The Transverse Vibration Characteristics of Circular Saw Blade on Mobile Cantilever-Type CNC Sawing Machine

Abstract

:1. Introduction

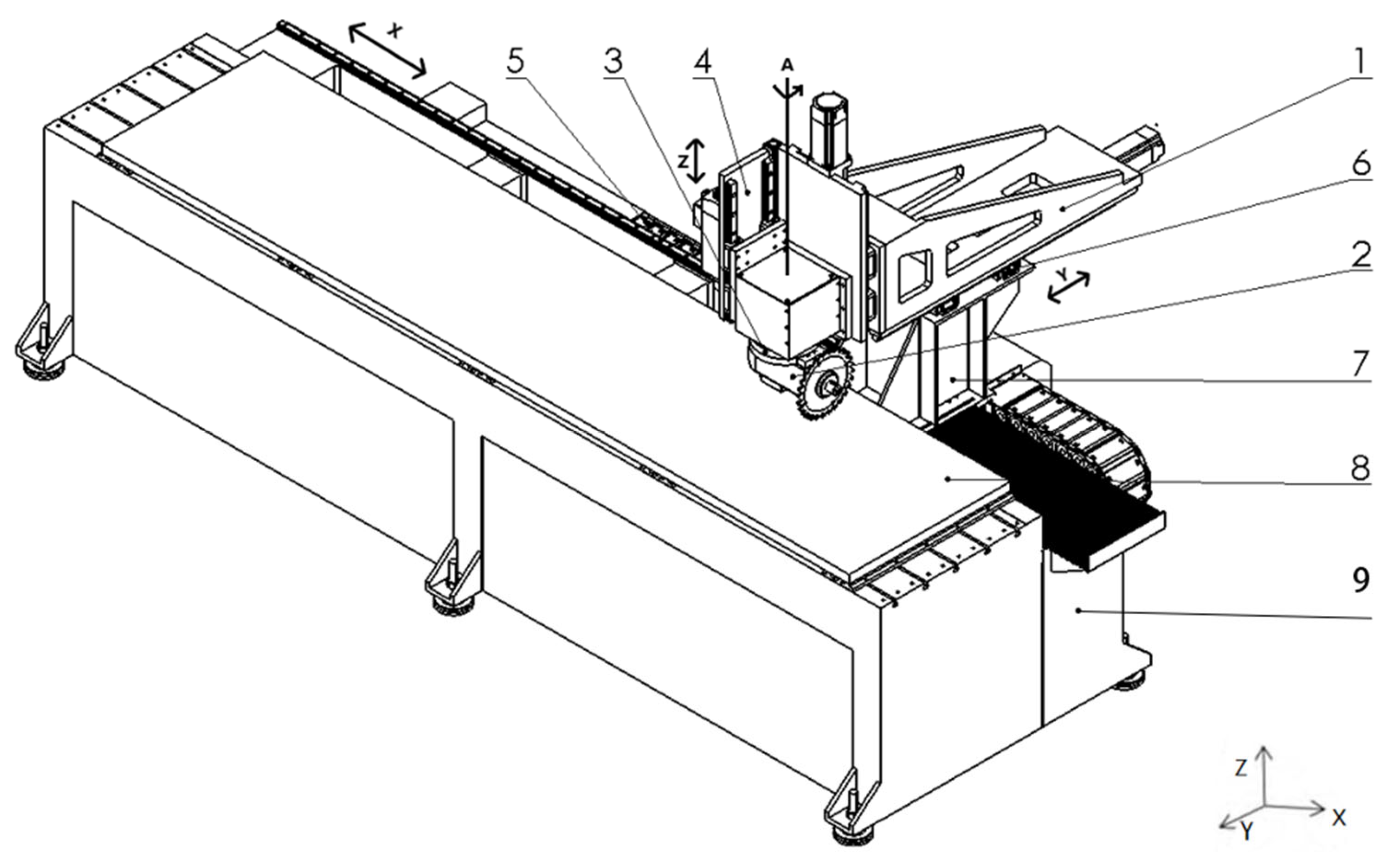

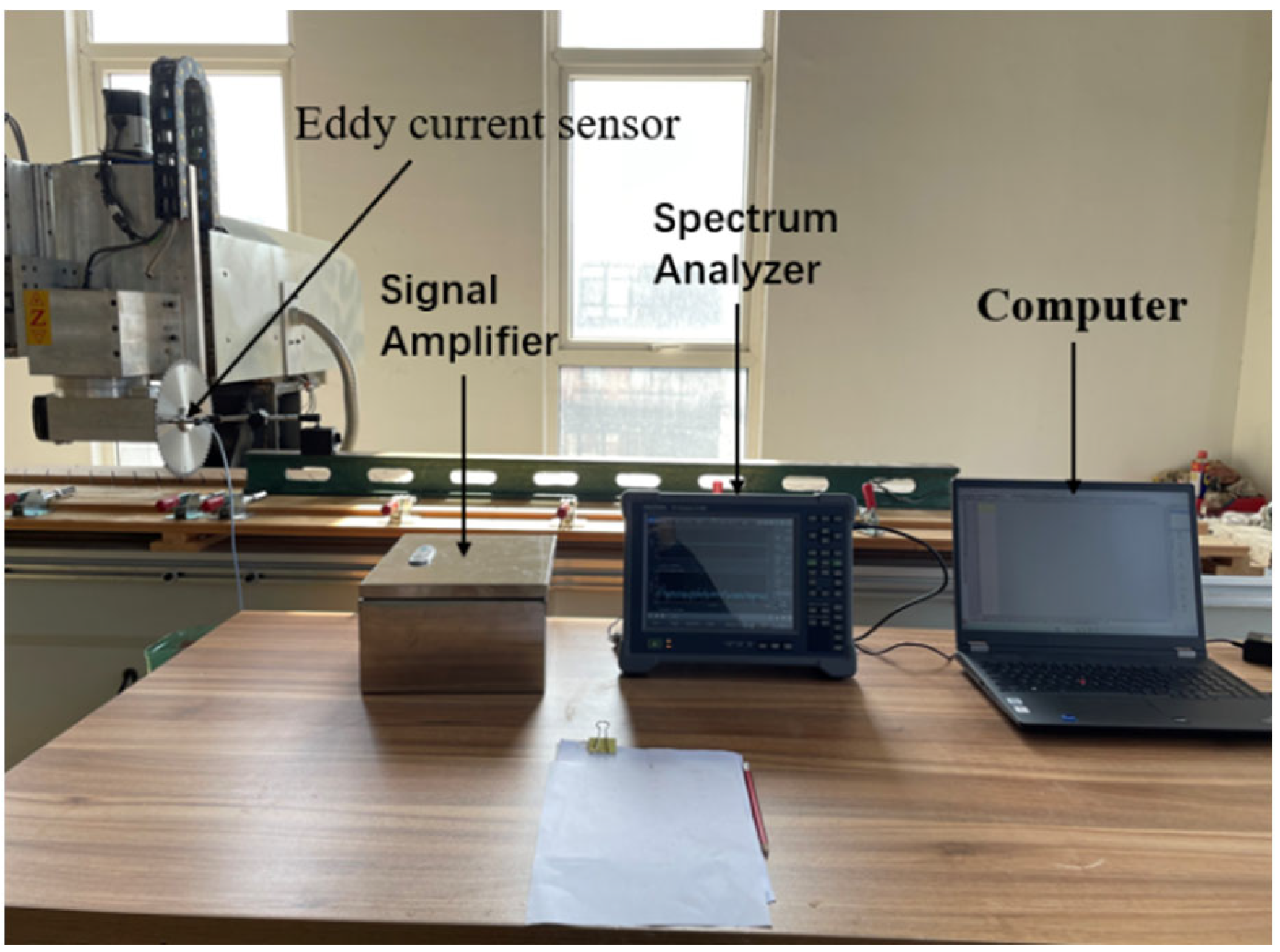

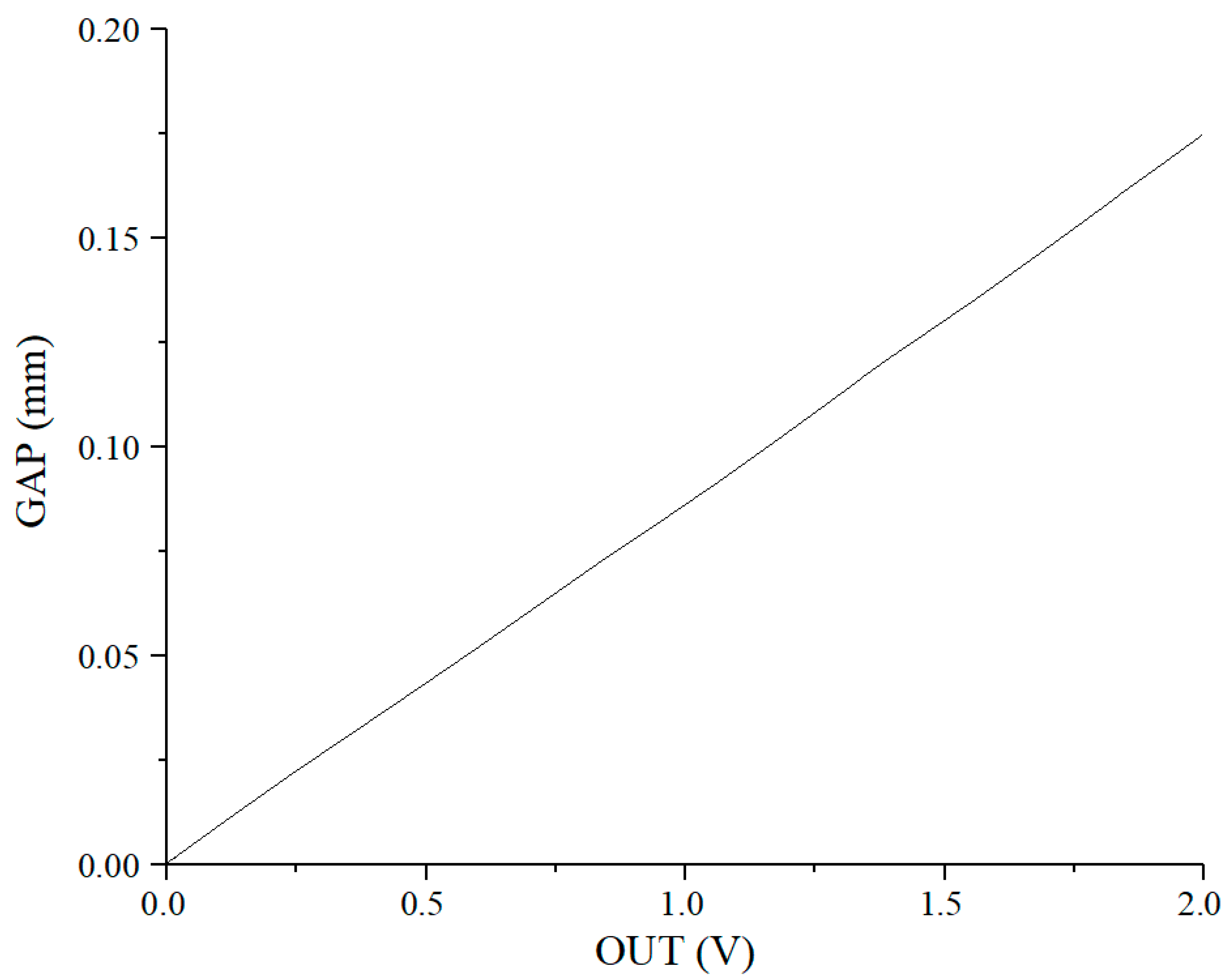

2. Experimental Equipment and Methods

2.1. Experimental Equipment and Materials

2.2. Experimental Procedures, Signal Acquisition, and Processing

- Change the overhang length of circular saw blade, keep the constant radius distance between the detection point and the center of the circular saw blade, and then detect the transverse vibration of no-load saw blade.

- Change the radius distance of the detection point away from the center of the circular saw blade, keep the constant overhanging length, and then detect the transverse vibration of no-load saw blade.

- Sawing: set the overhang length starting from 0 to 300 mm (Y-axis direction), keep the constant cutting speed, feed speed, and cutting depth, and then detect the transverse vibration of the circular saw when Y-axis was set as 0, 150 mm, and 300 mm, separately.

