Simultaneous Estimation of Vehicle Sideslip and Roll Angles Using an Event-Triggered-Based IoT Architecture

Abstract

1. Introduction

- Using the velocities and accelerations of the axes X, Z;

- Merging the lateral accelerations and the roll rate [20];

- Combining the data obtained using a gyroscope and an inertial angle sensor [21];

- Operating using the values obtained using a six-dimensional IMU [22];

- Using a low-cost GPS together with the values from sensors located on the wheels [23].

- The sampling rate of the sensors must be high in order to ensure that information is received fast enough to act in case of a particular event;

- It is necessary to obtain information from low-cost sensors or devices already included in series-production automobiles in order to ensure the vehicle prices are reasonable;

- Whenever data cannot be obtained directly, they must be estimated from direct measurements;

- The elapsed time to perform computational tasks should be as short as possible in order to guarantee a rapid response to different events;

- The developed system must have a low power consumption in order not to exhaust the vehicle resources.

2. Research Approach

2.1. IoT Hardware and Communications Perspective

- Racelogic IMU04. This sensor measures pitch, roll, and yaw rates using three rate gyroscopes. Moreover, it obtains the accelerations in the x, y, and z directions via three accelerometers with a ±20 g linear acceleration range and a g acceleration resolution, and a ±450/s angular rate range with a 0.00085/s resolution;

- Racelogic VBOX 3i Dual Antenna. Depending on the mounting configuration, this sensor can be used to measure the roll, pitch, and sideslip angles, and determine vehicle positioning with a 1 cm distance resolution, a km/h velocity resolution, less than a sideslip angle RMS accuracy, and a roll angle RMS accuracy;

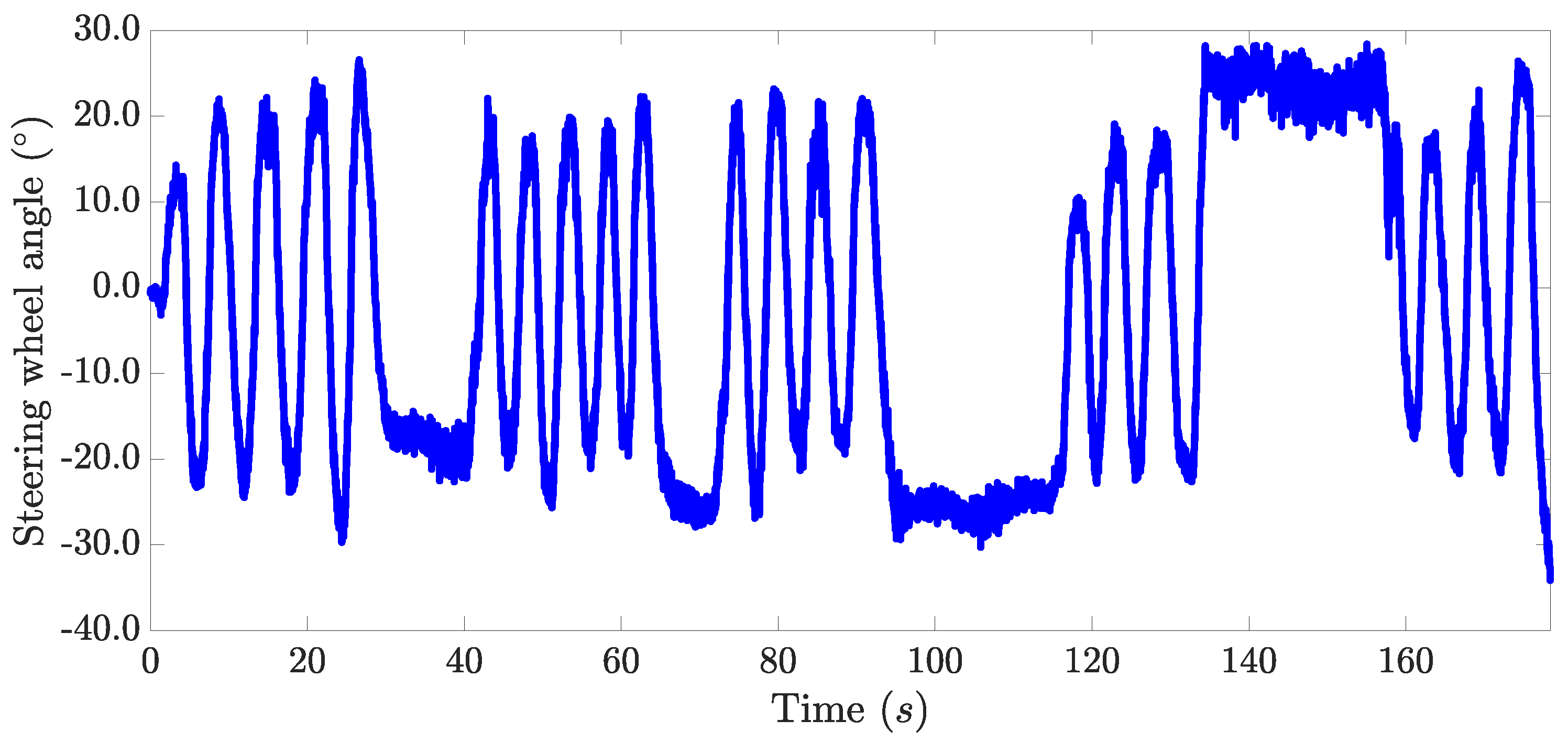

- Kistler steering wheel DTI sensor. This sensor can measure the steering wheel angle and torque with the following specifications: a Nm steering moment range, a steering angle range, a maximum 2000/s steering speed, and a steering angle resolution.

2.2. Event-Triggered Vehicle Sideslip and Roll Angles Observer

- When , the system (5) is asymptotically stable;

- Under the zero initial condition, holds for , with being the performance index.

