Effect of Wiper Edge Geometry on Machining Performance While Turning AISI 1045 Steel in Dry Conditions Using the VIKOR-ML Approach

Abstract

1. Introduction

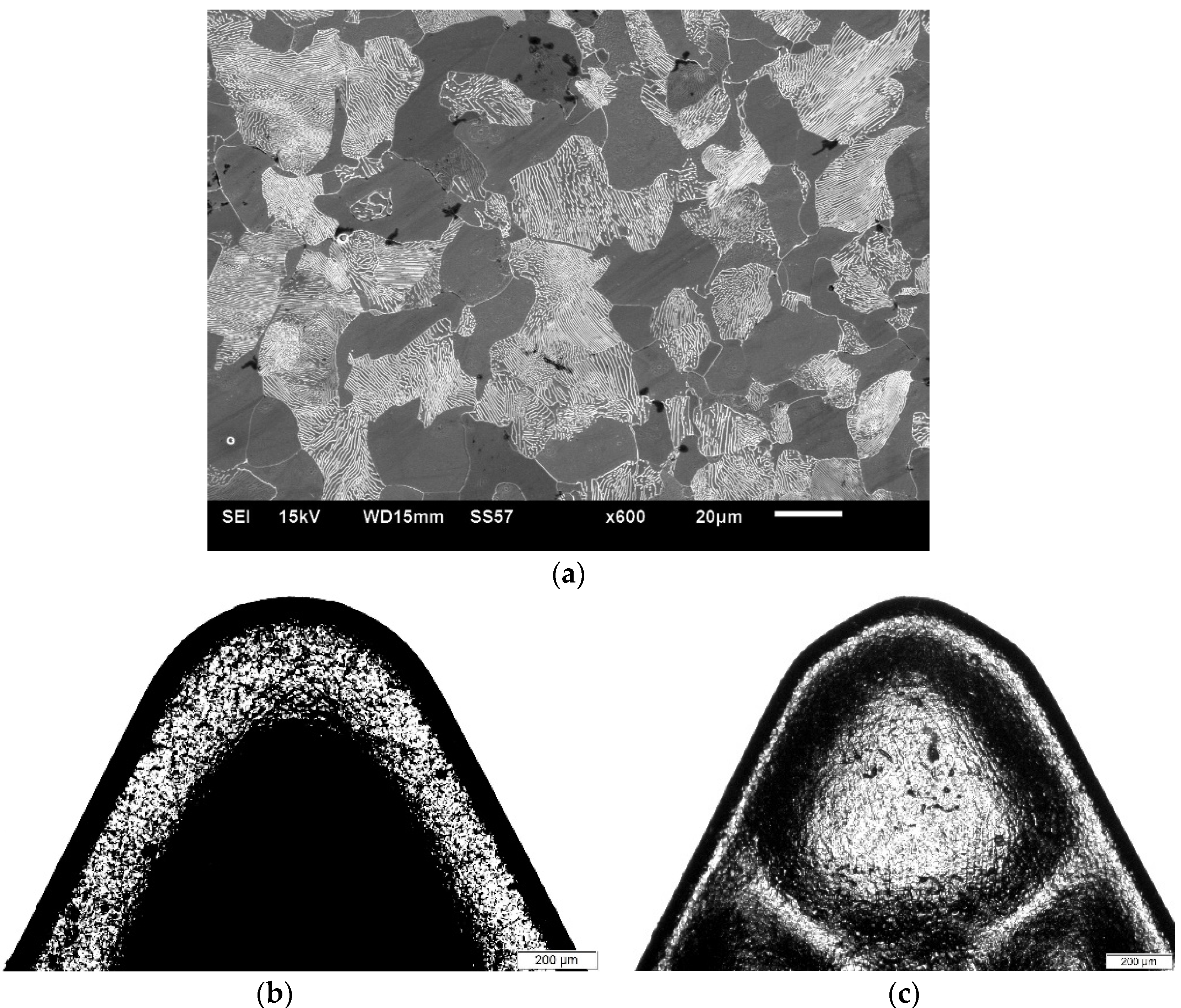

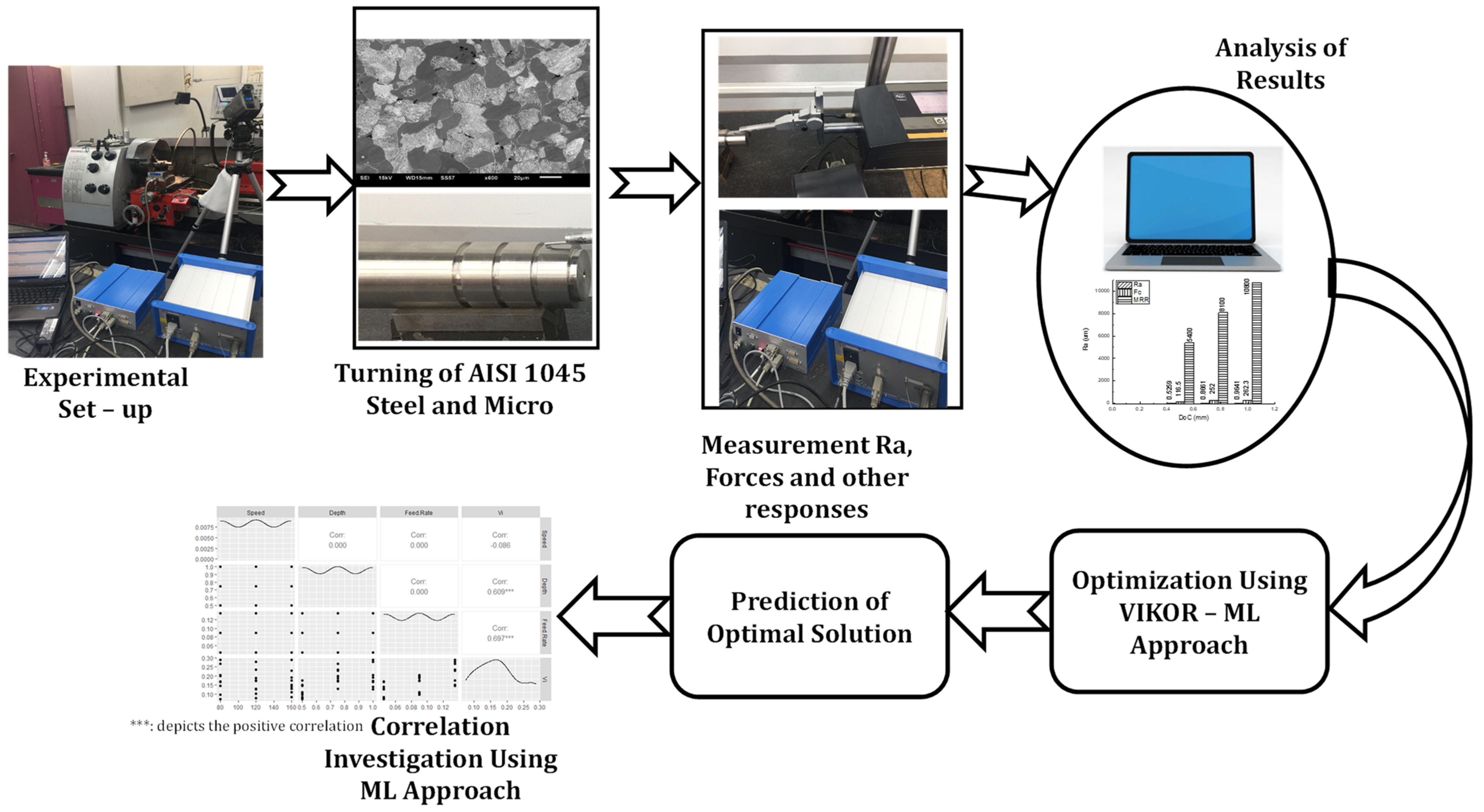

2. Materials and Methods

- = Surface speed (m/min)

- = Feed rate (mm/rev)

- = Depth of cut (mm)

- MRR was measured in (mm3/min)