3. Results and Discussion

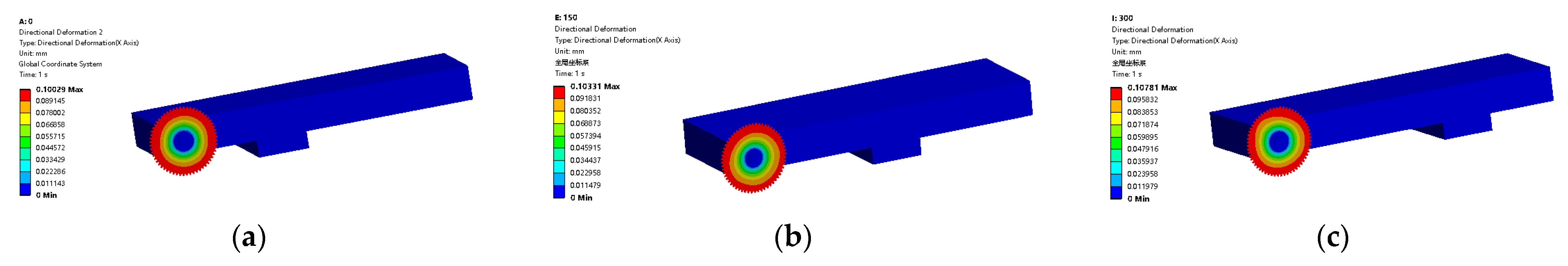

3.1. Simulation Results

3.2. Transverse Vibration of Saw Blade with Different Overhang Lengths at No-Load

