Experimental Investigation of the Effects of Coolant Temperature on Cutting Tool Wear in the Machining Process

Abstract

1. Introduction

2. Material and Methods

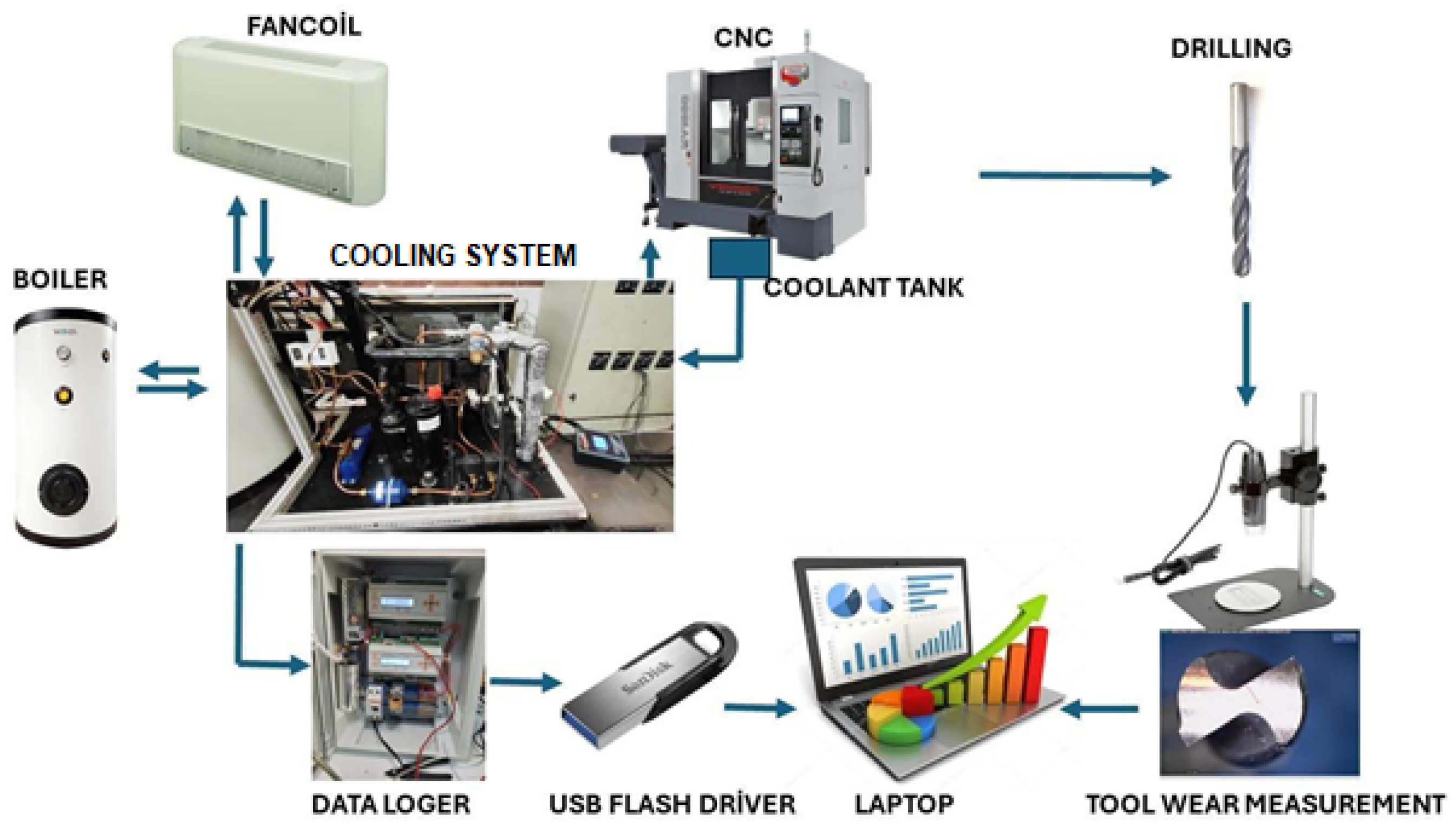

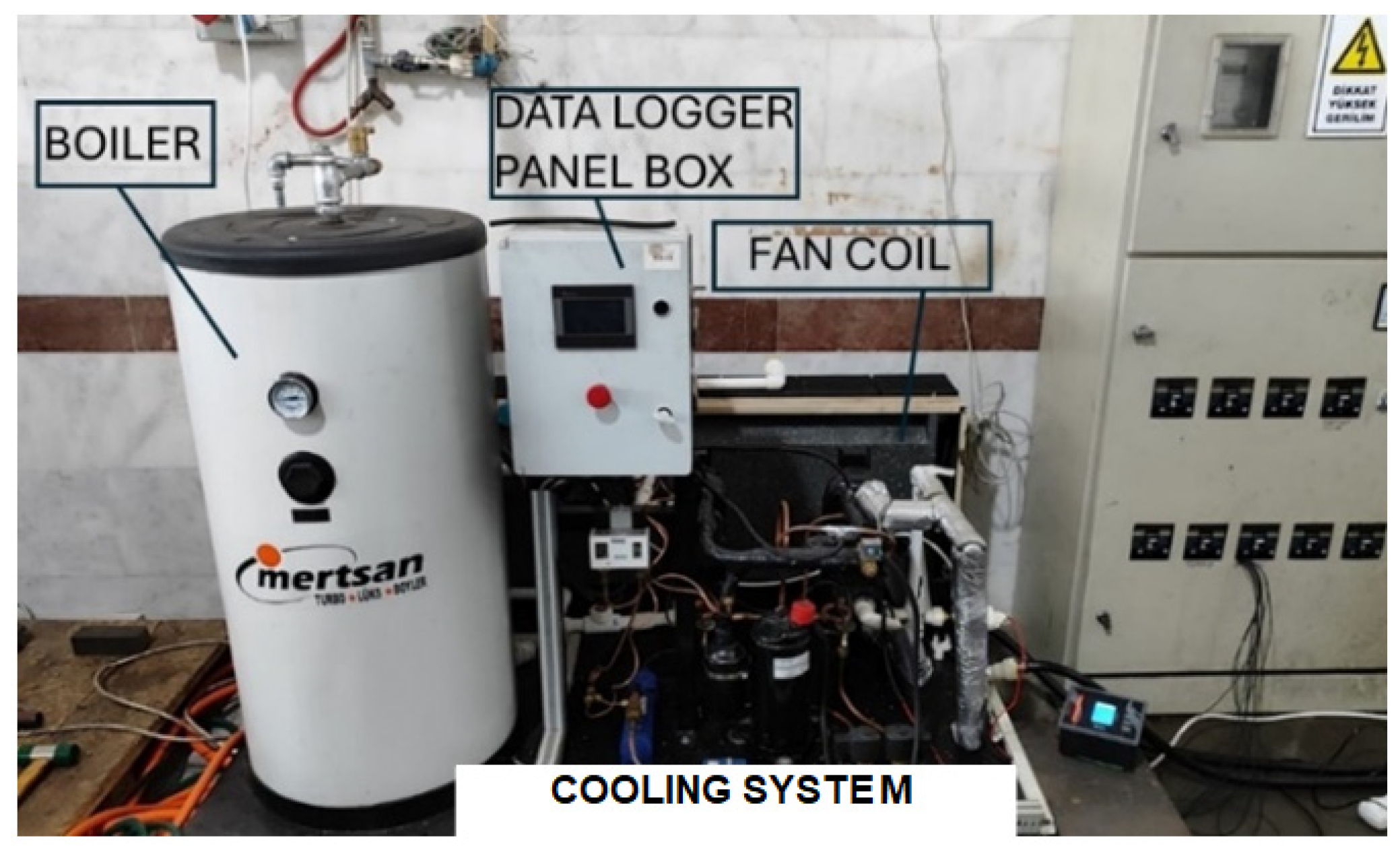

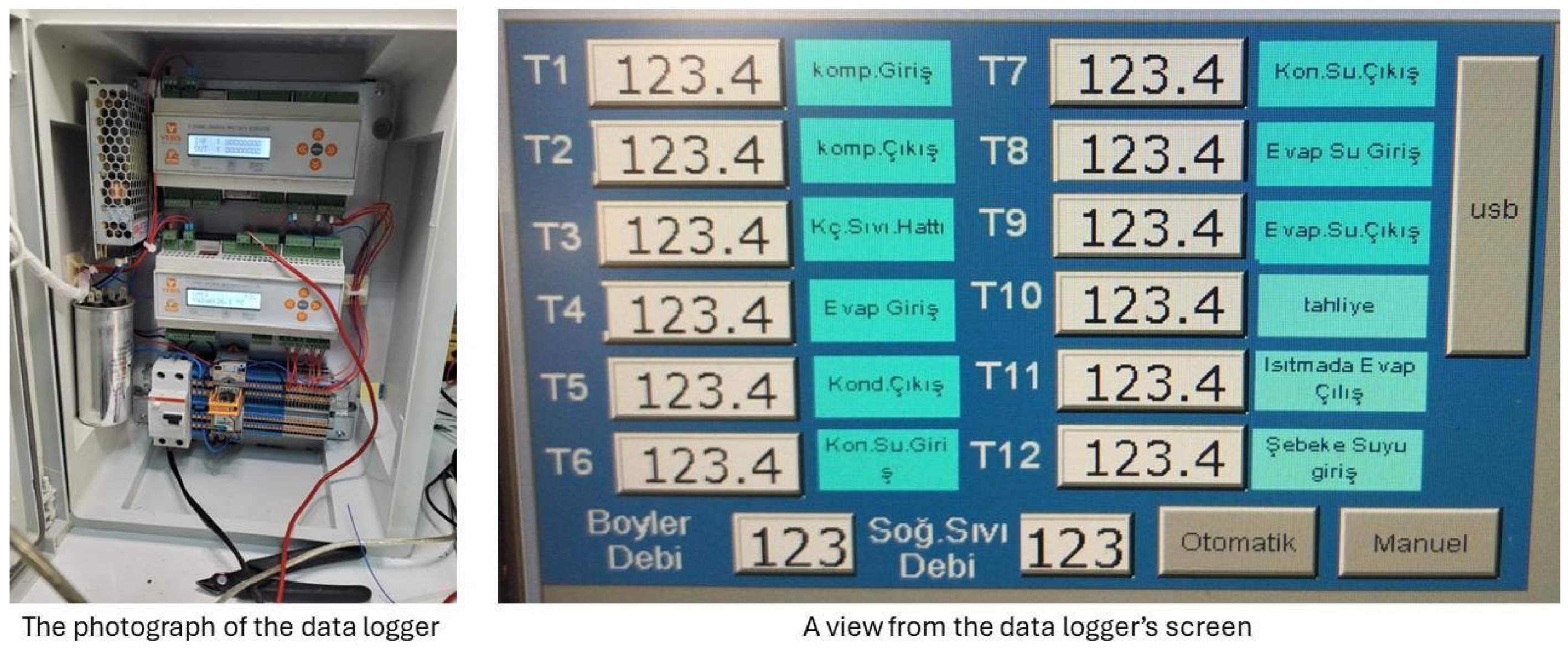