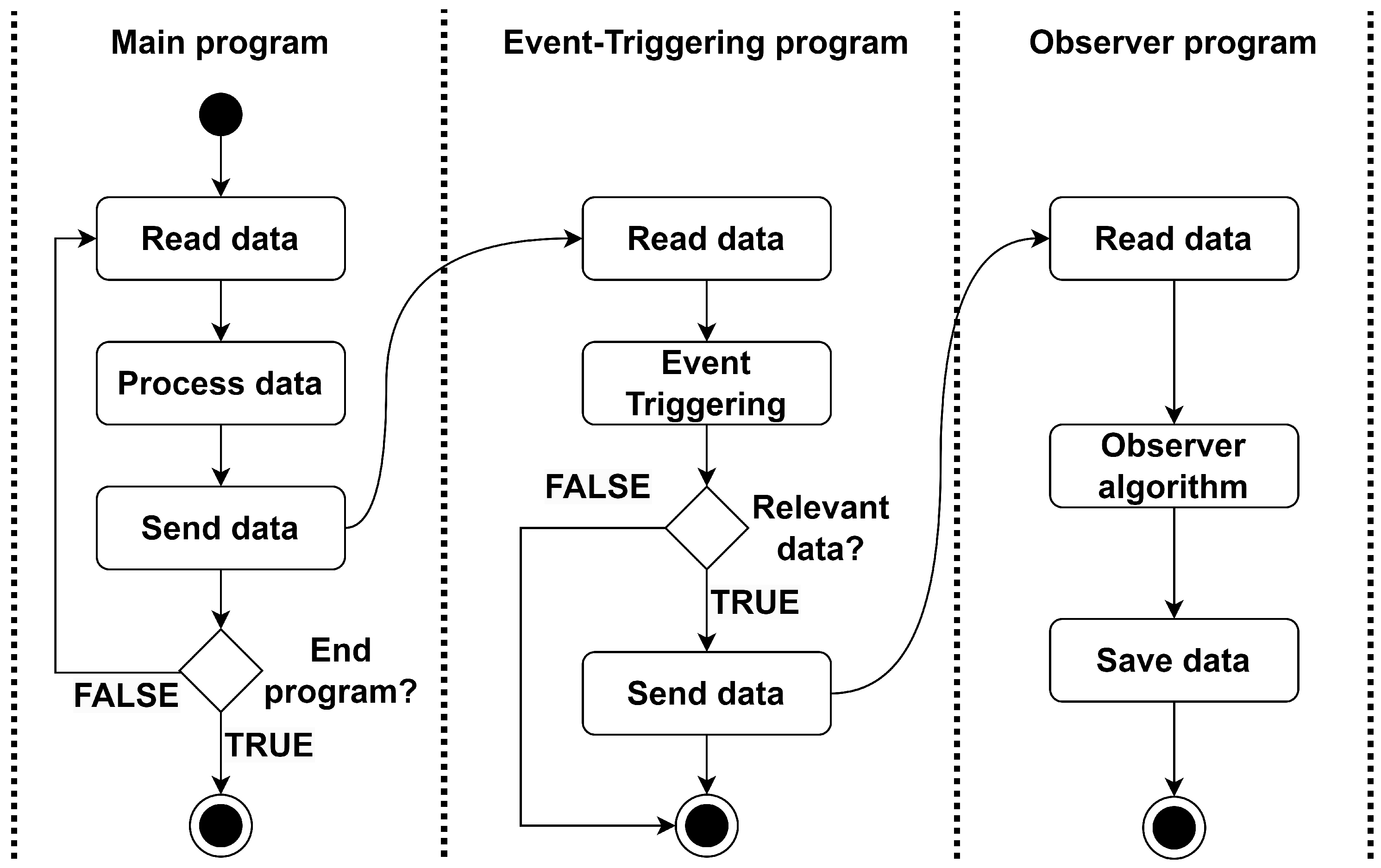

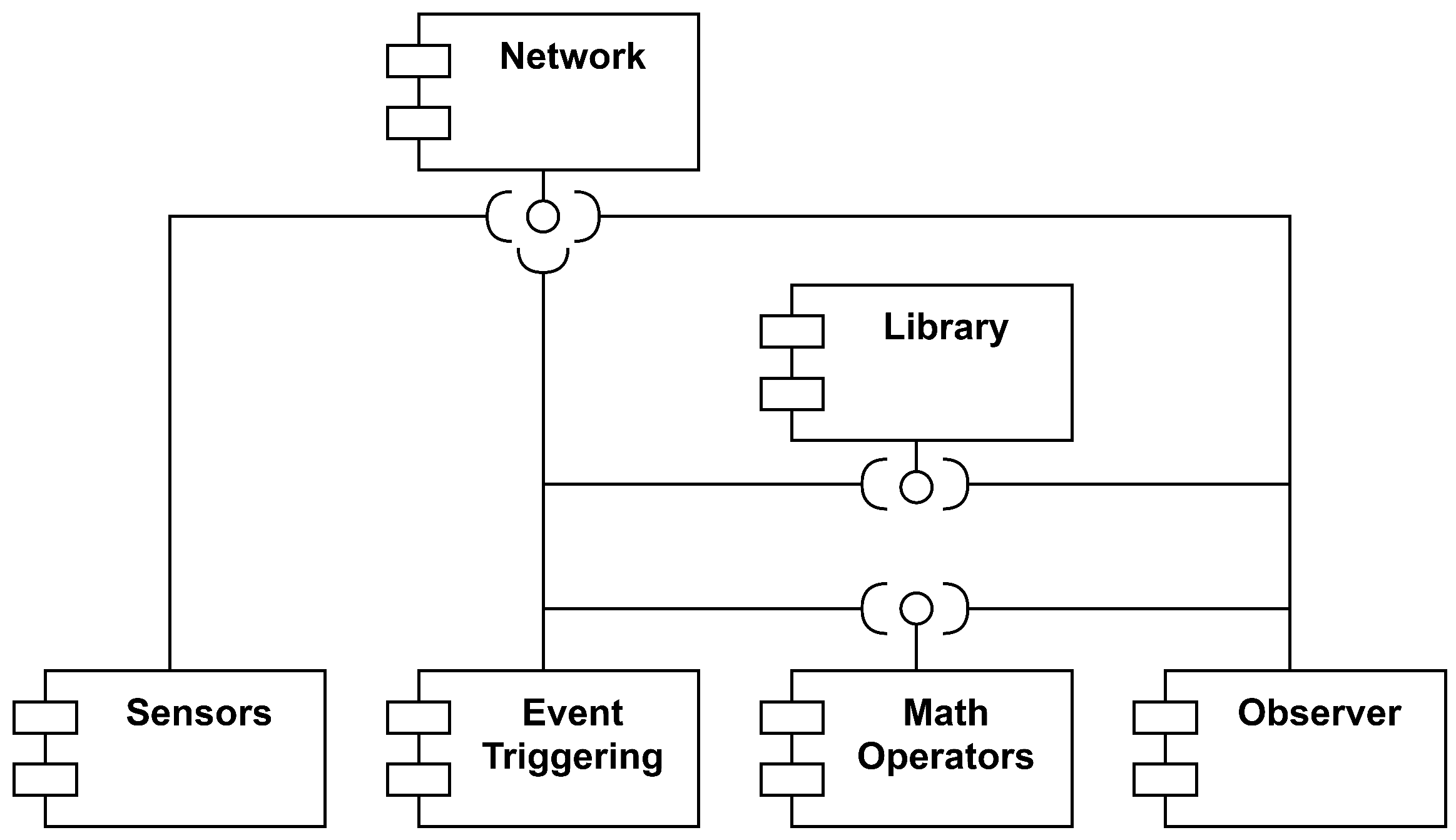

2.3. Software Perspective

- a.

- Network. This component incorporates the essential logic required to facilitate communication among the computers within the system. At the time of writing this article, the system employed a client–server model utilizing TCP sockets for data exchange. This component furnishes various implementations for distinct operations, including:

- Establish communication: (a) receives the IP and port of the machine; and (b) returns a socket descriptor that is used to exchange data with the process;

- Set socket listener port: (a) receives the port number in which the server will be listening for new connections; and (b) returns a number that will be used by the server as socket descriptor;

- Send message: (a) receives the message to send, the length of the message, and one socket descriptor; and (b) returns 0 in case of success and −1 if an error occurs;

- Receive message; (a) receives a buffer where the message will be stored, the length of the message, and one socket descriptor; and (b) returns 0 in case of success and −1 if an error occurs.

- b.

- Math operators. The programs in development must execute various mathematical operations, including matrix calculations. The responsibility of this block is to ensure the efficient implementation of these operators. Among the functions offered by this component are:

- Create matrix;

- Multiply matrix by number;

- Add matrices;

- Multiply matrices;

- Transpose matrix;

- Convert degrees to radians.

- c.

- Sensors. This component represents the array of sensors utilized by the Raspberry Pi for environmental data collection. To enhance the system modularity, it was determined that this component should employ the network interface for data transmission instead of being integrated into the event-triggering block. This choice enables developers to separate the data collection process from its subsequent processing.

- d.

- Event triggering. This block executes the event-triggering algorithm. It processes data from sensors and transmits that information to the observer. Given that the algorithm involves matrix operations, it is imperative to ensure the availability and integration of the math component for its proper functionality.

- e.

- Observer. This component is the last piece of the algorithm. It processes the data sent by the event-triggering program and estimates both the vehicle sideslip and roll angles.Note: Both the event-triggering program and the observer are required not only to communicate with each other and perform mathematical operations, but also to generate graphics once the programs have finished. This is why they are connected to the library component.

- Main: this program is responsible for obtaining data from the sensors and transmitting them to the event-triggering program;

- Event triggering: this code receives data from the sensors and performs several mathematical operations in order to decide whether the processed information must be sent to the observer or not;

- Observer: this program calculates the slip and roll angles as its final outputs.