3.3. The Transverse Vibration of Different Detecting Points on Saw Blade at No-Load

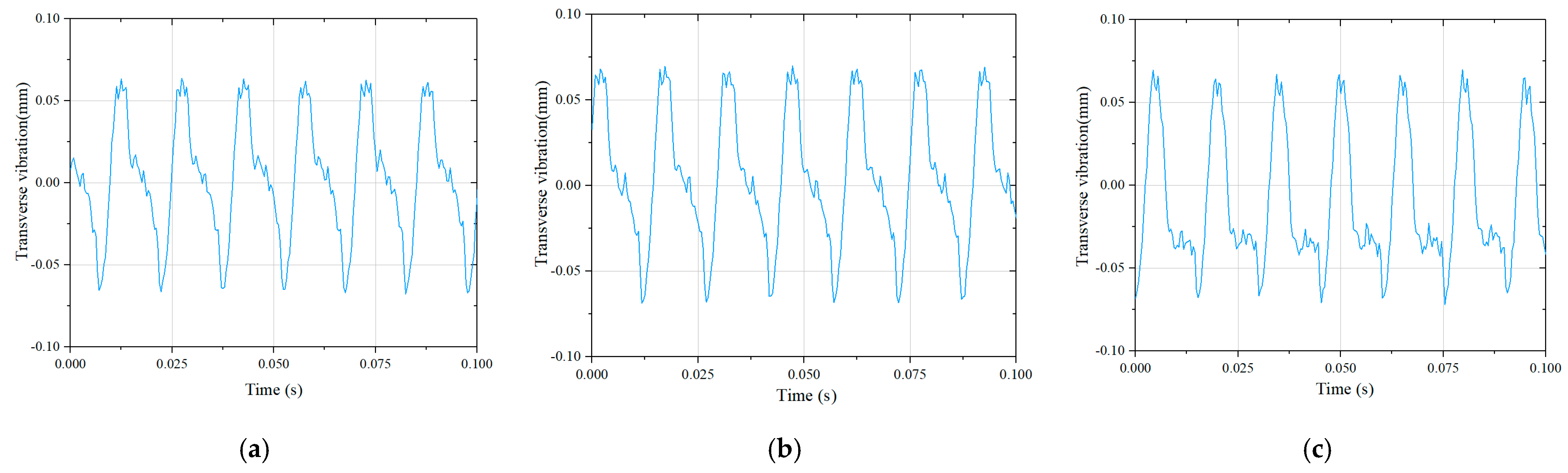

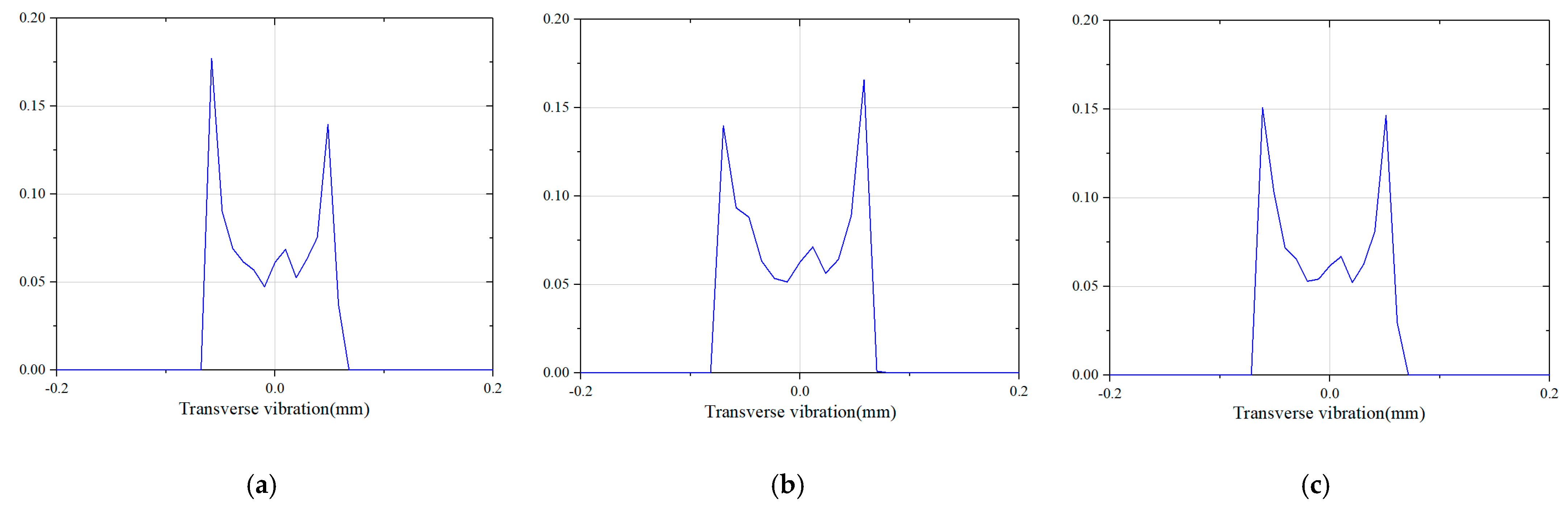

