Quasi-Zero Stiffness Isolator Suitable for Low-Frequency Vibration

Abstract

1. Introduction

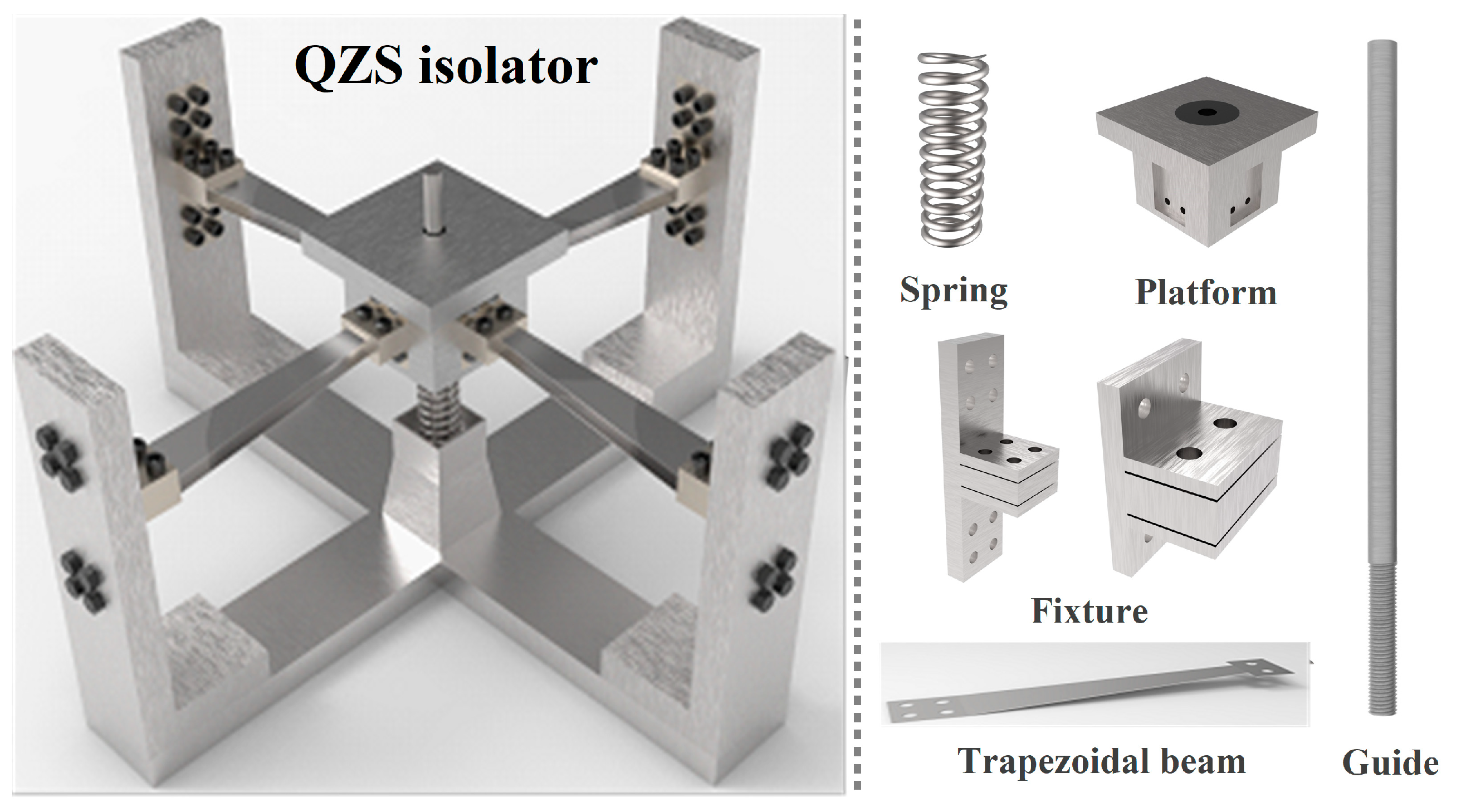

2. Working Principle of QZS Isolator

2.1. Structural Design

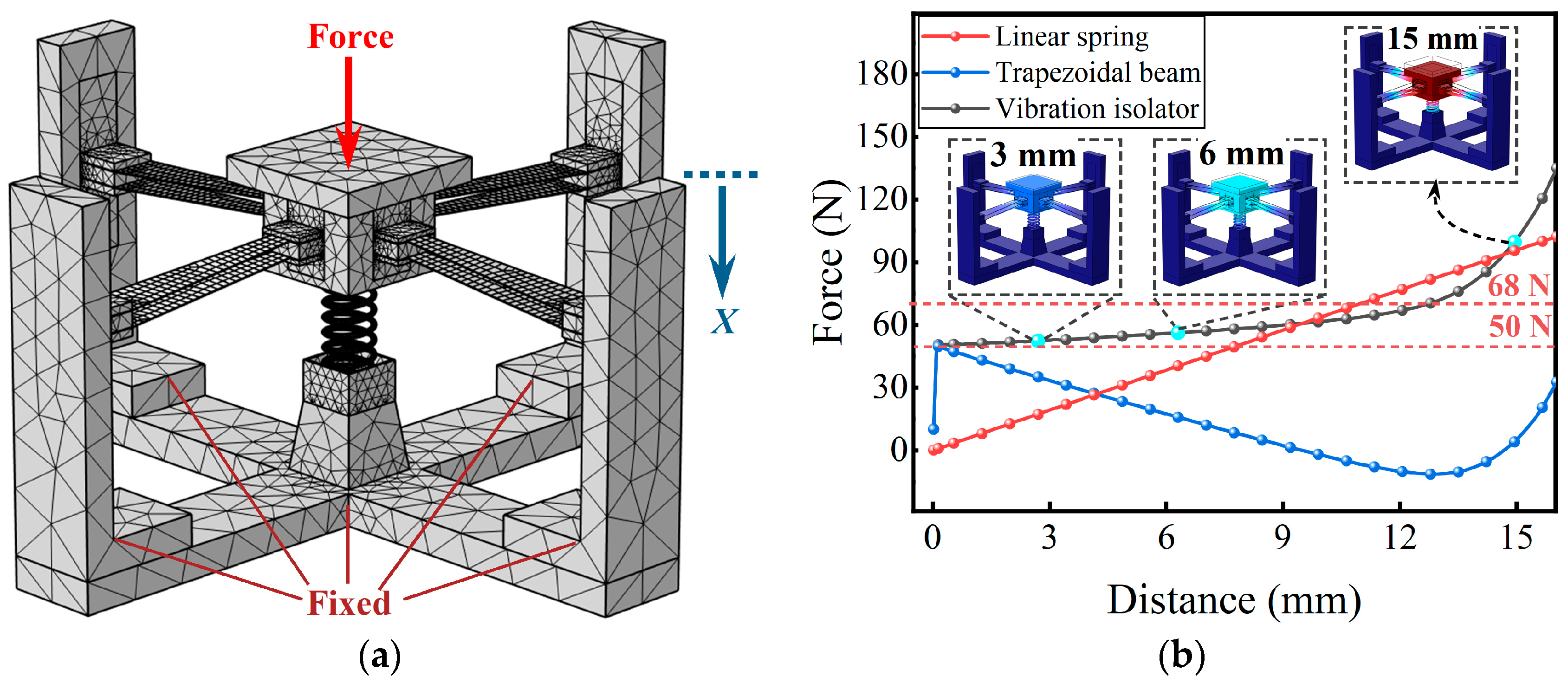

2.2. Static Analysis

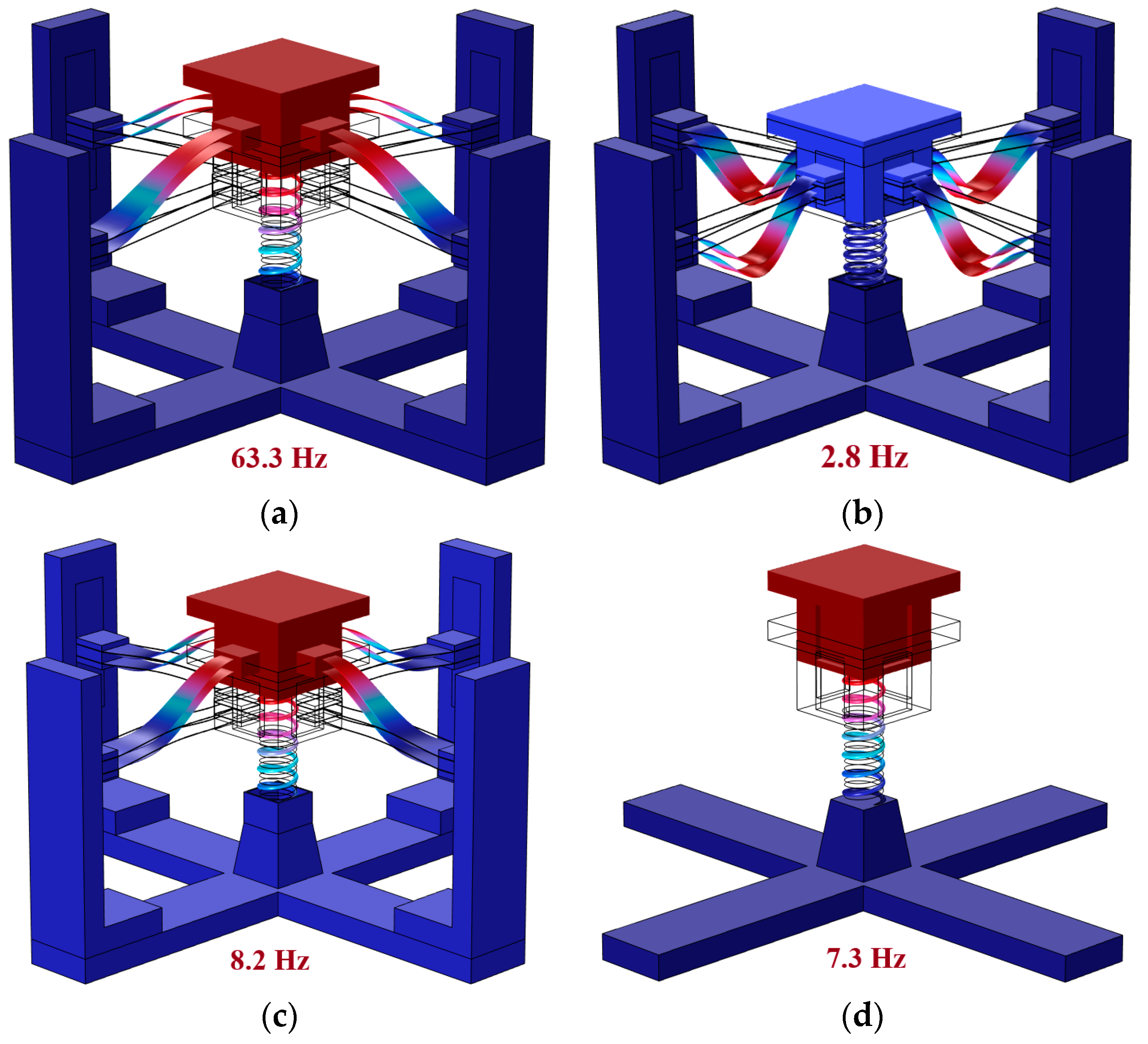

3. Dynamics Analysis

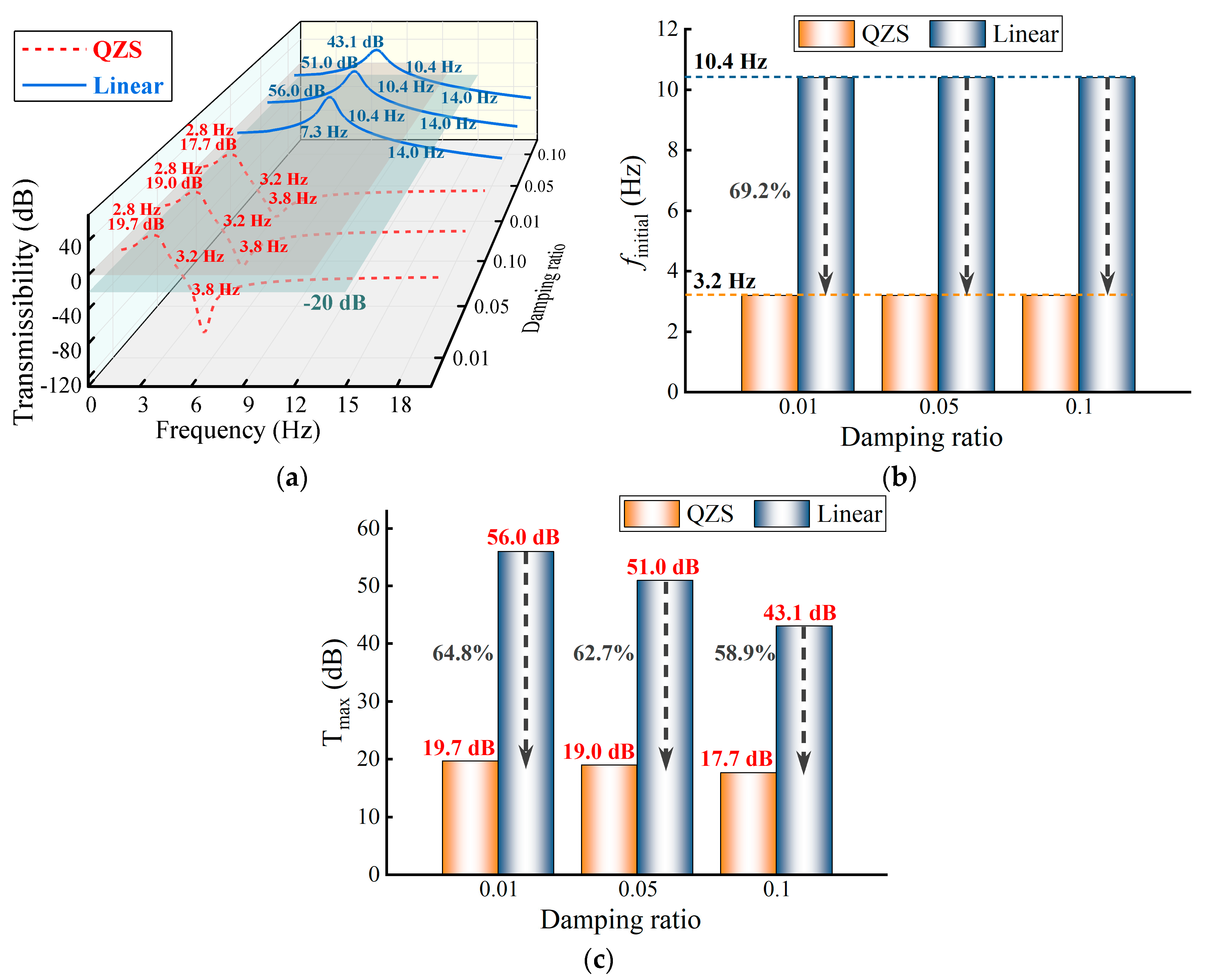

3.1. Effects of the Damping

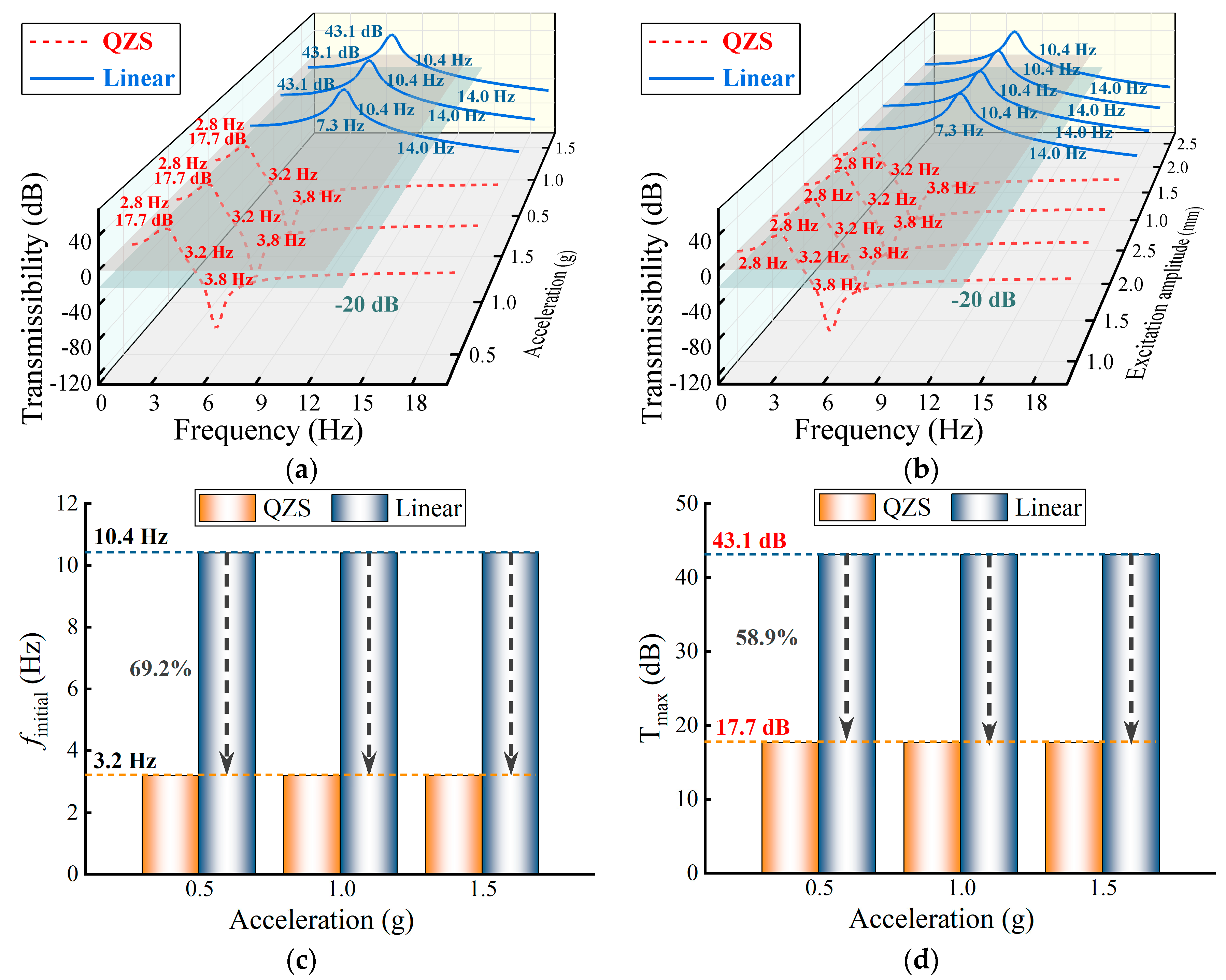

3.2. Effects of the Acceleration and Amplitude

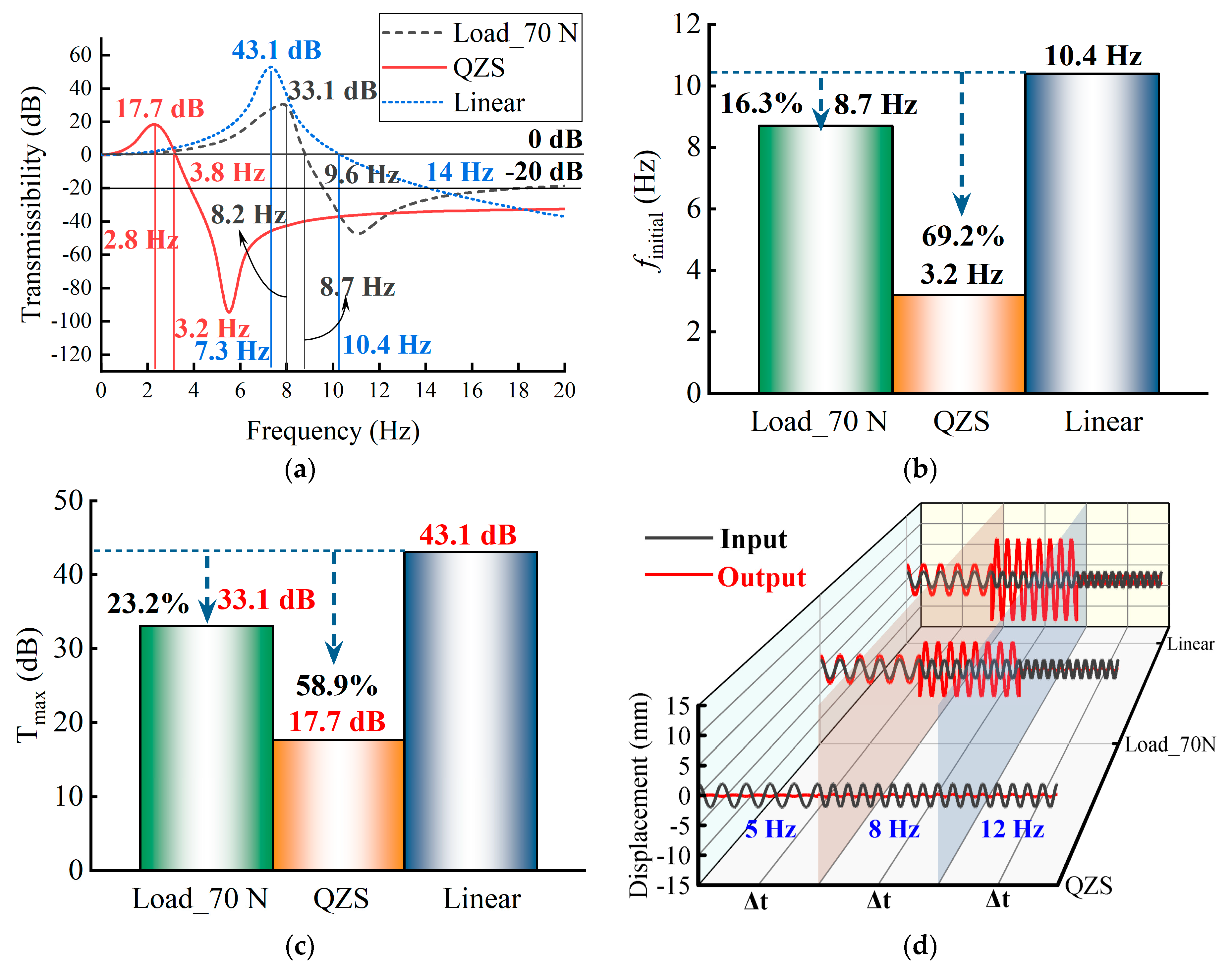

3.3. Effects of the Load

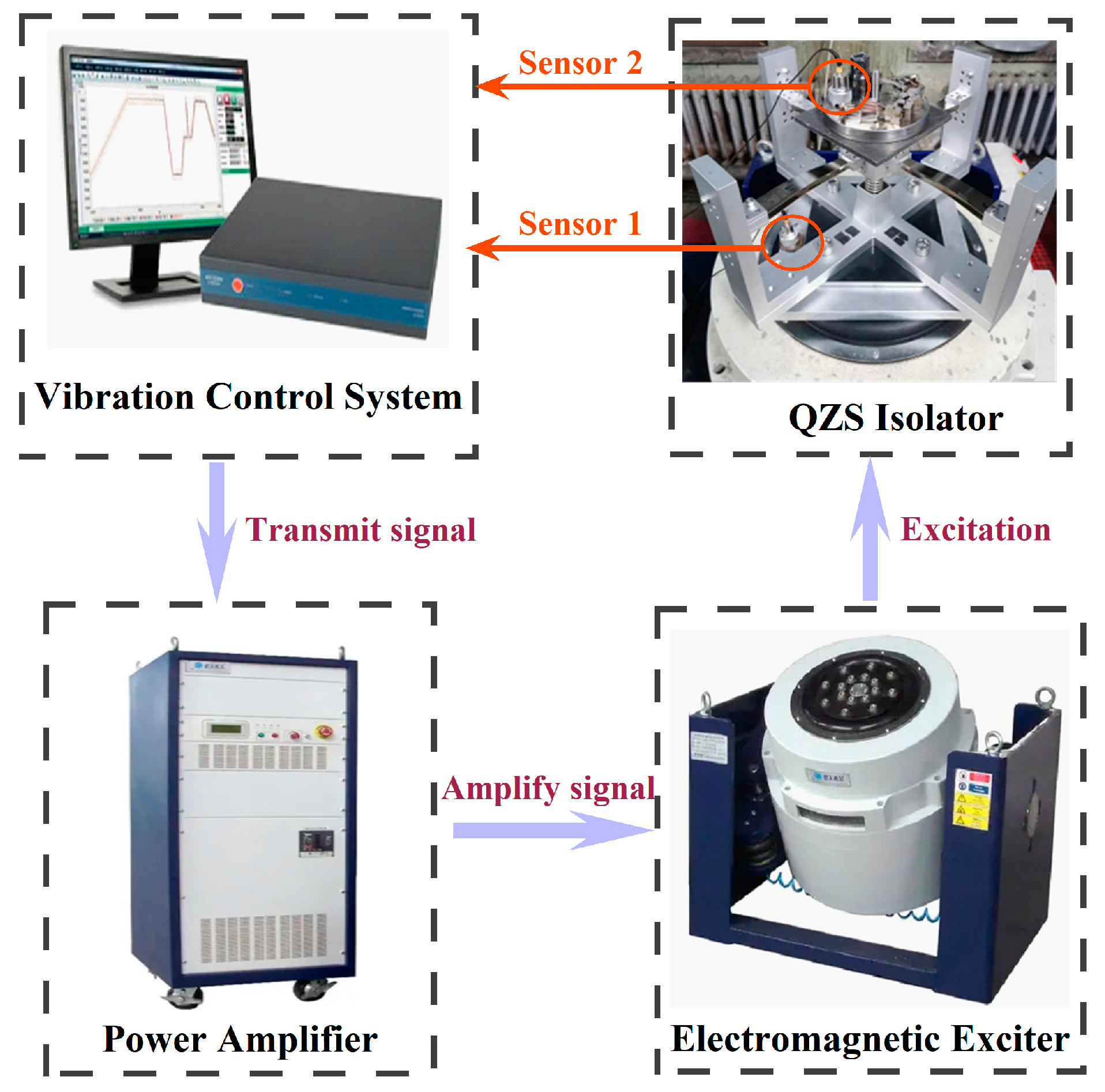

