Experimental Study and 3D Optimization of Small-Scale Solar-Powered Radial Turbine Using 3D Printing Technology

Abstract

1. Introduction

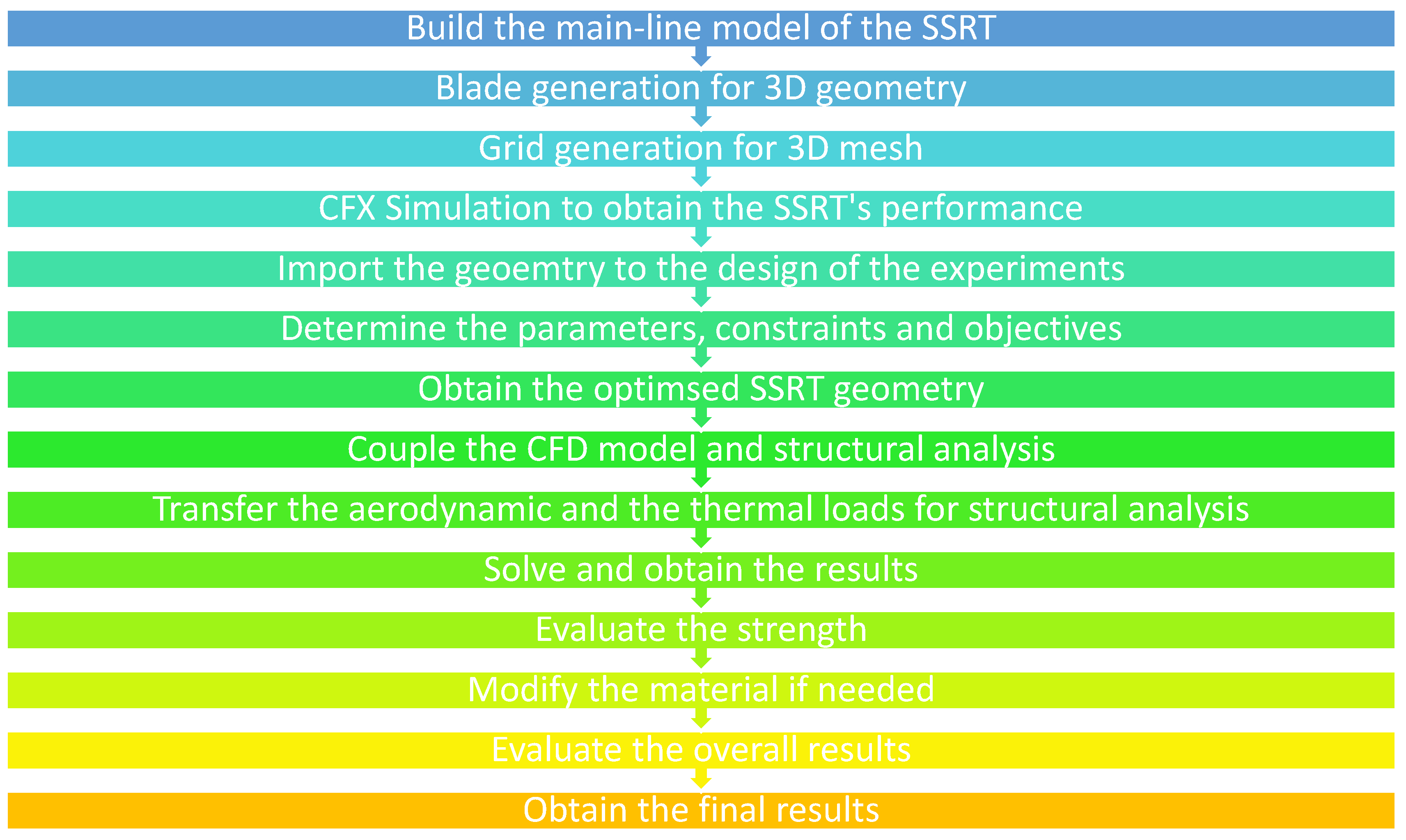

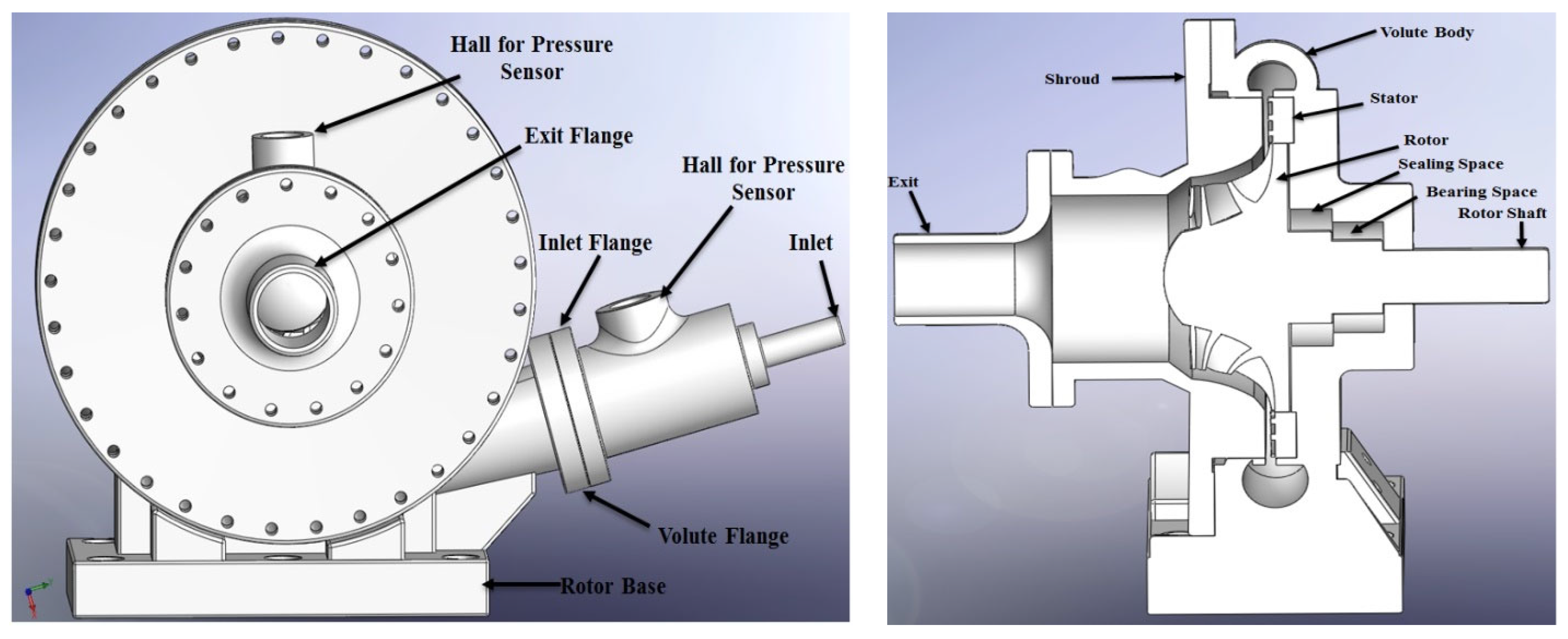

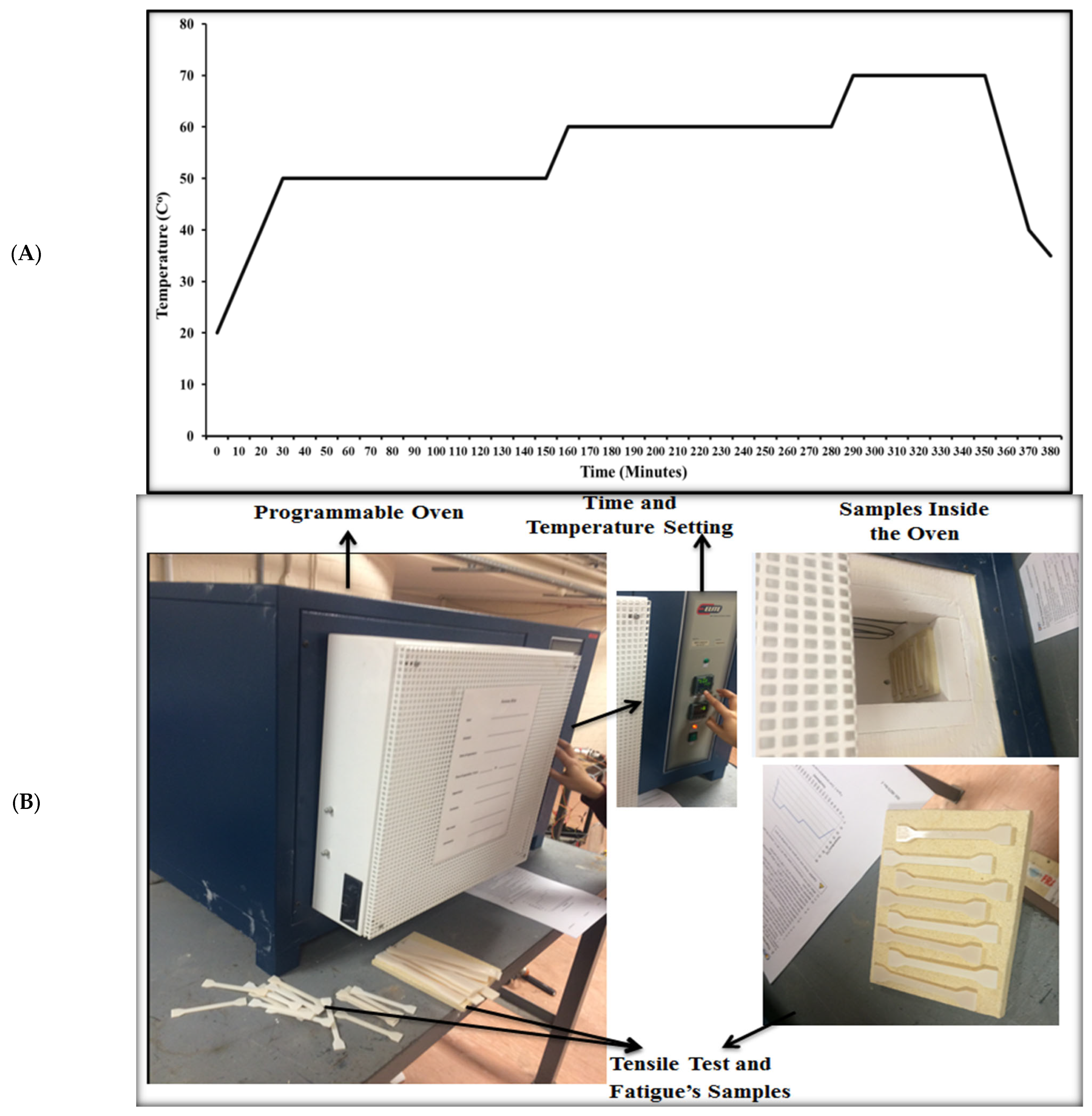

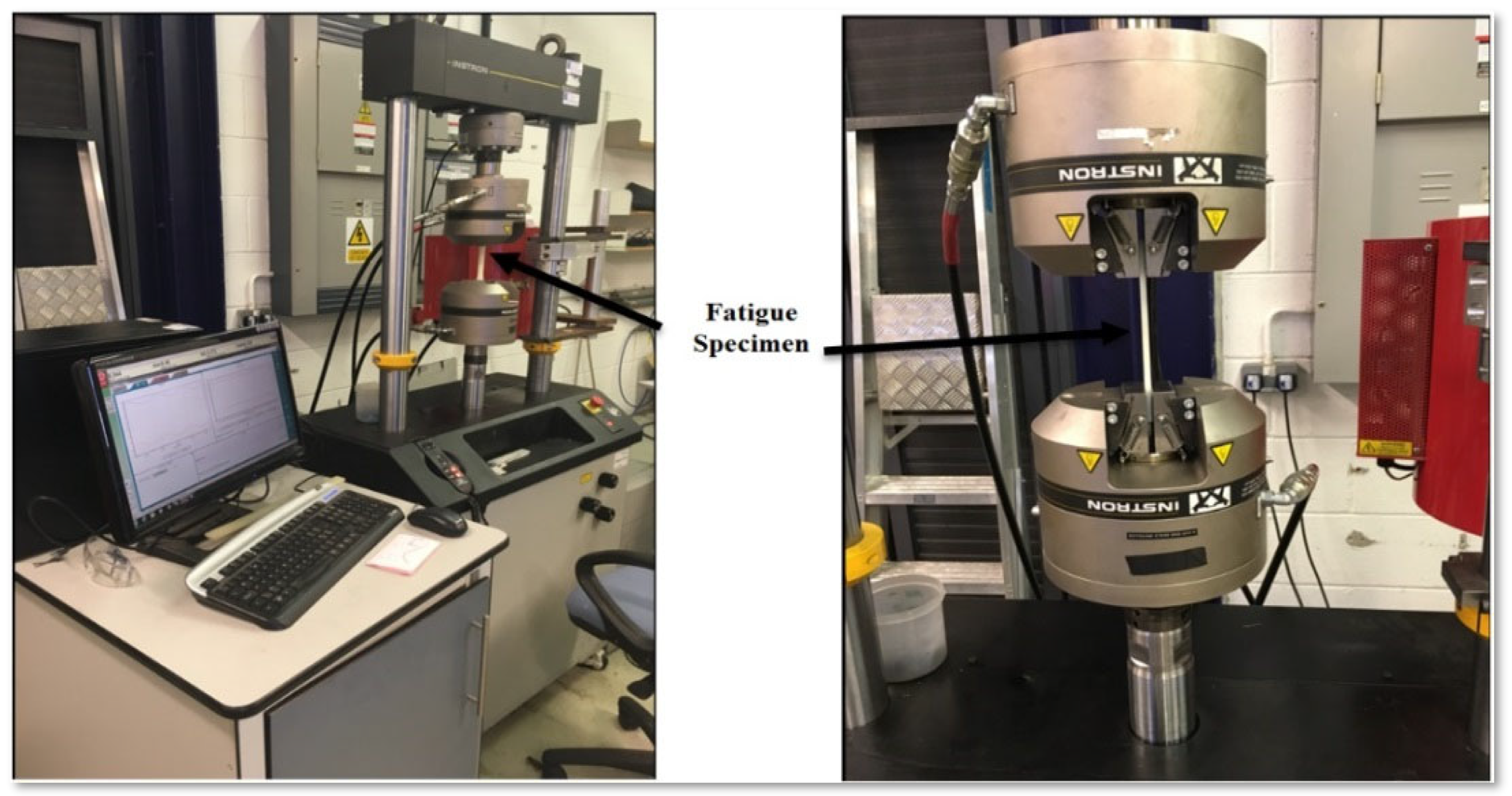

2. Methodology and Experimental Work

3. Governing Equations for Structural Analysis

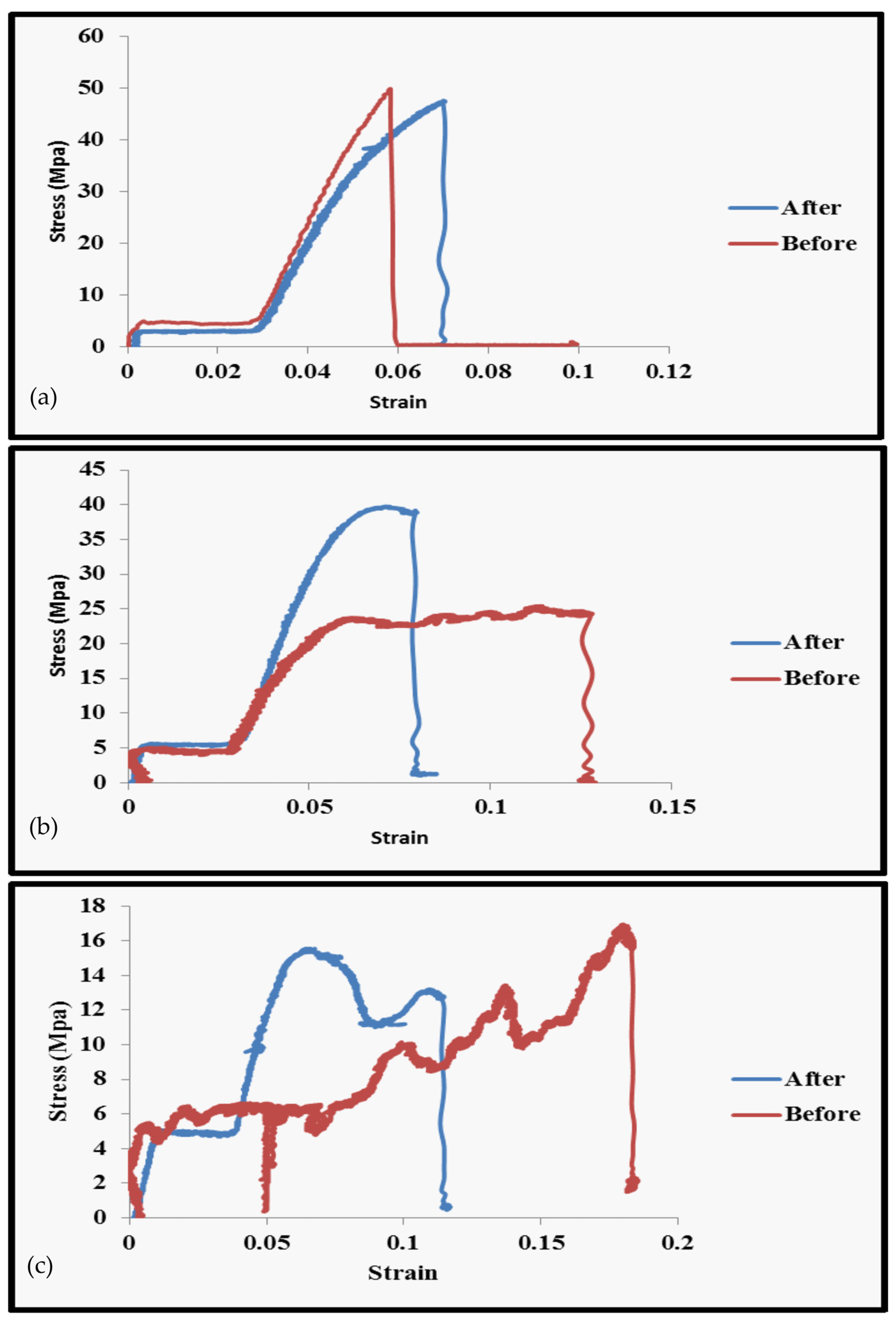

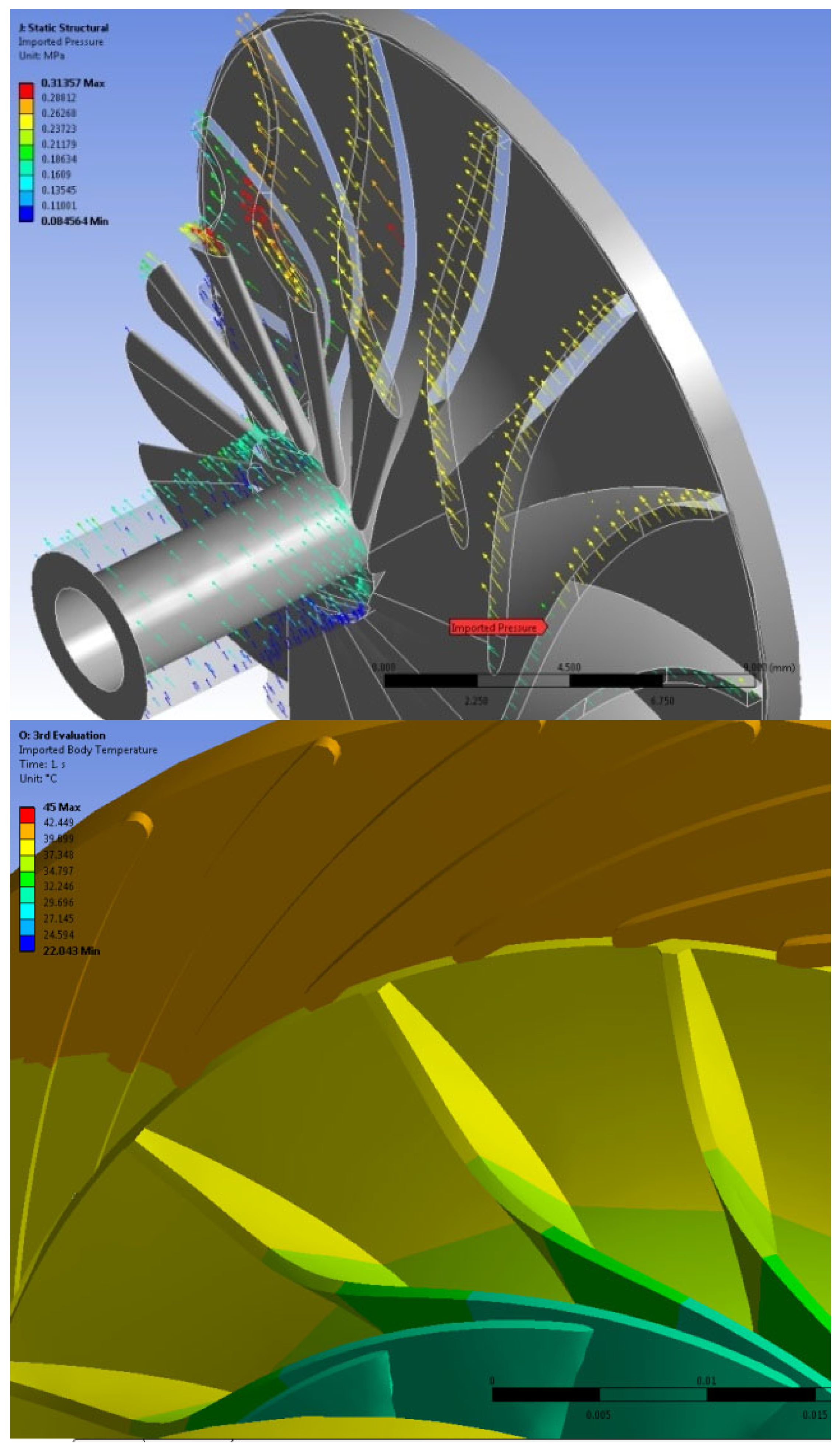

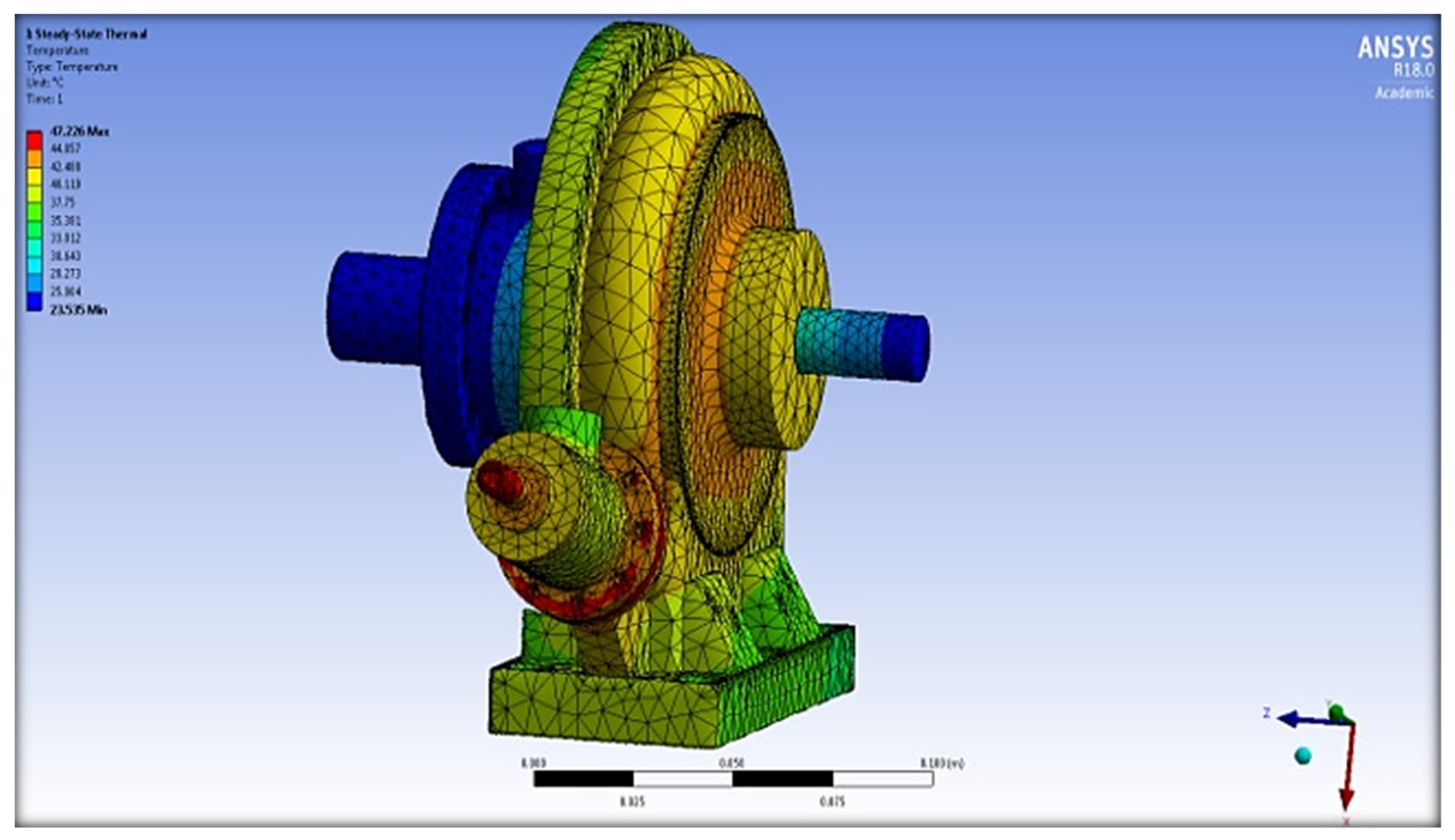

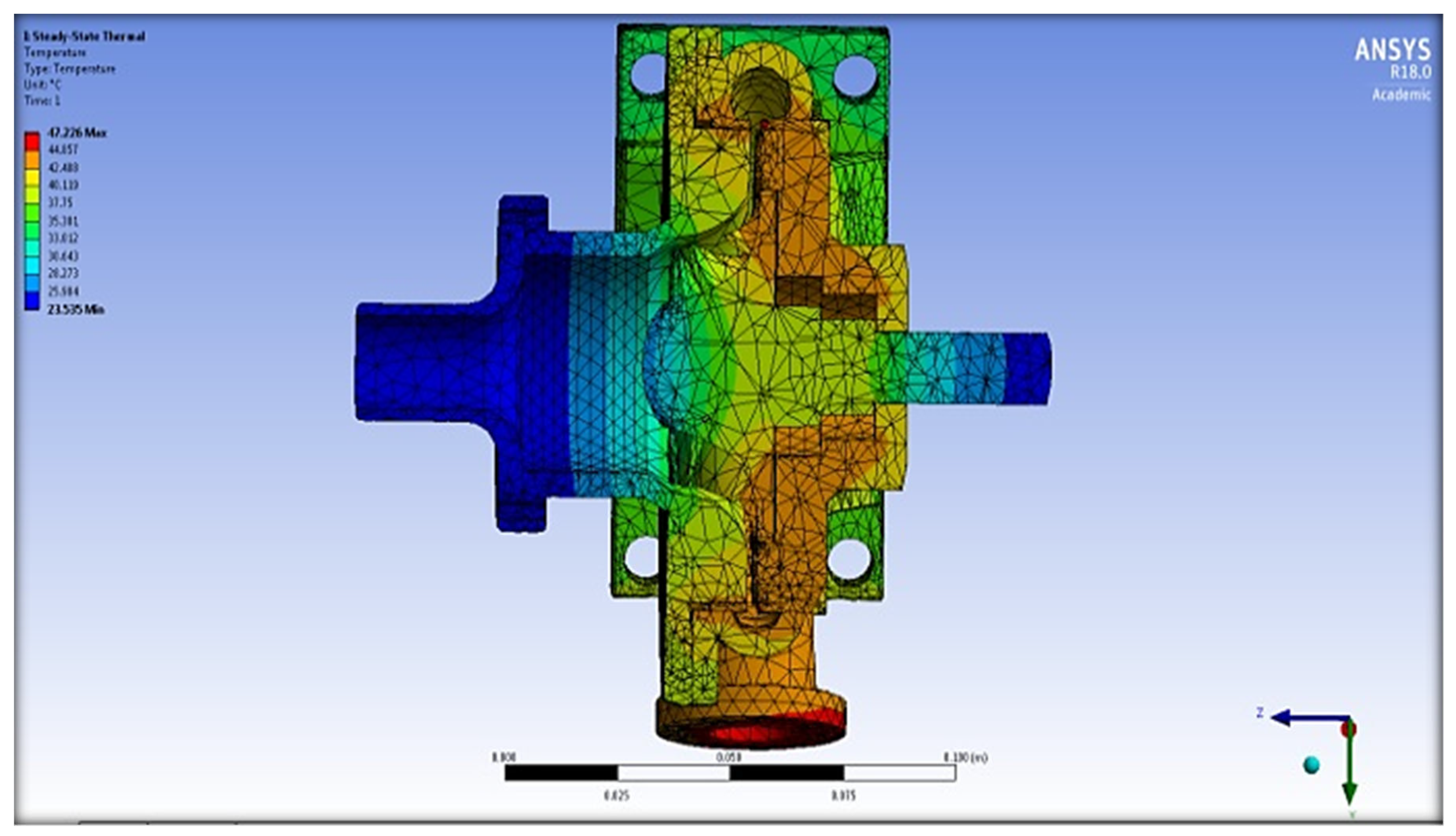