3. Results and Discussion

3.1. Statistical Analysis of Response Variables

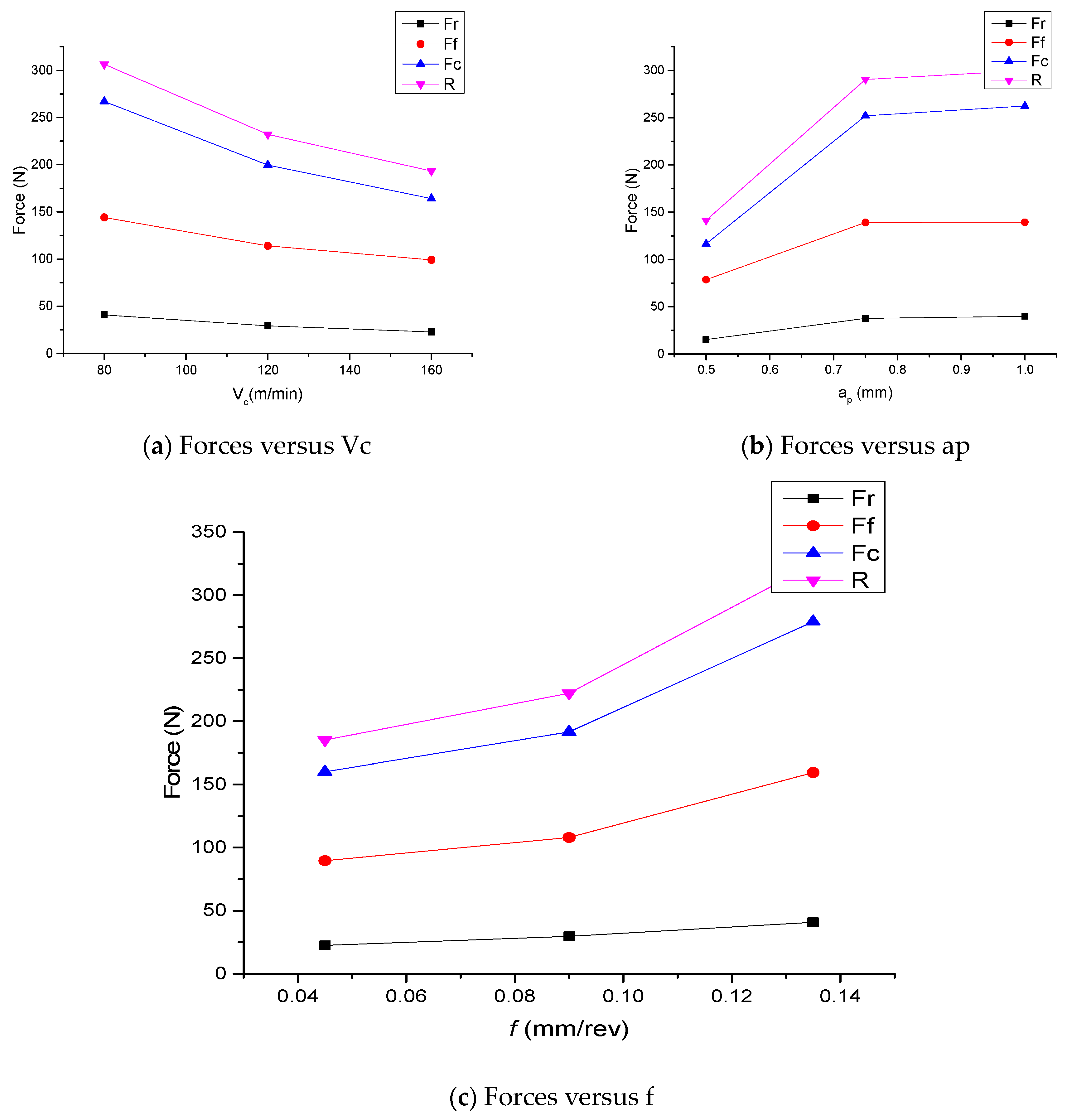

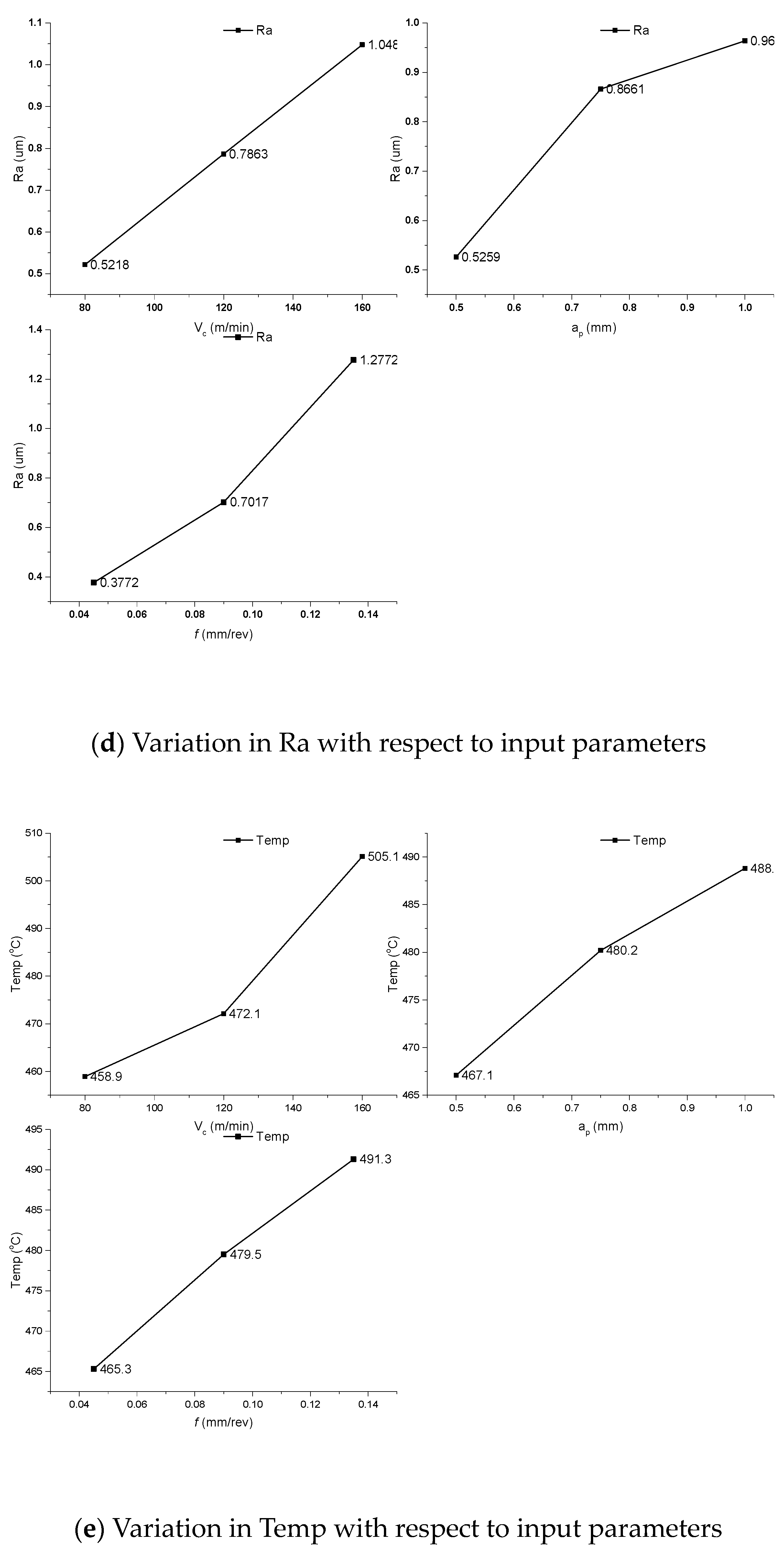

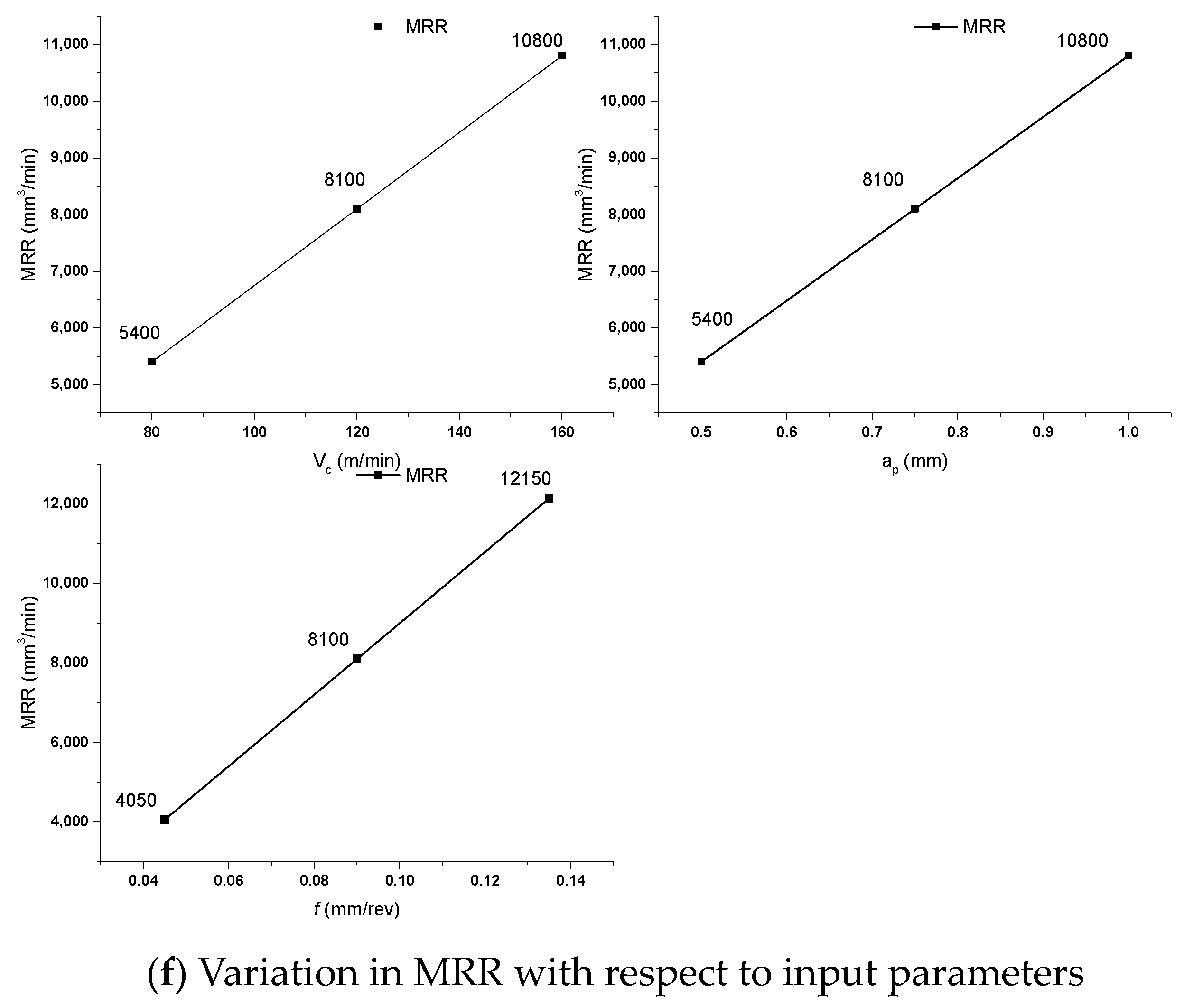

3.2. Variation in Response Variables with Respect to Machining Variables

4. Implementation of VIKOR-ML Approach

4.1. VIKOR Approach

4.2. Machine Learning Approach

5. Conclusions

- Feed (f) had the maximum influence (56.84%) on Ra while turning AISI 1045 steel, followed by Vc (18.94%) and ap (14.47%). The interactions of Vc and ap, Vc and f and ap and f had a significant influence on the investigation of Ra due to a p-value less than 0.05.

