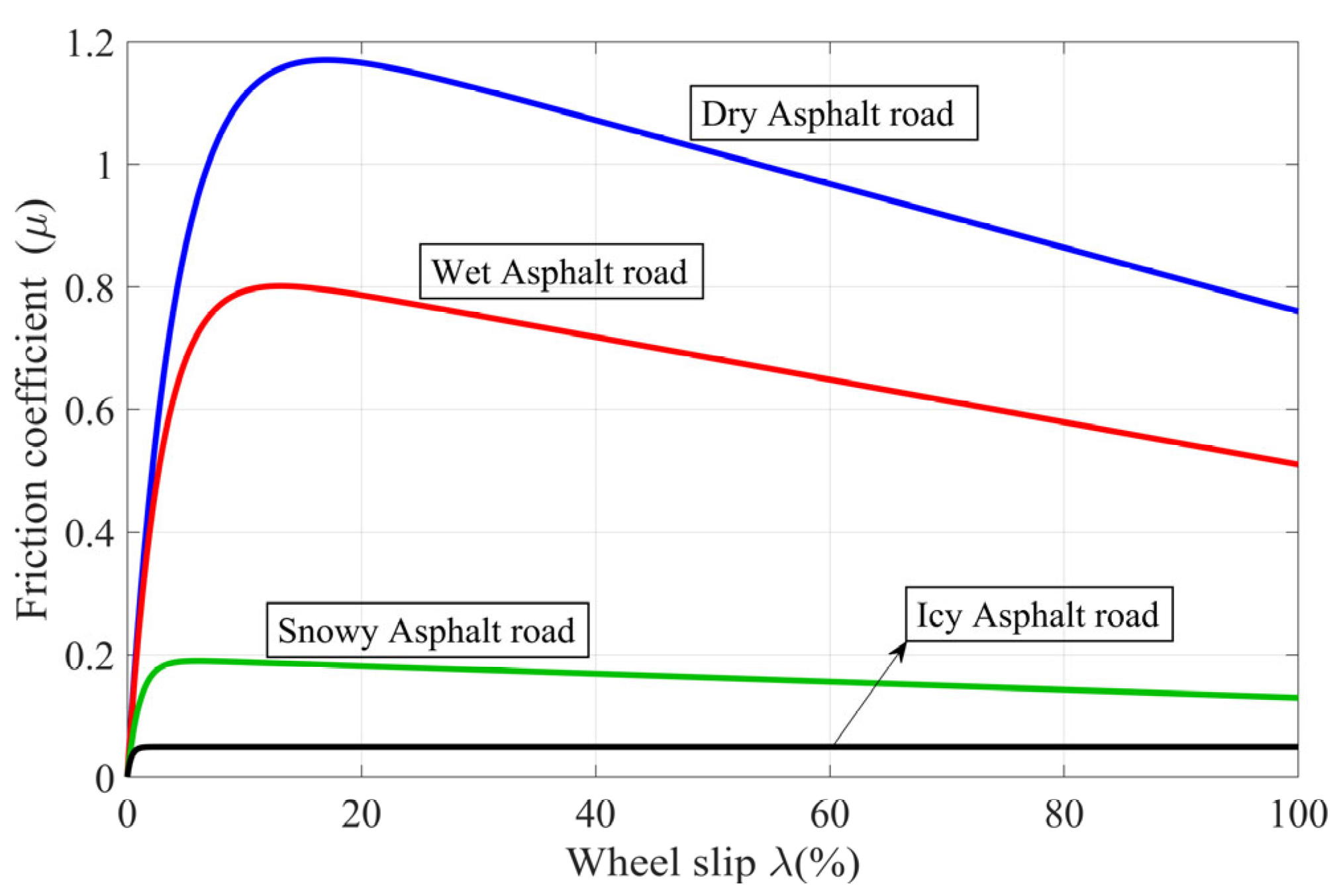

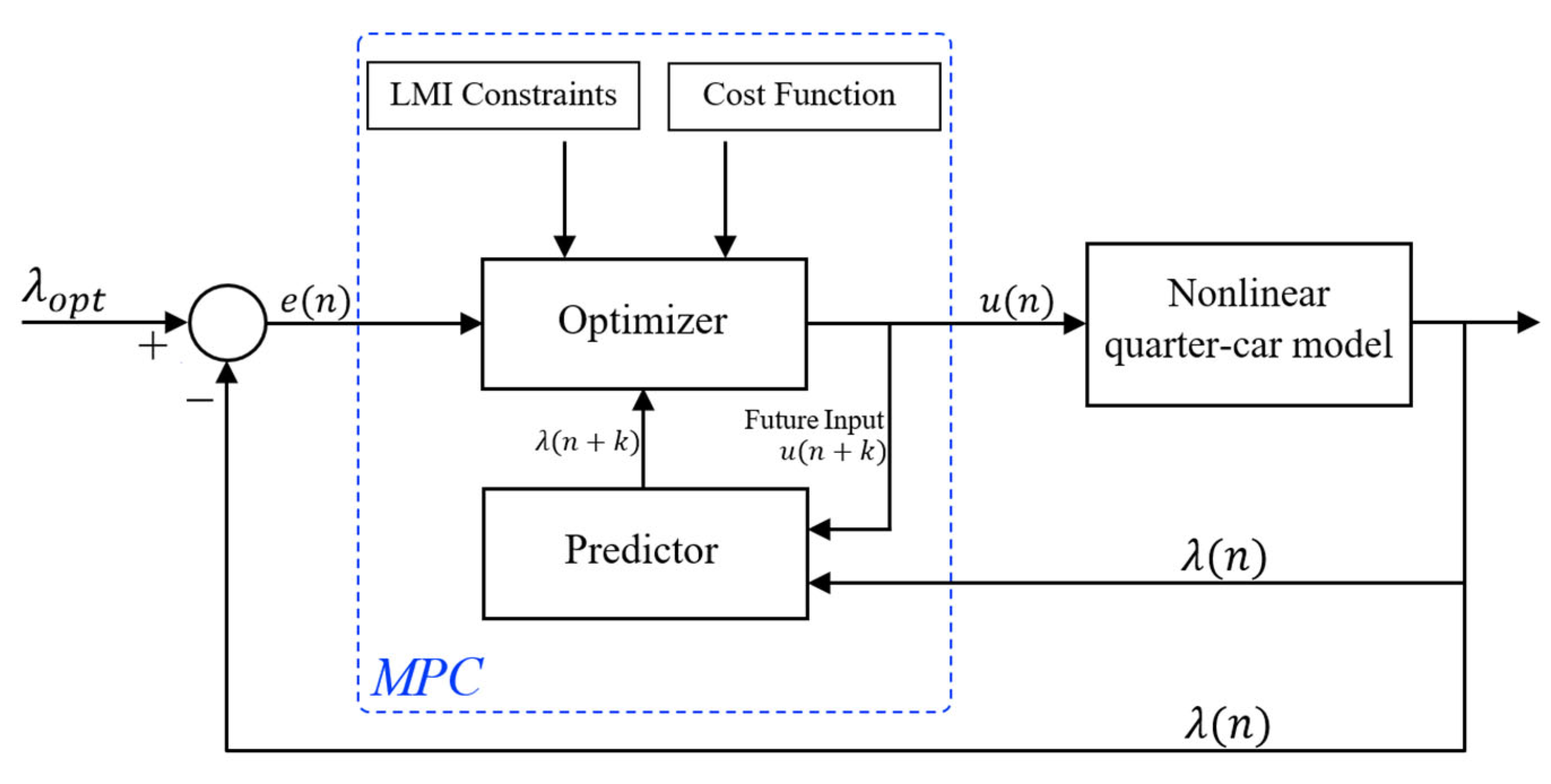

In the MPC approach, the design procedure is typically carried out using the linearized model of the system. However, it is important to note that the nonlinear ABS model does not possess a specific equilibrium point. Instead, there exists an equilibrium manifold within the stable region of the tire–road friction curves [

36]. By considering the peak values of the tire–road friction curves depicted in

Figure 2, it is possible to determine the optimal values of wheel slip for different road profiles. The stable performance region of the ABS is then identified to lie within the range of

0 <

λ <

(

0 <

μ <

), where

and

denote the optimal and peak values, respectively. For more in-depth information on this topic, interested readers are referred to [

37]. A comprehensive listing of the optimal and peak values for various road profiles can be found in

Table 3.

4.1. Simulations and Results