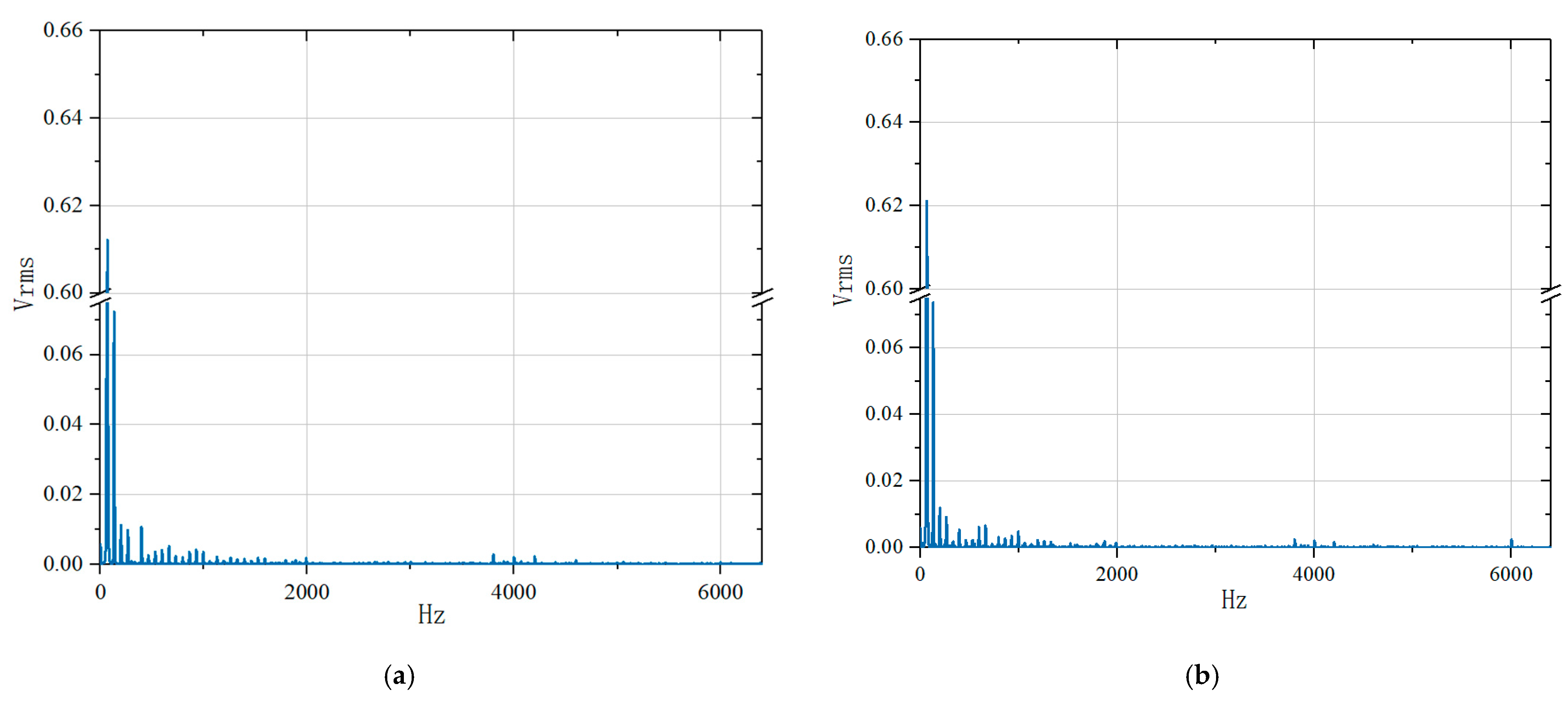

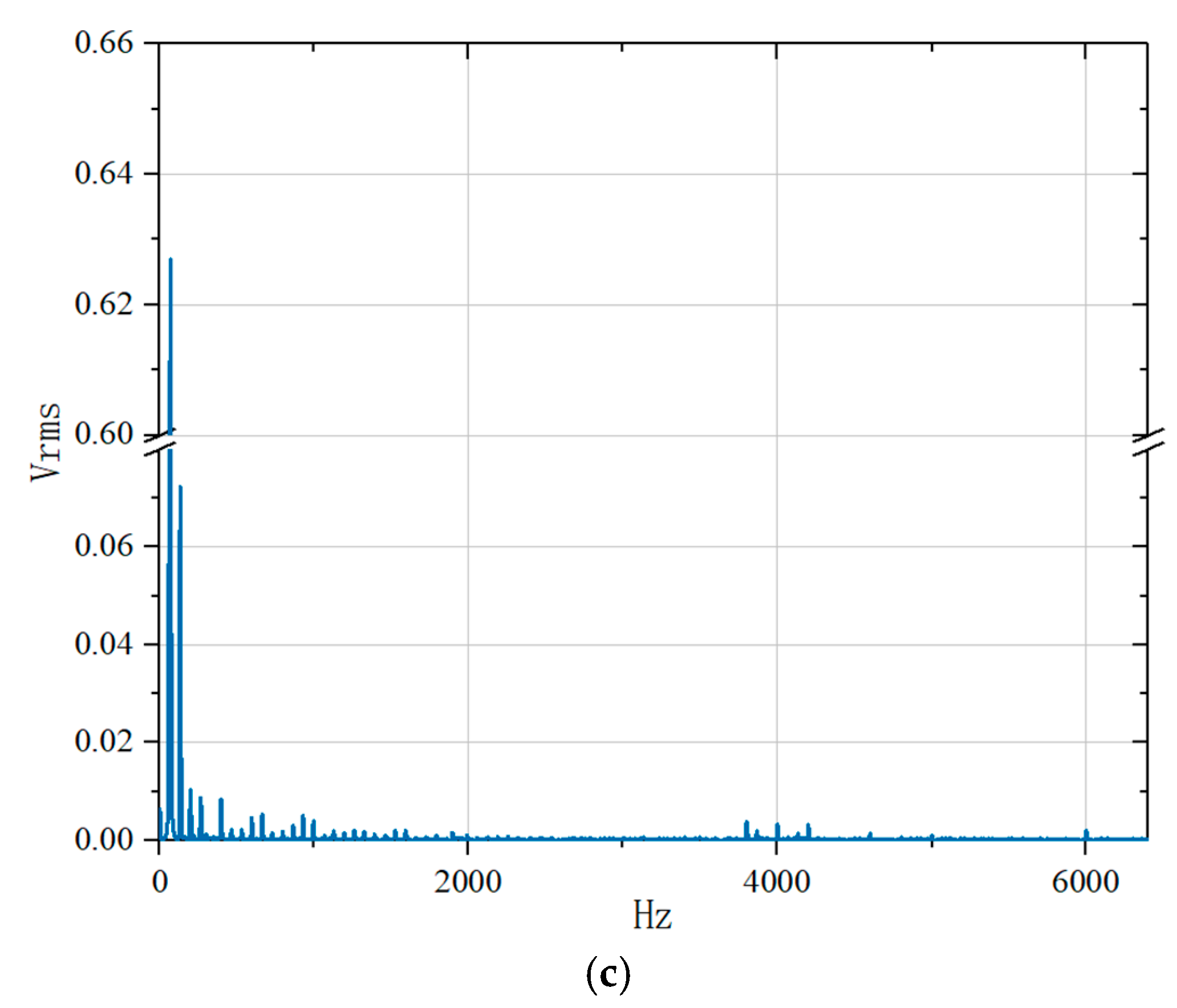

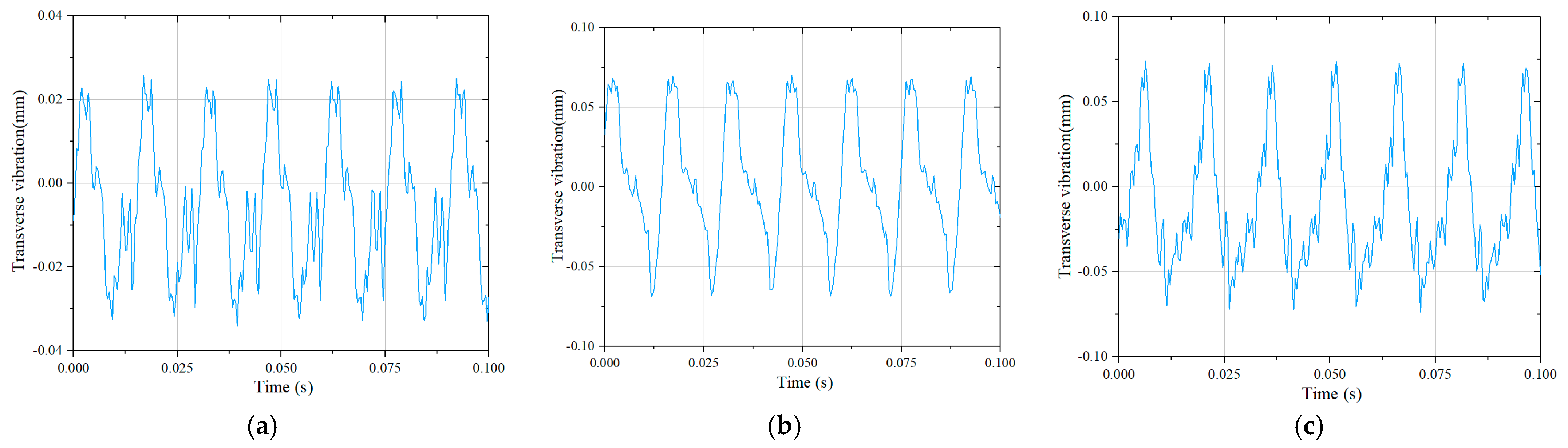

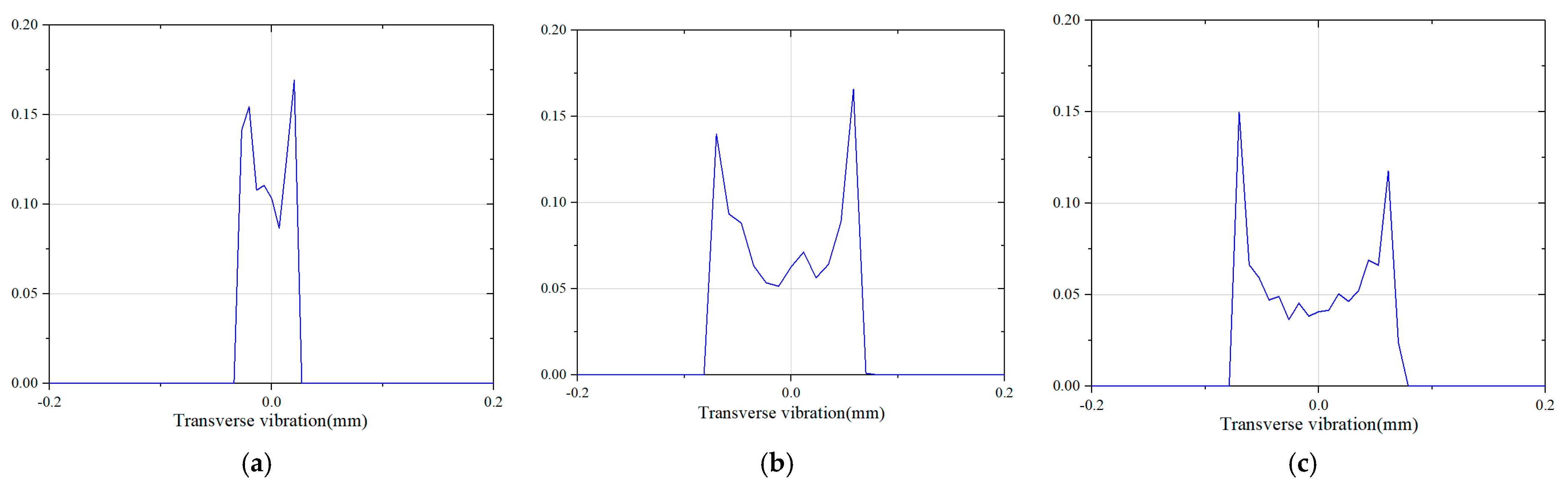

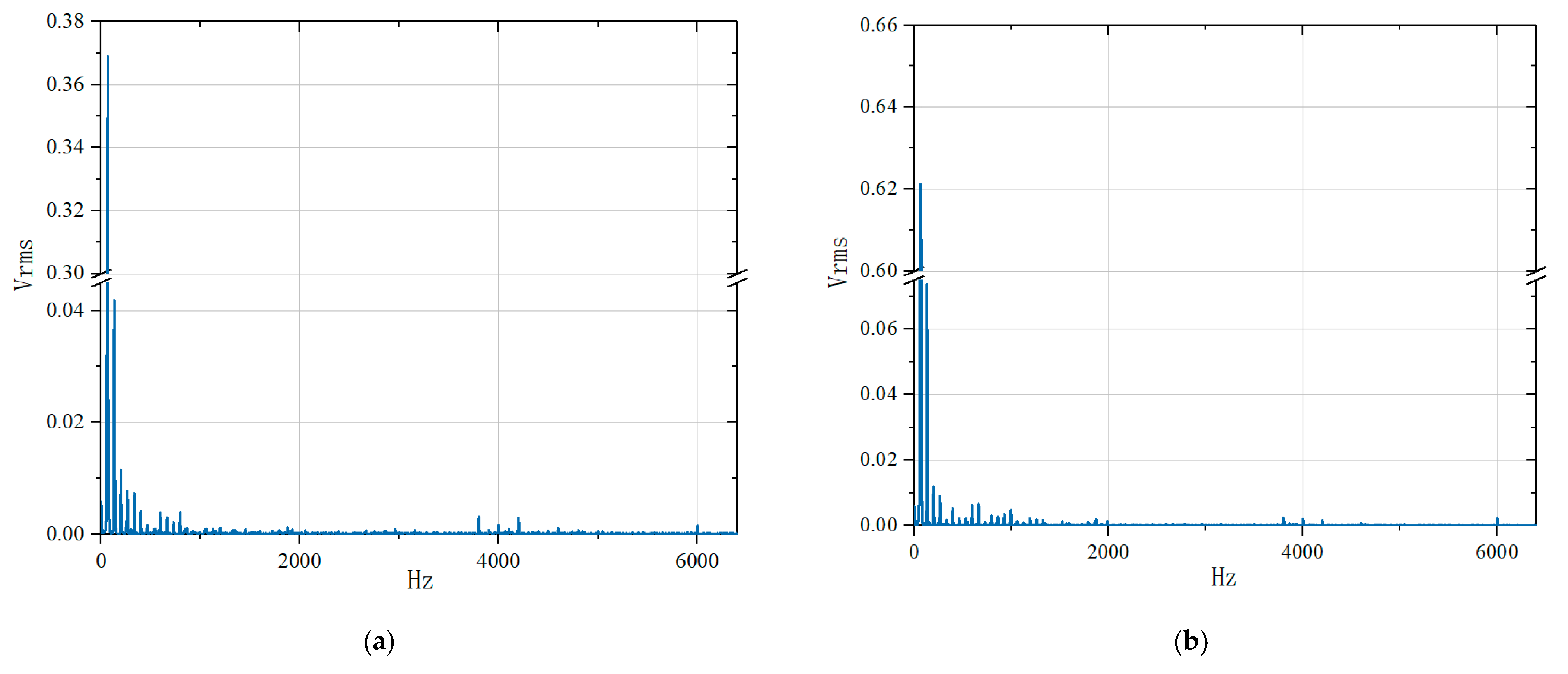

