1. Introduction

The contact forces between the tires and the road are essential factors that affect the precise control of the vehicle [

1]. Without rapid driver response, sudden changes in road adhesion coefficient may compromise the safety of the vehicle. Therefore, for highly automated vehicles, accurate perception of environmental conditions is critical to vehicle safety and handling [

2]. The effectiveness of automatic control systems can be further improved by measuring or accurately estimating lateral, longitudinal, and vertical tire force. Direct measurement of three-directional tire forces is difficult and requires expensive sensors, and thus, an alternative to direct measurements is performing an estimation [

3].

The premise tire force estimation depends on the accurate estimation of the road adhesion coefficient [

4]. Accurate estimation of the road adhesion coefficient and wheel slip ratio also improves the control effect of the anti-lock braking system (ABS) [

5]. Huang [

6] combined an extended Kalman filter (EKF) with a finite memory filter to estimate the road adhesion coefficient. Gao [

7] also designed a nonlinear observer based on the vehicle dynamics and kinematics model. In [

8] the road adhesion coefficient during vehicle steering was estimated by using lateral acceleration and lateral displacement. Furthermore, Singh [

9] designed an observer to estimate the road adhesion coefficient based on longitudinal dynamics and the relationship between tire alignment torque and the road adhesion coefficient.

With the development of autonomous vehicles, new environmental sensors have been added to vehicles. Such sensors provide more information that can be used to estimate the road adhesion coefficient [

10]. For instance, Rajamani [

11] proposed three different algorithms that utilize engine torque, braking torque, and GPS measurement data to estimate the adhesion coefficient of each wheel. Also, a model-based solution that combined GPS signals with an EKF algorithm and internal navigation sensors to estimate the vehicle’s state parameters. However, measurement delays and noise are inevitable issues of GPS and vision systems [

12]. Wang [

13] constructed an improved Kalman filter based on vehicle dynamics and road surface constraints. Bevly [

14] also proposed a method to obtain road adhesion coefficient by direct measurement based on optical and GPS sensors. Nevertheless, using optical sensors in vehicles is challenged by their high cost and sensitivity to environmental conditions [

15]. Adaptive control by analyzing the tire model can also be used to identify road conditions or friction coefficients [

16].

Neural networks are shown to be very efficient in dealing with non-linear problems such as accurate estimation of the road adhesion coefficient estimation. Using neural networks to estimate the road adhesion coefficient can ensure real-time response without significantly increasing the vehicle production cost [

17]. The Extended Kalman filter method was also proposed to fuse the measurement data based on IDANFIS [

18]. Ribeiro [

19] designed a time delay neural network (TDNN) to deal with the estimation of the road adhesion coefficient through lateral tire force [

20]. The neural network can map the input feature space to the output space of multiple pattern classes; hence, it accurately identifies different road types. In [

21], the sideslip angles under the three road conditions were estimated by three independent regression networks. The correct output was then selected by the pattern recognition classifier. The depth neural network was also used to estimate the road adhesion coefficient and identify the road type [

22].

The stability and performance of the chassis are largely dependent on tire–road contact forces. The existing tire force measuring equipment is very expensive. The calibration of the tire models also requires extensive tests. Therefore, it is essential to develop efficient algorithms for estimating tire forces. The accuracy of tire forces estimation directly depends on the recognition accuracy of the road adhesion coefficient [

23]. Extended Kalman filter and observer were used to estimate tire force in [

24,

25], respectively. Rezaeian [

26] also estimated the longitudinal tire force and vertical tire force through two independent nonlinear observer modules. Further, Gustafsson [

27] proposed a method to estimate tire forces during normal driving using only the wheel slip. Using this method, the driver was provided with the maximum adhesion and notified if the road adhesion coefficient suddenly changed. Baffet [

28] also combined the vehicle and tire force models and further considered the change of road adhesion coefficient to establish an adaptive observer to estimate lateral tire force, vehicle sideslip angle, and road adhesion.

Neural networks have been widely used in data classification, soft sensing, and nonlinear system modeling [

29]. Luque [

30] developed a real-time algorithm using an extended Kalman filter and neural network technology to estimate the torque of tires and their forces. The limit of safe driving conditions was determined by identifying the maximum adhesion coefficient of the vehicle. Nevertheless, a large number of samples were generated in the process of real-time collection of sensors that might adversely affect modeling performance in terms of calculation time. Alternatively, the improved LM (Levenberg–Marquardt) algorithm only requires calculating the multiplication of Jacobian matrix row vectors. This greatly reduces the calculation time and storage space; hence, it is especially suitable for online modeling [

31]. Xie [

32] designed an improved second-order (ISO) algorithm for training radial basis function (RBF) networks, including the center, width, output weight, and input weight connected between the input and hidden layers. The least-square algorithm [

33] has also been used to construct an online self-organizing fuzzy neural network in which the neurons rules for growth and pruning depend on a preset radius. Wang [

34] also proposed a hierarchical self-organizing network structure method based on fuzzy reasoning and a polynomial neural network (PNN). In [

35] the error reduction rate and Kalman filter were used to build an online self-organizing fuzzy neural network model to solve the problems of overfitting in conventional fuzzy neural networks.

Modular design can improve the adaptability of vehicles in different scenes [

36]. Considering the cost and adaptability to working conditions, an integrated online estimation method, namely the Levenberg–Marquarelt Multi-Module and Self-Organizing Feedforward Neural Networks (LM-MMSOFNN) has been proposed, which can meet the accuracy requirements in different road surfaces and different speeds. This method is able to recognize the road type and observe the longitudinal, lateral, and vertical forces of each tire simultaneously. The main contributions of this paper are summarized as follows.

- (1)

A tire dynamic model based on LM-MMSOFNN was designed to replace the simplified model. The slip ratio, road type, and tire forces in each wheel were estimated independently. This was conducive to the accurate control of distributed drive vehicles.

- (2)

The improved LM, EKF, and MA algorithms and the increase or decrease of self-organizing neurons reduced the computational complexity and storage capacity.

- (3)

The road surface adhesion coefficient pattern recognizer selected the smallest error, which was helpful for the adhesion coefficient and the tire force estimation accuracy.

The rest of this paper is organized as follows.