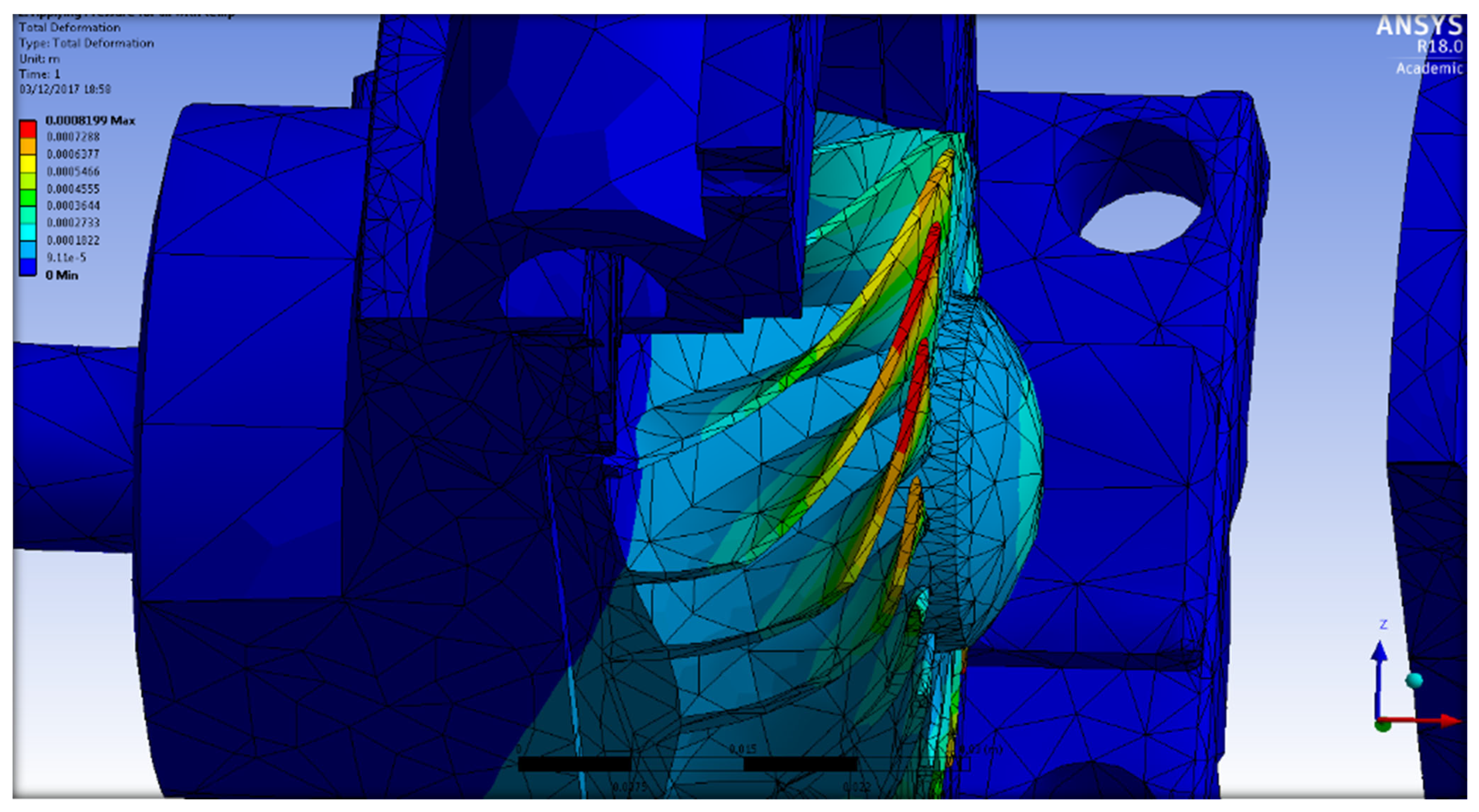

3.1. Mechanical Stresses Analysis

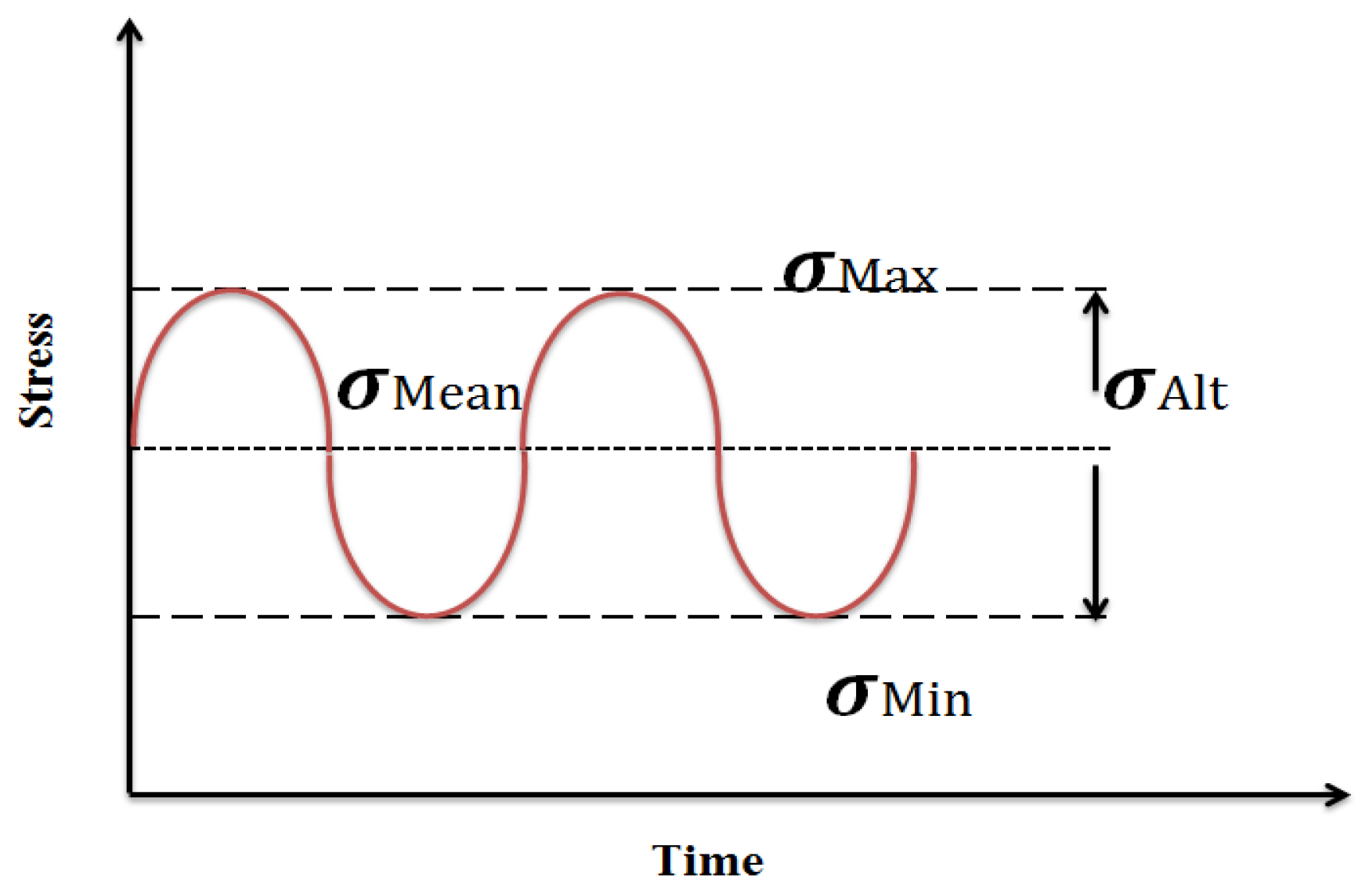

3.2. Fatigue Analysis

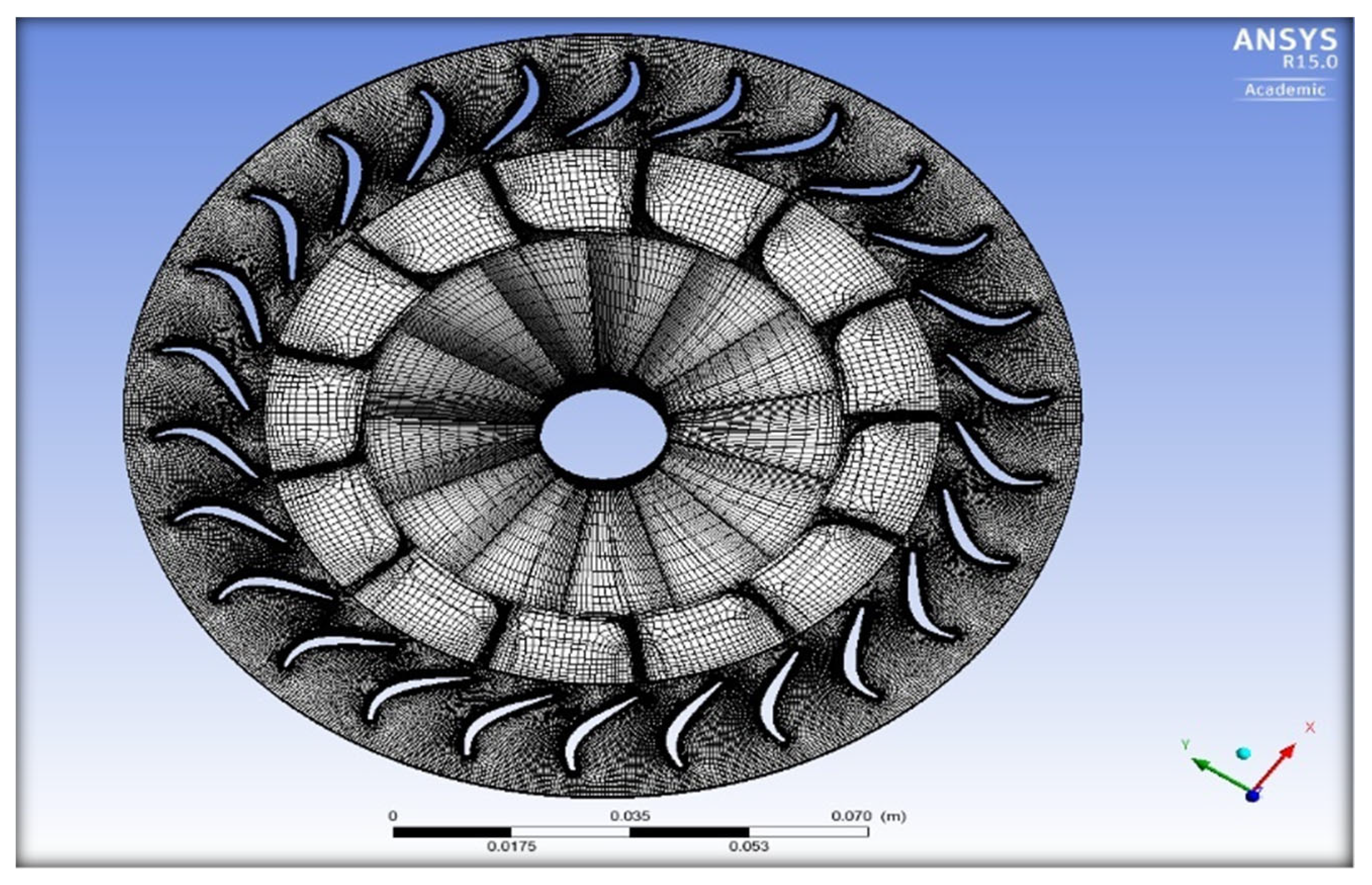

4. Numerical Modelling

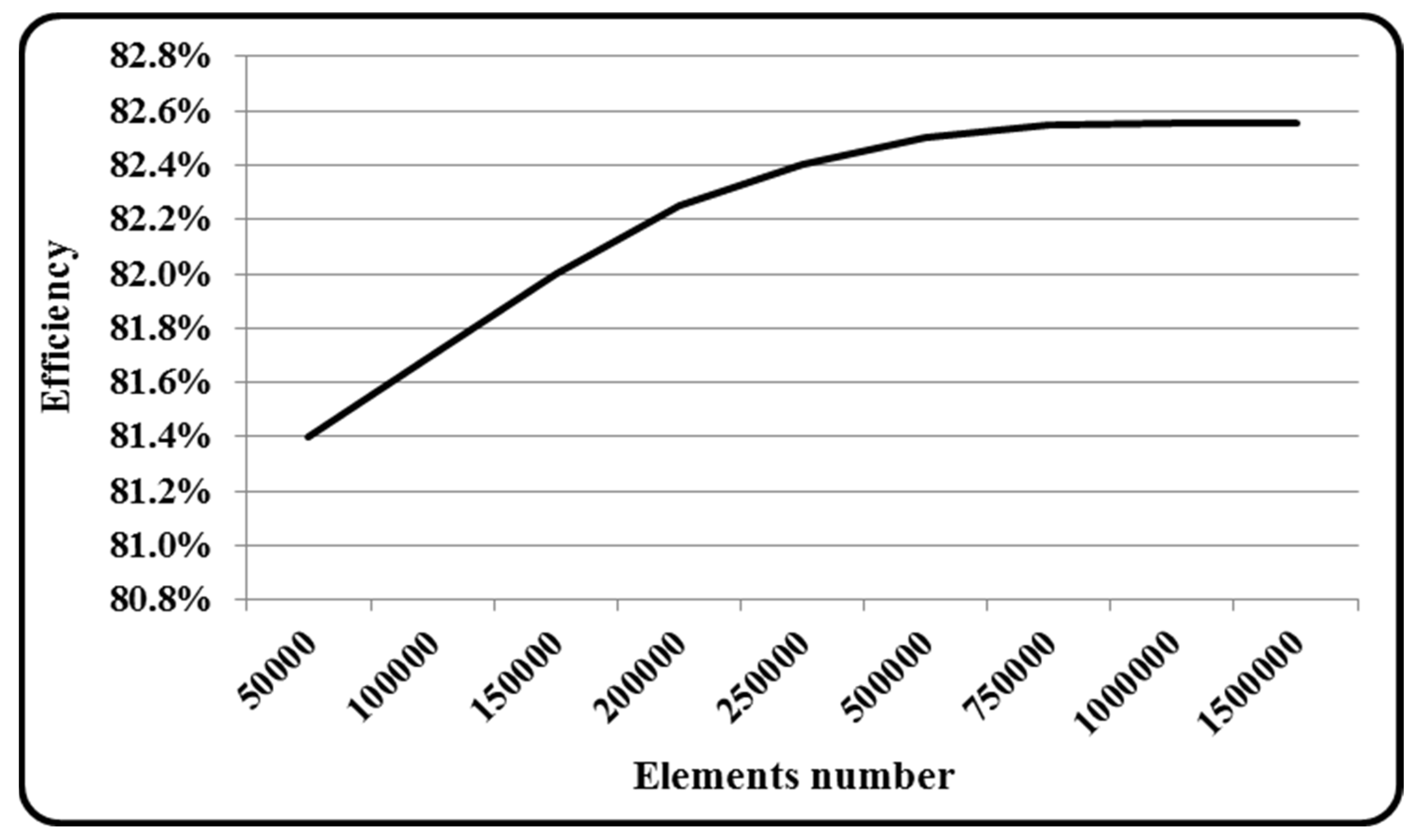

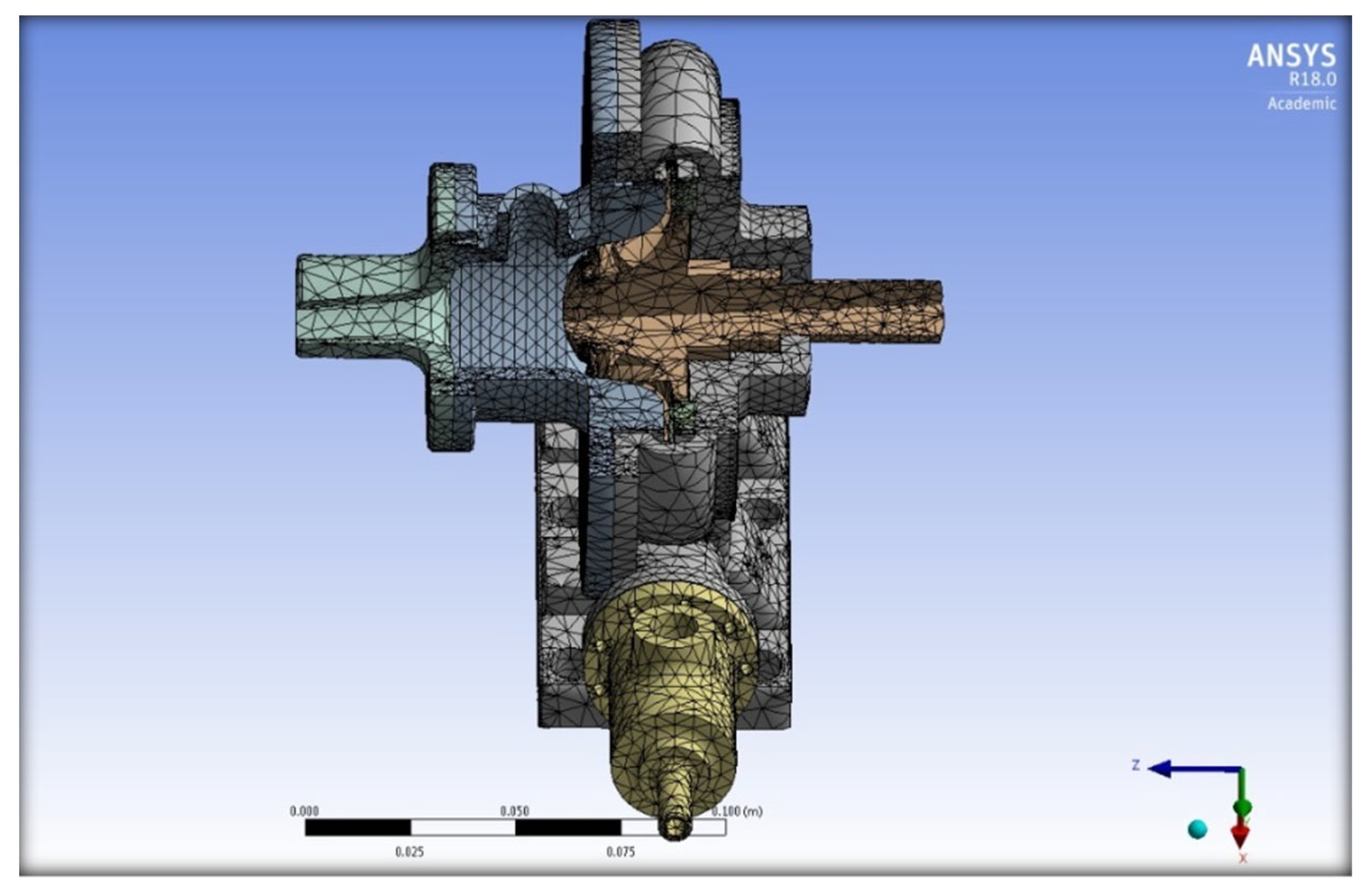

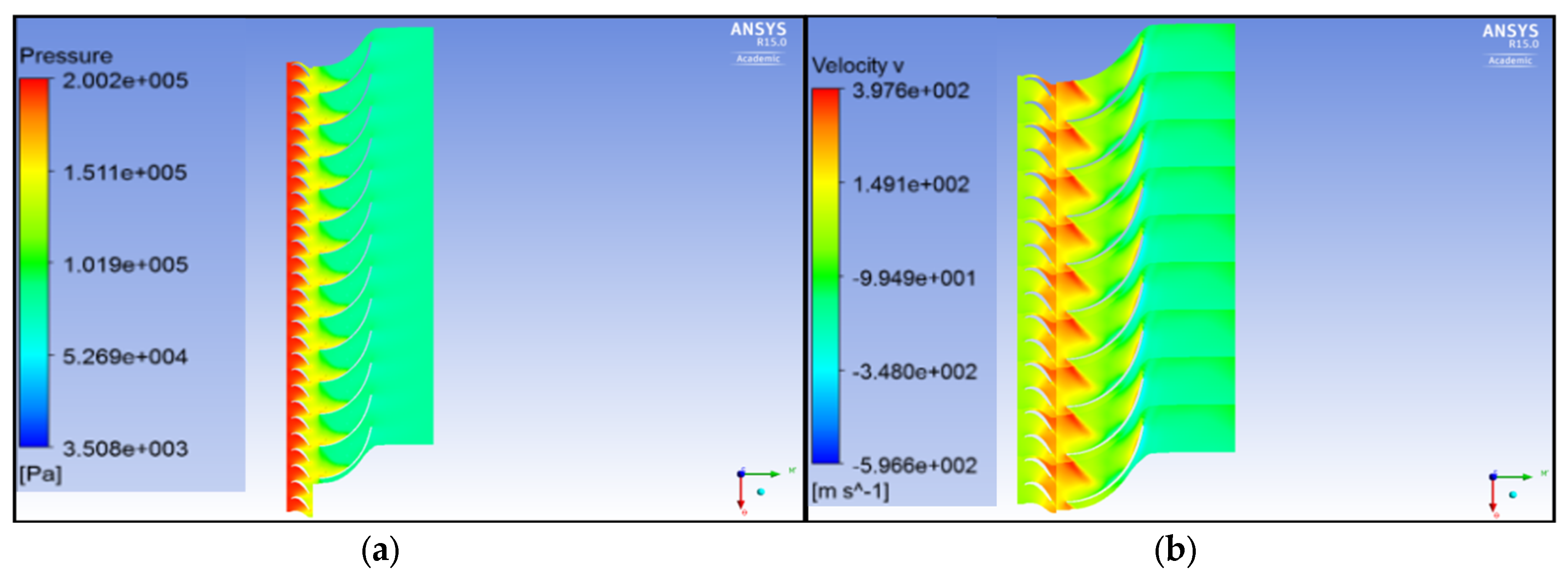

4.1. CFD and Structural Modeling

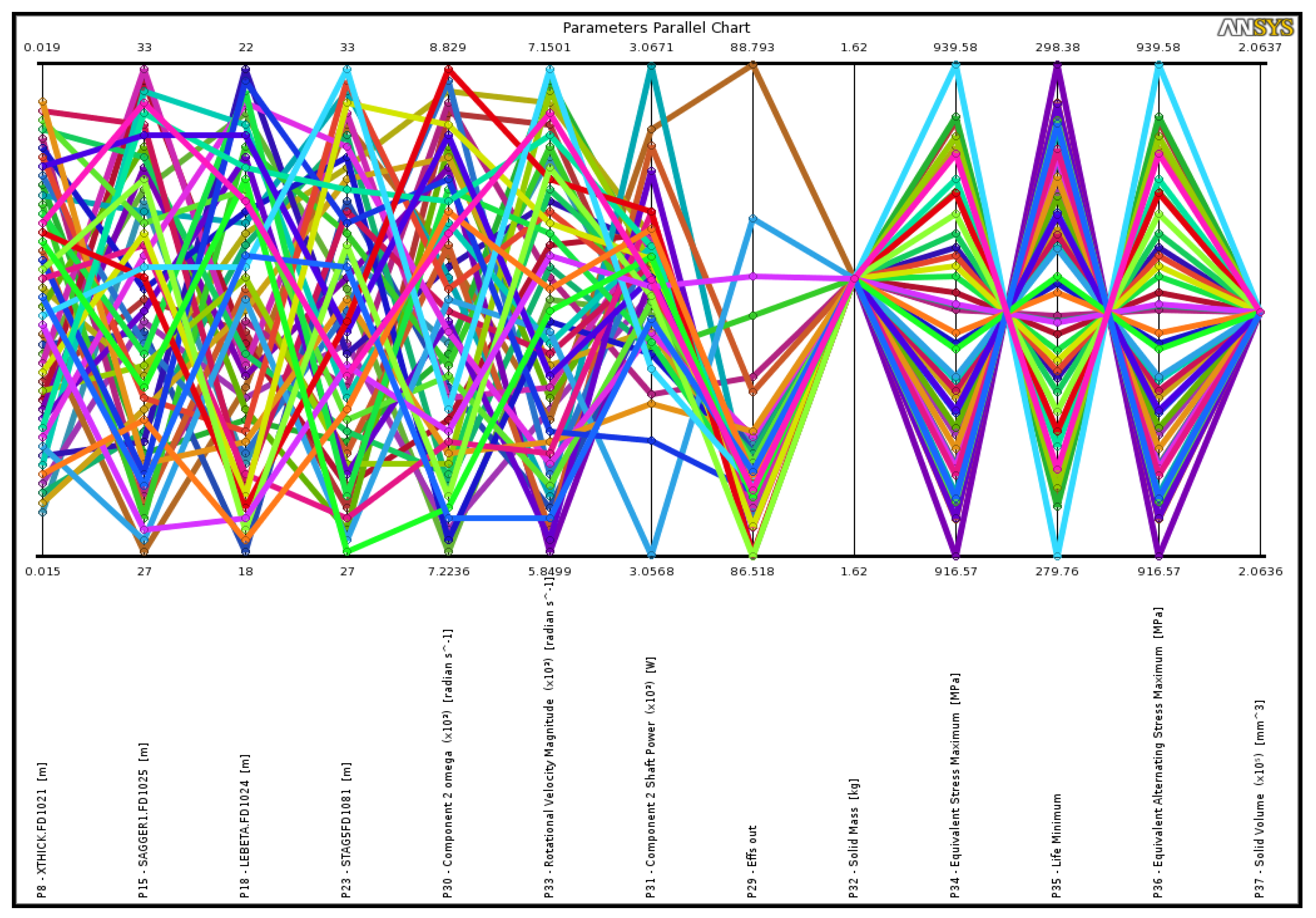

4.2. SSRT Multidisciplinary Optimization

5. Results and Discussion

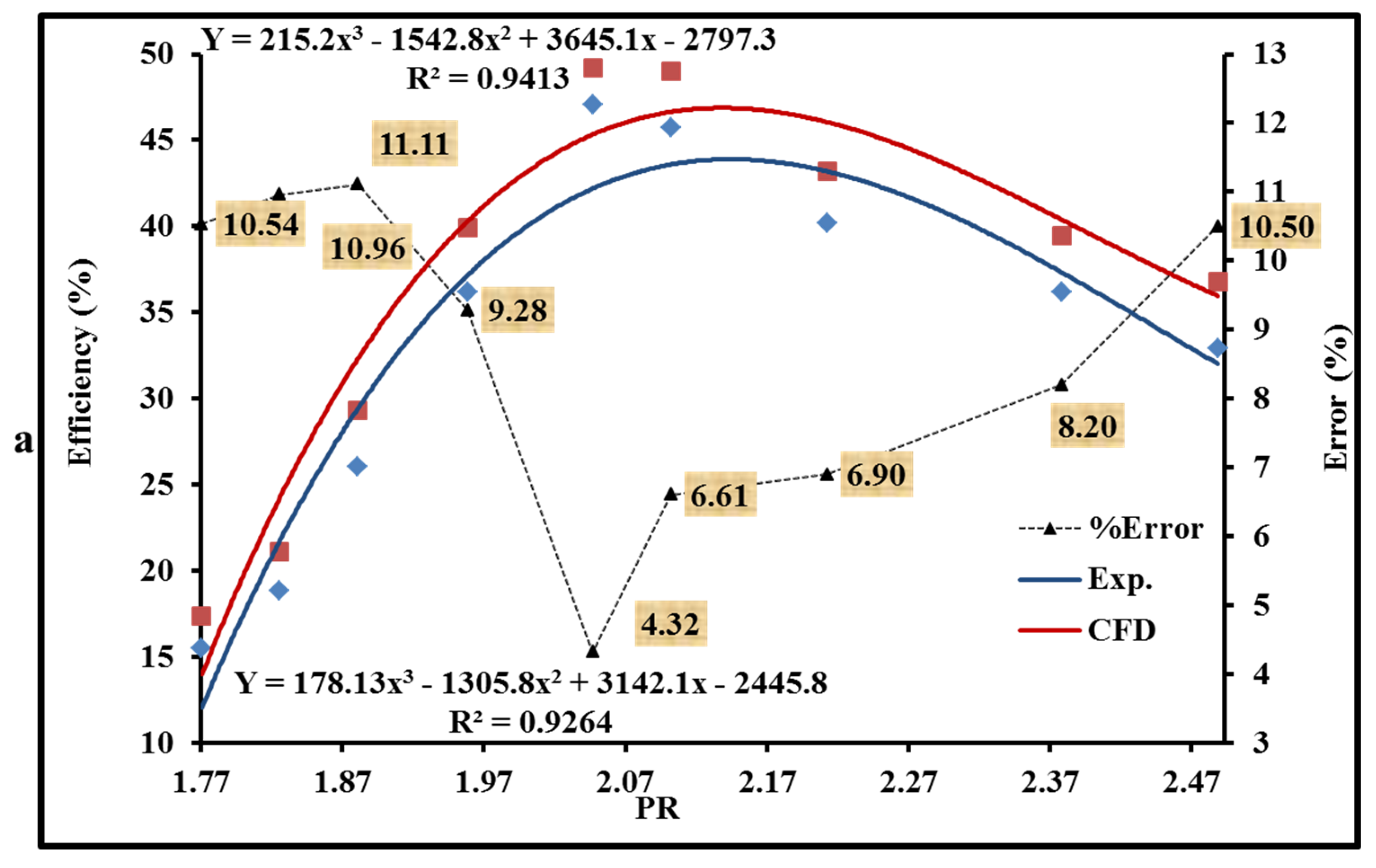

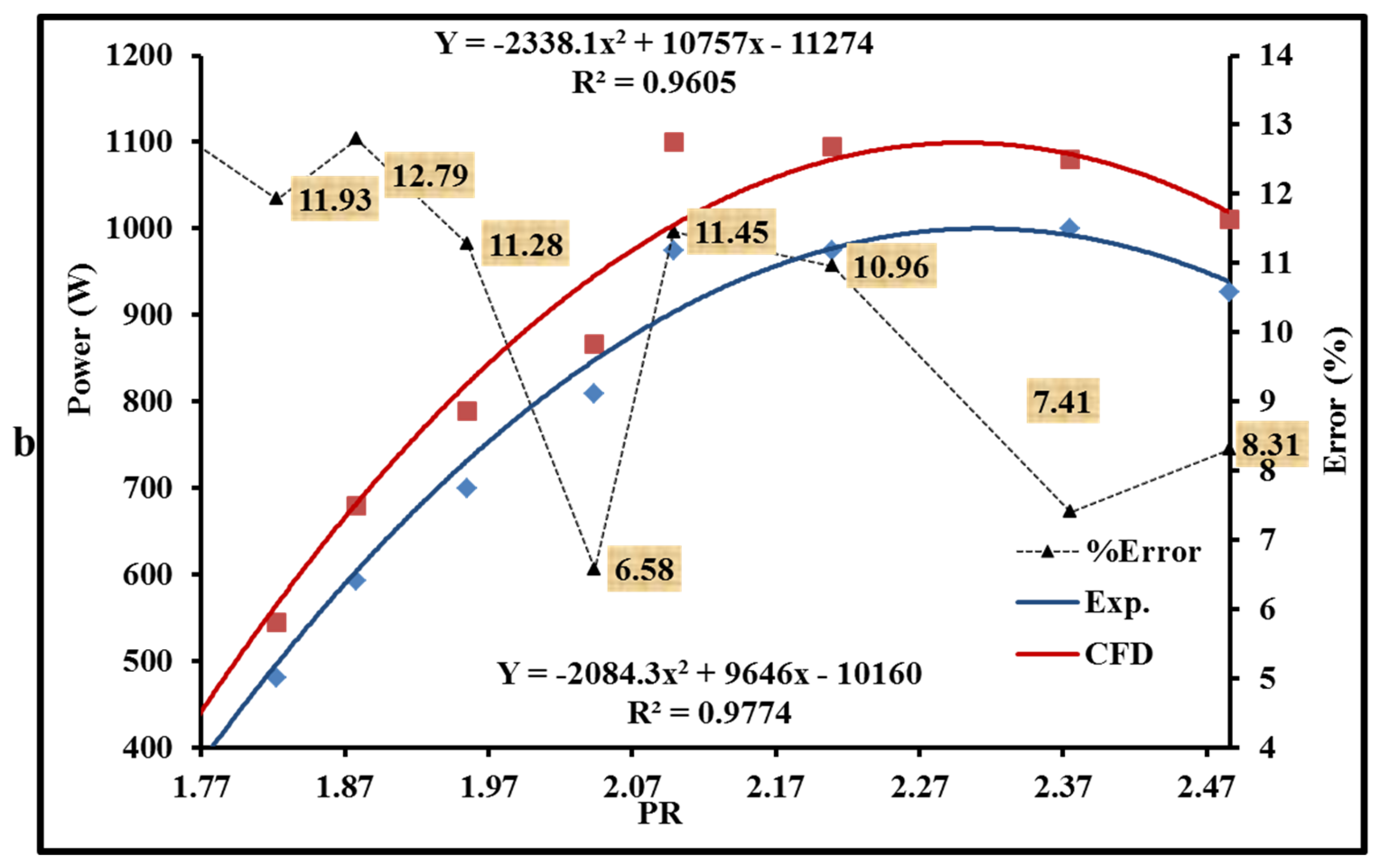

5.1. Experimental Validation of the CFD Model of SSRT

- The compressed air was allowed to flow from its storage tank, at atmospheric temperature, to a pressure regulator, which is used to achieve the required value of the inlet pressure.

- During its journey to the turbine, the compressed air was heated by passing through the thermal receiver. The required temperature value can be achieved using various levels between the light source and the thermal receiver, as shown in the previous section.

- By doing so, the compressed air now has both thermal and kinetic energy, and is guided to the expander, representing by the SSRT, in order to extract that energy and convert it into useful energy. As a result, the turbine performance can be examined at different scenarios.

- By changing the inlet total pressure and inlet mass flow rate, and keeping the inlet temperature of the SSRT fixed, the first one was carried out at different values of compressed air inlet temperature.

- The second scenario was established by fixing both the inlet mass flow rate and pressure values and changing the SSRT inlet temperature. This was the case at different values of compressed air mass flow rate and inlet pressure.

- The numerical investigation was conducted under ideal boundary conditions, with a steady-state flow and negligible heat dissipation through the turbine structure. However, the real-world operating conditions differed significantly.

- The measurements in the experimental study encompassed the surface roughness of the SSRT model, whereas the numerical analysis conducted with ANSYS CFX did not account for this aspect.