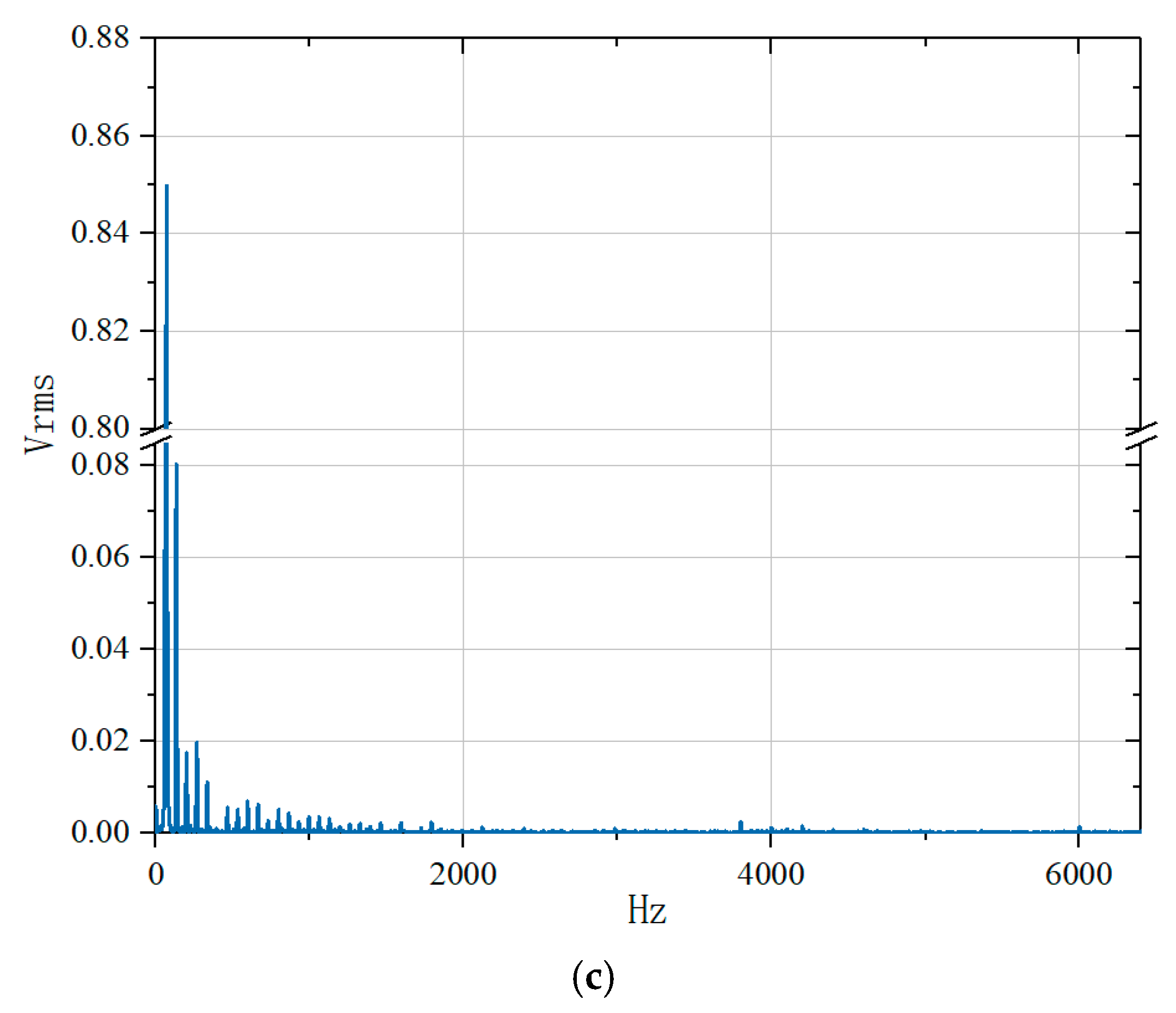

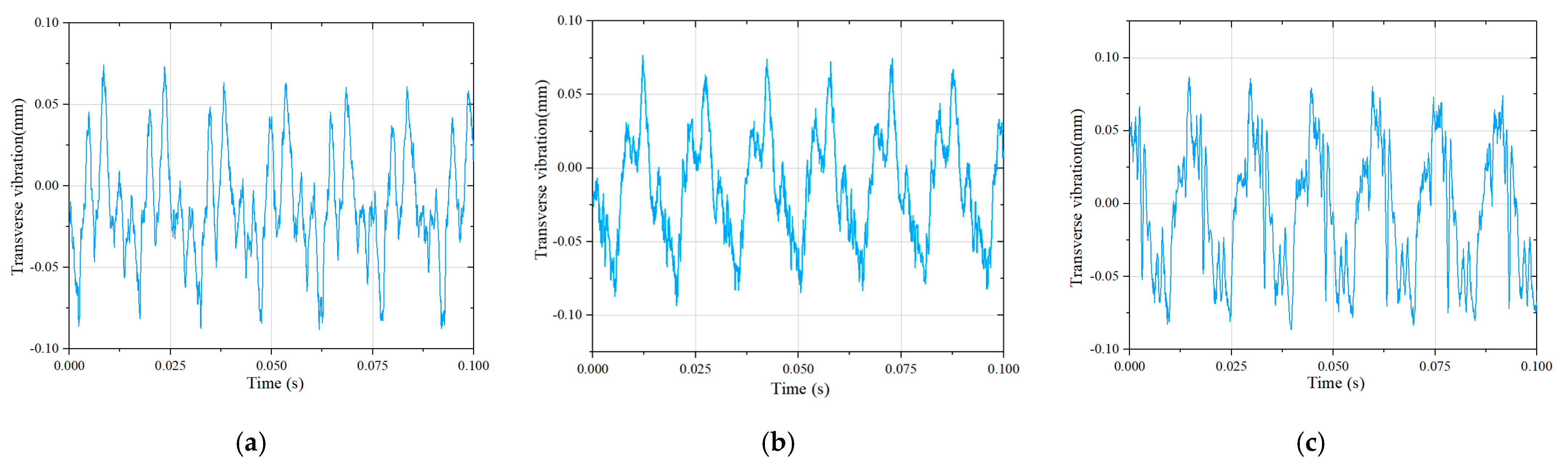

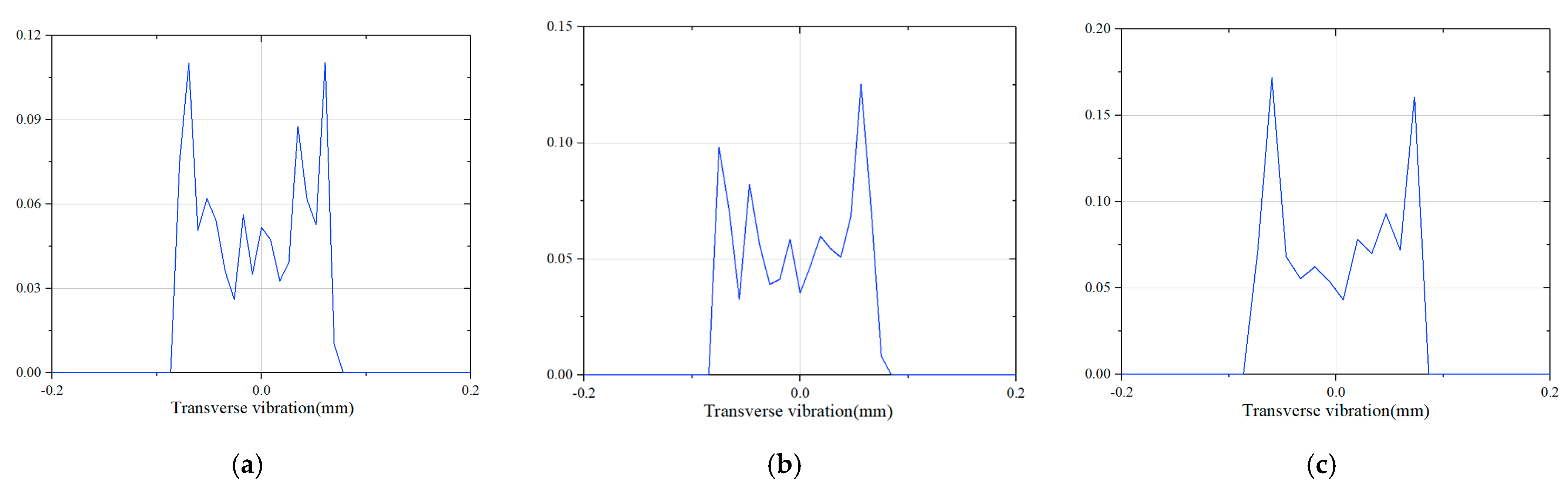

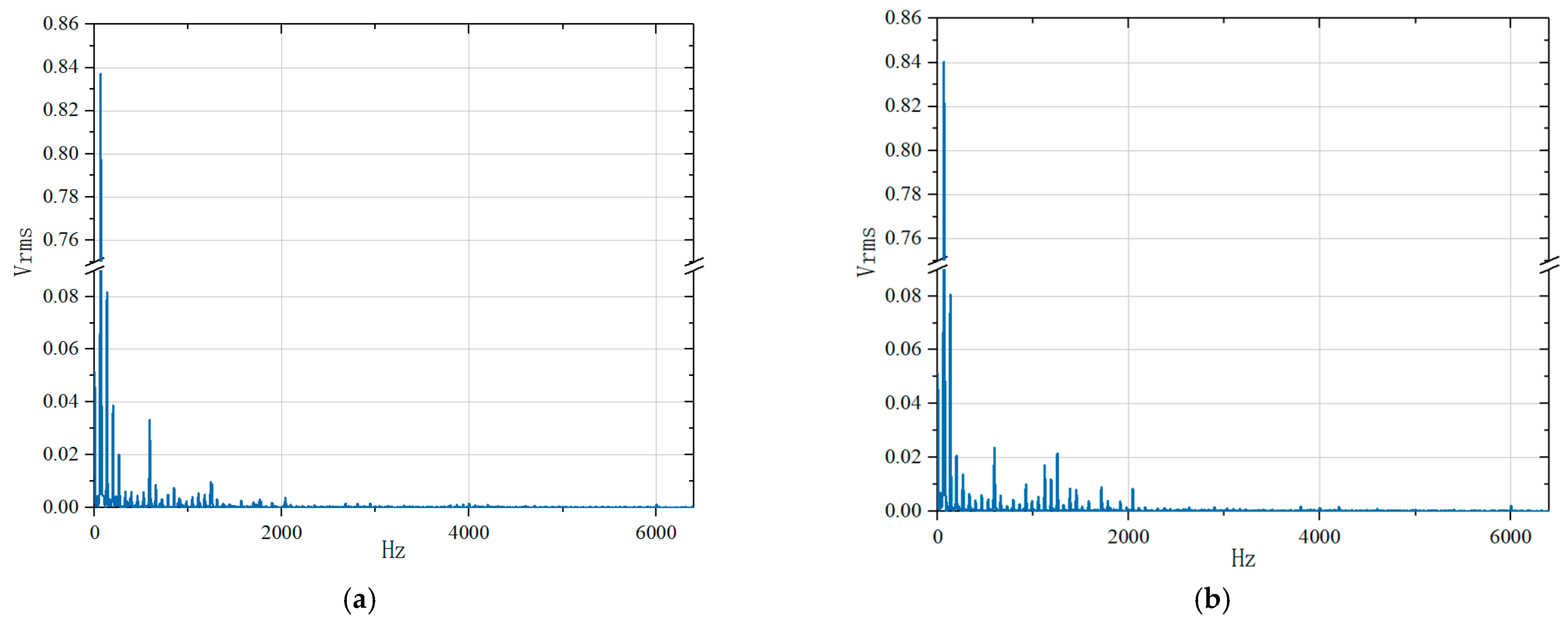

