Microwave Frequency Offset Induced by Subsurface Damage in Abrasive-Machined Semiconductor Ceramic Waveguide

Abstract

:1. Introduction

2. Experimental Setup

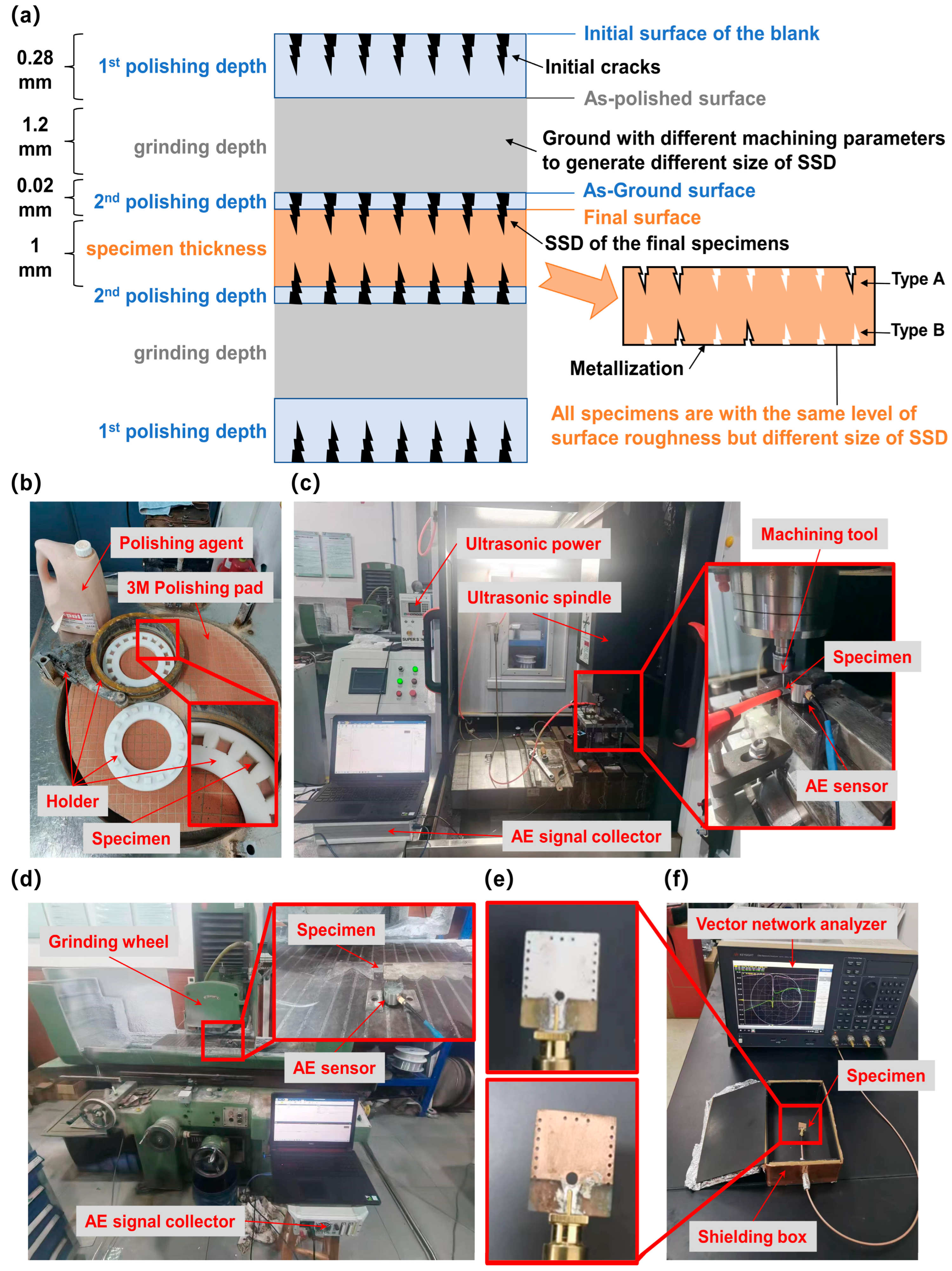

2.1. Design for the Specimen

- Making a given SSD capable of causing as much frequency offset as possible;

- Choosing an appropriate material so that the size of SSD caused by a given abrasive-machined process is as stable as possible;

- Ensuring the specimens can be manufactured and tested.

