Impact Performance Prediction and Optimization of a Circumferentially Corrugated Tube with Variable Wall Thickness Using Support Vector Machine

Abstract

:1. Introduction

2. Methods

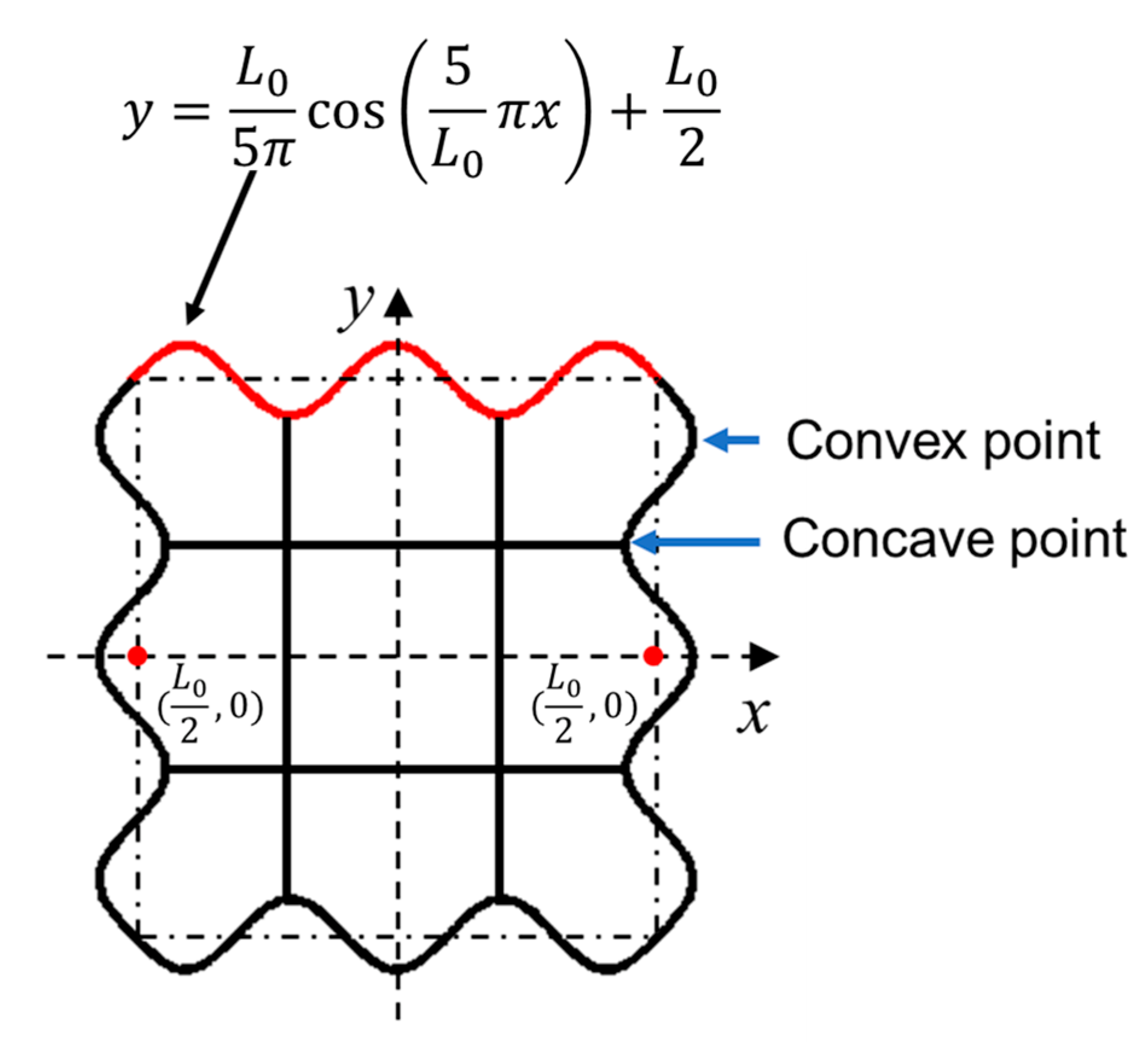

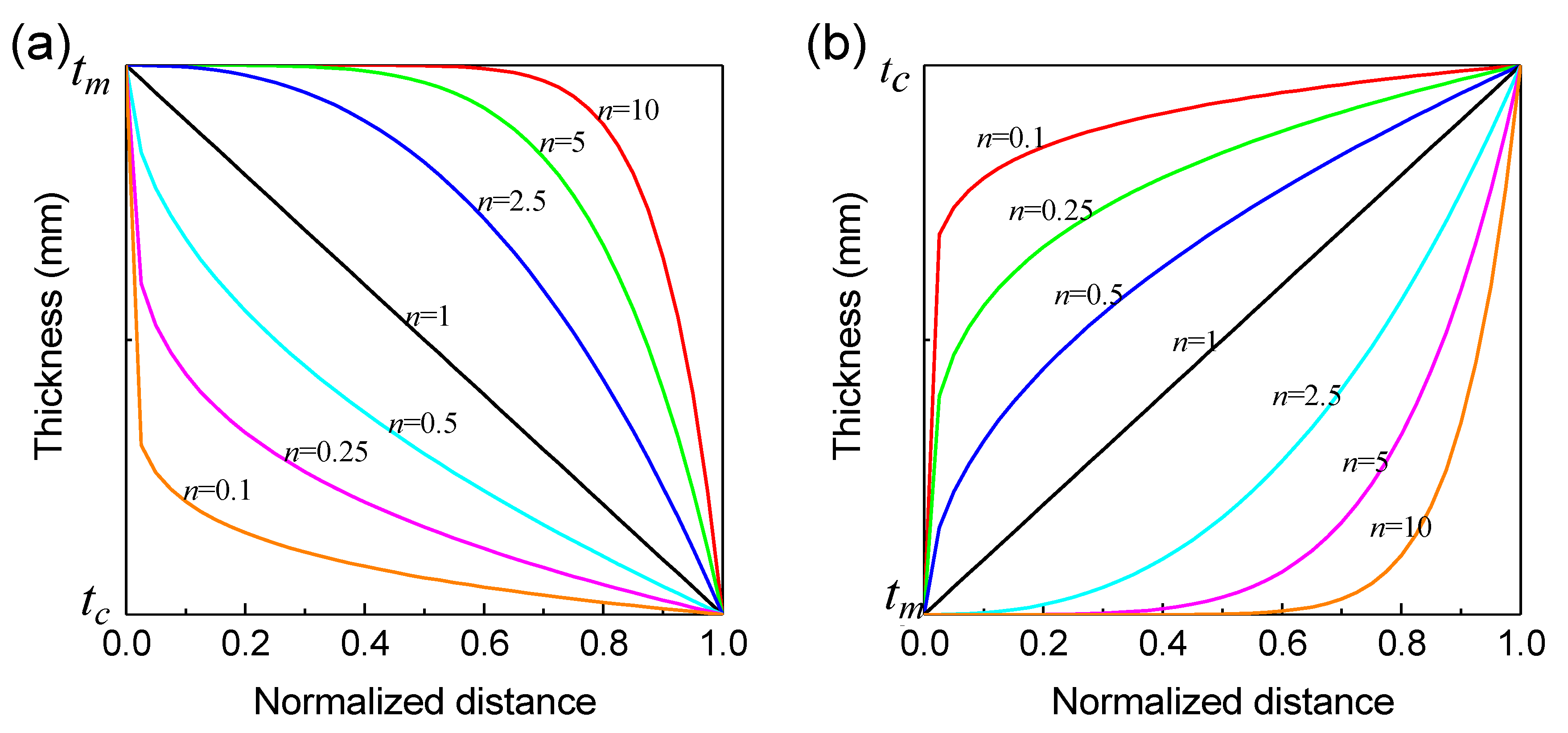

2.1. Structural Design

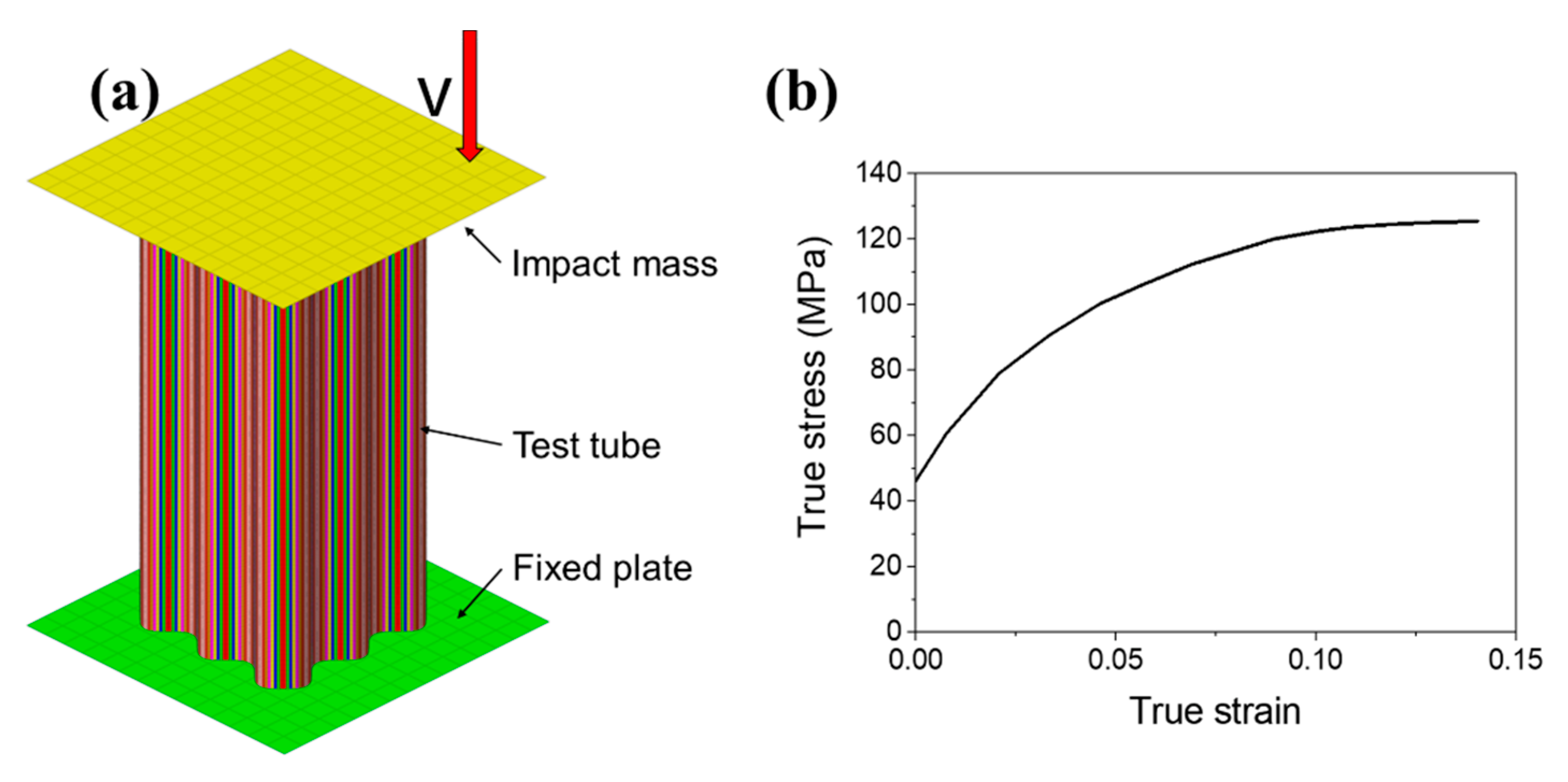

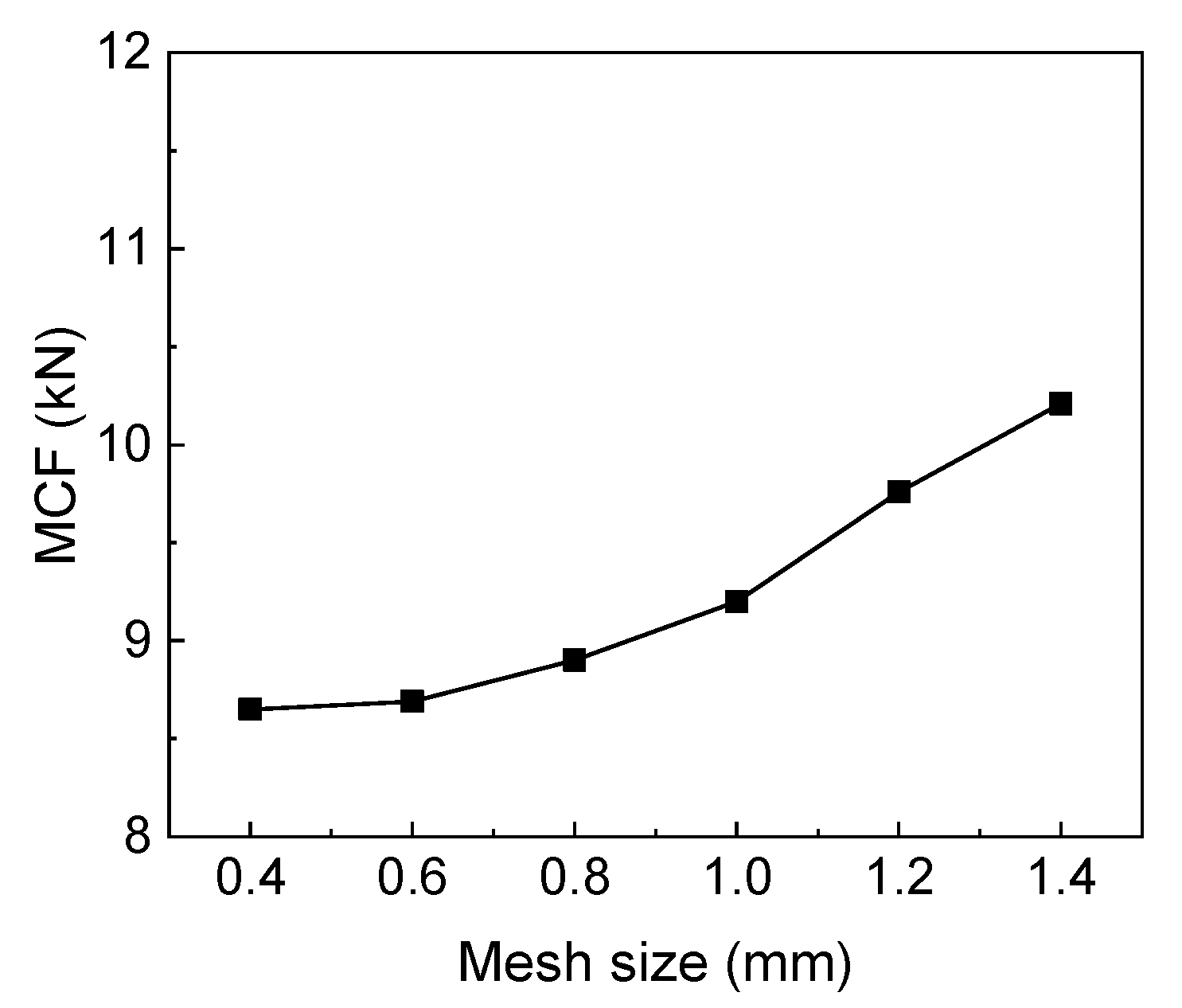

2.2. Finite Element Model

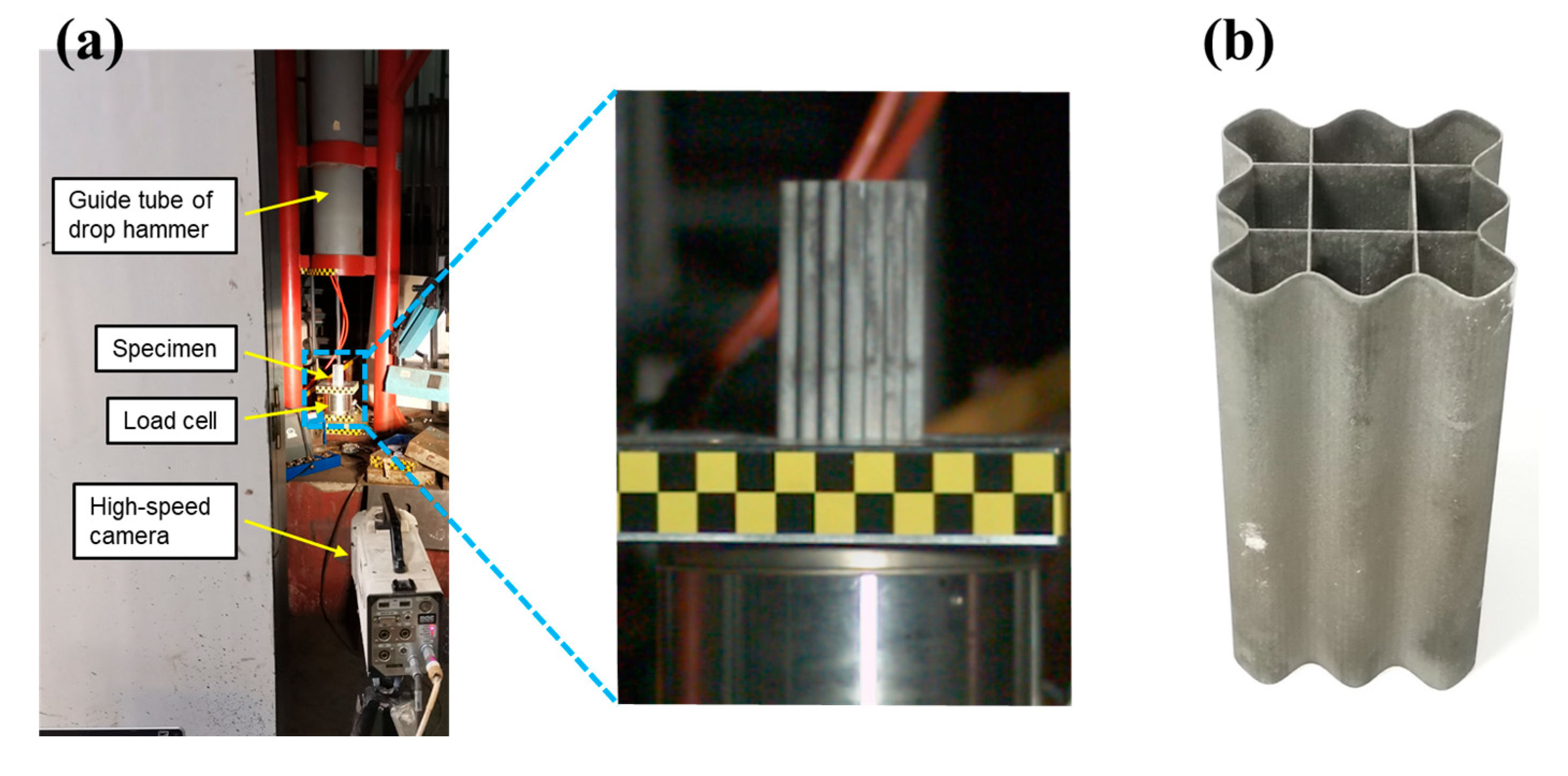

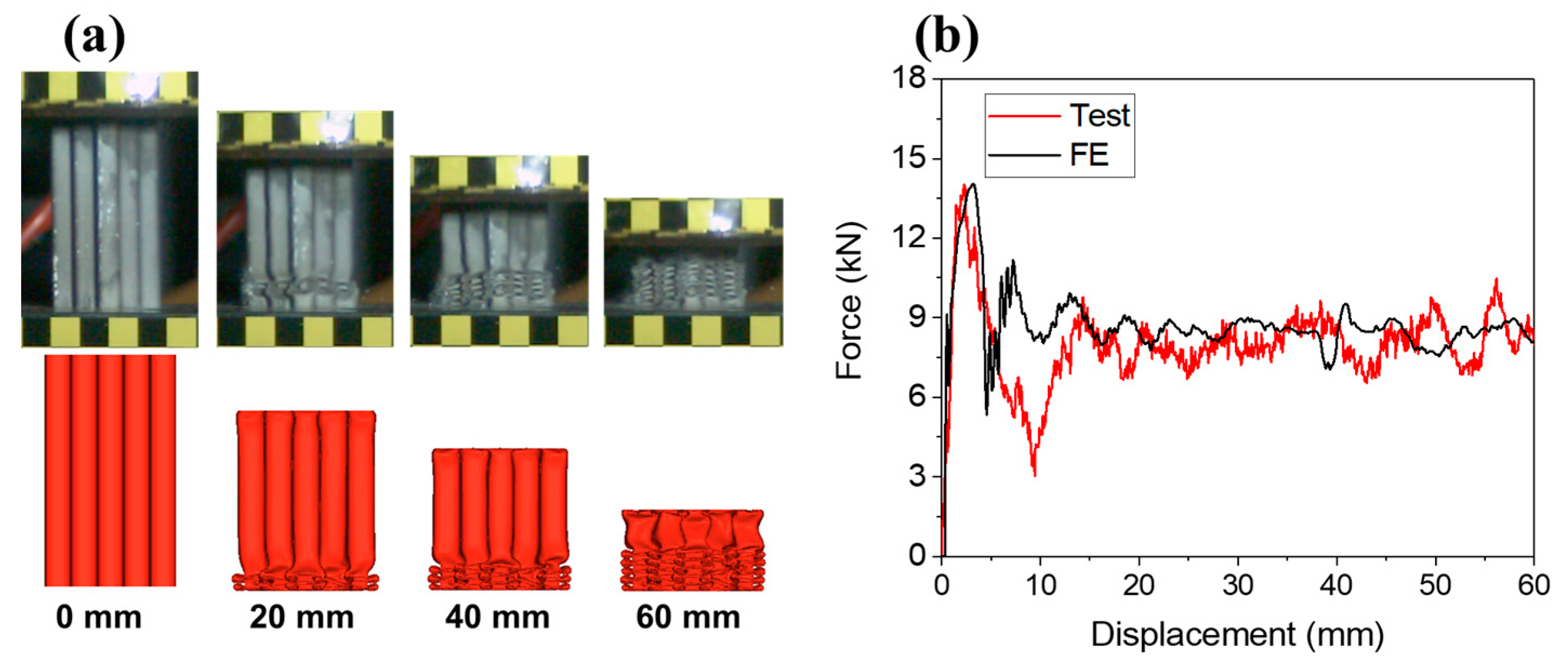

2.3. Validation of the FE Model

2.4. Support Vector Machine

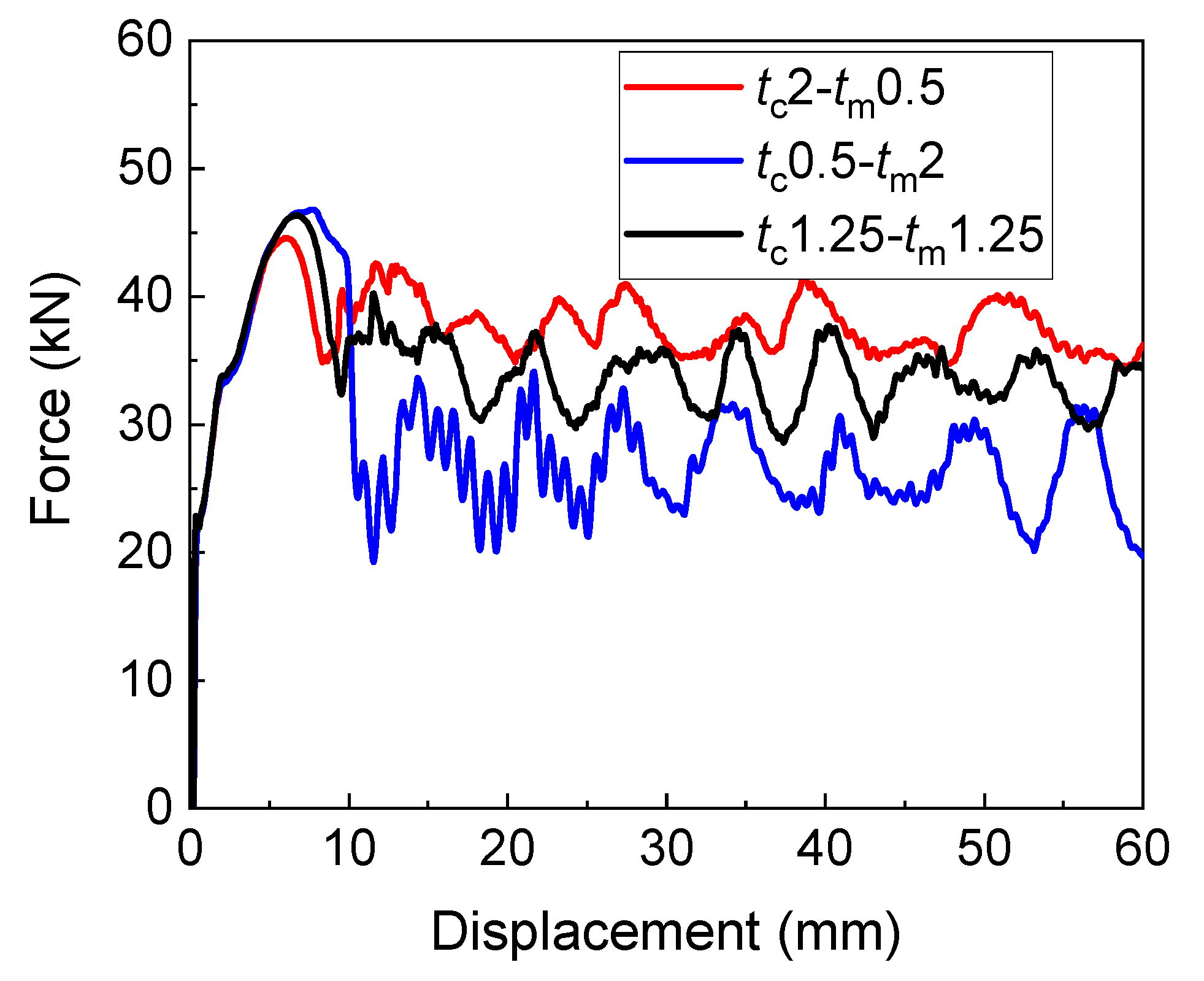

3. Comparison of Three Wall Thickness Variation

4. Prediction

4.1. Correlation Analysis

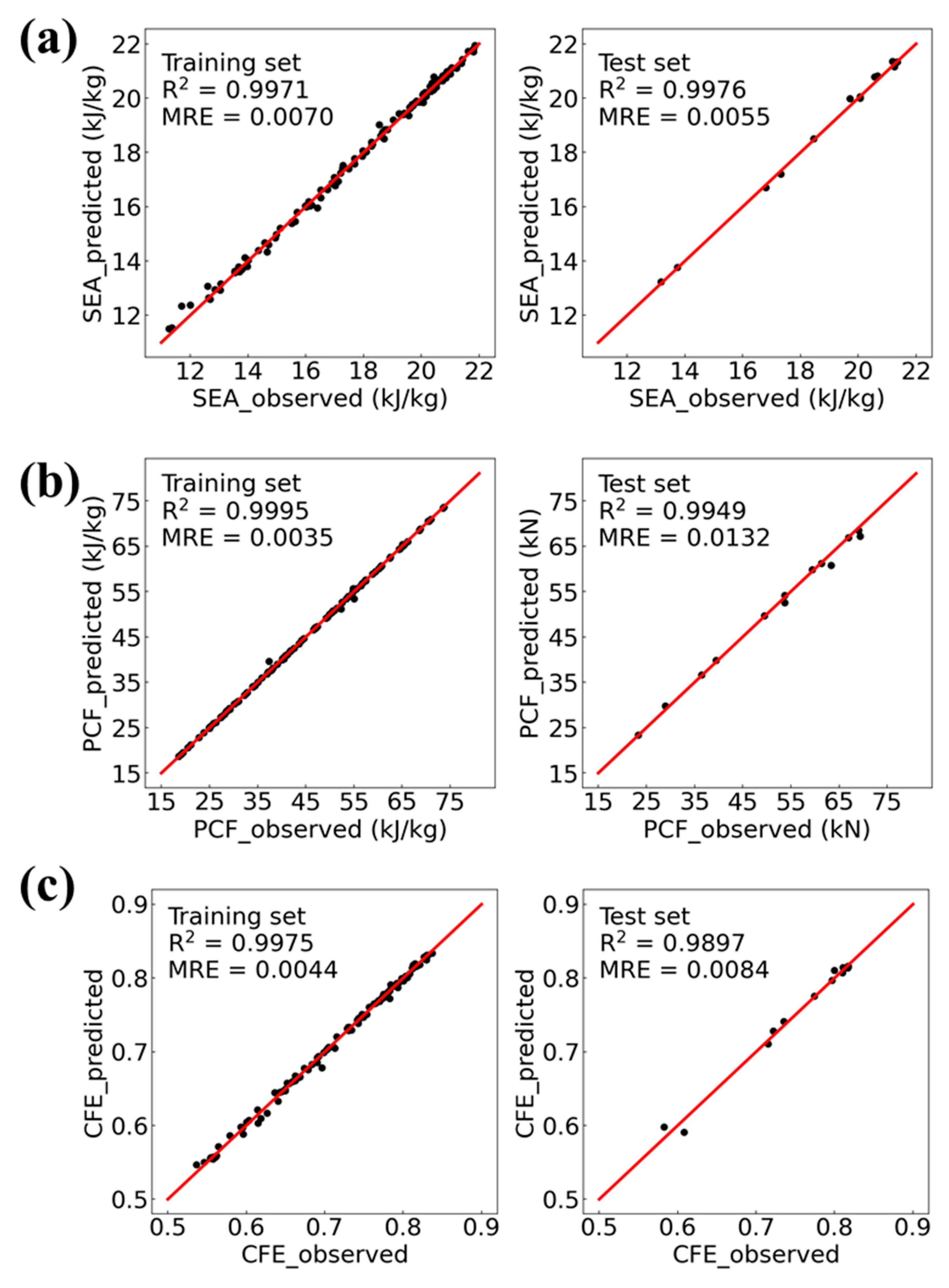

4.2. Prediction of the Energy Absorption Responses

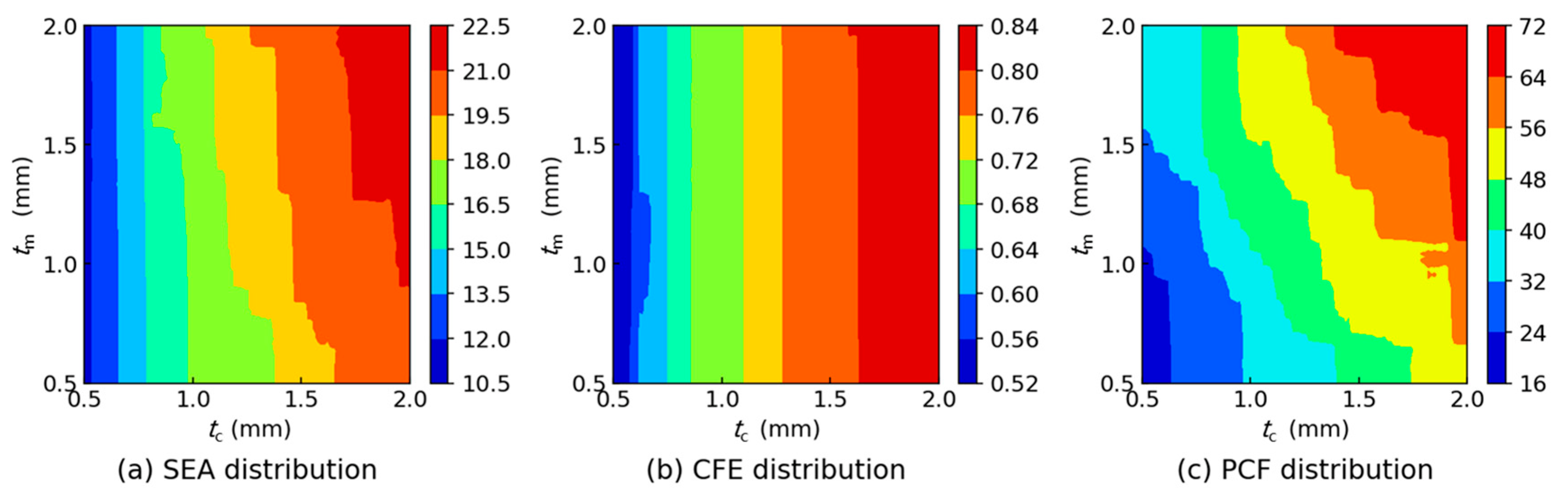

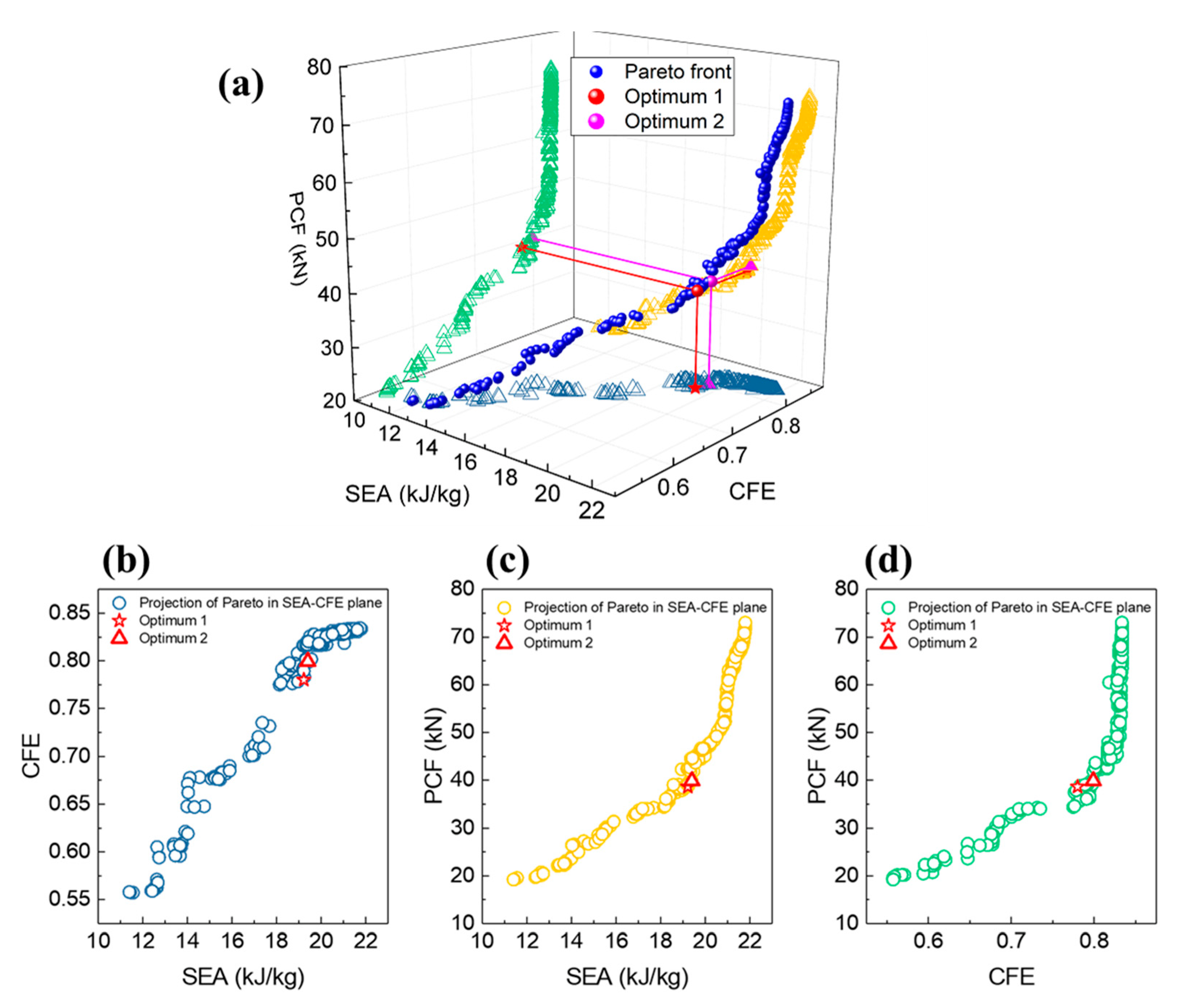

5. Optimization