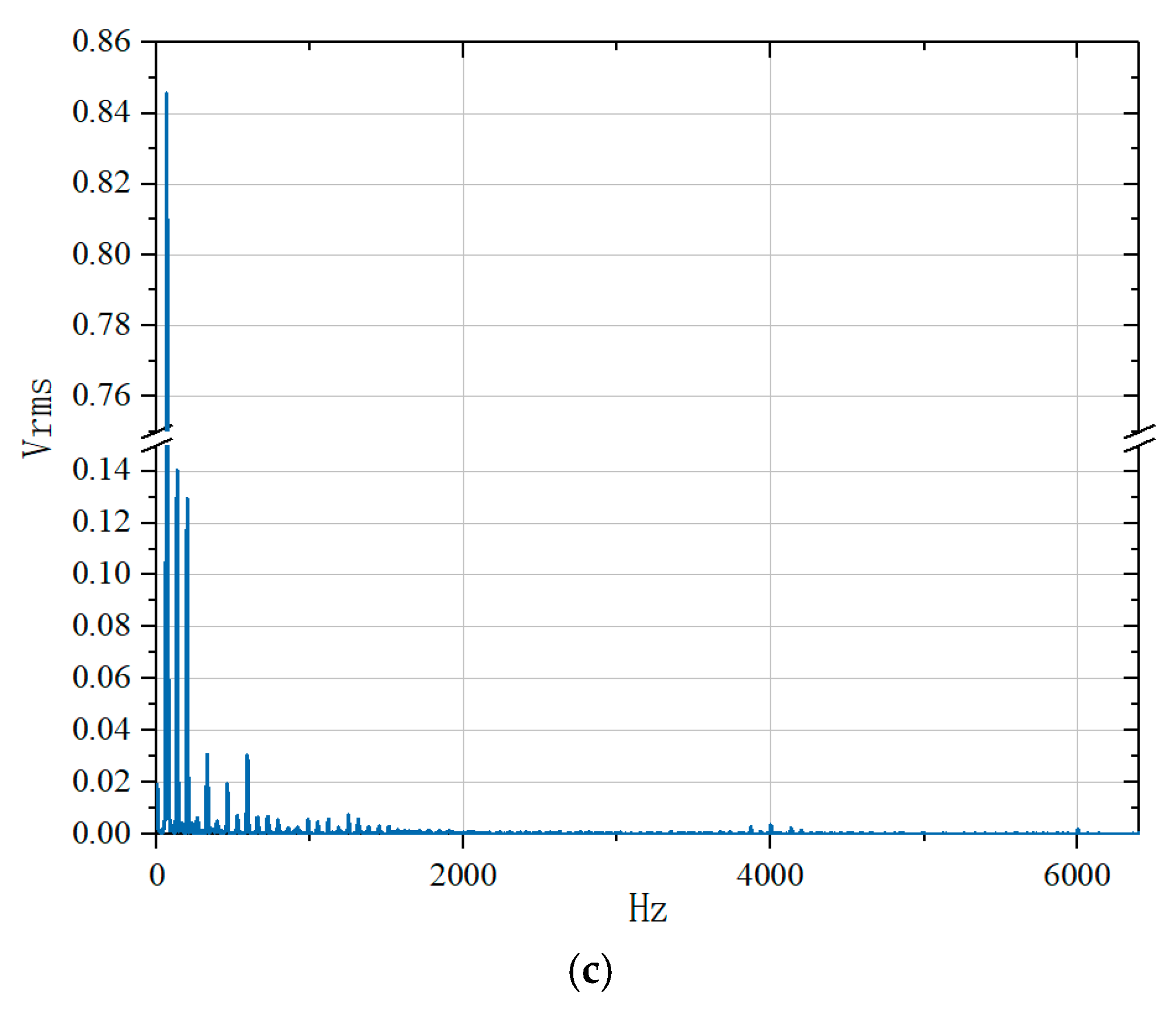

3.4. The Transverse Vibration of Circular Saw Blade When Sawing

3.5. The Establishment of Mathematical Models

4. Conclusions

- (1)