2.1. Experimental Setup

2.2. Cooling System

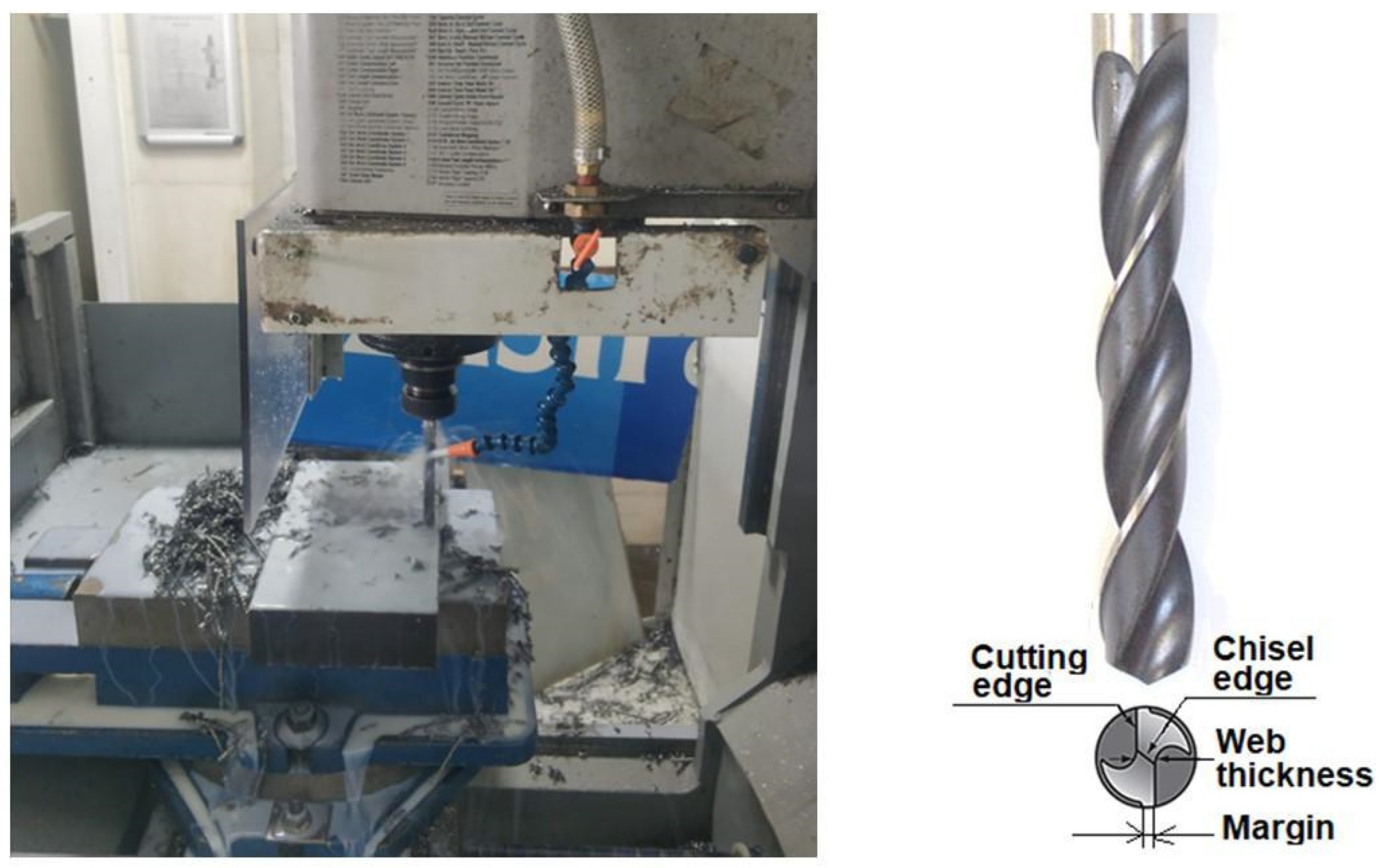

2.3. Cutting Parameters and Experimental Conditions

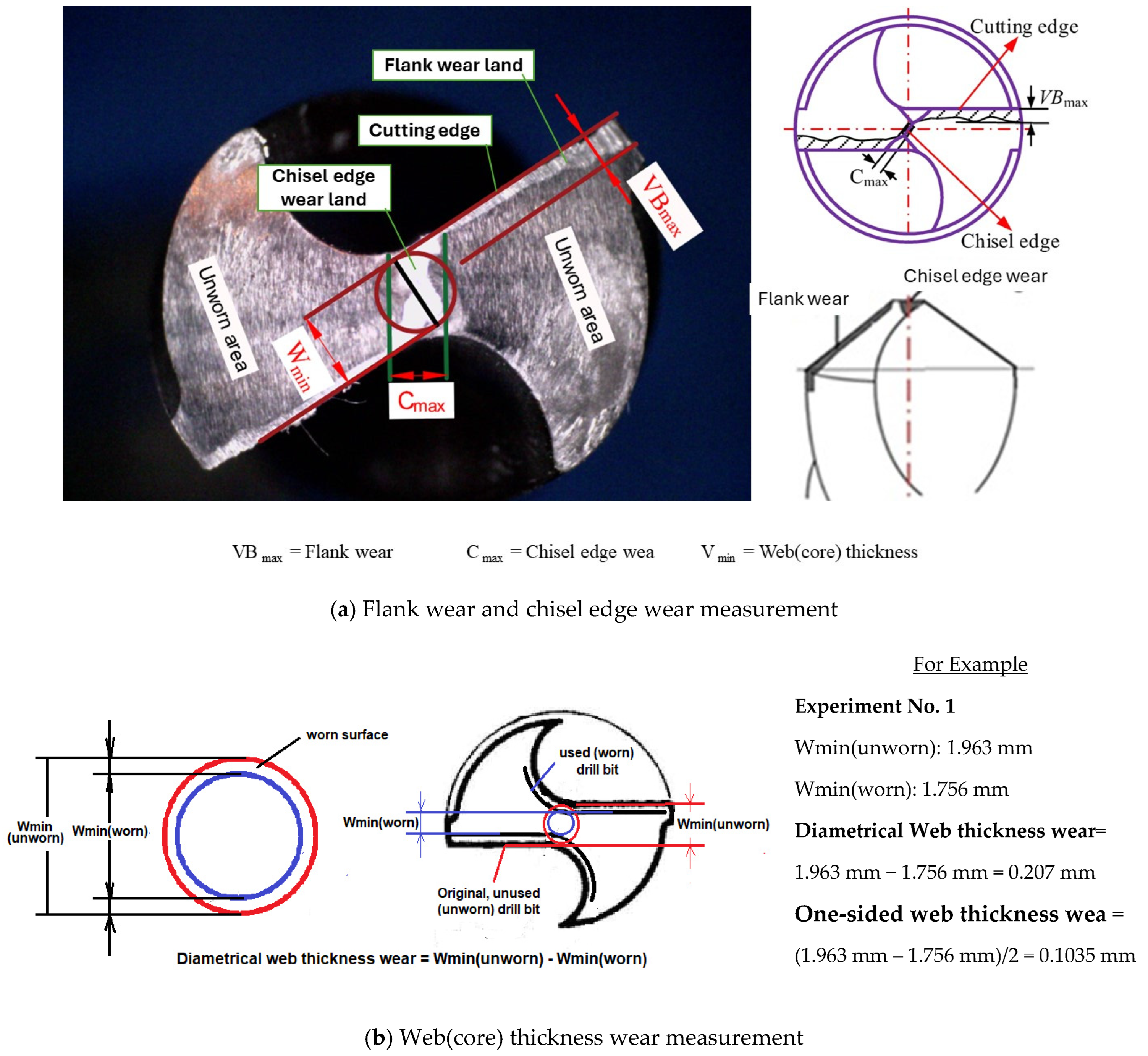

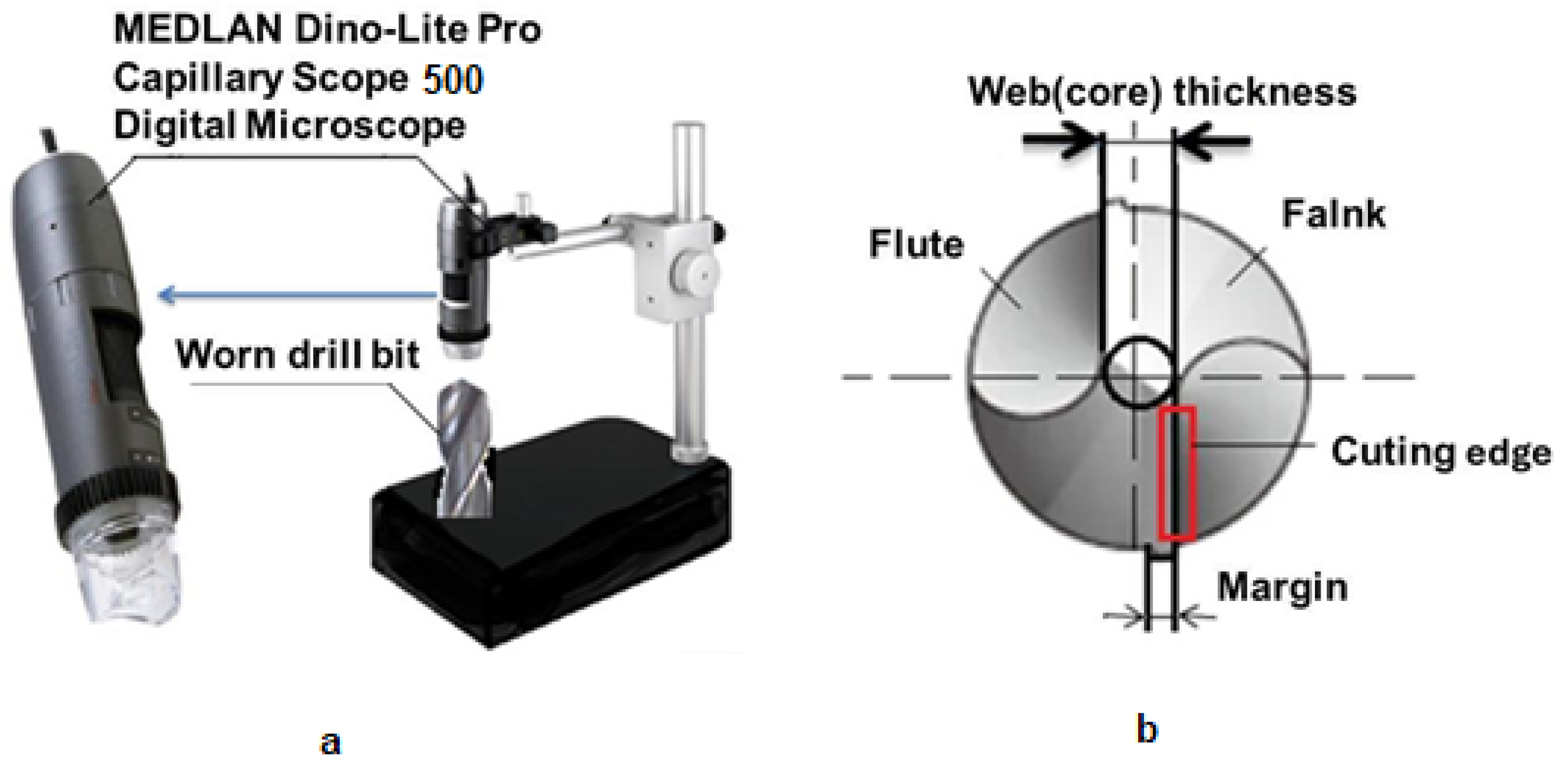

2.4. Measurement of Drill Bit Wear

2.5. The Method and Approaches