2.2. Process Designed to Cause Different SSD Sizes

3. Experimental Result

3.1. Observation and Measurement of the SSD

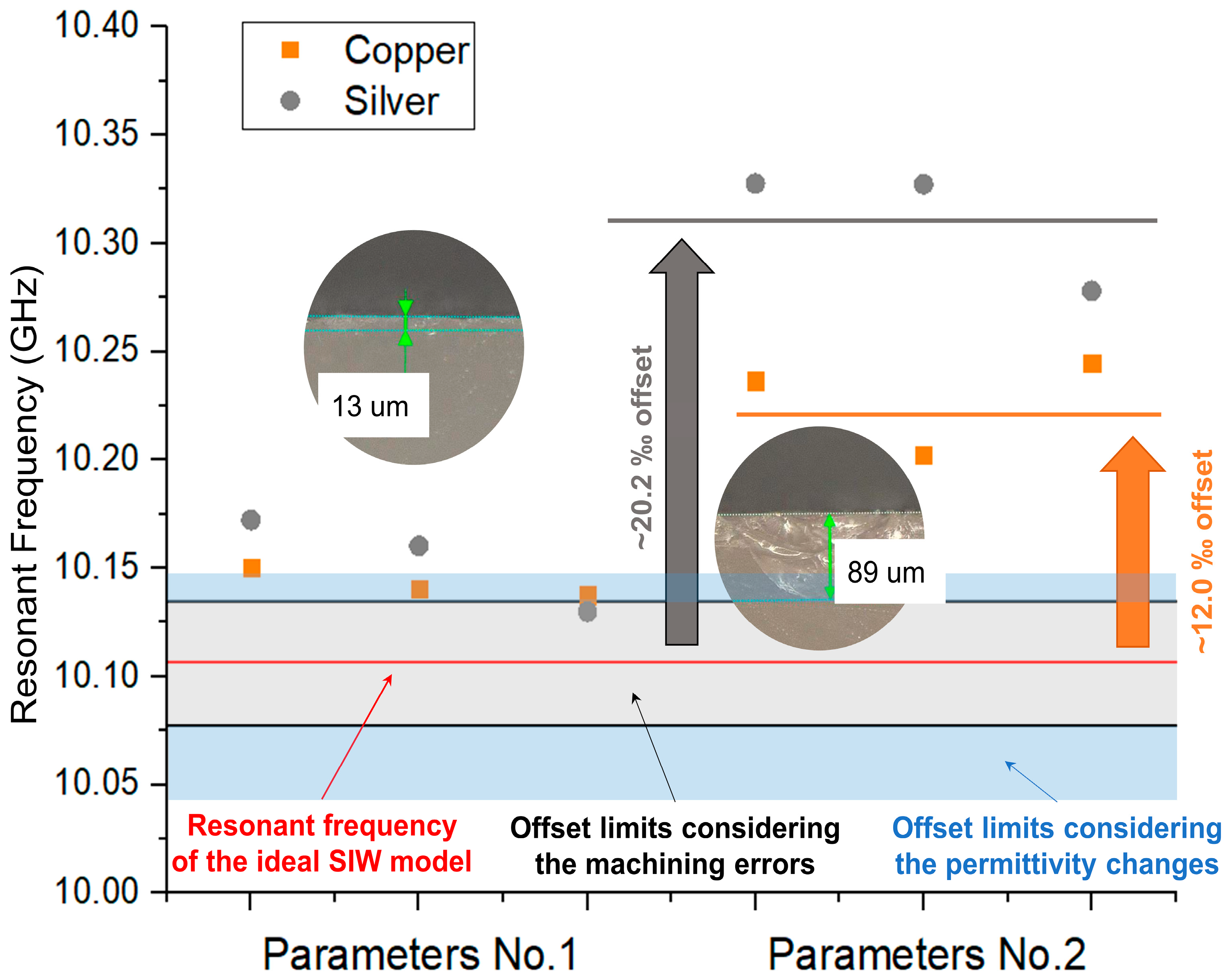

3.2. Measured Frequency Offsets Induced by SSD

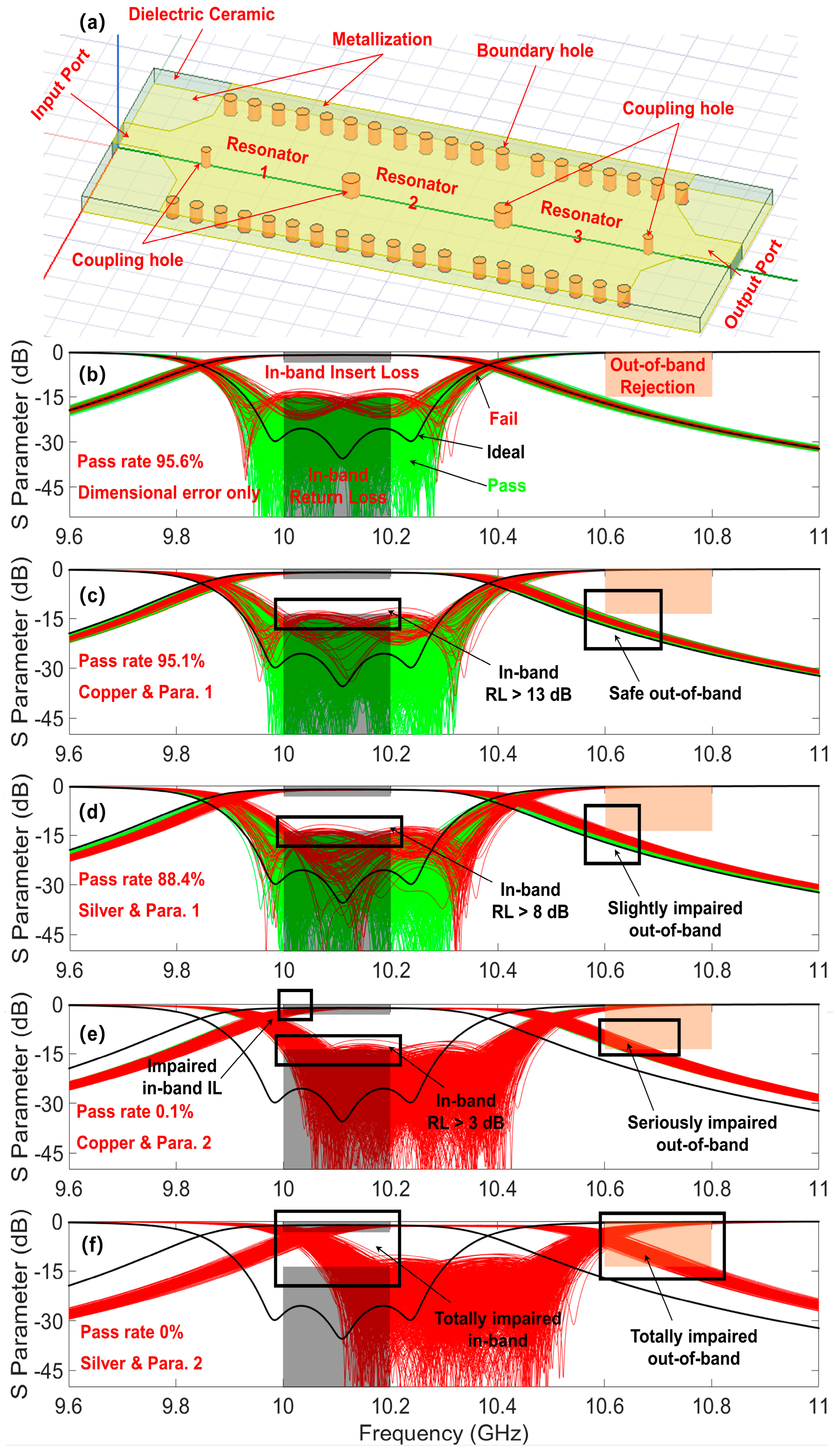

3.3. Impacts of SSD on System Performance

- In each case, generate 3000 cavities, with frequencies following a normal distribution by an expectation value of Aver. Freq. and a standard deviation of STD Freq., as listed in Table 3.

