Dynamics Modeling and Analysis of Rolling Bearings Variable Stiffness System with Local Faults

Abstract

:1. Introduction

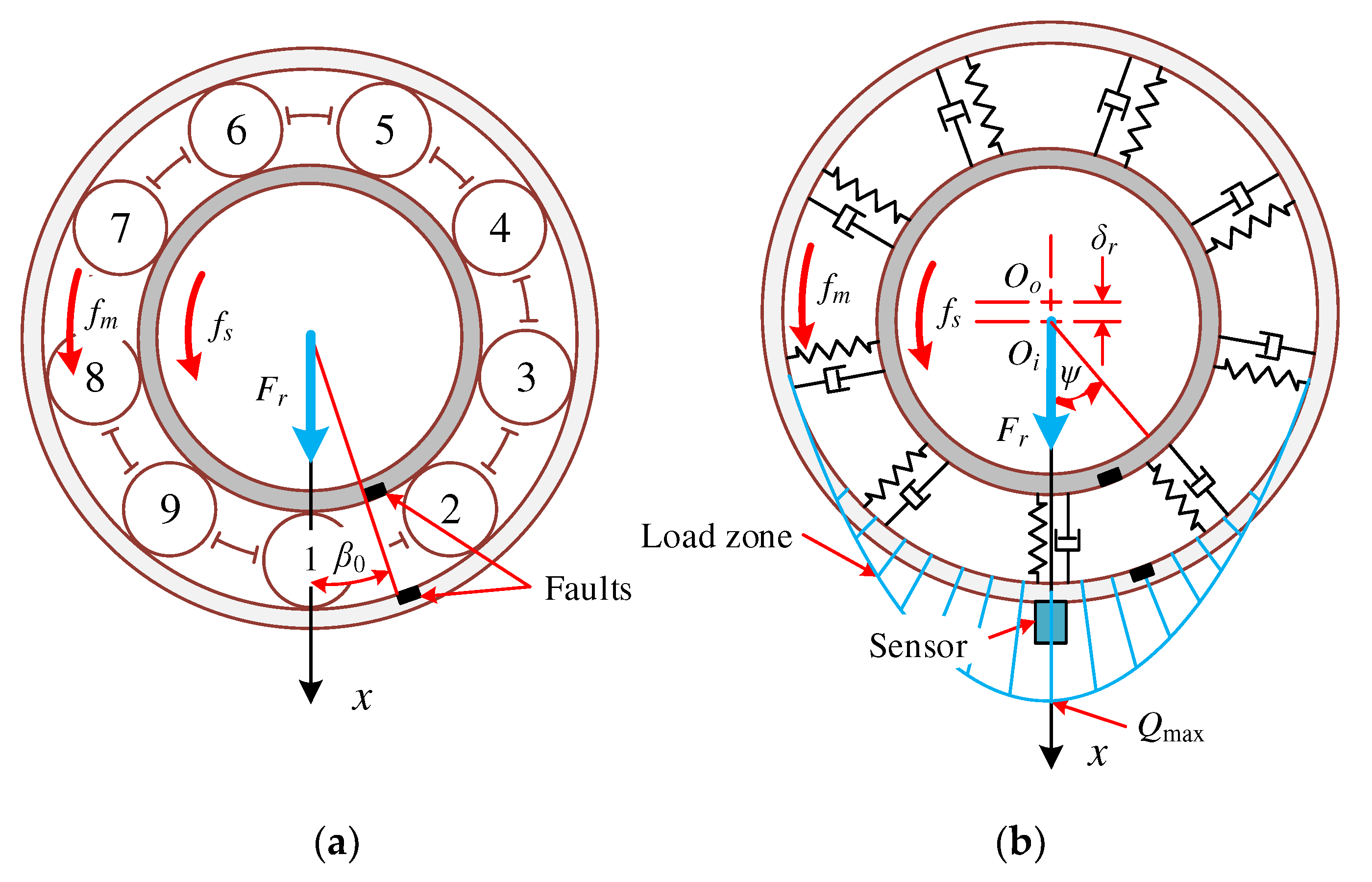

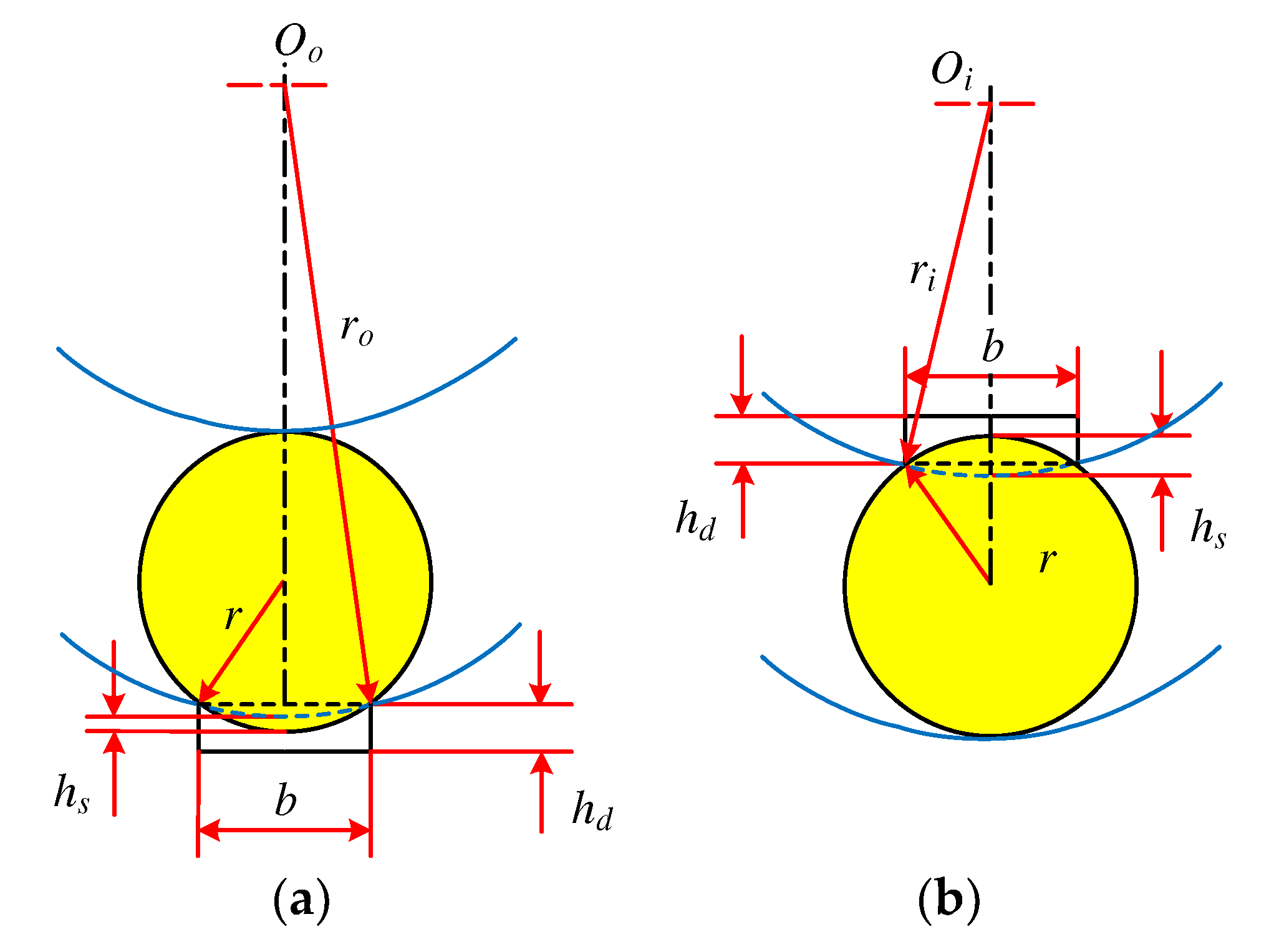

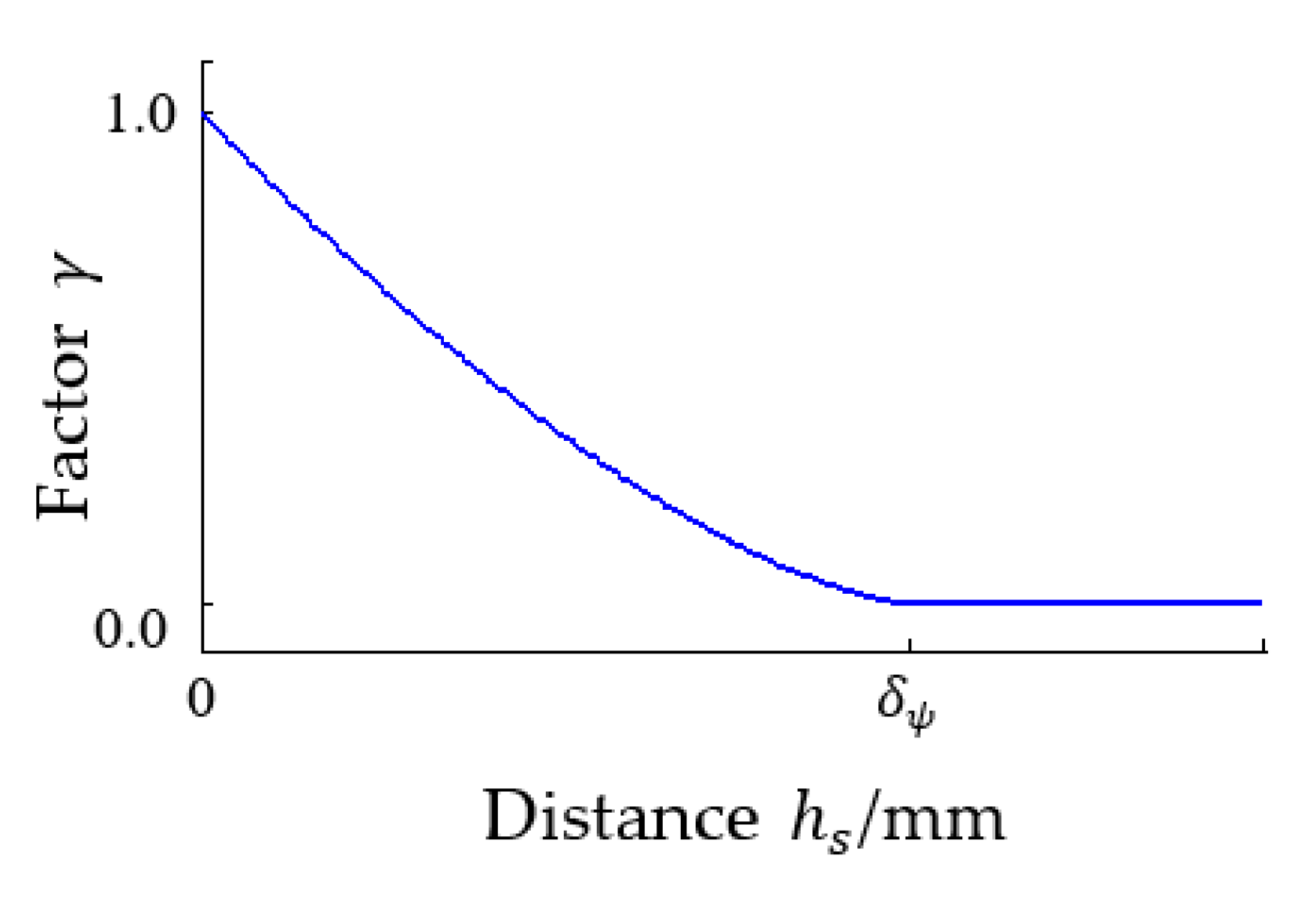

