Replacing Induction Motors without Defined Efficiency Class by IE Class: Example of Energy, Economic, and Environmental Evaluation in 1.5 kW—IE3 Motors

Abstract

1. Introduction

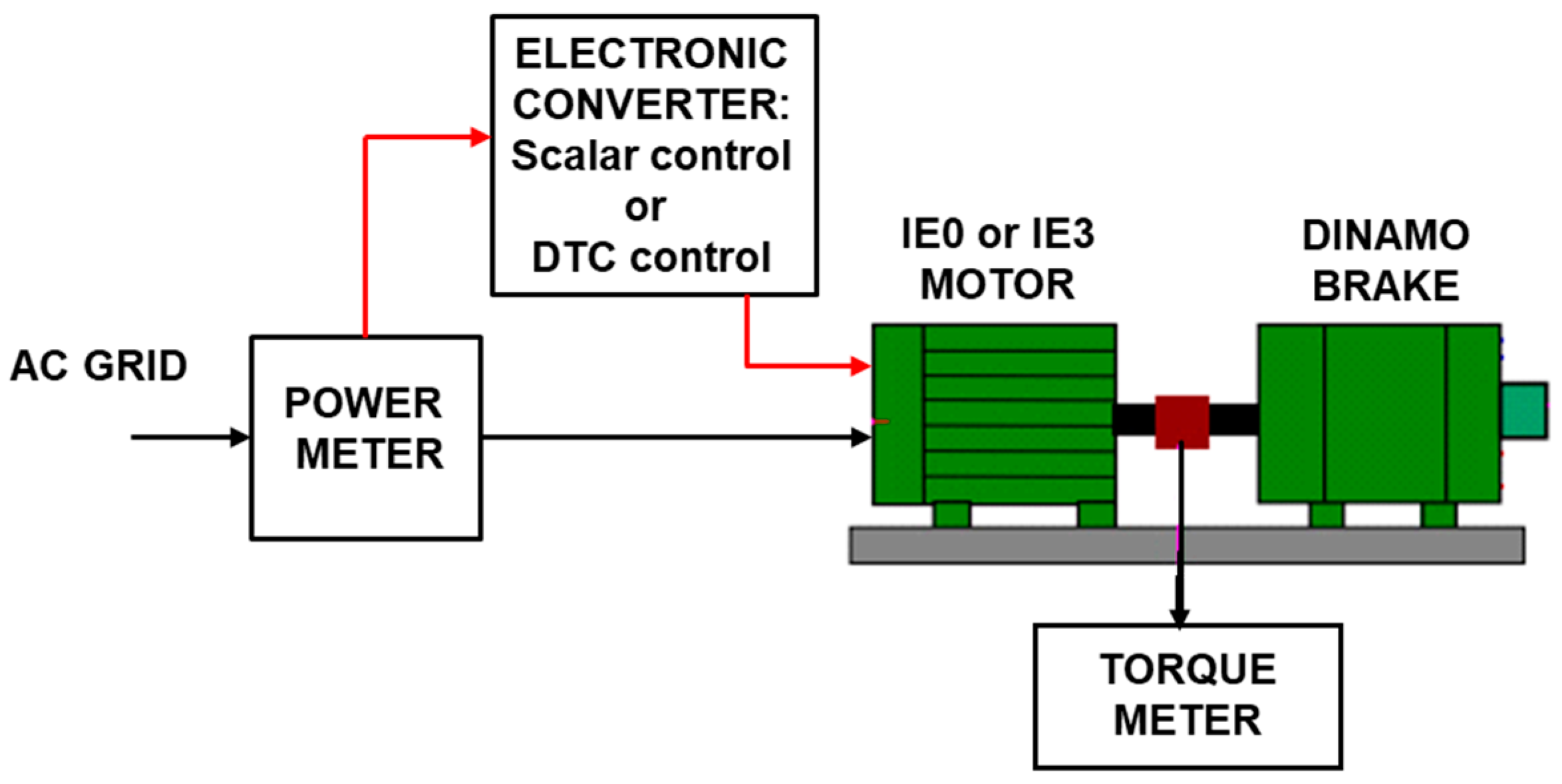

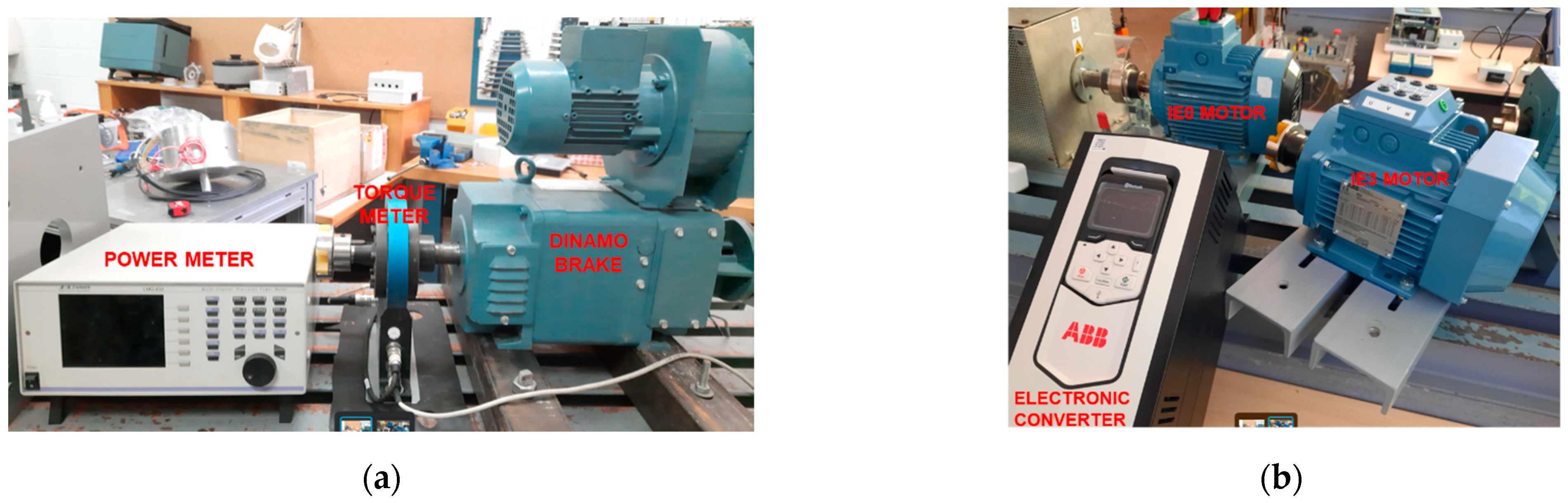

2. Laboratory Setup

3. Experimental Measurements

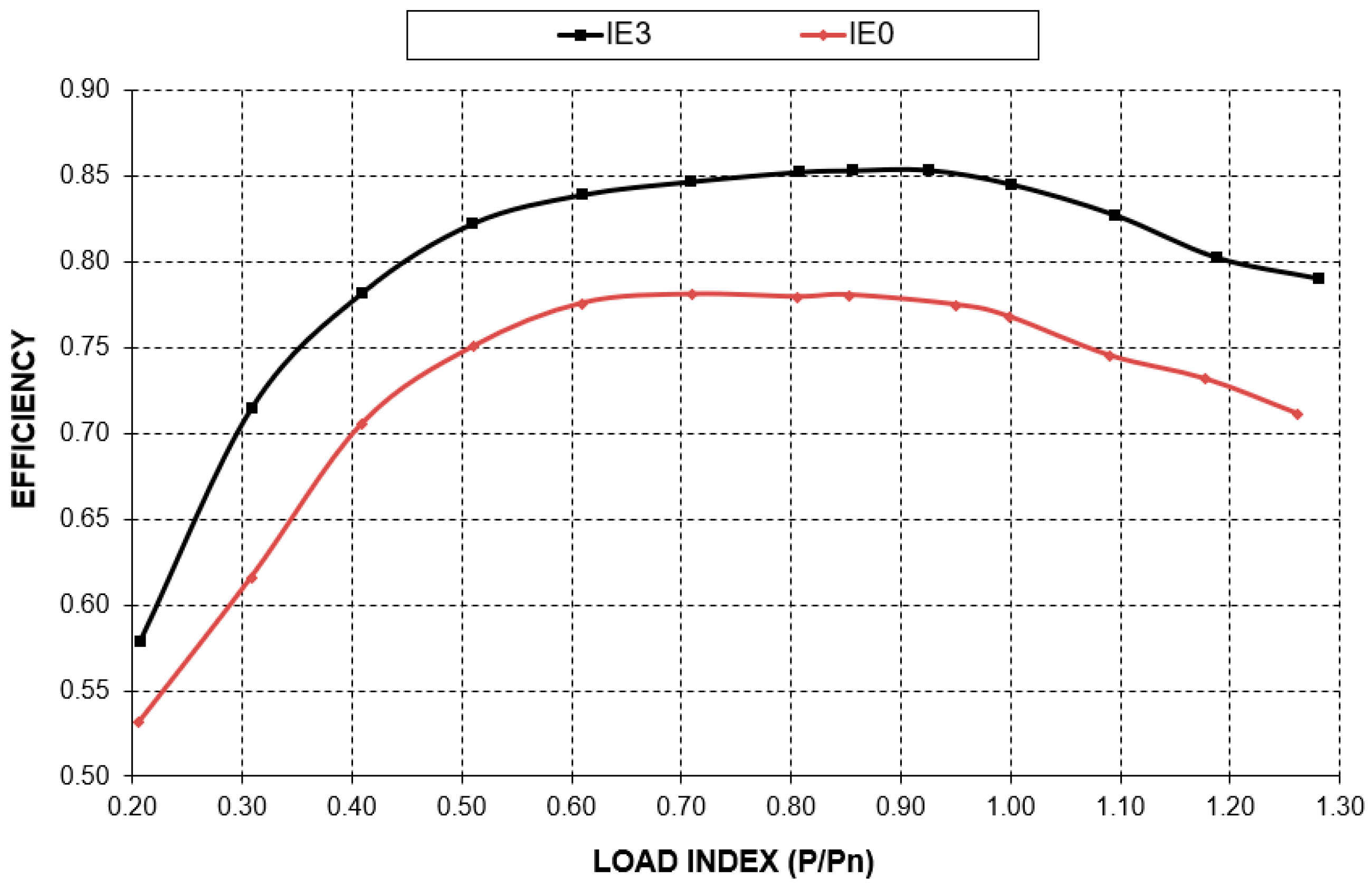

3.1. Direct Power Supply from the ac Grid

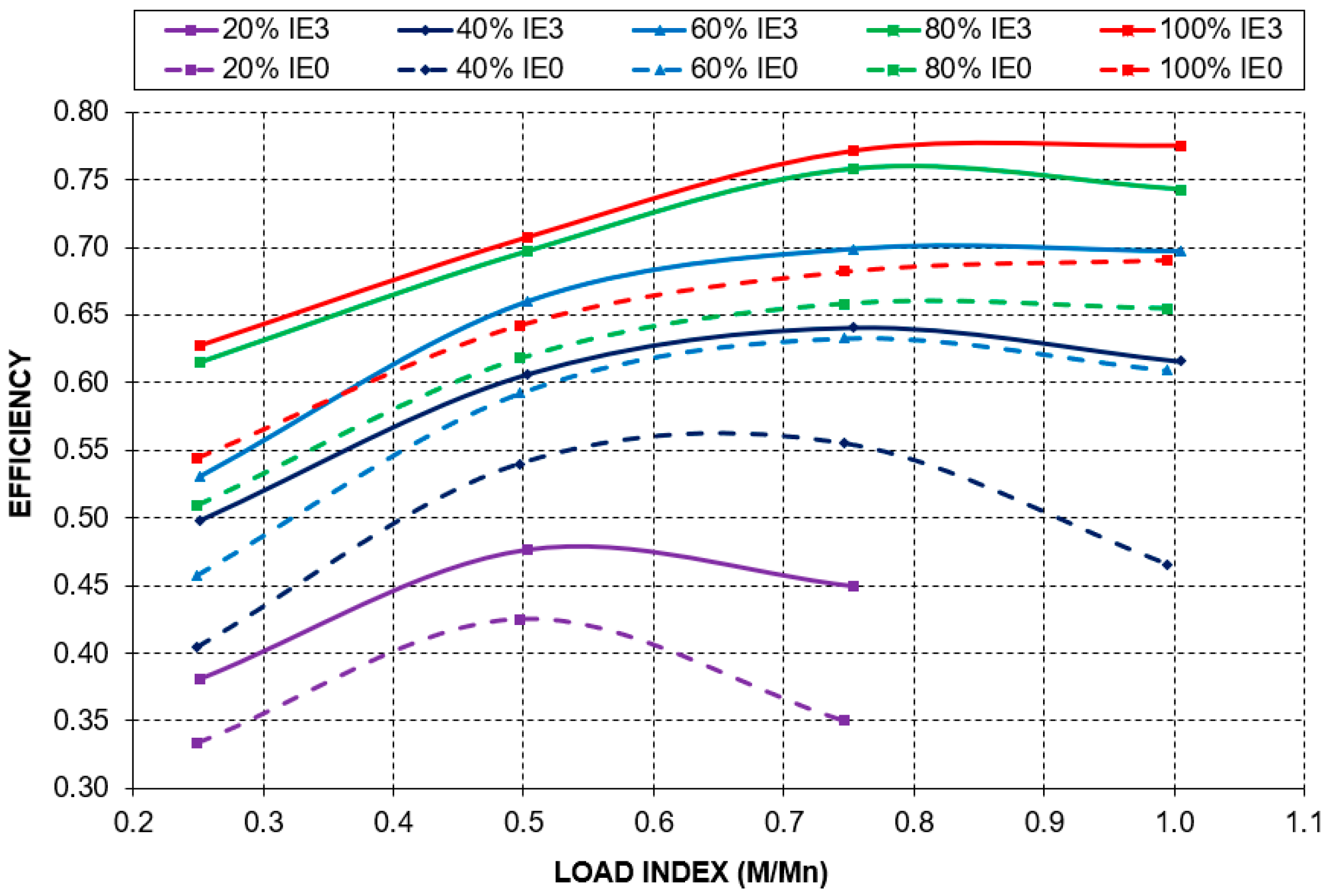

3.2. Scalar Control (V/f)

- Five-speed references are defined as a % in relation to the motor-rated synchronous speed (20%, 40%, 60%, 80%, and 100%).

- The load index has been defined as the ratio between the torque and the nominal torque (M/Mn).

3.3. Direct Torque Control (DTC)

- Five-speed references are defined as a % in relation to the motor-rated synchronous speed (20%, 40%, 60%, 80%, and 100%).

- The load index has been defined as the ratio between the torque and the nominal torque (M/Mn).

4. Energy Saving, Economic and Environmental Criteria

4.1. Energy Saving

- -

- ES = annual energy savings (kWh/year).

- -

- Pn = rated power of the motor (kW).

