4D Printing: A Methodical Approach to Product Development Using Smart Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Methods

- Task clarification;

- Conceptual design;

- Embodiment design;

- Manufacturing.

2.2. Application Example

2.3. Materials

3. Results

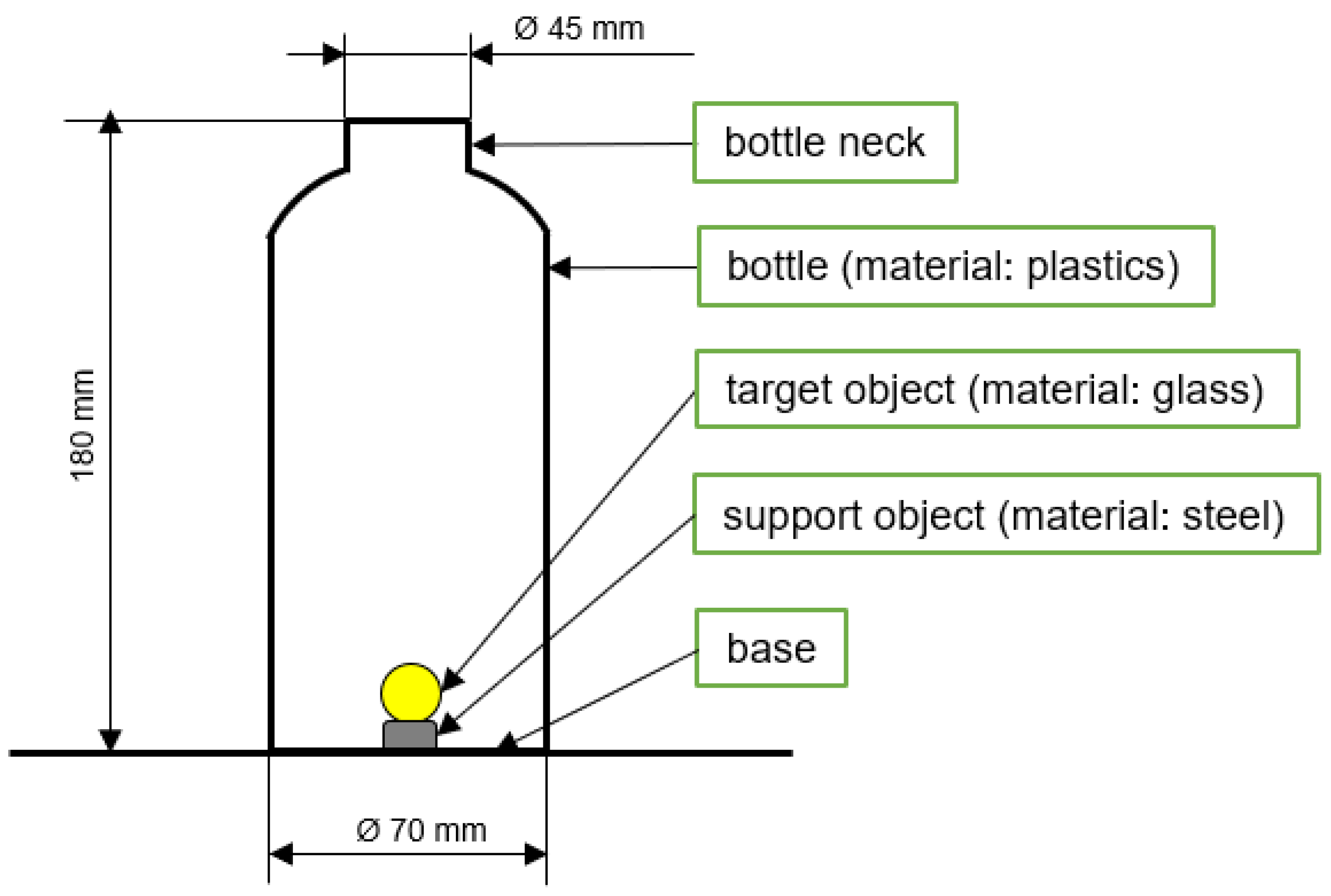

3.1. Task Clarification