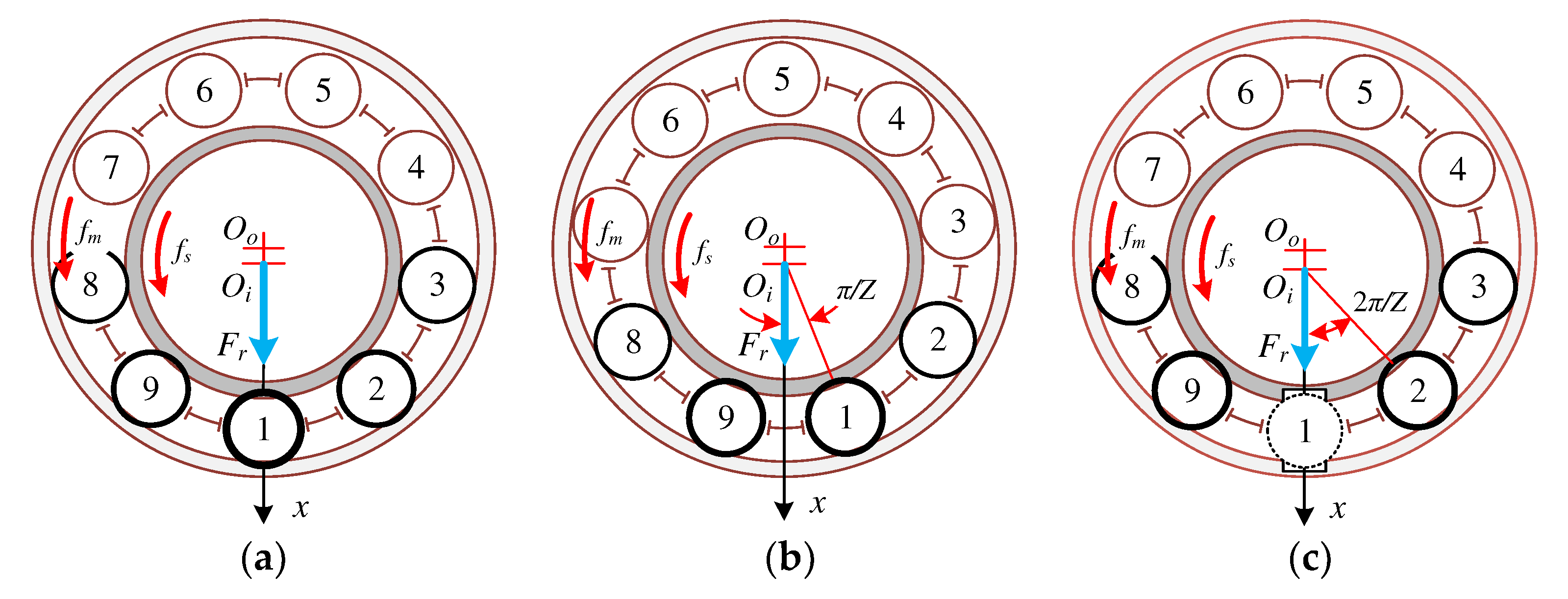

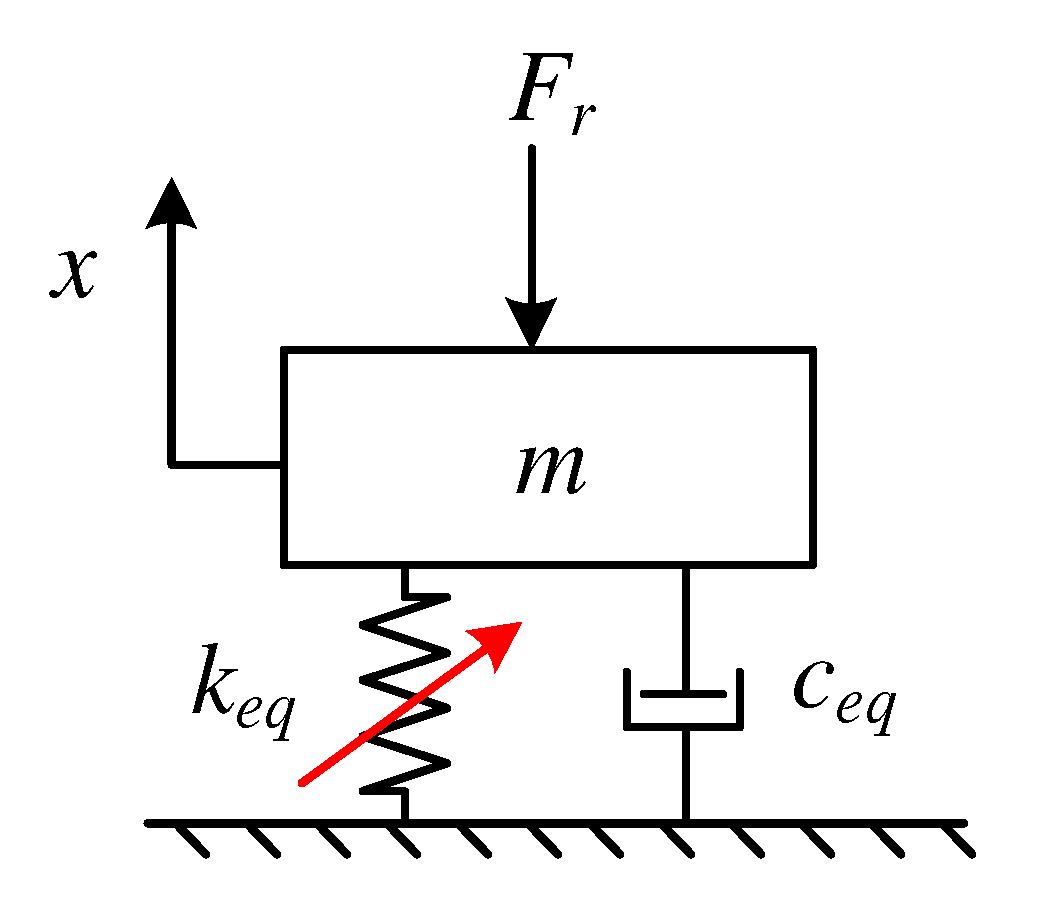

2. Establish a Dynamic Model of the System with Fault

- (1)

- At , then , that is, the contact deformation at the rolling element is partially released, providing a partially effective contact load.