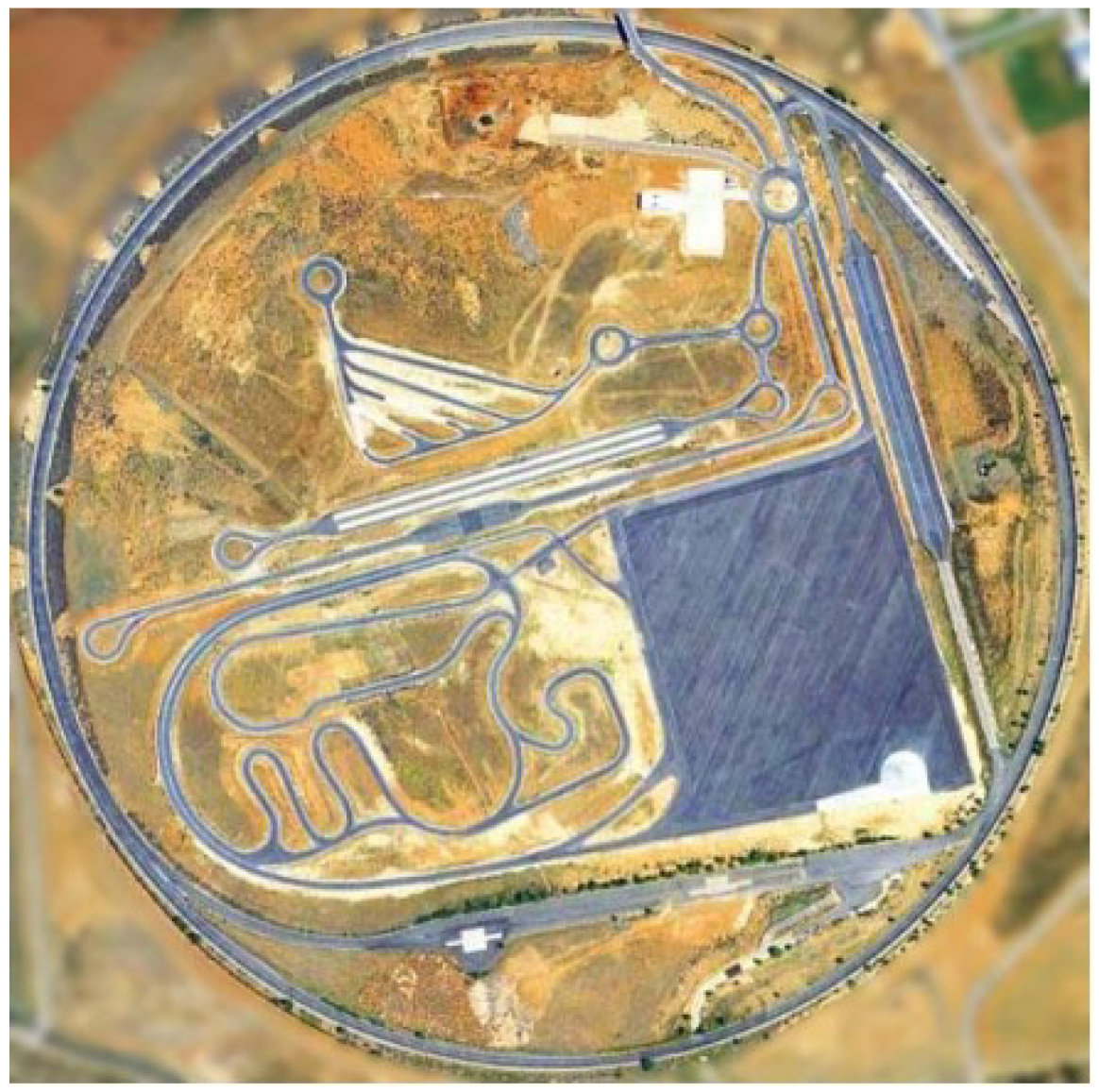

2.4. Experimental Design

- a.

- Spiral. During a spiral movement, the driver steers the vehicle along a path that gradually narrows or widens in a spiral shape. The challenge is to maintain control and follow the curvature of the road.

- b.

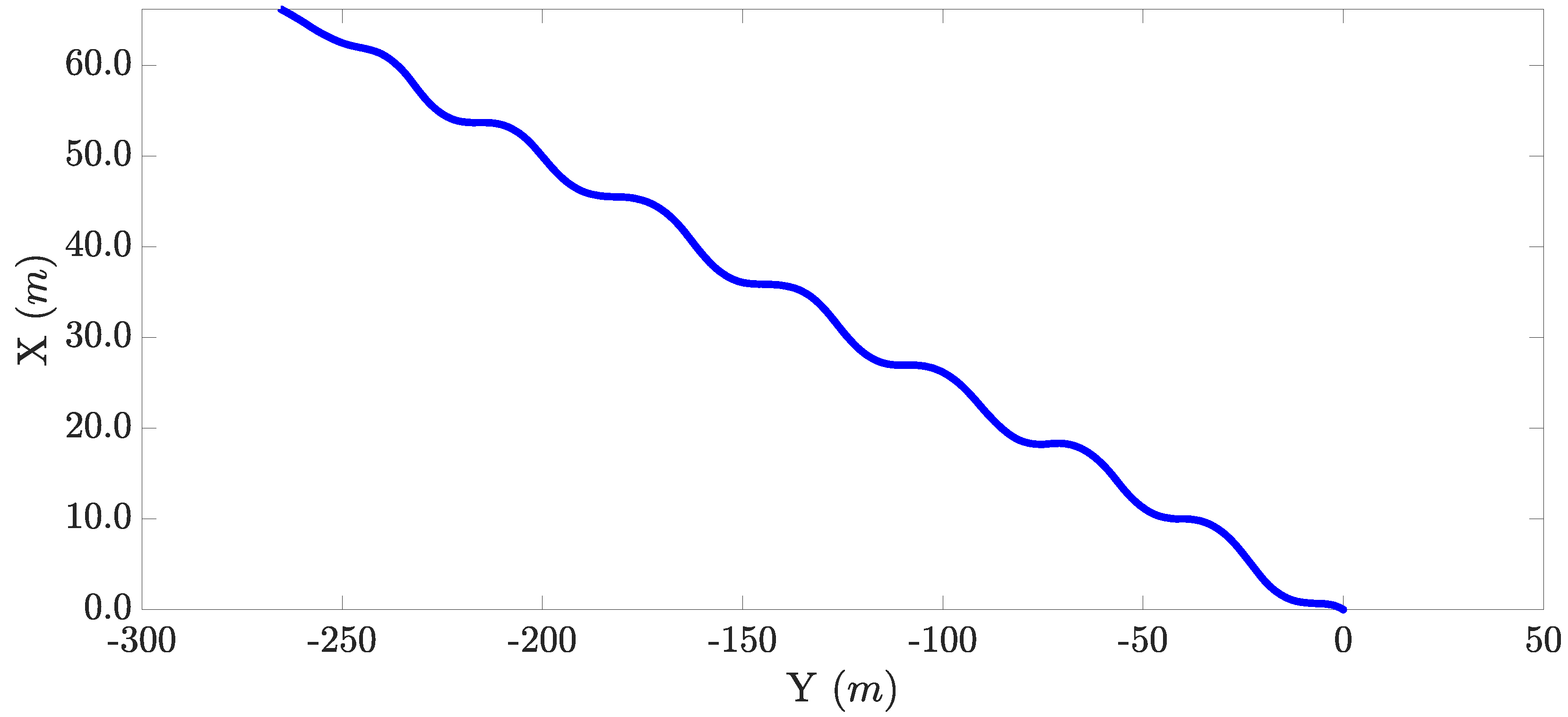

- Slalom. The slalom is a driving course that consists of a series of gates or markers arranged in a zigzag pattern. The driver must navigate through the obstacles by making rapid turns and quick changes in direction.

- c.

- Lane change. The ability to change lanes is a crucial driving skill that has many practical applications in everyday driving scenarios. For example, changing lanes allows overtaking slower vehicles, adjusting to traffic conditions, and avoiding obstacles.