- Randomly select three cavities from the pool of 3000 to form a three-cavity filter. Repeat this selection and forming process 1000 times, resulting in a total of 1000 generated filters.

- Calculate the S parameters of each filter.

- Plot the S parameters in a figure, where the green line indicates that the corresponding filter meets the specified requirements, while the red line signifies that the filter does not qualify.

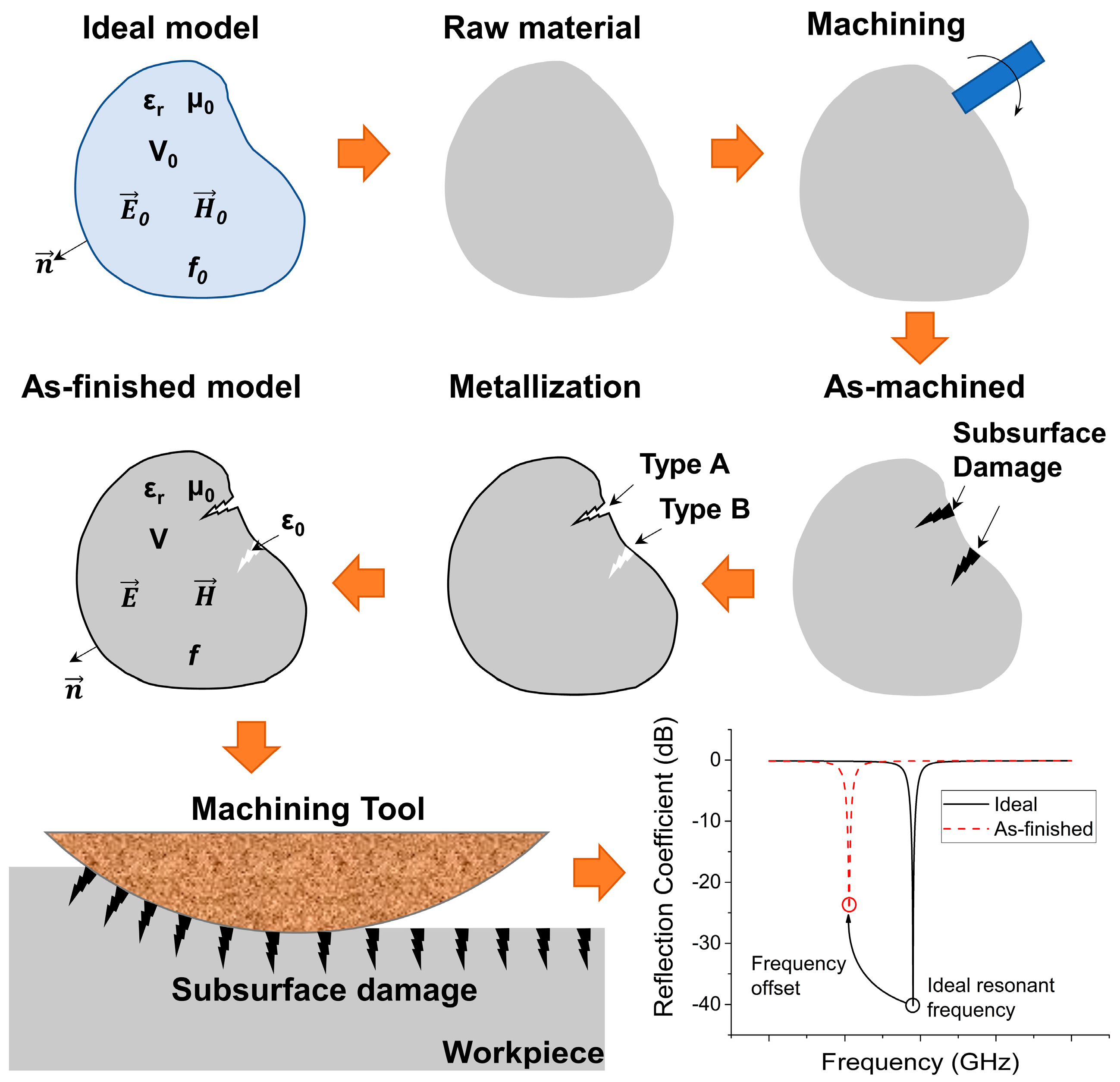

4. Theoretic Analysis on Mechanism

4.1. Discussion on General Cases

4.2. Discussion on the SIW in the Experiments

- If all cracks are of Type A, then the induced frequency offset is calculated through (A9).

- If all cracks are of Type B, then (A10) can be employed.