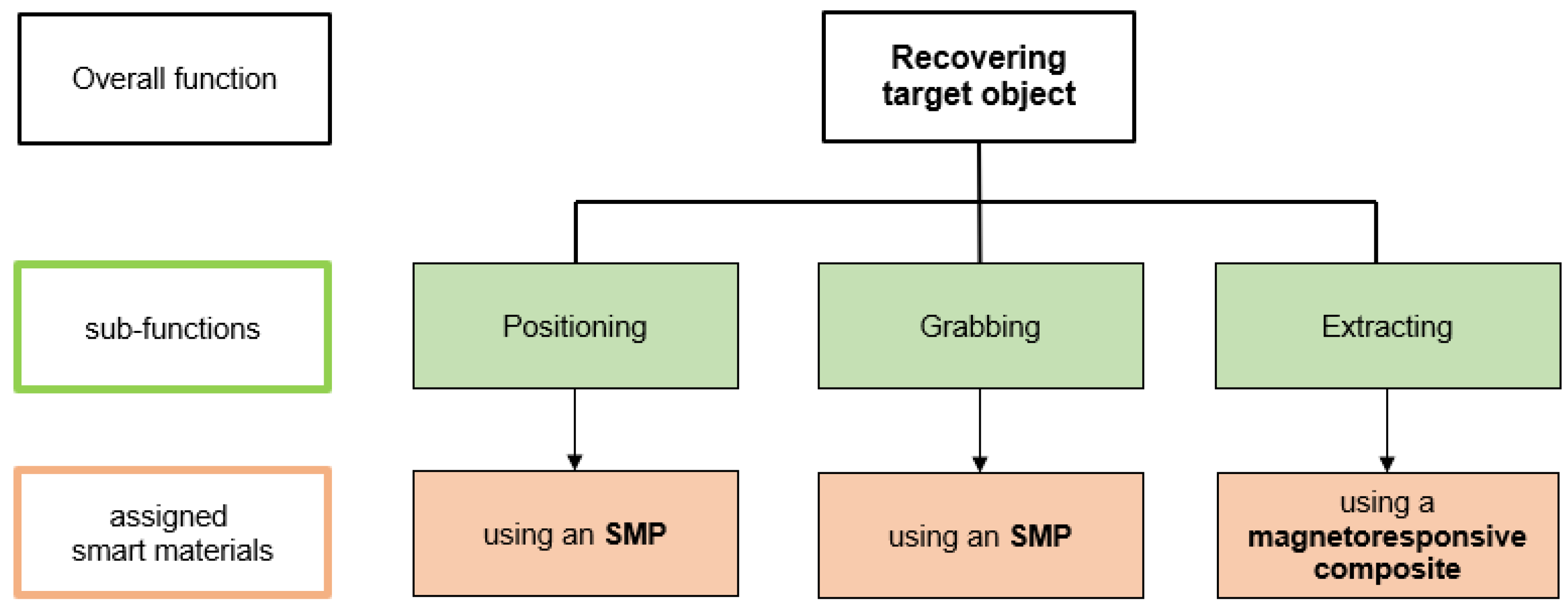

3.2. Conceptual Design

3.2.1. Shape-Memory Polymers

3.2.2. Magnetic Composite Material

3.3. Embodiment Design

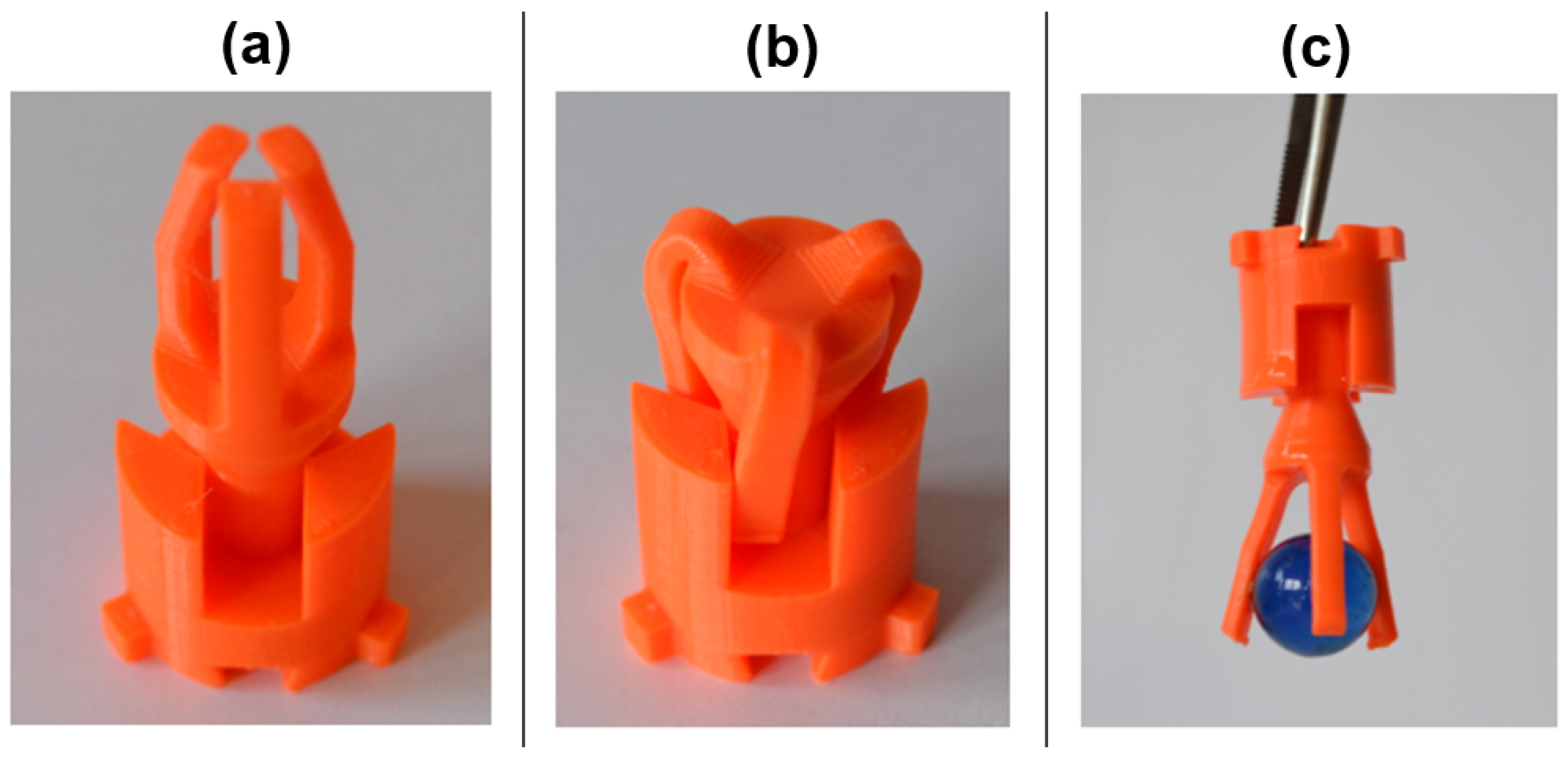

3.3.1. First Designs

- Positioning system:

- Gripping system:

- Extraction system:

3.3.2. Analysis, Dimensioning, and Optimization of the First Designs

- The heating time ;

- The cooling time ;

- The duration of the external force application ;

- The deformation temperature ;

- The shape recovery temperature .

- Heating time ;

- Cooling time ;

- Duration of the external force application ;

- Deformation temperature ;

- Shape recovery temperature .