- For the investigation of Fr, ap had the maximum influence (45.7%), followed by f (21%) and Vc (20.4%). However, in the investigation of Ff, f played a pivotal role (38.3%), preceded by ap (35.7%) and Vc (15.3%). In the calculation of Fc, the ap contribution was 44.57%, followed by f (25.60%) and Vc (18.37%). Due to a p-value less than 0.05 for the interactions of Vc and ap and f and ap, a major contribution to the calculation of Fc was observed during the turning of AISI 1045 steel by the carbide tool (wiper edge geometry). However, in the investigation of Ff, f played a pivotal role. As ‘R’ was the combination of all the forces; thus, all the input parameters and their interactions had an influential effect on the investigation of the reaction (R).

- For the investigation of MRR, f had the major role (48.18%), followed by ap and Vc with 21.41% each. All the interactions (Vc and ap; Vc and f; ap and f) also had a major contribution to MRR. The values of R2 and Adj-R2 for all the performance measures were greater than 95%, which signified the outperformance of the present work for future outcomes.

- The VIKOR-based performance index (Vi) suggests the best optimal setting, which was Vc: 160 m/min; ap: 1 mm; f: 0.135 mm/rev. Corresponding to this optimal setting, the Vi value was maximum (0.2883). The value of performance measured Ra, Fr, Ff, Fc, R, temperature and MRR, which were 2.111 µm, 43.85 N, 159.33 N, 288.13 N, 332,16 N, 554.4 °C and 21,600 mm3/min, respectively, corresponding to this setting.