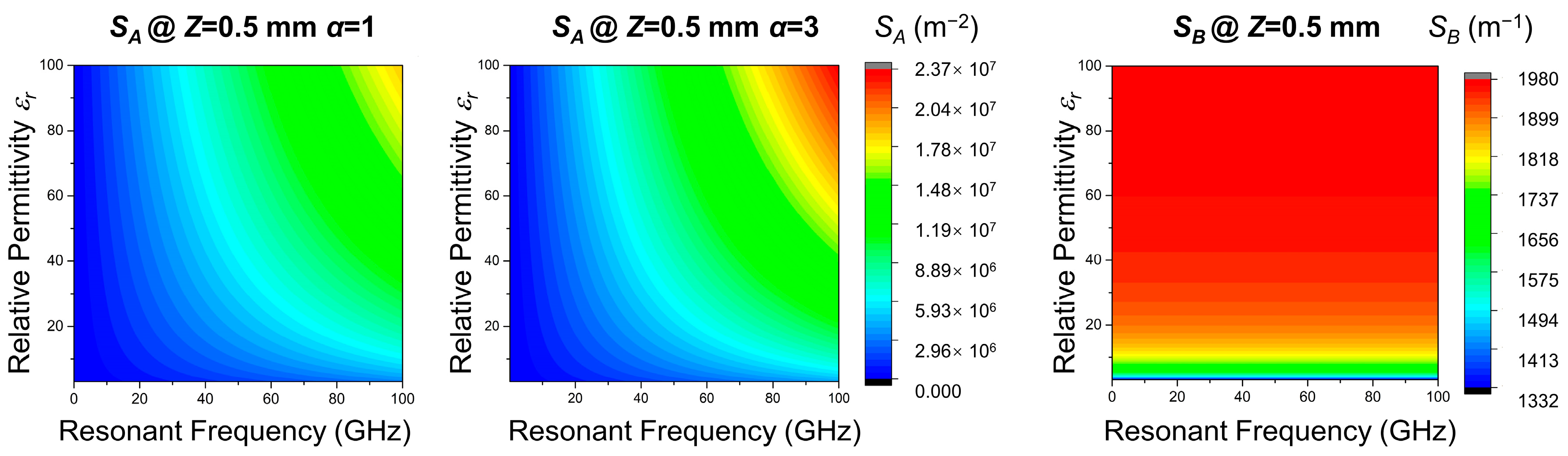

4.3. Discussion on SA and SB

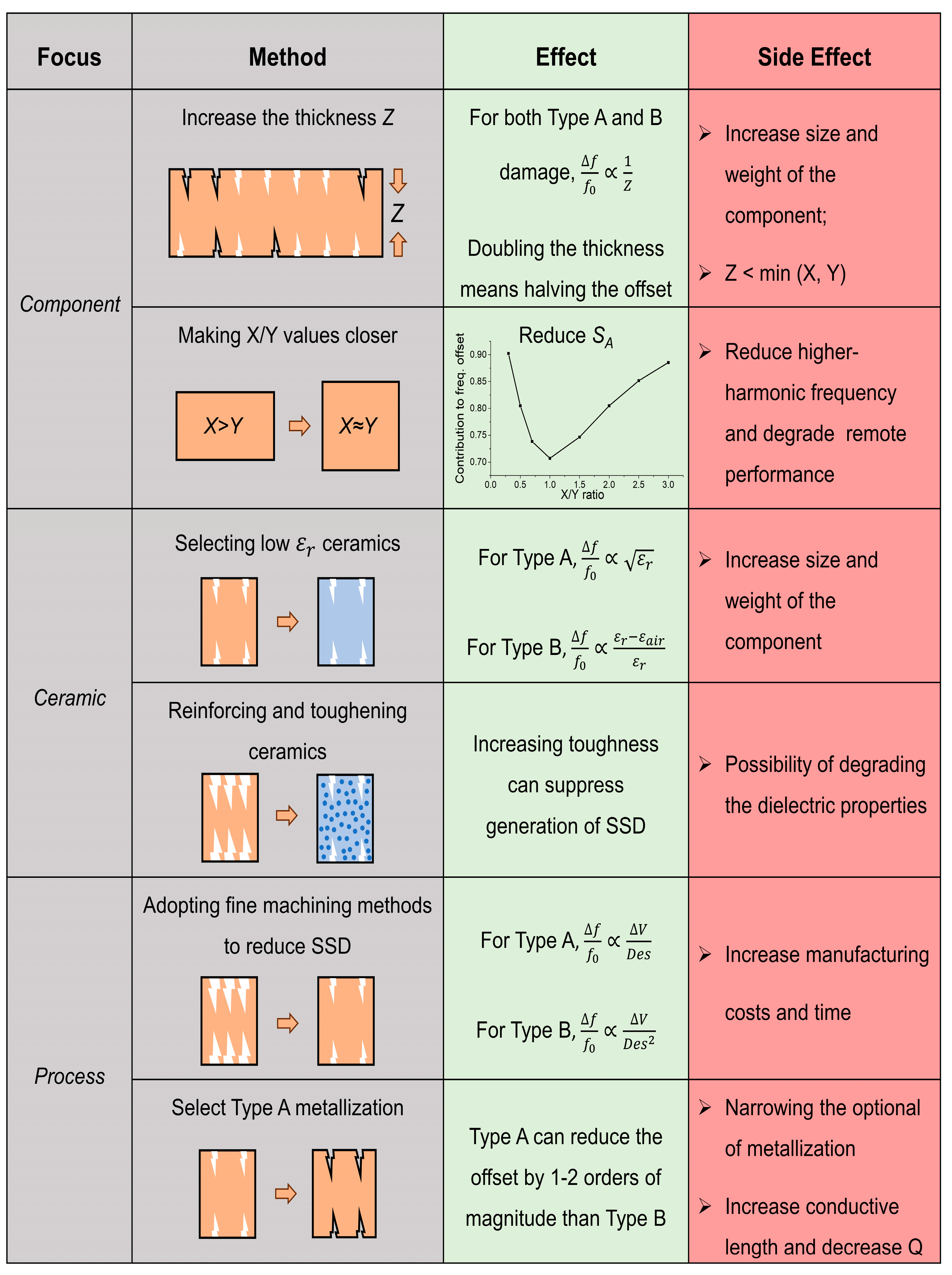

4.4. Methods to Reduce the Offset Induced by SSD

5. Conclusions

- This study presents, for the first time, the impact of SSD on the frequency performance of ceramic waveguide components, experimentally confirming a maximum frequency offset of 20.2% at 10.1 GHz and theoretically calculating a maximum frequency offset of 176% at 70 GHz.