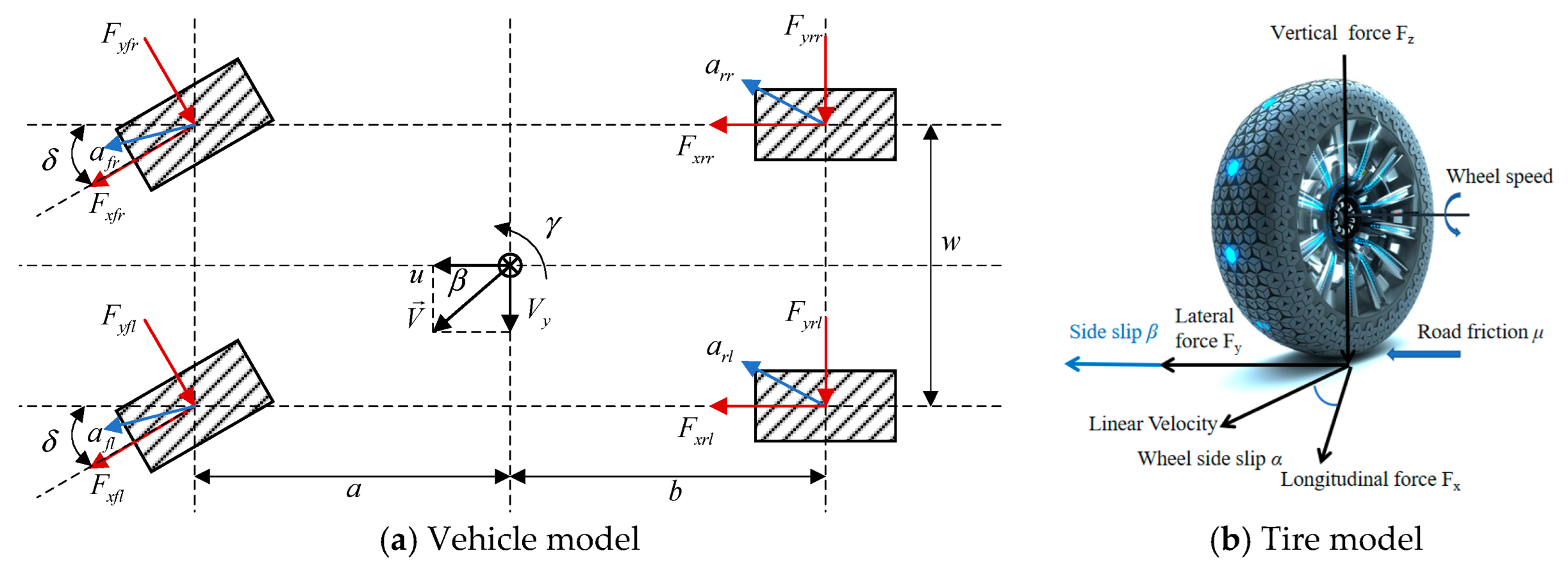

Section 2 presents the proposed vehicle model, tire model, and relevant parameters.

Section 3 presents the multi-module self-organizing neural network based on the improved LM learning algorithm. In addition, the structure of the road tire force integrated online estimation is described in detail.

Section 4 presents verification of the proposed method through simulations using Carsim and vehicle tests on dry asphalt roads. Finally, the conclusions are presented in

Section 5.

3. LM-MMSOFNN Algorithm for Identification of Three-Way Tire Forces

3.1. Self-Organizing Feedforward Neural Networks (SOFNN)

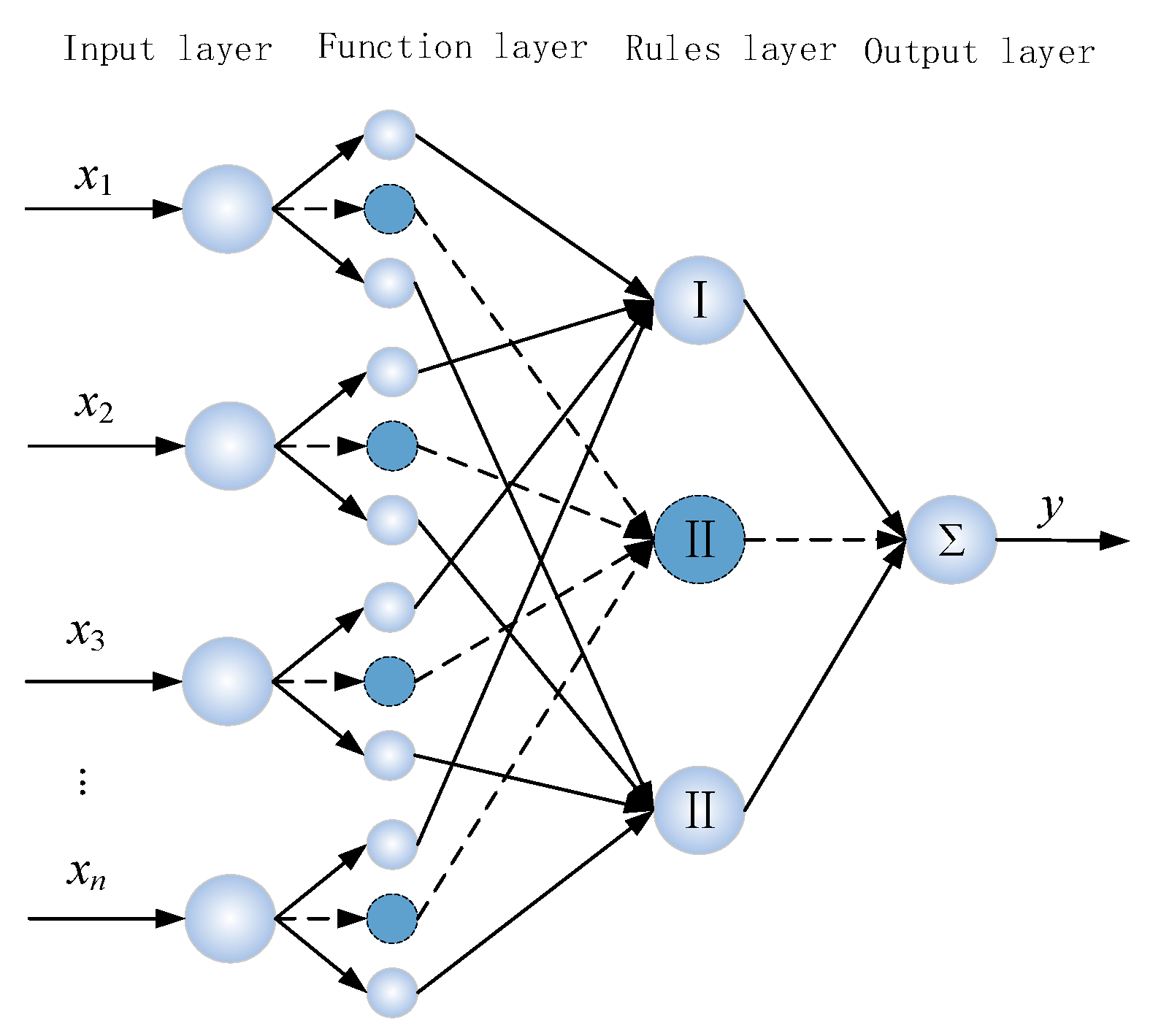

In order to meet the demands of online computing, the LM method was selected to improve the computing performance of self-organizing neural networks. The multi-module neural network can calculate the three-way tire force of four wheels at the same time, which also reduces the online running time of the system. The self-organizing neural network automatically finds the internal rules in the samples by adaptively changing the network structure parameters. Therefore, the self-organizing neural network has stronger adaptability to different road types and driving speeds, and higher estimation accuracy than other methods. This can not only preserve the topological mapping between the samples, but it can also reduce the dimension of input feature space and improve computational efficiency. Due to the excellent performance of self-organizing neural networks in classification and prediction, it has strong advantages in the field of road adhesion coefficient recognition and tire force estimation.

The road adhesion coefficient was calculated first, and then the tire forces of four tires were estimated using SOFNN. The self-organizing network structure was composed of a four-layer network composed of an input layer, a membership function layer, an adaptive rule layer, and an output layer (

Figure 6)

3.2. Improved LM Learning Algorithm

The parameters of a self-organizing neural network included the center,

, and width,

in the second layer, the weight matrix between the second and third layers,

, and the weight matrix between the third and fourth layers,

. In the learning of layer 2, for the online modeling of FNN, the expected target value was:

, and the output target value was

. A single sample was sent to the network for training, and the error

was:

where

indicates the sample number. The Jacobian matrix

was expressed as:

The gradient sub-vector

and sub-matrix

were obtained according to Equations (10) and (11).

It was seen that the improved LM algorithm only generated row vectors

, thus avoiding the multiplication of the Jacobian matrices in the algorithm. This reduced the storage space and improved the running speed. For all the training samples in the current sliding window, the gradient vector

and Hessian matrix

were calculated by cyclic accumulation:

The parameter update of the improved LM algorithm was based on:

where

. Finally, substituting (13) and (14) into (15) realized online learning of the parameters.

