A Knowledge Graph-Based Approach for Assembly Sequence Recommendations for Wind Turbines

Abstract

:1. Introduction

- (1)

- The assembly information representation model is designed to describe the assembly information data from multiple sources in a unified way. Then, multiple modal assembly entity joint extraction methods are proposed to construct a multimodal knowledge graph for wind turbine assembly.

- (2)

- A knowledge graph-based optimal assembly sequence recommendation is proposed. The retrieval of similar assembly process items based on BERT-GMN is proposed to predict the assembly sequence subgraphs. Also, a SWRL-based assembly process item inference method is proposed to automatically generate subassembly sequences by combining component assembly relationships. Then, a multi-objective sequence optimization algorithm for the final assembly is designed to output the optimal assembly sequences.

2. Related Work

2.1. Knowledge Graph Construction in Assembly

2.2. Assembly Sequence Planning

- (1)

- Assembly sequence information model

- (2)

- Assembly optimization algorithm

3. Knowledge Graph-Based Assembly Sequence Recommendations for Wind Turbines

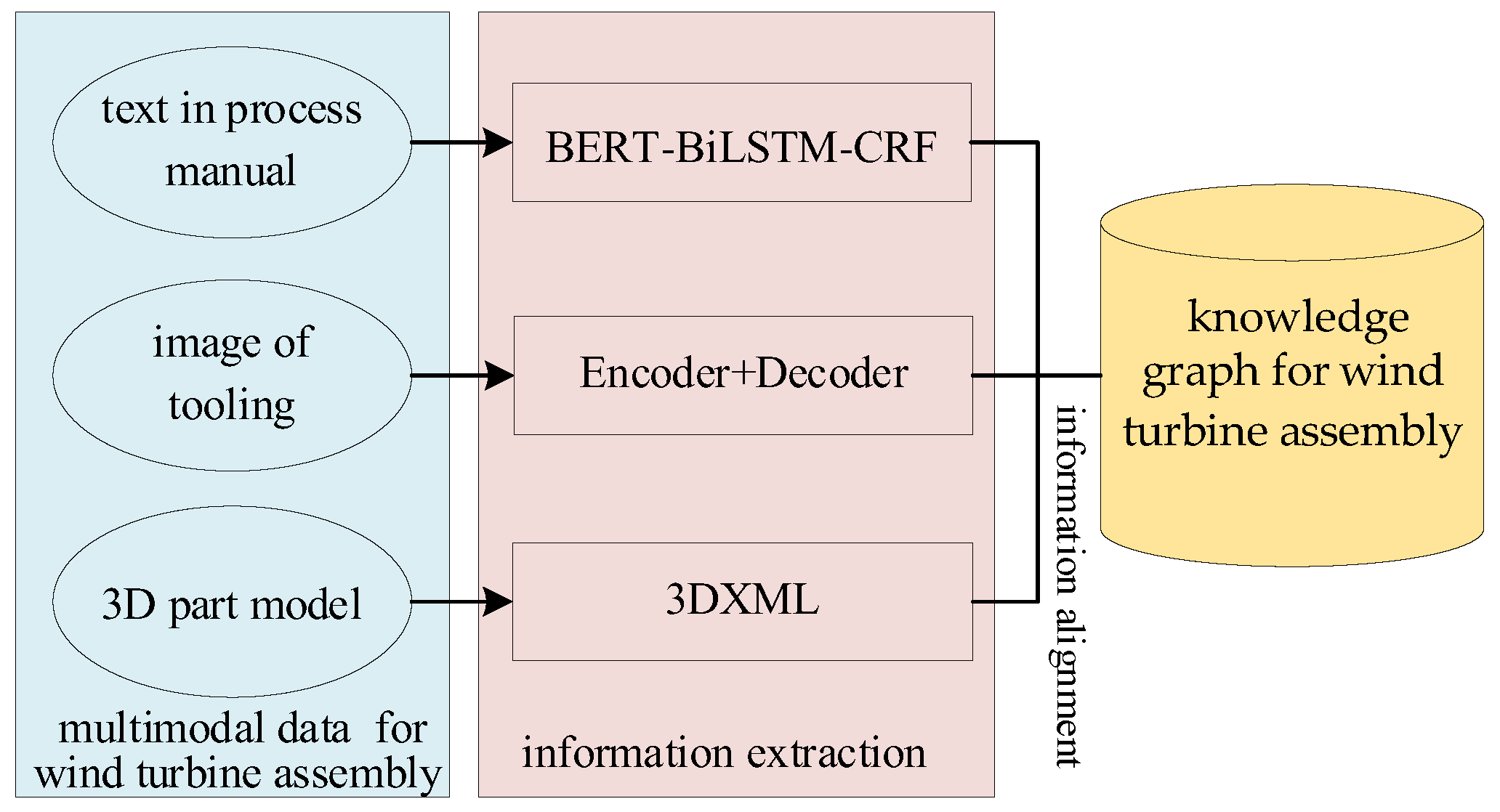

3.1. Multimodal Knowledge Graph Construction for Wind Turbine Assembly

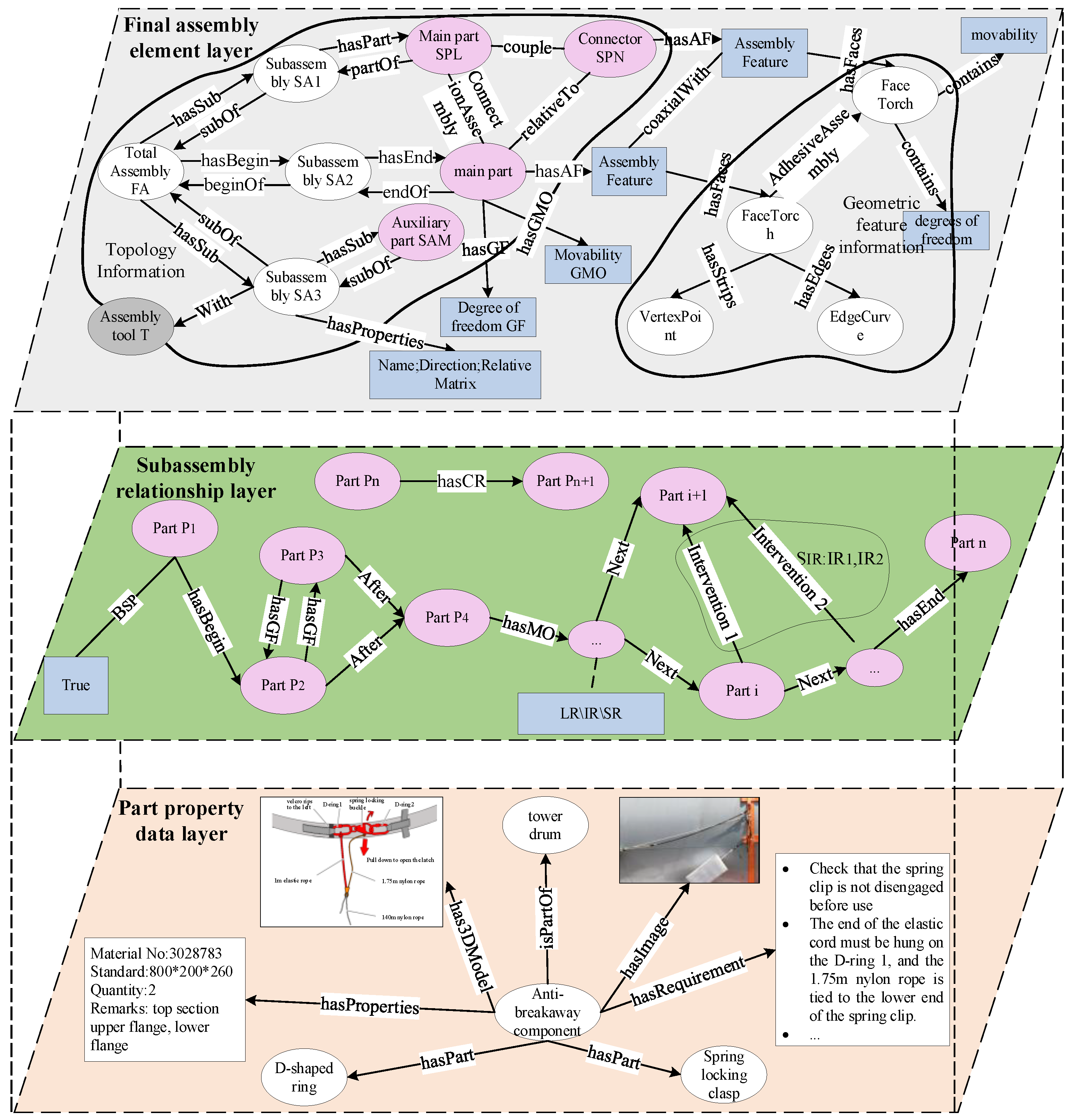

3.1.1. Multi-Process Assembly Information Modeling

- (1)

- Assembly feature information

- (2)

- Assembly semantic information

- (3)