- (2)

- At , then , that is, the contact deformation at the rolling element is all released, and the effective contact load cannot be provided.

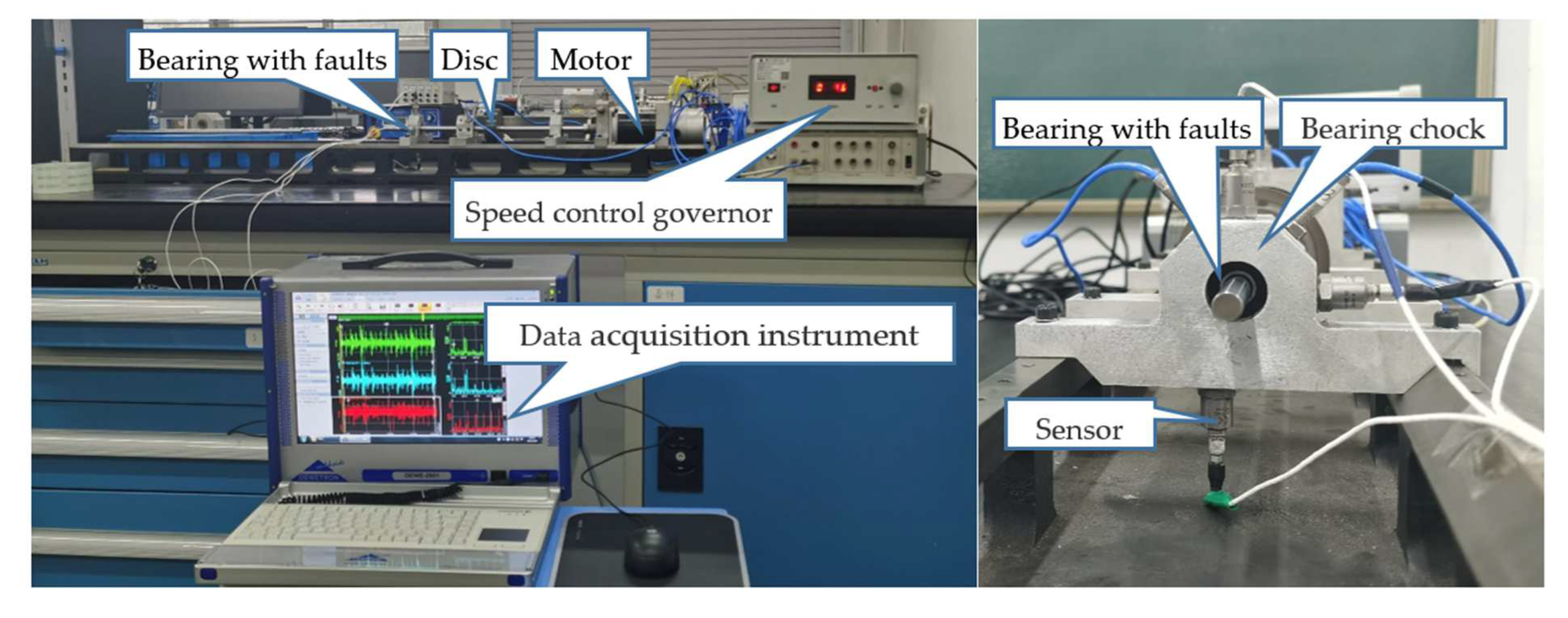

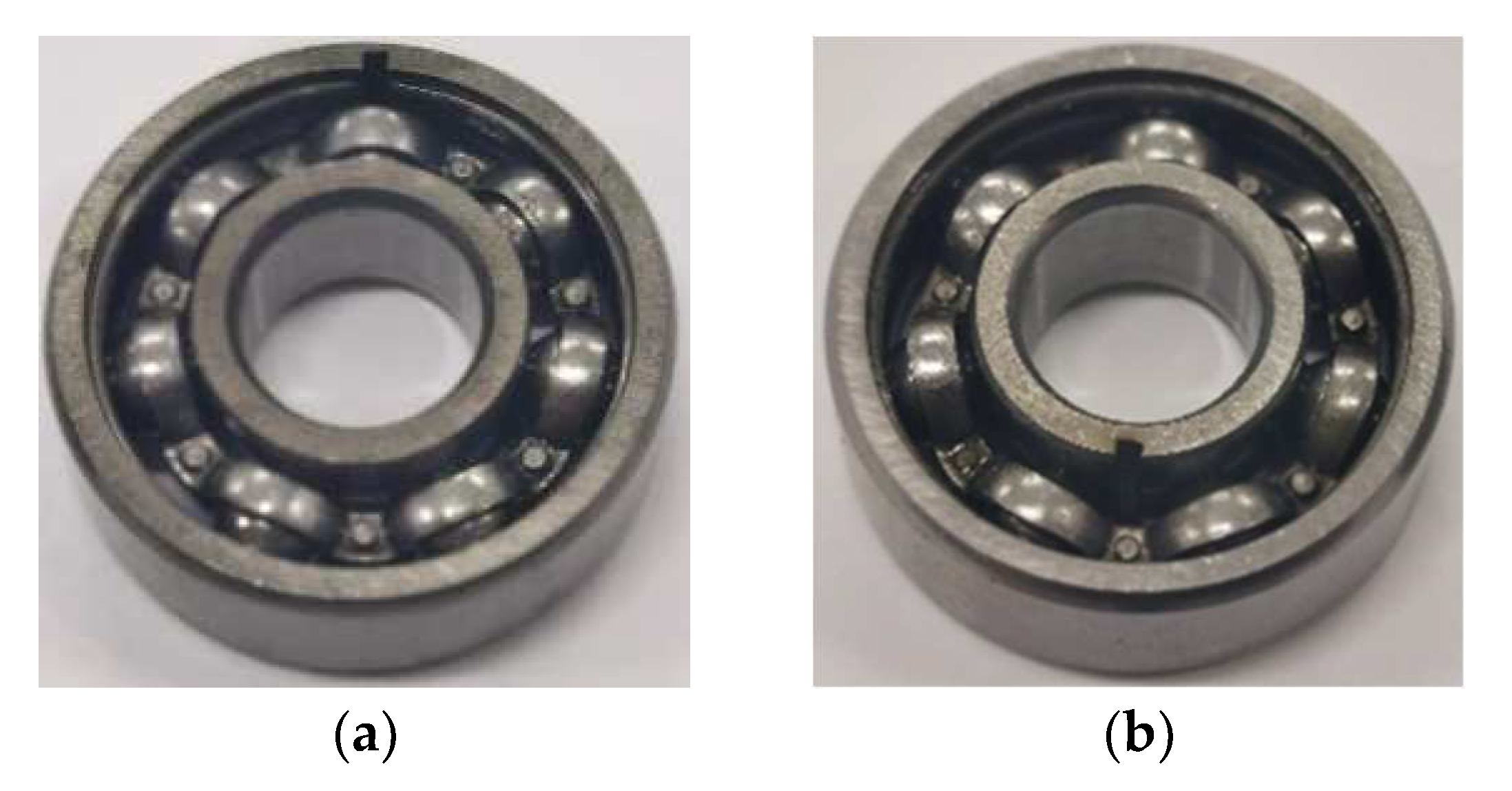