To consider the design limitations and structural constraints arising from different road conditions, certain bounds are imposed on the states and inputs of the system. These bounds are summarized in

Table 4, providing explicit limits for the various variables involved in ABS control design. These constraints ensure that the system operates within safe and feasible ranges, taking into consideration factors such as vehicle dynamics, tire characteristics, and road conditions. By adhering to these bounds, the control algorithm can effectively regulate the system’s behavior and ensure stability and performance while accommodating the specific constraints imposed by the ABS application.

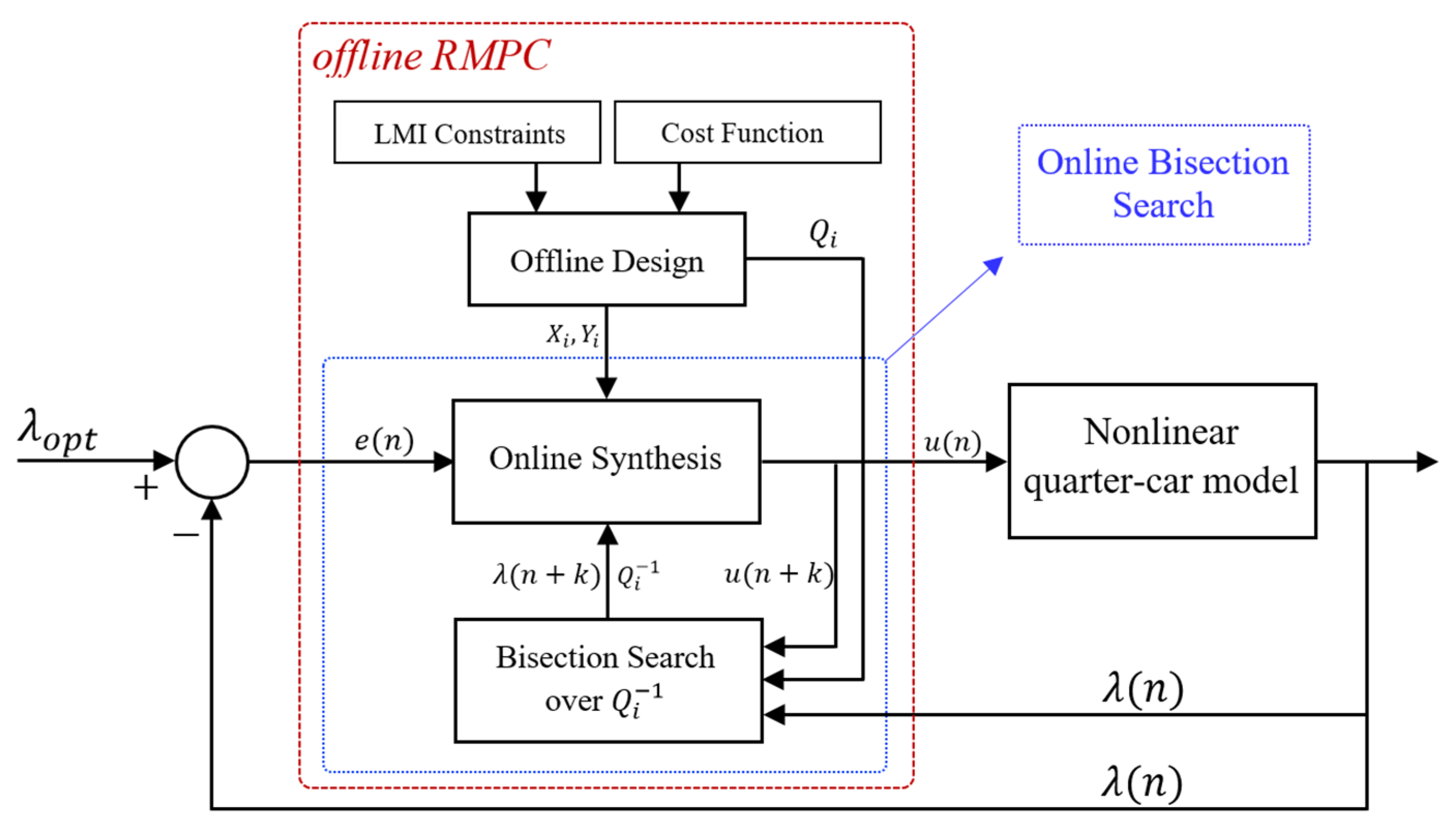

To design an offline RMPC for the dry road condition, the

axis is chosen as a one-dimensional subspace and discretized to a sequence of 10 states as

, which represent different wheel slips during braking until the vehicle velocity reaches its safe moment (

) in optimal wheel slip, at which point the ABS is cut off. The sequence of

is obtained from the offline part of Algorithm 1.