- Duration of heating ;

- Duration of cooling ;

- Duration of the external force application ;

- Temperature during deformation ;

- Temperature during shape recovery .

- Positioning system:

- Gripping system:

- Extraction system:

- Overall system:

3.4. Manufacturing

3.5. Application of the Component

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tibbits, S. 4D Printing: Multi-Material shape change. Archit. Des. 2014, 84, 116–121. [Google Scholar] [CrossRef]

- Quanjin, M.; Rejab, M.R.M.; Idris, M.S.; Kumar, N.M.; Abdullah, M.H.; Reddy, G.R. Recent 3D and 4D intelligent printing technologies: A comparative review and future perspective. Procedia Comput. Sci. 2020, 167, 1210–1219. [Google Scholar] [CrossRef]

- Zafar, M.Q.; Zhao, H. 4D Printing: Future Insight in Additive Manufacturing. Met. Mater. Int. 2020, 26, 564–585. [Google Scholar] [CrossRef]

- Zhang, J.; Yin, Z.; Ren, L.; Liu, Q.; Ren, L.; Yang, X.; Zhou, X. Advances in 4D Printed Shape Memory Polymers: From 3D Printing, Smart Excitation, and Response to Applications. Adv. Mater. Technol. 2022, 7, 2101568. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Piromalis, D. 4D Printing: Technology Overview and Smart Materials Utilized. J. Mechatron. Robot. 2023, 7, 1–14. [Google Scholar] [CrossRef]

- Momeni, F.; Hassani, S.M.M.; Liu, X.; Ni, J. A review of 4D printing. Mater. Des. 2017, 122, 42–79. [Google Scholar] [CrossRef]

- Pei, E.; Loh, G.H.; Nam, S. Concepts and Terminologies in 4D Printing. Appl. Sci. 2020, 10, 4443. [Google Scholar] [CrossRef]

- Ponnamma, D.; Reddy, M.S.B.; Maurya, M.R.; Kulkarni, O.; Paswan, M.; Sadasivuni, K.K.; Geetha, M.M.M.N.; Al-Maadeed, M.A. Recent Developments on 4D Printings and Applications. In Shape Memory Composites Based on Polymers and Metals for 4D Printing; Maurya, M.R., Sadasivuni, K.K., Cabibihan, J., Ahmad, S., Kazim, S., Eds.; Springer: Cham, Switzerland, 2022; pp. 361–388. [Google Scholar]

- Imrie, P.; Jin, J. Polymer 4D printing: Advanced shape-change and beyond. J. Polym. Sci. 2021, 2, 149–174. [Google Scholar] [CrossRef]

- Chu, H.; Yang, W.; Sun, L.; Cai, S.; Yang, R.; Liang, W.; Yu, H.; Liu, L. 4D Printing: A Review on Recent Progresses. Micromachines 2020, 11, 796. [Google Scholar] [CrossRef]

- Champeau, M.; Heinze, D.A.; Viana, T.N.; de Souza, E.R.; Chinellato, A.C.; Titotto, S. 4D Printing of Hydrogels: A Review. Adv. Funct. Mater. 2020, 30, 1910606. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Soltani, P.; Weinberg, K.; Reinicke, T. Structural integrity of adhesively bonded 3D-printed joints. Polym. Test. 2021, 100, 107262. [Google Scholar] [CrossRef]

- Sharma, A.; Mukhopadhyay, T.; Kushvaha, V. Experimental data-driven uncertainty quantification for the dynamic fracture toughness of particulate polymer composites. Eng. Fract. Mech. 2022, 273, 108724. [Google Scholar] [CrossRef]

- Ge, Q.; Sakhaei, H.; Lee, H.; Dunn, C.K.; Fang, N.X.; Dunn, M.L. Multimaterial 4D Printing with Tailorable Shape Memory Polymers. Sci. Rep. 2016, 6, 31110. [Google Scholar] [CrossRef]