3. Simulation and Experimentation

3.1. Bearing Parameters and Conditions

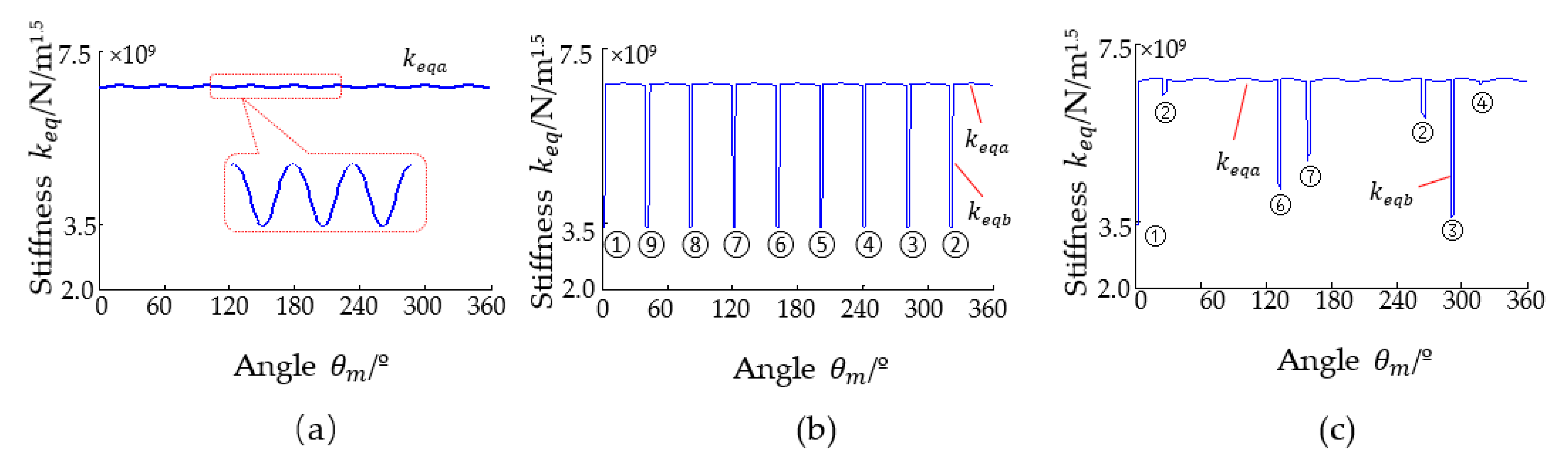

3.2. Simulation of Total Effective Stiffness

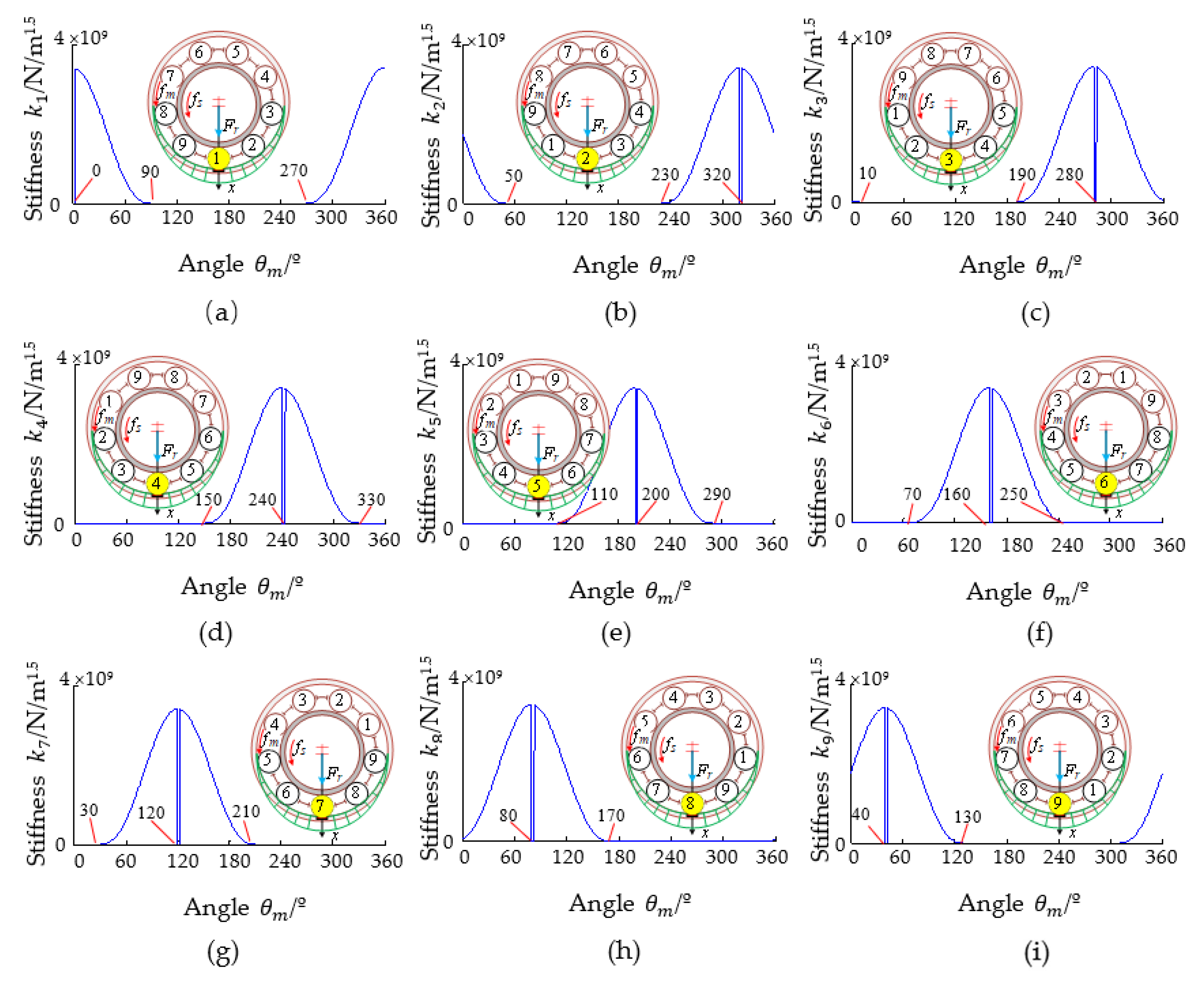