4. Experimental Results and Discussion

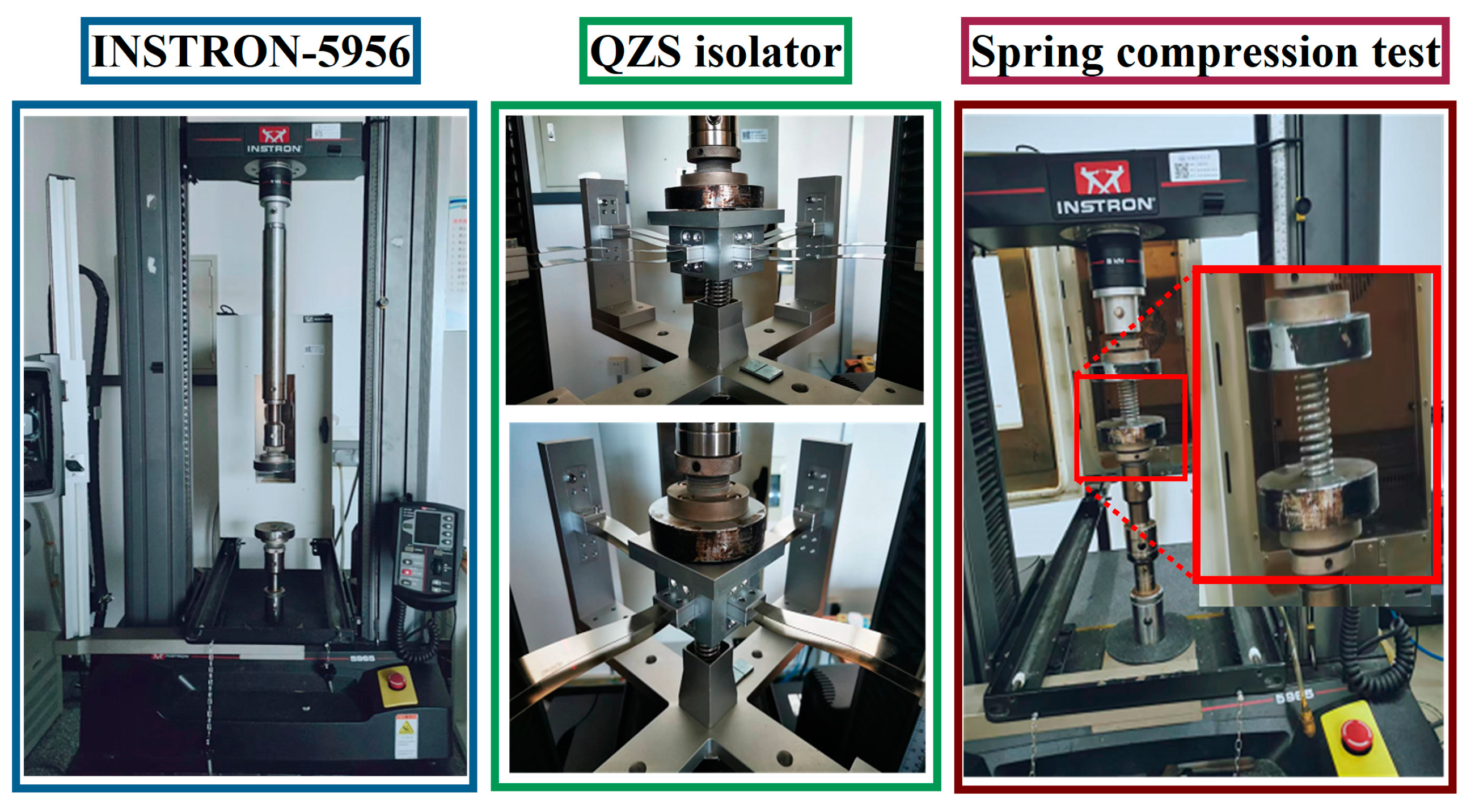

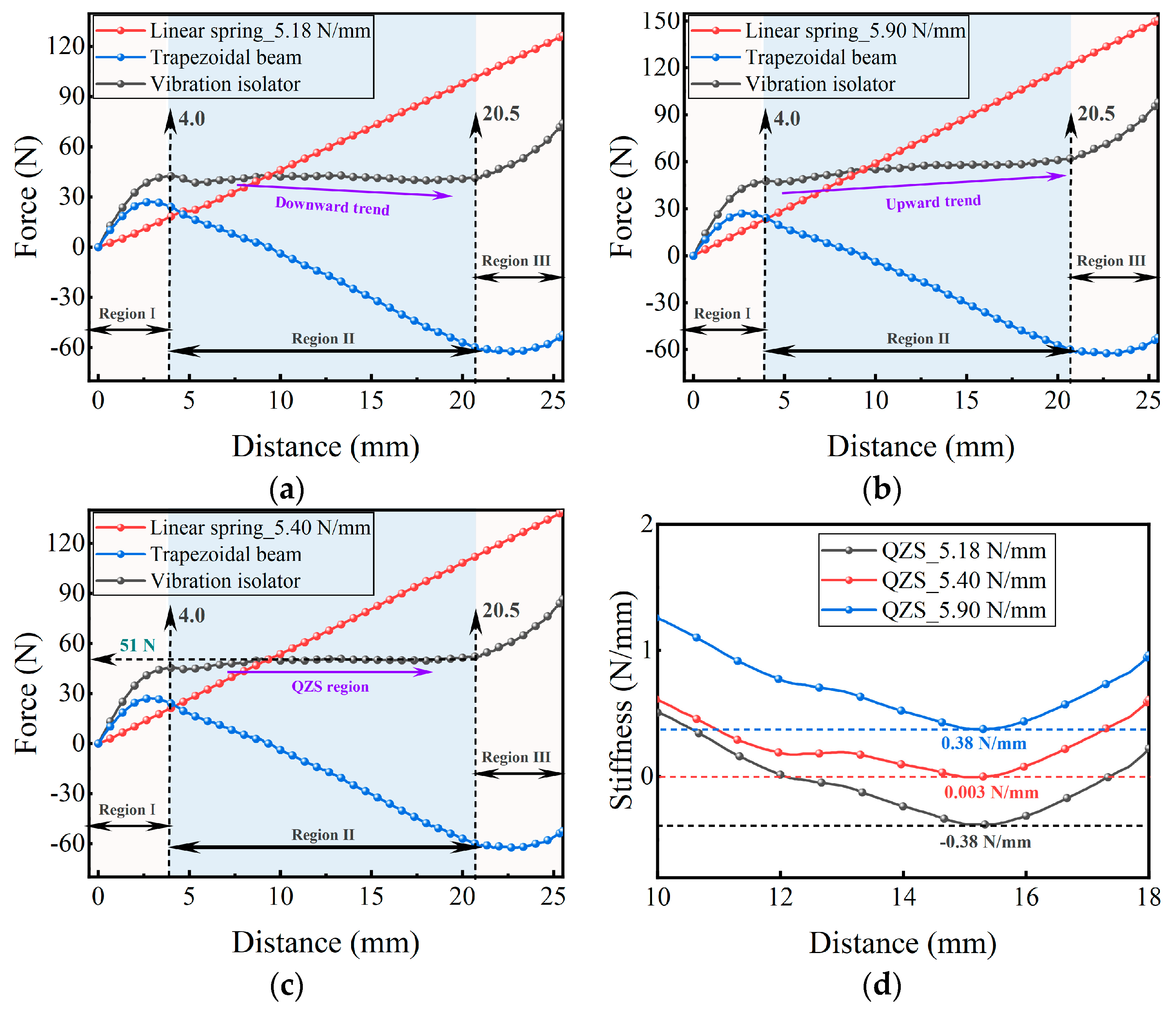

4.1. Static Experiment

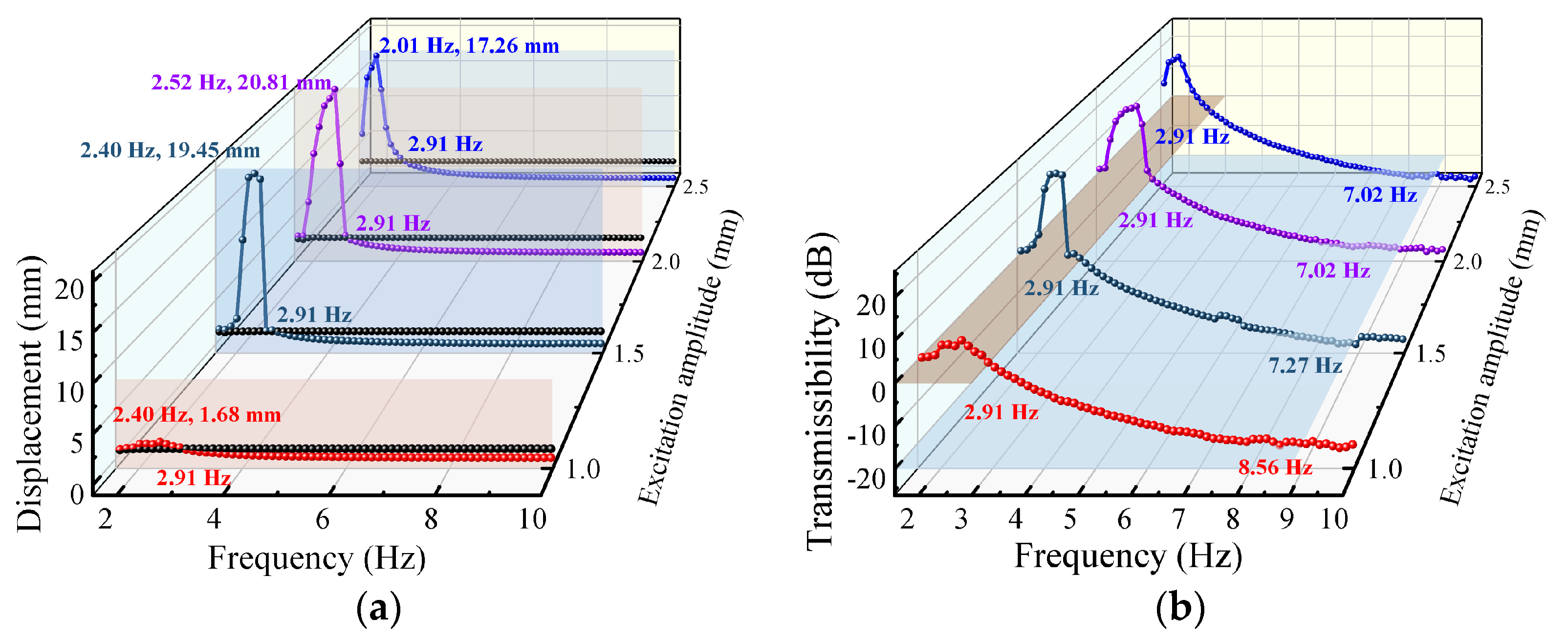

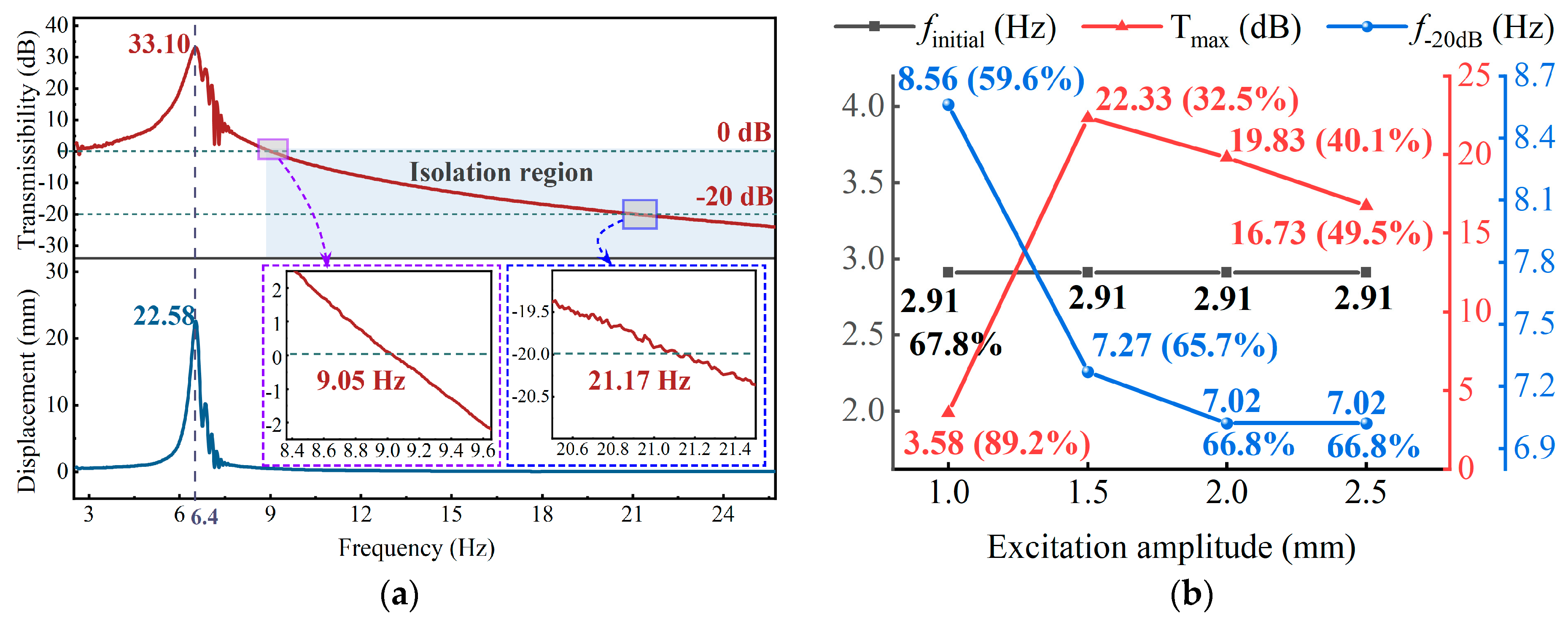

4.2. Dynamic Experiment

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Erfani, A.; Ghandehariun, A.; Afsharfard, A. Experimental investigation and optimization of low-frequency vibration-assisted drilling. Int. J. Adv. Manuf. Technol. 2022, 123, 3171–3182. [Google Scholar] [CrossRef]

- Xin, S.; Peng, F.; Tang, X.; Yan, R.; Li, Z.; Wu, J. Research on the influence of robot structural mode