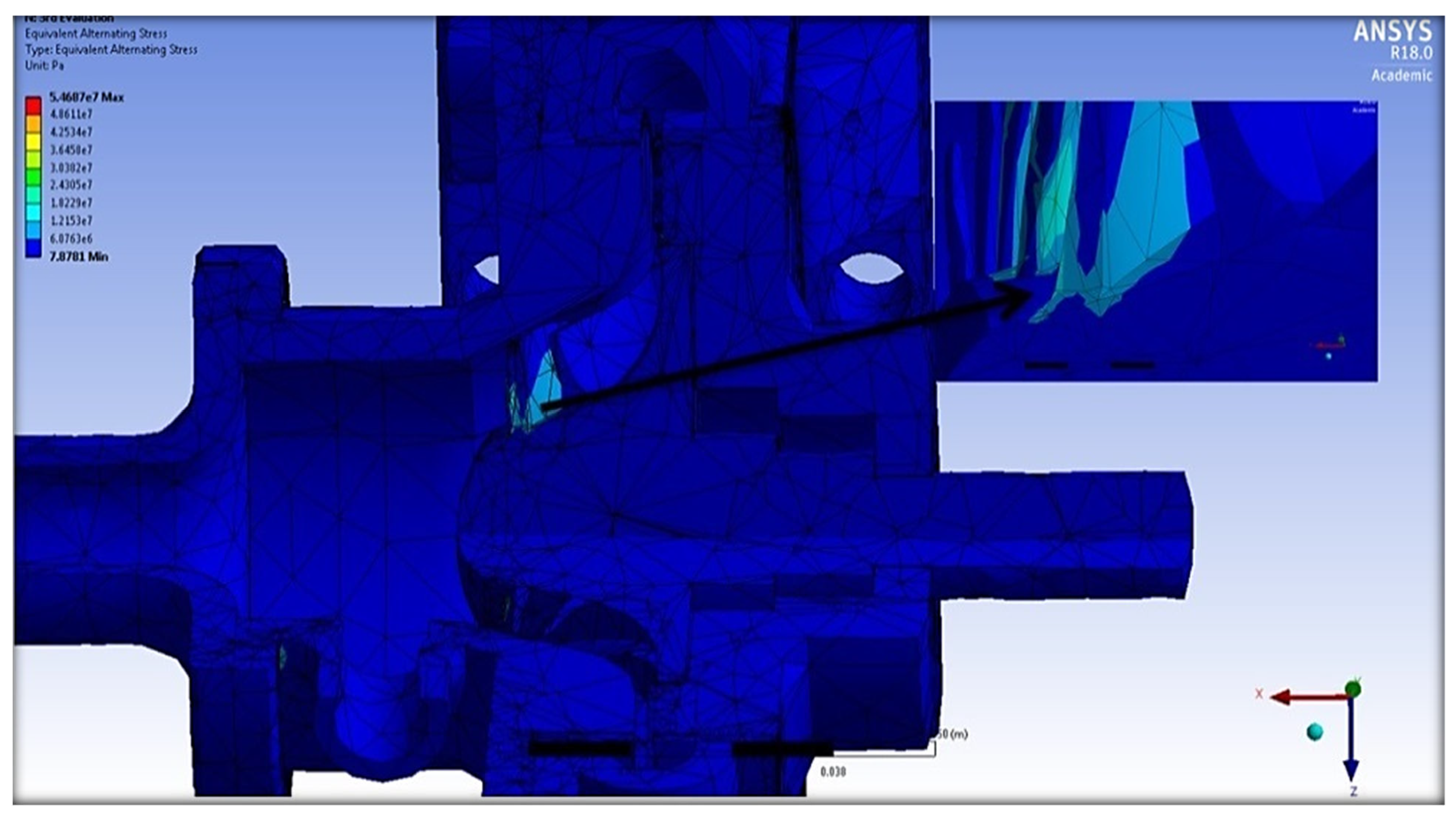

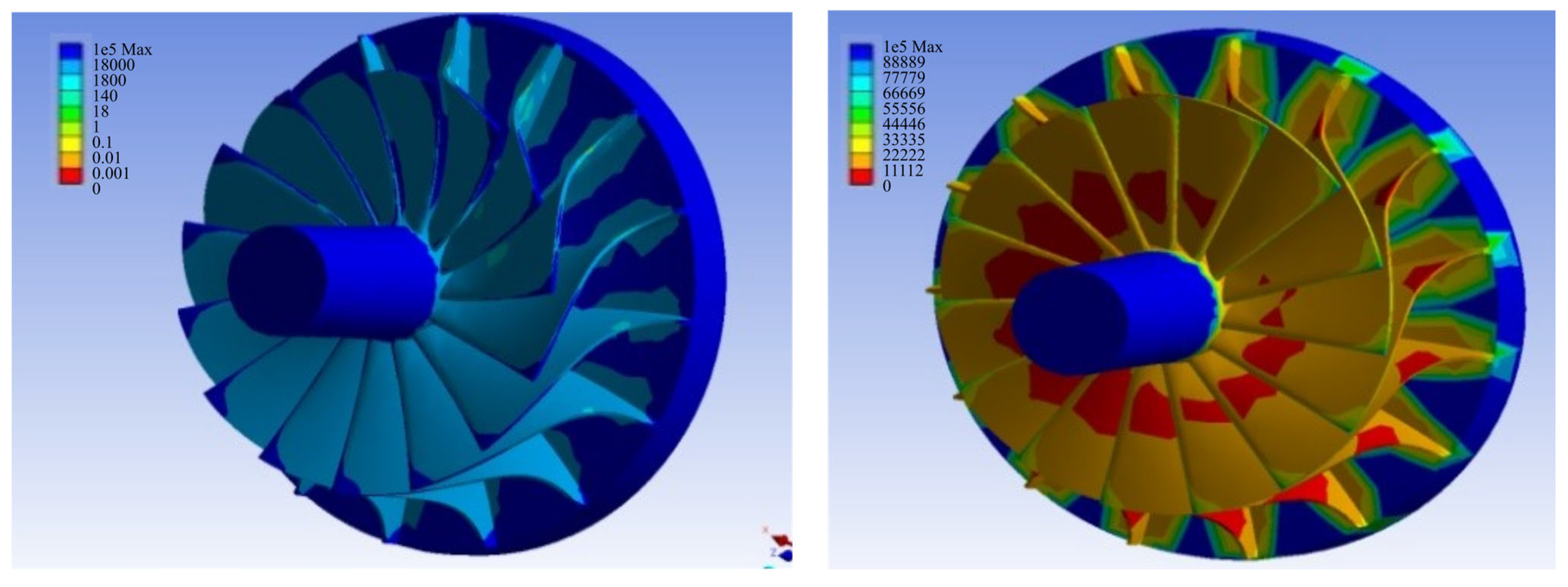

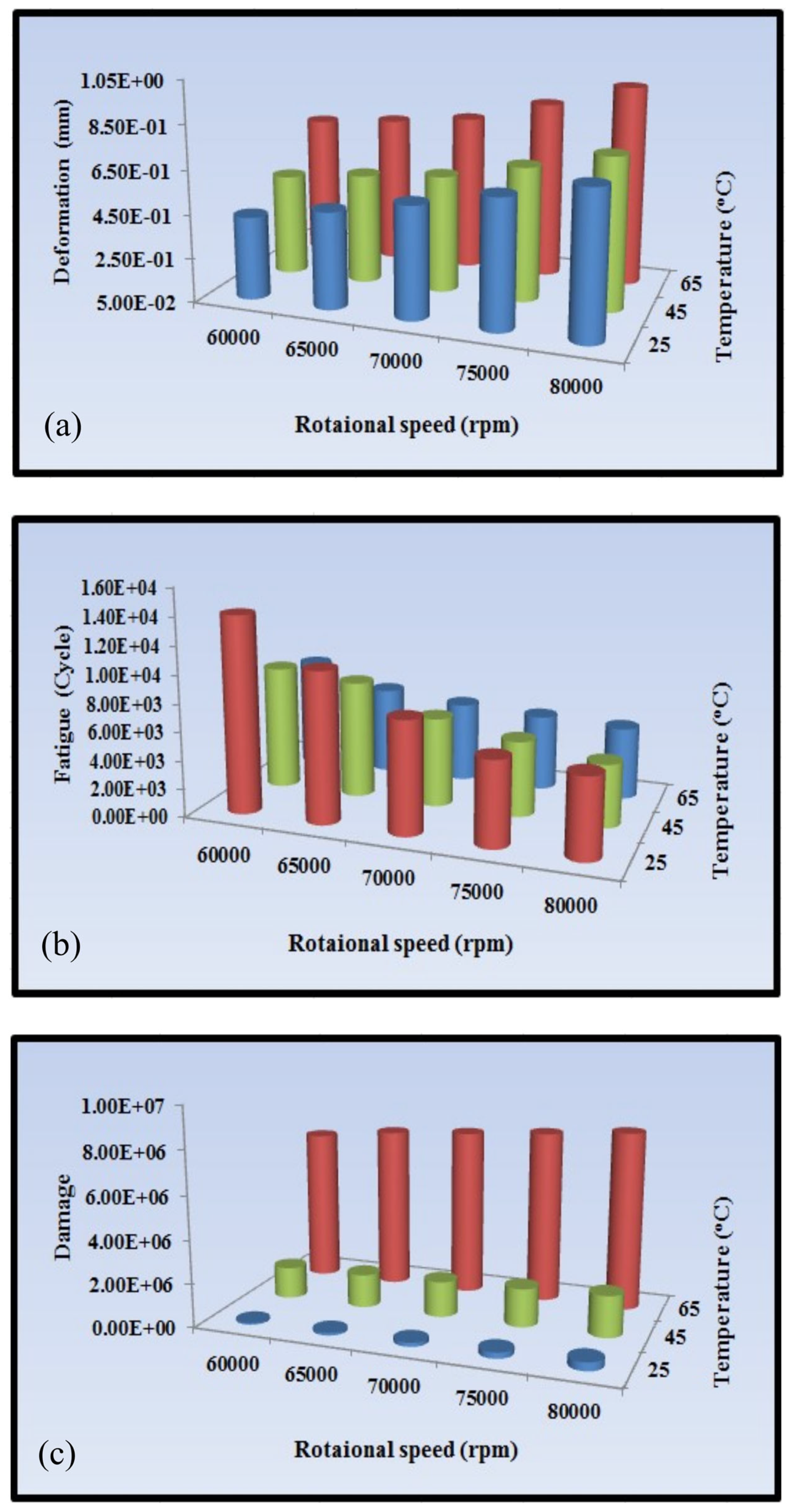

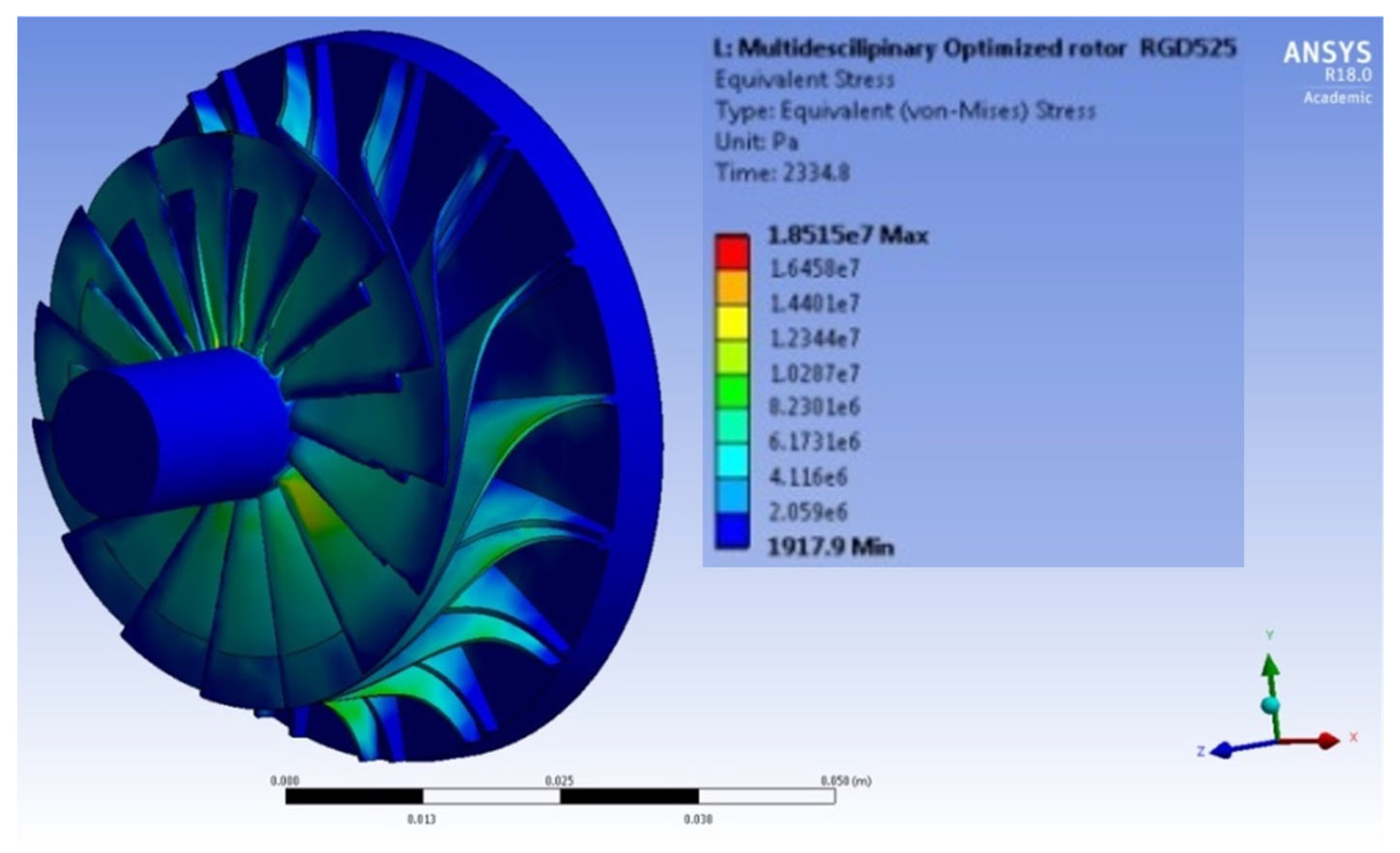

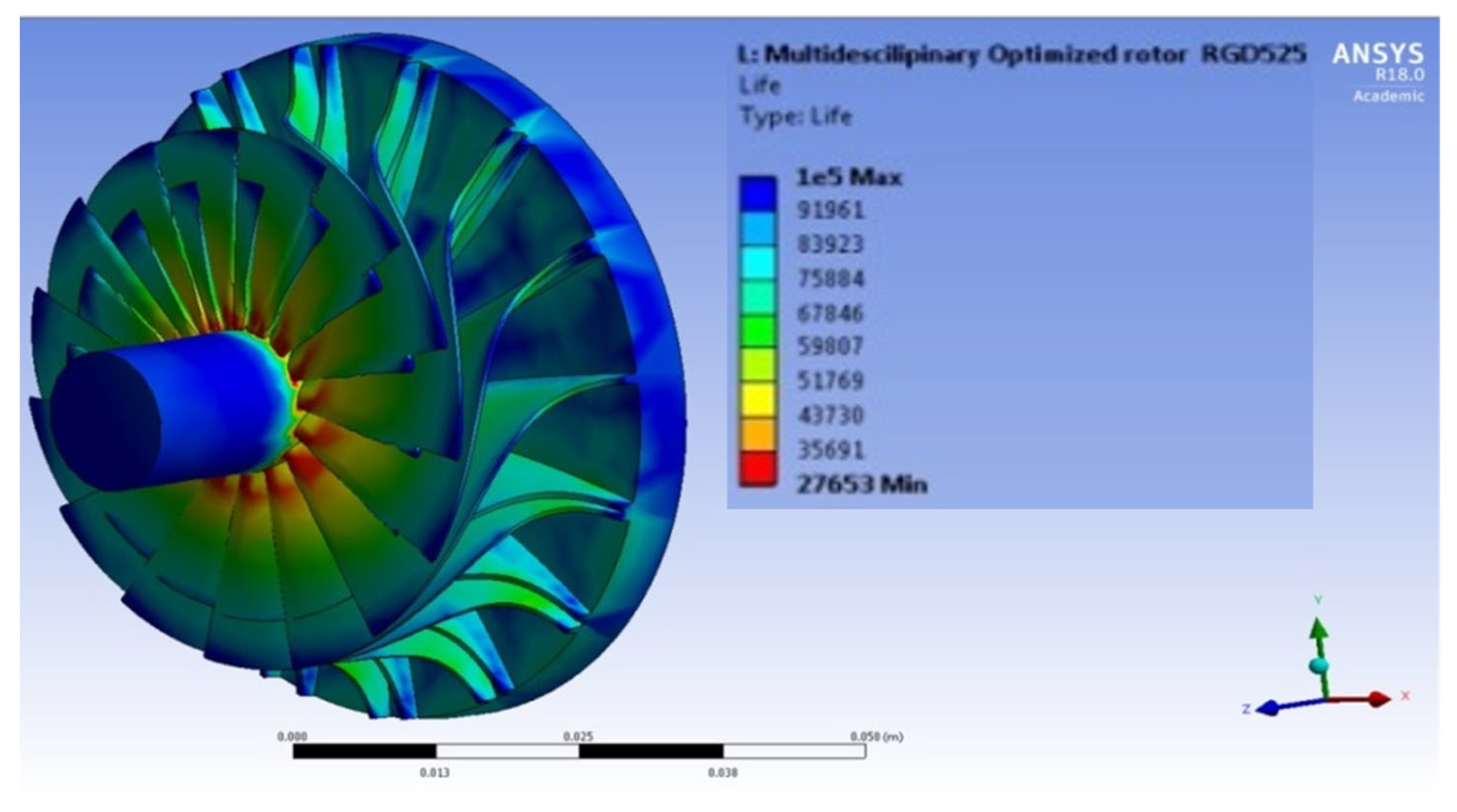

5.2. Structural Analysis Results

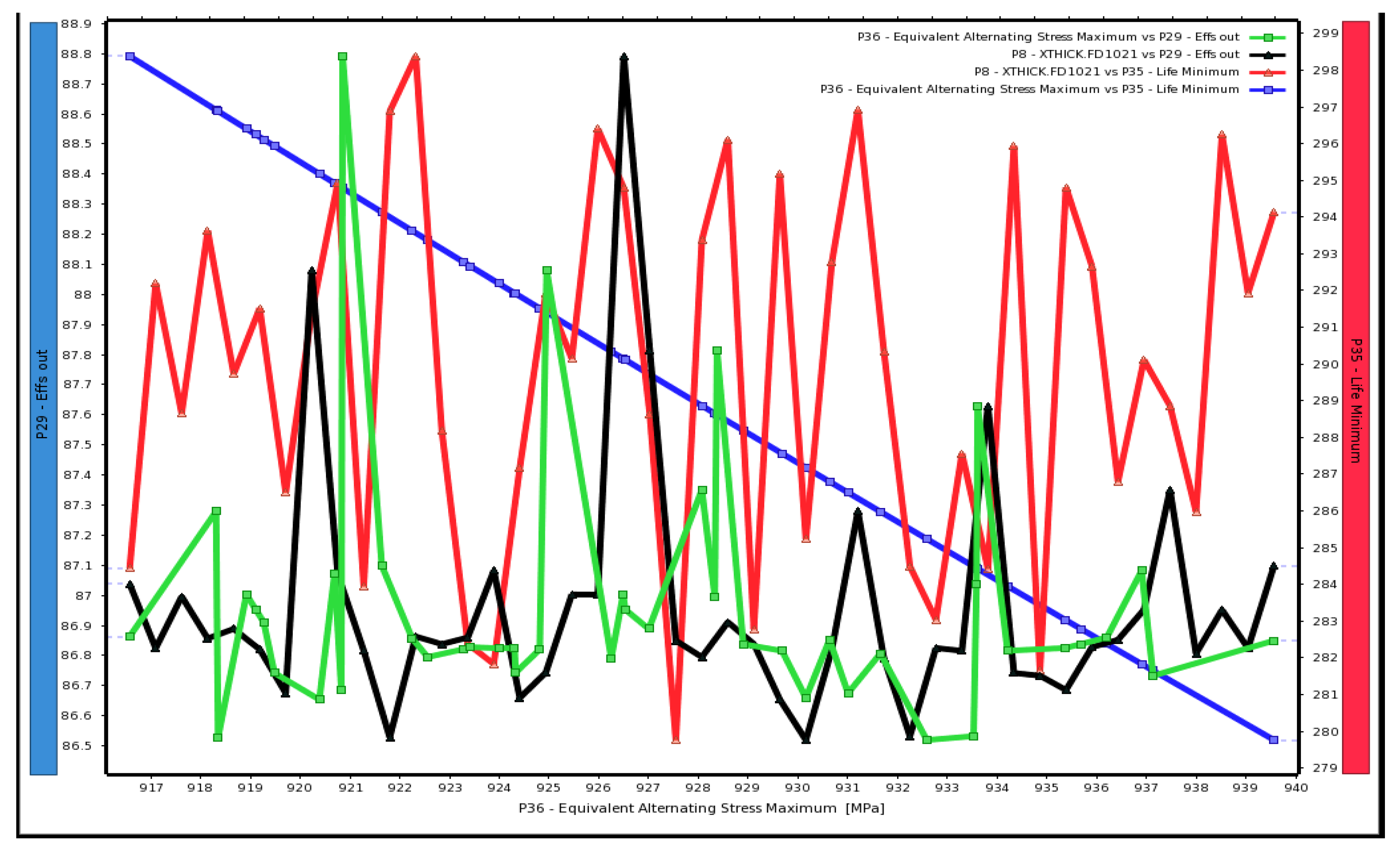

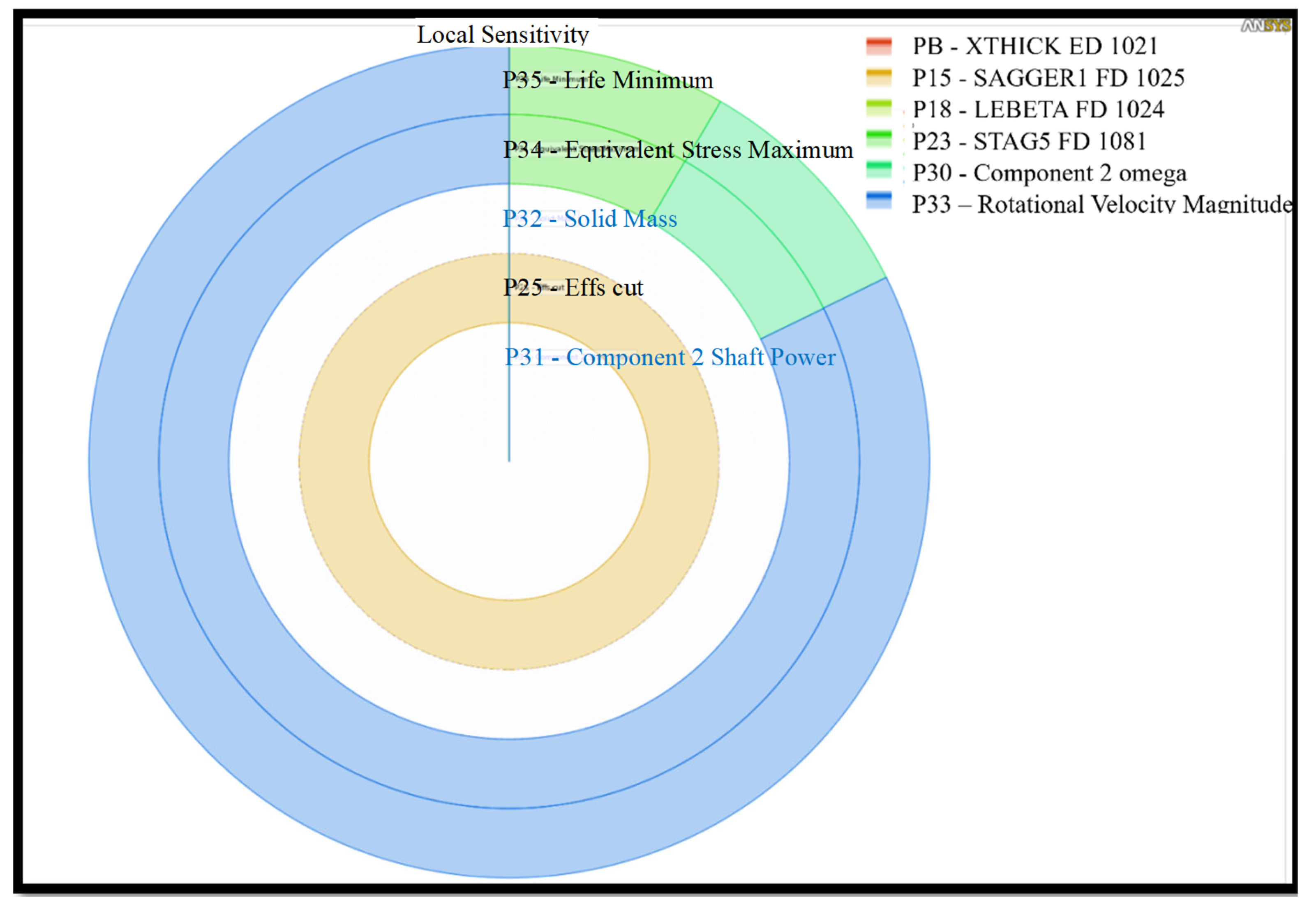

5.3. Multidisciplinary Optimization Results

6. Conclusions

- It was observed that the rotating speed of the rotor has a considerable influence on the amount of stress and displacement, with a maximum increase of 69% in stress and 59% in deformation seen at the highest examined rotational speed of 65 °C.

- The temperature of the fluid must also be carefully examined as a significant component. It was shown that reducing the temperature of compressed air to 25 °C reduced the aforementioned increases to about 27% and 7%, respectively.

- In terms of stress region, the stress concentration was mostly in the region between the hub and the blades; thus, this area must be strengthened to survive high stress intensity in this position.

- The region of the tip shroud in the rotor had greater deflection values at 21% of the blade tip width. Consequently, this distance between the blade tip and the shroud, as well as in between the blades, should be sufficient to accommodate the deflection.

- According to the fatigue study, the increased input temperature of the fluid and compressed air resulted in an 84% decrease in rotor fatigue life, particularly at higher rotational speeds. The region where the rotor’s blades link to the hub had the lowest fatigue life. This location sustained the most damage among the other rotor bodies.