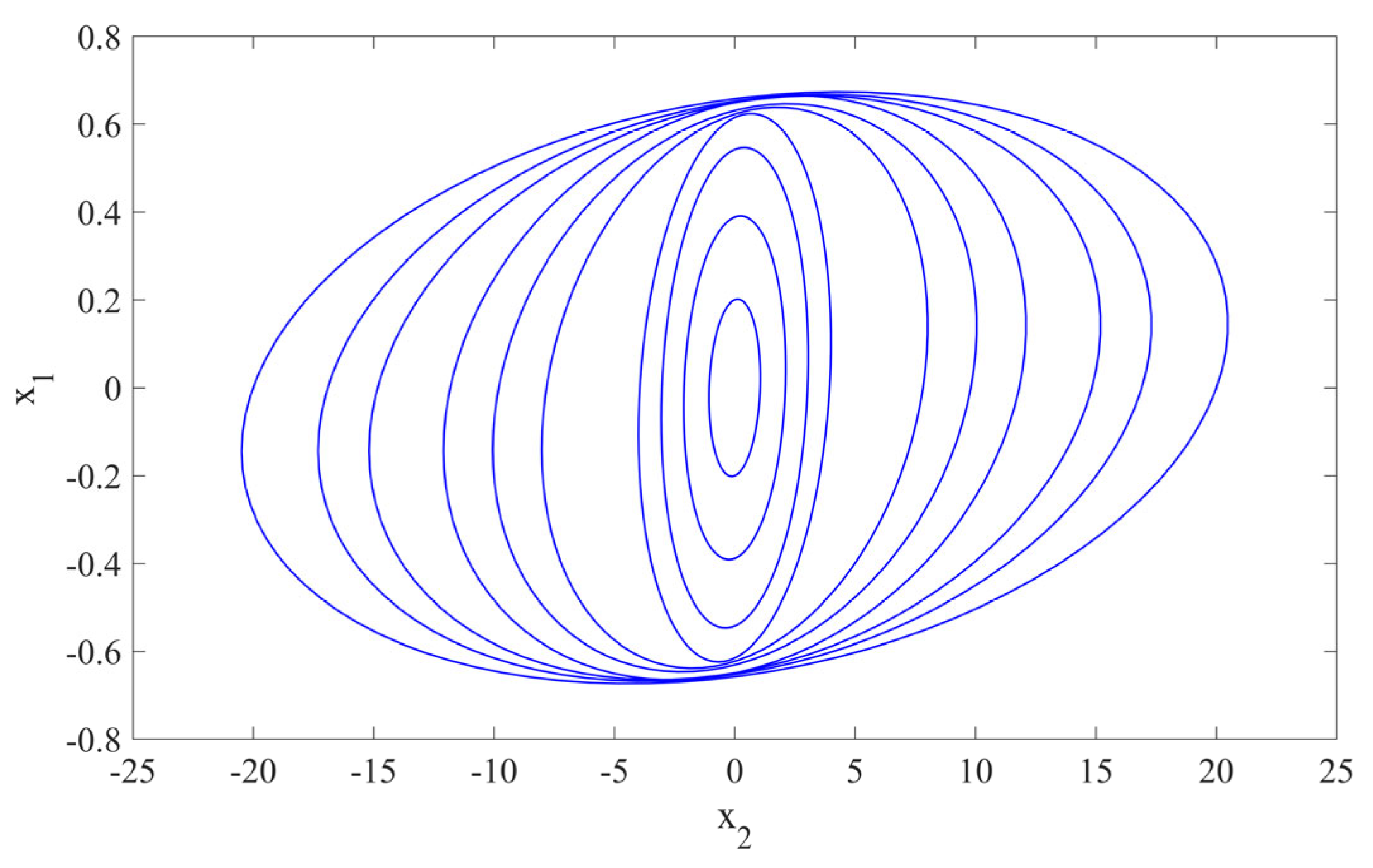

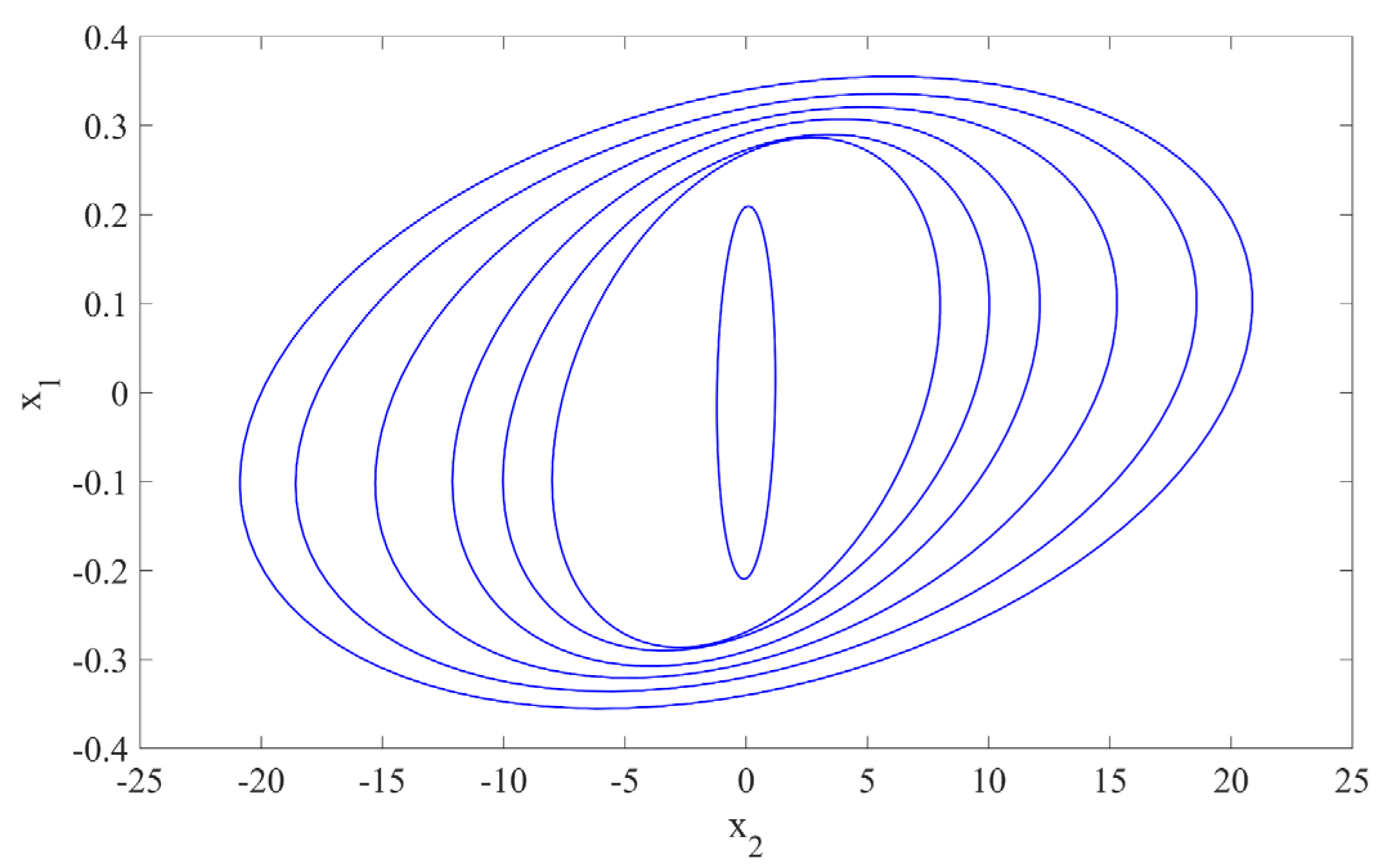

Figure 5 illustrates the relevant nested ellipsoids defined by

for ten discrete points.

In the first step for verification of the proposed algorithm for an ABS control, the moment during braking is considered as an initially disturbed state, which is specified as