on regenerative chatter in milling and analysis of stability boundary improvement domain. Int. J. Mach. Tools Manuf. 2022, 179, 103918. [Google Scholar] [CrossRef]

- Lian, X.; Deng, H.; Han, G.; Jiang, F.; Zhu, L.; Shao, M.; Liu, X.; Hu, R.; Gao, Y.; Ma, M.; et al. A low-frequency micro-vibration absorber based on a designable quasi-zero stiffness beam. Aerosp. Sci. Technol. 2023, 132, 108044. [Google Scholar] [CrossRef]

- Li, Q.; Du, Z.; Liu, F.; Yu, H. Tactile Perception for Surgical Status Recognition in Robot-Assisted Laminectomy. IEEE Trans. Ind. Electron. 2022, 69, 11425–11435. [Google Scholar] [CrossRef]

- Ding, Y.; Rui, X.; Chen, Y.; Lu, H.; Chang, Y.; Wei, W. Theoretical and experimental investigation on the surface stripes formation in ultra-precision fly cutting machining. Int. J. Adv. Manuf. Technol. 2023, 124, 1041–1063. [Google Scholar] [CrossRef]

- Li, J.-Y.; Zhu, S. Self-Powered Active Vibration Control: Concept, Modeling, and Testing. Engineering 2022, 11, 126–137. [Google Scholar] [CrossRef]

- Liu, X.; Lv, L.; Peng, F.; Cai, G. Wave-based active vibration control of a membrane structure. J. Vib. Control 2023, 29, 118–130. [Google Scholar] [CrossRef]

