer Supported Cooperative Work in Design (CSCWD), Nanchang, China, 4–6 May 2016; IEEE: New York, NY, USA, 2016; pp. 670–675. [Google Scholar]

- Qi, Q.; Tao, F. Digital Twin and Big Data Towards Smart Manufacturing and Industry 4.0: 360 Degree Comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Wang, J.; Xu, C.; Zhang, J.; Zhong, R. Big data analytics for intelligent manufacturing systems: A review. J. Manuf. Syst. 2022, 62, 738–752. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-physical systems in manufacturing. CIRP Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Fidan, I.; Naikwadi, V.; Alkunte, S.; Mishra, R.; Tantawi, K. Energy Efficiency in Additive Manufacturing: Condensed Review. Technologies 2024, 12, 21. [Google Scholar] [CrossRef]

- Guo, Q.; Su, Z. The Application of Industrial Robot and the High-Quality Development of Manufacturing Industry: From a Sustainability Perspective. Sustainability 2023, 15, 12621. [Google Scholar] [CrossRef]

- Licardo, J.T.; Domjan, M.; Orehovački, T. Intelligent Robotics—A Systematic Review of Emerging Technologies and Trends. Electronics 2024, 13, 542. [Google Scholar] [CrossRef]

- Ulu, E.; Huang, R.; Kara, L.B.; Whitefoot, K.S. Concurrent Structure and Process Optimization for Minimum Cost Metal Additive Manufacturing. J. Mech. Des. 2019, 141, 061701. [Google Scholar] [CrossRef]

- Wuest, T.; Irgens, C.; Thoben, K.-D. An approach to monitoring quality in manufacturing using supervised machine learning on product state data. J. Intell. Manuf. 2014, 25, 1167–1180. [Google Scholar] [CrossRef]

- Shafiq, M.; Thakre, K.; Krishna, K.R.; Robert, N.J.; Kuruppath, A.; Kumar, D. Continuous quality control evaluation during manufacturing using supervised learning algorithm for Industry 4.0. Int. J. Adv. Manuf. Technol. 2023. [Google Scholar] [CrossRef]

- Mubaid, H.; Al Nasr, E.S.A.; Hussein, M. A methodology for mining material properties with unsupervised learning. Int. J. Rapid Manuf. 2009, 1, 237. [Google Scholar] [CrossRef]

- Radha, P.; Selvakumar, N.; Sekar, J.R.; Johnsonselva, J.V. Supervised and unsupervised learning for characterising the industrial material defects. Int. J. Bus. Intell. Data Min. 2022, 21, 233. [Google Scholar] [CrossRef]

- Larsen, S.; Hooper, P.A. Deep semi-supervised learning of dynamics for anomaly detection in laser powder bed fusion. J. Intell. Manuf. 2022, 33, 457–471. [Google Scholar] [CrossRef]

- Govindaiah, S.; Petty, M.D. Applying reinforcement learning to plan manufacturing material handling. Discov. Artif. Intell. 2021, 1, 8. [Google Scholar] [CrossRef]

- Zimmerling, C.; Poppe, C.; Stein, O.; Kärger, L. Optimisation of manufacturing process parameters for variable component geometries using reinforcement learning. Mater. Des. 2022, 214, 110423. [Google Scholar] [CrossRef]

- Dharmadhikari, S.; Menon, N.; Basak, A. A reinforcement learning approach for process parameter optimization in additive manufacturing. Addit. Manuf. 2023, 71, 103556. [Google Scholar] [CrossRef]

- Li, Y.; Yan, H.; Zhang, Y. A Deep Learning Method for Material Performance Recognition in Laser Additive Manufacturing. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; IEEE: New York, NY, USA, 2019; pp. 1735–1740. [Google Scholar]

- Wang, P.; Gao, R.X.; Yan, R. A deep learning-based approach to material removal rate prediction in polishing. CIRP Ann. 2017, 66, 429–432. [Google Scholar] [CrossRef]

- Zhang, Z.; Fidan, I.; Allen, M. Detection of Material Extrusion In-Process Failures via Deep Learning. Inventions 2020, 5, 25. [Google Scholar] [CrossRef]

- Bhuvaneswari, V.; Priyadharshini, M.; Deepa, C.; Balaji, D.; Rajeshkumar, L.; Ramesh, M. Deep learning for material synthesis and manufacturing systems: A review. Mater. Today Proc. 2021, 46, 3263–3269. [Google Scholar] [CrossRef]