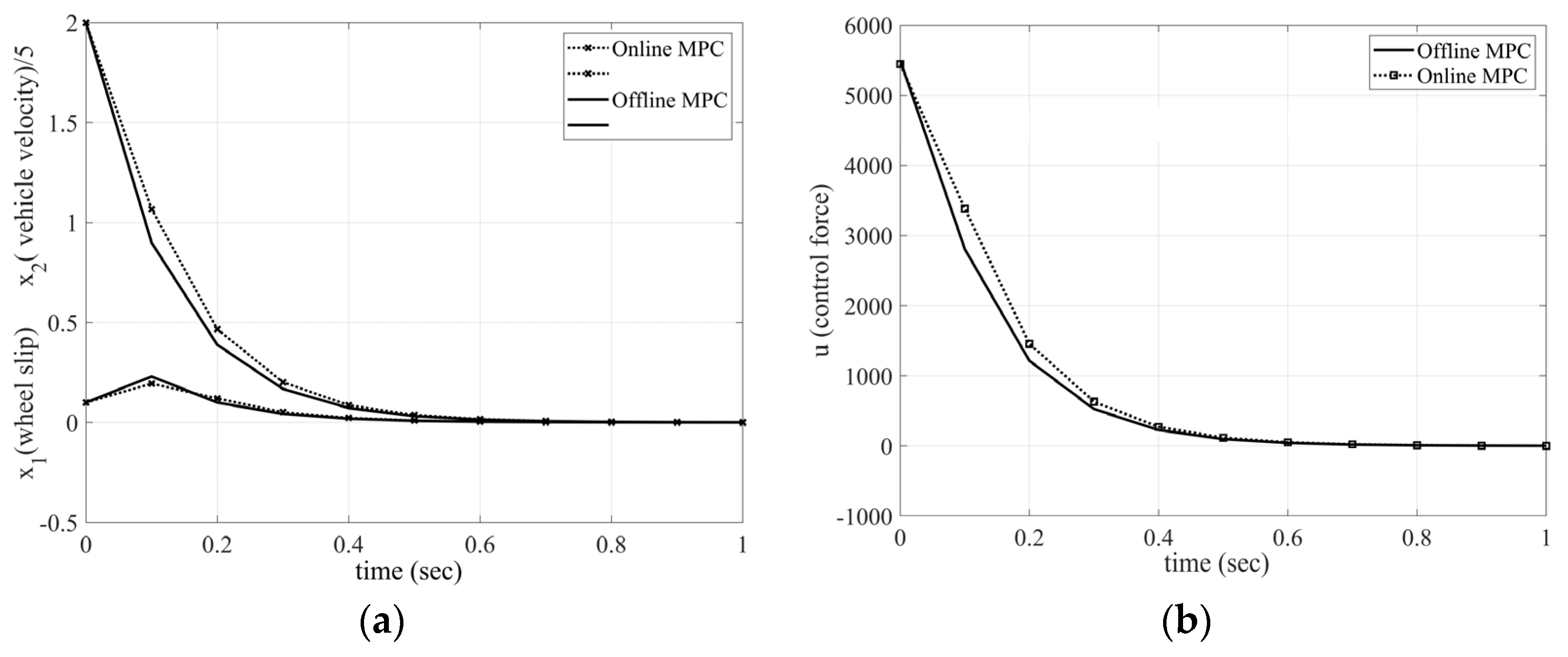

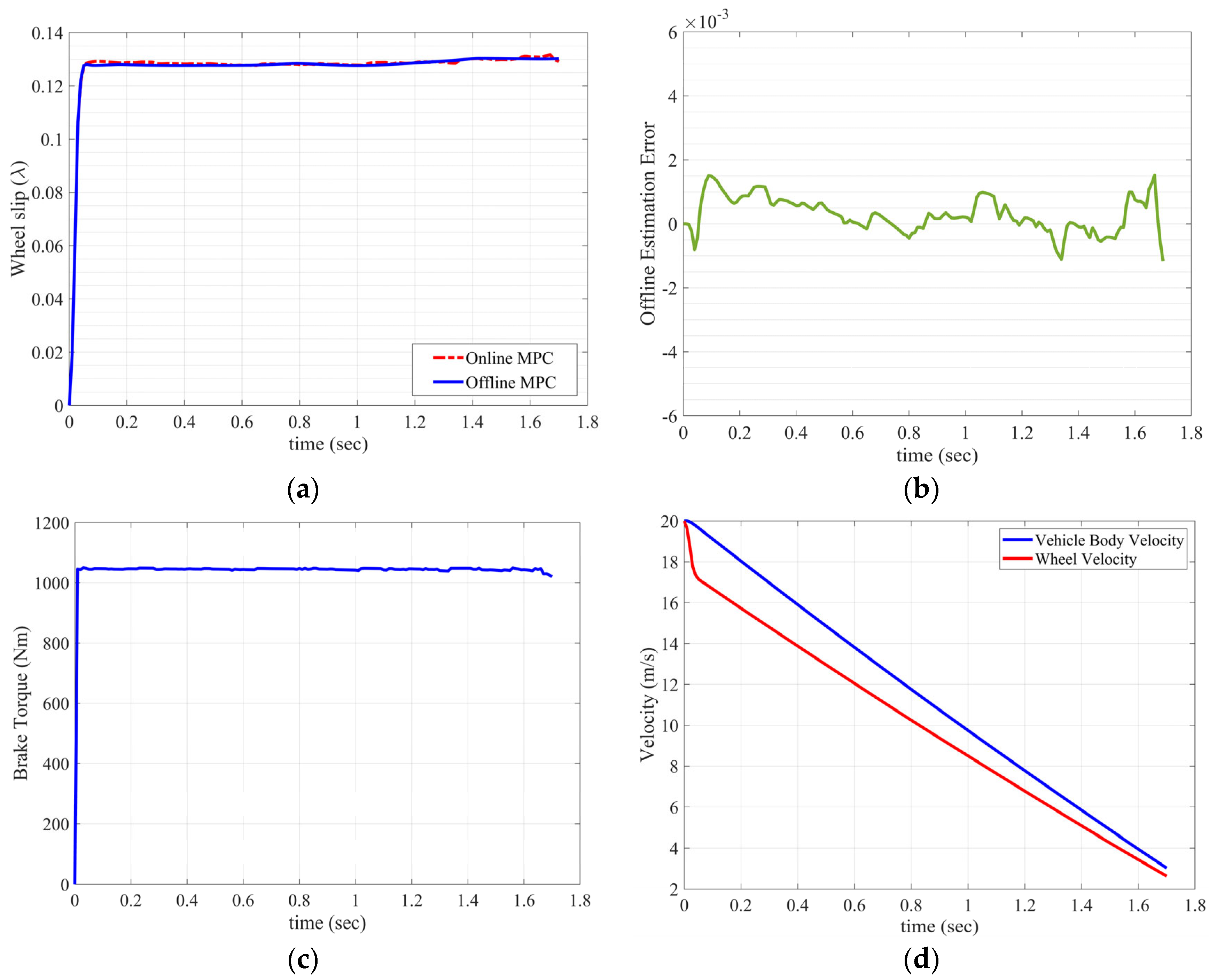

, in which the first element is wheel slip and the second element represents the vehicle speed. For the linearized system and discretization using a sampling time of 0.1, the control law and the closed-loop responses of the system are shown in

Figure 6.

Based on the observations from

Figure 6, it is evident that the offline RMPC algorithm operates effectively and exhibits comparable response and performance to the online MPC design when using the same control input. Moving forward, the simulation results of the nonlinear system will be discussed. In consideration of practical aspects, it is worth noting that during the braking process, the vehicle and wheel velocities eventually reach zero, resulting in the wheel slip tending towards infinity. At this point, certain manufacturers deactivate the ABS and transition it into a passive mode when the speed falls below a minimum limit. Consequently, the simulations are terminated when the vehicle velocity reaches 3 m/s, aligning with this industry practice.