- Xu, J.; Zhou, W.; Jing, J. An electromagnetic torsion active vibration absorber based on the FxLMS algorithm. J. Sound Vibr. 2022, 524, 116734. [Google Scholar] [CrossRef]

- Abe, M.; Hara, Y.; Otsuka, K.; Makihara, K. Semi-active switching vibration control with tree-based prediction and optimization strategy. J. Intell. Mater. Syst. Struct. 2023, 34, 440–460. [Google Scholar] [CrossRef]

- Takamoto, I.; Abe, M.; Hara, Y.; Otsuka, K.; Makihara, K. Comprehensive predictive control for vibration suppression based on piecewise constant input formulation. J. Intell. Mater. Syst. Struct. 2022, 33, 901–917. [Google Scholar] [CrossRef]

- Zheng, S.; Shen, Q.; Guan, C.; Cheng, H.; Zhuang, H.; Zhou, M. Semi-Active Control of Seismic Response on Prestressed Concrete Continuous Girder Bridges with Corrugated Steel Webs. Appl. Sci. Basel 2022, 12, 12881. [Google Scholar] [CrossRef]

- Feng, X.; Jing, X.; Guo, Y. Vibration isolation with passive linkage mechanisms. Nonlinear Dyn. 2021, 106, 1891–1927. [Google Scholar] [CrossRef]

- Ikeda, Y.; Matsumoto, Y. Unified description of passive vibration control for buildings based on pole allocation applied to three-degree-of-freedom model. Struct. Control. Health Monit. 2022, 29, e2995. [Google Scholar] [CrossRef]