- -

- h = operating time per year (hours/year).

- -

- LI = load index.

- -

- ηIE0 = IE0 motor efficiency, at load index established.

- -

- ηIE3 = IE3 motor efficiency, at load index established.

4.2. Economic Criteria

- -

- ECS = Annual economic savings (€/year).

- -

- c = electricity cost (€/kWh).

- -

- I = investment (€ EUR).

- -

- i = rate of return.

- -

- T = number of time periods.

4.3. Environmental Criteria

- -

- Total Energy (GER)

- -

- Water (process)

- -

- Waste, non-hazardous/landfill

- -

- Greenhouse gases in GWP100

- -

- Acidification, emissions

- -

- Heavy metals

- -

- Particulate matter (PM, dust)

- -

- Eutrophication

- -

- TEI (i) IE3 = Total Environmental Impact (for the indicator i) using the IE3 motor.

- -

- TEI (i) IE0 = Total Environmental Impact (for the indicator i) using the IE0 motor.

5. Methodology Outputs

5.1. Energy Saving Results

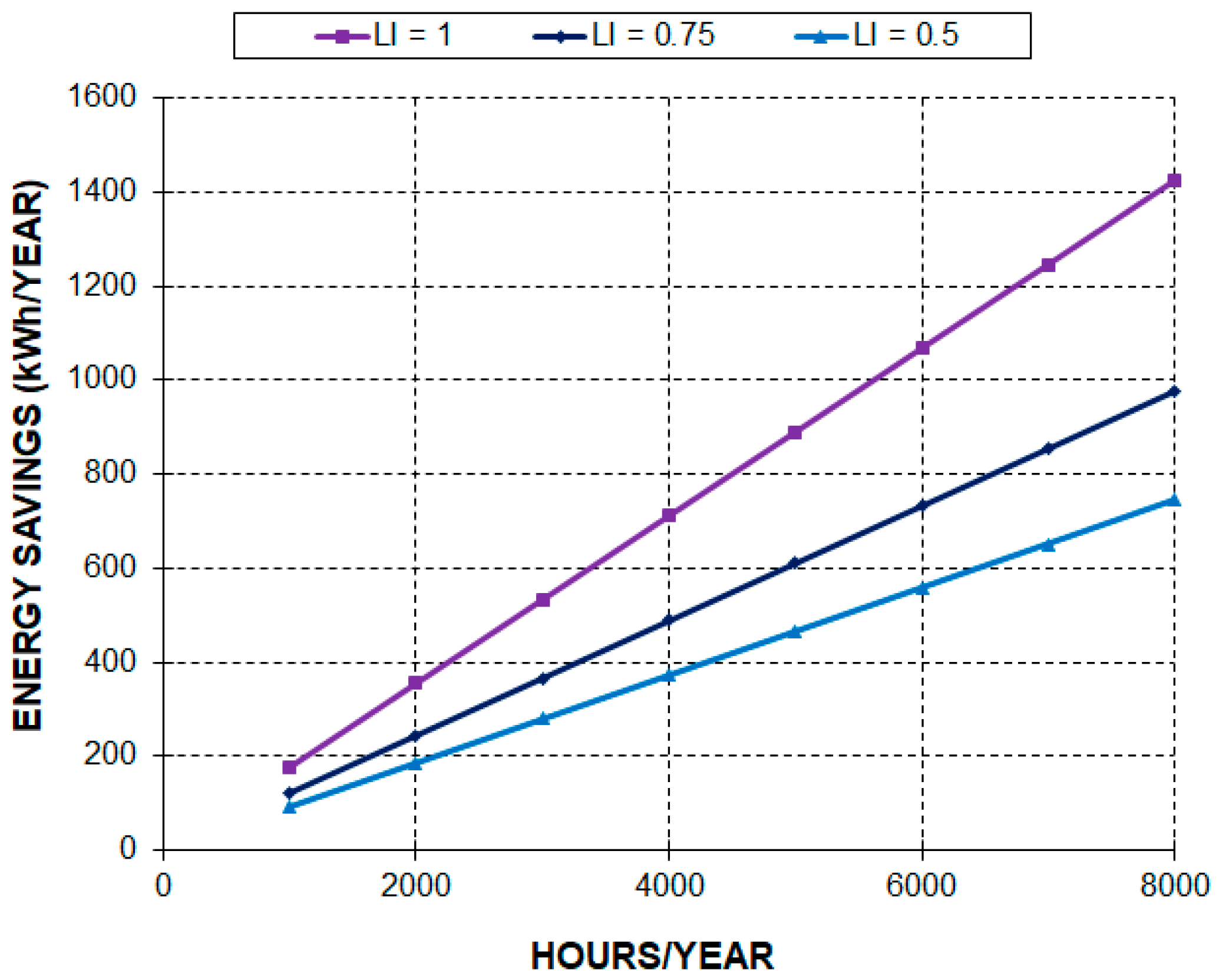

- According to Figure 4, it can be seen how the energy savings grow proportional to the load index if motors are directly fed from the grid.