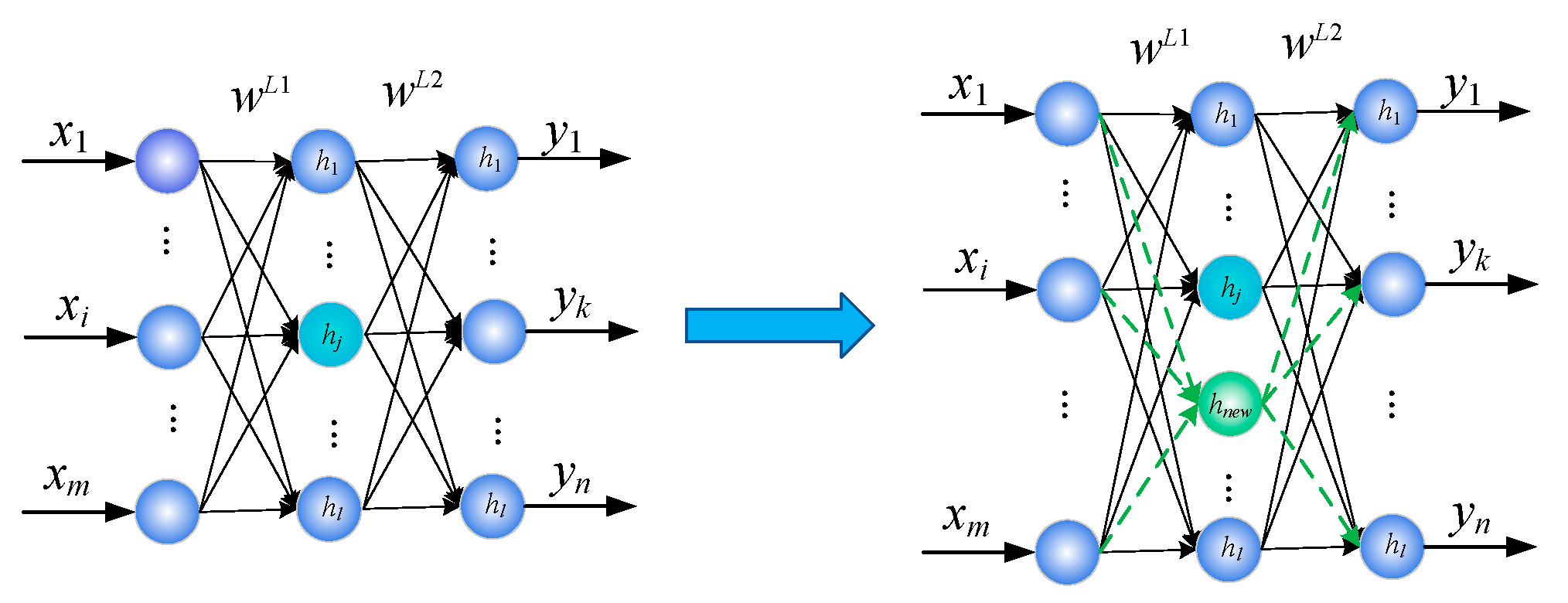

3.3. SOFNN Growth

The number of input and output neurons in SOFNN was determined by the training samples, while the number of hidden layer neurons had a great impact on the network structure. Having too many neurons might increase the complexity of the network, whereas fewer neurons might reduce the nonlinear fitting ability of the network [

40]. Therefore, the appropriate network structure was required to ensure the computational efficiency of the network while ensuring the required accuracy of tire force estimation. The growth process of the neurons of SOFNN is shown in

Figure 7.

In

Figure 7,

is the output neuron in the regular layer, and

T denotes the total number of learning samples. For a large number of samples or online learning,

T is obtained using a sliding window.

The neuron growth index with NGI for SOFNN was:

and

was the threshold for the adaptive growth of SOFNN neurons:

where

is the number of hidden neurons before growth,

is the upper bound of hidden layer neurons, and

is the adaptive growth coefficient, with a value range of (0,1]. During the growth process, a new neuron was added if the

jth hidden neuron NGI

j > G

th.

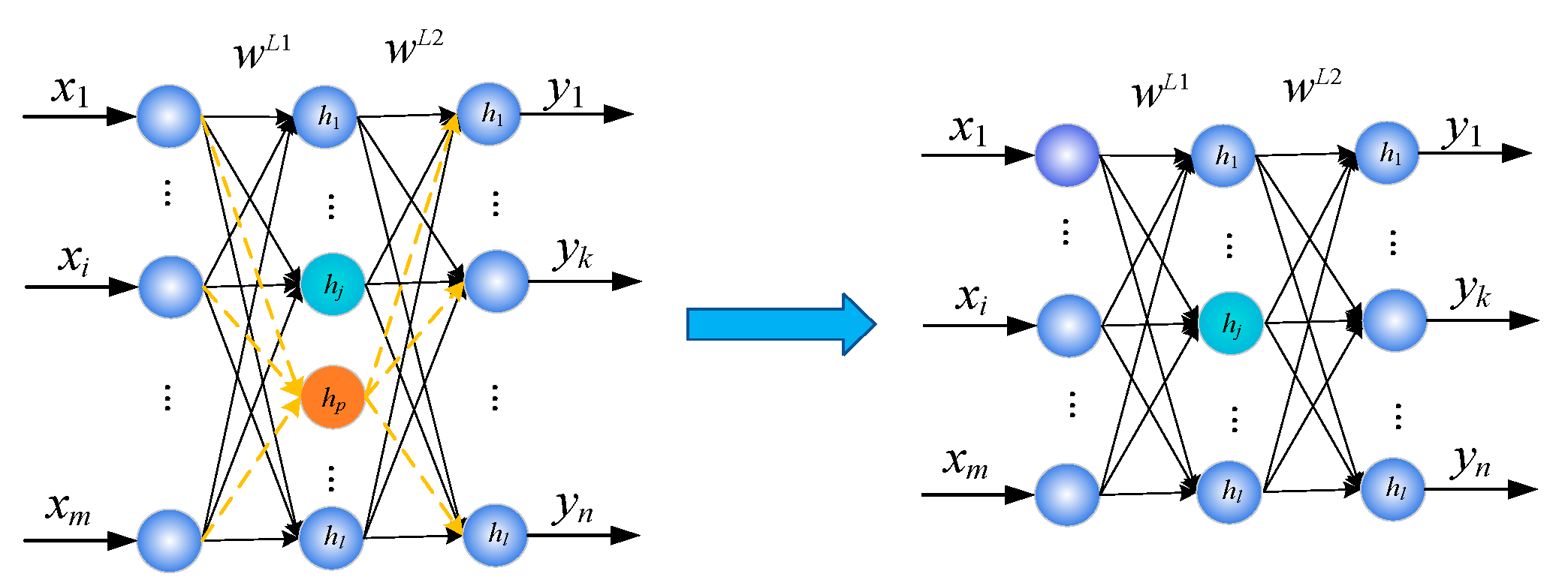

3.4. SOFNN Pruning

The neural pruning index NPI was defined based on the output variance and output mean of the nodes in the rule layer:

Combining NPI, we also determined the neuron pruning threshold,

to be:

where

is the adaptive pruning coefficient, with a value range of (0,1]. The pruning process of SOFNN is shown in

Figure 8.

In the process of neuronal modification, if the jth hidden neuron NPIj < , then the jth neuron contributed very little to the network; hence, this neuron is pruned off.