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, S.; Zhou, H. Impact characteristics of a composite energy absorbing bearing structure for railway vehicles. Compos. Part B Eng. 2014, 67, 455–463. [Google Scholar] [CrossRef]

- Zhang, H.; Peng, Y.; Hou, L.; Wang, D.; Tian, G.; Li, Z. Multistage Impact Energy Distribution for Whole Vehicles in High-Speed Train Collisions: Modeling and Solution Methodology. IEEE Trans. Ind. Inform. 2020, 16, 2486–2499. [Google Scholar] [CrossRef]

- Hou, L.; Peng, Y.; Sun, D. Dynamic analysis of railway vehicle derailment mechanism in train-to-train collision accidents. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2020, 235, 1022–1034. [Google Scholar] [CrossRef]

- Liu, J.; Chen, W.; Hao, H.; Wang, Z. Numerical study of low-speed impact response of sandwich panel with tube filled honeycomb core. Compos. Struct. 2019, 220, 736–748. [Google Scholar] [CrossRef]

- Yang, C.; Xu, P.; Yao, S.; Xie, S.; Li, Q.; Peng, Y. Optimization of honeycomb strength assignment for a composite energy-absorbing structure. Thin-Walled Struct. 2018, 127, 741–755. [Google Scholar] [CrossRef]

- Sun, G.; Tian, J.; Liu, T.; Yan, X.; Huang, X. Crashworthiness optimization of automotive parts with tailor rolled blank. Eng. Struct. 2018, 169, 201–215. [Google Scholar] [CrossRef]

- Zhou, J.; Qin, R.; Chen, B. On the Folding Mechanics of Square Columns with Double-Surfaced Gradients. Math. Probl. Eng. 2019, 2019, 4706563. [Google Scholar] [CrossRef]

- Li, Z.; Ma, W.; Yao, S.; Xu, P.; Hou, L.; Deng, G. A machine learning based optimization method towards removing undesired deformation of energy-absorbing structures. Struct. Multidiscip. Optim. 2021, 64, 919–934. [Google Scholar] [CrossRef]