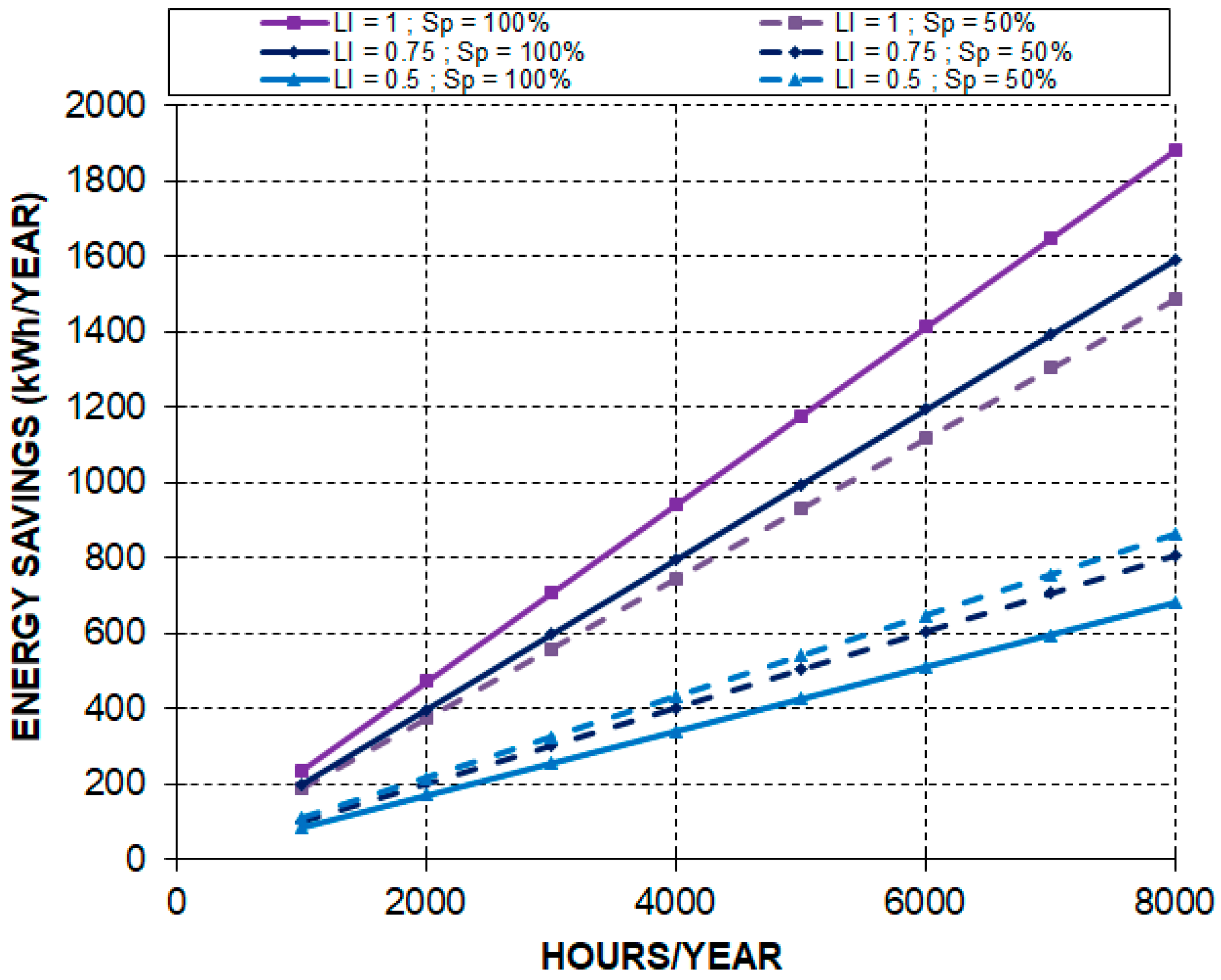

- In the case of V/f control, Figure 5 shows the energy savings are greater at high speeds if the load index is greater than 0.75. However, for low index loads (below 0.5), greater energy saving is obtained with the lowest speeds.

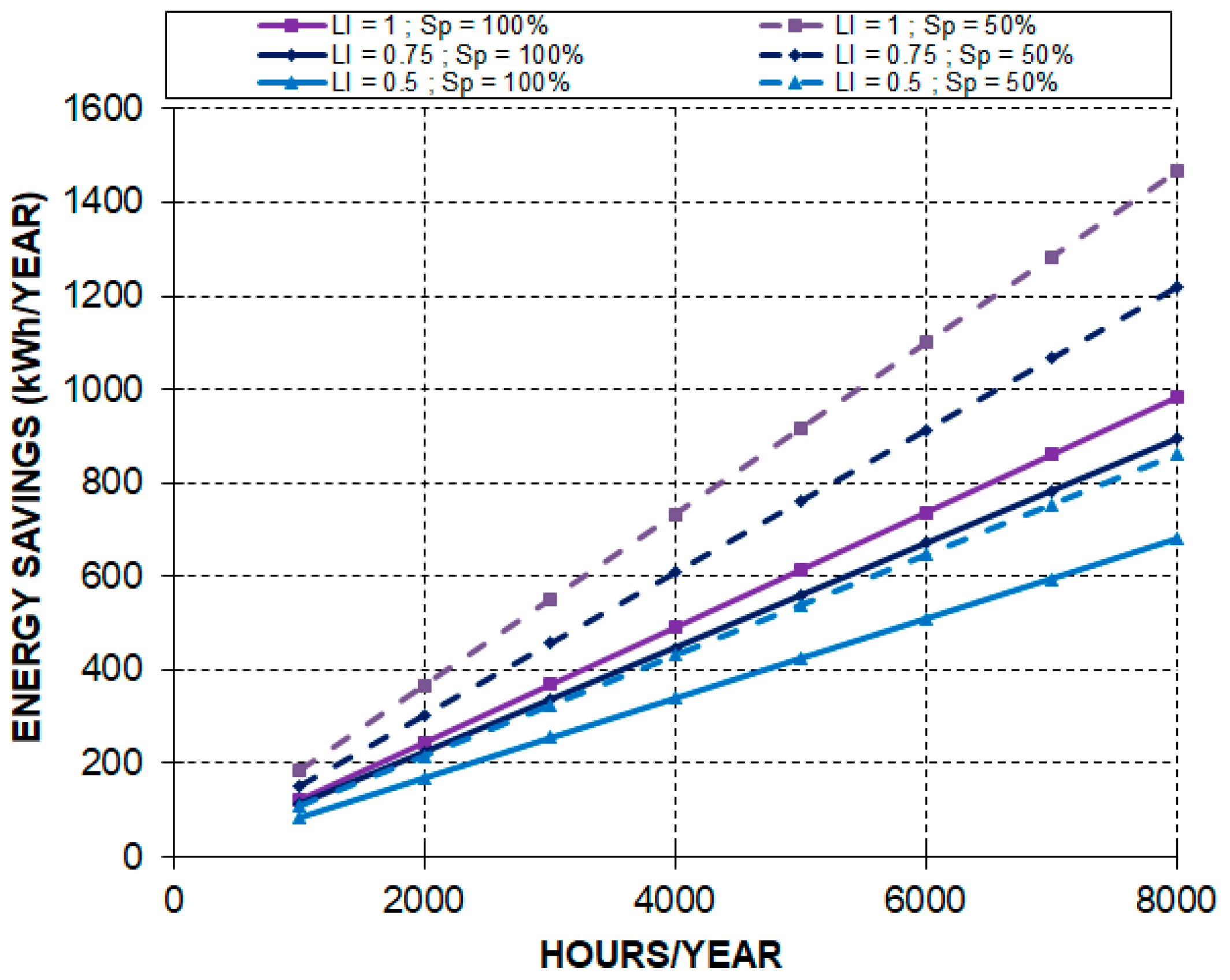

- Finally, in Figure 6, with DTC, energy savings are greater at low speeds with independence of load index.