- Jiang, G.; Wang, Y.; Li, F.; Jing, X. An integrated nonlinear passive vibration control system and its vibration reduction properties. J. Sound Vibr. 2021, 509, 116231. [Google Scholar] [CrossRef]

- Al Rifaie, M.; Abdulhadi, H.; Mian, A. Advances in mechanical metamaterials for vibration isolation: A review. Adv. Mech. Eng. 2022, 14, 16878132221082872. [Google Scholar] [CrossRef]

- Gong, W.; Li, A.; Huang, C.; Che, H.; Feng, C.; Qin, F. Effects and Prospects of the Vibration Isolation Methods for an Atomic Interference Gravimeter. Sensors 2022, 22, 583. [Google Scholar] [CrossRef]

- Chong, X.; Wu, Z.; Li, F. Vibration isolation properties of the nonlinear X-combined structure with a high-static and low-dynamic stiffness: Theory and experiment. Mech. Syst. Signal Proc. 2022, 179, 109352. [Google Scholar] [CrossRef]

- Su, P.; Jun, C.; Liu, S.; Wu, J. Design and Analysis of a Vibration Isolator with Adjustable High Static-Low Dynamic Stiffness. Iran J. Sci. Technol. Trans. Mech. Eng. 2022, 46, 1195–1207. [Google Scholar] [CrossRef]

- Wang, X.; Yu, N.; Wu, C.; Zhang, W.; Yan, B. Lever-type high-static-low-dynamic-stiffness vibration isolator with electromagnetic shunt damping. Int. J. Non Linear Mech. 2022, 146, 104128. [Google Scholar] [CrossRef]

- Habegger, J.; Hassan, M.; Oliver, M. An Experimental Investigation of the Displacement Transmissibility for a Two-Stage HSLD Stiffness System. Vibration 2022, 5, 676–691. [Google Scholar] [CrossRef]

- van Dorsser, W.D.; Barents, R.; Wisse, B.M.; Schenk, M.; Herder, J.L. Energy-free adjustment of gravity equilibrators by adjusting the spring stiffness. Proc. Inst. Mech. Eng. Part C J. Eng. Mech. Eng. Sci. 2008, 222, 1839–1846. [Google Scholar] [CrossRef]

- Franco, J.A.; Gallego, J.A.; Herder, J.L. Static Balancing of Four-Bar Compliant Mechanisms With Torsion Springs by Exerting Negative Stiffness Using Linear Spring At the Instant Center of Rotation. J. Mech. Robot. 2021, 13, 031010. [Google Scholar] [CrossRef]

- Nguyen, V.L. Gravity Balancing of a Two-Degree-of-Freedom Parallel Robotic Platform With Variable Payloads. J. Mech. Des. 2023, 145, 024501. [Google Scholar] [CrossRef]

- Mottola, G.; Cocconcelli, M.; Rubini, R.; Carricato, M. Gravity Balancing of Parallel Robots by Constant-Force Generators. In Gravity Compensation in Robotics; Arakelian, V., Ed.; Springer International Publishing: Cham, Switzerland, 2022; pp. 229–273. [Google Scholar]

- Wang, P.; Xu, Q. Design and modeling of constant-force mechanisms: A survey. Mech. Mach. Theory 2018, 119, 1–21. [Google Scholar] [CrossRef]

- Ling, J.; Ye, T.; Feng, Z.; Zhu, Y.; Li, Y.; Xiao, X. A survey on synthesis of compliant constant force/torque mechanisms? Mech. Mach. Theory 2022, 176, 104970. [Google Scholar] [CrossRef]

- Tong, Z.; Zhang, X.; Wang, G. Automatic Optimization for Compliant Constant Force Mechanisms. Actuators 2023, 12, 61. [Google Scholar] [CrossRef]

- Zhang, Q.; Yan, P.; Wang, H. A curved-beam based quasi-constant force mechanism supporting large range and force-sensitive robotic manipulation. Mech. Mach. Theory 2022, 172, 104799. [Google Scholar] [CrossRef]

- Schenk, M.; Guest, S.D. On zero stiffness. Proc. Inst. Mech. Eng. Part C J. Eng. Mech. Eng. Sci. 2014, 228, 1701–1714. [Google Scholar] [CrossRef]

- Ma, Z.; Zhou, R.; Yang, Q. Recent Advances in Quasi-Zero Stiffness Vibration Isolation Systems: An Overview and Future Possibilities. Machines 2022, 10, 813. [Google Scholar] [CrossRef]

- Cai, C.; Zhou, J.; Wang, K.; Lin, Q.; Xu, D.; Wen, G. Quasi-zero-stiffness metamaterial pipe for low-frequency wave attenuation. Eng. Struct. 2023, 279, 115580. [Google Scholar] [CrossRef]

- Yan, G.; Zou, H.X.; Wang, S.; Zhao, L.C.; Gao, Q.H.; Tan, T.; Zhan, W.M. Large stroke quasi-zero stiffness vibration isolator using three-link mechanism. J. Sound Vibr. 2020, 478, 115344. [Google Scholar] [CrossRef]

- Zhang, Q.; Guo, D.; Hu, G. Tailored Mechanical Metamaterials with Programmable Quasi-Zero-Stiffness Features for Full-Band Vibration Isolation. Adv. Funct. Mater. 2021, 31, 2101428. [Google Scholar] [CrossRef]

- Yan, L.; Gong, X. Experimental Study of Vibration Isolation Characteristics of a Geometric Anti-Spring Isolator. Appl. Sci. Basel 2017, 7, 711. [Google Scholar] [CrossRef]

- Yan, L.; Xuan, S.; Gong, X. Shock isolation performance of a geometric anti-spring isolator. J. Sound Vibr. 2018, 413, 120–143. [Google Scholar] [CrossRef]

- Zhou, J.; Pan, H.; Cai, C.; Xu, D. Tunable ultralow frequency wave attenuations in one-dimensional quasi-zero-stiffness metamaterial. Int. J. Mech. Mater. Des. 2021, 17, 285–300. [Google Scholar] [CrossRef]

- Wang, D.W.; Zhang, Q.; Hu, G.K. Low Frequency Waterborne Sound Insulation Based on Sandwich Panels With Quasi-Zero-Stiffness Truss Core. J. Appl. Mech. Trans. ASME 2023, 90, 031006. [Google Scholar] [CrossRef]

- Yu, B.; Liu, H.; Fan, D.; Xie, X. Design of quasi-zero stiffness compliant shock isolator under strong shock excitation. Precis. Eng. J. Int. Soc. Precis. Eng. Nanotechnol. 2022, 78, 47–59. [Google Scholar] [CrossRef]

- Liu, C.; Yu, K. Design and experimental study of a quasi-zero-stiffness vibration isolator incorporating transverse groove springs. Arch. Civ. Mech. Eng. 2020, 20, 67. [Google Scholar] [CrossRef]

- Xu, D.; Zhang, Y.; Zhou, J.; Lou, J. On the analytical and experimental assessment of the performance of a quasi-zero-stiffness isolator. J. Vib. Control 2014, 20, 2314–2325. [Google Scholar] [CrossRef]

- Meng, H.; Huang, X.; Chen, Y.; Theodossiades, S.; Chronopoulos, D. Structural vibration absorption in multilayered sandwich structures using negative stiffness nonlinear oscillators. Appl. Acoust. 2021, 182, 108240. [Google Scholar] [CrossRef]