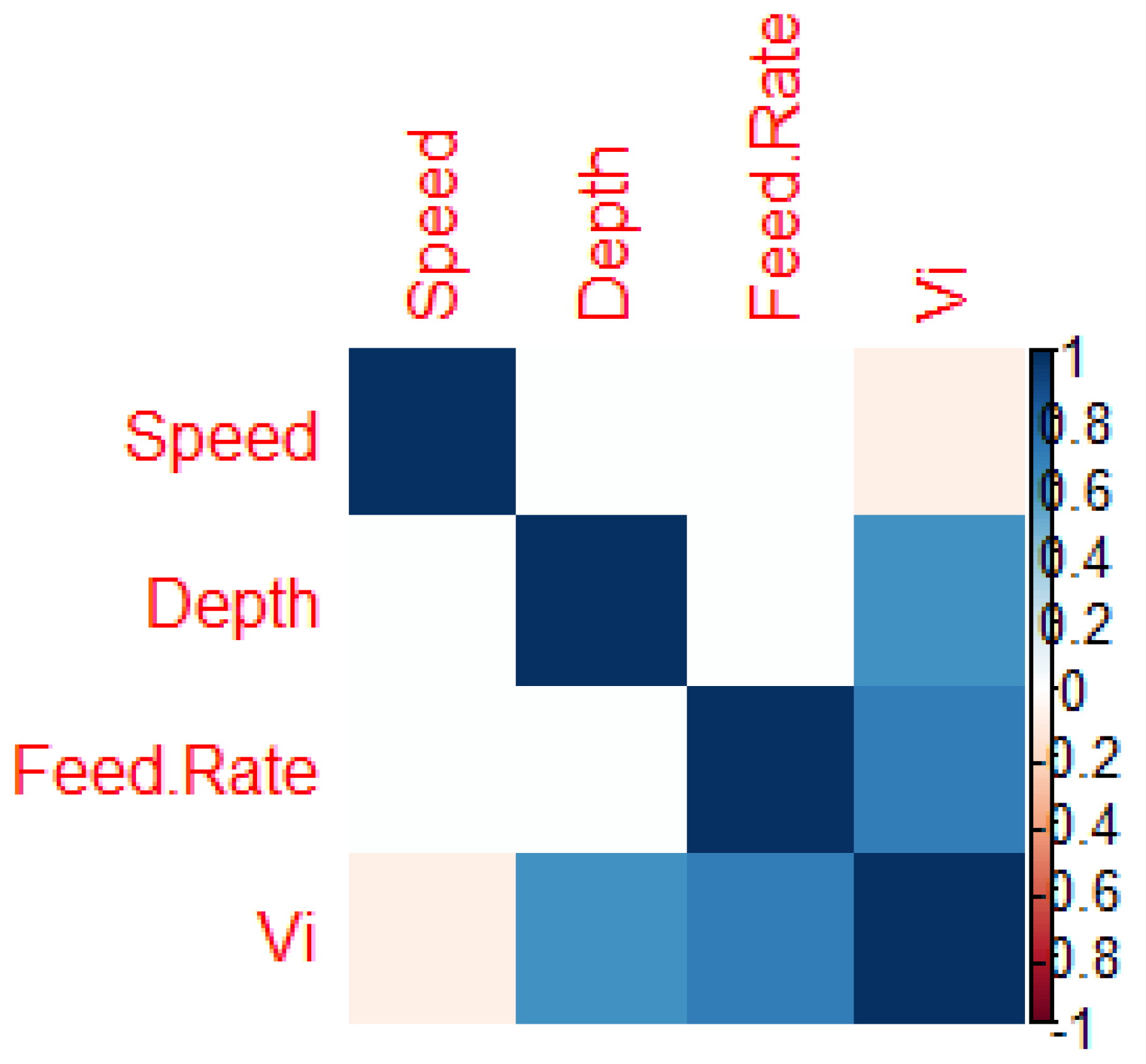

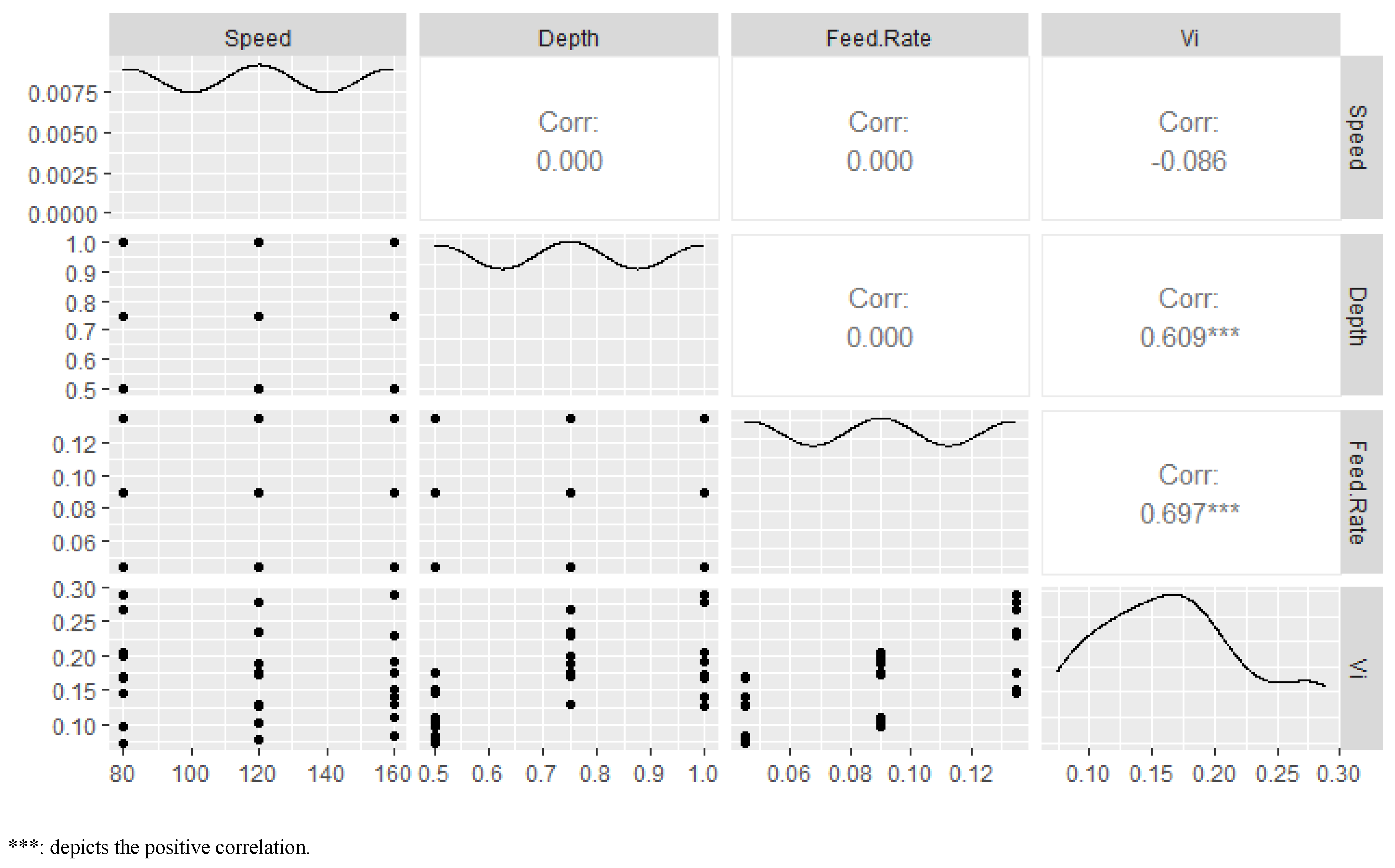

- The ML approach investigated the correlation between the input process variables and Vi, by which a strong correlation could be observed between Vi and f (0.697), followed by Vi and ap (0.609) and Vi and Vc (−0.086). The proposed approach of Vi-ML could be effectively used for the investigation of parametric optimization and correlation mapping.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ruibin, X.; Wu, H. Study on Cutting Mechanism of Ti6Al4V in Ultra-Precision Machining. Int. J. Adv. Manuf. Technol. 2016, 86, 1311–1317. [Google Scholar] [CrossRef]

- Selvam, M.D.; Senthil, P. Investigation on the Effect of Turning Operation on Surface Roughness of Hardened C45 Carbon Steel. Aust. J. Mech. Eng. 2016, 14, 131–137. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Effects of Minimum Quantity Lubrication (MQL) in Machining Processes Using Conventional and Nanofluid Based Cutting Fluids: A Comprehensive Review. J. Clean. Prod. 2016, 127, 1–18. [Google Scholar] [CrossRef]

- Leppert, T. Effect of Cooling and Lubrication Conditions on Surface Topography and Turning Process of C45 Steel. Int. J. Mach. Tools Manuf. 2011, 51, 120–126. [Google Scholar] [CrossRef]

- Walker, T. The MQL Handbook, A Guide to Machining with Minimum Quantity Lubrication; V1.0.7; 2015; Unist, Inc.: Grand Rapids, MI, USA, 2015. [Google Scholar]

- Le Coz, G.; Marinescu, M.; Devillez, A.; Dudzinski, D.; Velnom, L. Measuring Temperature of Rotating Cutting Tools: Application to MQL Drilling and Dry Milling of Aerospace Alloys. Appl. Therm. Eng. 2012, 36, 434–441. [Google Scholar] [CrossRef]

- Hamdan, A.; Sarhan, A.; Hamdi, M. An Optimization Method of the Machining Parameters in High-Speed Machining of Stainless Steel Using Coated Carbide Tool for Best Surface Finish. Int. J. Adv. Manuf. Technol. 2012, 58, 81–91. [Google Scholar] [CrossRef]

- Kurgin, S.; Dasch, J.M.; Simon, D.L.; Barber, G.C.; Zou, Q. Evaluation of the Convective Heat Transfer Coefficient for Minimum Quantity Lubrication (MQL). Ind. Lubr. Tribol. 2012, 64, 376–386. [Google Scholar] [CrossRef]

- Elmunafi, M.H.S.; Kurniawan, D.; Noordin, M.Y. Use of Castor Oil as Cutting Fluid in Machining of Hardened Stainless Steel with Minimum Quantity of Lubricant. Procedia Cirp 2015, 26, 408–411. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental Friendly Cutting Fluids and Cooling Techniques in Machining: A Review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Rahim, E.A.; Sasahara, H. An Analysis of Surface Integrity When Drilling Inconel 718 Using Palm Oil and Synthetic Ester under MQL Condition. Mach. Sci. Technol. 2011, 15, 76–90. [Google Scholar] [CrossRef]

- Lawal, S.A.; Choudhury, I.A.; Nukman, Y. A Critical Assessment of Lubrication Techniques in Machining Processes: A Case for Minimum Quantity Lubrication Using Vegetable Oil-Based Lubricant. J. Clean. Prod. 2013, 41, 210–221. [Google Scholar] [CrossRef]

- Schwarz, M.; Dado, M.; Hnilica, R.; Veverková, D. Environmental and Health Aspects of Metalworking Fluid Use. Polish J. Environ. Stud. 2015, 24, 37–45. [Google Scholar]

- Islam, M.N.; Anggono, J.M.; Pramanik, A.; Boswell, B. Effect of Cooling Methods on Dimensional Accuracy and Surface Finish of a Turned Titanium Part. Int. J. Adv. Manuf. Technol. 2013, 69, 2711–2722. [Google Scholar] [CrossRef]