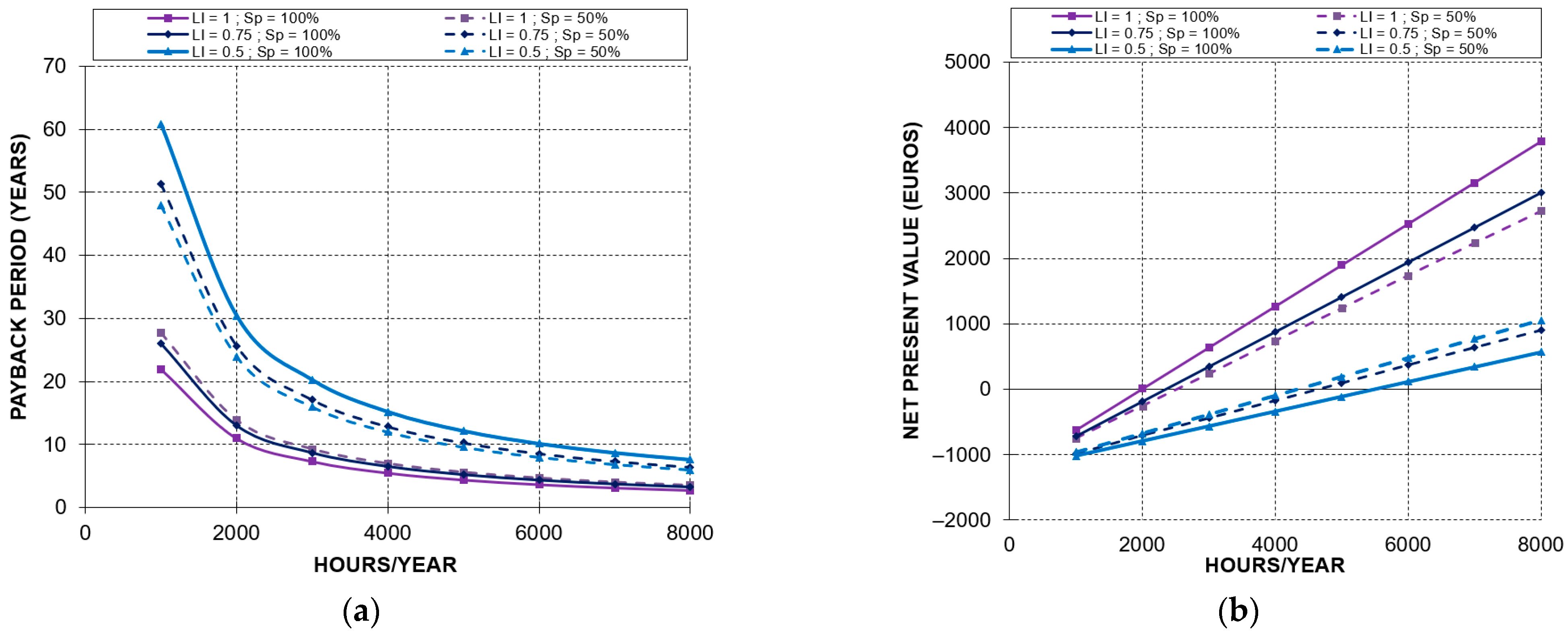

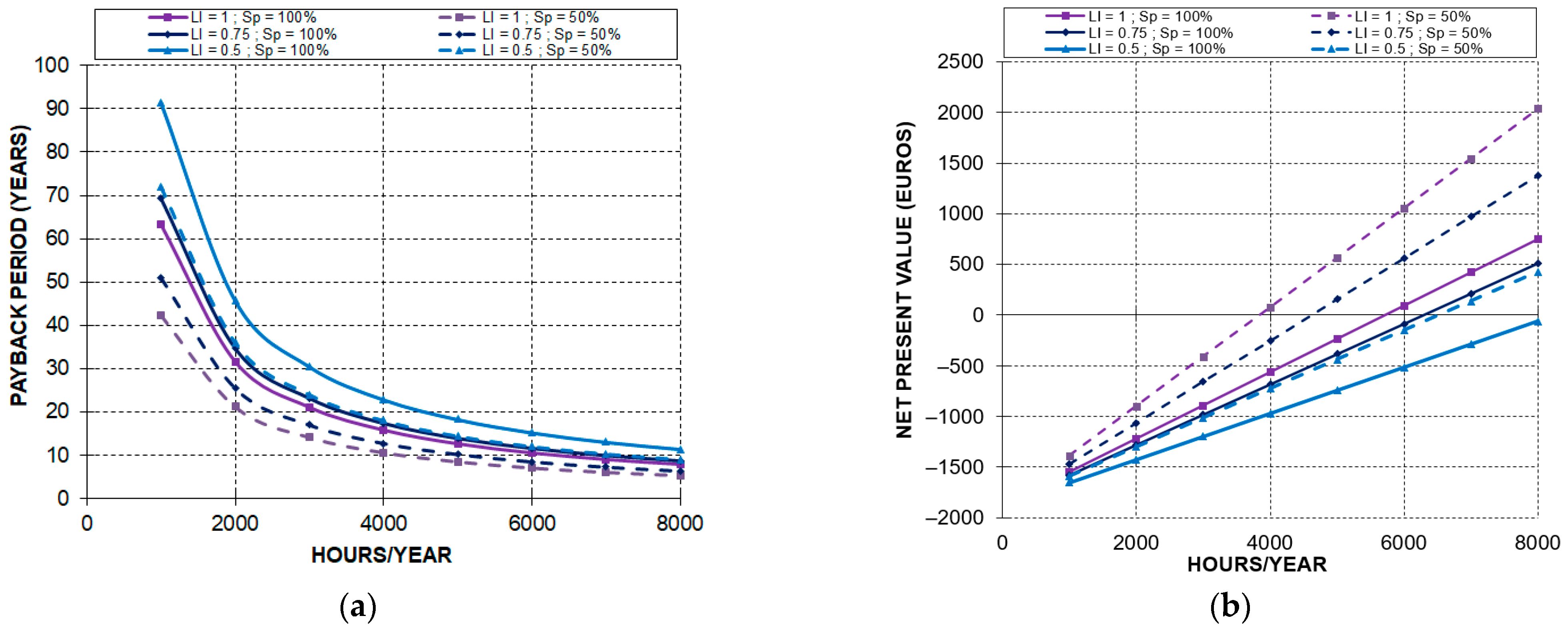

5.2. Economic Results

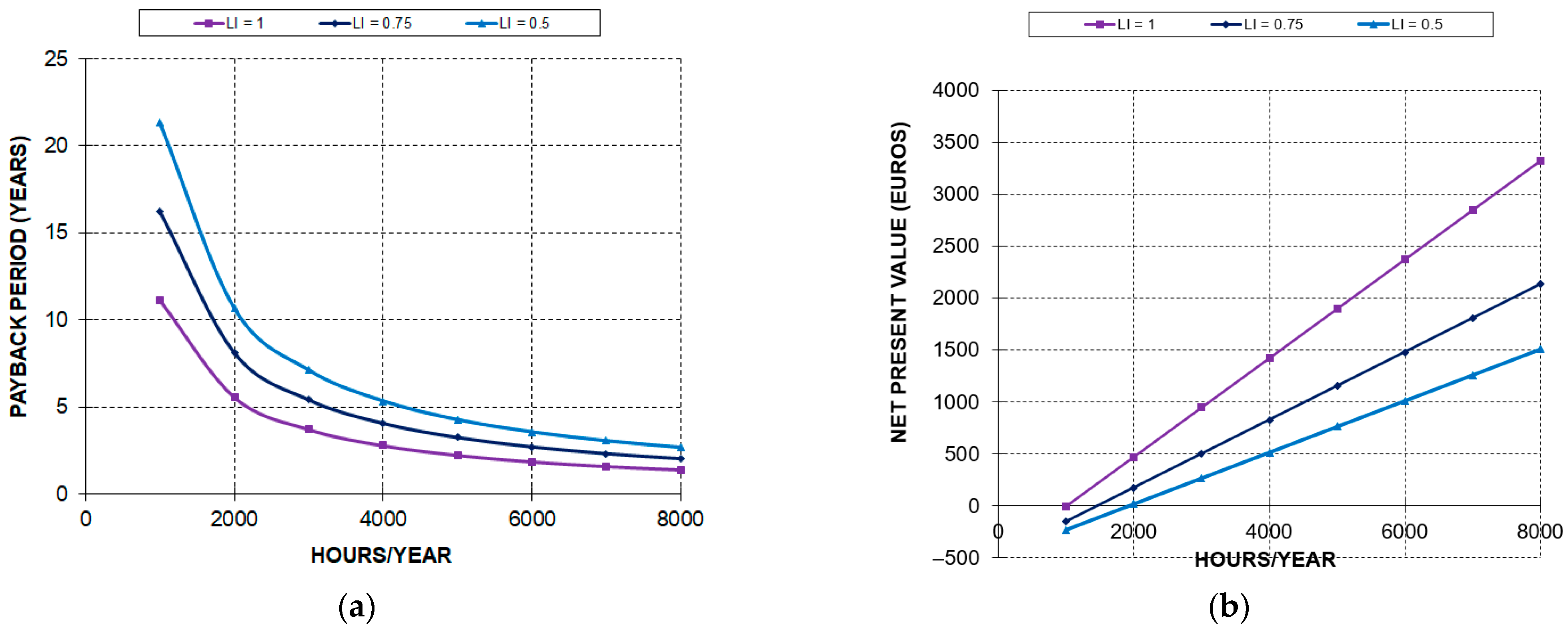

- An electricity cost of 0.242 € EUR/kWh. This value corresponds to the average cost among the 27 countries of the European Union during the first half of 2022. An annual increase in this cost of 2% has been considered.

- Investment in the purchase of the IE3 motor: 480 € EUR.

- Investment in the purchase of the ACS 550 electronic converter with scalar control: 770 € EUR.

- Investment in the purchase of the electronic converter with direct torque control ACS 880: 1400 € EUR.

- Rate of return: 3%.

- Number of time periods: 12.

- In the case of direct connection to the grid (Figure 7), the Payback Period is roughly half of the number of time periods established (six years) for full-load performance and 2000 h/year, 0.75 load and 3000 h/year, and half-load and 4000 h/year. The NPV is positive at 1000 h/year at full load, 1500 h/year at 0.75 load, and 2000 h/year and half load.

- With scalar control (Figure 8), the Payback Period is roughly half of the number of time periods established (six years) for the two analyzed speeds. The motor has a 0.75 load at rated speed for 5000 h/year. For load index below 0.75 and half speed, it is not possible to go below the six-year period. The NPV is positive at 1000 h/year at full load, 1500 h/year at 0.75 load, and 2000 h/year and half load. The NPV is positive from 2000 h/year at full load and rated speed or 2500 h/year at half speed, even more for a 0.75 load index at half-rated speed. In contrast, the value of hours/year must grow to 4500 or even to 6000 for half-load and half-rated speed.

- When the DTC is applied the Payback Period, it is not below the established period in any of the analyzed cases. The NPV take positive values from 4000 h/year to 6500 h/year in case of full-load and half-rated speed and 0.75 load index and rated speed, respectively. It must be noted that, for half-load and rated speed, the NPV is always negative in all the hours/year range.