- Assembly property information

3.1.2. Knowledge Extraction for Multimodal Data

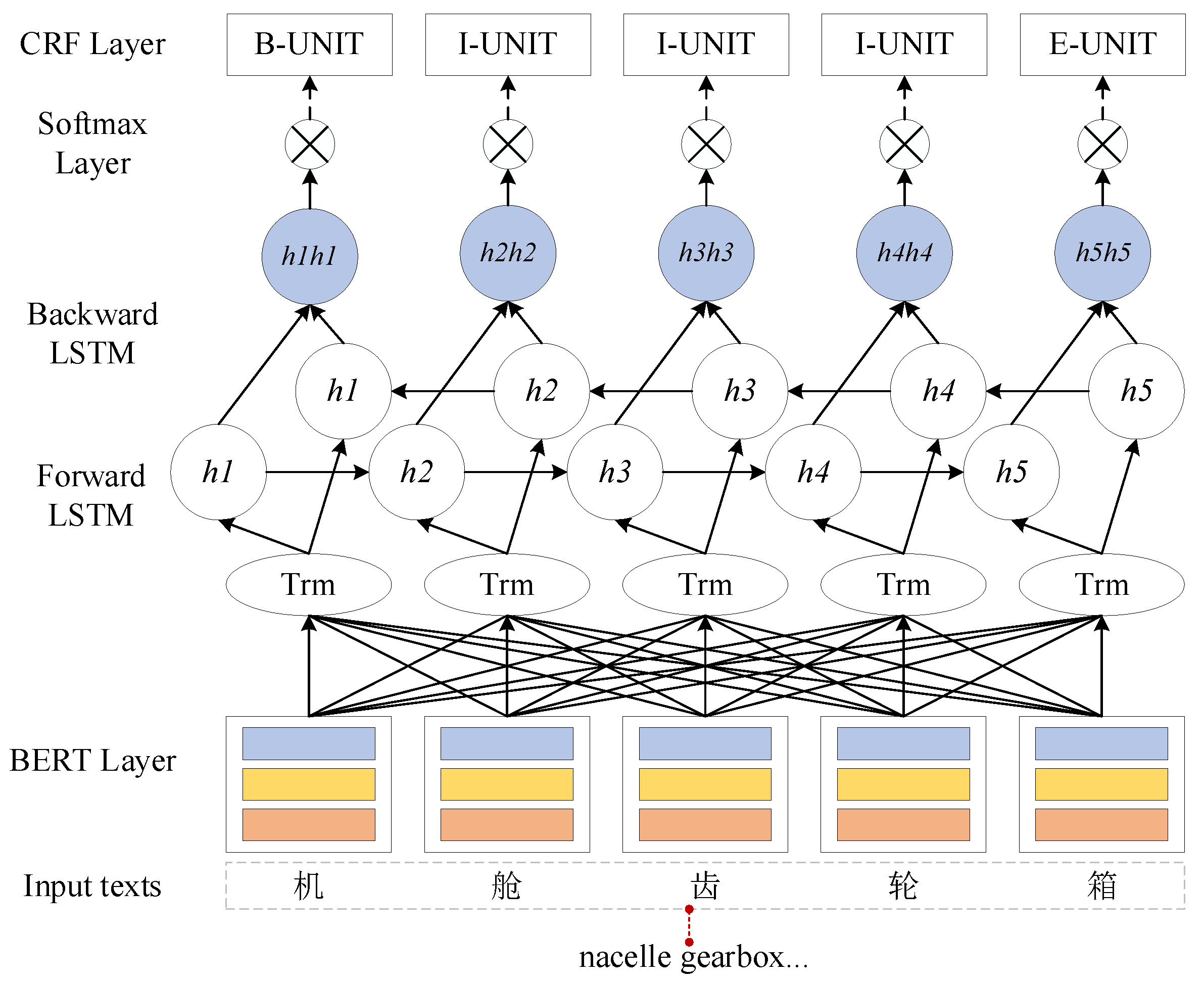

- Textual Data Knowledge Extraction

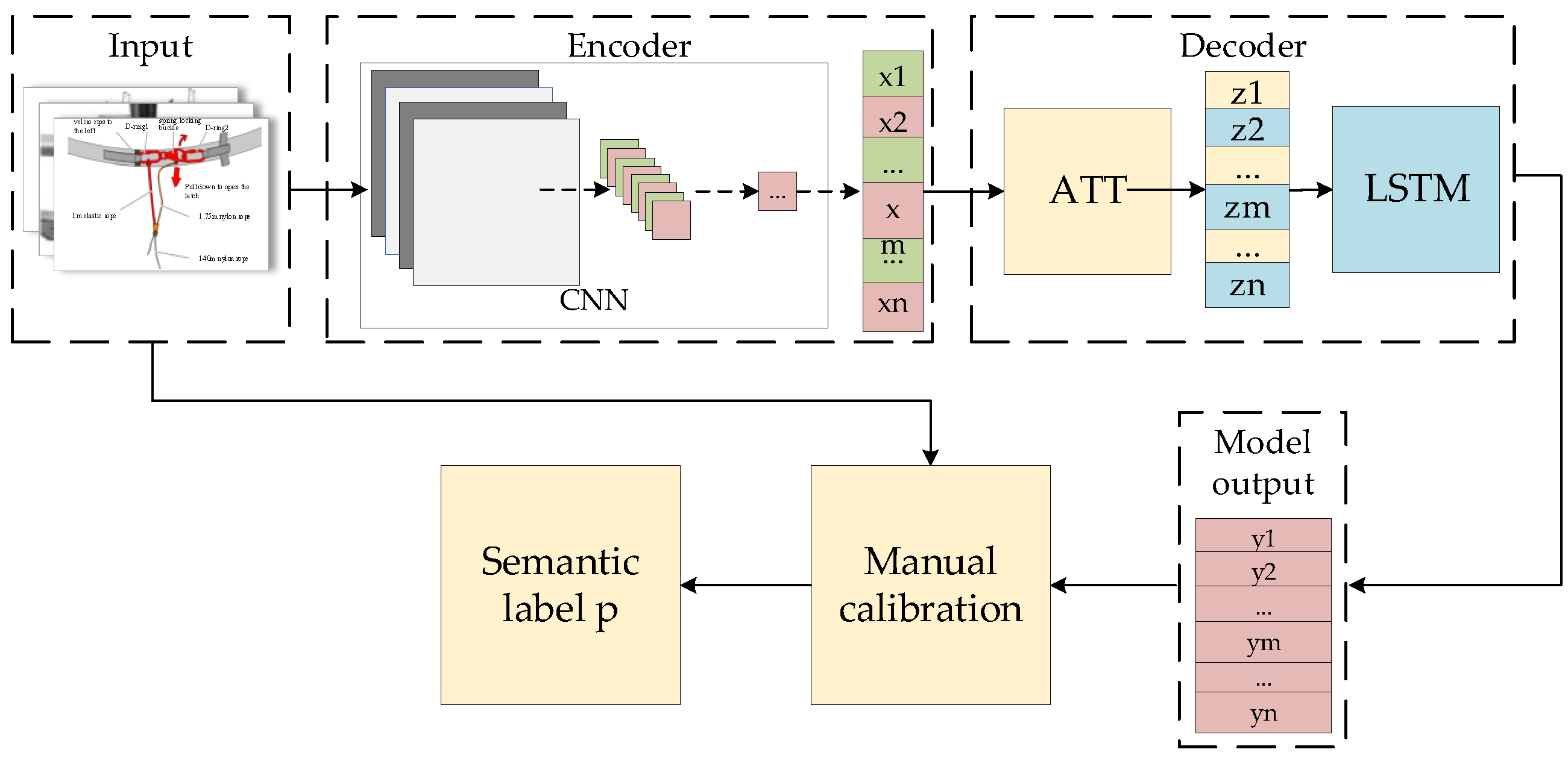

- Knowledge Extraction for Image Data

- Information extraction for 3D models

3.2. Knowledge Graph-Based Assembly Sequence Retrieval and Reasoning for Wind Turbine

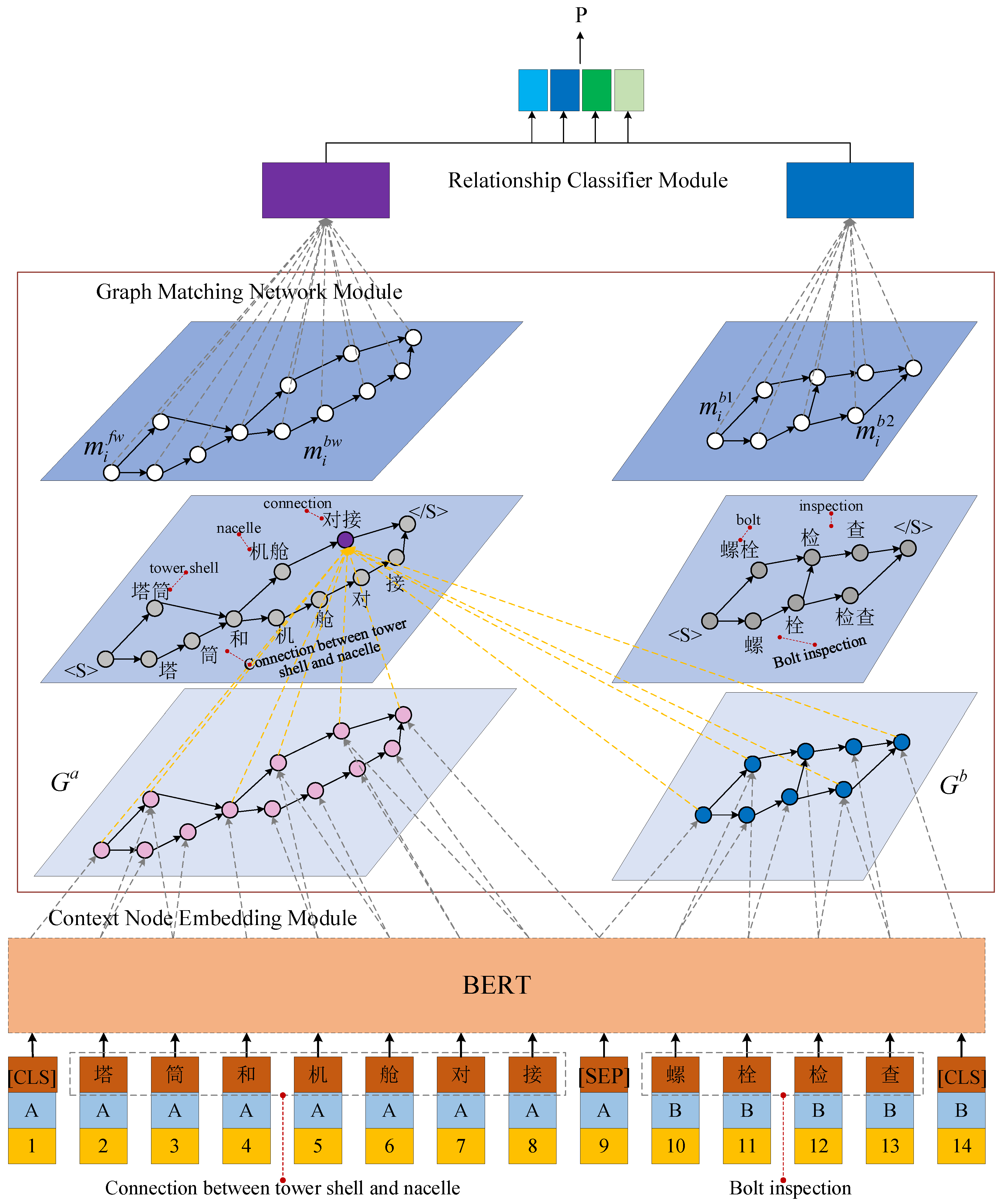

3.2.1. Retrieval of Similar Assembly Process Items Based on BERT-GMN

- Context Node Embedding Module

- Graph Matching Neural Network Module

- Relational Classifier Module

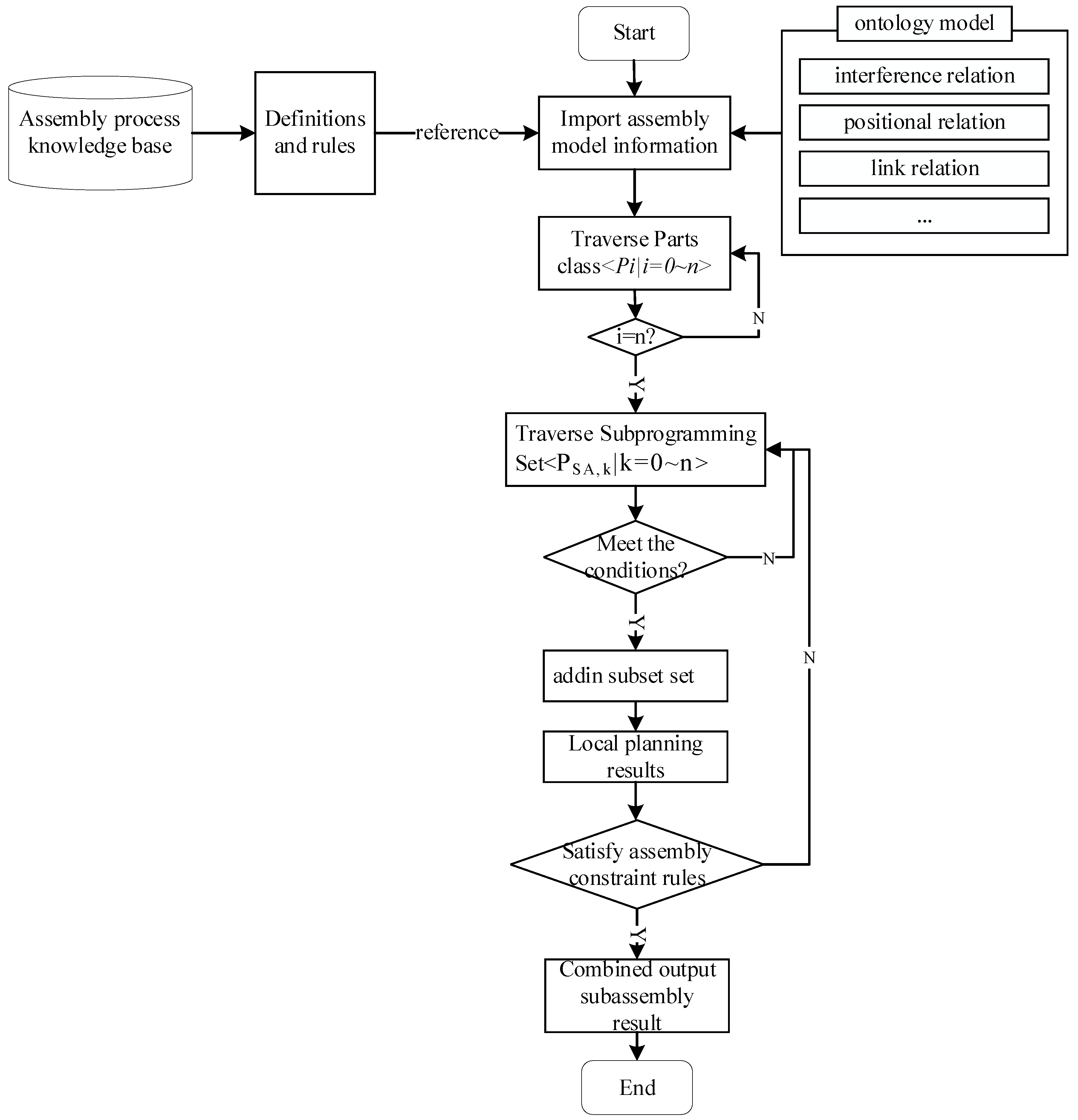

3.2.2. Reasoning about Instance Items of Assembly Process Based on SWRL

