Influence of Piston Mass and Working Pressure on the Impact Performance of a Hydraulic Rock Drill Using the Stress Wave Method

Abstract

:1. Introduction

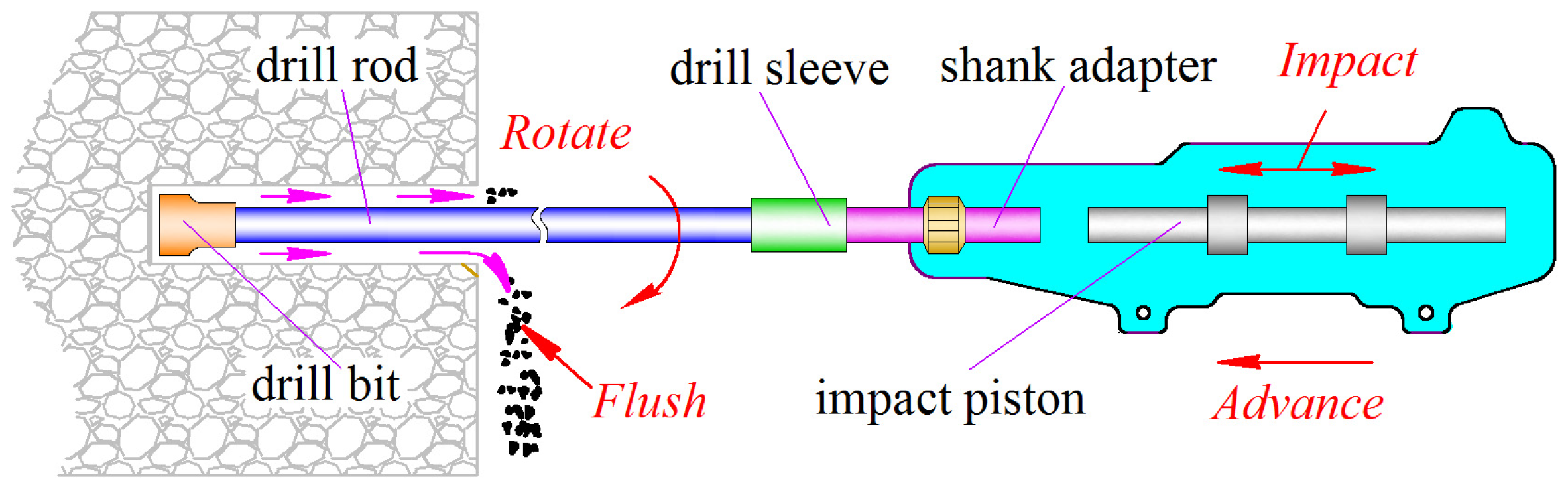

2. Rock-Drilling Process

3. Construction of Experimental Platform

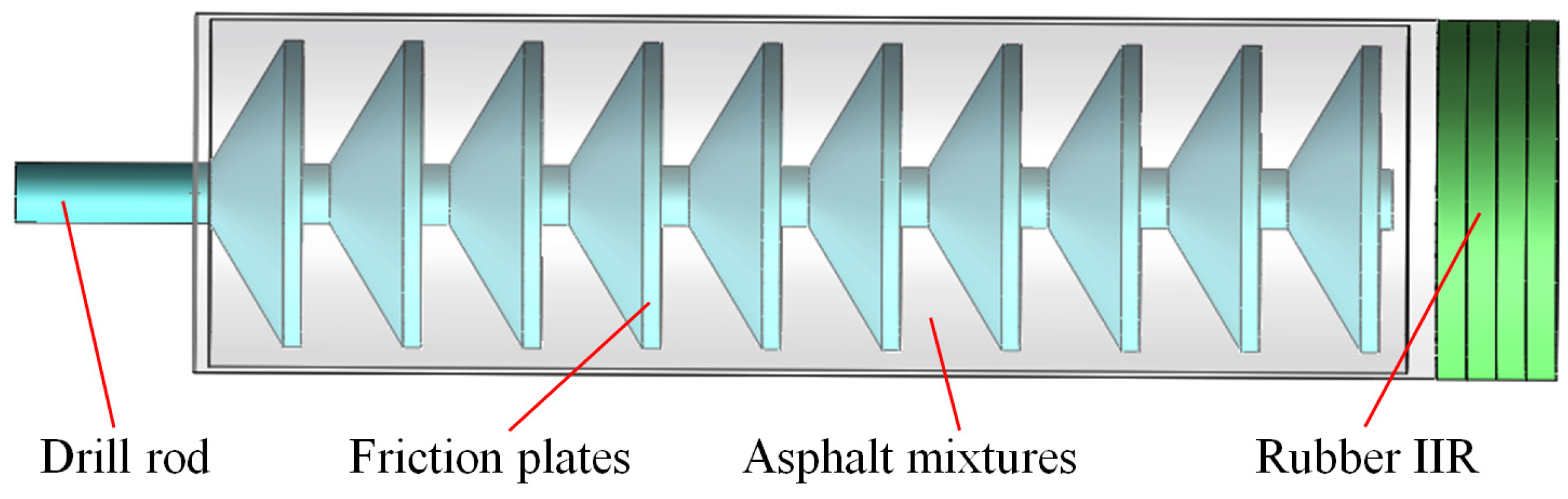

3.1. Introduction to the Test Bench

3.2. Impact Energy Transfer Process

3.3. Experimental Calibration

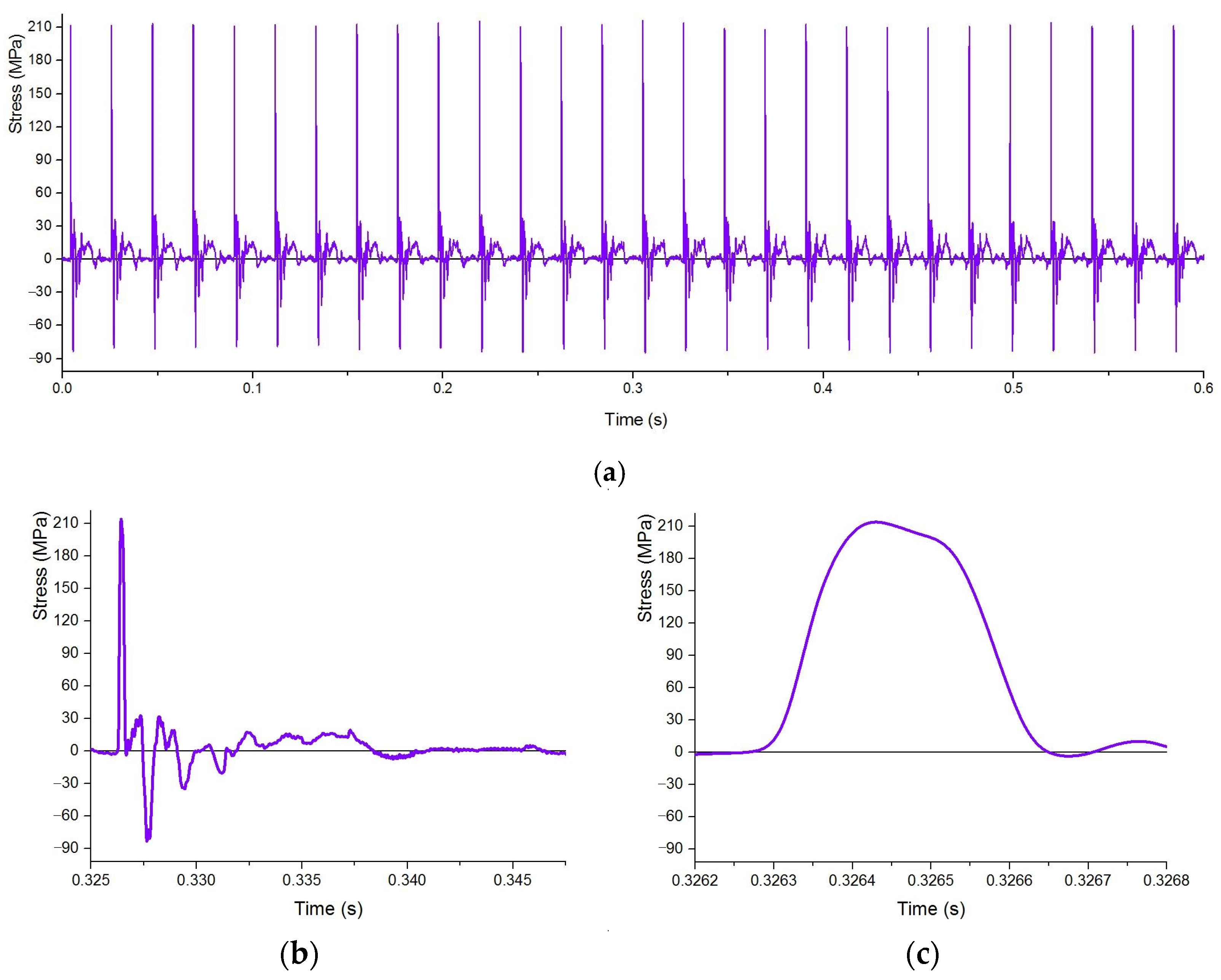

4. Data Collection

4.1. Stress Spectrum

4.2. Impact Results

5. Impact Performance Analysis

5.1. Impact Performance When Piston Mass Changes

5.2. Impact Performance When Working Pressure Changes

5.3. Energy Utilization Rate

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Long, R.; Sun, S.; Lian, Z. Research on the hard-rock breaking mechanism of hydraulic drilling impact tunneling. Math. Probl. Eng. 2015, 16, 153648. [Google Scholar] [CrossRef]