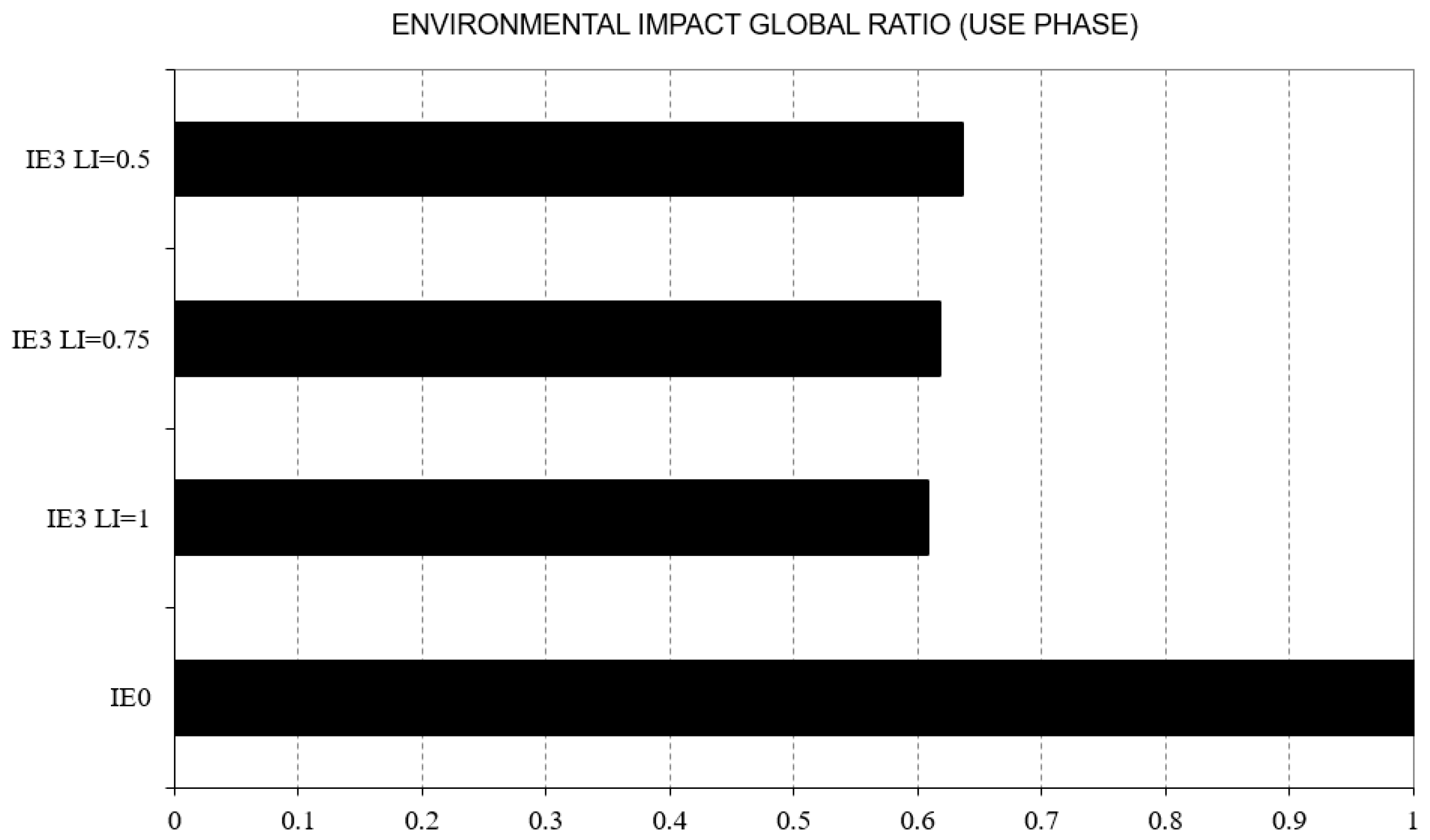

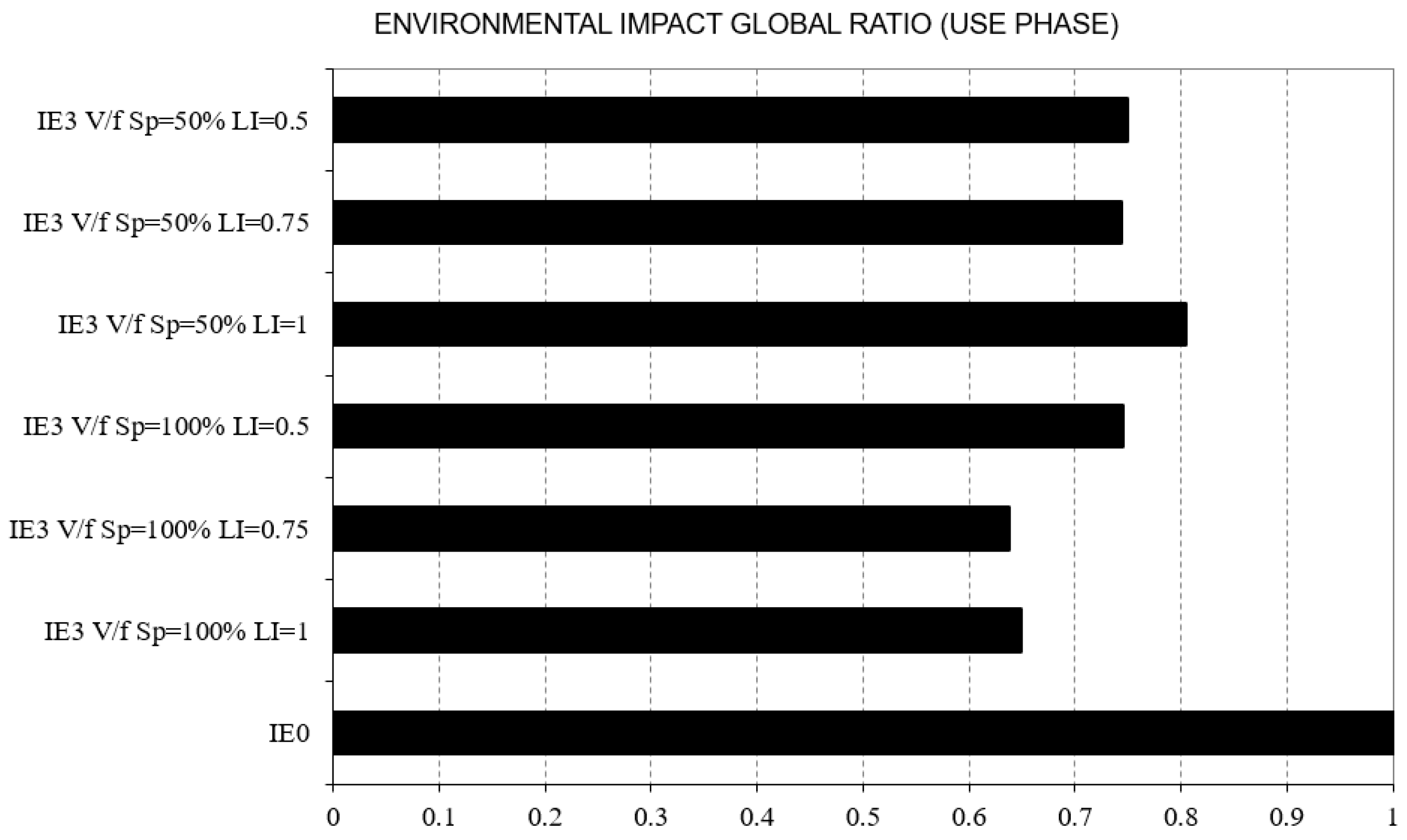

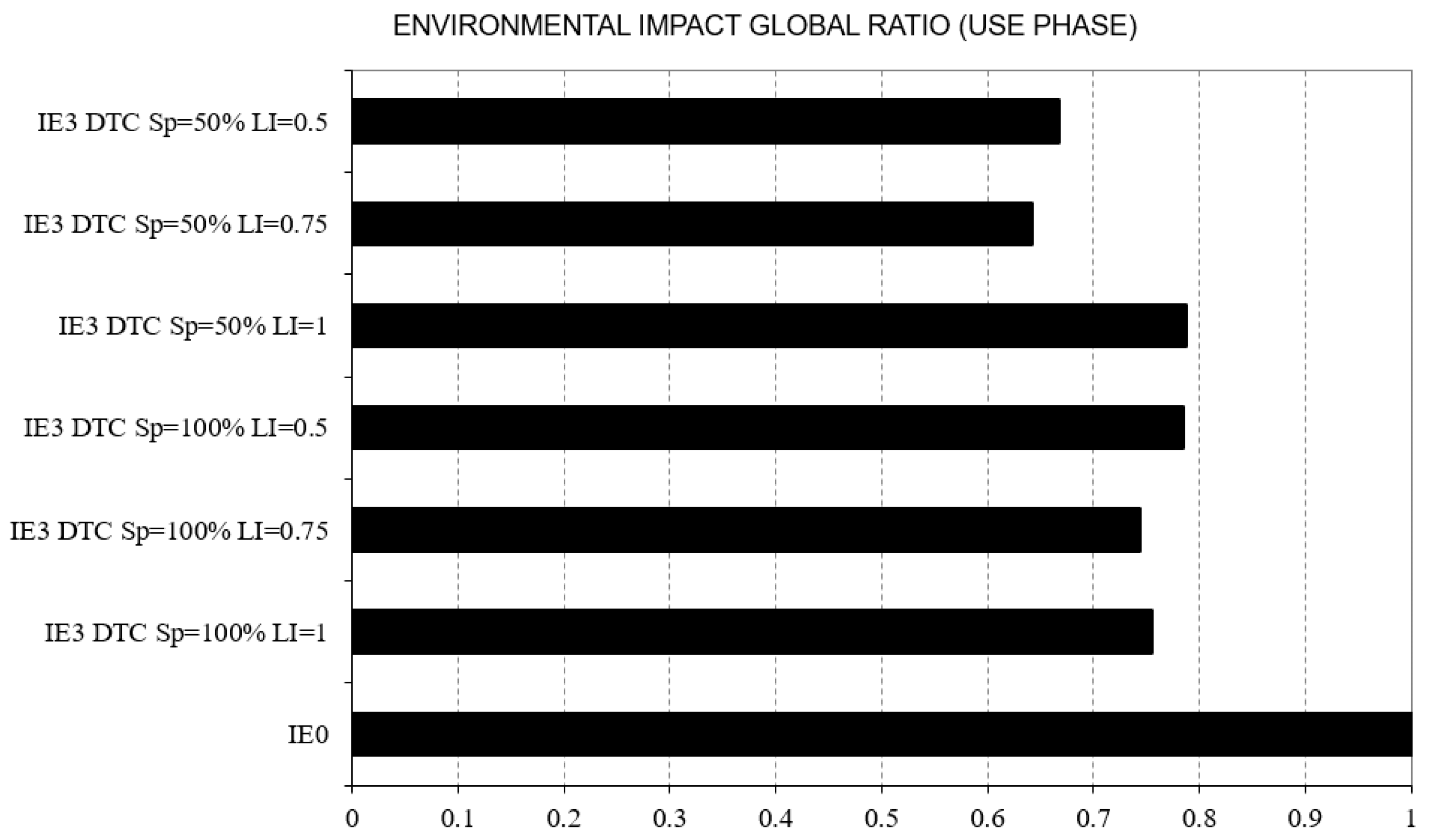

5.3. Environmental Impact Results

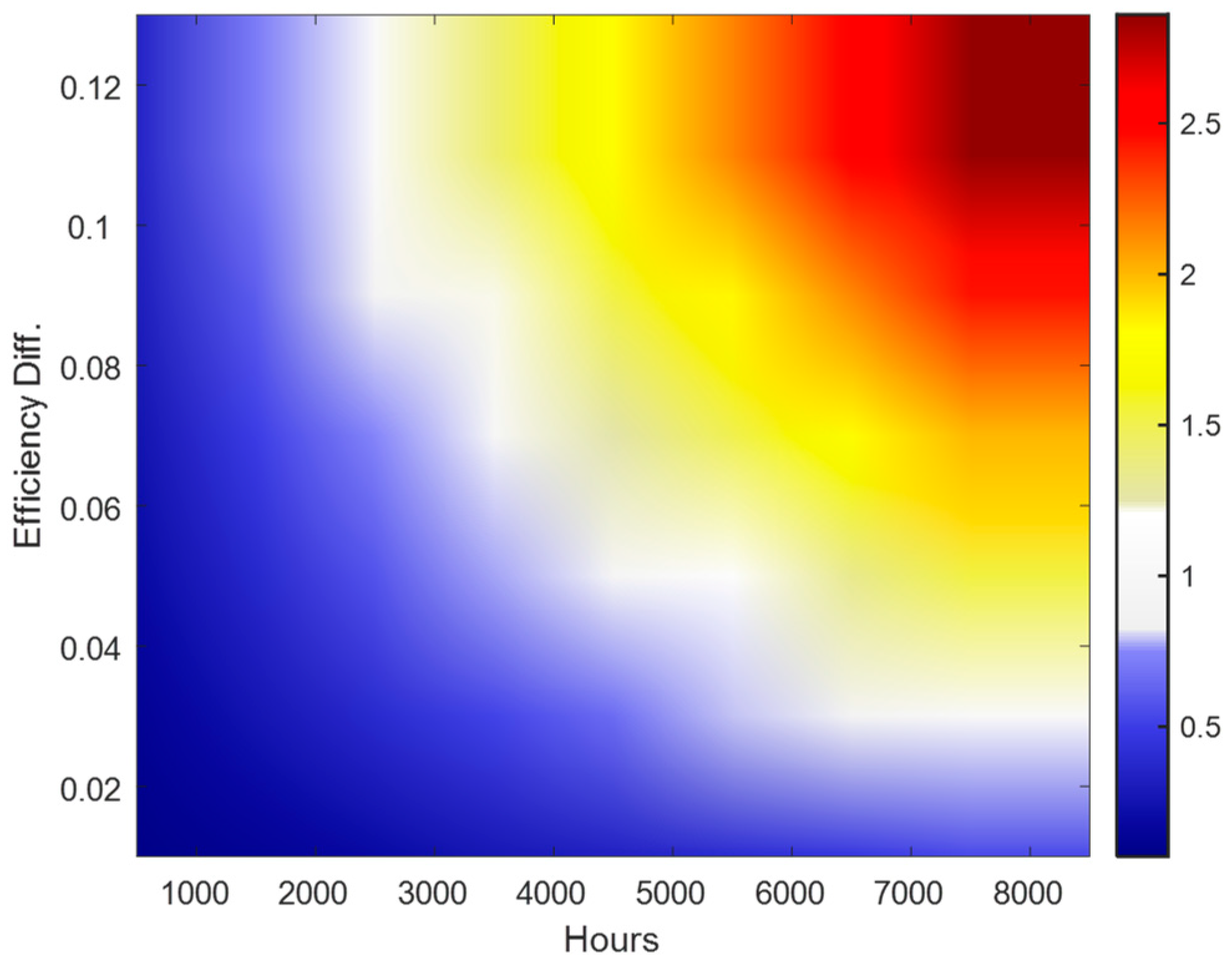

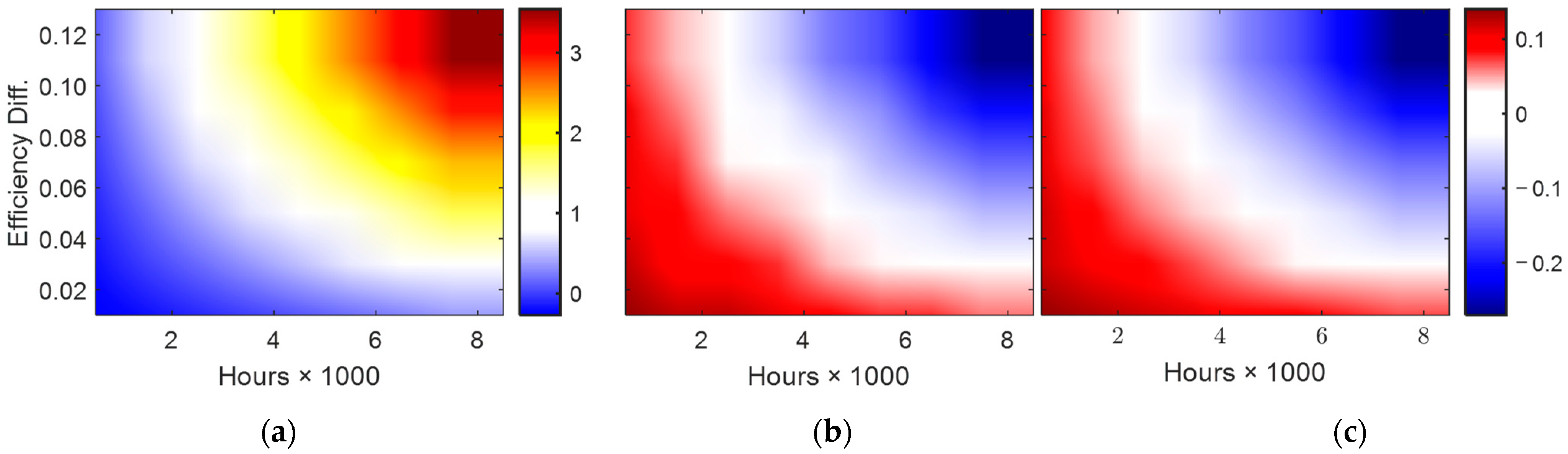

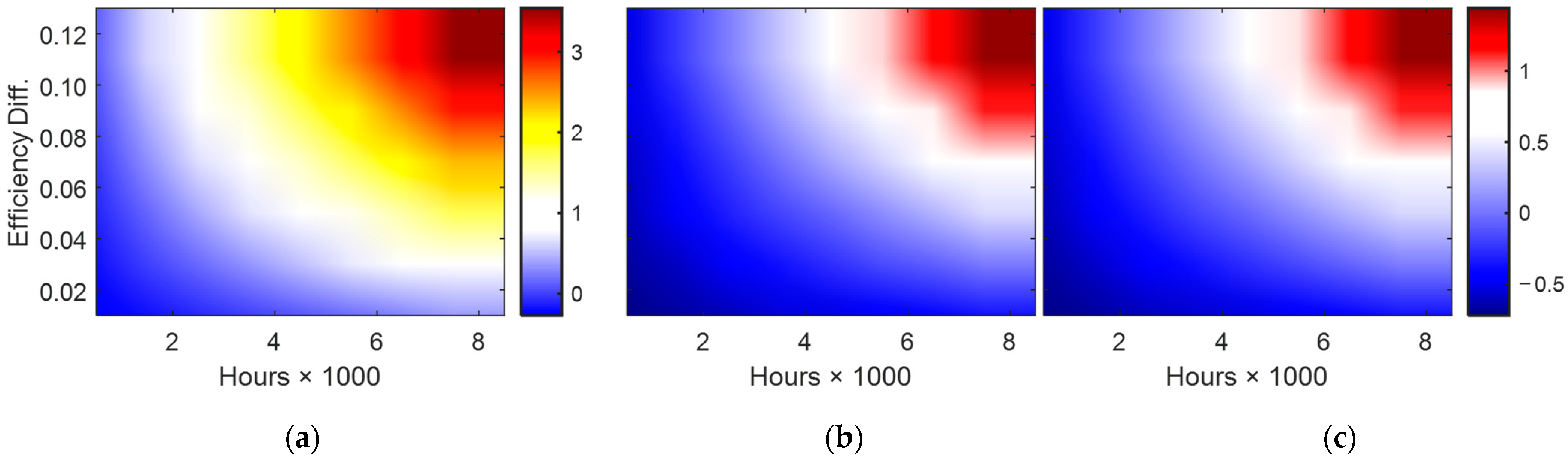

6. Sensitivity Analysis

6.1. Energy Saving Analysis

6.2. Economic Analysis

6.3. Environmental Analysis

7. Discussion

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Hours/Year | ||||||||

|---|---|---|---|---|---|---|---|---|

| Efficiency Difference | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 |

| 0.02 | 0.07 | 0.13 | 0.20 | 0.27 | 0.34 | 0.40 | 0.47 | 0.54 |

| 0.04 | 0.13 | 0.26 | 0.39 | 0.52 | 0.66 | 0.79 | 0.92 | 1.05 |

| 0.06 | 0.19 | 0.38 | 0.58 | 0.77 | 0.96 | 1.15 | 1.34 | 1.54 |

| 0.08 | 0.25 | 0.50 | 0.75 | 1 | 1.25 | 1.50 | 1.75 | 2.00 |

| 0.1 | 0.31 | 0.61 | 0.92 | 1.22 | 1.53 | 1.83 | 2.14 | 2.44 |

| 0.12 | 0.36 | 0.72 | 1.07 | 1.43 | 1.79 | 2.15 | 2.51 | 2.86 |

| Hours/Year | ||||||||

|---|---|---|---|---|---|---|---|---|

| Efficiency Difference | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 |

| 0.02 | 14.87 | 7.43 | 4.96 | 3.72 | 2.97 | 2.48 | 2.12 | 1.86 |

| 0.04 | 7.62 | 3.81 | 2.54 | 1.91 | 1.52 | 1.27 | 1.09 | 0.95 |

| 0.06 | 5.21 | 2.60 | 1.74 | 1.30 | 1.04 | 0.87 | 0.74 | 0.65 |

| 0.08 | 4.00 | 2.00 | 1.33 | 1 | 0.80 | 0.67 | 0.57 | 0.50 |

| 0.1 | 3.28 | 1.64 | 1.09 | 0.82 | 0.66 | 0.55 | 0.47 | 0.41 |

| 0.12 | 2.79 | 1.40 | 0.93 | 0.70 | 0.56 | 0.47 | 0.40 | 0.35 |

| Hours/Year | ||||||||

|---|---|---|---|---|---|---|---|---|

| Efficiency Difference | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 |

| 0.02 | −0.27 | −0.18 | −0.09 | 0.00 | 0.10 | 0.19 | 0.28 | 0.37 |

| (−0.18; −0.13) | (−0.1; −0.05) | (−0.01; 0.03) | (0.07; 0.11) | (0.16; 0.19) | (0.24; 0.28) | (0.33; 0.36) | (0.41; 0.44) | |

| 0.04 | −0.18 | 0.00 | 0.17 | 0.35 | 0.53 | 0.71 | 0.89 | 1.07 |

| (−0.1; −0.06) | (0.06; 0.1) | (0.23; 0.26) | (0.4; 0.42) | (0.56; 0.58) | (0.73; 0.74) | (0.9; 0.9) | (1.06; 1.06) | |