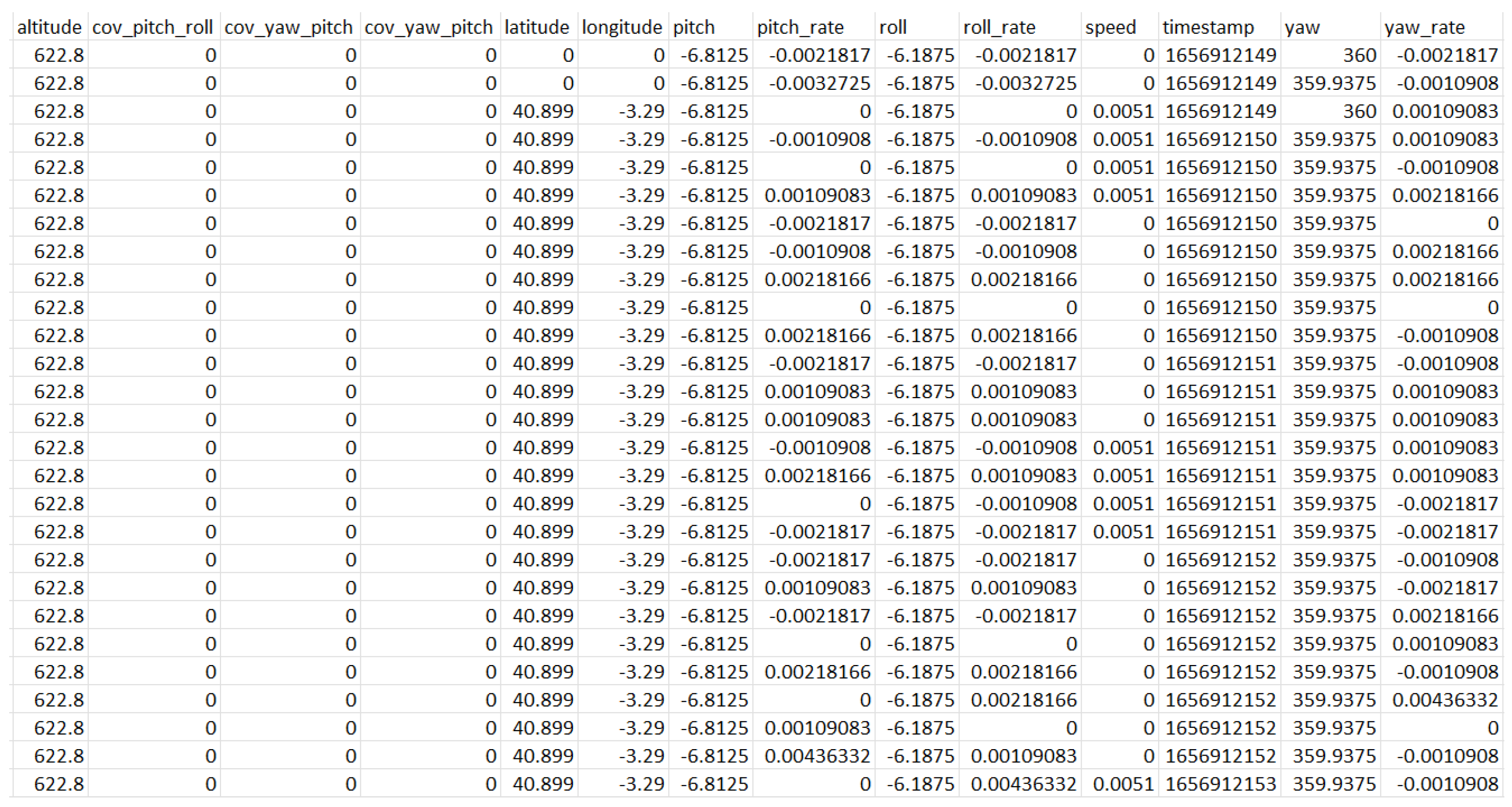

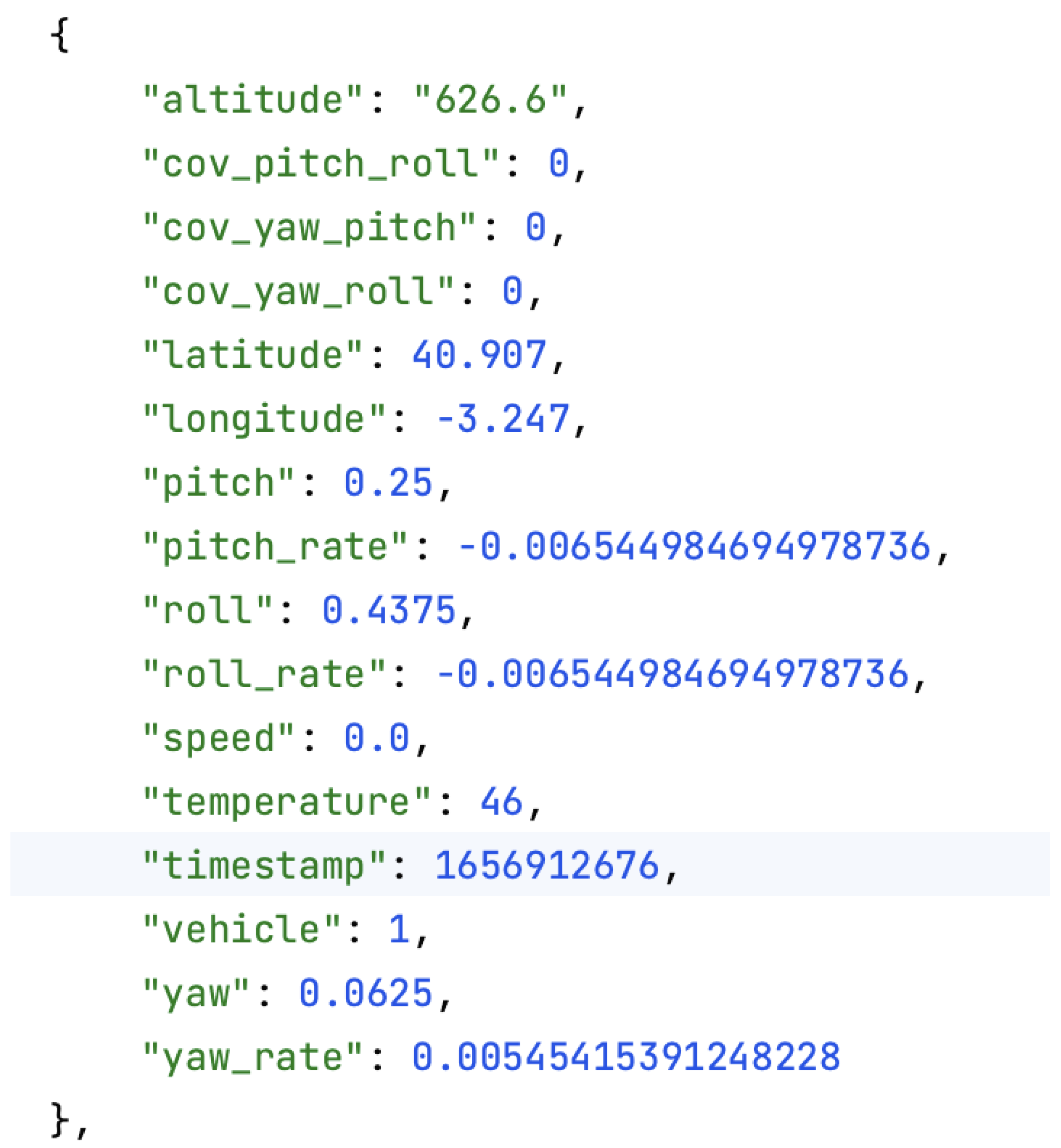

2.5. Data Gathering

- Covariance between pitch and roll angles;

- Covariance between yaw and pitch angles;

- Covariance between yaw and roll angles;

- Altitude;

- Latitude;

- Longitude;

- Pitch angle;

- Pitch rate;

- Roll angle;

- Roll rate;

- Yaw angle;

- Yaw rate;

- Vehicle speed;

- Timestamp.

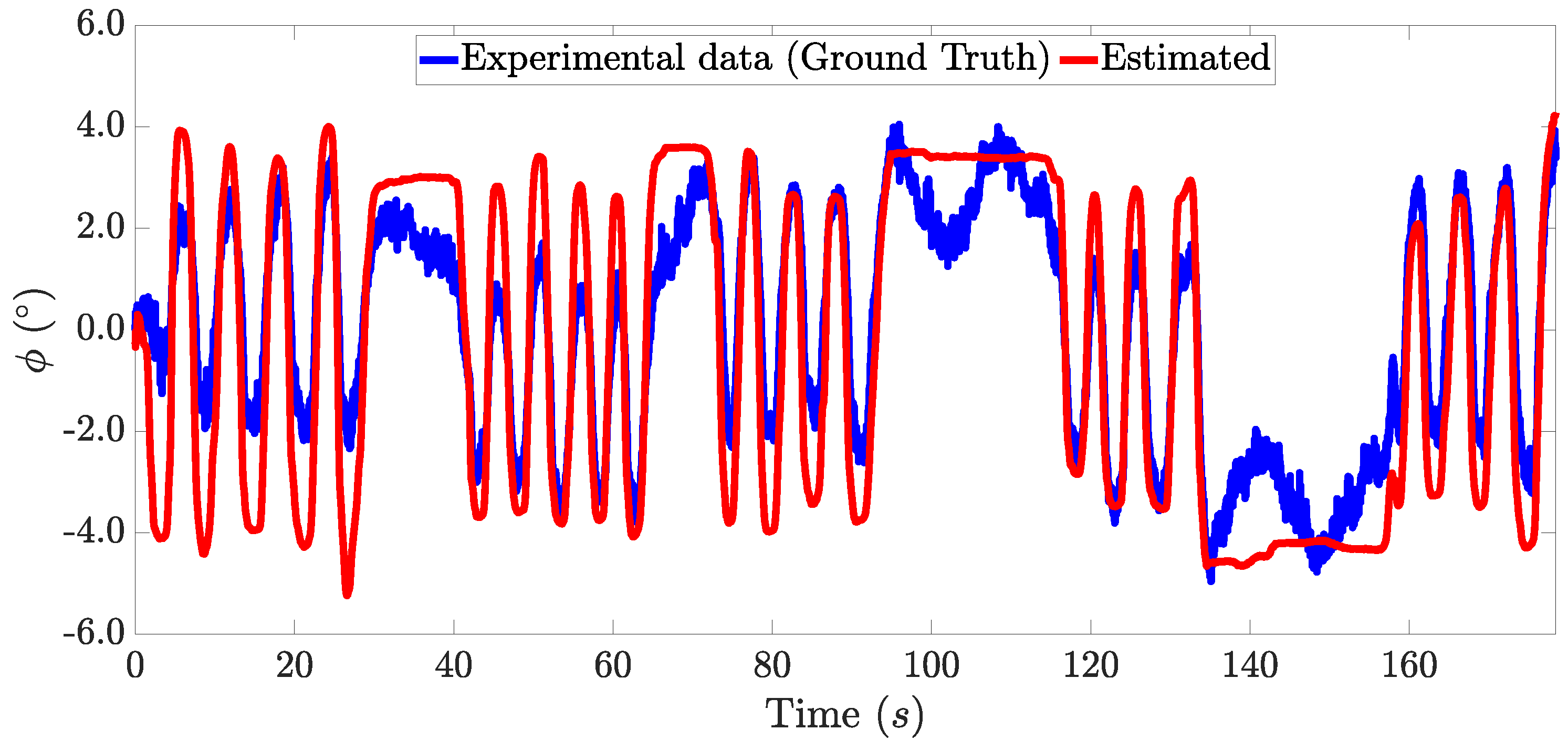

3. Experimental Results

- It was assumed that the longitudinal velocity was bounded in the interval [2 m/s, 20 m/s];

- The maximum variation in the tire cornering stiffness was 5% of its nominal value;

- The data sampling frequency was 100 Hz, with minimum and maximum transmission time delays of 5 and 20 ms, respectively.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ADS | Automated driving system |

| GPS | Global positioning system |

| NCS | Networked control system |

| IMU | Inertial measurement unit |

| IoT | Internet of Things |

| LPV | Linear parameter varying |

| RMS | Root mean square |

Appendix A. Example of Data Logged During the Experiments

References

- Viadero-Monasterio, F.; Nguyen, A.T.; Lauber, J.; Boada, M.J.L.; Boada, B.L. Event-Triggered Robust Path Tracking Control Considering Roll Stability Under Network-Induced Delays for Autonomous Vehicles. IEEE Trans. Intell. Transp. Syst. 2023, 24, 14743–14756. [Google Scholar] [CrossRef]