3. Results and Discussion

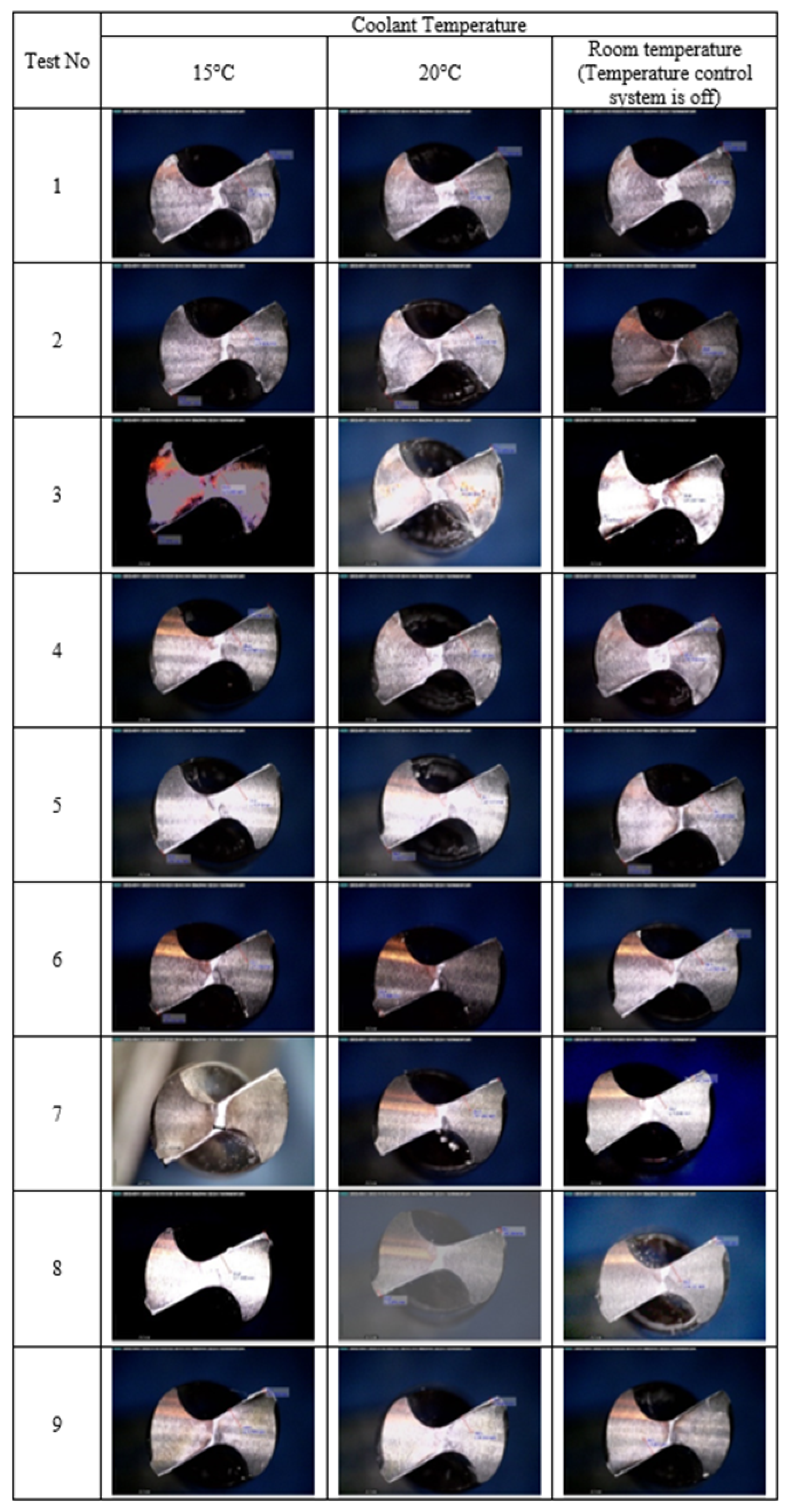

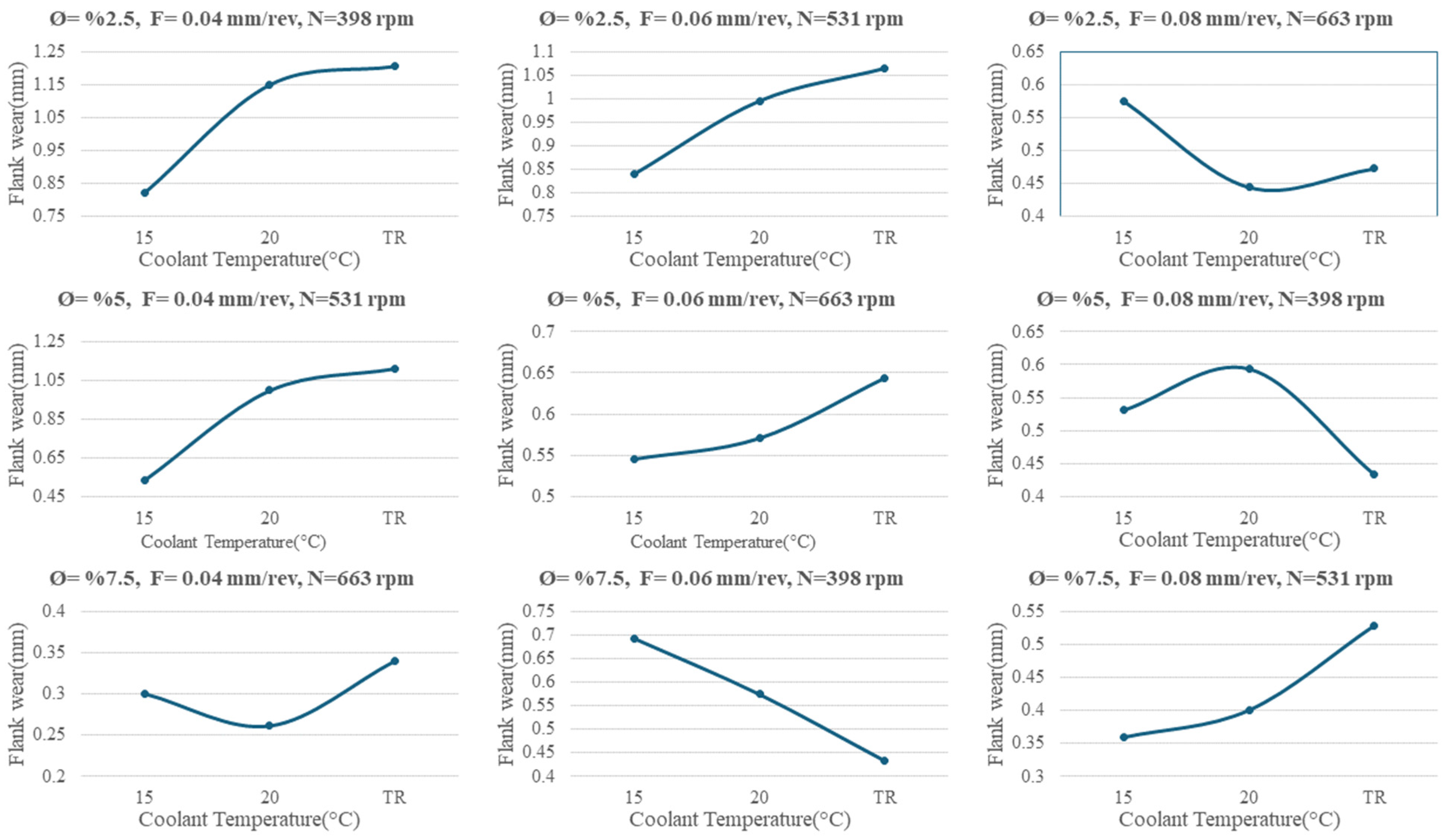

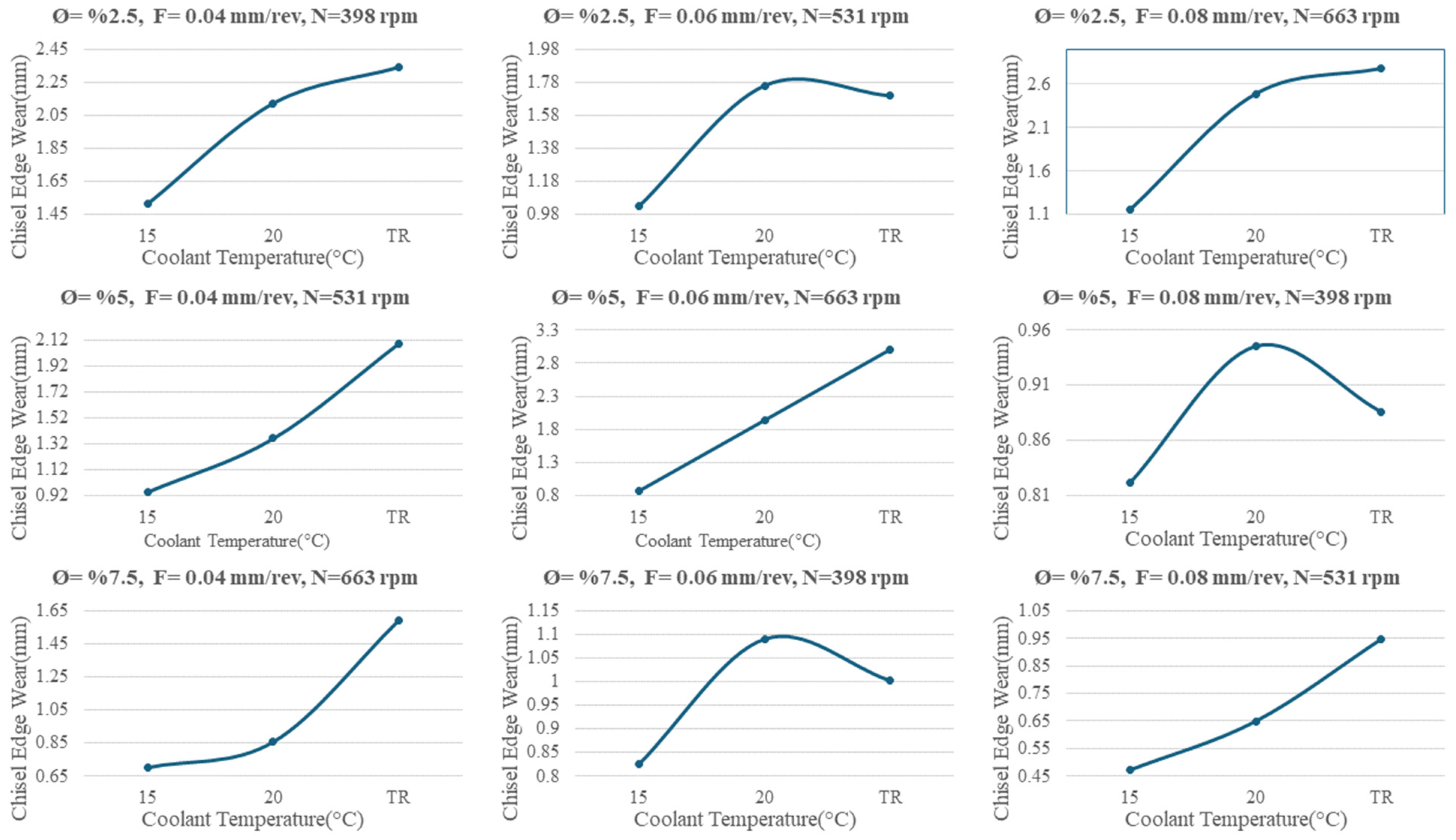

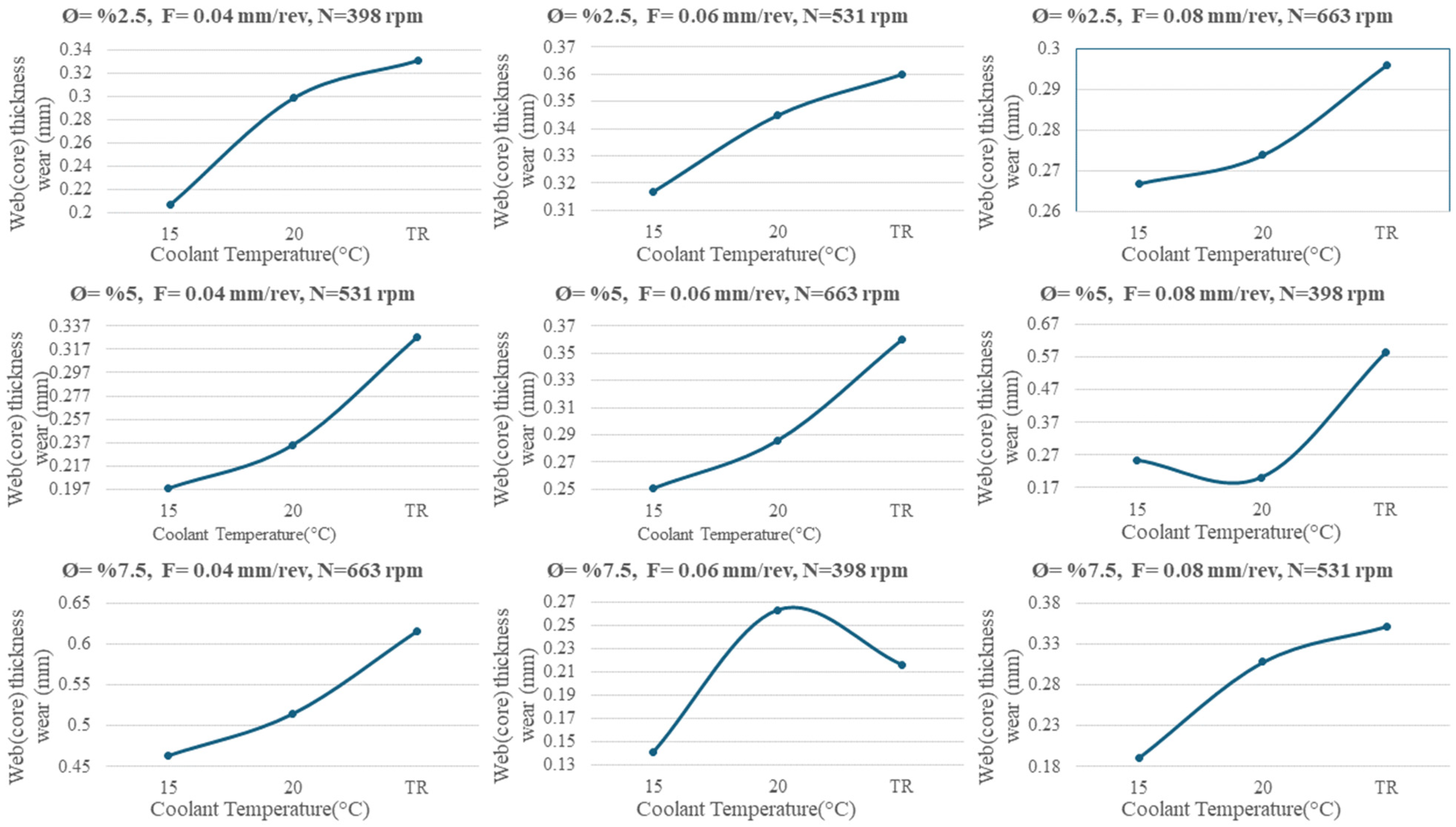

3.1. Drill Bit Wear

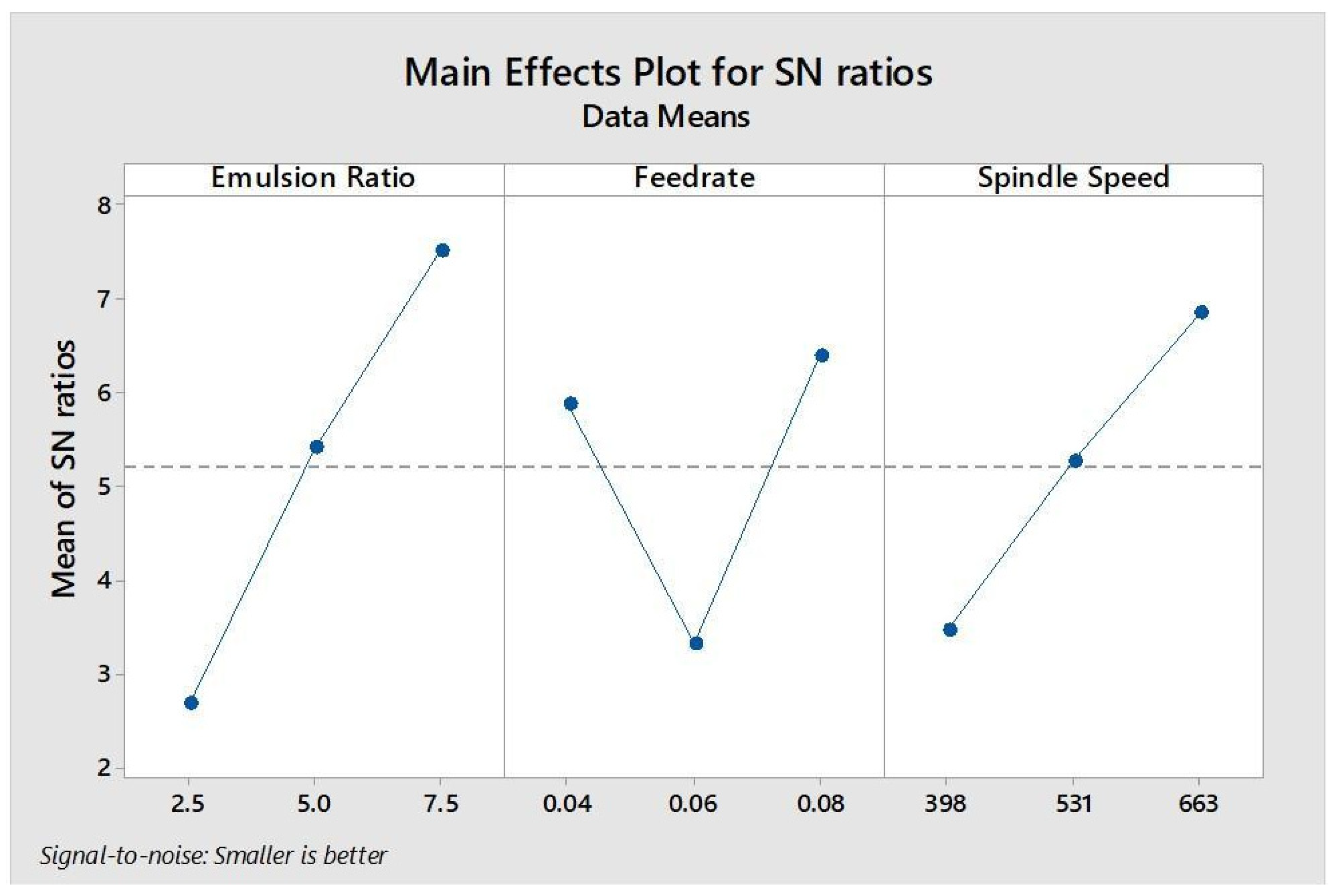

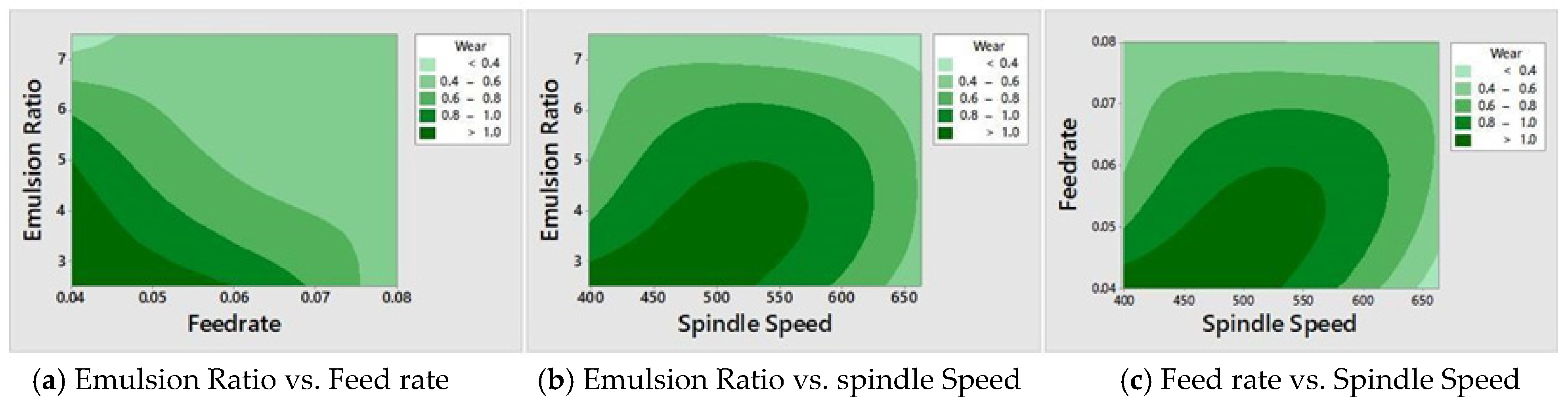