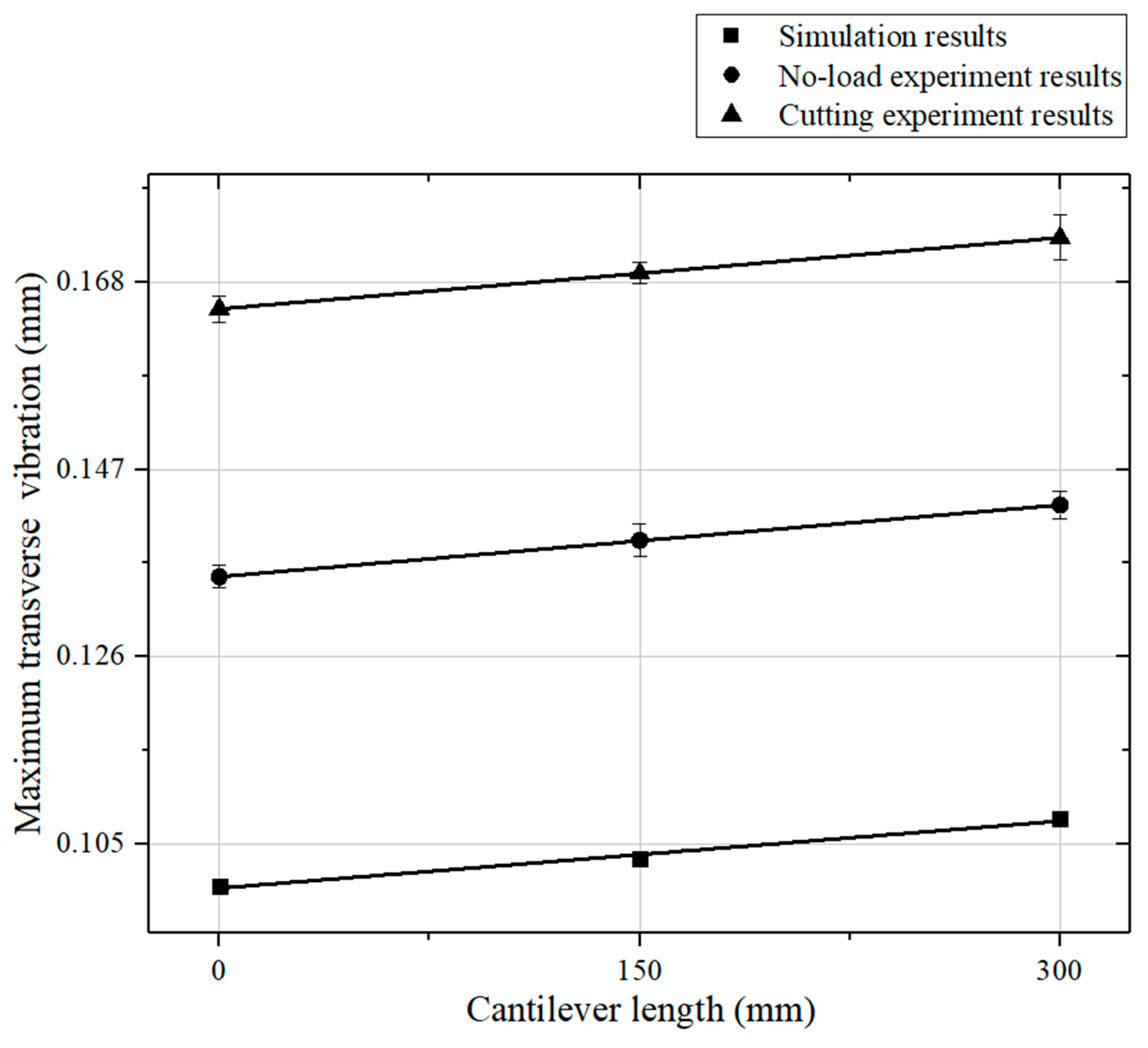

- The maximum amplitude of the transverse vibration of the circular saw blade was augmented with the increase in cantilever length in the simulation, no-load, and actual cutting.

- (2)

- The transverse vibration of the circular saw blade was gradually increased from the center to the outer edge along with the radius direction when the overhang length was kept constant, and the transverse vibration of the circular saw blade was the smallest at the place clamped with the flange. The maximum transverse vibration value of the circular saw blade is increased from 0.061 mm to 0.154 mm when the detecting point changes from 45 mm to 95 mm.

- (3)

- The transverse amplitudes of the circular saw blade were 0.165, 0.169, and 0.173 mm, respectively, corresponding to the overhang length of 0, 150, and 300mm during wood sawing, indicating the transverse vibration was hardly changed within 300 mm of overhang length.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yao, T.; Duan, G.L.; Cai, J. Review of vibration characteristics and noise reduction technique of circular saws. J. Vib. Shock. 2008, 27, 162–166. [Google Scholar]

- Nasir, V.; Cool, J. A review on wood machining: Characterization, optimization, and monitoring of the sawing process. Wood Mater. Sci. Eng. 2018, 15, 1–16. [Google Scholar] [CrossRef]

- Kopecký, Z.; Svoreň, J.; Peršin, M.; Rousek, M.; Klepárník, J. Circular saw blades vibrations effect on parameters of a cutting process. In Proceedings of the 2nd International Scientific Conference on Woodworking Technique, Zalesina, Croatia, 11–15 September 2007; pp. 267–276. [Google Scholar]

- Yuan, M.H.; Tong, S.G.; Cai, Q.; Tang, N. Dynamics study and damping optimization of circular saw based on numerical simulation and experimental analysis. In Proceedings of the 3rd International Conference on Engineering Design and Optimization (ICEDO 2012), Shaoxing, China, 25–27 May 2012; pp. 364–369. [Google Scholar]

- Chen, Y.; Wang, X.G.; Sun, C.; Devine, F.; De Silva, C.W. Active vibration control with state feedback in woodcutting. J. Vib. Control 2003, 9, 645–664. [Google Scholar] [CrossRef]

- Stevenson, D.; Gray, W.; Hoong, K.; Speller, M. Quietening circular saws by reducing blade vibration. Noise Control Eng. J. 1989, 33, 33–37. [Google Scholar] [CrossRef]

- Wang, X.; Xi, F.J.; Li, D.; Qin, Z. Estimation and control of vibrations of circular saws. In Proceedings of the 1999 IEEE International Conference on Control Applications (Cat No 99CH36328), Kohala Coast, HI, USA, 22–27 August 1999; pp. 514–520. [Google Scholar]

- Li, L.; Xi, B.T.; Yang, Y.F. The developments in the vibration, dynamic stability and control research of circular saw-the analysis on vibration and dynamic stability of cicular saw. China J. Woodwork. Mach. 2002, 2, 5–10. [Google Scholar]

- Hlaskova, L.; Kopecky, Z.; Vesely, P.; Svoboda, E.; Kowalski, M. Resonance stages of circular saw-blades with irregular tooth pitch and kerf quality. In Proceedings of the 8th International Science Conference on Chip and Chipless Woodworking Processes, Zvolen, Slovakia, 6–8 September 2012; pp. 125–130. [Google Scholar]

- Guo, X.L.; Cao, P.X.; Wang, H.L. Mechanism of the noise generation of a circular saw blade and technique for noise reduction. China J. For. Grassl. Mach. 2006, 2, 48–52. [Google Scholar]

- Nasir, V.; Mohammadpanah, A.; Cool, J. The effect of rotation speed on the power consumption and cutting accuracy of guided circular saw: Experimental measurement and analysis of saw critical and flutter speeds. Wood Mater. Sci. Eng. 2020, 15, 140–146. [Google Scholar] [CrossRef]

- Svoren, J.; Nascak, L.; Barcik, S.; Koleda, P.; Stehlik, S. Influence of Circular Saw Blade Design on Reducing Energy Consumption of a Circular Saw in the Cutting Process. Appl. Sci. 2022, 12, 1276. [Google Scholar] [CrossRef]