- Liu, X.; Aldrich, C. Deep Learning Approaches to Image Texture Analysis in Material Processing. Metals 2022, 12, 355. [Google Scholar] [CrossRef]

- Maulud, D.; Abdulazeez, A.M. A Review on Linear Regression Comprehensive in Machine Learning. J. Appl. Sci. Technol. Trends 2020, 1, 140–147. [Google Scholar] [CrossRef]

- Guan, B.; Wang, D.; Shu, D.; Zhu, S.; Ji, X.; Sun, B. Data-driven casting defect prediction model for sand casting based on random forest classification algorithm. China Foundry 2024, 21, 137–146. [Google Scholar] [CrossRef]

- Arulprakash, M.; Raman, R.; Gokhale, A.A.; Saravanan, K.; Ishwarya, M.V.; Sujatha, S. Adaptive Cleaning in Manufacturing: A Decision Tree Model for Efficient Factory Sanitation. In Proceedings of the 2024 4th International Conference on Innovative Practices in Technology and Management (ICIPTM), Noida, India, 21–23 February 2024; IEEE: New York, NY, USA, 2024; pp. 1–5. [Google Scholar]

- Zhang, C.; Liu, H.; Zhou, Q.; Wang, Y. A support vector regression-based method for modeling geometric errors in CNC machine tools. Int. J. Adv. Manuf. Technol. 2024, 131, 2691–2705. [Google Scholar] [CrossRef]

- Wang, H.; Li, B.; Lei, L.; Xuan, F. Uncertainty-aware fatigue-life prediction of additively manufactured Hastelloy X superalloy using a physics-informed probabilistic neural network. Reliab. Eng. Syst. Saf. 2024, 243, 109852. [Google Scholar] [CrossRef]

- Fattoruso, G.; Barbati, M.; Ishizaka, A. An AHP parsimonious based approach to handle manufacturing errors in production processes. Prod. Plan. Control 2024, 1–30. [Google Scholar] [CrossRef]

- Wuest, T.; Weimer, D.; Irgens, C.; Thoben, K.-D. Machine learning in manufacturing: Advantages, challenges, and applications. Prod. Manuf. Res. 2016, 4, 23–45. [Google Scholar] [CrossRef]

- Salahshoor, K.; Kordestani, M.; Khoshro, M.S. Fault detection and diagnosis of an industrial steam turbine using fusion of SVM (support vector machine) and ANFIS (adaptive neuro-fuzzy inference system) classifiers. Energy 2010, 35, 5472–5482. [Google Scholar] [CrossRef]

- Sun, J.; Rahman, M.; Wong, Y.S.; Hong, G.S. Multiclassification of tool wear with support vector machine by manufacturing loss consideration. Int. J. Mach. Tools Manuf. 2004, 44, 1179–1187. [Google Scholar] [CrossRef]

- Widodo, A.; Yang, B.-S. Support vector machine in machine condition monitoring and fault diagnosis. Mech. Syst. Signal Process 2007, 21, 2560–2574. [Google Scholar] [CrossRef]

- Çaydaş, U.; Ekici, S. Support vector machines models for surface roughness prediction in CNC turning of AISI 304 austenitic stainless steel. J. Intell. Manuf. 2012, 23, 639–650. [Google Scholar] [CrossRef]

- Ribeiro, B. Support Vector Machines for Quality Monitoring in a Plastic Injection Molding Process. IEEE Trans. Syst. Man Cybern. Part C (Appl. Rev.) 2005, 35, 401–410. [Google Scholar] [CrossRef]

- Azadeh, A.; Saberi, M.; Kazem, A.; Ebrahimipour, V.; Nourmohammadzadeh, A.; Saberi, Z. A flexible algorithm for fault diagnosis in a centrifugal pump with corrupted data and noise based on ANN and support vector machine with hyper-parameters optimization. Appl. Soft Comput. 2013, 13, 1478–1485. [Google Scholar] [CrossRef]

- Chinnam, R.B. Support vector machines for recognizing shifts in correlated and other manufacturing processes. Int. J. Prod. Res. 2002, 40, 4449–4466. [Google Scholar] [CrossRef]

- Wu, D.; Jennings, C.; Terpenny, J.; Gao, R.X.; Kumara, S. A Comparative Study on Machine Learning Algorithms for Smart Manufacturing: Tool Wear Prediction Using Random Forests. J. Manuf. Sci. Eng. 2017, 139, 071018. [Google Scholar] [CrossRef]