3.2. Statistical Analysis of Tool Wear

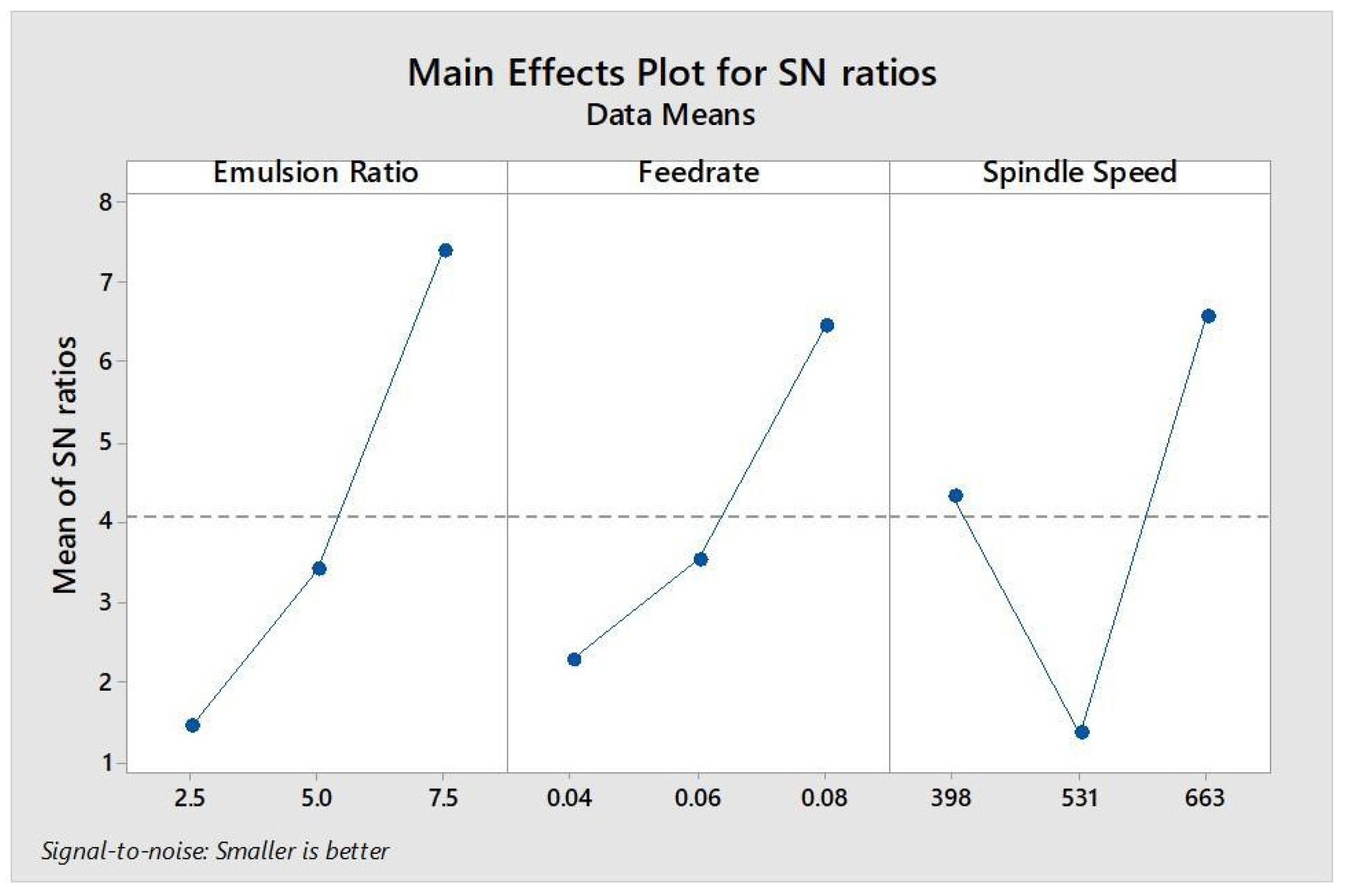

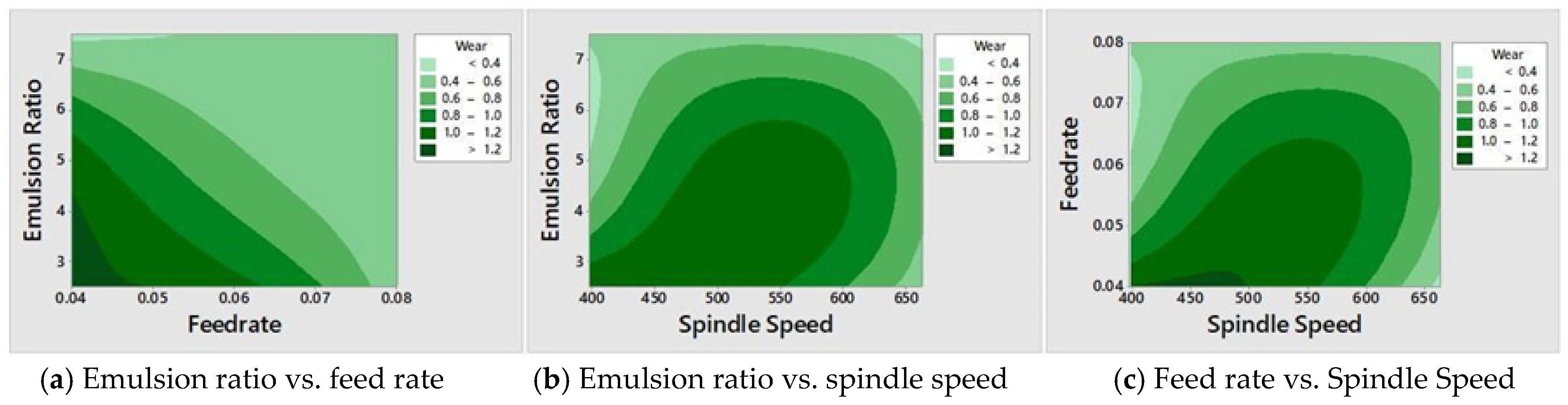

3.2.1. Tool Wear for 15 °C Coolant Temperature

3.2.2. Tool Wear for 20 °C Coolant Temperature

3.2.3. Tool Wear When Coolant Temperature Is Not Controlled (At Room Temperature)

4. Conclusions

5. Future Studies

- Using coolant at extremely low temperatures, especially when machining steel, can pose risks such as thermal shock, increased tool wear and changes in material behavior. In this regard, it would be beneficial to conduct tests at coolant temperatures lower than 15 °C in the future.

- A new study can be conducted with different optimization techniques, including heuristic optimization algorithms using experimental data from this study. In this context, a multi-objective optimization study can also be carried out to ensure that tool life is maximized.