- Orlowski, K.; Sandak, J.; Tanaka, C. The critical rotational speed of circular saw: Simple measurement method and its practical implementations. J. Wood Sci. 2007, 53, 388–393. [Google Scholar] [CrossRef]

- Ukvalbergiene, K.; Vobolis, J. Experimental studies of wood circular saw forms. Wood Res. 2005, 50, 47–58. [Google Scholar]

- Xinpei, X.; Chengyong, W.; Jiayan, C.; Yasen, W. Effect of roll tensioning and clamping ratio on natural frequency of circular saw blade for wood cutting process. In Proceedings of the 13th International Conference on Tools (ICT 2012), Miskolc, Hungary, 27–28 March 2012; pp. 89–94. [Google Scholar]

- Schajer, G. Simple formulas for natural frequencies and critical speeds of circular saws. For. Prod. J. 1986, 36, 36–43. [Google Scholar]

- Dugdale, D.S. Stiffness of a spinning disc clamped at its center. J. Mech. Phys. Solids 1966, 14, 349–356. [Google Scholar] [CrossRef]

- Marui, E.; Ema, S.; Miyachi, R. An experimental investigation of circular saw vibration via a thin plate model. Int. J. Mach. Tools Manuf. 1994, 34, 893–905. [Google Scholar] [CrossRef]

- Cheng, W.; Yokochi, H.; Kimura, S.; Mano, K. Dynamic characteristics of circular saws in the region of the critical rotation speed. Mokuzai Gakkaishi 2000, 46, 311–319. [Google Scholar]

- Raman, A.; Mote, C.D. Remarks on the non-linear vibration of an axisymmetric circular disk near critical speed. Int. J. Non-Linear Mech. 2002, 37, 35–41. [Google Scholar] [CrossRef]

- Baddour, N.; Zu, J.W. A revisit of spinning disk models. Part I: Derivation of equations of motion. Appl. Math. Model. 2001, 25, 541–559. [Google Scholar] [CrossRef]

- Baddour, N.; Zu, J.W. A revisit of spinning disk models. Part II: Linear transverse vibration. Appl. Math. Model. 2001, 25, 561–578. [Google Scholar] [CrossRef]

- Pahlitzsch, G.; Rowinski, B. Über das Schwingungsverhalten von Kreissägeblättern—Zweite Mitteilung: Ermittlung und Auswirkungen der kritischen Drehzahlen und Eigenfrequenzen der Sägeblätter. Eur. J. Wood Wood Prod. 1966, 24, 341–346. [Google Scholar] [CrossRef]

- Tobias, S.; Arnold, R. The influence of dynamical imperfection on the vibration of rotating disks. Proc. Inst. Mech. Eng. 1957, 171, 669–690. [Google Scholar] [CrossRef]

- Leu, M.; Mote, C. Origin of idling noise in circular saws and its suppression. Wood Sci. Technol. 1984, 18, 33–49. [Google Scholar] [CrossRef]

- Nishio, S.; Marui, E. Effects of slots on the lateral vibration of a circular saw blade. Int. J. Mach. Tools Manuf. 1996, 36, 771–787. [Google Scholar] [CrossRef]

- Yu, R.-C.; Mote, C.D. Vibration of circular saws containing slots. Holz Roh Werkst. 1987, 45, 155–160. [Google Scholar] [CrossRef]

- Wang, Y.K.; Mote, C.D., Jr. Analysis of an arbitrary shaped guide bearing subject to normal oscillation and translation of a plate. Wear 1996, 198, 115–121. [Google Scholar] [CrossRef]

- Tian, J.F.; Hutton, S.G. Cutting-induced vibration in circular saws. J. Sound Vib. 2001, 242, 907–922. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, G.; Qi, Y.; Chen, S.; Zhang, Z. Research Survey of Dynamic Performance of Woodworking Circular Disk Saw. China J. For. Mach. Woodwork. Equip. 2000, 1, 4–9. [Google Scholar]

- Liu, X. Dynamic Study of Rotor System in Woodworking Circular Saw Machine. Ph.D. Thesis, Beijing Forestry University, Beijing, China, 2008. [Google Scholar]

- Vesel, P.; Kopeck, Z.; Hejmal, Z.; Pokorn, P. Diagnostics of Circular Sawblade Vibration by Displacement Sensors. Drv. Ind. 2012, 63, 81–86. [Google Scholar] [CrossRef]

- Droba, A.; Javorek, Ľ.; Svoreň, J.; Paulíny, D. New design of circular saw blade body and its influence on critical rotational speed. Drewno 2015, 58, 147–158. [Google Scholar]

- Kaczmarek, A.; Orlowski, K.; Javorek, L. A brief review and comparison of selected experimental methods for measuring natural frequencies of circular saw blades. Drewno 2016, 59, 197. [Google Scholar]

- Munz, U. Vibration behavior and residual manufacturing stresses of circular sawblades. In Proceedings of the 17th International Wood Machining Seminar, Rosenheim, Germany, 26–28 September 2005. [Google Scholar]

- Ma, G.; Xu, M.; An, Z.; Wu, C.; Miao, W. Active vibration control of an axially moving cantilever structure using MFC. Int. J. Appl. Electromagn. Mech. 2016, 52, 967–974. [Google Scholar] [CrossRef]

- Mote, C.D., Jr. Stability of circular plates subjected to moving loads. J. Frankl. Inst. 1970, 290, 329–344. [Google Scholar] [CrossRef]

- Yao, T. Mechanism Study on Vibration and Noise Reduction of Circular Saw with Slots. Ph.D. Thesis, Hebei University of Technology, Hebei, China, 2009. [Google Scholar]

- Cheng, W.; Yokochi, H.; Kimura, S. Aerodynamic sound and self-excited vibration of circular saw with step thickness I: Comparison of dynamic characteristics between the common circular saw and the circular saw with step thickness. J. Wood Sci. 1998, 44, 177–185. [Google Scholar] [CrossRef]

| No-Load Experiment | Sawing Experiment | ||

|---|---|---|---|

| Experiment Procedure | A | B | C |

| Overhanging length of circular saw blade (mm) | 0 | 150 | 0 |

| 150 | 150 | ||

| 300 | 300 | ||

| Circular saw blade diameter (mm) | 254 | 254 | 254 |

| The number of teeth | 60 | 60 | 60 |

| Flange diameter (mm) | 50 | 50 | 50 |

| Clamping ratio | 0.197 | 0.197 | 0.197 |

| Circular saw blade rotation speed (rad/min) | 4000 | 4000 | 4000 |

| Saw blade frequency (Hz) | 66.7 | 66.7 | 66.7 |

| Cutting speed (m/s) | 53 | 53 | 53 |

| Distance from the center of the circular saw blade to the detecting point (mm) | 70 | 45 | 95 |

| 70 | |||

| 95 | |||

| The distance of the probe from the side of the circular saw blade (mm) | 1 | 1 | 1 |

| Feed speed (m/min) | 0 | 0 | 3 |

| Cutting depth (mm) | 10 | ||

| Sawing direction | Parallel to Y-axis and with the texture direction of the wood | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Cui, Y.; Qiu, H.; Ding, T.; Zhu, N.; Wang, B. The Transverse Vibration Characteristics of Circular Saw Blade on Mobile Cantilever-Type CNC Sawing Machine. Machines 2023, 11, 549. https://doi.org/10.3390/machines11050549

Yan X, Cui Y, Qiu H, Ding T, Zhu N, Wang B. The Transverse Vibration Characteristics of Circular Saw Blade on Mobile Cantilever-Type CNC Sawing Machine. Machines. 2023; 11(5):549. https://doi.org/10.3390/machines11050549

Chicago/Turabian StyleYan, Xinyu, Yunqi Cui, Hongru Qiu, Tao Ding, Nanfeng Zhu, and Baojin Wang. 2023. "The Transverse Vibration Characteristics of Circular Saw Blade on Mobile Cantilever-Type CNC Sawing Machine" Machines 11, no. 5: 549. https://doi.org/10.3390/machines11050549

APA StyleYan, X., Cui, Y., Qiu, H., Ding, T., Zhu, N., & Wang, B. (2023). The Transverse Vibration Characteristics of Circular Saw Blade on Mobile Cantilever-Type CNC Sawing Machine. Machines, 11(5), 549. https://doi.org/10.3390/machines11050549