- The perturbation method is introduced to conceptually explain why SSD can cause a frequency offset in a ceramic waveguide component. The derivation provides a quantitative estimation of the limiting range of the offset caused by given SSD, demonstrating that miniaturized resonators working at high frequencies are more affected.

- The rationalized design of waveguided components can decrease sensitivity to SSD, while optimized processing can reduce the size of SSD. Metallization processes using smaller particles are also beneficial. These considerations are crucial for advanced applications of ceramic devices in high-performance communication and frequency control systems.

- This work exemplifies the interdisciplinary intersection of microwave engineering, materials science, and manufacturing technology. It highlights that only by combining electromagnetic design methods, high-performance materials, and optimized machining processes, can high-quality and highly reliable microwave components be produced. This research paves the way for further interdisciplinary studies on microwave semiconductor components and systems. Methods for measuring the volume and density of SSD are also anticipated.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Detailed Statistical Information

| Type of Instance | Conditions | Resonant Frequency (GHz) | Frequency Offset (%) | Average Offset (%) | STD. Offset (%) | Data Application | ||

|---|---|---|---|---|---|---|---|---|

| Size Error | SSD | Metallization | ||||||

| Simulation | No | No | Ideal | 10.1065 | 0 | 0 | - | Figure 1c |

| Yes | No | Ideal | 10.0773 | −2.8892 | 0.3025 | 1.5418 | Figure 1e Table 3 | |

| 10.092 | −1.4347 | |||||||

| 10.0997 | −0.6728 | |||||||

| 10.1032 | −0.3265 | |||||||

| 10.1053 | −0.1187 | |||||||

| 10.1074 | 0.089 | |||||||

| 10.1102 | 0.3661 | |||||||

| 10.113 | 0.6431 | |||||||

| 10.1144 | 0.7816 | |||||||

| 10.1284 | 2.1669 | |||||||

| 10.1291 | 2.2361 | |||||||

| 10.1347 | 2.7902 | |||||||

| Experiment | Yes | Para. No. 1 | Silver | 10.17230 | 6.5106 | 4.7229 | 1.755 | Figure 4 Table 3 |

| 10.16027 | 5.3203 | |||||||

| 10.13013 | 2.338 | |||||||

| Yes | Para. No. 1 | Copper | 10.15009 | 4.313 | 3.5953 | 0.5227 | ||

| 10.14076 | 3.3898 | |||||||

| 10.13766 | 3.0831 | |||||||

| Yes | Para. No. 2 | Silver | 10.32758 | 21.875 | 20.2265 | 2.3047 | ||

| 10.32720 | 21.8374 | |||||||

| 10.27798 | 16.9672 | |||||||

| Yes | Para. No. 2 | Copper | 10.23660 | 12.8729 | 12.0127 | 1.8152 | ||

| 10.20239 | 9.4879 | |||||||

| 10.24473 | 13.6773 | |||||||

| Calculation | No | ∆V = 4 × 10−5 mm3 and Des = 0.03 mm | If all cracks are Type A | - | - | 0.25 | - | Table 4 |

| If all cracks are Type B | - | - | 31.7 | - | ||||

Appendix B. Detailed Perturbation Derivation for the SIW Resonator with SSD

- For the condition that all cracks are Type A:

- For the condition that all cracks are Type B:

- On the top and bottom surfaces (xy plane, z = 0 and z = Z):

- On the left and right surfaces (xz plane, y = 0 and y = Y):

- On the front and back surfaces (yz plane, x = 0 and x = X):

- If all cracks are Type A, then

- If all cracks are Type B, then

References

- Ohsato, H.; Tsunooka, T.; Sugiyama, T.; Kakimoto, K.-I.; Ogawa, H. Forsterite ceramics for millimeterwave dielectrics. J. Electroceram. 2006, 17, 445–450. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, S.; Yang, H.; Wen, Q.; Yang, Q.; Gui, L.; Zhao, Q.; Li, E. The latest process and challenges of microwave dielectric ceramics based on pseudo phase diagrams. J. Adv. Ceram. 2021, 10, 885–932. [Google Scholar] [CrossRef]

- Ermawati, F.U. The Response of (Mg0.6Zn0.4)TiO3 Ceramic System as A Dielectric Resonator Oscillator at C-Band. J. Phys. Conf. Ser. 2021, 1805, 012039. [Google Scholar] [CrossRef]

- Ni, L.; Li, L.; Du, M.; Zhan, Y. Wide temperature stable Ba(MgxTa2/3)O3 microwave dielectric ceramics with ultra-high-Q applied for 5G dielectric filter. Ceram. Int. 2021, 47, 1034–1039. [Google Scholar] [CrossRef]

- Zhou, M.F.; Hu, C.C.; Yin, J.B.; Jiang, Y.; Liu, B.; Song, K.X. Cold sintering optimized SrF2 microwave dielectric ceramics for the development of dielectric resonator antenna at 5G millimeter-wave band. Ceram. Int. 2022, 48, 29847–29853. [Google Scholar] [CrossRef]

- Chen, Y.-C.; Weng, M.-Z.; Du, Y.-X.; Hsiao, C.-L. Microwave dielectric properties of Nd(Ti0.5−xZrx)W0.5O4 ceramics for application in antenna temperature sensor. J. Mater. Sci. Mater. Electron. 2018, 29, 4717–4723. [Google Scholar] [CrossRef]