- Ma, W.; Xie, S.; Li, Z.; Feng, Z.; Jing, K. Crushing behaviors of horse-hoof-wall inspired corrugated tubes under multiple loading conditions. Mech. Adv. Mater. Struct. 2021, 29, 3263–3280. [Google Scholar] [CrossRef]

- Ma, W.; Xie, S.; Li, Z. Mechanical performance of bio-inspired corrugated tubes with varying vertex configurations. Int. J. Mech. Sci. 2020, 172, 105399. [Google Scholar] [CrossRef]

- Xie, S.; Yang, W.; Wang, N.; Li, H. Crashworthiness analysis of multi-cell square tubes under axial loads. Int. J. Mech. Sci. 2017, 121, 106–118. [Google Scholar] [CrossRef]

- Li, Z.; Ma, W.; Xu, P.; Yao, S. Crashworthiness of multi-cell circumferentially corrugated square tubes with cosine and triangular configurations. Int. J. Mech. Sci. 2020, 165, 105205. [Google Scholar] [CrossRef]

- Sun, G.; Liu, T.; Huang, X.; Zheng, G.; Li, Q. Topological configuration analysis and design for foam filled multi-cell tubes. Eng. Struct. 2018, 155, 235–250. [Google Scholar] [CrossRef]

- Wu, S.; Sun, G.; Wu, X.; Li, G.; Li, Q. Crashworthiness analysis and optimization of fourier varying section tubes. Int. J. Non-Linear Mech. 2017, 92, 41–58. [Google Scholar] [CrossRef]

- Pirmohammad, S.; Marzdashti, S.E. Crushing behavior of new designed multi-cell members subjected to axial and oblique quasi-static loads. Thin-Walled Struct. 2016, 108, 291–304. [Google Scholar] [CrossRef]

- Sun, F.; Lai, C.; Fan, H.; Fang, D. Crushing mechanism of hierarchical lattice structure. Mech. Mater. 2016, 97, 164–183. [Google Scholar] [CrossRef]

- Luo, Y.; Fan, H. Energy absorbing ability of rectangular self-similar multi-cell sandwich-walled tubular structures. Thin-Walled Struct. 2018, 124, 88–97. [Google Scholar] [CrossRef]

- Zhou, J.; Qin, R.; Chen, B. Energy absorption properties of multi-cell thin-walled tubes with a double surface gradient. Thin-Walled Struct. 2019, 145, 106386. [Google Scholar] [CrossRef]

- Abramowicz, W.; Jones, N. Dynamic progressive buckling of circular and square tubes. Int. J. Impact Eng. 1986, 4, 243–270. [Google Scholar] [CrossRef]

- Xiang, Y.; Yu, T.; Yang, L. Comparative analysis of energy absorption capacity of polygonal tubes, multi-cell tubes and honeycombs by utilizing key performance indicators. Mater. Des. 2016, 89, 689–696. [Google Scholar] [CrossRef]

- Zhang, X.; Huh, H. Crushing analysis of polygonal columns and angle elements. Int. J. Impact Eng. 2010, 37, 441–451. [Google Scholar] [CrossRef]

- Yao, S.; Tian, Y.; Li, Z.; Yang, F.; Xu, P. Crushing characteristic of polygonal tubes with hierarchical triangular cells. Thin-Walled Struct. 2020, 157, 107031. [Google Scholar] [CrossRef]