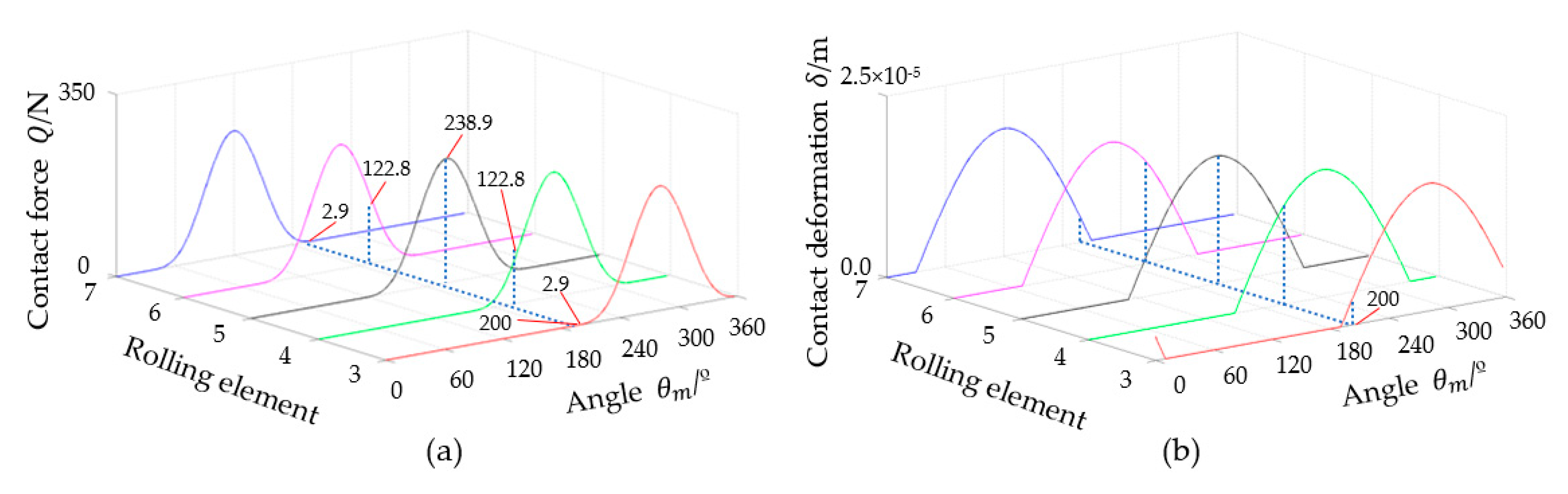

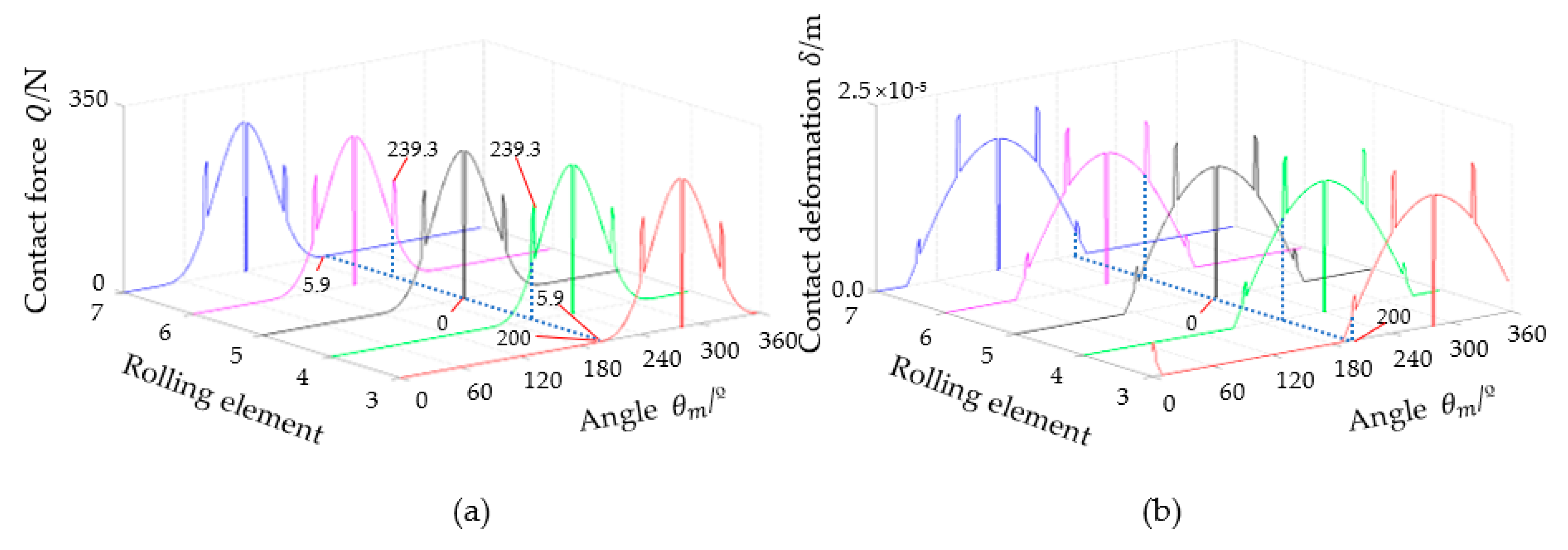

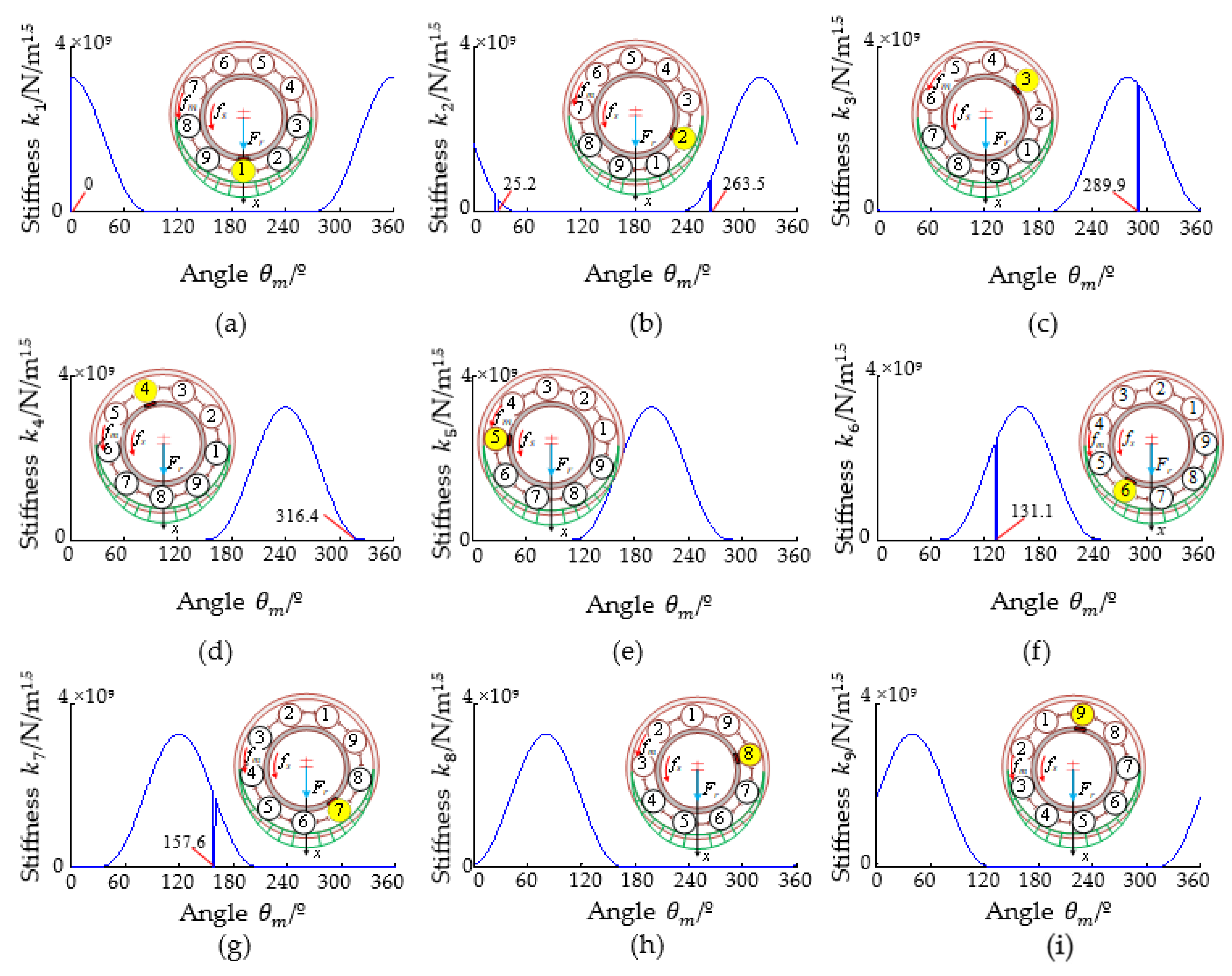

3.3. Simulation of Stiffness, Contact Force, and Contact Deformation of Each Rolling Element in Case of Outer Race Fault