- Kazemi, N.; Abdolrazzaghi, M.; Light, P.E.; Musilek, P. In–human testing of a non-invasive continuous low–energy microwave glucose sensor with advanced machine learning capabilities. Biosens. Bioelectron. 2023, 241, 115668. [Google Scholar] [CrossRef]

- Abdolrazzaghi, M.; Kazemi, N.; Nayyeri, V.; Martin, F. AI-Assisted Ultra-High-Sensitivity/Resolution Active-Coupled CSRR-Based Sensor with Embedded Selectivity. Sensors 2023, 23, 6236. [Google Scholar] [CrossRef]

- Kamutzki, F.; Schneider, S.; Barowski, J.; Gurlo, A.; Hanaor, D.A.H. Silicate dielectric ceramics for millimetre wave applications. J. Eur. Ceram. Soc. 2021, 41, 3879–3894. [Google Scholar] [CrossRef]

- Narang, S.B.; Bahel, S. Low loss dielectric ceramics for microwave applications: A review. J. Ceram. Process. Res. 2010, 11, 316–321. [Google Scholar]

- Abdolrazzaghi, M.; Nayyeri, V.; Martin, F. Techniques to Improve the Performance of Planar Microwave Sensors: A Review and Recent Developments. Sensors 2022, 22, 6946. [Google Scholar] [CrossRef] [PubMed]

- Basu, J.; Bhattacharyya, T.K. Microelectromechanical resonators for radio frequency communication applications. Microsyst. Technol. 2011, 17, 1557. [Google Scholar] [CrossRef]

- Zhai, W.; Xin, Y.; Xie, M.; Zhao, M.; Huang, S. Phase noise suppression for RF signal remote fiber transmission using phase balance compensation feedback network in phase shifter. Optik 2019, 177, 131–135. [Google Scholar] [CrossRef]

- Wang, J.; Chen, X.M.; Yang, J.S. Temperature-stable dielectric ceramics in Ba4Nd2Ti4Ta6O30/(La0.1Bi0.9)2Ti2O7 biphase system. J. Mater. Res. 1999, 14, 3375–3378. [Google Scholar] [CrossRef]

- Wang, K.; Zhou, H.; Luan, X.; Hu, S.; Zhou, X.; He, S.; Wang, X.; Zhou, S.; Chen, X. NaTaO3 microwave dielectric ceramic a with high relative permittivity and as an excellent compensator for the temperature coefficient of resonant frequency. Ceram. Int. 2021, 47, 121–129. [Google Scholar] [CrossRef]

- Dou, Z.; Wang, G.; Jiang, J.; Zhang, F.; Zhang, T. Understanding microwave dielectric properties of (1−x)CaTiO3–xLaAlO3 ceramics in terms of A/B-site ionic-parameters. J. Adv. Ceram. 2017, 6, 20–26. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, F.; Guo, J.; Zhang, Y.; Yang, H.; Zhang, Q. Surface-modified Zn0.5Ti0.5NbO4 particles filled polytetrafluoroethylene composite with extremely low dielectric loss and stable temperature dependence. J. Adv. Ceram. 2020, 9, 726–738. [Google Scholar] [CrossRef]

- Teberio, F.; Gomez-Torrent, A.; Arregui, I.; Percaz, J.M.; Arnedo, I.; Chudzik, M.; Lopetegi, T.; Laso, M.A.G. Sensitivity analysis of a 3-D printed low-cost compact waveguide low-pass filter. In Proceedings of the EuMW 2016—Conference Proceedings; 46th European Microwave Conference, EuMC, London, UK, 4–6 October 2016; European Microwave Week 2016: “Microwaves Everywhere”. pp. 249–252. [Google Scholar]

- Teberio, F.; Soto, P.; Arregui, I.; Lopetegi, T.; Cogollos, S.; Arnedo, I.; Martin-Iglesias, P.; Boria, V.E.; Laso, M.A.G. Waveguide band-pass filter with reduced sensitivity to fabrication tolerances for Q-band payloads. In Proceedings of the IEEE MTT-S International Microwave Symposium Digest, Honolulu, HI, USA, 4–9 June 2017; pp. 1464–1467. [Google Scholar]

- Yang, H.; Dhayalan, Y.; Shang, X.; Lancaster, M.J.; Liu, B.; Wang, H.; Henry, M.; Huggard, P.G. WR-3 Waveguide Bandpass Filters Fabricated Using High Precision CNC Machining and SU-8 Photoresist Technology. IEEE Trans. Terahertz Sci. Technol. 2018, 8, 100–107. [Google Scholar] [CrossRef]

- Wang, H.; Wei, J.; Lin, B.; Zhang, Y.; Hou, H.; Sui, T. Ultraprecise Resonant Frequency Prediction of Microwave Cavities with Deformations. IEEE Trans. Microw. Theory Tech. 2023, 1–10. [Google Scholar] [CrossRef]

- Zhang, B.; Yin, J. The ‘skin effect’ of subsurface damage distribution in materials subjected to high-speed machining. Int. J. Extrem. Manuf. 2019, 1, 012007. [Google Scholar] [CrossRef]

- Bin, L.; Junpeng, Z.; Zhong-Chen, C.; Jiannan, Z.; Tian, H. Theoretical and experimental investigation on surface generation and subsurface damage in fixed abrasive lapping of optical glass. Int. J. Mech. Sci. 2022, 215, 106941. [Google Scholar] [CrossRef]

- Jiwang, Y.; Xiaohui, G.; Hirofumi, H. Subsurface damage of single crystalline silicon carbide in nanoindentation tests. J. Nanosci. Nanotechnol. 2010, 10, 7808–7811. [Google Scholar]

- Li, H.N.; Yu, T.B.; Zhu, L.D.; Wang, W.S. Analytical modeling of grinding-induced subsurface damage in monocrystalline silicon. Mater. Des. 2017, 130, 250–262. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, X.; Liu, H.; Wang, F.; Jiang, X.; Wu, W.; Tang, Y.; Zheng, W. Influence of subsurface defects on damage performance of fused silica in ultraviolet laser. Opt. Eng. 2013, 52, 024203. [Google Scholar] [CrossRef]