- Fan, Z.; Lu, G.; Liu, K. Quasi-static axial compression of thin-walled tubes with different cross-sectional shapes. Eng. Struct. 2013, 55, 80–89. [Google Scholar] [CrossRef]

- Liu, W.; Lin, Z.; He, J.; Wang, N.; Deng, X. Crushing behavior and multi-objective optimization on the crashworthiness of sandwich structure with star-shaped tube in the center. Thin-Walled Struct. 2016, 108, 205–214. [Google Scholar] [CrossRef]

- Li, Y.; You, Z. Origami concave tubes for energy absorption. Int. J. Solids Struct. 2019, 169, 21–40. [Google Scholar] [CrossRef]

- Liu, S.; Tong, Z.; Tang, Z.; Liu, Y.; Zhang, Z. Bionic design modification of non-convex multi-corner thin-walled columns for improving energy absorption through adding bulkheads. Thin-Walled Struct. 2015, 88, 70–81. [Google Scholar] [CrossRef]

- Tang, Z.; Liu, S.; Zhang, Z. Energy absorption properties of non-convex multi-corner thin-walled columns. Thin-Walled Struct. 2012, 51, 112–120. [Google Scholar] [CrossRef]

- Li, Z.; Ma, W.; Xu, P.; Yao, S. Crushing behavior of circumferentially corrugated square tube with different cross inner ribs. Thin-Walled Struct. 2019, 144, 106370. [Google Scholar] [CrossRef]

- Eyvazian, A.; Habibi, M.K.; Hamouda, A.M.; Hedayati, R. Axial crushing behavior and energy absorption efficiency of corrugated tubes. Mater. Des. 2014, 54, 1028–1038. [Google Scholar] [CrossRef]

- Deng, X.; Liu, W. Experimental and numerical investigation of a novel sandwich sinusoidal lateral corrugated tubular structure under axial compression. Int. J. Mech. Sci. 2019, 151, 274–287. [Google Scholar] [CrossRef]

- Deng, X.; Liu, W. Multi-objective optimization of thin-walled sandwich tubes with lateral corrugated tubes in the middle for energy absorption. Thin-Walled Struct. 2019, 137, 303–317. [Google Scholar] [CrossRef]

- Li, Z.; Yao, S.; Ma, W.; Xu, P.; Che, Q. Energy-absorption characteristics of a circumferentially corrugated square tube with a cosine profile. Thin-Walled Struct. 2019, 135, 385–399. [Google Scholar] [CrossRef]

- Li, Z.; Ma, W.; Yao, S.; Xu, P. Crashworthiness performance of corrugation- reinforced multicell tubular structures. Int. J. Mech. Sci. 2021, 190, 106038. [Google Scholar] [CrossRef]

- Yao, S.; Xing, Y.; Zhao, K. Crashworthiness analysis and multiobjective optimization for circular tubes with functionally graded thickness under multiple loading angles. Adv. Mech. Eng. 2017, 9, 1687814017696660. [Google Scholar] [CrossRef]

- Pang, T.; Zheng, G.; Fang, J.; Ruan, D.; Sun, G. Energy absorption mechanism of axially-varying thickness (AVT) multicell thin-walled structures under out-of-plane loading. Eng. Struct. 2019, 196, 109130. [Google Scholar] [CrossRef]

- Duan, S.; Tao, Y.; Lei, H.; Wen, W.; Liang, J.; Fang, D. Enhanced out-of-plane compressive strength and energy absorption of 3D printed square and hexagonal honeycombs with variable-thickness cell edges. Extreme Mech. Lett. 2018, 18, 9–18. [Google Scholar] [CrossRef]

- Fang, J.; Gao, Y.; Sun, G.; Zheng, G.; Li, Q. Dynamic crashing behavior of new extrudable multi-cell tubes with a functionally graded thickness. Int. J. Mech. Sci. 2015, 103, 63–73. [Google Scholar] [CrossRef]

- Qin, R.; Zhou, J.; Chen, B. Crashworthiness Design and Multiobjective Optimization for Hexagon Honeycomb Structure with Functionally Graded Thickness. Adv. Mater. Sci. Eng. 2019, 2019, 8938696. [Google Scholar] [CrossRef]

- Sun, G.; Pang, T.; Xu, C.; Zheng, G.; Song, J. Energy absorption mechanics for variable thickness thin-walled structures. Thin-Walled Struct. 2017, 118, 214–228. [Google Scholar] [CrossRef]

- Song, J.F.; Xu, S.C.; Wang, H.X.; Wu, X.Q.; Zou, M. Bionic design and multi-objective optimization for variable wall thickness tube inspired bamboo structures. Thin-Walled Struct. 2018, 125, 76–88. [Google Scholar] [CrossRef]

- Chen, Y.; Bai, Z.; Zhang, L.; Wang, Y.; Sun, G.; Cao, L. Crashworthiness analysis of octagonal multi-cell tube with functionally graded thickness under multiple loading angles. Thin-Walled Struct. 2017, 110, 133–139. [Google Scholar] [CrossRef]

- Sun, G.; Xu, F.; Li, G.; Li, Q. Crashing analysis and multiobjective optimization for thin-walled structures with functionally graded thickness. Int. J. Impact Eng. 2014, 64, 62–74. [Google Scholar] [CrossRef]

- Zheng, G.; Pang, T.; Sun, G.; Wu, S.; Li, Q. Theoretical, numerical, and experimental study on laterally variable thickness (LVT) multi-cell tubes for crashworthiness. Int. J. Mech. Sci. 2016, 118, 283–297. [Google Scholar] [CrossRef]

- Mohammadiha, O.; Ghariblu, H. Crush response of variable thickness distribution inversion tubes under oblique loading. Thin-Walled Struct. 2016, 109, 159–173. [Google Scholar] [CrossRef]

- Sun, G.; Tian, X.; Fang, J.; Xu, F.; Li, G.; Huang, X. Dynamical bending analysis and optimization design for functionally graded thickness (FGT) tube. Int. J. Impact Eng. 2015, 78, 128–137. [Google Scholar] [CrossRef]

- Yu, K.; Liu, Y.; Zhang, Z. Energy-absorbing analysis and reliability-based multiobjective optimization design of graded thickness B pillar with grey relational analysis. Thin-Walled Struct. 2019, 145, 106364. [Google Scholar] [CrossRef]

- Fang, J.; Sun, G.; Qiu, N.; Kim, N.H.; Li, Q. On design optimization for structural crashworthiness and its state of the art. Struct. Multidiscip. Optim. 2016, 55, 1091–1119. [Google Scholar] [CrossRef]

- Fang, J.; Gao, Y.; Sun, G.; Qiu, N.; Li, Q. On design of multi-cell tubes under axial and oblique impact loads. Thin-Walled Struct. 2015, 95, 115–126. [Google Scholar] [CrossRef]

- Qiu, N.; Gao, Y.; Fang, J.; Feng, Z.; Sun, G.; Li, Q. Crashworthiness analysis and design of multi-cell hexagonal columns under multiple loading cases. Finite Elem. Anal. Des. 2015, 104, 89–101. [Google Scholar] [CrossRef]