- Assembly Semantic Rule Generation

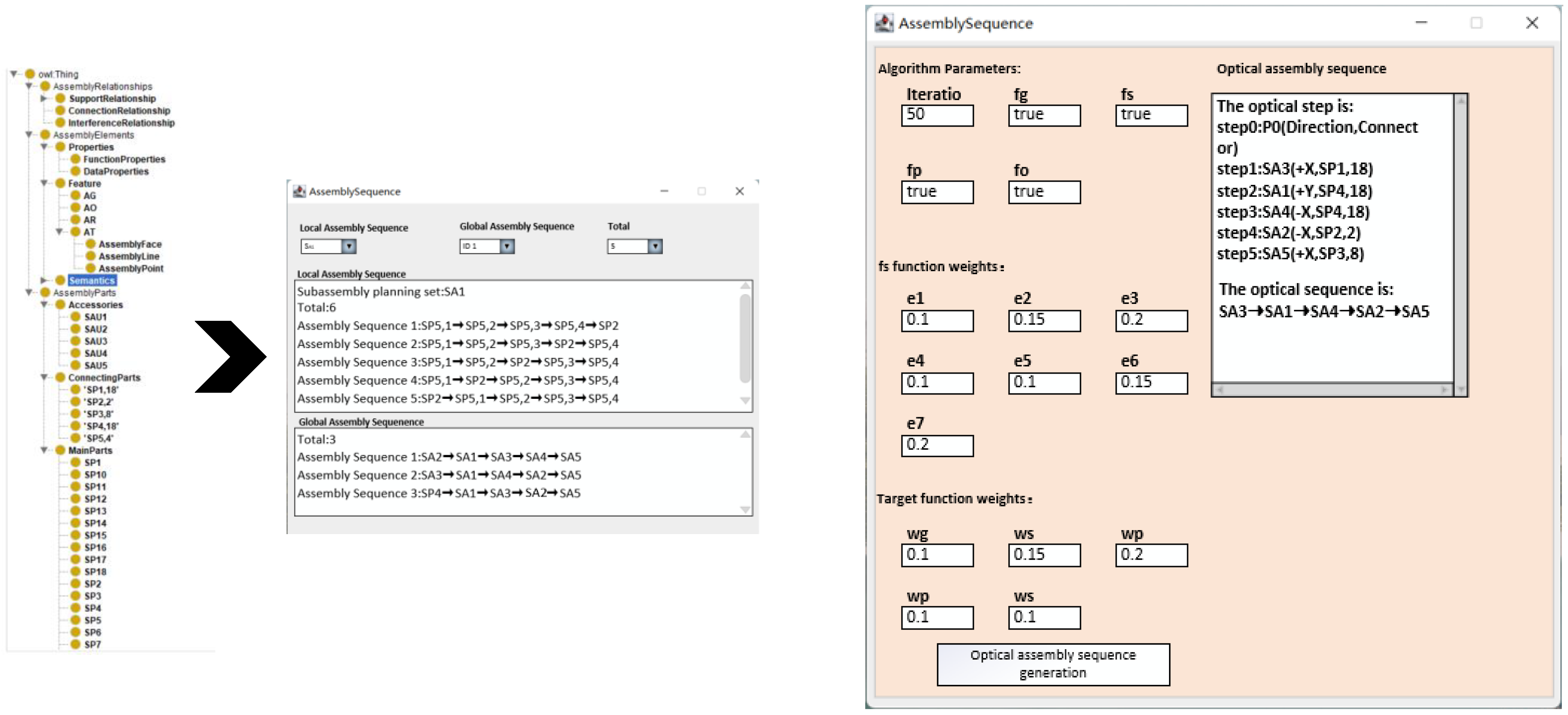

- Automatic generation of subassembly sequences

- Final Assembly Sequence Prioritization Calculation

- (1)

- The geometric feasibility of the final assembly sequence

- (2)

- The stability of the assembly operations

- (3)

- The cohesiveness of the assembly process

- (4)

- The number of assembly reorientations

- Multi-objective sequence optimization algorithm

| Algorithm 1 Assembly sequence generation algorithm |

| Input: list i//Serial information for subassemblies in the list Output: list AS//Final assembly results after multi-objective sequential optimization Algorithm GenerateAssemblySequences(List list) 1: list AP = createArrayList() 2: list a = createArrayList() 3: list b = createArrayList() 4: FOR each list Pj, in the list i.P 5: IF list Pj.Bsp = TRUE 6: list b.add(list Pj.ID) 7: list AS. add(list b) 8: IF list AS=NULL 9: FOR each list Pj in the list i.P 10: IF list Pj.NPR = maxof(list Pj)//Find the maximum number of locational relations 11: list b. add(listPj.ID) 12: list AS.add(listb)//Base parts for assembly sequences 13: WHILE//Iterate over all subassembly sequences 14: FOR each list b in the list AS 15: IF list Pi.SA(fg) ≠ NULL 16: IF list Pi.SA(fs) ≠ NULL 17: IF list Pi.SA(fp) ≠ NULL 18: IF list Pi.SA(fo) ≠ NULL 19: IF list Pi.SA(fr) ≠ NULL 20: list Pj.add(list b*) 21: return |