- Chunyang, W.; Rongting, G.; Xuelian, L.; Yana, C.; Tiantian, L. Study on the relationship between the fluorescence characteristics of quantum dots and the subsurface damage of fused silica. In Proceedings of the 2021 IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO), Xi’an, China, 2–6 August 2021; pp. 258–263. [Google Scholar]

- Kakinuma, Y.; Azami, S.; Tanabe, T. Evaluation of subsurface damage caused by ultra-precision turning in fabrication of CaF2 optical micro resonator. CIRP Ann. 2015, 64, 117–120. [Google Scholar] [CrossRef]

- Mazzù, A.; Solazzi, L.; Lancini, M.; Petrogalli, C.; Ghidini, A.; Faccoli, M. An experimental procedure for surface damage assessment in railway wheel and rail steels. Wear 2015, 342–343, 22–32. [Google Scholar] [CrossRef]

- Levikari, S.; Kärkkäinen, T.J.; Andersson, C.; Tammminen, J.; Silventoinen, P. Acoustic Detection of Cracks and Delamination in Multilayer Ceramic Capacitors. IEEE Trans. Ind. Appl. 2019, 55, 1787–1794. [Google Scholar] [CrossRef]

- Cao, X.; Jin, F.; Jeon, I. Rayleigh surface wave in a piezoelectric wafer with subsurface damage. Appl. Phys. Lett. 2009, 95, 261906. [Google Scholar] [CrossRef]

- Tian, Y.; Li, J.; Luo, G.; Fang, Q. Tribological property and subsurface damage of nanotwinned Cu/FeCoCrNi high entropy alloy nanolaminates at various scratching velocities and normal loads. Tribol. Int. 2022, 169, 107435. [Google Scholar] [CrossRef]

- Li, B.; Li, P.; Zhou, R.; Feng, X.-Q.; Zhou, K. Contact mechanics in tribological and contact damage-related problems: A review. Tribol. Int. 2022, 171, 107534. [Google Scholar] [CrossRef]

- Agarwal, S.; Rao, P.V. Experimental investigation of surface/subsurface damage formation and material removal mechanisms in SiC grinding. Int. J. Mach. Tools Manuf. 2008, 48, 698–710. [Google Scholar] [CrossRef]

- Gu, Y.; Zhou, Y.; Lin, J.; Yi, A.; Kang, M.; Lu, H.; Xu, Z. Analytical Prediction of Subsurface Damages and Surface Quality in Vibration-Assisted Polishing Process of Silicon Carbide Ceramics. Materials 2019, 12, 1690. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Qiu, Z.; Lu, C.; Li, X.; Tang, J. Modelling the strain rate sensitivity on the subsurface damages of scratched glass ceramics. Ceram. Int. 2017, 43, 12930–12938. [Google Scholar] [CrossRef]

- Wang, H.; Chen, H.; Xiao, L.; Zhang, B.; Jiang, Z. Fast Predicting Statistical Subsurface Damage Parameters of the K9 Sample. Int. J. Optomechatronics 2015, 9, 248–259. [Google Scholar] [CrossRef]

- Yoo Jin, K.; Jofre, L.; Flaviis, F.D.; Feng, M.Q. Microwave reflection tomographic array for damage detection of civil structures. IEEE Trans. Antennas Propag. 2003, 51, 3022–3032. [Google Scholar] [CrossRef]

- Dong, J.; Pomarède, P.; Chehami, L.; Locquet, A.; Meraghni, F.; Declercq, N.F.; Citrin, D.S. Visualization of subsurface damage in woven carbon fiber-reinforced composites using polarization-sensitive terahertz imaging. NDT E Int. 2018, 99, 72–79. [Google Scholar] [CrossRef]

- Dai, H.; Zhang, F.; Chen, J. A study of ultraprecision mechanical polishing of single-crystal silicon with laser nano-structured diamond abrasive by molecular dynamics simulation. Int. J. Mech. Sci. 2019, 157–158, 254–266. [Google Scholar] [CrossRef]

- Ahmed, Y.; Cong, W.L.; Stanco, M.R.; Xu, Z.G.; Pei, Z.J.; Treadwell, C.; Zhu, Y.L.; Li, Z.C. Rotary Ultrasonic Machining of Alumina Dental Ceramics: A Preliminary Experimental Study on Surface and Subsurface Damages. J. Manuf. Sci. Eng. 2012, 134, 064501. [Google Scholar] [CrossRef]

- Zhou, H.; Jiang, W.; Ji, J.; Ren, X.; Zhu, Z.; Zhang, C. Prediction and experimental investigation of depth of subsurface damage in semi-consolidated abrasive grinding of cleavable gallium oxide crystals. Int. J. Adv. Manuf. Technol. 2022, 119, 855–864. [Google Scholar] [CrossRef]

- Junpeng, Z.; Zhong-Chen, C.; Yang, Z.; Bin, L. Investigation on surface evolution and subsurface damage in abrasive lapping of hard and brittle materials using a novel fixed lapping tool. J. Manuf. Process. 2022, 75, 729–738. [Google Scholar] [CrossRef]

- Lin, B.; Jiang, X.-M.; Cao, Z.-C.; Li, Y. Novel Disc Hydrodynamic Polishing Process and Tool for High-Efficiency Polishing of Ultra-Smooth Surfaces. Micromachines 2018, 9, 333. [Google Scholar] [CrossRef] [PubMed]

- Hong, J.-S. Microstrip Filters for RF/Microwave Applications, 2nd ed.; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2011; pp. 62–65. [Google Scholar]