- Ma, W.; Geng, X.; Jia, C.; Gao, L.; Liu, Y.; Tian, X. Percussion characteristic analysis for hydraulic rock drill with no constant-pressurized chamber through numerical simulation and experiment. Adv. Mech. Eng. 2019, 4. [Google Scholar] [CrossRef]

- Li, Y. Research on the matching of impact performance and collision coefficient of hydraulic rock drill. Shock Vib. 2021, 2021, 6651860. [Google Scholar] [CrossRef]

- Seo, J.; Noh, D.K.; Lee, G.H.; Jang, J.S. A percussion performance analysis for rock-drill drifter through simulation modeling and experimental validation. Int. J. Precis. Eng. Man. 2016, 17, 163–170. [Google Scholar] [CrossRef]

- Giuffrida, A.; Laforgia, D. Modelling and Simulation of a Hydraulic Breaker. Int. J. Fluid Power 2005, 6, 47–56. [Google Scholar] [CrossRef]

- Song, C.; Chung, J.; Kim, J.H.; Oh, J.Y. Design optimization of a drifter using the taguchi method for efficient percussion drilling. J. Mech. Sci. Technol. 2017, 31, 1797–1803. [Google Scholar] [CrossRef]

- Song, C.H.; Kwon, K.B.; Cho, M.G.; Oh, J.Y.; Shin, D.Y.; Cho, J.W. Development of lab-scale rock drill apparatus for testing performance of a drill bit. Int. J. Precis. Eng. Man. 2015, 16, 1405–1414. [Google Scholar] [CrossRef]

- Hu, Q.; Yang, C.; Zheng, H.; Chen, M. Dynamic simulation and test research of impact performance of hydraulic rock drill with no constant-pressurized chamber. Automat. Constr. 2014, 37, 211–216. [Google Scholar] [CrossRef]

- Yang, S.Y.; Ou, Y.B.; Guo, Y.; Wu, X.M. Analysis and optimization of the working parameters of the impact mechanism of hydraulic rock drill based on a numerical simulation. Int. J. Precis. Eng. Man. 2017, 18, 971–977. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Ji, H.; Li, Y.G. Analysis on the main design parameters influencing the impact efficiency of dual-chamber-controlled hydraulic drifter. Int. J. Precis. Eng. Man. 2018, 19, 1781–1791. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Ji, H.; Li, Y.G. Existence scope of only primary vibration within one impact period of a hydraulic drifter piston via point transformation. J. Adv. Mech. Des. Syst. 2018, 12, JAMDSM0123. [Google Scholar] [CrossRef]