- According to the obtained results, a programmable cooling system that can automatically adjust the cooling system of the machine tool according to the cutting parameters and processing conditions can be developed and adapted to the machine tool. This application study can be formatted as a scientific publication and presented as a case study.

- Studies can be carried out to adapt the developed system to other related production tools, such as lathes and milling and injection machines.

6. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Q.; Zhang, D.; Chen, B.; Zhang, Y.; Wu, B. Energy Consumption Model for Drilling Processes Based on Cutting Force. Appl. Sci. 2019, 9, 4801. [Google Scholar] [CrossRef]

- Balogun, V.A.; Mativenga, P.T. Modelling of Direct Energy Requirements in Mechanical Machining Processes. J. Clean. Prod. 2013, 41, 179–186. [Google Scholar] [CrossRef]

- Bi, Z.M.; Wang, L. Optimization of Machining Processes from the Perspective of Energy Consumption: A Case Study. J. Manuf. Syst. 2012, 31, 420–428. [Google Scholar] [CrossRef]

- Moradnazhad, M.; Unver, H.O. Energy Efficiency of Machining Operations: A Review. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2017, 231, 1871–1889. [Google Scholar] [CrossRef]

- Li, C.; Xiao, Q.; Tang, Y.; Li, L. A Method Integrating Taguchi, RSM and MOPSO to CNC Machining Parameters Optimization for Energy Saving. J. Clean. Prod. 2016, 135, 263–275. [Google Scholar] [CrossRef]

- Li, L.; Li, C.; Tang, Y.; Li, L. An Integrated Approach of Process Planning and Cutting Parameter Optimization for Energy-Aware CNC Machining. J. Clean. Prod. 2017, 162, 458–473. [Google Scholar] [CrossRef]

- Li, L.; Li, C.; Tang, Y.; Yi, Q. Influence Factors and Operational Strategies for Energy Efficiency Improvement of CNC Machining. J. Clean. Prod. 2017, 161, 220–238. [Google Scholar] [CrossRef]

- KIYAK, M. Investigation of the Effect of Drill Bit Feature on Hole Surface Quality and Tool Wear. DÜMF Mühendislik Derg. 2021, 12, 661–667. [Google Scholar] [CrossRef]

- Aamir, M.; Giasin, K.; Tolouei-Rad, M.; Vafadar, A. A Review: Drilling Performance and Hole Quality of Aluminium Alloys for Aerospace Applications. J. Mater. Res. Technol. 2020, 9, 12484–12500. [Google Scholar] [CrossRef]

- Gaitonde, V.N.; Karnik, R.S.; Davim, J.P. Minimum Quantity Lubrication in Machining. In Sustainable Manufacturing; Wiley: Hoboken, NJ, USA, 2013; pp. 79–110. [Google Scholar]

- Jiang, Z.; Zhou, F.; Zhang, H.; Wang, Y.; Sutherland, J.W. Optimization of Machining Parameters Considering Minimum Cutting Fluid Consumption. J. Clean. Prod. 2015, 108, 183–191. [Google Scholar] [CrossRef]

- Pradeepkumar, M.; Amarnath, K.; Sunilkumar, M. A Review on Heat Generation in Metal Cutting. Int. J. Eng. Manag. Res. 2015, 5, 193–197. [Google Scholar]

- Grzesik, W. Modelling of Heat Generation and Transfer in Metal Cutting: A Short Review. J. Mach. Eng. 2020, 20, 24–33. [Google Scholar] [CrossRef]

- Abukhshim, N.A.; Mativenga, P.T.; Sheikh, M.A. Heat Generation and Temperature Prediction in Metal Cutting: A Review and Implications for High Speed Machining. Int. J. Mach. Tools Manuf. 2006, 46, 782–800. [Google Scholar] [CrossRef]

- Yan, P.; Rong, Y.; Wang, G. The Effect of Cutting Fluids Applied in Metal Cutting Process. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2016, 230, 19–37. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Güllü, A. Taguchi Design and Response Surface Methodology Based Analysis of Machining Parameters in CNC Turning under MQL. J. Clean. Prod. 2014, 65, 604–616. [Google Scholar] [CrossRef]

- Akhil, C.S.; Ananthavishnu, M.H.; Akhil, C.K.; Afeez, P.M.; Akhilesh, R.; Rahul, R. Measurement of Cutting Temperature during Machining. IOSR J. Mech. Civ. Eng. 2016, 13, 108–122. [Google Scholar]

- Manel, S.; Kumar, S. Heat Generation and Temperature in Orthogonal Machining. Int. J. Sci. Eng. Res. 2017, 8, 31–33. [Google Scholar]

- Yashiro, T.; Ogawa, T.; Sasahara, H. Temperature Measurement of Cutting Tool and Machined Surface Layer in Milling of CFRP. Int. J. Mach. Tools Manuf. 2013, 70, 63–69. [Google Scholar] [CrossRef]

- Ogedengbe, T.S.; Abdulkareem, S.; Aweda, J.O.; Ogedengbe, T.S.; Abdulkareem, S. Effect of Coolant Temperature on Machining Characteristics of High Carbon Steel. 2018; Volume 1. Available online: http://repository.elizadeuniversity.edu.ng/handle/20.500.12398/1081 (accessed on 24 September 2024).

- Wang, W.; Wong, Y.S.; Hong, G.S. Flank Wear Measurement by Successive Image Analysis. Comput. Ind. 2005, 56, 816–830. [Google Scholar] [CrossRef]

- Zakeri, V.; Pourmostaghimi, V. Tool Wear Modelling in Drilling Process of AISI1020 and AISI8620 using Genetic Programming. Int. J. Adv. Des. Manuf. Technol. 2017, 10, 93–100. [Google Scholar]

- Zhou, J.; Yu, J. Chisel Edge Wear Measurement of High-Speed Steel Twist Drills Based on Machine Vision. Comput. Ind. 2021, 128, 103436. [Google Scholar] [CrossRef]

- Xu, J.; Ji, M.; Chen, M. On the Quantitative Analysis of Drill Edge Wear When Machining CFRP/Ti6Al4V Stacks. Int. J. Adv. Manuf. Technol. 2020, 108, 1463–1472. [Google Scholar] [CrossRef]

- Liang, Z.; Guo, H.; Wang, X.; Ma, Y.; Zhou, T.; Sun, X.; Jiang, L. Influence of Chisel Edge Axial Rake Angle on the Drilling Performance of Helical Point Micro-Drill. Int. J. Adv. Manuf. Technol. 2020, 107, 2137–2149. [Google Scholar] [CrossRef]

- Abdelrahman Elkaseer, A.M.; Dimov, S.S.; Popov, K.B.; Minev, R.M. Tool Wear in Micro-Endmilling: Material Microstructure Effects, Modeling, and Experimental Validation. J. Micro Nanomanuf 2014, 2, 044502. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Sarıkaya, M.; Kıvak, T.; Şirin, Ş. The Effect of Addition of HBN Nanoparticles to Nanofluid-MQL on Tool Wear Patterns, Tool Life, Roughness and Temperature in Turning of Ni-Based Inconel 625. Tribol. Int. 2019, 134, 443–456. [Google Scholar] [CrossRef]

- Dhar, N.R.; Rashid, M.H.; Siddiqui, A.T. Effect Of High Pressure Coolant On Chip, Roundness Deviation And Tool Wear In Drilling Aisi-4340 Steel. ARPN J. Eng. Appl. Sci. 2006, 1, 53–59. [Google Scholar]

- Jessy, K.; Satish kumar, S.; Dinakaran, D.; Seshagiri Rao, V. Influence of Different Cooling Methods on Drill Temperature in Drilling GFRP. Int. J. Adv. Manuf. Technol. 2015, 76, 609–621. [Google Scholar] [CrossRef]

- Thirukkumaran, K.; Menaka, M.; Mukhopadhyay, C.K.; Venkatraman, B. A Study on Temperature Rise, Tool Wear, and Surface Roughness During Drilling of Al–5%SiC Composite. Arab. J. Sci. Eng. 2020, 45, 5407–5419. [Google Scholar] [CrossRef]