- Alrejjal, A.; Farid, A.; Ksaibati, K. Investigating factors influencing rollover crash risk on mountainous interstates. J. Saf. Res. 2022, 80, 391–398. [Google Scholar] [CrossRef]

- Rezapour, M.; Ksaibati, K. Contributory factors to the severity of single-vehicle rollover crashes on a mountainous area, generalized additive model. Int. J. Inj. Control. Saf. Promot. 2022, 29, 281–288. [Google Scholar] [CrossRef] [PubMed]

- Xiao, L.; Wang, M.; Zhang, B.; Zhong, Z. Vehicle roll stability control with active roll-resistant electro-hydraulic suspension. Front. Mech. Eng. 2020, 15, 43–54. [Google Scholar] [CrossRef]

- Dandiwala, A.; Chakraborty, B.; Chakravarty, D.; Sindha, J. Vehicle dynamics and active rollover stability control of an electric narrow three-wheeled vehicle: A review and concern towards improvement. Veh. Syst. Dyn. 2023, 61, 399–422. [Google Scholar] [CrossRef]

- Vu, V.T.; Sename, O.; Dugard, L.; Gáspár, P. Enhancing roll stability of heavy vehicle by LQR active anti-roll bar control using electronic servo-valve hydraulic actuators. Veh. Syst. Dyn. 2017, 55, 1405–1429. [Google Scholar] [CrossRef]

- Tota, A.; Dimauro, L.; Velardocchia, F.; Paciullo, G.; Velardocchia, M. An intelligent predictive algorithm for the anti-rollover prevention of heavy vehicles for off-road applications. Machines 2022, 10, 835. [Google Scholar] [CrossRef]

- Pomoni, M. Exploring Smart Tires as a Tool to Assist Safe Driving and Monitor Tire–Road Friction. Vehicles 2022, 4, 744–765. [Google Scholar] [CrossRef]

- de Carvalho Pinheiro, H.; Carello, M.; Punta, E. Torque vectoring control strategies comparison for hybrid vehicles with two rear electric motors. Appl. Sci. 2023, 13, 8109. [Google Scholar] [CrossRef]

- He, S.; Fan, X.; Wang, Q.; Chen, X.; Zhu, S. Review on torque distribution scheme of four-wheel in-wheel motor electric vehicle. Machines 2022, 10, 619. [Google Scholar] [CrossRef]

- Singh, K.B.; Arat, M.A.; Taheri, S. Literature review and fundamental approaches for vehicle and tire state estimation. Veh. Syst. Dyn. 2018, 57, 1643–1665. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Wang, X.; Zhao, Y.; Wang, C. Estimation of Intelligent Commercial Vehicle Sideslip Angle Based on Steering Torque. Appl. Sci. 2023, 13, 7974. [Google Scholar] [CrossRef]

- Alonso, L.; Milanés, V.; Torre-Ferrero, C.; Godoy, J.; Oria, J.P.; De Pedro, T. Ultrasonic sensors in urban traffic driving-aid systems. Sensors 2011, 11, 661–673. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Luo, Y.; Li, K.; Dai, Y. Coordinated path-following and direct yaw-moment control of autonomous electric vehicles with sideslip angle estimation. Mech. Syst. Signal Process. 2018, 105, 183–199. [Google Scholar] [CrossRef]

- Strano, S.; Terzo, M. Vehicle sideslip angle estimation via a Riccati equation based nonlinear filter. Meccanica 2017, 52, 3513–3529. [Google Scholar] [CrossRef]

- Boada, B.L.; Viadero-Monasterio, F.; Zhang, H.; Boada, M.J.L. Simultaneous Estimation of Vehicle Sideslip and Roll Angles Using an Integral-Based Event-Triggered H∞ Observer Considering Intravehicle Communications. IEEE Trans. Veh. Technol. 2023, 72, 4411–4425. [Google Scholar] [CrossRef]

- Habibnejad Korayem, A.; Khajepour, A.; Fidan, B. Road angle estimation for a vehicle-trailer with machine learning and system model-based approaches. Veh. Syst. Dyn. 2022, 60, 3583–3604. [Google Scholar] [CrossRef]

- Dong, X.; Chen, G.; Tian, X.; Yan, X. Real-time estimation of roll angles by magnetometer based on two-step adaptive Kalman filter. Measurement 2022, 198, 111349. [Google Scholar] [CrossRef]

- Ni, Y.; Liu, X.; Yang, C. Sensor Scheduling for Remote State Estimation with Limited Communication Resources: A Time-and Event-Triggered Hybrid Approach. Sensors 2023, 23, 8667. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, Z. Vehicle velocity and roll angle estimation with road and friction adaptation for four-wheel independent drive electric vehicle. Math. Probl. Eng. 2014, 2014, 801628. [Google Scholar] [CrossRef]

- Rajamani, R.; Piyabongkarn, D.; Tsourapas, V.; Lew, J. Real-time estimation of roll angle and CG height for active rollover prevention applications. In Proceedings of the 2009 American Control Conference, St. Louis, MO, USA, 10–12 June 2009; pp. 433–438. [Google Scholar] [CrossRef]

- Jiang, G.; Liu, L.; Guo, C.; Chen, J.; Muhammad, F.; Miao, X. A novel fusion algorithm for estimation of the side-slip angle and the roll angle of a vehicle with optimized key parameters. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2017, 231, 161–174. [Google Scholar] [CrossRef]

- Jo, K.; Chu, K.; Sunwoo, M. Interacting Multiple Model Filter-Based Sensor Fusion of GPS With In-Vehicle Sensors for Real-Time Vehicle Positioning. IEEE Trans. Intell. Transp. Syst. 2012, 13, 329–343. [Google Scholar] [CrossRef]

- Boada, M.J.L.; Boada, B.L.; Zhang, H. Event-triggering H∞-based observer combined with NN for simultaneous estimation of vehicle sideslip and roll angles with network-induced delays. Nonlinear Dyn. 2021, 103, 2733–2752. [Google Scholar] [CrossRef]

- Cao, Y.; Zhao, N.; Xu, N.; Zhao, X.; Alsaadi, F.E. Minimal-approximation-based adaptive event-triggered control of switched nonlinear systems with unknown control direction. Electronics 2022, 11, 3386. [Google Scholar] [CrossRef]