4. Case Study

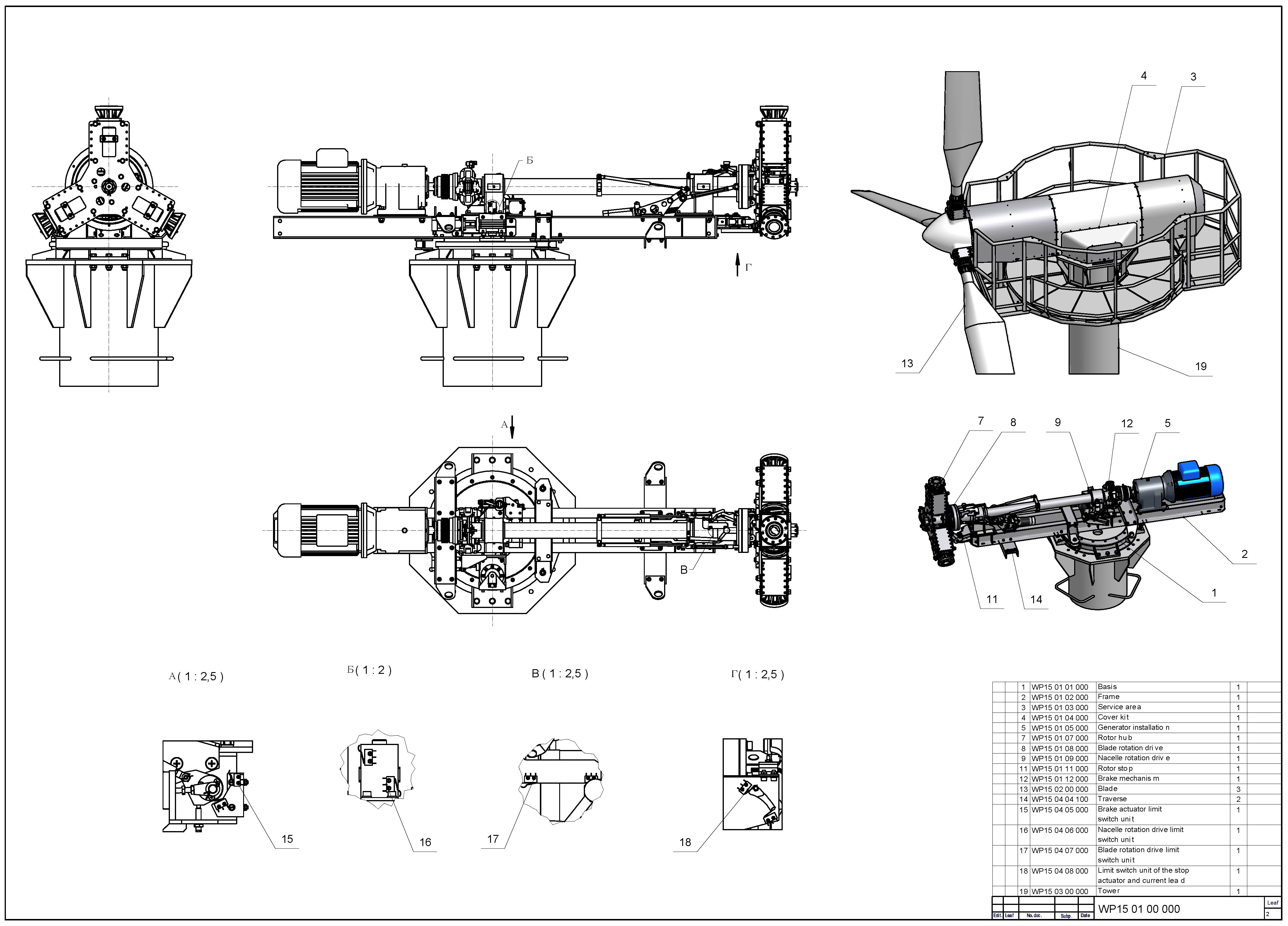

4.1. Case Illustration

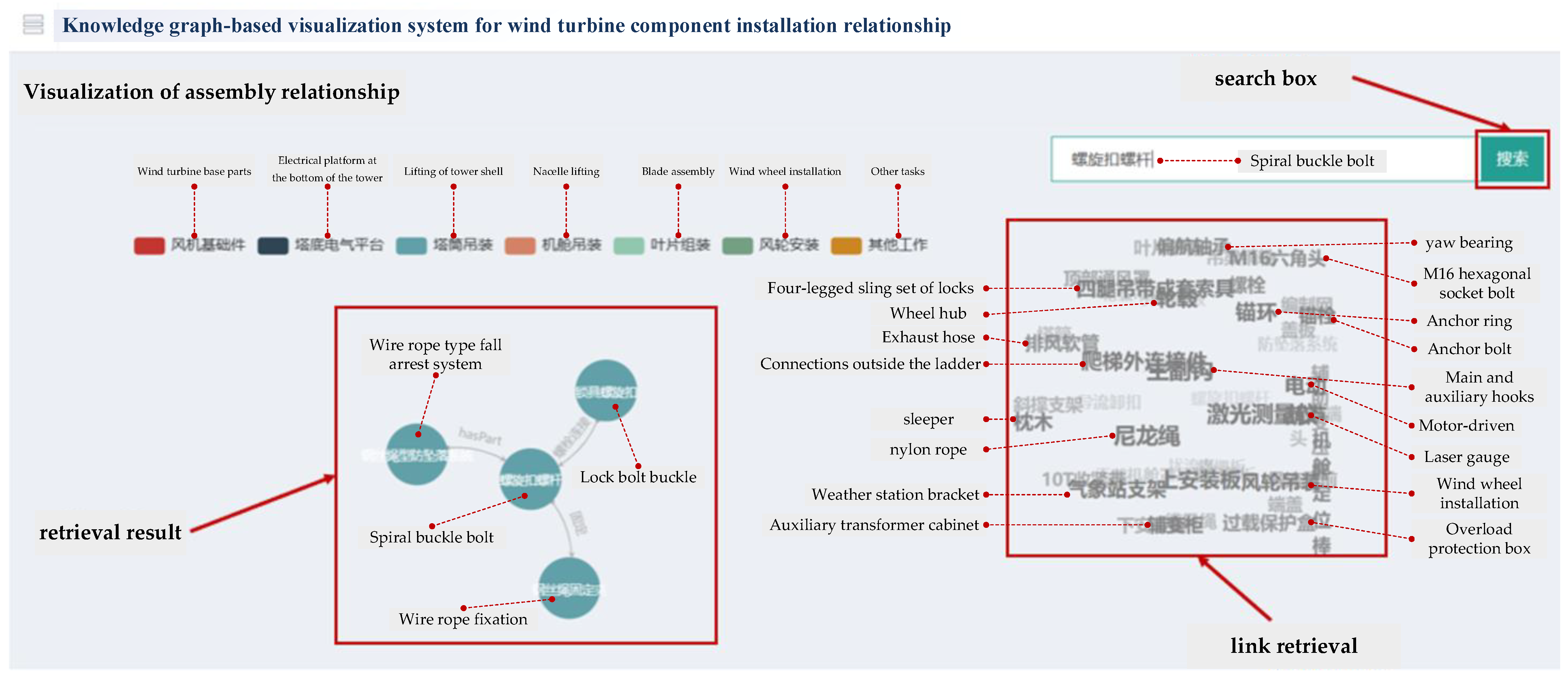

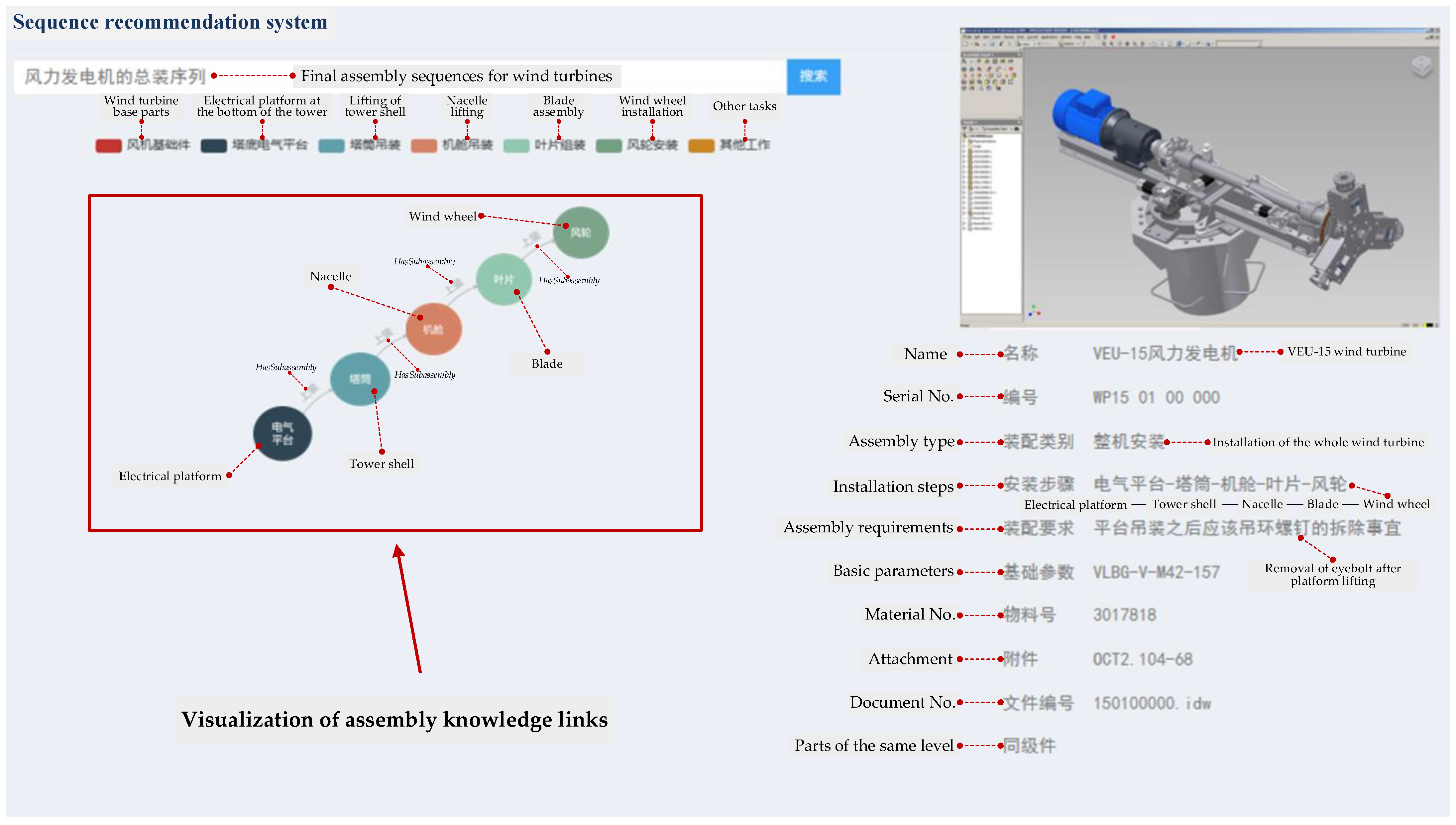

4.2. Knowledge Graph Construction and Wind Turbine Assembly Sequence Generation

- Statistics of assembly process information

- Knowledge extraction and knowledge graph generation from assembly information

4.3. Knowledge Graph-Based Assembly Sequence Recommendation for Wind Turbine

- Component assembly relationship rule generation and knowledge reasoning

- Optimization of assembly sequences for wind turbines

5. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zheng, P.; Chen, C.-H.; Shang, S. Towards an Automatic Engineering Change Management in Smart Product-Service Systems—A DSM-Based Learning Approach. Adv. Eng. Inform. 2019, 39, 203–213. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, X.; Wang, L. Smart Manufacturing Process and System Automation—A Critical Review of the Standards and Envisioned Scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar] [CrossRef]

- Liu, J.; Sun, Q.; Cheng, H.; Liu, X.; Ding, X.; Liu, S.; Xiong, H. The State-of-the-Art, Connotation and Developing Trends of the Products Assembly Technology. J. Mech. Eng. 2018, 54, 2–28. [Google Scholar] [CrossRef]

- Ji, Z. Intelligent Manufacturing—Main Direction of “Made in China 2025”. China Mech. Eng. 2015, 26, 2273. [Google Scholar]

- Kumar, G.A.; Bahubalendruni, M.V.A.R.; Vara Prasad, V.S.S.; Ashok, D.; Sankaranarayanasamy, K. A Novel Geometric Feasibility Method to Perform Assembly Sequence Planning through Oblique Orientations. Eng. Sci. Technol. Int. J. 2022, 26, 100994. [Google Scholar] [CrossRef]

- Tao, C.; Chunhui, L.; Hui, X.; Zhiheng, Z.; Guangyue, W. A Review of Digital Twin Intelligent Assembly Technology and Application for Complex Mechanical Products. Int. J. Adv. Manuf. Technol. 2023, 127, 4013–4033. [Google Scholar] [CrossRef]

- Mahajan, R.; Sankman, B. 3D Packaging Architectures and Assembly Process Design. In 3D Microelectronic Packaging: From Fundamentals to Applications; Li, Y., Goyal, D., Eds.; Springer Series in Advanced Microelectronics; Springer International Publishing: Cham, Switzerland, 2017; pp. 17–46. ISBN 978-3-319-44586-1. [Google Scholar]