- Raynor, P.C.; Kim, S.W.; Bhattacharya, M. Mist Generation from Metalworking Fluids Formulated Using Vegetable Oils. Ann. Occup. Hyg. 2005, 49, 283–293. [Google Scholar]

- Davim, J.P. Green Manufacturing Processes and Systems; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 3642337929. [Google Scholar]

- Boubekri, N.; Shaikh, V.; Foster, P.R. A Technology Enabler for Green Machining: Minimum Quantity Lubrication (MQL). J. Manuf. Technol. Manag. 2010, 21, 556–566. [Google Scholar] [CrossRef]

- Astakhov, V. Ecological Machining: Near-dry Machining. In Machining; Springer: London, UK, 2008. [Google Scholar] [CrossRef]

- Selvam, M.D.; Sivaram, N. The Effectiveness of Various Cutting Fluids on the Surface Roughness of AISI 1045 Steel during Turning Operation Using Minimum Quantity Lubrication System. J. Futur. Eng. Technol. 2017, 13, 36–43. [Google Scholar]

- Krishnaraj, V.; Krishna, B.H.; Sheikh-Ahmad, J.Y. An Experimental Study on End Milling of Titanium Alloy (Ti-6Al-4V) under Dry and Minimum Quantity Lubrication Conditions. Int. J. Mach. Mach. Mater. 2017, 19, 325–342. [Google Scholar] [CrossRef]

- Babu, M.N.; Manimaran, G.; Muthukrishnan, N. Experimental Estimation of Minimum Quantity Lubrication in Turning on AISI 410 Stainless Steel. Int. J. Mach. Mach. Mater. 2017, 19, 522–537. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Choudhury, S.K. Comparative Evaluations of Nose Wear Progression and Failure Modes during Hard Turning under Dry and Near-Dry Cutting Conditions. Int. J. Mach. Mach. Mater. 2016, 18, 466–482. [Google Scholar] [CrossRef]

- Boswell, B.; Islam, M.N. The Challenge of Adopting Minimal Quantities of Lubrication for End Milling Aluminium. In Proceedings of the IAENG Transactions on Engineering Technologies: Special Volume of the World Congress on Engineering, London, UK, 4–6 July 2012; Springer: Berlin/Heidelberg, Germany, 2013; pp. 713–724. [Google Scholar]

- Singh, T.; Singh, P.; Dureja, J.S.; Dogra, M.; Singh, H.; Bhatti, M.S. A Review of near Dry Machining/Minimum Quantity Lubrication Machining of Difficult to Machine Alloys. Int. J. Mach. Mach. Mater. 2016, 18, 213–251. [Google Scholar] [CrossRef]

- Nicolo, B. Quality by Design: Taguchi Techniques for Industrial Experimentation; Prentice Hall: Hoboken, NJ, USA, 1995; ISBN 0-13-186362-2. [Google Scholar]

- Sivaiah, P.; Chakradhar, D. Performance Improvement of Cryogenic Turning Process during Machining of 17-4 PH Stainless Steel Using Multi Objective Optimization Techniques. Meas. J. Int. Meas. Confed. 2019, 136, 326–336. [Google Scholar] [CrossRef]

- Manikandan, N.; Kumanan, S.; Sathiyanarayanan, C. Optimisation of Electrochemical Drilling Process Using Taguchi Method and Regression Analysis. Int. J. Mach. Mach. Mater. 2017, 19, 136–159. [Google Scholar] [CrossRef]

- Goel, B.; Singh, S.; Sarepaka, R.G. V Optimisation of Machining Parameters for Single Point Diamond Turning of Chromium Zirconium Copper Alloy C18150 Using Taguchi and Grey Relational Analysis. Int. J. Mach. Mach. Mater. 2017, 19, 95–109. [Google Scholar] [CrossRef]

- Bajić, D.; Lela, B.; Živković, D. Modeling of Machined Surface Roughness and Optimization of Cutting Parameters in Face Milling. Metalurgija 2008, 47, 331–334. [Google Scholar]

- Yang, J.L.; Chen, J.C. A Systematic Approach for Identifying Optimum Surface Roughness Performance in End-Milling Operations. J. Ind. Technol. 2001, 17, 1–8. [Google Scholar]

- Caldeirani Filho, J.; Diniz, A.E. Influence of Cutting Conditions on Tool Life, Tool Wear and Surface Finish in the Face Milling Process. J. Brazilian Soc. Mech. Sci. 2002, 24, 10–14. [Google Scholar] [CrossRef]

- Tsao, C.C. Grey–Taguchi Method to Optimize the Milling Parameters of Aluminum Alloy. Int. J. Adv. Manuf. Technol. 2009, 40, 41–48. [Google Scholar] [CrossRef]

- Abbas, A.T.; Gupta, M.K.; Soliman, M.S.; Mia, M.; Hegab, H.; Luqman, M.; Pimenov, D.Y. Sustainability Assessment Associated with Surface Roughness and Power Consumption Characteristics in Nanofluid MQL-Assisted Turning of AISI 1045 Steel. Int. J. Adv. Manuf. Technol. 2019, 105, 1311–1327. [Google Scholar] [CrossRef]

- Abbas, A.T.; Al-Abduljabbar, A.A.; Alnaser, I.A.; Aly, M.F.; Abdelgaliel, I.H.; Elkaseer, A. A Closer Look at Precision Hard Turning of AISI4340: Multi-Objective Optimization for Simultaneous Low Surface Roughness and High Productivity. Materials 2022, 15, 2106. [Google Scholar] [CrossRef]

- Abbas, A.T.; Al-Abduljabbar, A.A.; El Rayes, M.M.; Benyahia, F.; Abdelgaliel, I.H.; Elkaseer, A. Multi-Objective Optimization of Performance Indicators in Turning of AISI 1045 under Dry Cutting Conditions. Metals 2023, 13, 96. [Google Scholar] [CrossRef]

- Abbas, A.T.; El Rayes, M.M.; Al-Abduljabbar, A.A.; Ragab, A.E.; Benyahia, F.; Elkaseer, A. Effects of Tool Edge Geometry and Cutting Conditions on the Performance Indicators in Dry Turning AISI 1045 Steel. Machines 2023, 11, 397. [Google Scholar] [CrossRef]

- Szwajka, K.; Trzepiecinski, T. On the Machinability of Medium Density Fiberboard by Drilling. BioResources 2018, 13, 8263–8278. [Google Scholar] [CrossRef]