The simulations are conducted in the MATLAB/Simulink environment, utilizing YALMIP’s MOSEK optimization solver toolbox [

38], and the hardware platform consists of an Intel i7-10510U CPU with a clock speed of 4.3 GHz and 16 GB RAM. To clearly illustrate the performance of the proposed offline RMPC approach compared to the online method in the nonlinear system, a sampling time of 0.005 s is set. For the dry asphalt road, the initial speed of the vehicle and the wheel slip at the moment of braking are set to 20 m/s (72 km/h) and 0, respectively.

The main objective of the MPC feedback controller design is to regulate the tire–road friction around its peak value (

) while minimizing the tracking error of the wheel slip set point. In the first step, the online MPC controller is designed according to Equations (12)–(16). Subsequently, the offline RMPC is designed based on Algorithm 1.

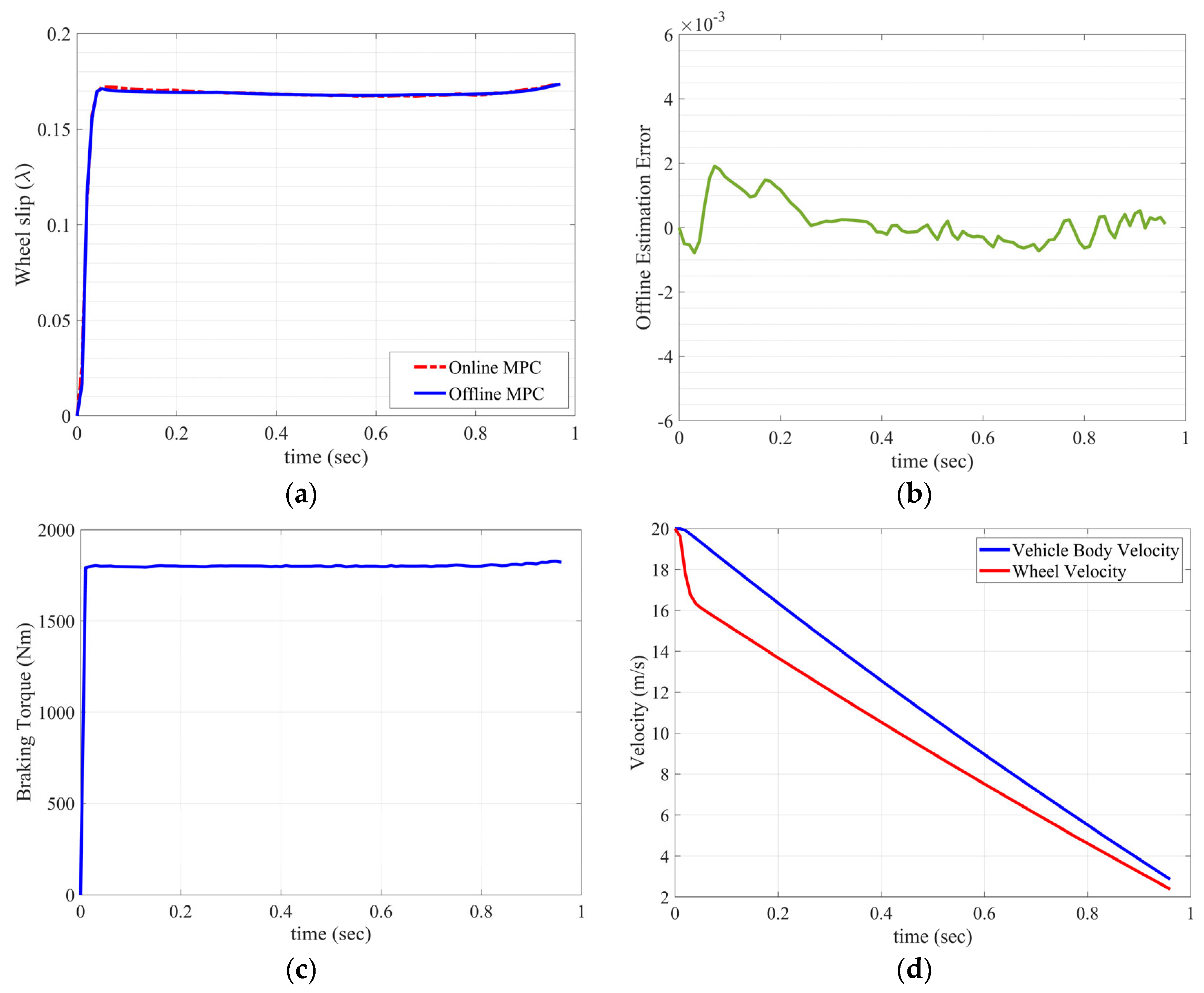

Figure 7 illustrates the simulation results of the proposed offline controller compared to the online controller.