- Yi, Y.; Yan, Y.; Liu, X.; Ni, Z.; Feng, J.; Liu, J. Digital Twin-Based Smart Assembly Process Design and Application Framework for Complex Products and Its Case Study. J. Manuf. Syst. 2021, 58, 94–107. [Google Scholar] [CrossRef]

- Eschen, H.; Kötter, T.; Rodeck, R.; Harnisch, M.; Schüppstuhl, T. Augmented and Virtual Reality for Inspection and Maintenance Processes in the Aviation Industry. Procedia Manuf. 2018, 19, 156–163. [Google Scholar] [CrossRef]

- Chen, Z.; Bao, J.; Zheng, X.; Liu, T. Assembly Information Model Based on Knowledge Graph. J. Shanghai Jiaotong Univ. 2020, 25, 578–588. [Google Scholar] [CrossRef]

- Shi, X.; Tian, X.; Gu, J.; Yang, F.; Ma, L.; Chen, Y.; Su, T. Knowledge Graph-Based Assembly Resource Knowledge Reuse towards Complex Product Assembly Process. Sustainability 2022, 14, 15541. [Google Scholar] [CrossRef]

- Zhou, B.; Bao, J.; Chen, Z.; Liu, Y. KGAssembly: Knowledge Graph-Driven Assembly Process Generation and Evaluation for Complex Components. Int. J. Comput. Integr. Manuf. 2022, 35, 1151–1171. [Google Scholar] [CrossRef]

- Li, X.; Zhang, S.; Huang, R.; Huang, B.; Xu, C.; Kuang, B. Structured Modeling of Heterogeneous CAM Model Based on Process Knowledge Graph. Int. J. Adv. Manuf. Technol. 2018, 96, 4173–4193. [Google Scholar] [CrossRef]

- Wang, M.; Wang, H.; Li, B.; Zhao, X.; Wang, X. Survey on Key Technologies of New Generation Knowledge Graph. J. Comput. Res. Dev. 2022, 59, 1947–1965. [Google Scholar] [CrossRef]

- Cheng, B.; Zhu, J.; Guo, M. MultiJAF: Multi-Modal Joint Entity Alignment Framework for Multi-Modal Knowledge Graph. Neurocomputing 2022, 500, 581–591. [Google Scholar] [CrossRef]

- Ding, Y.; Yu, J.; Liu, B.; Hu, Y.; Cui, M.; Wu, Q. MuKEA: Multimodal Knowledge Extraction and Accumulation for Knowledge-Based Visual Question Answering. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, New Orleans, LA, USA, 19–20 June 2022; pp. 5089–5098. [Google Scholar]