| 0.06 | −0.10 | 0.16 | 0.42 | 0.68 | 0.95 | 1.21 | 1.47 | 1.73 |

| (−0.03; 0.02) | (0.22; 0.25) | (0.46; 0.48) | (0.71; 0.72) | (0.95; 0.95) | (1.19; 1.18) | (1.44; 1.42) | (1.68; 1.65) | |

| 0.08 | −0.02 | 0.32 | 0.66 | 1 | 1.34 | 1.68 | 2.02 | 2.36 |

| (0.05; 0.09) | (0.37; 0.39) | (0.68; 0.7) | (1; 1) | (1.32; 1.3) | (1.63; 1.61) | (1.95; 1.91) | (2.27; 2.22) | |

| 0.1 | 0.05 | 0.47 | 0.89 | 1.30 | 1.72 | 2.13 | 2.55 | 2.96 |

| (0.12; 0.16) | (0.51; 0.53) | (0.89; 0.9) | (1.28; 1.27) | (1.67; 1.64) | (2.06; 2.01) | (2.44; 2.38) | (2.83; 2.75) | |

| 0.12 | 0.13 | 0.61 | 1.10 | 1.59 | 2.08 | 2.56 | 3.05 | 3.54 |

| (0.18; 0.22) | (0.64; 0.66) | (1.09; 1.09) | (1.55:1.53) | (2; 1.96) | (2.46; 2.4) | (2.91; 2.83) | (3.37; 3.27) | |

| Hours/Year | ||||||||

|---|---|---|---|---|---|---|---|---|

| Efficiency Difference | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 |

| 0.02 | −0.27 | −0.18 | −0.09 | 0.00 | 0.10 | 0.19 | 0.28 | 0.37 |

| (−0.55; −0.99) | (−0.44; −0.85) | (−0.33; −0.7) | (−0.21; −0.56) | (−0.1; −0.42) | (0.01; −0.27) | (0.12; −0.13) | (0.23; 0.01) | |

| 0.04 | −0.18 | 0.00 | 0.17 | 0.35 | 0.53 | 0.71 | 0.89 | 1.07 |

| (−0.44; −0.85) | (−0.23; −0.57) | (−0.01; −0.29) | (0.21; −0.01) | (0.43; 0.27) | (0.65; 0.55) | (0.86; 0.83) | (1.08; 1.11) | |

| 0.06 | −0.10 | 0.16 | 0.42 | 0.68 | 0.95 | 1.21 | 1.47 | 1.73 |

| (−0.34; −0.72) | (−0.02; −0.31) | (0.3; 0.1) | (0.61; 0.51) | (0.93; 0.91) | (1.25; 1.32) | (1.57; 1.73) | (1.89; 2.14) | |

| 0.08 | −0.02 | 0.32 | 0.66 | 1 | 1.34 | 1.68 | 2.02 | 2.36 |

| (−0.25; −0.6) | (0.17; −0.07) | (0.58; 0.47) | (1; 1) | (1.42; 1.53) | (1.83; 2.07) | (1.25; 2.6) | (2.66; 3.13) | |

| 0.1 | 0.05 | 0.47 | 0.89 | 1.30 | 1.72 | 2.13 | 2.55 | 2.96 |

| (−0.15; −0.48) | (0.35; 0.17) | (0.86; 0.82) | (1.37; 1.47) | (1.88; 2.12) | (2.38; 2.77) | (2.89; 3.43) | (3.4; 4.08) | |

| 0.12 | 0.13 | 0.61 | 1.10 | 1.59 | 2.08 | 2.56 | 3.05 | 3.54 |

| (−0.07; −0.37) | (0.53; 0.39) | (1.12; 1.16) | (1.72:1.92) | (2.31; 2.69) | (2.91; 3.45) | (3.5; 4.21) | (4.1; 4.98) | |