- Wang, J.; Ma, Y.; Zhang, L.; Gao, R.X.; Wu, D. Deep learning for smart manufacturing: Methods and applications. J. Manuf. Syst. 2018, 48, 144–156. [Google Scholar] [CrossRef]

- Zhao, R.; Wang, D.; Yan, R.; Mao, K.; Shen, F.; Wang, J. Machine Health Monitoring Using Local Feature-Based Gated Recurrent Unit Networks. IEEE Trans. Ind. Electron. 2018, 65, 1539–1548. [Google Scholar] [CrossRef]

- Yang, Z.-X.; Wang, X.-B.; Zhong, J.-H. Representational Learning for Fault Diagnosis of Wind Turbine Equipment: A Multi-Layered Extreme Learning Machines Approach. Energies 2016, 9, 379. [Google Scholar] [CrossRef]

- Jia, S.; Chiesi, A.; Kuo, W.P. Onward to 2016. J. Circ. Biomark. 2016, 5, 2. [Google Scholar] [CrossRef]

- Masci, J.; Meier, U.; Ciresan, D.; Schmidhuber, J.; Fricout, G. Steel defect classification with Max-Pooling Convolutional Neural Networks. In Proceedings of the 2012 International Joint Conference on Neural Networks (IJCNN), Brisbane, QLD, Australia, 10–15 June 2012; IEEE: New York, NY, USA, 2012; pp. 1–6. [Google Scholar]

- Weimer, D.; Scholz-Reiter, B.; Shpitalni, M. Design of deep convolutional neural network architectures for automated feature extraction in industrial inspection. CIRP Ann. 2016, 65, 417–420. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, T.; Ju, W.; Shi, S. Materials discovery and design using machine learning. J. Mater. 2017, 3, 159–177. [Google Scholar] [CrossRef]

- Yun, L.; Wang, D.; Li, L. Explainable multi-agent deep reinforcement learning for real-time demand response towards sustainable manufacturing. Appl. Energy 2023, 347, 121324. [Google Scholar] [CrossRef]

- Kang, H.; Jung, S.; Jeoung, J.; Hong, J.; Hong, T. A bi-level reinforcement learning model for optimal scheduling and planning of battery energy storage considering uncertainty in the energy-sharing community. Sustain. Cities Soc. 2023, 94, 104538. [Google Scholar] [CrossRef]

- Ogunfowora, O.; Najjaran, H. Reinforcement and deep reinforcement learning-based solutions for machine maintenance planning, scheduling policies, and optimization. J. Manuf. Syst. 2023, 70, 244–263. [Google Scholar] [CrossRef]

- Liu, R.; Piplani, R.; Toro, C. Deep reinforcement learning for dynamic scheduling of a flexible job shop. Int. J. Prod. Res. 2022, 60, 4049–4069. [Google Scholar] [CrossRef]

- Waschneck, B.; Reichstaller, A.; Belzner, L.; Altenmüller, T.; Bauernhansl, T.; Knapp, A.; Kyek, A. Optimization of global production scheduling with deep reinforcement learning. Procedia CIRP 2018, 72, 1264–1269. [Google Scholar] [CrossRef]

- Chen, R.; Yang, B.; Li, S.; Wang, S. A self-learning genetic algorithm based on reinforcement learning for flexible job-shop scheduling problem. Comput. Ind. Eng. 2020, 149, 106778. [Google Scholar] [CrossRef]

- Aydin, M.E.; Öztemel, E. Dynamic job-shop scheduling using reinforcement learning agents. Rob. Auton. Syst. 2000, 33, 169–178. [Google Scholar] [CrossRef]

- Balasubramanian, S. Intrinsically Motivated Multi-Goal Reinforcement Learning Using Robotics Environment Integrated with OpenAI Gym. J. Sci. Technol. 2023, 4, 46–60. [Google Scholar] [CrossRef]

- Han, D.; Mulyana, B.; Stankovic, V.; Cheng, S. A Survey on Deep Reinforcement Learning Algorithms for Robotic Manipulation. Sensors 2023, 23, 3762. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Davari, H.; Singh, J.; Pandhare, V. Industrial Artificial Intelligence for industry 4.0-based manufacturing systems. Manuf. Lett. 2018, 18, 20–23. [Google Scholar] [CrossRef]

- Abouelyazid, M. Advanced Artificial Intelligence Techniques for Real-Time Predictive Maintenance in Industrial IoT Systems: A Comprehensive Analysis and Framework. J. AI-Assist. Sci. Discov. 2023, 3, 271–313. [Google Scholar]