- Zhou, B.; Hua, B.; Gu, X.; Lu, Y.; Peng, T.; Zheng, Y.; Shen, X.; Bao, J. An End-to-End Tabular Information-Oriented Causality Event Evolutionary Knowledge Graph for Manufacturing Documents. Adv. Eng. Inform. 2021, 50, 101441. [Google Scholar] [CrossRef]

- Liu, P.; Qian, L.; Zhao, X.; Tao, B. The Construction of Knowledge Graphs in the Aviation Assembly Domain Based on a Joint Knowledge Extraction Model. IEEE Access 2023, 11, 26483–26495. [Google Scholar] [CrossRef]

- Wen, Y.; Luo, B.; Zhao, Y. IMKGA-SM: Interpretable Multimodal Knowledge Graph Answer Prediction via Sequence Modeling. arXiv 2023, 1–12. [Google Scholar] [CrossRef]

- Bahubalendruni, M.V.A.R.; Gulivindala, A.K.; Varupala, S.S.V.P.; Palavalasa, D.K. Optimal Assembly Sequence Generation through Computational Approach. Sādhanā 2019, 44, 174. [Google Scholar] [CrossRef]

- Bortolini, M.; Ferrari, E.; Gamberi, M.; Pilati, F.; Faccio, M. Assembly System Design in the Industry 4.0 Era: A General Framework. IFAC-PapersOnLine 2017, 50, 5700–5705. [Google Scholar] [CrossRef]

- Anthony, L.; Regli, W.C.; John, J.E.; Lombeyda, S.V. An Approach to Capturing Structure, Behavior, and Function of Artifacts in Computer-Aided Design. J. Comput. Inf. Sci. Eng. 2001, 1, 186–192. [Google Scholar] [CrossRef]

- Kopena, J.B.; Regli, W. Functional Modeling of Engineering Designs for the Semantic Web. IEEE Data Eng. Bull. 2003, 26, 55–61. [Google Scholar]

- Wang, X.; Ong, S.K.; Nee, A.Y.C. A Comprehensive Survey of Augmented Reality Assembly Research. Adv. Manuf. 2016, 4, 1–22. [Google Scholar] [CrossRef]

- Chen, X.; Gao, S.; Yang, Y.; Zhang, S. Multi-Level Assembly Model for Top-down Design of Mechanical Products. Comput.-Aided Des. 2012, 44, 1033–1048. [Google Scholar] [CrossRef]

- Zhou, W.; Zheng, J.; Wang, J. Nested Partitions Method for Assembly Sequences Merging. Expert. Syst. Appl. 2011, 38, 9918–9923. [Google Scholar] [CrossRef]

- Gao, S.; Jin, R.; Lu, W. Design for Manufacture and Assembly in Construction: A Review. Build. Res. Inf. 2020, 48, 538–550. [Google Scholar] [CrossRef]

- Duan, G.; Shen, Z.; Liu, R. An MBD Based Framework for Relative Position Accuracy Measurement in Digital Assembly of Large-Scale Component. Assem. Autom. 2019, 39, 685–695. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, H.; Li, J.; Zhang, Q.; Tang, Y. CKGAT: Collaborative Knowledge-Aware Graph Attention Network for Top-N Recommendation. Appl. Sci. 2022, 12, 1669. [Google Scholar] [CrossRef]

- Champatiray, C.; Samal, S.; Bahubalendruni, M.V.A.R.; Mahapatra, R.N.; Mishra, D.; Balabantaray, B.K. Modified Cat Swarm Optimization for Optimal Assembly Sequence Planning Problems. Int. J. Perform. Eng. 2022, 18, 289. [Google Scholar] [CrossRef]

- Shen, X.; Liu, S.; Zhang, C.; Bao, J. Intelligent Material Distribution and Optimization in the Assembly Process of Large Offshore Crane Lifting Equipment. Comput. Ind. Eng. 2021, 159, 107496. [Google Scholar] [CrossRef]

- Han, Z.; Mo, R.; Hao, L. Clustering and Retrieval of Mechanical CAD Assembly Models Based on Multi-Source Attributes Information. Robot. Comput.-Integr. Manuf. 2019, 58, 220–229. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, F.; Zhang, H.; Shi, Z.; Zhu, H. Optimization of Assembly Sequence of Building Components Based on Simulated Annealing Genetic Algorithm. Alex. Eng. J. 2023, 62, 257–268. [Google Scholar] [CrossRef]

- Xie, Z.; Du, J.; Chen, Q.; Wang, X. Enhancing the Labor Division in the Balancing of Apparel Assembly Lines with Parallel Workstation through an Improved Ant Colony Algorithm. J. Eng. Fibers Fabr. 2021, 16, 15589250211055784. [Google Scholar] [CrossRef]

- Li, F.; Yang, C.; Shao, J. Research on Ant Colony Algorithm for Wing Assembly Sequence Planning. In Proceedings of the 2021 2nd International Conference on Intelligent Computing and Human-Computer Interaction (ICHCI), Shenyang, China, 17–19 November 2021; pp. 175–178. [Google Scholar]

- Chaudhari, P.; Thakur, A.K.; Kumar, R.; Banerjee, N.; Kumar, A. Comparison of NSGA-III with NSGA-II for Multi Objective Optimization of Adiabatic Styrene Reactor. Mater. Today Proc. 2022, 57, 1509–1514. [Google Scholar] [CrossRef]

- Ehsaeyan, E.; Zolghadrasli, A. FOA: Fireworks Optimization Algorithm. Multimed. Tools Appl. 2022, 81, 33151–33170. [Google Scholar] [CrossRef]

- Fountas, N.A.; Kechagias, J.D.; Vaxevanidis, N.M. Optimization of Selective Laser Sintering/Melting Operations by Using a Virus-Evolutionary Genetic Algorithm. Machines 2023, 11, 95. [Google Scholar] [CrossRef]

- Dunford, R.; Su, Q.; Tamang, E. The Pareto Principle. Plymouth Stud. Sci. 2014, 7, 140–148. [Google Scholar]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A Fast and Elitist Multiobjective Genetic Algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

| Assembly Category | Scope | Range | Interpretation of Nouns | Functional Description |

|---|---|---|---|---|

| AF | topology | {Total assembly, sub-assembly, parts} | Define component structure relations | |

| Geometric solid | {FaceTorch, EdgeCurve, VertexPoint} | {face, edge, point} | Describe the form of contact of parts | |

| Assembly operations | {ConnectionAssembly, AdhesiveAssembly, WeldAssembly} | {coupling, bonding, welding} | Determine the type of component connection | |

| Assembly Tools | {Assembly Tools} | Auxiliary parts assembly process | ||

| AS | Localization semantic relation | {Degrees of Freedom, Mobility} | Parts Positioning | |

| Connection semantic information | {HasSub, Subof, HasPart, Partof, HasGFD, HasBegin, HasEnd, HasGMO} | {Collection of connection relations} | Parts Connection Relation | |

| AP | Data property | {Name, RelativeMatrix, Direction, Weight, Num} | {Collection of Part Properties} | Retention of parts’ own properties |

| Constraint property | {hasGF, hasGMO} | {Degree-of-freedom relation, Constraint relation} | Constraint information for parts | |

| {TRUE, FALSE} | Determine whether to start parts | |||

| {Auxiliary parts collection, Collection of Connectors} | Auxiliary and connecting parts required before installation | |||