- Ficarella, A.; Giuffrida, A.; Laforgia, D. Numerical investigations on the working cycle of a hydraulic breaker: Off-design performance and influence of design parameters. Int. J. Fluid Power 2006, 7, 41–50. [Google Scholar] [CrossRef]

- Dutta, P.K. The determination of stress wave forms produced by percussive drill pistons of various geometrical designs. Int. J. Rock Mech. Min. 1968, 5, 501–510. [Google Scholar] [CrossRef]

- Changming, W. An analytical study of percussive energy transfer in hydraulic rock drills. Min. Sci. Technol. 1991, 13, 57–68. [Google Scholar] [CrossRef]

- Nygren, T.; Andersson, L.E.; Lundberg, B. Optimization of elastic junctions with regard to transmission of wave energy. Wave Motion 2001, 240, 467–481. [Google Scholar] [CrossRef]

- Nygren, T.; Andersson, L.E.; Lundberg, B. Synthesis of elastic junctions with wave transmission properties of a given junction. Wave Motion 1999, 30, 143–158. [Google Scholar] [CrossRef]

- Lundberg, B.; Okrouhlik, M. Efficiency of a percussive rock drilling process with consideration of wave energy radiation into the rock. Int. J. Impact. Eng. 2006, 32, 1573–1583. [Google Scholar] [CrossRef]

- Chiang, L.E.; Elas, D.A. Modeling impact in down-the-hole rock drilling. Int. J. Rock Mech. Min. 2000, 37, 599–613. [Google Scholar] [CrossRef]

- Kahraman, S.A.İ.R.; Bilgin, N.; Feridunoglu, C. Dominant rock properties affecting the penetration rate of percussive drills. Int. J. Rock Mech. Min. 2003, 40, 711–723. [Google Scholar] [CrossRef]

- Li, X.; Rupert, G.; Summers, D.A.; Santi, P.; Liu, D. Analysis of impact hammer rebound to estimate rock drill ability. Rock Mech. Rock Eng. 2000, 33, 1–13. [Google Scholar] [CrossRef]

- Zhang, K.; Hou, R.; Zhang, G.; Zhang, G.; Zhang, H. Rock drillability assessment and lithology classification based on the operating parameters of a drifter: Case study in a coal mine in China. Rock Mech. Rock Eng. 2016, 49, 329–334. [Google Scholar] [CrossRef]

- Arffman, A.; Marjamäki, M.; Keskinen, J. Simulation of low pressure impactor collection efficiency curves. J. Aerosol Sci. 2011, 42, 329–340. [Google Scholar] [CrossRef]

- Oh, J.Y.; Lee, G.H.; Kang, H.S.; Song, C.S. Modeling and performance analysis of rock drill drifters for rock stiffness. Int. J. Precis. Eng. Man. 2012, 13, 2187–2193. [Google Scholar] [CrossRef]

- Oh, J.Y.; Song, C.H.; Kim, D.J.; Kim, J.G.; Park, J.Y.; Cho, J.W. Numerical investigation of performance of hydraulic percussion drifter. Int. J. Precis. Eng. Man. 2016, 17, 879–885. [Google Scholar] [CrossRef]

- DD ISO/TS 17104-2006; Rotary Tool for Threaded Fasteners-Hydraulic Impulse Tools-Performance Test Method. ISO: Geneva, Switzerland, 2006.

- DD ISO 2787-1984; Rotary and Percussive Pneumatic Tools-Performance Tests. ISO: Geneva, Switzerland, 1984.