| Hours/Year | ||||||||

|---|---|---|---|---|---|---|---|---|

| Efficiency Difference | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 |

| 0.02 | −0.27 | −0.18 | −0.09 | 0.00 | 0.10 | 0.19 | 0.28 | 0.37 |

| (−0.31; −0.36) | (−0.22; −0.26) | (−0.12; −0.17) | (−0.03; −0.07) | (0.07; 0.03) | (0.16; 0.13) | (0.25; 0.23) | (0.35; 0.33) | |

| 0.04 | −0.18 | 0.00 | 0.17 | 0.35 | 0.53 | 0.71 | 0.89 | 1.07 |

| (−0.22; −0.27) | (−0.04; −0.08) | (0.15; 0.11) | (0.33; 0.31) | (0.52; 0.5) | (0.7; 0.69) | (0.88; 0.88) | (1.07; 1.07) | |

| 0.06 | −0.10 | 0.16 | 0.42 | 0.68 | 0.95 | 1.21 | 1.47 | 1.73 |

| (−0.14; −0.18) | (0.13; 0.1) | (0.4; 0.38) | (0.67; 0.66) | (0.94; 0.94) | (1.21; 1.22) | (1.48; 1.5) | (1.76; 1.78) | |

| 0.08 | −0.02 | 0.32 | 0.66 | 1 | 1.34 | 1.68 | 2.02 | 2.36 |

| (−0.06; −0.1) | (0.3; 0.27) | (0.65; 0.63) | (1; 1) | (1.35; 1.37) | (1.7; 1.73) | (2.06; 2.1) | (2.41; 2.46) | |

| 0.1 | 0.05 | 0.47 | 0.89 | 1.30 | 1.72 | 2.13 | 2.55 | 2.96 |

| (0.02; −0.01) | (0.45; 0.43) | (0.88; 0.88) | (1.31; 1.32) | (1.74; 1.77) | (2.17; 2.22) | (2.6; 2.66) | (3.03; 3.11) | |

| 0.12 | 0.13 | 0.61 | 1.10 | 1.59 | 2.08 | 2.56 | 3.05 | 3.54 |

| (0.1; 0.06) | (0.6; 0.59) | (1.1; 1.11) | (1.61:1.63) | (2.11; 2.15) | (2.62; 2.68) | (3.12; 3.2) | (3.63; 3.72) | |

Appendix B

References

- De Almeida, A.T.; Falkner, H.; Fong, J.; Jugdoyal, K. EuP Lot 30: Electric Motors and Drives; Final Report; University of Coimbra: Coimbra, Portugal, 2014. [Google Scholar]

- IEC 60034-30-1; Standard on Efficiency Classes for Low Voltage AC Motors. 2014. Available online: https://webstore.iec.ch/publication/136 (accessed on 11 April 2023).

- Ecodesign Electric Motors. Commission Regulation (EU) No 4/2014 of 6 January 2014 Amending Regulation (EC) No 640/2009 Implementing Directive 2005/32/EC of the European Parliament and of the Council with Regard to Ecodesign Requirements for Electric Motors. Available online: https://www.eumonitor.eu/9353000/1/j9vvik7m1c3gyxp/vjgp6pule7zm (accessed on 11 April 2023).