| {Parts collection} | Collection of parts and components that are coupled |

| 1 | WP15 01 01 000 | Wind turbine base parts | 1 | |||

| 2 | WP15 01 02 000 | plunger | 1 | |||

| 3 | WP15 01 03 000 | Control tower | 1 | |||

| 4 | WP15 01 04 000 | Complete shells | 1 | |||

| 5 | WP15 01 05 000 | alternators | 1 | |||

| 6 | WP15 01 06 000 | nacelle | 1 | |||

| 7 | WP15 02 01 000 | Rotor plug-in | 1 | |||

| 8 | WP15 02 02 000 | Blade steering transmission device | 1 | |||

| 9 | WP15 02 03 000 | Pod steering transmission device | 1 | |||

| 10 | WP15 02 04 000 | Wind wheel | 1 | |||

| 11 | WP15 02 05 000 | Rotor stopper | 1 | |||

| 12 | WP15 02 06 000 | brake mechanism | 1 | |||

| 13 | WP15 03 01 000 | blade | 3 | |||

| 14 | WP15 03 02 000 | steering | 2 | |||

| 15 | WP15 04 01 000 | Brake mechanism terminal switch group | 1 | |||

| 16 | WP15 04 02 000 | Pod slewing transmission terminal switch group | 1 | |||

| 17 | WP15 04 03 000 | Blade steering transmission terminal switch group | 1 | |||

| 18 | WP15 04 04 000 | Current limiter drive terminal switch group | 1 | |||

| 19 | WP15 05 01 000 | Tower shell | 1 | |||

| WP15 01 00 000 | ||||||

| file | subassembly | serial No. | attachment | date | ||

| Feature Type | Number of Instances | Feature Type | Number of Instances |

|---|---|---|---|

| subassembly/SA | 5 | SubassemblyOf | 196 |

| FaceTorch | 82 | HasPart | 205 |

| EdgeCurve | 503 | PartOf | 205 |

| VertexPoint | 1052 | GF | 550 |

| ConnectionAssembly | 847 | GMO | 275 |

| AdhesiveAssembly | 48 | RelativeMatrix | 46 |

| HasSubassembly | 196 | Direction | 3411 |

| Evaluation Indicators | Entity | Link |

|---|---|---|

| 0.85 | 0.81 | |

| 0.86 | 0.83 | |

| 0.85 | 0.82 |

| Methods | Approximate Optimal Solution | Global Assembly Sequences |

|---|---|---|

| Pareto ant colony algorithm | p1 | P2 → (P5, −Z) → (P4, +X) → (P3, − X) → (P13, +Y) → (P14, +Y) → (P6, −Z) → (P7, +X) → (P8, +X) → (P9, +X) → (P15, +X) → (P18, −X) → (P16, +Y) → (P17, +Y) → (P12, −Z) → (P11, +X) → (P10, +X) → (P1, −Z) → (P19, −Z) |

| p2 | P2 → (P3, −Z) → (P4, +X) → (P5, −X) → (P13, +Y) → (P14, +Y) → (P9, −Z) → (P8, +X) → (P7, +X) → (P6, +X) → (P15, +X) → (P18, −X) → (P16, +Y) → (P17, +Y) → (P10, −Z) → (P12, +X) → (P11, +X) → (P1, −Z) → (P19, −Z) | |

| p3 | P2 → (P5, −Z) → (P4, +X) → (P3, −X) → (P14, −X) → (P13, +Y) → (P7, −Z) → (P8, +X) → (P6, +X) → (P9, +X) → (P15, +X) → (P18, −X) → (P16, +Y) → (P17, +Y) → (P11, −Z) → (P12, +X) → (P10, +X) → (P1, −Z) → (P19, −Z) | |

| NSGA-II algorithm | n1 | P2 → (P12, −Z) → (P10, +X) → (P11, −X) → (P14, −X) → (P13, +Y) → (P8, −Z) → (P9, +X) → (P7, +X) → (P6, +X) → (P15, +X) → (P18, −X) → (P16, +Y) → (P17, +Y) → (P4, −Z) → (P3, +X) → (P5, −X) → (P1, −Z) → (P19, −Z) |

| n2 | P2 → (P11, −Z) → (P10, +X) → (P12, −X) → (P15, +X) → (P18, −X) → (P16, +Y) → (P17, +Y) → (P6, −Z) → (P9, +X) → (P7, +X) → (P8, +X) → (P14, −X) → (P13, +Y) → (P4, −Z) → (P3, +X) → (P5, −X) → (P1, −Z) → (P19, −Z) | |

| n3 | P2 → (P12, −Z) → (P11, +X) → (P10, −X) → (P8, −Z) → (P7, +X) → (P6, +X) → (P9, +X) → (P5, −Z) → (P3, +X) → (P4, −X) → (P13, +Y) → (P14, +Y) → (P15, +X) → (P18, −X) → (P16, +Y) → (P17, +Y) → (P1, −Z) → (P19, −Z) | |

| KG-driven rule-based reasoning algorithm | k1 | P2 → (P8, −Z) → (P9, +X) → (P7, +X) → (P6, −Z) → (P13, +Y) → (P14, +Y) → (P15, +X) → (P18, −X) → (P16, +Y) → (P17, +Y) → (P4, +X) → (P3, +X) → (P5, +X) → (P12, −Z) → (P11, +X) → (P10, +X) → (P1, −Z) → (P19, −Z) |

| k2 | P2 → (P8, −Z) → (P9, +X) → (P6, +X) → (P7, −Z) → (P15, +X) → (P18, −X) → (P16, +Y) → (P17, +Y) → (P10, +X) → (P11, +X) → (P12, +X) → (P4, −Z) → (P3, +X) → (P5, +X) → (P13, +Y) → (P14, +Y) → (P1, −Z) → (P19, −Z) | |

| k3 | P2 → (P8, −Z) → (P6, +X) → (P9, +X) → (P7, +X) → (P13, +Y) → (P14, +Y) → (P15, +X) → (P18, −X) → (P16, +Y) → (P17, +Y) → (P12, +X) → (P11, +X) → (P10, +X) → (P4, +X) → (P5, +X) → (P3, +X) → (P1, −Z) → (P19, −Z) |

| Serial No. | Stability Affiliation Degree | Reorientation Affiliation Degree | Polymerization Affiliation Degree | Relative Closeness |

|---|---|---|---|---|

| p1 | 0.77 | 0.41 | 0.28 | 0.37 |

| p2 | 0.78 | 0.46 | 0.31 | 0.41 |

| p3 | 0.82 | 0.48 | 0.34 | 0.49 |

| n1 | 0.75 | 0.82 | 0.40 | 0.47 |

| n2 | 0.78 | 0.86 | 0.43 | 0.48 |

| n3 | 0.81 | 0.88 | 0.48 | 0.54 |

| k1 | 0.74 | 0.89 | 0.45 | 0.63 |

| k2 | 0.79 | 0.92 | 0.51 | 0.65 |

| k3 | 0.82 | 0.95 | 0.51 | 0.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Zhou, B.; Li, J.; Li, X.; Bao, J. A Knowledge Graph-Based Approach for Assembly Sequence Recommendations for Wind Turbines. Machines 2023, 11, 930. https://doi.org/10.3390/machines11100930

Liu M, Zhou B, Li J, Li X, Bao J. A Knowledge Graph-Based Approach for Assembly Sequence Recommendations for Wind Turbines. Machines. 2023; 11(10):930. https://doi.org/10.3390/machines11100930

Chicago/Turabian StyleLiu, Mingfei, Bin Zhou, Jie Li, Xinyu Li, and Jinsong Bao. 2023. "A Knowledge Graph-Based Approach for Assembly Sequence Recommendations for Wind Turbines" Machines 11, no. 10: 930. https://doi.org/10.3390/machines11100930

APA StyleLiu, M., Zhou, B., Li, J., Li, X., & Bao, J. (2023). A Knowledge Graph-Based Approach for Assembly Sequence Recommendations for Wind Turbines. Machines, 11(10), 930. https://doi.org/10.3390/machines11100930