- Fu, J.; Liu, Q.; Liufu, K.; Deng, Y.; Fang, J.; Li, Q. Design of bionic-bamboo thin-walled structures for energy absorption. Thin-Walled Struct. 2019, 135, 400–413. [Google Scholar] [CrossRef]

- Kim, Y.; Yang, C.; Kim, Y.; Gu, G.X.; Ryu, S. Designing an Adhesive Pillar Shape with Deep Learning-Based Optimization. ACS Appl. Mater. Interfaces 2020, 12, 24458–24465. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Fu, H.; He, X.; Wang, C.; Jiang, L.; Chen, L.-Q.; Xie, J. Dramatically Enhanced Combination of Ultimate Tensile Strength and Electric Conductivity of Alloys via Machine Learning Screening. Acta Mater. 2020, 200, 803–810. [Google Scholar] [CrossRef]

- Bessa, M.A.; Glowacki, P.; Houlder, M. Bayesian Machine Learning in Metamaterial Design: Fragile Becomes Supercompressible. Adv. Mater. 2019, 31, e1904845. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Ma, W.; Hou, L.; Xu, P.; Yao, S. Crashworthiness analysis of corrugations reinforced multi-cell square tubes. Thin-Walled Struct. 2020, 150, 106708. [Google Scholar] [CrossRef]

- Li, X.; Yao, R. A machine-learning-based approach to predict residential annual space heating and cooling loads considering occupant behaviour. Energy 2020, 212, 118676. [Google Scholar] [CrossRef]

- Çevik, A.; Kurtoğlu, A.E.; Bilgehan, M.; Gülşan, M.E.; Albegmprli, H. Support vector machines in structural engineering: A review. J. Civ. Eng. Manag. 2015, 21, 261–281. [Google Scholar] [CrossRef]

- Li, Q.; Meng, Q.; Cai, J.; Yoshino, H.; Mochida, A. Predicting hourly cooling load in the building: A comparison of support vector machine and different artificial neural networks. Energy Convers. Manag. 2009, 50, 90–96. [Google Scholar] [CrossRef]

- Zhu, P.; Pan, F.; Chen, W.; Zhang, S. Use of support vector regression in structural optimization: Application to vehicle crashworthiness design. Math. Comput. Simul. 2012, 86, 21–31. [Google Scholar] [CrossRef]

- Wang, W.; Xu, Z.; Lu, W.; Zhang, X. Determination of the spread parameter in the Gaussian kernel for classification and regression. Neurocomputing 2003, 55, 643–663. [Google Scholar] [CrossRef]

- Vapnik, V.; Golowich, S.; Smola, A. Support Vector Method for Function Approximation, Regression Estimation, and Signal Processing. In Advances in Neural Information Processing Systems; MIT Press: Cambridge, MA, USA, 1996. [Google Scholar]

- Shao, M.; Wang, X.; Bu, Z.; Chen, X.; Wang, Y. Prediction of energy consumption in hotel buildings via support vector machines. Sustain. Cities Soc. 2020, 57, 102128. [Google Scholar] [CrossRef]

- Mozumder, R.A.; Roy, B.; Laskar, A.I. Support Vector Regression Approach to Predict the Strength of FRP Confined Concrete. Arab. J. Sci. Eng. 2016, 42, 1129–1146. [Google Scholar] [CrossRef]

- Yang, C.; Li, Q. Structural optimisation for the collapse zone of a railway vehicle. Int. J. Mech. Sci. 2020, 165, 105201. [Google Scholar] [CrossRef]

- Peng, Y.; Hou, L.; Che, Q.; Xu, P.; Li, F. Multi-objective robust optimization design of a front-end underframe structure for a high-speed train. Eng. Optim. 2018, 51, 753–774. [Google Scholar] [CrossRef]

- Deb, K.; Jain, H. An Evolutionary Many-Objective Optimization Algorithm Using Reference-Point-Based Nondominated Sorting Approach, Part I: Solving Problems with Box Constraints. IEEE Trans. Evol. Comput. 2014, 18, 577–601. [Google Scholar] [CrossRef]

| PCF (kN) | MCF (kN) | EA (J) | SEA (kJ/kg) | CFE | |

|---|---|---|---|---|---|

| Test | 14.02 | 7.97 | 478.32 | 10.61 | 0.57 |

| FE | 14.03 | 8.69 | 521.62 | 11.57 | 0.62 |

| Difference (%) | 0.07 | 9.03 | 9.05 | 9.05 | 8.77 |

| Tube | PCF (kN) | SEA (kJ/kg) | CFE | Mass (g) |

|---|---|---|---|---|

| tc2-tm0.5 | 44.55 | 19.94 | 0.84 | 112.72 |

| tc0.5-tm2 | 46.80 | 15.26 | 0.61 | 112.72 |

| tc1.25-tm1.25 | 46.33 | 18.30 | 0.74 | 112.72 |

| Weights | Geometric Parameters | Responses | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| w-SEA | w-CFE | w-PCF | tc | tm | n | SEA | CFE | PCF | ||

| Initial design | 1.25 | 1.25 | 18.30 | 0.74 | 46.33 | |||||

| Optimum 1 | SVR | 0.4 | 0.2 | 0.4 | 1.50 | 0.59 | 0.45 | 19.23 | 0.78 | 38.65 |

| FE | 20.11 | 0.82 | 38.41 | |||||||

| Difference (%) | 4.38 | 4.88 | 0.62 | |||||||

| Improvement (%) | 5.08 | 5.41 | −16.58 | |||||||

| Optimum 2 | SVR | 0.33 | 0.33 | 0.33 | 1.63 | 0.65 | 0.7 | 19.39 | 0.8 | 39.83 |

| FE | 20.12 | 0.85 | 38.89 | |||||||

| Difference (%) | 3.46 | 5.88 | 2.42 | |||||||

| Improvement (%) | 5.96 | 8.11 | −14.03 | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Yang, C.; Yao, S. Impact Performance Prediction and Optimization of a Circumferentially Corrugated Tube with Variable Wall Thickness Using Support Vector Machine. Machines 2023, 11, 217. https://doi.org/10.3390/machines11020217

Li Z, Yang C, Yao S. Impact Performance Prediction and Optimization of a Circumferentially Corrugated Tube with Variable Wall Thickness Using Support Vector Machine. Machines. 2023; 11(2):217. https://doi.org/10.3390/machines11020217

Chicago/Turabian StyleLi, Zhixiang, Chengxing Yang, and Shuguang Yao. 2023. "Impact Performance Prediction and Optimization of a Circumferentially Corrugated Tube with Variable Wall Thickness Using Support Vector Machine" Machines 11, no. 2: 217. https://doi.org/10.3390/machines11020217

APA StyleLi, Z., Yang, C., & Yao, S. (2023). Impact Performance Prediction and Optimization of a Circumferentially Corrugated Tube with Variable Wall Thickness Using Support Vector Machine. Machines, 11(2), 217. https://doi.org/10.3390/machines11020217