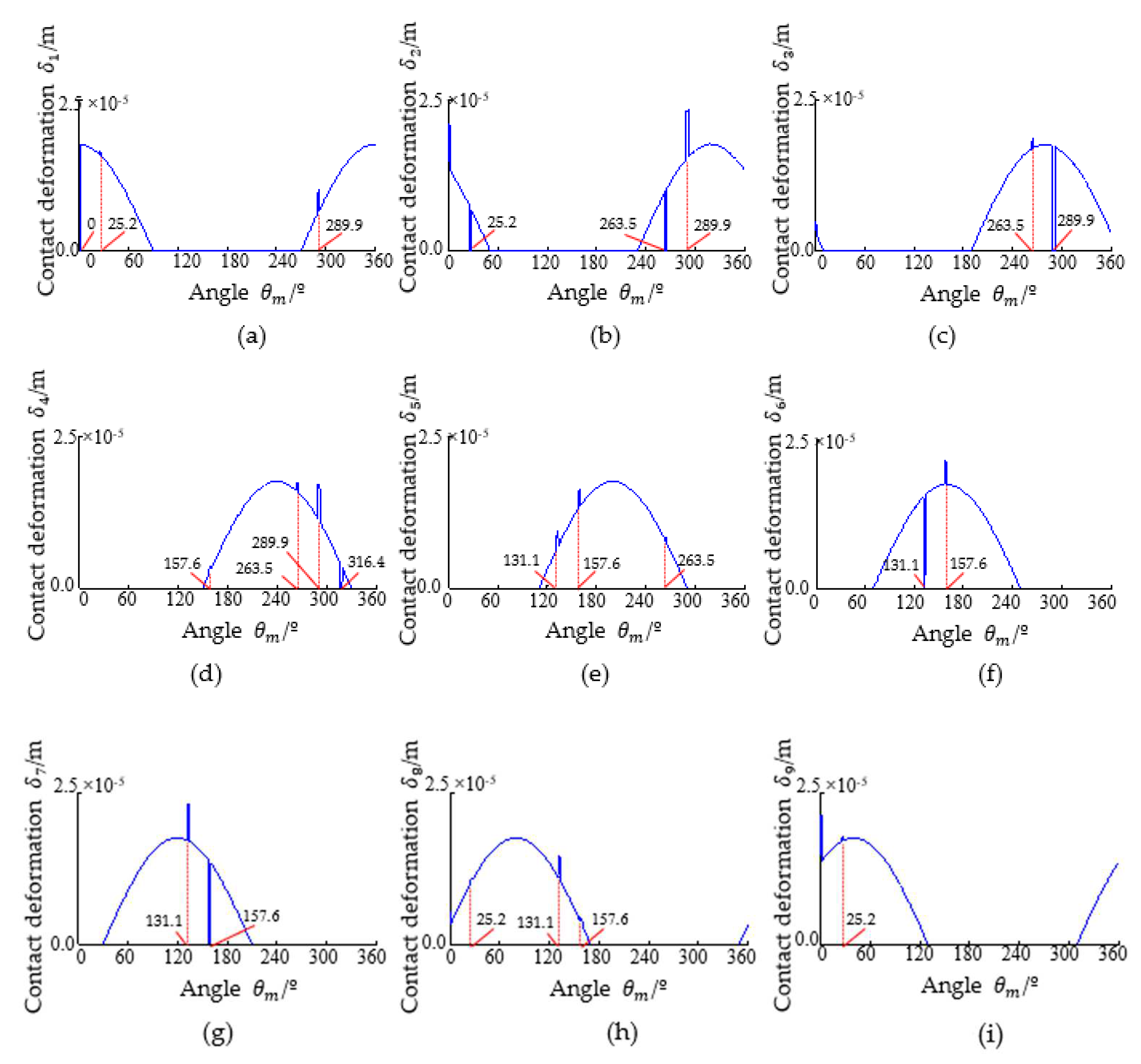

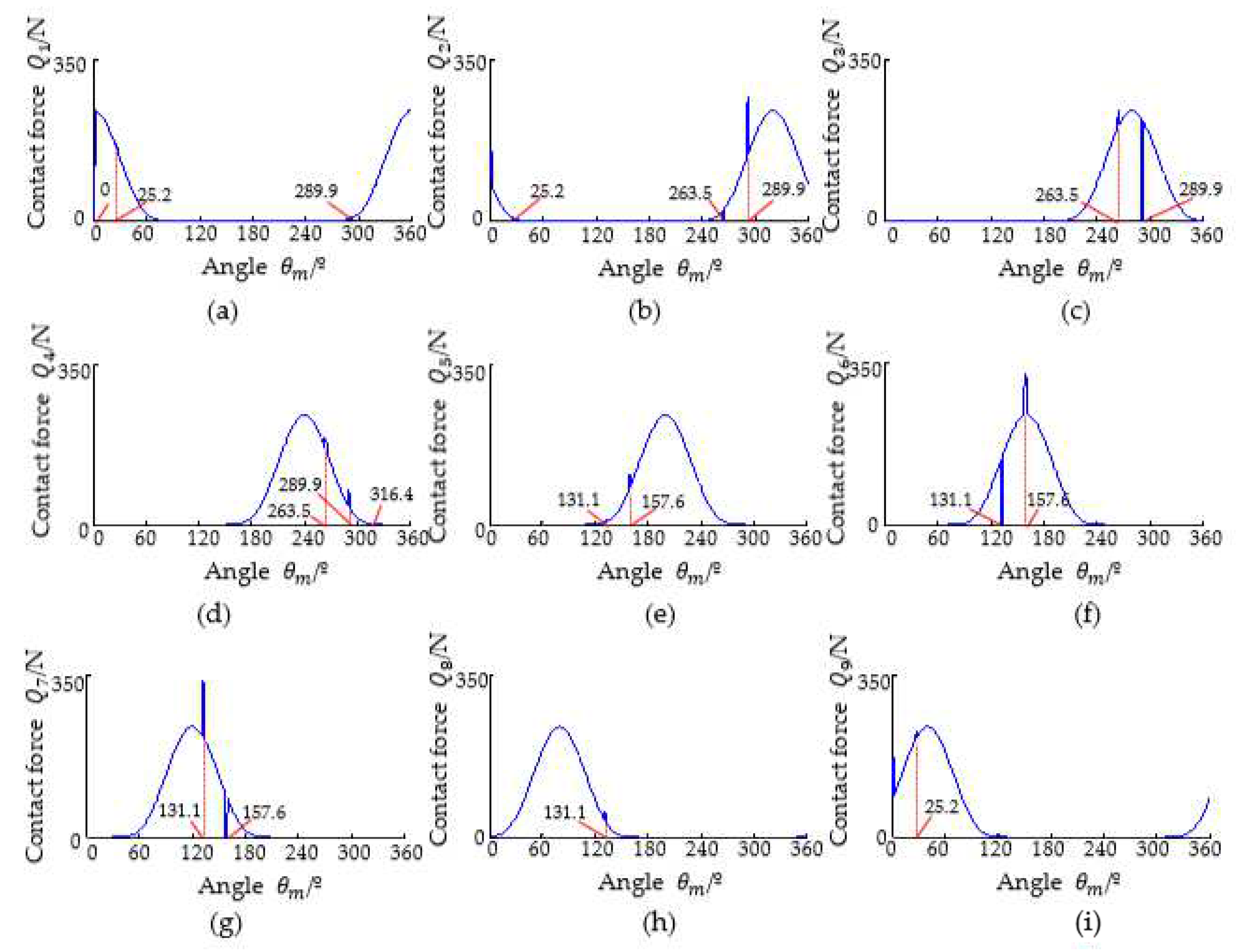

3.4. Simulation of the Stiffness, Contact Force, and Contact Deformation of Each Rolling Element in Case of the Inner Race Fault