- Nur, R.; Yusof, N.M.; Sudin, I.; Nor, F.M.; Kurniawan, D. Determination of Energy Consumption during Turning of Hardened Stainless Steel Using Resultant Cutting Force. Metals 2021, 11, 565. [Google Scholar] [CrossRef]

- Szwajka, K.; Zielińska-Szwajka, J.; Trzepiecinski, T. Experimental Study on Drilling MDF with Tools Coated with TiAlN and ZrN. Materials 2019, 12, 386. [Google Scholar] [CrossRef]

- Sharma, N.; Gupta, R.D.; Khanna, R.; Sharma, R.C.; Sharma, Y.K. Machining of Ti-6Al-4V Biomedical Alloy by WEDM: Investigation and Optimization of MRR and Rz Using Grey-Harmony Search. World J. Eng. 2021, 20, 221–234. [Google Scholar] [CrossRef]

- Abbas, A.T.; Sharma, N.; Alsuhaibani, Z.A.; Sharma, V.S.; Soliman, M.S.; Sharma, R.C. Processing of Al/SiC/Gr Hybrid Composite on EDM by Different Electrode Materials Using RSM-COPRAS Approach. Metals 2023, 13, 1125. [Google Scholar] [CrossRef]

- Demir, H.; Gündüz, S. The Effects of Aging on Machinability of 6061 Aluminium Alloy. Mater. Des. 2009, 30, 1480–1483. [Google Scholar] [CrossRef]

- Shaw, M.C.; Cookson, J.O. Metal Cutting Principles; Oxford University Press: New York, NY, USA, 2005; Volume 2. [Google Scholar]

- Hosseini, A.; Kishawy, H.A. Cutting Tool Materials and Tool Wear. In Machining of Titanium Alloys; Springer: Berlin/Heidelberg, Germany, 2014; pp. 31–56. [Google Scholar] [CrossRef]

- Opricovic, S.; Tzeng, G.-H. Compromise Solution by MCDM Methods: A Comparative Analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 2004, 156, 445–455. [Google Scholar] [CrossRef]

- Gul, M.; Celik, E.; Aydin, N.; Gumus, A.T.; Guneri, A.F. A State of the Art Literature Review of VIKOR and Its Fuzzy Extensions on Applications. Appl. Soft Comput. 2016, 46, 60–89. [Google Scholar] [CrossRef]

- Khan, A.; Maity, K.P. A novel MCDM approach for simultaneous optimization of some correlated machining parameters in turning of CP-titanium grade 2. Int. J. Eng. Res. Africa 2016, 22, 94–111. [Google Scholar] [CrossRef]

- Sharma, N.; Ahuja, N.; Goyal, R.; Rohilla, V. Parametric optimization of EDD using RSM-Grey-TLBO-based MCDM approach for commercially pure titanium. Grey Sys.: Theory Appl. 2020, 10, 231–245. [Google Scholar] [CrossRef]

- Shahali, H.; Yazdi, M.R.S.; Mohammadi, A.; Iimanian, E. Optimization of Surface Roughness and Thickness of White Layer in Wire Electrical Discharge Machining of DIN 1.4542 Stainless Steel Using Micro-Genetic Algorithm and Signal to Noise Ratio Techniques. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 803–812. [Google Scholar] [CrossRef]

- Vendan, S.A.; Kamal, R.; Karan, A.; Gao, L.; Niu, X.; Garg, A. Welding and Cutting Case Studies with Supervised Machine Learning; Springer: Berlin/Heidelberg, Germany, 2020; Volume 1, ISBN 9811393818. [Google Scholar]

- Bisaria, H.; Shandilya, P. Wire Electric Discharge Machining Induced Surface Integrity for Ni55. 95Ti44. 05 Shape Memory Alloy. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2021, 235, 178–185. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, R.; Gupta, A.K. Experimental Investigation of WEDM Process through Integrated Desirability and Machine Learning Technique on Implant Material. J. Mech. Behav. Mater. 2021, 30, 38–48. [Google Scholar] [CrossRef]

| Element | S | P | Mn | C | Fe |

|---|---|---|---|---|---|

| Percentage % | 0.04 | 0.03 | 0.65 | 0.45 | Balance |

| Characteristics | Value | ||||

| Hardness, Vickers | 170 | ||||

| Young’s Elasticity | 200 GPa | ||||

| Reduction in Area | 40% | ||||

| Tensile Strength, Yield | 310 MPa | ||||

| Tensile Strength, Ultimate | 565 MPa | ||||

| Elongation at Break (in 50 mm) | 16% | ||||

| Source | DF | Ra | Fr | Ff | Fc | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| pcp * | F * | p * | pcp | F | p | pcp | F | p | pcp | F | p | ||

| Vc | 2 | 18.9 | 83.39 | 0 | 20.4 | 55.96 | 0 | 15.3 | 97.48 | 0 | 18.38 | 107.7 | 0 |

| ap | 2 | 14.4 | 63.72 | 0 | 45.7 | 125.15 | 0 | 35.7 | 226.92 | 0 | 44.58 | 261.3 | 0 |

| f | 2 | 56.8 | 250.2 | 0 | 21 | 57.53 | 0 | 38.3 | 243.12 | 0 | 25.6 | 150.1 | 0 |

| Vc * ap | 4 | 3.33 | 7.32 | 0.009 | 8.09 | 11.08 | 0.002 | 5.94 | 18.84 | 0 | 6.88 | 20.17 | 0 |

| Vc * f | 4 | 2.8 | 6.16 | 0.014 | 1.2 | 1.63 | 0.257 | 1.62 | 5.14 | 0.024 | 1.14 | 3.33 | 0.069 |

| ap * f | 4 | 2.71 | 5.96 | 0.016 | 2.12 | 2.9 | 0.093 | 2.35 | 7.46 | 0.008 | 2.74 | 8.04 | 0.007 |

| Residual Error | 8 | 0.91 | R2 = 99.09 | R2 (adj) = 97.05 | 1.46 | R2 = 98.54 | R2 (adj) = 95.25 | 0.63 | R2 = 99.37 | R2 (adj) = 99.95 | 0.68 | R2 = 99.32 | R2 (adj) = 97.78 |