- De Almeida, A.T.; Ferreira, F.J.T.E.; Fong, J. Perspectives on Electric Motor Market Transformation for a Net Zero Carbon Economy. Energies 2023, 16, 1248. [Google Scholar] [CrossRef]

- Bortoni, E.C.; Bernardes, J.V.; da Silva, P.V.; Faria, V.A.; Vieira, P.A. Evaluation of manufacturers strategies to obtain high-efficient induction motors. Sustain. Energy Technol. Assess. 2019, 31, 221–227. [Google Scholar] [CrossRef]

- Aishwarya, M.; Brisilla, R.M. Design of Energy-Efficient Induction motor using ANSYS software. Results Eng. 2022, 16, 100616. [Google Scholar] [CrossRef]

- Lu, S.-M. A review of high-efficiency motors: Specification, policy, and technology. Renew. Sustain. Energy Rev. 2016, 59, 1–12. [Google Scholar] [CrossRef]

- Goman, V.; Prakht, V.; Kazakbaev, V.; Dmitrievskii, V. Comparative Study of Induction Motors of IE2, IE3 and IE4 Efficiency Classes in Pump Applications Taking into Account CO2 Emission Intensity. Appl. Sci. 2020, 10, 8536. [Google Scholar] [CrossRef]

- Available online: https://www.zes.com/en/Products/Precision-Power-Analyzers/LMG450 (accessed on 11 April 2023).

- Available online: https://www.kistler.com/ES/en/cp/torque-measuring-flange-system-kitorq-rotor-measuring-ranges-100-to-10000-nm-4550a/P0000244 (accessed on 11 April 2023).

- Tabora, J.M.; Tostes, M.E.D.L.; Bezerra, U.H.; De Matos, E.O.; Filho, C.L.P.; Soares, T.M.; Rodrigues, C.E.M. Assessing Energy Efficiency and Power Quality Impacts Due to High-Efficiency Motors Operating Under Nonideal Energy Supply. IEEE Access 2021, 9, 121871–121882. [Google Scholar] [CrossRef]

- Martinez, M.A.; Gutierrez, J.M.; Malagon, S.M.; Mendoza, F.; Rodriguez, J. A speed performance comparative of field oriented control and scalar control for induction motors. In Proceedings of the 2016 IEEE Conference on Mechatronics, Adaptive and Intelligent Systems (MAIS), Hermosillo, Mexico, 20–22 October 2016. [Google Scholar] [CrossRef]

- IEC 519; Recommended Practice and Requirements for Harmonic Control in Electric Power Systems. 2014. Available online: https://edisciplinas.usp.br/pluginfile.php/1589263/mod_resource/content/1/IEE%20Std%20519-2014.pdf (accessed on 11 April 2023).

- IEC 60034-2-1; Standard Methods for Determining Losses and Efficiency from Tests (Excluding Machines for Traction Vehicles). 2014. Available online: https://webstore.iec.ch/publication/121 (accessed on 11 April 2023).

- IEC 60034-2-3; Rotating Electrical Machines—Part 2–3: Specific Test Methods for Determining Losses and Efficiency of Converter-Fed AC Motors. 2020. Available online: https://webstore.iec.ch/publication/30919 (accessed on 11 April 2023).

- Boglietti, A.; Cavagnino, A.; Cossale, M.; Tenconi, A.; Vaschetto, S. Efficiency Determination of Converter-Fed Induction Motors: Waiting for the IEC 60034-2-3 Standard. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013. [Google Scholar] [CrossRef]

- Aminu, M.; Mushenya, J.; Barendse, P.S.; Khan, M.A. Converter-fed Induction Motor Efficiency Measurement under Variable Frequency/Load Points: An Extension of the IEC/TS 60034-2-3. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September 2019–3 October 2019. [Google Scholar] [CrossRef]

- Karkkainen, H.; Aarniovuori, L.; Niemela, M.; Pyrhonen, J. Converter-Fed Induction Motor Efficiency: Practical Applicability of IEC Methods. IEEE Ind. Electron. Mag. 2017, 11, 45–57. [Google Scholar] [CrossRef]

- Rachev, S.; Dimitrov, L.; Ivanov, I.; Karakoulidis, K. Study the Effects of No Nominal Conditions on the Performance of High Efficiency Induction Motor. In Proceedings of the 2017 IEEE International Conference on Energy and Environment (CIEM 2017), Bucharest, Romania, 19–20 October 2017. [Google Scholar] [CrossRef]

- IEC 61800-9-2; Adjustable Speed Electrical Power Drive Systems—Part 9-2: Ecodesign for Power Drive Systems, Motor Starters, Power Electronics and Their Driven Applications—Energy Efficiency Indicators for Power Drive Systems and Motor Starters. 2017. Available online: https://webstore.iec.ch/publication/31527 (accessed on 11 April 2023).

- Aarniovuori, L.; Karkkainen, H.; Anuchin, A.; Pyrhonen, J.J.; Lindh, P.; Cao, W. Voltage-Source Converter Energy Efficiency Classification in Accordance With IEC 61800-9-2. IEEE Trans. Ind. Electron. 2020, 67, 8242–8251. [Google Scholar] [CrossRef]

- Saidur, R. A review on electrical motors energy use and energy savings. Renew. Sustain. Energy Rev. 2010, 14, 877–898. [Google Scholar] [CrossRef]

- Jardot, D.; Eichhammer, W.; Fleiter, T. Effects of economies of scale and experience on the costs of energy-efficient technologies—Case study of electric motors in Germany. Energy Effic. 2010, 3, 331–346. [Google Scholar] [CrossRef]

- Gugaliya, A.; Naikan, V. A model for financial viability of implementation of condition based maintenance for induction motors. J. Qual. Maint. Eng. 2020, 26, 213–230. [Google Scholar] [CrossRef]

- Methodology for Ecodesign of Energy-Related Products, MEErP, Final Report. 2011. Available online: https://op.europa.eu/s/yGHF (accessed on 11 April 2023).

- Torrent, M.; Martínez, E.; Andrada, P. Life cycle analysis on the design of induction motors. Int. J. Life Cycle Assess. 2011, 17, 1–8. [Google Scholar] [CrossRef]

- Torrent, M.; Martinez, E.; Andrada, P. Assessing the environmental impact of induction motors using manufacturer’s data and life cycle analysis. IET Electr. Power Appl. 2012, 6, 473–483. [Google Scholar] [CrossRef]

- Available online: https://new.abb.com/motors-generators/iec-low-voltage-motors/general-performance-motors (accessed on 11 April 2023).

- Available online: https://new.abb.com/drives/low-voltage-ac/industrial-drives (accessed on 11 April 2023).

- Rai, K.; Seksena, S.B.L.; Thakur, A.N. Economic Efficiency Measure of Induction Motors for Industrial Applications. Int. J. Electr. Comput. Eng. IJECE 2017, 7, 1661–1670. [Google Scholar] [CrossRef]

- Rajinder; Sreejeth, M.; Singh, M. Sensitivity Analysis of Induction Motor Performance Variables. In Proceedings of the 2016 IEEE 1st International Conference on Power Electronics, Intelligent Control and Energy Systems (ICPEICES), Delhi, India, 4–6 July 2016. [Google Scholar] [CrossRef]

- Paes, R.; Toner, B.; Bankay, G.; Agashe, G. Energy Optimization for Adjustable-Speed Drive Applications: Increasing Efficiency to Cut Costs and Preserve Assets. IEEE Ind. Appl. Mag. 2021, 27, 37–46. [Google Scholar] [CrossRef]

- Lee, K.; Qi, J. Energy Efficiency Performance Evaluation of Direct Torque and Flux Control in Induction Machines Driven by Adjustable Speed Drives. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020. [Google Scholar] [CrossRef]

- Zhang, Z.; Bazzi, A.M. Robust Sensorless Scalar Control of Induction Motor Drives with Torque Capability Enhancement at Low Speeds. In Proceedings of the 2019 IEEE International Electric Machines & Drives Conference (IEMDC), San Diego, CA, USA, 12–15 May 2019. [Google Scholar] [CrossRef]

| Voltage (V) | Current (A) | Speed (rpm) | Power Factor | Weight (kg) | |

|---|---|---|---|---|---|

| IE0 | 220 | 6.6 | 1420 | 0.75 | 16.7 |

| IE3 | 230 | 5.6 | 1439 | 0.78 | 22 |

| Efficiency Difference | EIGR |

|---|---|

| 0.02 | 0.65 |

| 0.04 | 0.64 |

| 0.06 | 0.62 |

| 0.08 | 0.61 |

| 0.1 | 0.59 |

| 0.12 | 0.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torrent, M.; Blanqué, B.; Monjo, L. Replacing Induction Motors without Defined Efficiency Class by IE Class: Example of Energy, Economic, and Environmental Evaluation in 1.5 kW—IE3 Motors. Machines 2023, 11, 567. https://doi.org/10.3390/machines11050567

Torrent M, Blanqué B, Monjo L. Replacing Induction Motors without Defined Efficiency Class by IE Class: Example of Energy, Economic, and Environmental Evaluation in 1.5 kW—IE3 Motors. Machines. 2023; 11(5):567. https://doi.org/10.3390/machines11050567

Chicago/Turabian StyleTorrent, Marcel, Balduí Blanqué, and Lluís Monjo. 2023. "Replacing Induction Motors without Defined Efficiency Class by IE Class: Example of Energy, Economic, and Environmental Evaluation in 1.5 kW—IE3 Motors" Machines 11, no. 5: 567. https://doi.org/10.3390/machines11050567

APA StyleTorrent, M., Blanqué, B., & Monjo, L. (2023). Replacing Induction Motors without Defined Efficiency Class by IE Class: Example of Energy, Economic, and Environmental Evaluation in 1.5 kW—IE3 Motors. Machines, 11(5), 567. https://doi.org/10.3390/machines11050567