- Wang, X.; Kwon, P.Y.; Sturtevant, C.; Kim, D.; Dae, W.; Lantrip, J. Comparative Tool Wear Study Based on Drilling Experiments on CFRp/Ti Stack and Its Individual Layers. Wear 2014, 317, 265–276. [Google Scholar] [CrossRef]

| Factor | Level | ||

|---|---|---|---|

| a | b | c | |

| Coolant temperature (°C) | 15 | 20 | Room temperature |

| Coolant emulsion ratio (%) | 2.5 | 5 | 7.5 |

| Feed rate (mm/rev) | 0.04 | 0.06 | 0.08 |

| Spindle speed (rpm) | 398 | 531 | 663 |

| Test No | Coolant Set Temperatures (°C) | Coolant Emulsion Rates | Feed Rate (mm/rev) | Spindle Speed (rev./m) | |

|---|---|---|---|---|---|

| 1 | a | 15 | 2.50 | 0.04 | 398 |

| b | 20 | 2.50 | 0.04 | 398 | |

| c | Room temperature | 2.50 | 0.04 | 398 | |

| 2 | a | 15 | 2.50 | 0.06 | 531 |

| b | 20 | 2.50 | 0.06 | 531 | |

| c | Room temperature | 2.50 | 0.06 | 531 | |

| 3 | a | 15 | 2.50 | 0.08 | 663 |

| b | 20 | 2.50 | 0.08 | 663 | |

| c | Room temperature | 2.50 | 0.08 | 663 | |

| 4 | a | 15 | 5.00 | 0.04 | 531 |

| b | 20 | 5.00 | 0.04 | 531 | |

| c | Room temperature | 5.00 | 0.04 | 531 | |

| 5 | a | 15 | 5.00 | 0.06 | 663 |

| b | 20 | 5.00 | 0.06 | 663 | |

| c | Room temperature | 5.00 | 0.06 | 663 | |

| 6 | a | 15 | 5.00 | 0.08 | 398 |

| b | 20 | 5.00 | 0.08 | 398 | |

| c | Room temperature | 5.00 | 0.08 | 398 | |

| 7 | a | 15 | 7.50 | 0.04 | 663 |

| b | 20 | 7.50 | 0.04 | 663 | |

| c | Room temperature | 7.50 | 0.04 | 663 | |

| 8 | a | 15 | 7.50 | 0.06 | 398 |

| b | 20 | 7.50 | 0.06 | 398 | |

| c | Room temperature | 7.50 | 0.06 | 398 | |

| 9 | a | 15 | 7.50 | 0.08 | 531 |

| b | 20 | 7.50 | 0.08 | 531 | |

| c | Room temperature | 7.50 | 0.08 | 531 | |

| Model | Formula |

|---|---|

| Nominal is better | |

| Smaller is better | |

| Larger is better |

| Test No | Temperature Level | Coolant Temperature (°C) | Emulsion Ratio (%) | Feed Rate (mm/rev) | Spindle Speed (rpm) | Flank Wear (mm) | Chisel Edge Wear (mm) | Web (Core) Thickness Wear (mm) |

|---|---|---|---|---|---|---|---|---|

| 1 | a | 15 | 2.50 | 0.04 | 398 | 0.821 | 1.515 | 0.207 |

| 1 | b | 20 | 2.50 | 0.04 | 398 | 1.15 | 2.122 | 0.299 |

| 1 | c | Room Temperature | 2.50 | 0.04 | 398 | 1.206 | 2.34 | 0.331 |

| 2 | a | 15 | 2.50 | 0.06 | 531 | 0.841 | 1.033 | 0.317 |

| 2 | b | 20 | 2.50 | 0.06 | 531 | 0.996 | 1.761 | 0.345 |

| 2 | c | Room Temperature | 2.50 | 0.06 | 531 | 1.065 | 1.7 | 0.360 |

| 3 | a | 15 | 2.50 | 0.08 | 663 | 0.575 | 1.159 | 0.267 |

| 3 | b | 20 | 2.50 | 0.08 | 663 | 0.445 | 2.487 | 0.274 |

| 3 | c | Room Temperature | 2.50 | 0.08 | 663 | 0.473 | 3.0 | 0.296 |

| 4 | a | 15 | 5 | 0.04 | 531 | 0.534 | 0.95 | 0.198 |

| 4 | b | 20 | 5.00 | 0.04 | 531 | 0.998 | 1.362 | 0.235 |

| 4 | c | Room Temperature | 5.00 | 0.04 | 531 | 1.111 | 2.0 | 0.327 |

| 5 | a | 15 | 5.00 | 0.06 | 663 | 0.546 | 0.864 | 0.251 |

| 5 | b | 20 | 5.00 | 0.06 | 663 | 0.571 | 1.932 | 0.286 |

| 5 | c | Room Temperature | 5.00 | 0.06 | 663 | 0.643 | 3.0 | 0.360 |

| 6 | a | 15 | 5 | 0.08 | 398 | 0.531 | 0.822 | 0.254 |

| 6 | b | 20 | 5.00 | 0.08 | 398 | 0.594 | 0.945 | 0.201 |

| 6 | c | Room Temperature | 5.00 | 0.08 | 398 | 0.433 | 0.886 | 0.583 |

| 7 | a | 15 | 7.50 | 0.04 | 663 | 0.3 | 0.7 | 0.463 |

| 7 | b | 20 | 7.50 | 0.04 | 663 | 0.261 | 0.856 | 0.514 |

| 7 | c | Room Temperature | 7.50 | 0.04 | 663 | 0.34 | 1.593 | 0.615 |

| 8 | a | 15 | 7.50 | 0.06 | 398 | 0.692 | 0.825 | 0.141 |

| 8 | b | 20 | 7.50 | 0.06 | 398 | 0.574 | 1.09 | 0.263 |

| 8 | c | Room Temperature | 7.50 | 0.06 | 398 | 0.433 | 1.002 | 0.216 |

| 9 | a | 15 | 7.50 | 0.08 | 531 | 0.36 | 0.471 | 0.190 |

| 9 | b | 20 | 7.50 | 0.08 | 531 | 0.401 | 0.648 | 0.308 |

| 9 | c | Room Temperature | 7.50 | 0.08 | 531 | 0.529 | 0.947 | 0.352 |

| Source | DF | Seq SS | Adj SS | Adj MS | F | P |

|---|---|---|---|---|---|---|

| Emulsion Ratio | 2 | 35.259 | 35.259 | 17.630 | 13.02 | 0.071 |

| Feedrate | 2 | 16.239 | 16.239 | 8.120 | 6.00 | 0.143 |

| Spindle Speed | 2 | 17.069 | 17.069 | 8.534 | 6.30 | 0.137 |

| Residual Error | 2 | 2.708 | 2.708 | 1.354 | ||

| Total | 8 | 71.275 |

| Source | DF | Seq SS | Adj SS | Adj MS | F | P |

|---|---|---|---|---|---|---|

| Emulsion Ratio | 2 | 64.788 | 64.788 | 32.394 | 14.39 | 0.065 |

| Feedrate | 2 | 19.716 | 19.716 | 9.858 | 4.38 | 0.186 |

| Spindle Speed | 2 | 53.438 | 53.438 | 26.719 | 11.87 | 0.078 |

| Residual Error | 2 | 4.503 | 4.503 | 2.252 | ||

| Total | 8 | 142.444 |

| Source | DF | Seq SS | Adj SS | Adj MS | F | P |

|---|---|---|---|---|---|---|

| Emulsion Ratio | 2 | 55.14 | 55.14 | 27.570 | 4.66 | 0.177 |

| Feedrate | 2 | 27.33 | 27.33 | 13.667 | 2.31 | 0.302 |

| Spindle Speed | 2 | 41.00 | 41.00 | 20.499 | 3.47 | 0.224 |

| Residual Error | 2 | 11.83 | 11.83 | 5.914 | ||

| Total | 8 | 135.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Şahin, O.; Karayel, D.; Ertürk, M.A.; Nart, E.; Seçgin, Ö. Experimental Investigation of the Effects of Coolant Temperature on Cutting Tool Wear in the Machining Process. Machines 2024, 12, 677. https://doi.org/10.3390/machines12100677

Şahin O, Karayel D, Ertürk MA, Nart E, Seçgin Ö. Experimental Investigation of the Effects of Coolant Temperature on Cutting Tool Wear in the Machining Process. Machines. 2024; 12(10):677. https://doi.org/10.3390/machines12100677

Chicago/Turabian StyleŞahin, Osman, Durmuş Karayel, Mustafa Ali Ertürk, Ergün Nart, and Ömer Seçgin. 2024. "Experimental Investigation of the Effects of Coolant Temperature on Cutting Tool Wear in the Machining Process" Machines 12, no. 10: 677. https://doi.org/10.3390/machines12100677

APA StyleŞahin, O., Karayel, D., Ertürk, M. A., Nart, E., & Seçgin, Ö. (2024). Experimental Investigation of the Effects of Coolant Temperature on Cutting Tool Wear in the Machining Process. Machines, 12(10), 677. https://doi.org/10.3390/machines12100677