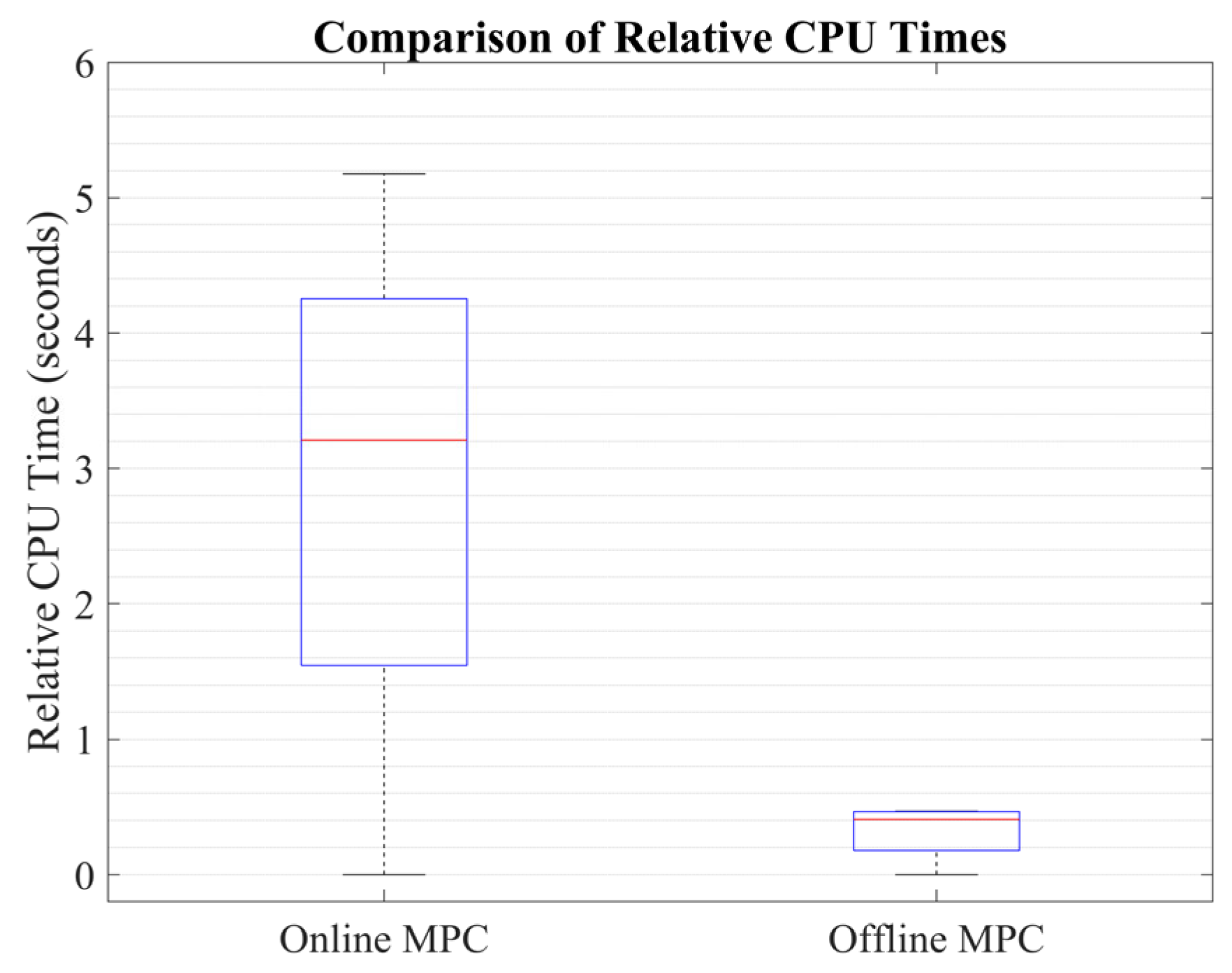

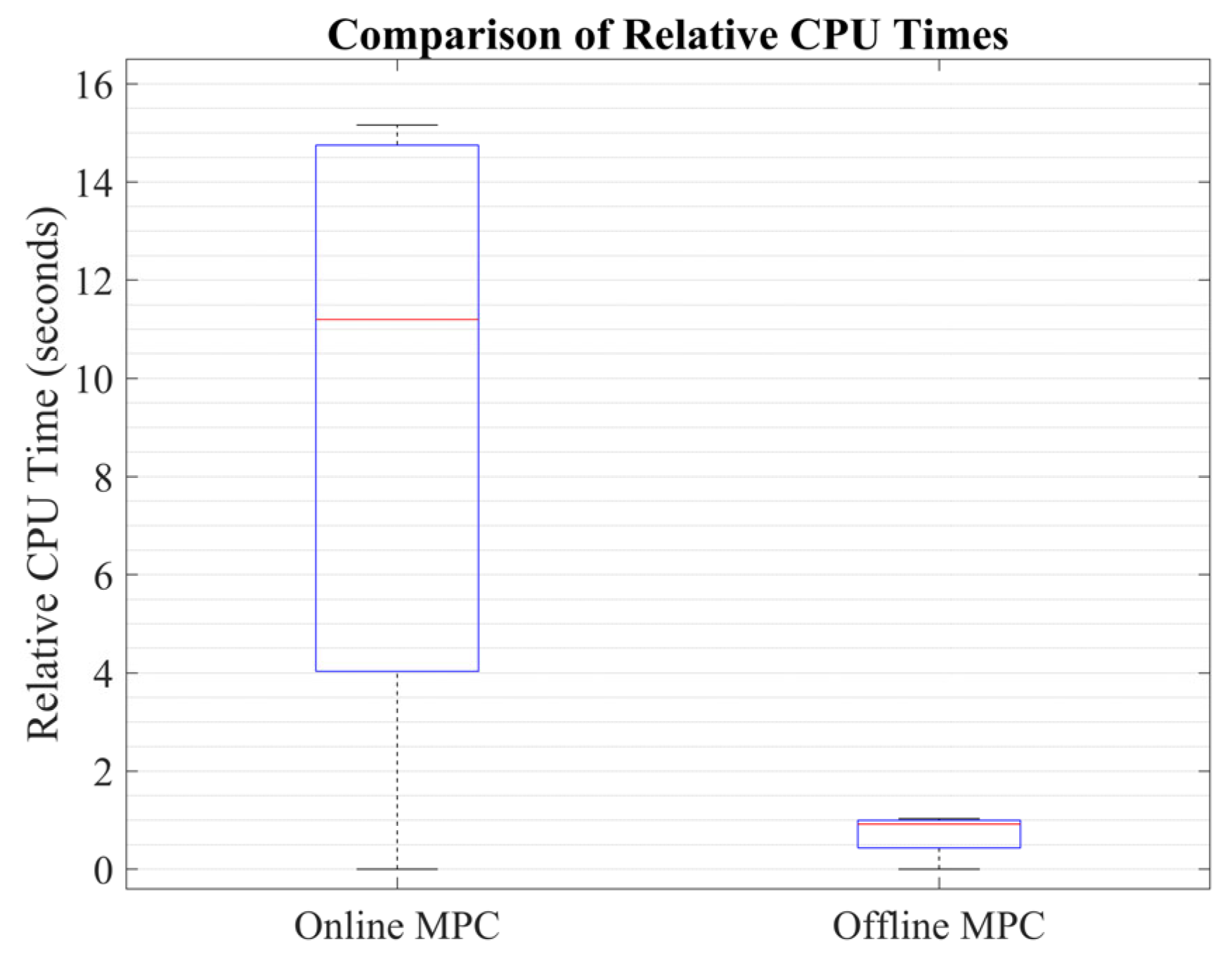

From

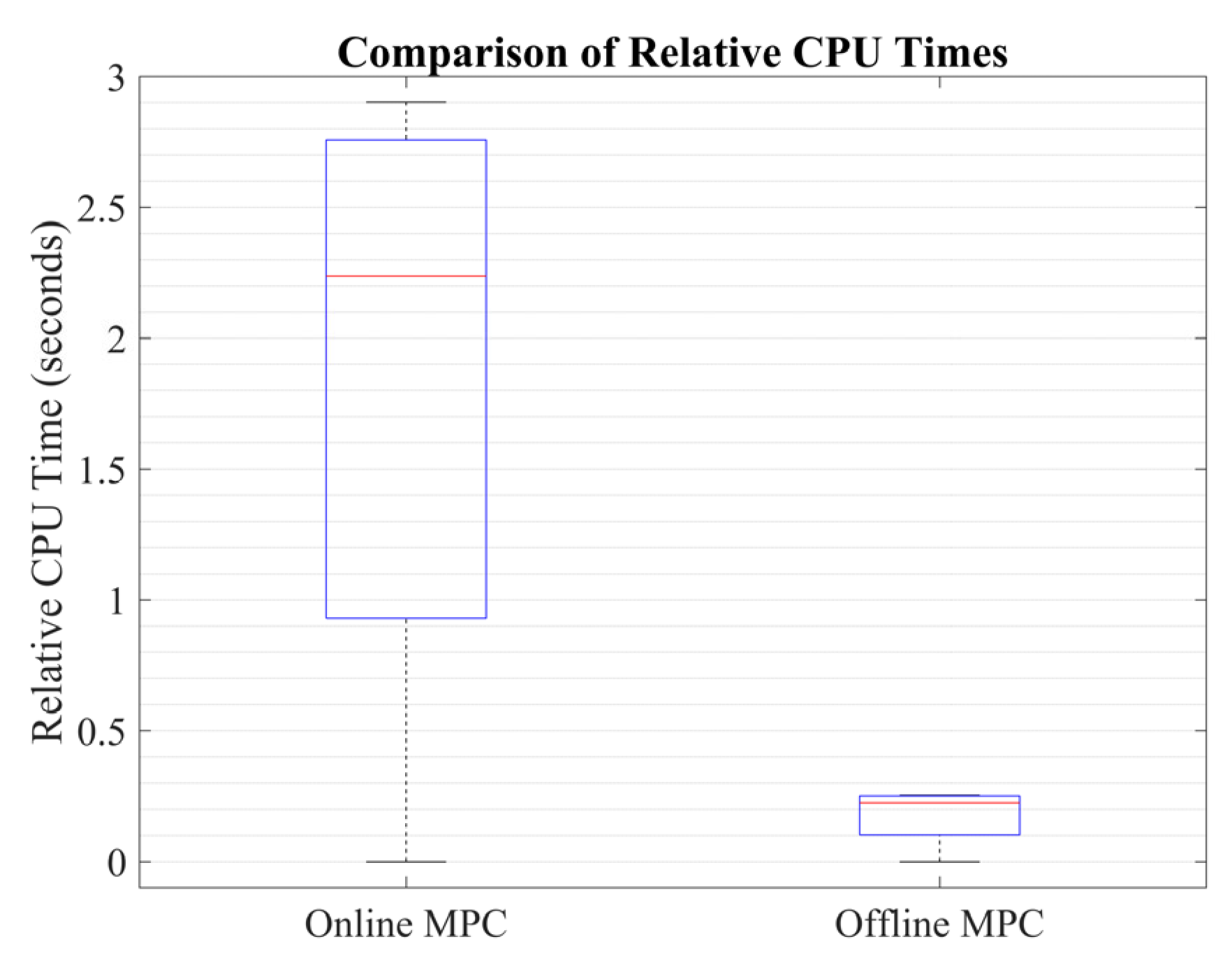

Figure 7, it is evident that the online RMPC approach effectively tracks the design objectives and ensures the satisfaction of the design constraints. Moreover, the offline RMPC algorithm performs impressively by closely overlapping the results obtained from the online controller. The significant advantage of the offline RMPC is its reduced computational burden, requiring much less time for computation compared to the online approach. The offline RMPC is approximately 12 times faster than the online controller, as shown in

Figure 8. The box–whisker plot visually represents the CPU time comparison between the online MPC and the proposed offline RMPC approach, further highlighting the computational efficiency of the offline method.

Using the algorithm described in the previous section, online and offline RMPC simulations are conducted for the wet asphalt road condition, similar to the dry asphalt condition. In the offline algorithm, the state variable (

) is discretized into a sequence of seven states, denoted as

.