- Tian, Y.; Tian, S.; Li, H.; Han, Q.; Wang, X. Event-Triggered Security Consensus for Multi-Agent Systems with Markov Switching Topologies under DoS Attacks. Energies 2022, 15, 5353. [Google Scholar] [CrossRef]

- Zhang, H.; Hong, Q.; Yan, H.; Luo, Y. Observer-based decentralized event-triggered H∞ control for networked systems. J. Frankl. Inst. 2017, 354, 3744–3759. [Google Scholar] [CrossRef]

- Ding, X.; Wang, Z.; Zhang, L. Event-triggered vehicle sideslip angle estimation based on low-cost sensors. IEEE Trans. Ind. Inform. 2021, 18, 4466–4476. [Google Scholar] [CrossRef]

- Viadero-Monasterio, F.; Boada, B.L.; Zhang, H.; Boada, M.J.L. Integral-Based Event Triggering Actuator Fault-Tolerant Control for an Active Suspension System Under a Networked Communication Scheme. IEEE Trans. Veh. Technol. 2023, 72, 13848–13860. [Google Scholar] [CrossRef]

- Li, L.; Zou, W.; Fei, S. Event-based dynamic output-feedback controller design for networked control systems with sensor and actuator saturations. J. Frankl. Inst. 2017, 354, 4331–4352. [Google Scholar] [CrossRef]

- Liu, C.; Hao, F. Dynamic output-feedback control for linear systems by using event-triggered quantisation. Iet Control. Theory Appl. 2015, 9, 1254–1263. [Google Scholar] [CrossRef]

- Wang, G.; Chadli, M.; Chen, H.; Zhou, Z. Event-triggered control for active vehicle suspension systems with network-induced delays. J. Frankl. Inst. 2019, 356, 147–172. [Google Scholar] [CrossRef]

- Zhang, X.M.; Han, Q.L. Event-triggered dynamic output feedback control for networked control systems. IET Control. Theory Appl. 2014, 8, 226–234. [Google Scholar] [CrossRef]

- Wang, X.; Lemmon, M.D. Event-triggering in distributed networked control systems. IEEE Trans. Autom. Control 2010, 56, 586–601. [Google Scholar] [CrossRef]

- Tan, L.N.; Gupta, N.; Derawi, M. H∞ Control for Oscillator Systems with Event-Triggering Signal Transmission of Internet of Things. IEEE Access 2023, 11, 8938–8949. [Google Scholar] [CrossRef]

- Li, L.; Jia, G.; Ran, X.; Song, J.; Wu, K. A variable structure extended Kalman filter for vehicle sideslip angle estimation on a low friction road. Veh. Syst. Dyn. 2014, 52, 280–308. [Google Scholar] [CrossRef]

- Zhang, H.; Zheng, X.; Yan, H.; Peng, C.; Wang, Z.; Chen, Q. Codesign of Event-Triggered and Distributed H∞ Filtering for Active Semi-Vehicle Suspension Systems. IEEE/ASME Trans. Mechatron. 2017, 22, 1047–1058. [Google Scholar] [CrossRef]

- Alizadeh, M.; Abyaneh, H.A.; Rouzbehi, K. An Enhanced Distributed Event-Triggered Mechanism of Cyber-Switched Communications for Control of Islanded AC Microgrids. IEEE Syst. J. 2022, 17, 1501–1511. [Google Scholar] [CrossRef]

- Lu, Z.; Guo, G. Control and communication scheduling co-design for networked control systems: A survey. Int. J. Syst. Sci. 2023, 54, 189–203. [Google Scholar] [CrossRef]

- Frazier, H. The 802.3 z gigabit ethernet standard. IEEE Netw. 1998, 12, 6–7. [Google Scholar] [CrossRef]

| Parameter | Value | Description |

|---|---|---|

| a | 1.42 m | Distance of the front axle from the center of gravity (CoG) |

| b | 0.85 m | Distance of the rear axle from the CoG |

| 31,752 N m/rad | Roll stiffness | |

| 7025.4 N m s/rad | Roll damping coefficient | |

| 30,000 N/rad | Cornering stiffness of the front tire | |

| 25,000 N/rad | Cornering stiffness of the rear tire | |

| g | 9.81 m/s | Acceleration of gravity |

| h | 0.35 m | Distance from roll center to CoG |

| 520 kg m | Moment of inertia about the roll axis | |

| 1110.9 kg m | Moment of inertia about the yaw axis | |

| m | 650 kg | Vehicle mass |

| m/s | Longitudinal speed |

| Sideslip Angle () | Roll Angle () | |

|---|---|---|

| MAX error | ||

| RMS error |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Viadero-Monasterio, F.; García, J.; Meléndez-Useros, M.; Jiménez-Salas, M.; Boada, B.L.; López Boada, M.J. Simultaneous Estimation of Vehicle Sideslip and Roll Angles Using an Event-Triggered-Based IoT Architecture. Machines 2024, 12, 53. https://doi.org/10.3390/machines12010053

Viadero-Monasterio F, García J, Meléndez-Useros M, Jiménez-Salas M, Boada BL, López Boada MJ. Simultaneous Estimation of Vehicle Sideslip and Roll Angles Using an Event-Triggered-Based IoT Architecture. Machines. 2024; 12(1):53. https://doi.org/10.3390/machines12010053

Chicago/Turabian StyleViadero-Monasterio, Fernando, Javier García, Miguel Meléndez-Useros, Manuel Jiménez-Salas, Beatriz López Boada, and María Jesús López Boada. 2024. "Simultaneous Estimation of Vehicle Sideslip and Roll Angles Using an Event-Triggered-Based IoT Architecture" Machines 12, no. 1: 53. https://doi.org/10.3390/machines12010053

APA StyleViadero-Monasterio, F., García, J., Meléndez-Useros, M., Jiménez-Salas, M., Boada, B. L., & López Boada, M. J. (2024). Simultaneous Estimation of Vehicle Sideslip and Roll Angles Using an Event-Triggered-Based IoT Architecture. Machines, 12(1), 53. https://doi.org/10.3390/machines12010053