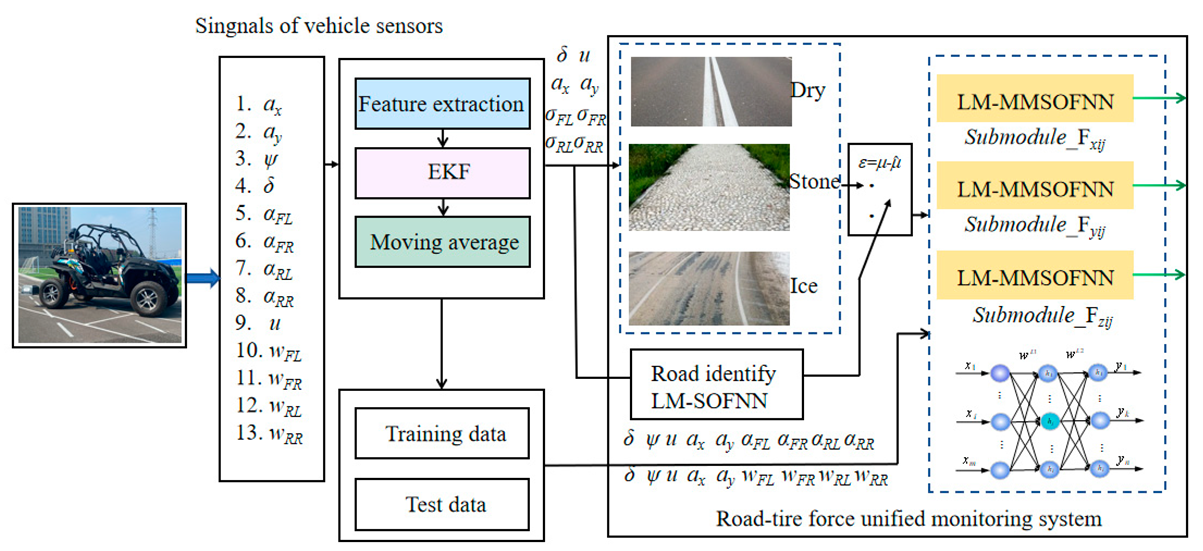

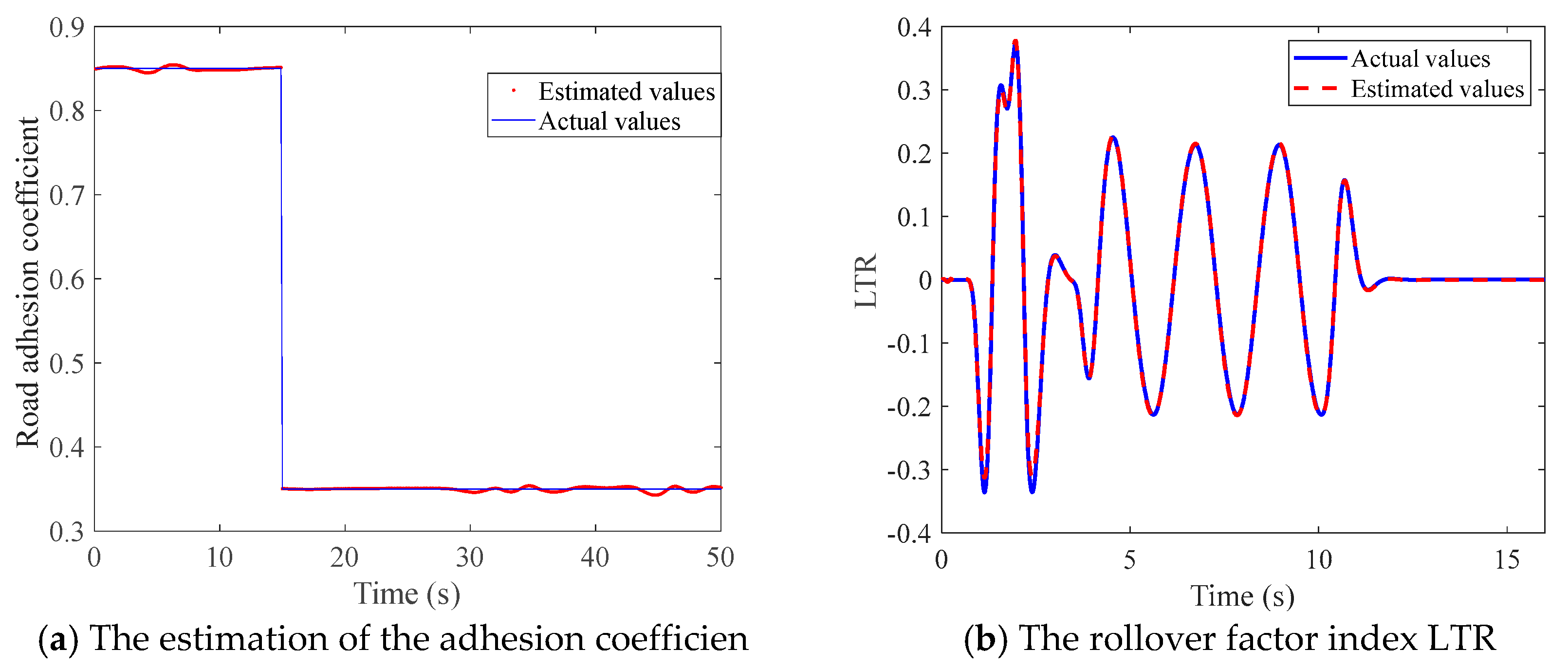

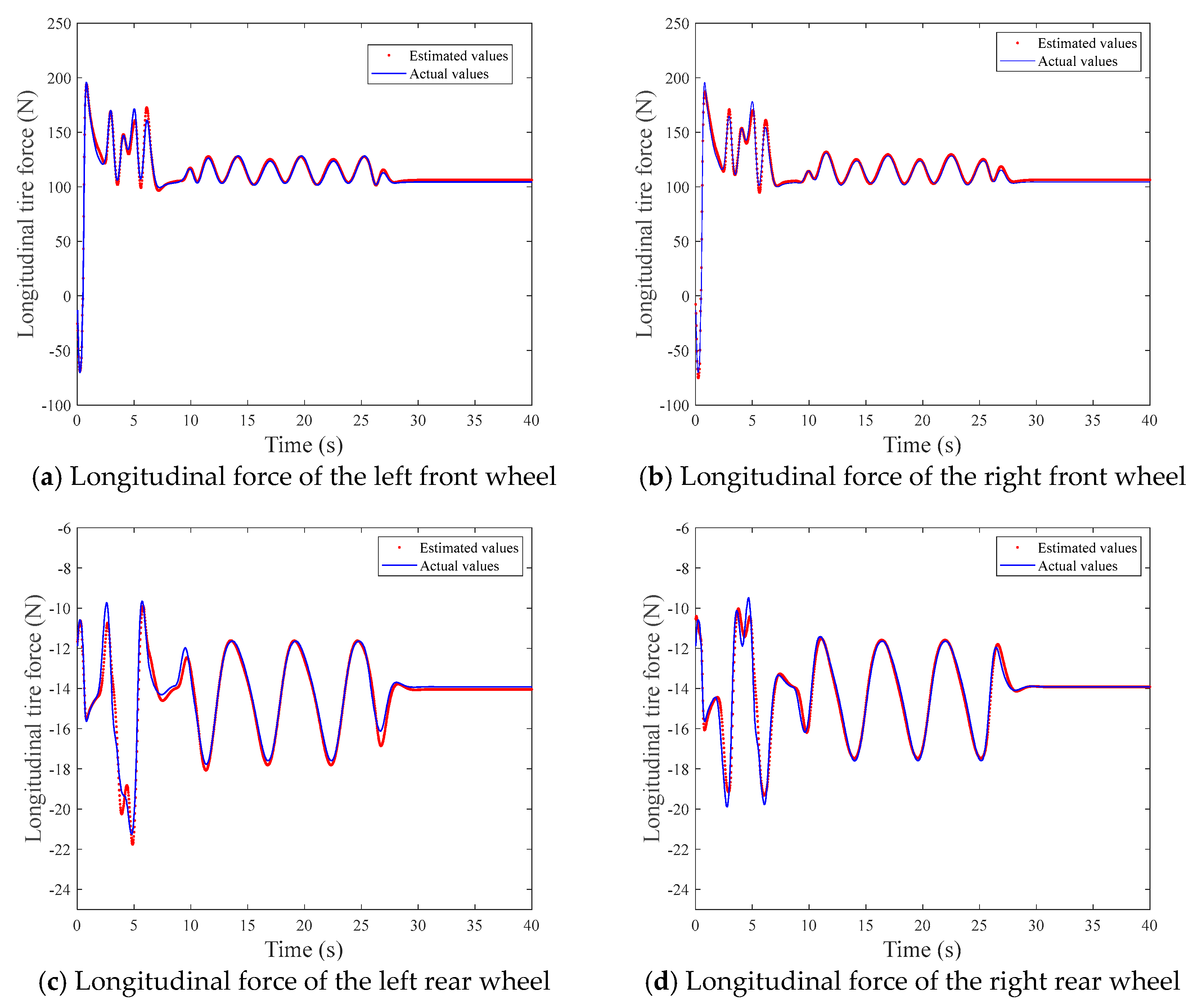

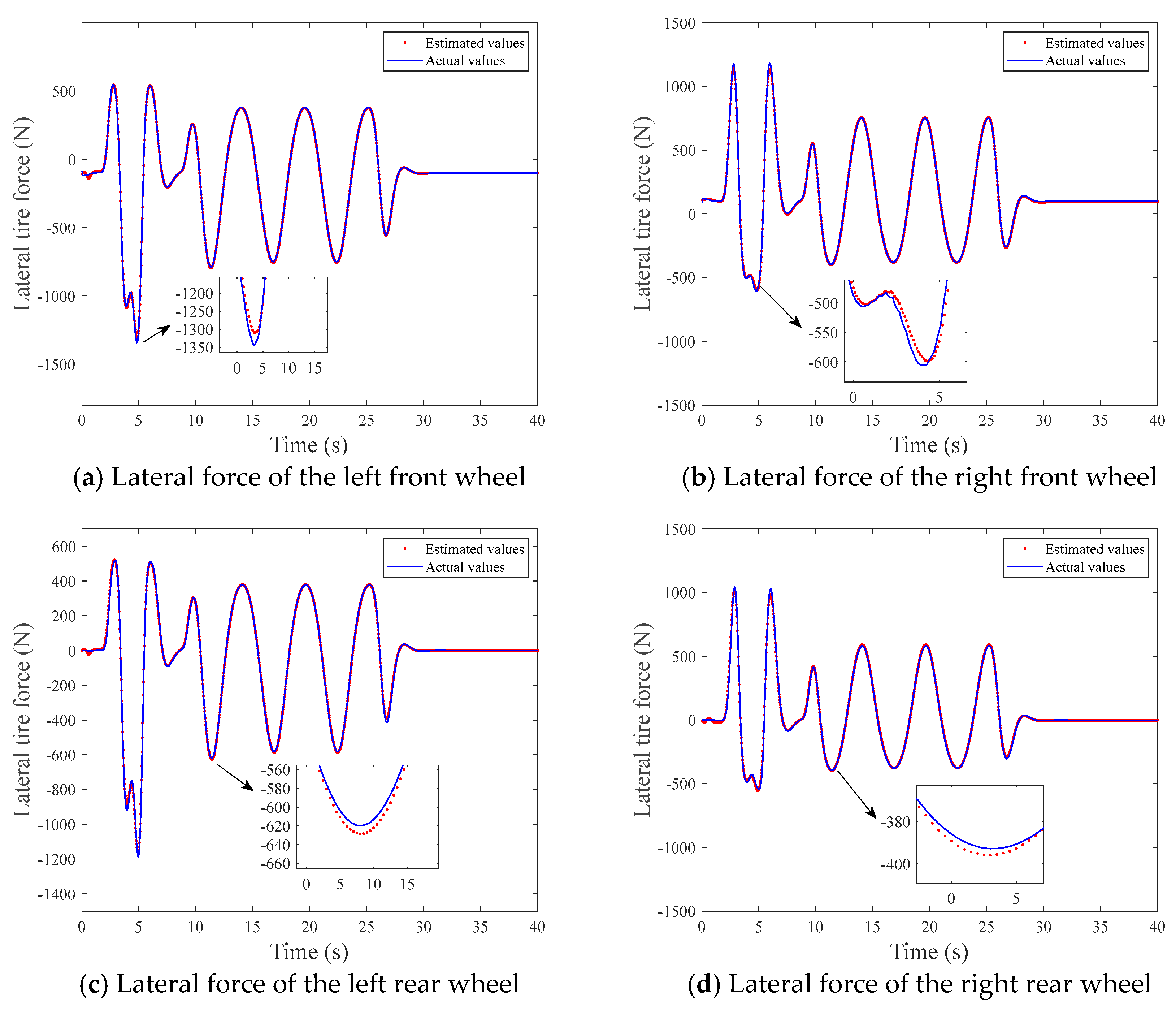

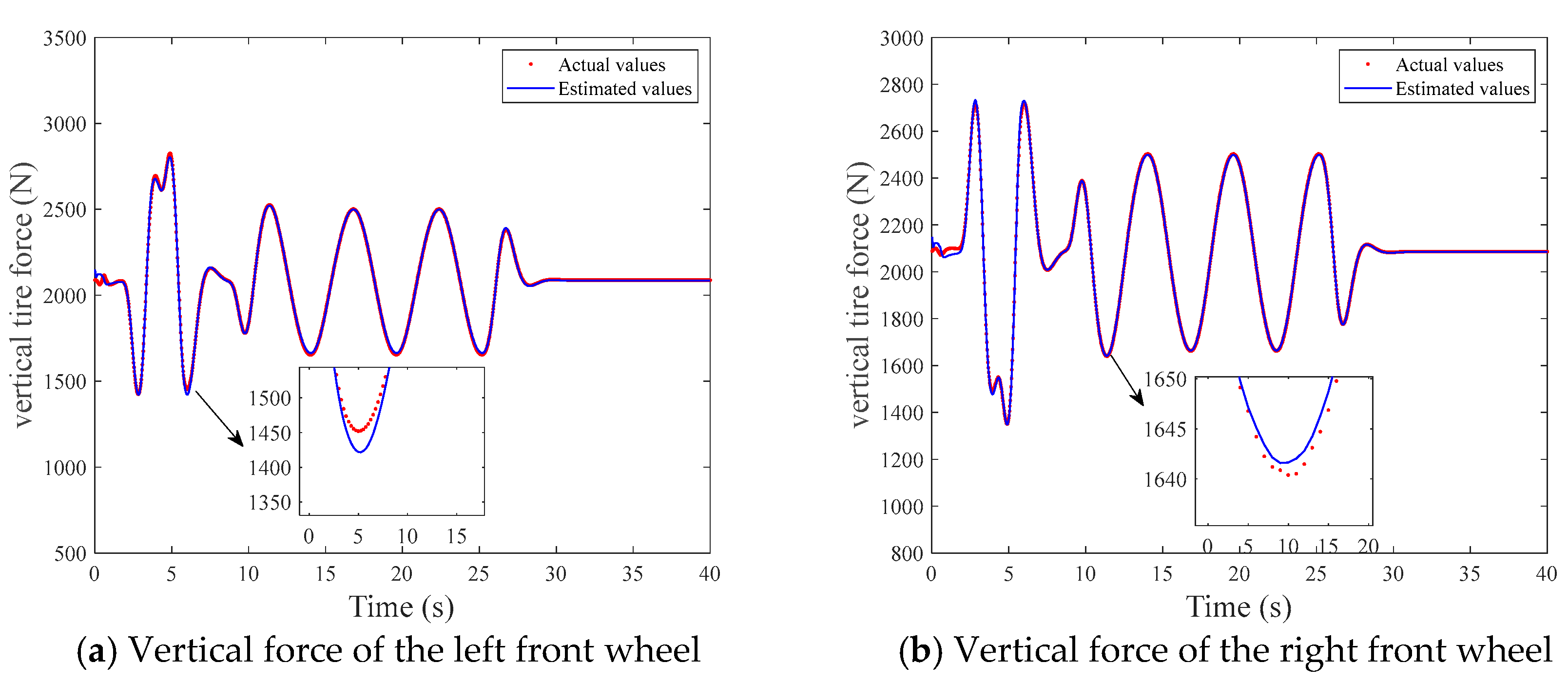

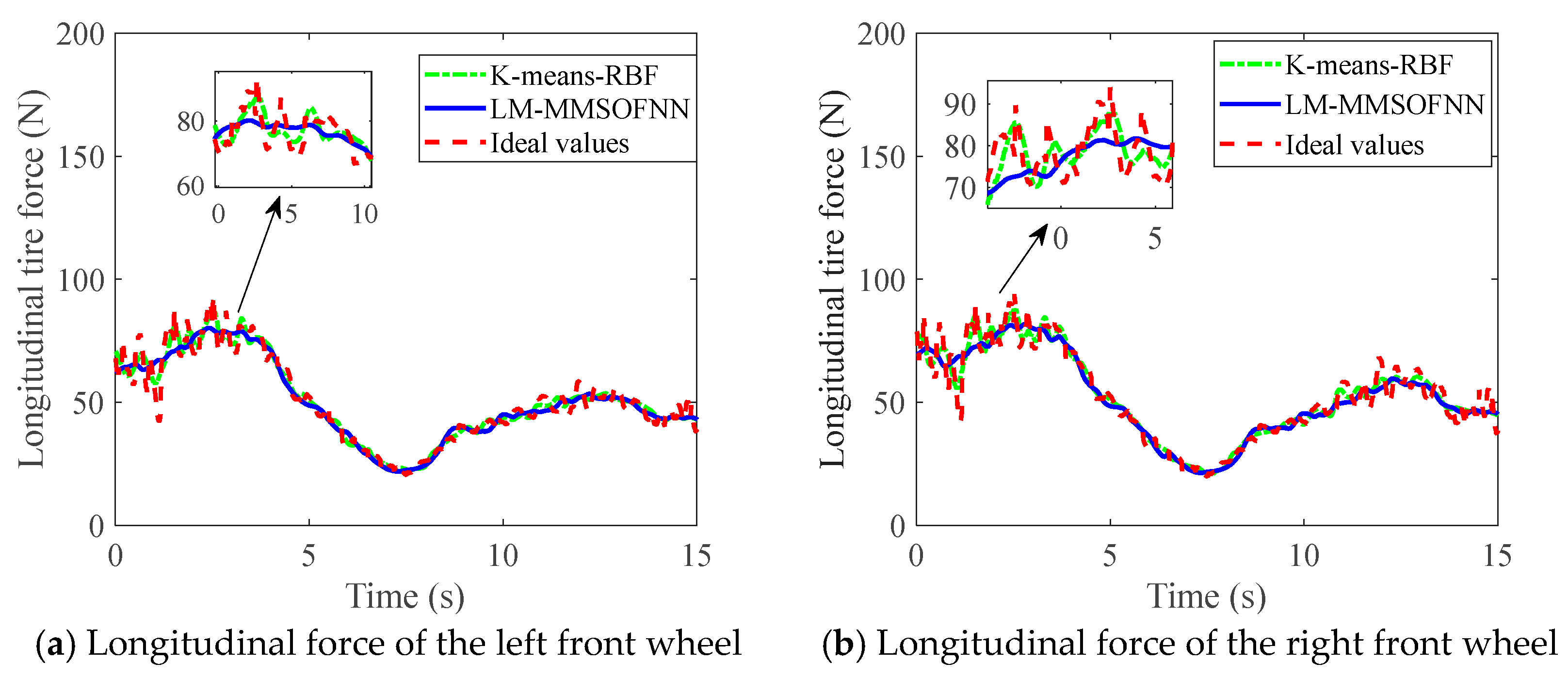

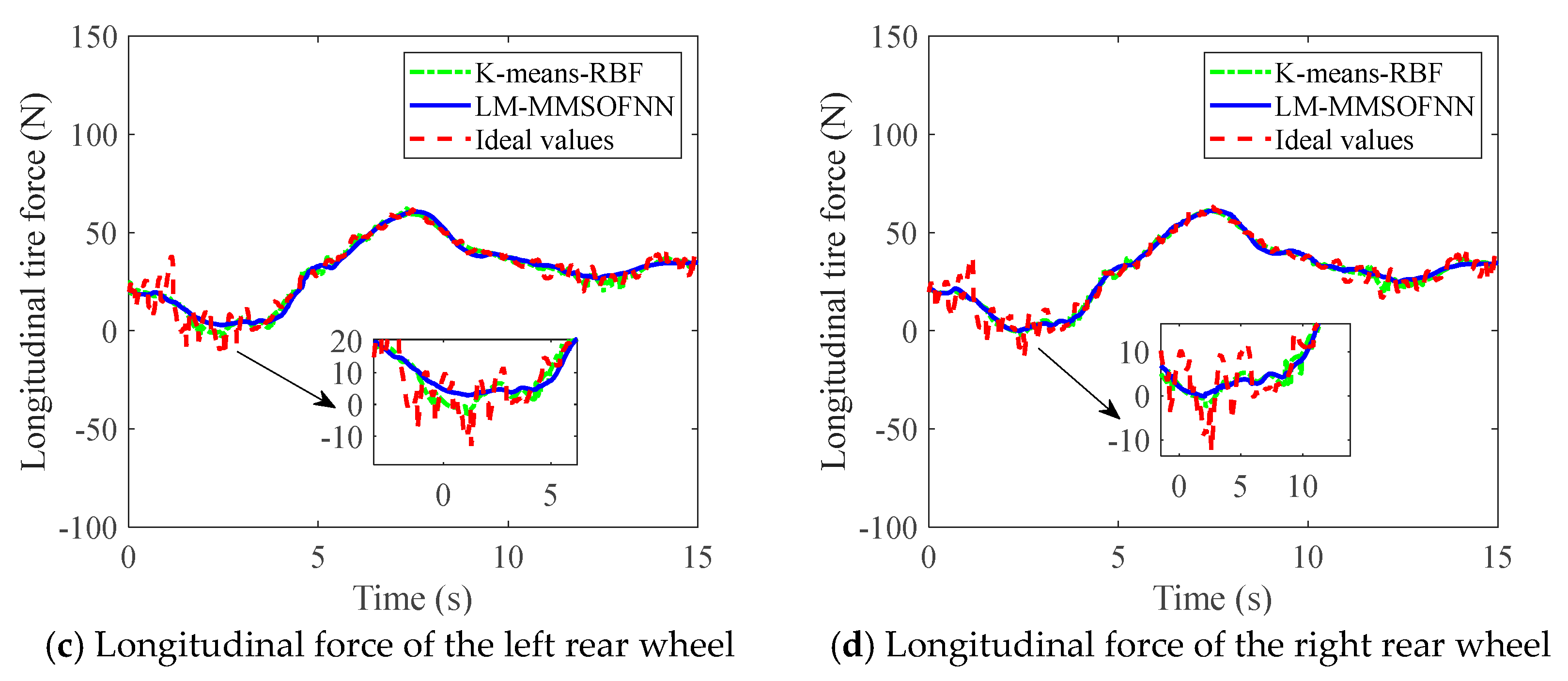

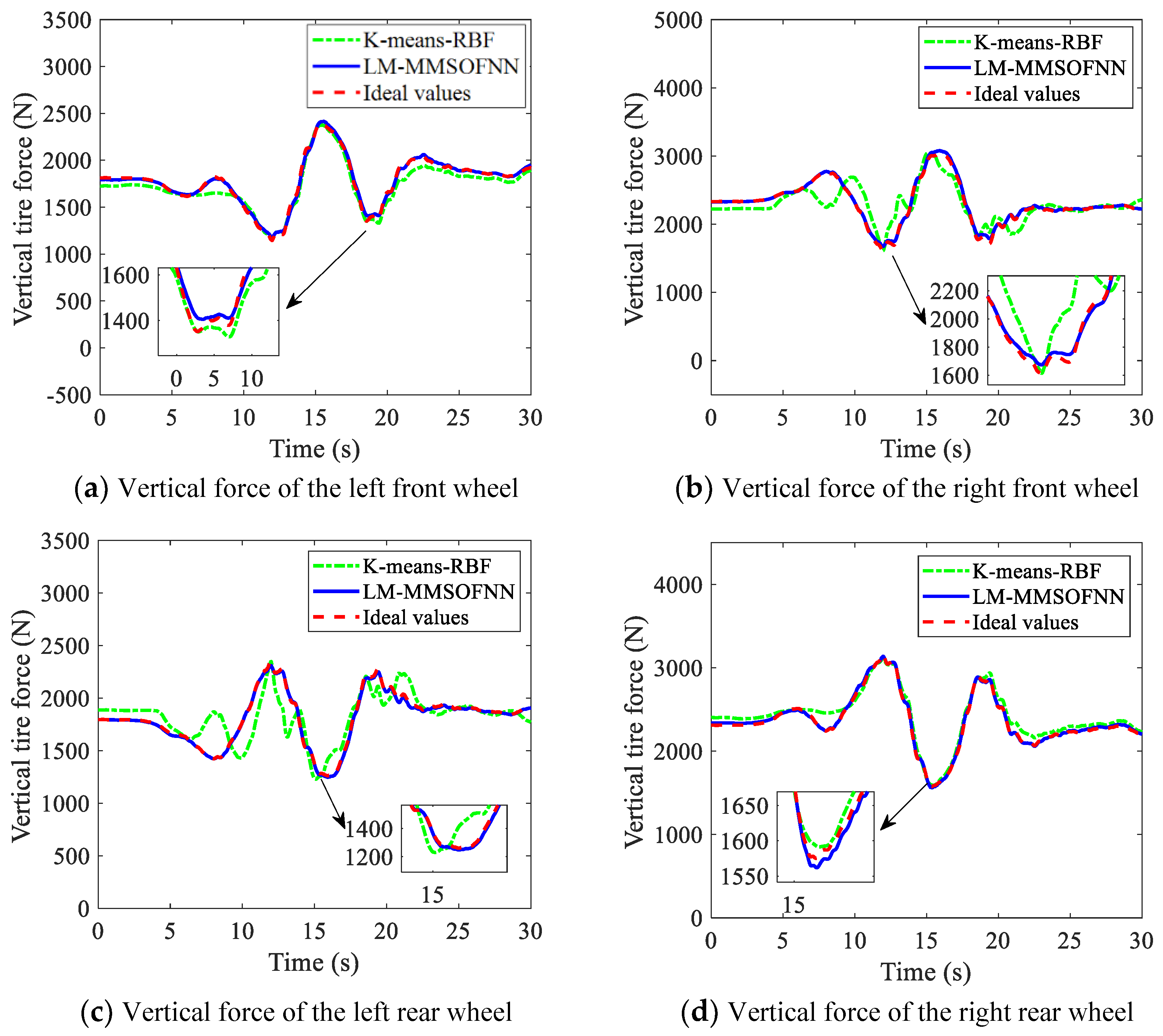

3.5. Road Recognition and Tire Force Estimation

The method based on the LM-MMSOFNN algorithm estimates the tire forces in three directions simultaneously online, which solves the problem that the front and rear lateral forces of the tire cannot be calculated by the same formula when the vehicle turns. Torque can be adjusted according to the actual situation, to achieve accurate stability control of the vehicle, and the slip ratio, road type, and tire forces in each wheel are estimated independently. The LM-MMSOFNN algorithm is designed to estimate the road adhesion coefficient and the data used for model training and testing are collected in real time. When we added multiple neural network sub-models, the classifier selected the one with the lowest error road type. This improved the accuracy of the pavement adhesion coefficient estimation and further improved the accuracy of the tire force estimation. At the same time, the modular design reduced the calculation time and improved the adaptability of online estimation in practical applications. The improved LM, EKF, and MA algorithms and the increase or decrease of self-organizing neurons reduced the computational complexity and the required storage capacity. This algorithm included three parts:

- (1)