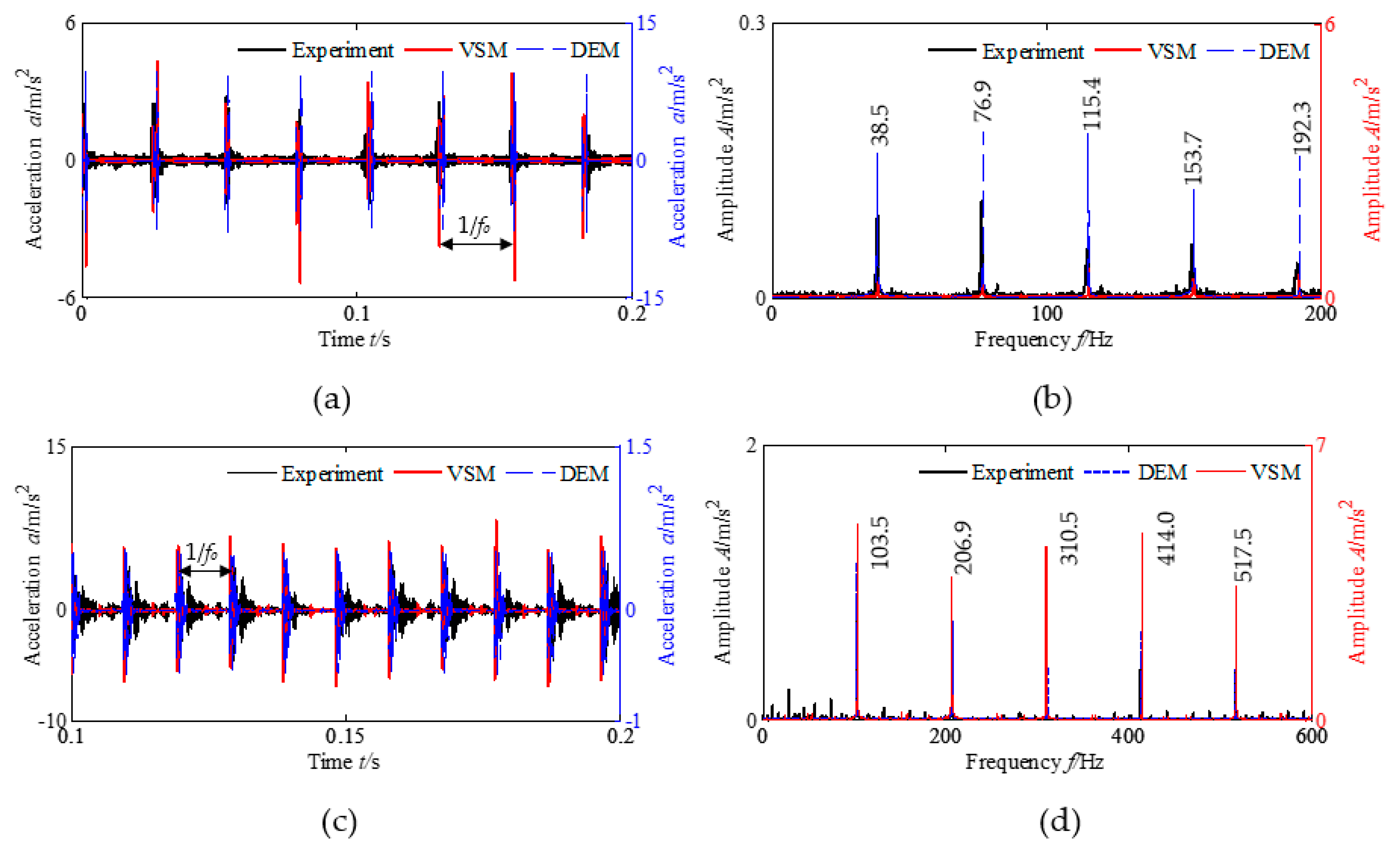

3.5. Simulation and Experiment of System Response

4. Conclusions

- (1)

- Based on the retention factor of contact deformation, the single-degree-of-freedom variable stiffness model of rolling bearings with fault is proposed, and the dynamics modeling of the variable stiffness of rolling bearings with fault is established.

- (2)

- The contact stiffness of the rolling elements abruptly decreases when the rolling elements fall into the fault position. The contact deformation and contact force of the load-carrying rolling elements in the load zone increases, rebalancing the external radial load while causing a sudden reduction in the total effective stiffness, resulting in the vibration of the system.

- (3)

- When different rolling elements fall into the outer race fault position, the change in the total effective stiffness and the system response are equal in magnitude. Additionally, there is significant outer race fault characteristic frequency and its frequency multiplication in the fault characteristic spectrums. When different rolling elements fall into the inner race fault position, the total effective stiffness is modulated by the inner race rotation and varies dramatically, resulting in the amplitude of the system time domain vibration response also being modulated by the inner race rotation and varying dramatically. Additionally, there are significant inner race rotational frequencies and their frequency multiplications, inner race fault characteristic frequencies and their frequency multiplication, and side frequency in the fault characteristic spectrums.

- (4)

- The VSM is more consistent with the experiment and provides some theoretical basis for the effective diagnosis of rolling bearing faults. The contact deformation retention factor is only for rectangular or circular faults, which has some limitations. In the subsequent research, the VSM will be applied to other types of rolling bearings to expand the application scope of the VSM.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| fault width (mm) | geometric distance (mm) | ||

| fault depth (mm) | diameter of rolling element (mm) | ||

| pitch diameter of bearing (mm) | retention factor of contact deformation | ||

| inner race/cage rotation frequency (Hz) | dimensionless parameters | ||

| fault characteristic frequency of inner/outer races (Hz) | rotation angle of the cage (°) | ||

| external radial load (N) | rotation angle of the -th rolling element with the cage (°) | ||

| contact stiffness coefficient () | rotation angle of the fault point with the inner race (°) | ||

| effective contact stiffness () | maximum/radial contact deformation (mm) | ||

| total effective stiffness () | maximum relative radial displacement (mm) | ||

| mass of the outer or inner race (kg) | load distribution range coefficient | ||

| radius of rolling element (mm) | azimuth (°) | ||

| radius of inner/outer raceway (mm) | angular range of the load zone (°) | ||

| radius of inner/outer groove (mm) | maximum/contact force (N) | ||

| damping coefficient (Ns/m) | radial clearance (mm) | ||

| contact angle (°) | displacement, velocity, acceleration of the outer or inner race () | ||

| initial angle of the fault location (°) | number of rolling elements | ||

| central angle (°) |

References

- Che, C.C.; Wang, H.W.; Xiong, M.; Ni, X.M. Few-shot fault diagnosis of rolling bearing under variable working conditions based on ensemble meta-learning. Digit. Signal Process. 2022, 131, 103777. [Google Scholar] [CrossRef]

- Huang, Y.J.; Liao, A.H.; Hu, D.Y.; Shi, W.; Zheng, S.B. Multi-scale convolutional network with channel attention mechanism for rolling bearing fault diagnosis. Measurement 2022, 203, 111935. [Google Scholar] [CrossRef]

- Shen, S.; Lu, H.; Sadoughi, M.; Hu, C.; Nemani, V.; Thelen, A.; Webster, K.; Darr, M.; Sidon, J.; Kenny, S. A physics-informed deep learning approach for bearing fault detection. Eng. Appl. Artif. Intell. 2021, 103, 104295. [Google Scholar] [CrossRef]

- Neupane, D.; Seok, J. Bearing fault detection and diagnosis using case western reserve university dataset with deep learning approaches: A review. IEEE Access 2020, 8, 93155–93178. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Ji, J.C.; Ren, Z.H.; Ni, Q.; Gu, F.S.; Feng, K.; Yu, K.; Ge, J.; Lei, Z.H.; Liu, Z. Digital twin-driven partial domain adaptation network for intelligent fault diagnosis of rolling bearing. Reliab. Eng. Syst. Saf. 2023, 234, 109186. [Google Scholar] [CrossRef]

- Gao, S.Z.; Xu, L.T.; Zhang, Y.M.; Pei, Z.M. Rolling bearing fault diagnosis based on SSA optimized self-adaptive DBN. ISA Trans. 2022, 128, 485–502. [Google Scholar] [CrossRef]

- Jiang, Z.H.; Zhang, K.; Xiang, L.; Yu, G.; Xu, Y.G. A time-frequency spectral amplitude modulation method and its applications in rolling bearing fault diagnosis. Mech. Syst. Signal Process. 2023, 185, 109832. [Google Scholar] [CrossRef]

- Wang, R.X.; Jiang, H.K.; Zhu, K.; Wang, Y.F.; Liu, C.Q. A deep feature enhanced reinforcement learning method for rolling bearing fault diagnosis. Adv. Eng. Inform. 2022, 54, 101750. [Google Scholar] [CrossRef]

- Liu, J.; Shao, Y.M. Overview of dynamic modelling and analysis of rolling element bearings with localized and distributed faults. Nonlinear Dyn. 2018, 93, 1765–1798. [Google Scholar] [CrossRef]

- Zhang, F.B.; Huang, J.F.; Chu, F.L.; Cui, L.L. Mechanism and method for outer raceway defect localization of ball bearings. IEEE Access 2020, 8, 4351–4360. [Google Scholar] [CrossRef]

- Shah, D.S.; Patel, V.N. A Review of dynamic modeling and fault identifications methods for rolling element bearing. Procedia Technol. 2014, 14, 447–456. [Google Scholar] [CrossRef]

- Khanam, S.; Dutt, J.K.; Tandon, N. Impact force based model for bearing local fault identification. J. Vib. Acoust. 2015, 137, 4029988. [Google Scholar] [CrossRef]

- Zhang, F.B.; Huang, J.F.; Chu, F.L.; Cui, L.L. Mechanism and method for the full-scale quantitative diagnosis of ball bearings with an inner race fault. J. Sound Vib. 2020, 488, 115641. [Google Scholar] [CrossRef]

- Patil, M.S.; Mathew, J.; Rajendrakumar, P.K.; Desai, S. A theoretical model to predict the effect of localized defect on vibrations associated with ball bearing. Int. J. Mech. Sci. 2010, 52, 1193–1201. [Google Scholar] [CrossRef]