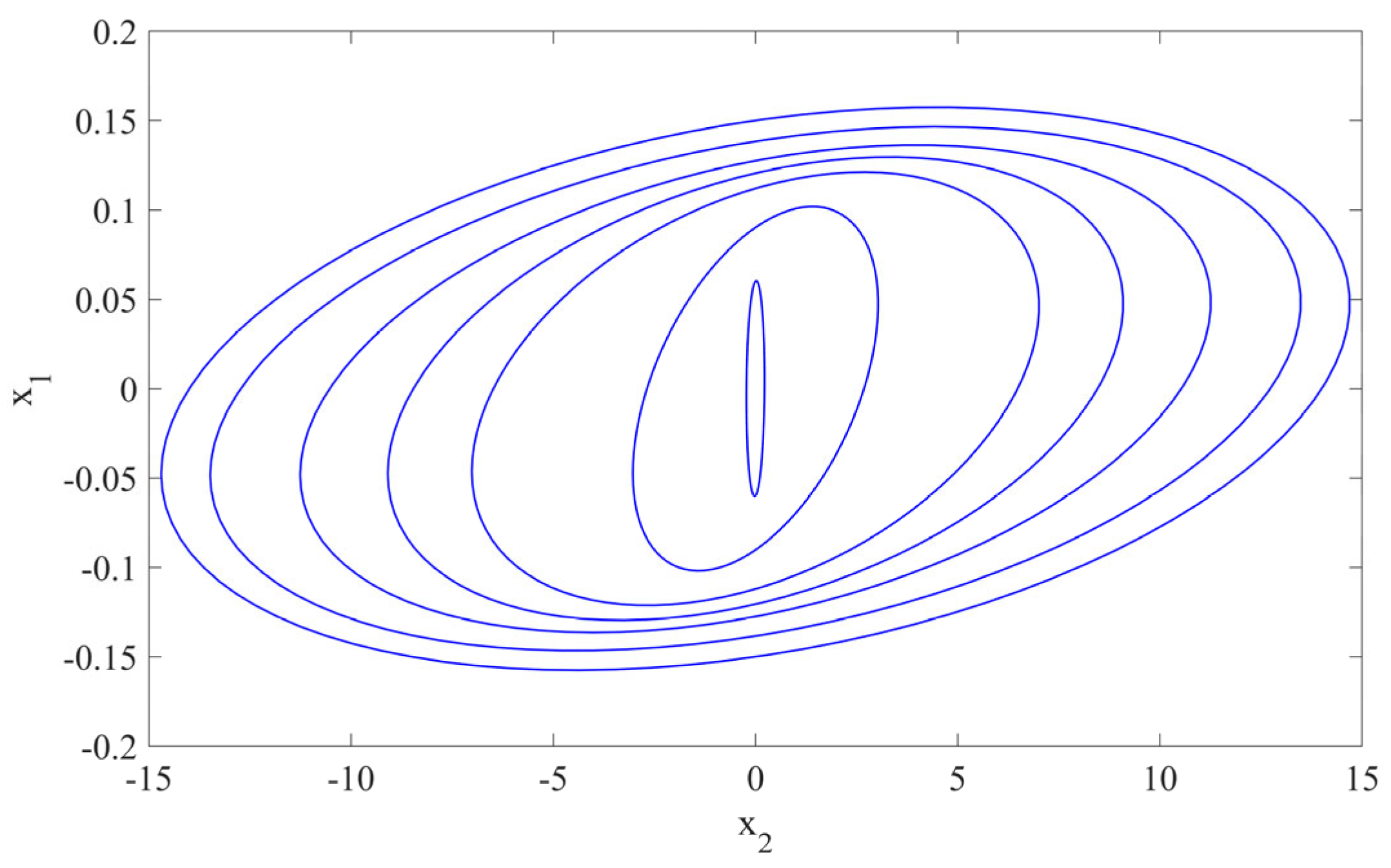

Figure 9 illustrates the relevant nested ellipsoids defined by

for these discretized points.

It is important to note that in the wet asphalt road condition, the optimal value for the wheel slip is obtained as from the peak of the road–tire friction equation. Therefore, the discretization of the state is performed using seven sequences to capture the range of optimal values.

In the case of wet asphalt road conditions, the initial values for the vehicle velocity and wheel slip at the moment of braking are assumed to be the same as those in dry asphalt conditions, namely 20 m/s and 0, respectively. The controller’s design objective in this road condition is to maintain the wheel slip at its optimal value of 0.131, which corresponds to the maximum tire–road friction and ensures safe braking without skidding.

Figure 10 depicts the simulation results of the ABS performance controlled with the MPC controller under these wet asphalt road conditions.

According to

Figure 10, the simulation results show satisfactory performance for both controllers in the given braking moment and design constraints under wet road conditions. Similar to the previous scenario, the offline RMPC design closely aligns with the online approach and accurately tracks the reference wheel slip value, and the control input remains within its upper bound. Notably, the offline approach exhibits a significantly reduced computational burden, resulting in a much faster CPU time usage: approximately 11.5 times faster.

Figure 11 illustrates the CPU time comparison between the two methods.

Snowy road conditions are used as another scenario to test the offline approach for the nonlinear ABS model. Due to reduced traction on snowy roads, vehicles are required to move at slower speeds. In this case, the vehicle’s speed during braking is set to 14 m/s (~50 Km/h). From

Table 4, the optimal wheel slip value for these conditions is determined to be 0.06. The objective of the controller is to track and maintain this wheel slip value during braking, preventing the vehicle from skidding. The

state is discretized to a sequence of seven states as

.

Figure 12 represents the nested ellipsoids.

Figure 13 illustrates the simulation results of online and offline RMPC designs.

Based on

Figure 13, it can be observed that both the online and offline RMPC approaches effectively track the reference wheel slip and satisfy the design constraints within their bounds for all three road scenarios. However, the computational burden of the offline RMPC is significantly lower compared to the online design. The offline RMPC approach achieves this by performing the optimization offline and using a bisection search during real-time implementation, resulting in a faster CPU time. The CPU time of the offline RMPC is approximately 15 times faster than the online MPC approach, as depicted in

Figure 14. This comparison of relative CPU times further highlights the efficiency of the offline RMPC in terms of computational speed and real-time implementation across different road scenarios.

In summary, for a more mathematical comparison, the CPU times of online and offline RMPC approaches are listed in

Table 5 for different road condition scenarios.

Based on the analysis of

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13, it can be concluded that the offline RMPC approach exhibits similar performance to the online MPC in controlling the nonlinear ABS model. It effectively addresses the main drawback of the online MPC design, which is the large computational burden. The offline RMPC significantly reduces the CPU time required for computation while maintaining consistent results with the online controller.