- Chondrogiannis, K.A.; Colombi, A.; Dertimanis, V.; Chatzi, E. Computational Verification and Experimental Validation of the Vibration-Attenuation Properties of a Geometrically Nonlinear Metamaterial Design. Phys. Rev. Appl. 2022, 17, 054023. [Google Scholar] [CrossRef]

- Zhao, Y.M.; Cui, J.N.; Zou, L.M. Genetic Optimization of Repulsive Magnetic Array Negative Stiffness Structure for High-Performance Precision Micro-vibration Isolation. J. Vib. Eng. Technol. 2022, 10, 1325–1336. [Google Scholar] [CrossRef]

- Wang, S.; Xin, W.; Ning, Y.; Li, B.; Hu, Y. Design, Experiment, and Improvement of a Quasi-Zero-Stiffness Vibration Isolation System. Appl. Sci. Basel 2020, 10, 2273. [Google Scholar] [CrossRef]

- Virk, K.; Monti, A.; Trehard, T.; Marsh, M.; Hazra, K.; Boba, K.; Remillat, C.D.L.; Scarpa, F.; Farrow, I.R. SILICOMB PEEK Kirigami cellular structures: Mechanical response and energy dissipation through zero and negative stiffness. Smart Mater. Struct. 2013, 22, 084014. [Google Scholar] [CrossRef]

- Carrella, A.; Brennan, M.J.; Waters, T.P. Static analysis of a passive vibration isolator with quasi-zero-stiffness characteristic. J. Sound Vibr. 2007, 301, 678–689. [Google Scholar] [CrossRef]

- Xie, Y.; Niu, F.; Sun, J.; Meng, L. Design and Analysis of a Novel Quasi-Zero Stiffness Isolator under Variable Loads. Math. Probl. Eng. 2022, 2022, 9082752. [Google Scholar] [CrossRef]

- Qi, W.H.; Yan, G.; Lu, J.J.; Yan, H.; Shi, J.W.; Wei, X.S.; Wang, S.; Zhang, W.M. Magnetically modulated sliding structure for low frequency vibration isolation. J. Sound Vibr. 2022, 526, 116819. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Q.H.; Lei, Y.G.; Cao, J.Y.; Liao, W.H. Halbach high negative stiffness isolator: Modeling and experiments. Mech. Syst. Signal Proc. 2023, 188, 110014. [Google Scholar] [CrossRef]

- Ye, K.; Ji, J.C.; Brown, T. Design of a quasi-zero stiffness isolation system for supporting different loads. J. Sound Vibr. 2020, 471, 115198. [Google Scholar] [CrossRef]

- Zheng, Y.W.; Shangguan, W.B.; Yin, Z.H.; Liu, X.A. Design and modeling of a quasi-zero stiffness isolator for different loads. Mech. Syst. Signal Proc. 2023, 188, 110017. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Xu, Z.D. Cylindrical metastructure simulating yielding with elastic deformation: Theoretical and experimental studies. Mater. Today Commun. 2022, 33, 104455. [Google Scholar] [CrossRef]

- Wang, D.X.; Zhao, J.L.; Ma, Q.; Zhou, G.; Zhang, D.Z.; Zhu, R. Uncertainty analysis of quasi-zero stiffness metastructure for vibration isolation performance. Front. Phys. 2022, 10, 957594. [Google Scholar] [CrossRef]

- Cai, C.Q.; Zhou, J.X.; Wu, L.C.; Wang, K.; Xu, D.L.; Ouyang, H.J. Design and numerical validation of quasi-zero-stiffness metamaterials for very low-frequency band gaps. Compos. Struct. 2020, 236, 111862. [Google Scholar] [CrossRef]

- Cortes, S.; Allison, J.; Morris, C.; Haberman, M.R.; Seepersad, C.C.; Kovar, D. Design, Manufacture, and Quasi-Static Testing of Metallic Negative Stiffness Structures within a Polymer Matrix. Exp. Mech. 2017, 57, 1183–1191. [Google Scholar] [CrossRef]

- Tan, X.; Wang, L.; Zhu, S.; Chen, S.; Wang, B.; Kadic, M. A general strategy for performance enhancement of negative stiffness mechanical metamaterials. Eur. J. Mech. A Solids 2022, 96, 104702. [Google Scholar] [CrossRef]

- Correa, D.M.; Klatt, T.; Cortes, S.; Haberman, M.; Kovar, D.; Seepersad, C. Negative stiffness honeycombs for recoverable shock isolation. Rapid Prototyp. J. 2015, 21, 193–200. [Google Scholar] [CrossRef]

- Zhao, J.; Jia, J.; He, X.; Wang, H. Post-buckling and snap-through behavior of inclined slender beams. J. Appl. Mech.-Trans. ASME 2008, 75, 041020. [Google Scholar] [CrossRef]

- Yan, G.; Wu, Z.Y.; Wei, X.S.; Wang, S.; Zou, H.X.; Zhao, L.C.; Qi, W.H.; Zhang, W.M. Nonlinear compensation method for quasi-zero stiffness vibration isolation. J. Sound Vibr. 2022, 523, 116743. [Google Scholar] [CrossRef]

- Liang, H.T.; Hao, G.B.; Olszewski, O.Z.; Pakrashi, V. Ultra-low wide bandwidth vibrational energy harvesting using a statically balanced compliant mechanism. Int. J. Mech. Sci. 2022, 219, 107130. [Google Scholar] [CrossRef]

- Xu, L.; Xiang, Z. Compliant quasi-zero stiffness device for vibration energy harvesting and isolation. Sens. Actuator A-Phys. 2022, 347, 113964. [Google Scholar] [CrossRef]

- Yu, H.; Gao, X. Modeling and Stiffness Properties for the Hydro-pneumatic Near-Zero Frequency Vibration Isolator with Piecewise Smooth Stiffness. J. Vib. Eng. Technol. 2022, 10, 527–539. [Google Scholar] [CrossRef]

| Parameters | Values | Units |

|---|---|---|

| Width | 30 and 15 | mm |

| Length | 130.35 | mm |

| Thickness | 0.5 | mm |

| Inclination angle | 4.2 | ° |

| Density | 7810 | kg/m3 |

| Young’s Modulus | 159.15 | GPa |

| Poisson’s Ratio | 0.3 | — |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sui, G.; Zhang, X.; Hou, S.; Shan, X.; Hou, W.; Li, J. Quasi-Zero Stiffness Isolator Suitable for Low-Frequency Vibration. Machines 2023, 11, 512. https://doi.org/10.3390/machines11050512

Sui G, Zhang X, Hou S, Shan X, Hou W, Li J. Quasi-Zero Stiffness Isolator Suitable for Low-Frequency Vibration. Machines. 2023; 11(5):512. https://doi.org/10.3390/machines11050512

Chicago/Turabian StyleSui, Guangdong, Xiaofan Zhang, Shuai Hou, Xiaobiao Shan, Weijie Hou, and Jianming Li. 2023. "Quasi-Zero Stiffness Isolator Suitable for Low-Frequency Vibration" Machines 11, no. 5: 512. https://doi.org/10.3390/machines11050512

APA StyleSui, G., Zhang, X., Hou, S., Shan, X., Hou, W., & Li, J. (2023). Quasi-Zero Stiffness Isolator Suitable for Low-Frequency Vibration. Machines, 11(5), 512. https://doi.org/10.3390/machines11050512