- Yan, J.; Meng, Y.; Lu, L.; Li, L. Industrial Big Data in an Industry 4.0 Environment: Challenges, Schemes, and Applications for Predictive Maintenance. IEEE Access 2017, 5, 23484–23491. [Google Scholar] [CrossRef]

- Miragliotta, G.; Sianesi, A.; Convertini, E.; Distante, R. Data driven management in Industry 4.0: A method to measure Data Productivity. IFAC-Pap. 2018, 51, 19–24. [Google Scholar] [CrossRef]

- Le, D.D.; Pham, V.; Nguyen, H.N.; Dang, T. Visualization and Explainable Machine Learning for Efficient Manufacturing and System Operations. Smart Sustain. Manuf. Syst. 2019, 3, 127–147. [Google Scholar] [CrossRef]

- Langone, R.; Cuzzocrea, A.; Skantzos, N. Interpretable Anomaly Prediction: Predicting anomalous behavior in industry 4.0 settings via regularized logistic regression tools. Data Knowl. Eng. 2020, 130, 101850. [Google Scholar] [CrossRef]

- Cohen, Y.; Naseraldin, H.; Chaudhuri, A.; Pilati, F. Assembly systems in Industry 4.0 era: A road map to understand Assembly 4.0. Int. J. Adv. Manuf. Technol. 2019, 105, 4037–4054. [Google Scholar] [CrossRef]

- Diez-Olivan, A.; Del Ser, J.; Galar, D.; Sierra, B. Data fusion and machine learning for industrial prognosis: Trends and perspectives towards Industry 4.0. Inf. Fusion 2019, 50, 92–111. [Google Scholar] [CrossRef]

- Bougdira, A.; Akharraz, I.; Ahaitouf, A. A traceability proposal for industry 4.0. J. Ambient. Intell. Humaniz. Comput. 2020, 11, 3355–3369. [Google Scholar] [CrossRef]

- Ang, J.; Goh, C.; Saldivar, A.; Li, Y. Energy-Efficient Through-Life Smart Design, Manufacturing and Operation of Ships in an Industry 4.0 Environment. Energies 2017, 10, 610. [Google Scholar] [CrossRef]

- Ucar, A.; Karakose, M.; Kırımça, N. Artificial Intelligence for Predictive Maintenance Applications: Key Components, Trustworthiness, and Future Trends. Appl. Sci. 2024, 14, 898. [Google Scholar] [CrossRef]

- Carletti, M.; Masiero, C.; Beghi, A.; Susto, G.A. Explainable Machine Learning in Industry 4.0: Evaluating Feature Importance in Anomaly Detection to Enable Root Cause Analysis. In Proceedings of the 2019 IEEE International Conference on Systems, Man and Cybernetics (SMC), Bari, Italy, 6–9 October 2019; IEEE: New York, NY, USA, 2019; pp. 21–26. [Google Scholar]

- Tao, Y.; Wang, X.; Sanchez, R.-V.; Yang, S.; Bai, Y. Spur Gear Fault Diagnosis Using a Multilayer Gated Recurrent Unit Approach with Vibration Signal. IEEE Access 2019, 7, 56880–56889. [Google Scholar] [CrossRef]

- Pan, J.; Zi, Y.; Chen, J.; Zhou, Z.; Wang, B. LiftingNet: A Novel Deep Learning Network with Layerwise Feature Learning From Noisy Mechanical Data for Fault Classification. IEEE Trans. Ind. Electron. 2018, 65, 4973–4982. [Google Scholar] [CrossRef]

- Luo, B.; Wang, H.; Liu, H.; Li, B.; Peng, F. Early Fault Detection of Machine Tools Based on Deep Learning and Dynamic Identification. IEEE Trans. Ind. Electron. 2019, 66, 509–518. [Google Scholar] [CrossRef]

- Li, L.; Ota, K.; Dong, M. Deep Learning for Smart Industry: Efficient Manufacture Inspection System with Fog Computing. IEEE Trans. Ind. Inform. 2018, 14, 4665–4673. [Google Scholar] [CrossRef]

- Villalba-Diez, J.; Schmidt, D.; Gevers, R.; Ordieres-Meré, J.; Buchwitz, M.; Wellbrock, W. Deep Learning for Industrial Computer Vision Quality Control in the Printing Industry 4.0. Sensors 2019, 19, 3987. [Google Scholar] [CrossRef]