- Patel, V.; Tandon, N.; Pandey, R. A dynamic model for vibration studies of deep groove ball bearings considering single and multiple defects in races. J. Tribol. 2010, 132, 041101. [Google Scholar] [CrossRef]

- Cui, L.L.; Zhang, Y.; Zhang, F.B.; Zhang, J.Y.; Lee, S. Vibration response mechanism of faulty outer race rolling element bearings for quantitative analysis. J. Sound Vib. 2016, 364, 67–76. [Google Scholar] [CrossRef]

- Wu, R.Q.; Wang, X.F.; Ni, Z.X.; Zeng, C. Dual-impulse behavior analysis and quantitative diagnosis of the raceway fault of rolling bearing. Mech. Syst. Signal Process. 2022, 169, 108734. [Google Scholar] [CrossRef]

- Qin, Y.; Cao, F.L.; Wang, Y.; Chen, W.W.; Chen, H.Z. Dynamics modelling for deep groove ball bearings with local faults based on coupled and segmented displacement excitation. J. Sound Vib. 2019, 447, 1–19. [Google Scholar] [CrossRef]

- Liu, J.; Wu, H.; Shao, Y.M. A theoretical study on vibrations of a ball bearing caused by a dent on the races. Eng. Fail. Anal. 2018, 83, 220–229. [Google Scholar] [CrossRef]

- Liu, J.; Shao, Y.M.; Lim, T.C. Vibration analysis of ball bearings with a localized defect applying piecewise response function. Mech. Mach. Theory 2012, 56, 156–169. [Google Scholar] [CrossRef]

- Jiang, Y.C.; Huang, W.T.; Luo, J.N.; Wang, W.J. An improved dynamic model of defective bearings considering the three-dimensional geometric relationship between the rolling element and defect area. Mech. Syst. Signal Process. 2019, 129, 694–716. [Google Scholar] [CrossRef]

- Gao, S.; Chatterton, S.; Pennacchi, P.; Chu, F. Behaviour of an angular contact ball bearing with three-dimensional cubic-like defect: A comprehensive non-linear dynamic model for predicting vibration response. Mech. Mach. Theory 2021, 163, 104376. [Google Scholar] [CrossRef]

- Luo, M.L.; Guo, Y.; Andre, H.; Wu, X.; Na, J. Dynamic modeling and quantitative diagnosis for dual-impulse behavior of rolling element bearing with a spall on inner race. Mech. Syst. Signal Process. 2021, 158, 107711. [Google Scholar] [CrossRef]

- Mufazzal, S.; Muzakkir, S.M.; Khanam, S. Theoretical and experimental analyses of vibration impulses and their influence on accurate diagnosis of ball bearing with localized outer race defect. J. Sound Vib. 2021, 513, 116407. [Google Scholar] [CrossRef]

- Lu, Z.G.; Wang, X.C.; Yue, K.Y.; Wei, J.Y.; Yang, Z. Coupling model and vibration simulations of railway vehicles and running gear bearings with multitype defects. Mech. Mach. Theory 2021, 157, 104215. [Google Scholar] [CrossRef]

- Yang, R.; Zhang, Z.Y.; Chen, Y.S. Analysis of vibration signals for a ball bearing-rotor system with raceway local defects and rotor eccentricity. Mech. Mach. Theory 2022, 169, 104594. [Google Scholar] [CrossRef]

- Petersen, D.; Howard, C.; Sawalhi, N.; Moazen Ahmadi, A.; Singh, S. Analysis of bearing stiffness variations, contact forces and vibrations in radially loaded double row rolling element bearings with raceway defects. Mech. Syst. Signal Process. 2015, 50–51, 139–160. [Google Scholar] [CrossRef]

- Petersen, D.; Howard, C.; Prime, Z. Varying stiffness and load distributions in defective ball bearings: Analytical formulation and application to defect size estimation. J. Sound Vib. 2015, 337, 284–300. [Google Scholar] [CrossRef]

- Moazen Ahmadi, A.; Petersen, D.; Howard, C. A nonlinear dynamic vibration model of defective bearings—The importance of modelling the finite size of rolling elements. Mech. Syst. Signal Process. 2015, 52–53, 309–326. [Google Scholar] [CrossRef]

- Singh, S.; Köpke, U.G.; Howard, C.Q.; Petersen, D. Analyses of contact forces and vibration response for a defective rolling element bearing using an explicit dynamics finite element model. J. Sound Vib. 2014, 333, 5356–5377. [Google Scholar] [CrossRef]

- Tedric, A.H.; Michael, N.K. Rolling Bearing Analysis: Essential Concepts of Bearing Technology, 5th ed.; China Machine Press: Beijing, China, 2011; pp. 135–138, 315–316. [Google Scholar]

- Sopanen, J.; Mikkola, A. Dynamic model of a deep-groove ball bearing including localized and distributed defects. J. Multi-Body Dyn. 2005, 217, 201–211. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| number of rolling elements Z | 9 |

| /mm | 7.94 |

| /mm | 39 |

| /° | 0 |

| /mm | 15.53 |

| /mm | 23.47 |

| /mm | 4.089 |

| /mm | 4.169 |

| /Ns/m | 200 |

| /kg | 0.3 |

| /N | 490.4 |

| Rolling Element | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Initial azimuth /° | 0 | 40 | 80 | 120 | 160 | 200 | 240 | 280 | 320 |

| Whether it is located in the load zone | Yes | Yes | Yes | No | No | No | No | No | No |

| Rotation angle required to enter the load zone /° | 150 | 110 | 70 | 30 | |||||

| Rotation angle required to exit load zone /° | 90 | 50 | 10 | 330 | 290 | 250 | 210 | 170 | 130 |

| The rotation angle of the cage where the rolling element meets the fault /° | 0 | 320 | 280 | 240 | 200 | 160 | 120 | 80 | 40 |

| Rolling Element | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Initial azimuth /° | 0 | 40 | 80 | 120 | 160 | 200 | 240 | 280 | 320 |

| Whether it is located in the load zone | Yes | Yes | Yes | No | No | No | No | Yes | Yes |

| Rotation angle of the cage where the rolling element meets the fault /° | 0 | 25.2 | 51.7 | 78.2 | 104.7 | 131.1 | 157.6 | 184.1 | 210.5 |

| Rotation angle of the fault when the rolling element meets the fault /° | 0 | 65.2 | 131.7 | 198.2 | 264.7 | 331.1 | 397.6 | 494.1 | 530.5 |

| Whether it is located in the load zone when the rolling element meets the fault | Yes | Yes | No | No | No | Yes | Yes | No | No |

| Parameter | Value |

|---|---|

| number of rolling elements Z | 7 |

| diameter of rolling element /mm | 4.762 |

| pitch diameter /mm | 17.8 |

| contact angle /° | 0 |

| radius of inner raceway /mm | 6.52 |

| radius of outer raceway /mm | 11.28 |

| damping coefficient /Ns/m | 100 |

| mass /kg | 0.01 |

| radial load /N | 10 |

| Position | ||||||

|---|---|---|---|---|---|---|

| inner race | SKF6205 | 0.93 | 5.31 | 471% | 7.92 | 752% |

| 6000 | 1.80 | 6.14 | 241% | 26.26 | 1359% | |

| outer race | SKF6205 | 3.88 | 6.71 | 73% | 0.54 | −86% |

| 6000 | 2.58 | 3.85 | 49% | 9.62 | 273% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, B.; Wu, W.; Zheng, J.; He, Y.; Zhang, J. Dynamics Modeling and Analysis of Rolling Bearings Variable Stiffness System with Local Faults. Machines 2023, 11, 609. https://doi.org/10.3390/machines11060609

Guo B, Wu W, Zheng J, He Y, Zhang J. Dynamics Modeling and Analysis of Rolling Bearings Variable Stiffness System with Local Faults. Machines. 2023; 11(6):609. https://doi.org/10.3390/machines11060609

Chicago/Turabian StyleGuo, Baoliang, Wenlong Wu, Jianxiao Zheng, Yumin He, and Jinhua Zhang. 2023. "Dynamics Modeling and Analysis of Rolling Bearings Variable Stiffness System with Local Faults" Machines 11, no. 6: 609. https://doi.org/10.3390/machines11060609

APA StyleGuo, B., Wu, W., Zheng, J., He, Y., & Zhang, J. (2023). Dynamics Modeling and Analysis of Rolling Bearings Variable Stiffness System with Local Faults. Machines, 11(6), 609. https://doi.org/10.3390/machines11060609