- Babitsky, V. Dynamics should be sexy. In On the Waves of a Pulsating World, 1st ed.; Gruzenberg, A., Ed.; Springer: Cham, Switzerland, 2019; pp. 119–123. [Google Scholar]

- Sun, F.; Chen, L.; Li, Y.; Wang, Z.; Xiao, B.; Chen, Z. Fidelity performance of coring bits during drilling and cutting in deep extreme environments. Appl. Sci. 2023, 13, 8173. [Google Scholar] [CrossRef]

- Zhao, T.W. Wave theory analysis of impact drilling process. In Dynamics of Percussive Drilling; Qing, Q.Y., Ed.; Metallurgical Industry Press: Beijing, China, 1996; pp. 99–116. [Google Scholar]

- Zhao, T.W. Testing the impact performance of rock drill. In Dynamics of Percussive Drilling; Qing, Q.Y., Ed.; Metallurgical Industry Press: Beijing, China, 1996; pp. 203–213. [Google Scholar]

- Song, H.; Shi, H.; Li, G. Numerical simulation of the energy transfer efficiency and rock damage in axial-torsional coupled percussive drilling. J. Petrol. Sci. Eng. 2021, 196, 107675. [Google Scholar] [CrossRef]

- Song, H.; Shi, H.; Chen, Z.; Li, G.; Chen, H. Numerical study on impact energy transfer and rock damage mechanism in percussive drilling based on high temperature hard rocks. Geothermics 2021, 96, 102215. [Google Scholar] [CrossRef]

- Hashiba, K.; Fukui, K.; Liang, Y.Z.; Koizumi, M.; Matsuda, T. Force-penetration curves of a button bit generated during impact penetration into rock. Int. J. Impact Eng. 2015, 85, 45–56. [Google Scholar] [CrossRef]

| Piston | Gear | Pressure (MPa) | Flow (L/min) | Average Stress (MPa) | Average Impact Energy (J) | Average Frequency (Hz) | Power (Kw) | Efficiency (%) |

|---|---|---|---|---|---|---|---|---|

| Long piston | low | 18 | 87.4 | 216.7 | 289.1 | 47.6 | 13.76 | 51.62 |

| 23 | 92.0 | 239.1 | 334.9 | 51.2 | 17.72 | 50.25 | ||

| middle | 18 | 74.4 | 198.5 | 241.0 | 52.6 | 12.68 | 53.82 | |

| 23 | 80.1 | 216.4 | 286.4 | 57.2 | 16.38 | 53.35 | ||

| high | 18 | 66.2 | 172.1 | 178.0 | 56.6 | 9.90 | 49.85 | |

| 23 | 70.8 | 188.1 | 209.9 | 62.0 | 13.01 | 47.94 | ||

| Short piston | low | 18 | 67.5 | 218.8 | 273.1 | 41.4 | 11.31 | 55.85 |

| 23 | 78.6 | 243.9 | 346.1 | 48.2 | 16.15 | 53.60 | ||

| middle | 18 | 64.6 | 199.7 | 226.0 | 48.0 | 10.85 | 55.99 | |

| 23 | 73.6 | 229.4 | 302.4 | 53.1 | 16.06 | 56.92 | ||

| high | 18 | 55.7 | 177.9 | 176.4 | 53.4 | 9.44 | 56.49 | |

| 23 | 61.6 | 201.2 | 223.4 | 58.9 | 13.16 | 55.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Li, J.; Yu, G. Influence of Piston Mass and Working Pressure on the Impact Performance of a Hydraulic Rock Drill Using the Stress Wave Method. Machines 2023, 11, 987. https://doi.org/10.3390/machines11110987

Yang Z, Li J, Yu G. Influence of Piston Mass and Working Pressure on the Impact Performance of a Hydraulic Rock Drill Using the Stress Wave Method. Machines. 2023; 11(11):987. https://doi.org/10.3390/machines11110987

Chicago/Turabian StyleYang, Zhenyi, Jun Li, and Guoyan Yu. 2023. "Influence of Piston Mass and Working Pressure on the Impact Performance of a Hydraulic Rock Drill Using the Stress Wave Method" Machines 11, no. 11: 987. https://doi.org/10.3390/machines11110987

APA StyleYang, Z., Li, J., & Yu, G. (2023). Influence of Piston Mass and Working Pressure on the Impact Performance of a Hydraulic Rock Drill Using the Stress Wave Method. Machines, 11(11), 987. https://doi.org/10.3390/machines11110987