- Wei, H.; Zhang, Q.; Yao, Y.; Liu, L.; Liu, Y.; Leng, J. Direct-Write Fabrication of 4D Active Shape-Changing Structures Based on a Shape Memory Polymer and Its Nanocomposite. ACS Appl. Mater. Interfaces 2017, 9, 876–883. [Google Scholar] [CrossRef]

- Alshebly, Y.; Nafea, M. Control of 4D Printed Actuators Twisting Behavior via Printing Direction. In Proceedings of the 2022 IEEE 20th Student Conference on Research and Development (SCOReD), Bangi, Malaysia, 8–9 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 163–167. [Google Scholar]

- Zhou, Y.; Huang, Z.; Li, X.; Lv, P. 4D Printing Pre-Strained Structures for Fast Thermal Actuation. Front. Mater. 2021, 8, 661999. [Google Scholar] [CrossRef]

- Nezhad, I.; Golzar, M.; Behravesh, A.; Zare, S. Comprehensive study on shape shifting behaviors in FDM-based 4D printing of bilayer structures. Int. J. Adv. Manuf. Technol. 2022, 120, 959–974. [Google Scholar] [CrossRef]

- Zhang, J.; Ji, D.; Yang, X.; Zhou, X.; Yin, Z. 4D printing of bilayer structures with programmable shape-shifting behavior. J. Mater. Sci. 2022, 57, 21309–21323. [Google Scholar] [CrossRef]

- Kuang, X.; Roach, D.; Wu, J.; Hamel, C.; Ding, Z.; Wang, T.; Dunn, M.; Qi, H. Advances in 4D Printing: Materials and Applications. Adv. Funct. Mater. 2019, 29, 1805290. [Google Scholar] [CrossRef]

- Raviv, D.; Zhao, W.; McKnelly, C.; Papadopoulou, A.; Kadambi, A.; Shi, B.; Hirsch, S.; Dikovsky, D.; Zyracki, M.; Olguin, C.; et al. Active Printed Materials for Complex Self-Evolving Deformations. Sci. Rep. 2014, 4, 7422. [Google Scholar] [CrossRef] [PubMed]

- Baker, A.; Bates, S.; Llewellyn-Jones, T.; Valori, L.; Dicker, M.; Trask, R. 4D printing with robust thermoplastic polyurethane hydrogel-elastomer trilayers. Mater. Des. 2019, 163, 107544. [Google Scholar] [CrossRef]

- Bakarich, S.E.; Gorkin, R.; in het Panhuis, M.; Spinks, G.M. 4D Printing with Mechanically Robust, Thermally Actuating Hydrogels. Macromol. Rapid Commun. 2015, 36, 1211–1217. [Google Scholar] [CrossRef] [PubMed]

- Zu, S.; Zhang, Z.; Liu, Q.; Wang, Z.; Song, Z.; Guo, Y.; Xin, Y.; Zhang, S. 4D printing of core–shell hydrogel capsules for smart controlled drug release. Bio-Des. Manuf. 2022, 5, 294–304. [Google Scholar] [CrossRef]

- Abdullah, T.; Okay, O. 4D Printing of Body Temperature-Responsive Hydrogels Based on Poly(acrylic acid) with Shape-Memory and Self-Healing Abilities. ACS Appl. Bio Mater. 2023, 6, 703–711. [Google Scholar] [CrossRef]

- Shiblee, M.N.I.; Ahmed, K.; Kawakami, M.; Furukawa, H. 4D Printing of Shape-Memory Hydrogels for Soft-Robotic Functions. Adv. Mater. Technol. 2019, 4, 1900071. [Google Scholar] [CrossRef]

- Cecchini, L.; Mariani, S.; Ronzan, M.; Mondini, A.; Pugno, N.; Mazzolai, B. 4D Printing of Humidity-Driven Seed Inspired Soft Robots. Adv. Sci. 2023, 10, 2205146. [Google Scholar] [CrossRef]