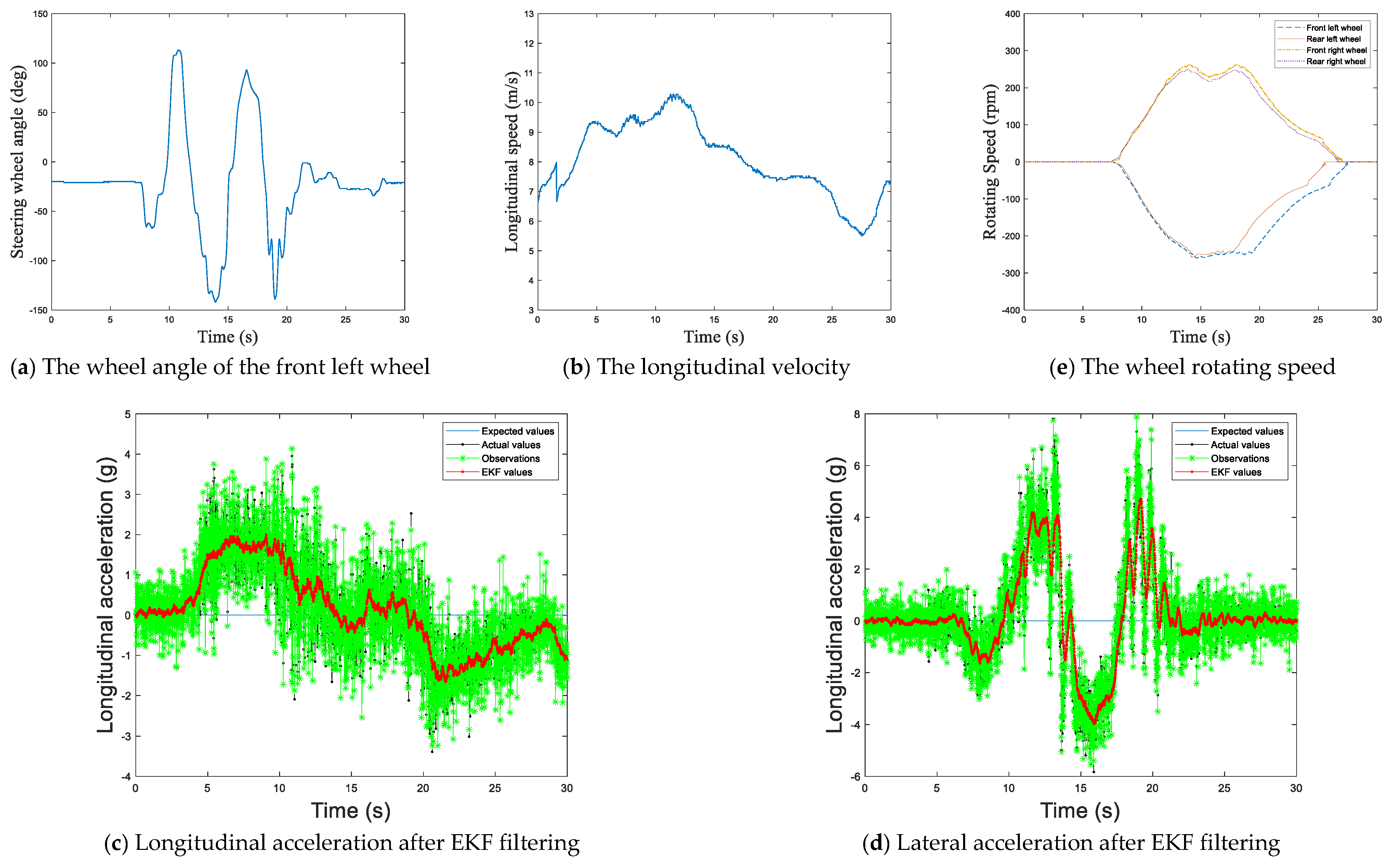

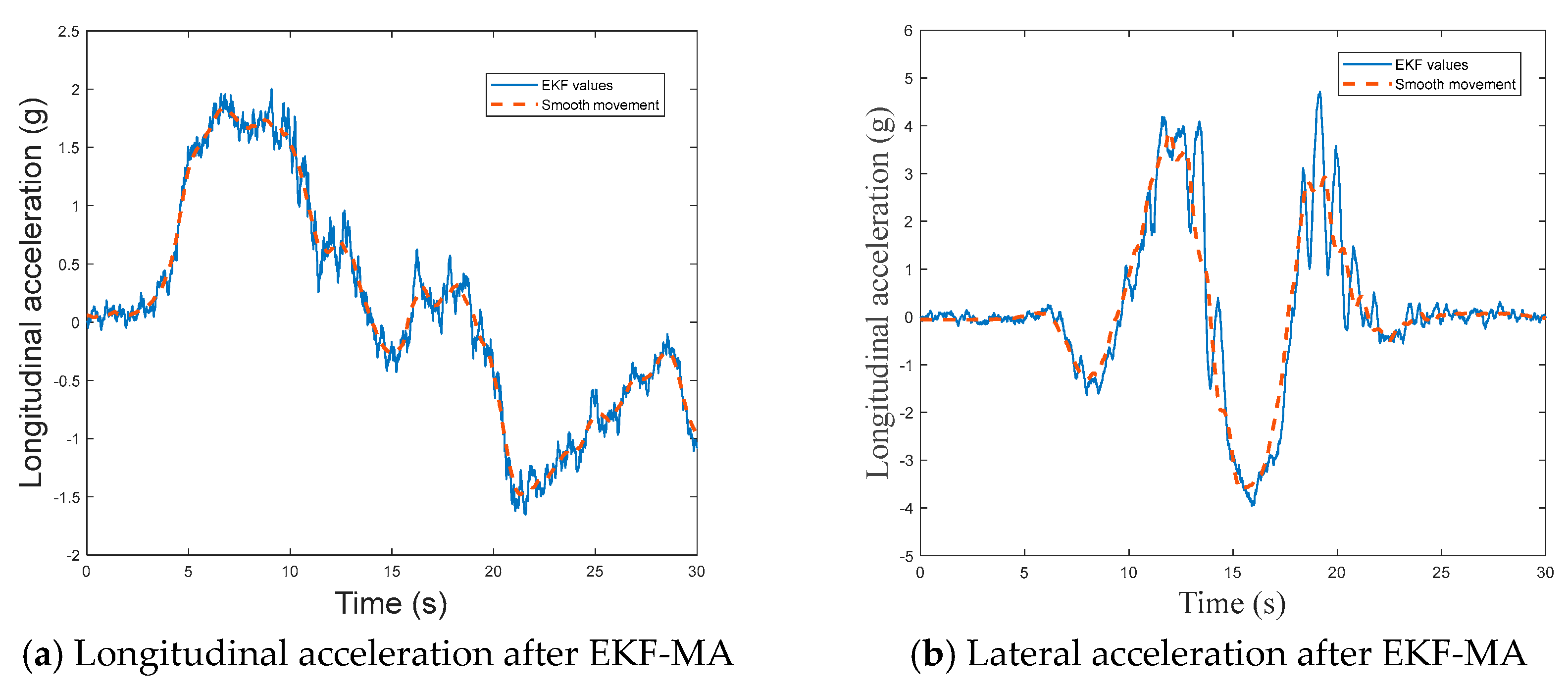

The noise of the measurement signal was reduced through the Extended Kalman Filter (EKF) and Moving Average.

- (2)

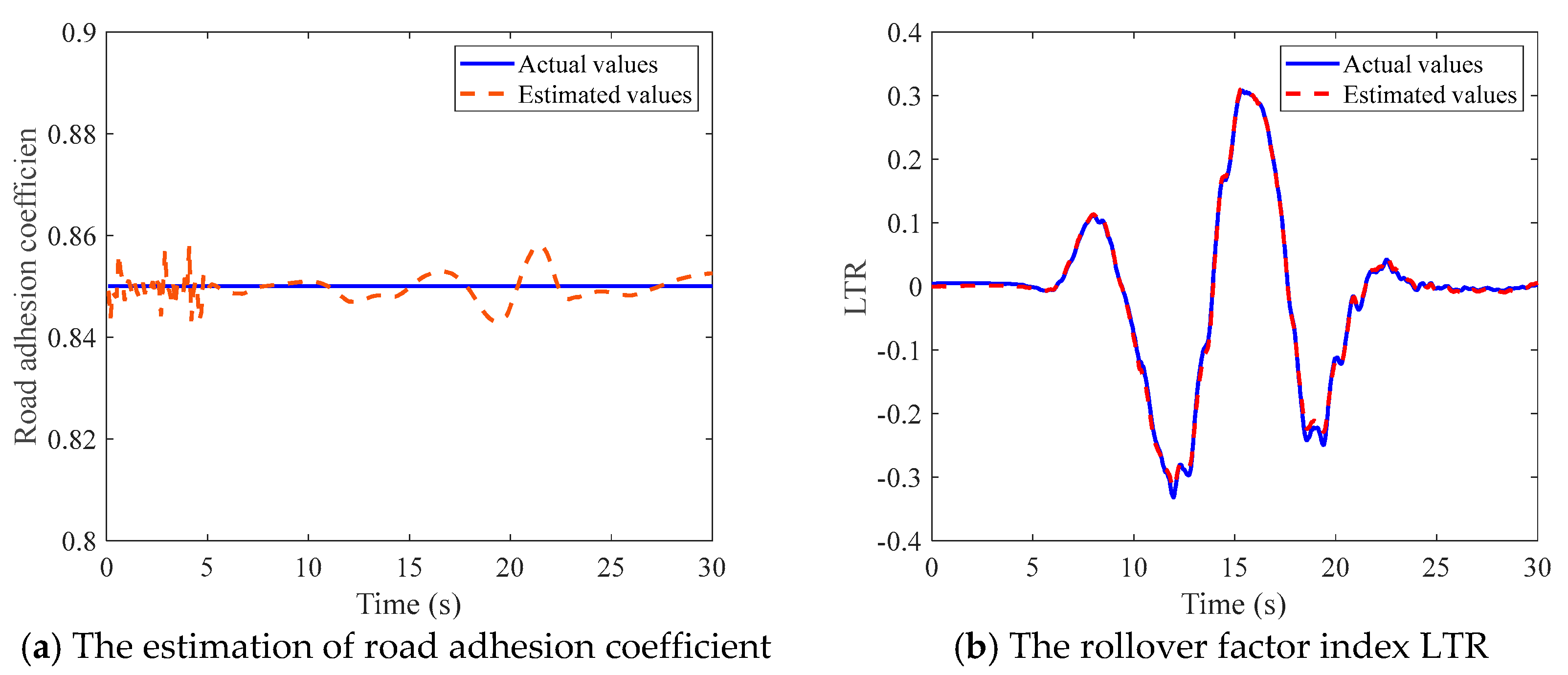

The LM-MMSOFNN algorithm was designed to estimate the road adhesion coefficient. The road type was then identified through a road adhesion coefficient recognition classifier.

- (3)

The multi-module neural network method was then proposed to calculate the longitudinal, lateral, and vertical tire forces of four tires at the same time. The structure is shown in

Figure 9.

The three initial road types were set as dry asphalt, gravel road, and ice road, with the initial road adhesion coefficients set as 0.85, 0.6, and 0.25. When the actual vehicle is driving, the road adhesion coefficients estimated by the neural network will select the closest road type in the classifier, which reduces the estimation error of the road adhesion coefficient and improves the stability of the network and adaptability to different road conditions. Note that the smaller the interval of adhesion coefficients in the initial road type classification, the higher accuracy of final adhesion coefficients obtained, and the estimation of tire force will also be more accurate.