| Total | 26 | 100 | 100 | 100 | 100 | ||||||||

| Source | DF | R | Temp | MRR | |||||||||

| pcp | F | p | pcp | F | p | pcp | F | p | |||||

| Vc | 2 | 17.9 | 133.9 | 0 | 53.2 | 42.85 | 0 | 21.4 | 324 | 0 | |||

| ap | 2 | 42.7 | 320.1 | 0 | 11.2 | 9.07 | 0.009 | 21.4 | 324 | 0 | |||

| f | 2 | 28.1 | 210.8 | 0 | 15.9 | 12.85 | 0.003 | 48.1 | 729 | 0 | |||

| Vc * ap | 4 | 6.75 | 25.25 | 0 | 11.7 | 4.71 | 0.03 | 1.58 | 12 | 0.002 | |||

| Vc * f | 4 | 1.2 | 4.51 | 0.034 | 2.81 | 1.13 | 0.407 | 3.56 | 27 | 0 | |||

| ap * f | 4 | 2.63 | 9.85 | 0.004 | 0.11 | 0.05 | 0.995 | 3.56 | 27 | 0 | |||

| Residual Error | 8 | 0.54 | R2 = 99.47 | R2 (adj) = 98.26 | 4.96 | R2 = 95.03 | R2 (adj) = 83.86 | 0.26 | R2 = 99.74 | R2 (adj) = 99.14 | |||

| Total | 26 | 100 | 100 | 100 | |||||||||

| Test No. | W Normalized MRR | W Normalized Ra | Normalized Fc | Normalized Fr | Normalized Ff | Normalized R | Normalized Temp | Pi |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.0052 | 0.0059 | 0.0097 | 0.0069 | 0.0120 | 0.0103 | 0.0236 | 0.0735 |

| 2 | 0.0103 | 0.0097 | 0.0122 | 0.0113 | 0.0152 | 0.0129 | 0.0250 | 0.0967 |

| 3 | 0.0155 | 0.0198 | 0.0205 | 0.0186 | 0.0240 | 0.0213 | 0.0253 | 0.1450 |

| 4 | 0.0077 | 0.0073 | 0.0332 | 0.0342 | 0.0302 | 0.0325 | 0.0257 | 0.1709 |

| 5 | 0.0155 | 0.0122 | 0.0368 | 0.0395 | 0.0335 | 0.0361 | 0.0259 | 0.1996 |

| 6 | 0.0232 | 0.0279 | 0.0476 | 0.0503 | 0.0456 | 0.0472 | 0.0269 | 0.2687 |

| 7 | 0.0103 | 0.0085 | 0.0308 | 0.0318 | 0.0300 | 0.0306 | 0.0264 | 0.1685 |

| 8 | 0.0206 | 0.0146 | 0.0370 | 0.0383 | 0.0324 | 0.0360 | 0.0266 | 0.2055 |

| 9 | 0.0310 | 0.0304 | 0.0504 | 0.0513 | 0.0495 | 0.0502 | 0.0267 | 0.2896 |

| 10 | 0.0077 | 0.0072 | 0.0096 | 0.0057 | 0.0123 | 0.0103 | 0.0260 | 0.0789 |

| 11 | 0.0155 | 0.0129 | 0.0121 | 0.0099 | 0.0140 | 0.0126 | 0.0266 | 0.1035 |

| 12 | 0.0232 | 0.0270 | 0.0231 | 0.0249 | 0.0258 | 0.0238 | 0.0270 | 0.1747 |

| 13 | 0.0116 | 0.0104 | 0.0217 | 0.0191 | 0.0192 | 0.0211 | 0.0260 | 0.1290 |

| 14 | 0.0232 | 0.0264 | 0.0270 | 0.0286 | 0.0284 | 0.0274 | 0.0274 | 0.1884 |

| 15 | 0.0348 | 0.0405 | 0.0329 | 0.0300 | 0.0368 | 0.0338 | 0.0272 | 0.2362 |

| 16 | 0.0155 | 0.0132 | 0.0172 | 0.0193 | 0.0176 | 0.0173 | 0.0259 | 0.1260 |

| 17 | 0.0310 | 0.0246 | 0.0223 | 0.0250 | 0.0222 | 0.0223 | 0.0260 | 0.1734 |

| 18 | 0.0464 | 0.0434 | 0.0423 | 0.0396 | 0.0392 | 0.0415 | 0.0268 | 0.2792 |

| 19 | 0.0103 | 0.0083 | 0.0088 | 0.0080 | 0.0113 | 0.0094 | 0.0269 | 0.0831 |

| 20 | 0.0206 | 0.0149 | 0.0110 | 0.0090 | 0.0146 | 0.0119 | 0.0272 | 0.1094 |

| 21 | 0.0310 | 0.0319 | 0.0143 | 0.0113 | 0.0195 | 0.0156 | 0.0287 | 0.1523 |

| 22 | 0.0155 | 0.0138 | 0.0181 | 0.0159 | 0.0199 | 0.0185 | 0.0273 | 0.1290 |

| 23 | 0.0310 | 0.0361 | 0.0189 | 0.0212 | 0.0216 | 0.0196 | 0.0277 | 0.1761 |

| 24 | 0.0464 | 0.0517 | 0.0264 | 0.0223 | 0.0277 | 0.0266 | 0.0288 | 0.2300 |

| 25 | 0.0206 | 0.0240 | 0.0178 | 0.0146 | 0.0168 | 0.0175 | 0.0276 | 0.1391 |

| 26 | 0.0413 | 0.0319 | 0.0223 | 0.0220 | 0.0223 | 0.0223 | 0.0300 | 0.1922 |

| 27 | 0.0619 | 0.0613 | 0.0334 | 0.0337 | 0.0335 | 0.0334 | 0.0312 | 0.2883 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, A.T.; Sharma, N.; Soliman, M.S.; El Rayes, M.M.; Sharma, R.C.; Elkaseer, A. Effect of Wiper Edge Geometry on Machining Performance While Turning AISI 1045 Steel in Dry Conditions Using the VIKOR-ML Approach. Machines 2023, 11, 719. https://doi.org/10.3390/machines11070719

Abbas AT, Sharma N, Soliman MS, El Rayes MM, Sharma RC, Elkaseer A. Effect of Wiper Edge Geometry on Machining Performance While Turning AISI 1045 Steel in Dry Conditions Using the VIKOR-ML Approach. Machines. 2023; 11(7):719. https://doi.org/10.3390/machines11070719

Chicago/Turabian StyleAbbas, Adel T., Neeraj Sharma, Mahmoud S. Soliman, Magdy M. El Rayes, Rakesh Chandmal Sharma, and Ahmed Elkaseer. 2023. "Effect of Wiper Edge Geometry on Machining Performance While Turning AISI 1045 Steel in Dry Conditions Using the VIKOR-ML Approach" Machines 11, no. 7: 719. https://doi.org/10.3390/machines11070719

APA StyleAbbas, A. T., Sharma, N., Soliman, M. S., El Rayes, M. M., Sharma, R. C., & Elkaseer, A. (2023). Effect of Wiper Edge Geometry on Machining Performance While Turning AISI 1045 Steel in Dry Conditions Using the VIKOR-ML Approach. Machines, 11(7), 719. https://doi.org/10.3390/machines11070719