- Kotikian, A.; Truby, R.; Boley, J.; White, T.; Lewis, J. 3D Printing of Liquid Crystal Elastomeric Actuators with Spatially Programed Nematic Order. Adv. Mater. 2018, 30, 1706164. [Google Scholar] [CrossRef]

- Kim, Y.; Yuk, H.; Zhao, R.; Chester, S.A.; Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 2018, 558, 274–279. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Q.; Yi, S.; Lin, Z.; Wang, C.; Chen, Z.; Jiang, L. 4D Printing of Magnetoactive Soft Materials for On-Demand Magnetic Actuation Transformation. ACS Appl. Mater. Interfaces 2021, 13, 4174–4184. [Google Scholar] [CrossRef] [PubMed]

- Junk, S.; Einloth, H.; Velten, D. A Methodical Approach to Product Development in 4D Printing Using Smart Materials. In Progress in Digital and Physical Manufacturing; Proceedings of ProDPM′21; Almeida, A.H., Vasco, J.C., Eds.; Springer: Cham, Switzerland, 2023; pp. 130–137. [Google Scholar]

- VDI—The Association of German Engineers, VDI 2221. Systematic Approach to the Development and Design of Technical Systems and Products. Available online: https://www.vdi.de/richtlinien/details/vdi-2221-methodik-zum-entwickeln-und-konstruieren-technischer-systeme-und-produkte (accessed on 22 October 2020).

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.H. Engineering Design: A Systematic Approach; Springer: London, UK, 2007. [Google Scholar]

| Property | Unit | Value |

|---|---|---|

| Density | g/cm3 | 1.24 |

| Glass Transition Temperature | °C | 55 |

| Tensile Yield Strength (Filament) | MPa | 57 |

| Property | Unit | Value |

|---|---|---|

| Density | g/cm3 | 1.85 |

| Glass Transition Temperature | °C | 60 |

| Tensile Yield Strength (Filament) | MPa | N/A |

| Printing Parameters | Unit | Value |

|---|---|---|

| Layer height | mm | 0.15 |

| Infill | % | 70 |

| Print speed | mm/s | 45 (perimeter), 80 (infill) |

| Nozzle temperature | °C | 230 |

| Print bed temperature | °C | 60 |

| Test Object 1 | Test Object 2 | Test Object 3 | |||||

|---|---|---|---|---|---|---|---|

| Investigated Factor | Unit | Test Value 1 | Test Value 2 | Test Value 3 | |||

| Heating time | s | 60 | 92.2% | 120 | 91.7% | 180 | 89.4% |

| Cooling time | s | 120 | 91.7% | 300 | 92.8% | 600 | 90.6% |

| Duration of external force | s | 45 | 91.1% | 90 | 91.7% | 180 | 91.7% |

| Deformation temperature | °C | 85 | 91.7% | 75 | 80.6% | 65 | 82.8% |

| Shape recovery temperature | °C | 85 | 91.1% | 75 | 91.7% | 65 | 88.3% |

| °C | 85 | 90.6% | 75 | 94.4% | 65 | 96.7% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Junk, S.; Einloth, H.; Velten, D. 4D Printing: A Methodical Approach to Product Development Using Smart Materials. Machines 2023, 11, 1035. https://doi.org/10.3390/machines11111035

Junk S, Einloth H, Velten D. 4D Printing: A Methodical Approach to Product Development Using Smart Materials. Machines. 2023; 11(11):1035. https://doi.org/10.3390/machines11111035

Chicago/Turabian StyleJunk, Stefan, Henning Einloth, and Dirk Velten. 2023. "4D Printing: A Methodical Approach to Product Development Using Smart Materials" Machines 11, no. 11: 1035. https://doi.org/10.3390/machines11111035

APA StyleJunk, S., Einloth, H., & Velten, D. (2023). 4D Printing: A Methodical Approach to Product Development Using Smart Materials. Machines, 11(11), 1035. https://doi.org/10.3390/machines11111035