- A structural analysis needs to be carefully and simultaneously considered during aerodynamic analysis in order to sustain what has been achieved in terms of aerodynamic analysis. Consequently, multi-objective optimization should also include some structural parameters and some of the objective function is needed in order to cover the stresses in other structural analyses.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| D | Stiffness matrix |

| ε | Mechanical strain |

| s | Stress |

| E | Modulus of elasticity |

| α | Coefficient of thermal expansion |

| νp | Poisson’s ratio |

| T | Temperature |

| m | Mass |

| r | Radius of rotation (distance between the rotor center of gravity and its rotation centre) |

| ωs | Rotor rotational speed |

| Fcf | Centrifugal force |

| ρ | Material density |

| A | The blade cross sectional area |

| z | The blade thickness |

| At | Cross sectional area of blade at the tip |

| Ar | Cross sectional area of blade at the root |

| lb | The blade length |

| ith natural circular frequency (radians per unit time) | |

| Time | |

| ith natural frequency (cycles per unit time) | |

| Nf | The number of cycles to failure |

| Fatigue strength parameter | |

| b | Fatigue life exponent |

| The ultimate strength of the material | |

| The alternating stress | |

| The mean stress | |

| σe | The endurance stress (endurance limit for completely reversed loading) |

| R | Stress ratio |

| ni | ith fatigue cycle |

| Df | Material damage due to fatigue |

| k | Turbulent flow kinetic energy |

| ω | Specific dissipation rate |

| Yk | Dissipation of k |

| Yω | Dissipation of ω |

| S | User-defined source term |

| Gk | The generation of k due to mean velocity gradients |

| Gω | The generation of ω |

| Γk | The effective diffusivity of k |

| Γω | The effective diffusivity of ω |

References

- Smadi, Y.; Alsood, E.; Aljaradin, M. A Solar Disinfection Water Treatment System for Rural Areas/Jordan. Al-Kitab J. Pure Sci. 2023, 5, 55–67. [Google Scholar] [CrossRef]

- Mahmood Ibrahim, A.; Ibraheem, R.R.; Bakr Weli, R. Energy Saving in Batteries Using the Photovoltaic System. Al-Kitab J. Pure Sci. 2023, 4, 78–94. [Google Scholar] [CrossRef]

- Edirisinghe, D.S.; Yang, H.S.; Gunawardane, S.D.G.S.P.; Alkhabbaz, A.; Tongphong, W.; Yoon, M.; Lee, Y.H. Numerical and Experimental Investigation on Water Vortex Power Plant to Recover the Energy from Industrial Wastewater. Renew. Energy 2023, 204, 617–634. [Google Scholar] [CrossRef]

- Alkhabbaz, A.; Yang, H.S.; Weerakoon, A.H.S.; Lee, Y.H. A Novel Linearization Approach of Chord and Twist Angle Distribution for 10 KW Horizontal Axis Wind Turbine. Renew. Energy 2021, 178, 1398–1420. [Google Scholar] [CrossRef]

- Daabo, A.M.; Al-Mola, Y.S.; Al-Rawy, A.Y.; Lattimore, T. State of the Art Single-Objective Optimization of Small Scale Cylindrical Cavity Receiver. Sustain. Energy Technol. Assess. 2019, 35, 278–290. [Google Scholar] [CrossRef]

- Daabo, A.M.; Bellos, E.; Pavlovic, S.; Bashir, M.A.; Mahmoud, S.; Al-Dadah, R.K. Characterization of a Micro Thermal Cavity Receiver–Experimental and Analytical Investigation. Therm. Sci. Eng. Prog. 2020, 18, 100554. [Google Scholar] [CrossRef]

- Zhang, R.; Xin, Z.; Huang, G.; Yan, B.; Zhou, X.; Deng, X. Characteristics and Modelling of Wake for Aligned Multiple Turbines Based on Numerical Simulation. J. Wind Eng. Ind. Aerodyn. 2022, 228, 105097. [Google Scholar] [CrossRef]

- Micallef, D.; Ferreira, C.; Herráez, I.; Höning, L.; Yu, W.; Capdevila, H. Assessment of Actuator Disc Models in Predicting Radial Flow and Wake Expansion. J. Wind Eng. Ind. Aerodyn. 2020, 207, 104396. [Google Scholar] [CrossRef]

- Collings, P.; Yu, Z. Modelling and Analysis of a Small-Scale Organic Rankine Cycle System with a Scroll Expander. Lect. Notes Eng. Comput. Sci. 2014, 2, 1472–1477. [Google Scholar]

- Daabo, A.M.; Mahmoud, S.; Al-Dadah, R.K.; Al Jubori, A.M.; Bhar Ennil, A. Numerical Analysis of Small Scale Axial and Radial Turbines for Solar Powered Brayton Cycle Application. Appl. Therm. Eng. 2017, 120, 672–693. [Google Scholar] [CrossRef]

- Gomes, R.P.F.; Henriques, J.C.C.; Gato, L.M.C.; Falcão, A.F.O. Multi-Point Aerodynamic Optimization of the Rotor Blade Sections of an Axial-Flow Impulse Air Turbine for Wave Energy Conversion. Energy 2012, 45, 570–580. [Google Scholar] [CrossRef]

- Shanechi, M.M.; Odabaee, M.; Hooman, K. Optimisation of a High Pressure Ratio Radial-Inflow Turbine: Coupled CFD-FE Analysis. Proc. ASME Turbo Expo 2015, 2C. [Google Scholar] [CrossRef]

- Barsi, D.; Perrone, A.; Ratto, L.; Simoni, D.; Zunino, P. Radial Inflow Turbine Design through Multi-Disciplinary Optimisation Technique. Proc. ASME Turbo Expo 2015, 8, V008T23A009. [Google Scholar] [CrossRef]

- Wang, H.L.; Xi, G. Effect of Thermal and Mechanical Loads on the Centrifugal Impeller Deformation and Its Structure Optimization. Proc. ASME Turbo Expo 2009, 5, 75–84. [Google Scholar] [CrossRef]

- Fu, L.; Shi, Y.; Deng, Q.; Li, H.; Feng, Z. Integrated Optimization Design for a Radial Turbine Wheel of a 100 KW-Class Microturbine. J. Eng. Gas Turbines Power 2012, 134, 012301. [Google Scholar] [CrossRef]

- Alawadhi, K.; Alhouli, Y.; Ashour, A.; Alfalah, A. Design and Optimization of a Radial Turbine to Be Used in a Rankine Cycle Operating with an OTEC System. J. Mar. Sci. Eng. 2020, 8, 855. [Google Scholar] [CrossRef]

- Feng, Z.; Deng, Q.; Li, J. Aerothermodynamic Design and Numerical Simulation of Radial Inflow Turbine Impeller for a 100kW Microturbine. Proc. ASME Turbo Expo 2005, 1, 873–880. [Google Scholar] [CrossRef]

- Causier, A.; Carret, G.; Boutin, C.; Berthelot, T.; Berthault, P. 3D-Printed System Optimizing Dissolution of Hyperpolarized Gaseous Species for Micro-Sized NMR. Lab A Chip 2015, 15, 2049–2054. [Google Scholar] [CrossRef]

- O’Neill, P.; Jolivet, L.; Kent, N.J.; Brabazon, D. Physical Integrity of 3D Printed Parts for Use as Embossing Tools. Adv. Mater. Process. Technol. 2017, 3, 308–317. [Google Scholar] [CrossRef]

- ANSYS CFX-Solver Theory Guide; ANSYS, Inc.: Canonsburg, PE, USA, 2009; Volume 15317, pp. 724–746.

- Singh, M. Steam Turbines-Design, Application, and Re-Rating; Mcgraw-hill Education-Europe: Sydney, Australia, 2008. [Google Scholar]

- Poblano-Salas, C.A.; Barceinas-Sanchez, J.D.O.; Sanchez-Jimenez, J.C. Failure Analysis of an AISI 410 Stainless Steel Airfoil in a Steam Turbine. Eng. Fail. Anal. 2011, 18, 68–74. [Google Scholar] [CrossRef]

- Dowling, N.; Dowling, N. Mechanical Behavior of Materials: Engineering Methods for Deformation; Pearson: London, UK, 2012; p. 59. Available online: https://www.amazon.co.uk/Mechanical-Behavior-Materials-Norman-Dowling/dp/0131395068 (accessed on 28 June 2023).

- Boentgen, R.R.; Clickner, S.J. Experimental Modal Analysis. CSI Reliab. Week 1983, 1, 581–584. [Google Scholar]

- Eftekhari, M.; Fatemi, A. Creep-Fatigue Interaction and Thermo-Mechanical Fatigue Behaviors of Thermoplastics and Their Composites. Int. J. Fatigue 2016, 91, 136–148. [Google Scholar] [CrossRef]

- Mura, A.; Ricci, A.; Canavese, G. Investigation of Fatigue Behavior of ABS and PC-ABS Polymers at Different Temperatures. Materials 2018, 11, 1818. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, A.A.; Dawood, A.S. Mixed Convection Heat Transfer in a Ventilated Enclosure with and without a Saturated Porous Medium. J. Porous Media 2016, 19, 347–366. [Google Scholar] [CrossRef]

- Alkhabbaz, A.; Yang, H.S.; Tongphong, W.; Lee, Y.H. Impact of Compact Diffuser Shroud on Wind Turbine Aerodynamic Performance: CFD and Experimental Investigations. Int. J. Mech. Sci. 2022, 216, 106978. [Google Scholar] [CrossRef]

- Djodikusumo, I.; Diasta, I.N.; Sanjaya Awaluddin, I. Geometric Modeling of a Propeller Turbine Runner Using ANSYS BladeGen, Meshing Using ANSYS TurboGrid and Fluid Dynamic Simulation Using ANSYS Fluent. Appl. Mech. Mater. 2016, 842, 164–177. [Google Scholar] [CrossRef]

- Ansys, Inc. ANSYS CFX-Solver Modeling Guide V14.0. ANSYS CFX V14.0; Ansys, Inc.: Canonsburg, PE, USA, 2011. [Google Scholar]

- Yang, H.S.; Alkhabbaz, A.; Edirisinghe, D.S.; Tongphong, W.; Lee, Y.H. FOWT Stability Study According to Number of Columns Considering Amount of Materials Used. Energies 2022, 15, 1653. [Google Scholar] [CrossRef]

- Korte, J.J.; Salas, A.O.; Dunn, H.J.; Alexandrov, N.M.; Follett, W.W.; Orient, G.E.; Hadid, A.H. Multidisciplinary Approach to Linear Aerospike Nozzle Design. J. Propuls. Power 2001, 17, 93–98. [Google Scholar] [CrossRef]

- Moustapha, H.; Zelesky, M.; Baines, N.; Japikse, D. Axial and Radial Turbines; Concepts NREC: White River Junction, VT, USA, 2003; p. 10. Available online: https://www.amazon.co.uk/Axial-Radial-Turbines-Haney-Moustapha/dp/0933283121 (accessed on 28 June 2023).

- Daabo, A.M.; Hammo, K.E.; Mohammed, O.A.; Hassan, A.A.; Lattimore, T. Performance Investigation and Design Optimization of Micro Scale Compressed Air Axial Turbine for Domestic Solar Powered Brayton Cycle. Sustain. Energy Technol. Assess. 2020, 37, 100583. [Google Scholar] [CrossRef]

| Properties | Value |

|---|---|

| Young’s Modulus, MPa | 2000 |

| Poisson’s Ratio | 0.3 |

| Flexural Modulus, MPa | 3300 |

| Tensile Strength, MPa | 75 |

| Density, kg/m3 | 1175 |

| Coefficient of Thermal Expansion, /C | 0.000012 |

| Specific Heat, J/kg °C | 434 |

| Thermal Conductivity, W/mm °C | 0.0605 |

| Physics Preference | Mechanical |

|---|---|

| Sizing: | |

| Relevance Centre | Medium |

| Initial Size Seed | Active Assembly |

| Smoothing | Medium |

| Transition | Fast |

| Span Angle Centre | Coarse |

| Minimum Edge Length | 0.0546 mm |

| Inflation: | |

| Inflation Option | Smooth Transition |

| Transition Ratio | 0.272 |

| Maximum Layers | 5 |

| Growth Rate | 1.2 |

| Inflation Algorithm | Pre |

| Patch Independent Options: | |

| Topology Checking | Yes |

| Advanced: | |

| Shape Checking | Standard Mechanical |

| Element Mid-side Nodes | Program Controlled |

| Extra Retries for Assembly | Yes |

| Rigid Body Behaviour | Dimensionally Reduced |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Daabo, A.M.; Hassan, A.A.; Bashir, M.A.; Hamza, H.; Salim, S.; Koprulu, A.; Badawy, T.; Mahmoud, S.; Al-Dadah, R. Experimental Study and 3D Optimization of Small-Scale Solar-Powered Radial Turbine Using 3D Printing Technology. Machines 2023, 11, 817. https://doi.org/10.3390/machines11080817

Daabo AM, Hassan AA, Bashir MA, Hamza H, Salim S, Koprulu A, Badawy T, Mahmoud S, Al-Dadah R. Experimental Study and 3D Optimization of Small-Scale Solar-Powered Radial Turbine Using 3D Printing Technology. Machines. 2023; 11(8):817. https://doi.org/10.3390/machines11080817

Chicago/Turabian StyleDaabo, Ahmed M., Ali Abdelhafeez Hassan, Muhammad Anser Bashir, Hudhaifa Hamza, Shahad Salim, Aisha Koprulu, Tawfik Badawy, Saad Mahmoud, and Raya Al-Dadah. 2023. "Experimental Study and 3D Optimization of Small-Scale Solar-Powered Radial Turbine Using 3D Printing Technology" Machines 11, no. 8: 817. https://doi.org/10.3390/machines11080817

APA StyleDaabo, A. M., Hassan, A. A., Bashir, M. A., Hamza, H., Salim, S., Koprulu, A., Badawy, T., Mahmoud, S., & Al-Dadah, R. (2023). Experimental Study and 3D Optimization of Small-Scale Solar-Powered Radial Turbine Using 3D Printing Technology. Machines, 11(8), 817. https://doi.org/10.3390/machines11080817