- Hakki, B.W.; Coleman, P.D. A Dielectric Resonator Method of Measuring Inductive Capacities in the Millimeter Range. IRE Trans. Microw. Theory Tech. 1960, 8, 402–410. [Google Scholar] [CrossRef]

- Huang, H.; Lawn, B.R.; Cook, R.F.; Marshall, D.B. Critique of materials-based models of ductile machining in brittle solids. J. Am. Ceram. Soc. 2020, 103, 6096–6100. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, L.; Lin, B.; Zhang, G.; Ni, C.; Sui, T. The grinding force modeling and experimental study of ZrO2 ceramic materials in ultrasonic vibration assisted grinding. Ceram. Int. 2019, 45, 8873–8889. [Google Scholar] [CrossRef]

- Li, C.; Zhang, F.; Meng, B.; Liu, L.; Rao, X. Material removal mechanism and grinding force modelling of ultrasonic vibration assisted grinding for SiC ceramics. Ceram. Int. 2017, 43, 2981–2993. [Google Scholar] [CrossRef]

- Huang, H.; Li, X.; Mu, D.; Lawn, B.R. Science and art of ductile grinding of brittle solids. Int. J. Mach. Tools Manuf. 2021, 161, 103675. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Y.; Lin, B.; Wei, J.; He, Y.; Zhao, F.; Fang, S. What roles do ceramic matrix and woven fibers have in bending strength of SiO2/SiO2 composites: An experimental investigation and acoustic emission analysis. Ceram. Int. 2019, 45, 1143–1149. [Google Scholar] [CrossRef]

- Pozar, D.M. Microwave Engineering, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Wang, S.; Zhao, Q.; Yang, X. Surface and subsurface microscopic characteristics in sapphire ultra-precision grinding. Tribol. Int. 2022, 174, 107710. [Google Scholar] [CrossRef]

| Density | Young’s Modulus | Scratch Hardness | Poisson’s Ratio | Fracture Toughness |

|---|---|---|---|---|

| E | H | KC | ||

| g/cm3 | GPa | GPa | ||

| 2.201 | 72.5 | 7.4 | 0.17 | 0.75 |

| Set No. | 1 | 2 | ||

| Drilling Method | A | B | ||

| Grinding depth | dg | mm | 0.02 | 0.08 |

| Spindle speed | ns | rpm | 5000 | 5000 |

| Feeding speed | vw | mm/s | 10 | 10 |

| Mesh number | M | # | 600 | 600 |

| Wheel diameter | dw | mm | 300 | 300 |

| Maximum undeformed chip thickness | Hm | nm | 24.1 | 34.1 |

| Material removal mode | Ductile | Brittle |

| Cases in Figure 5 | Size Errors | Set of Machining Parameters | Metallization | Aver. Frequency (GHz) | STD. Frequency (GHz) | Data Source |

|---|---|---|---|---|---|---|

| (b) | Yes | No SSD | Ideal | 10.109 | 0.015 | Figure 1e |

| (c) | Yes | 1 | Copper | 10.142 | 0.015 | Figure 4 |

| (d) | Yes | 1 | Silver | 10.154 | 0.017 | Figure 4 |

| (e) | Yes | 2 | Copper | 10.227 | 0.018 | Figure 4 |

| (f) | Yes | 2 | Silver | 10.310 | 0.023 | Figure 4 |

| Frequency | Z | εr | SA | SB | |||

|---|---|---|---|---|---|---|---|

| GHz | mm | ×105 m−2 | % | ×103 m−1 | % | ||

| 3.5 | 5 | 1.5 | 21 | 0.32 | 0.04 | 0.19 | 8.47 |

| 3.5 | 5 | 3 | 80 | 0.74 | 0.09 | 0.20 | 8.78 |

| 10 | 1 | 1.5 | 3.5 | 1.86 | 0.25 | 0.71 | 31.7 |

| 10 | 0.25 | 3 | 21 | 21.7 | 2.89 | 3.81 | 169 |

| 30 | 1 | 1.5 | 3.5 | 5.59 | 0.74 | 0.71 | 31.7 |

| 30 | 0.25 | 3 | 21 | 65.0 | 8.66 | 3.81 | 169 |

| 70 | 1 | 1.5 | 3.5 | 13.0 | 1.74 | 0.71 | 31.7 |

| 70 | 0.25 | 3 | 21 | 152 | 20.2 | 3.81 | 169 |

| 70 | 0.25 | 3 | 80 | 296 | 39.4 | 3.95 | 176 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Wei, J.; Lin, B.; Cui, X.; Hou, H.; Fu, Z.; Ding, J.; Sui, T. Microwave Frequency Offset Induced by Subsurface Damage in Abrasive-Machined Semiconductor Ceramic Waveguide. Machines 2023, 11, 1057. https://doi.org/10.3390/machines11121057

Wang H, Wei J, Lin B, Cui X, Hou H, Fu Z, Ding J, Sui T. Microwave Frequency Offset Induced by Subsurface Damage in Abrasive-Machined Semiconductor Ceramic Waveguide. Machines. 2023; 11(12):1057. https://doi.org/10.3390/machines11121057

Chicago/Turabian StyleWang, Haoji, Jinhua Wei, Bin Lin, Xiaoqi Cui, Hetian Hou, Zhiyuan Fu, Jianchun Ding, and Tianyi Sui. 2023. "Microwave Frequency Offset Induced by Subsurface Damage in Abrasive-Machined Semiconductor Ceramic Waveguide" Machines 11, no. 12: 1057. https://doi.org/10.3390/machines11121057

APA StyleWang, H., Wei, J., Lin, B., Cui, X., Hou, H., Fu, Z., Ding, J., & Sui, T. (2023). Microwave Frequency Offset Induced by Subsurface Damage in Abrasive-Machined Semiconductor Ceramic Waveguide. Machines, 11(12), 1057. https://doi.org/10.3390/machines11121057