Literature Review of Suspension Systems for Superconducting Elements

Abstract

1. Introduction

2. Methodology

- The “⋯” operator is used to include a specific word or sentence in the search.

- Parentheses, AND, and OR operators follow the common Boolean algebra.

- The “∼” operator allows the browser to search for synonyms of a word.

- The “-” operator excludes a word from the results.

- The “intitle:” operator forces the browser to find results that contain a specific word in the title.

- The architecture, i.e., the arrangement of supports with respect to the superconducting body.

- The geometry of the single supporting element of the suspension system.

- The materials used for the supporting element.

- The characteristics of the supported body, such as its mass and length.

- The cool-down effect, i.e., the kinematic behavior of the architecture when the superconducting body undergoes a thermal cycle.

- The adjustability and classification of the adjustment system.

3. Results

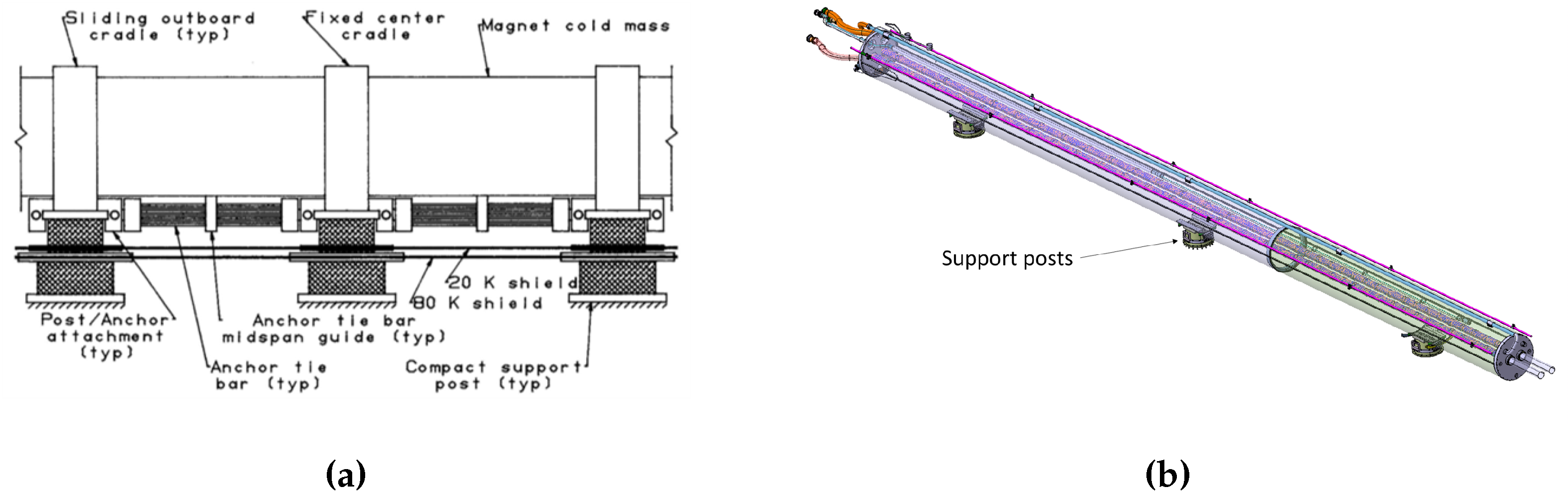

3.1. The “Multi-Post” Architecture and Geometry

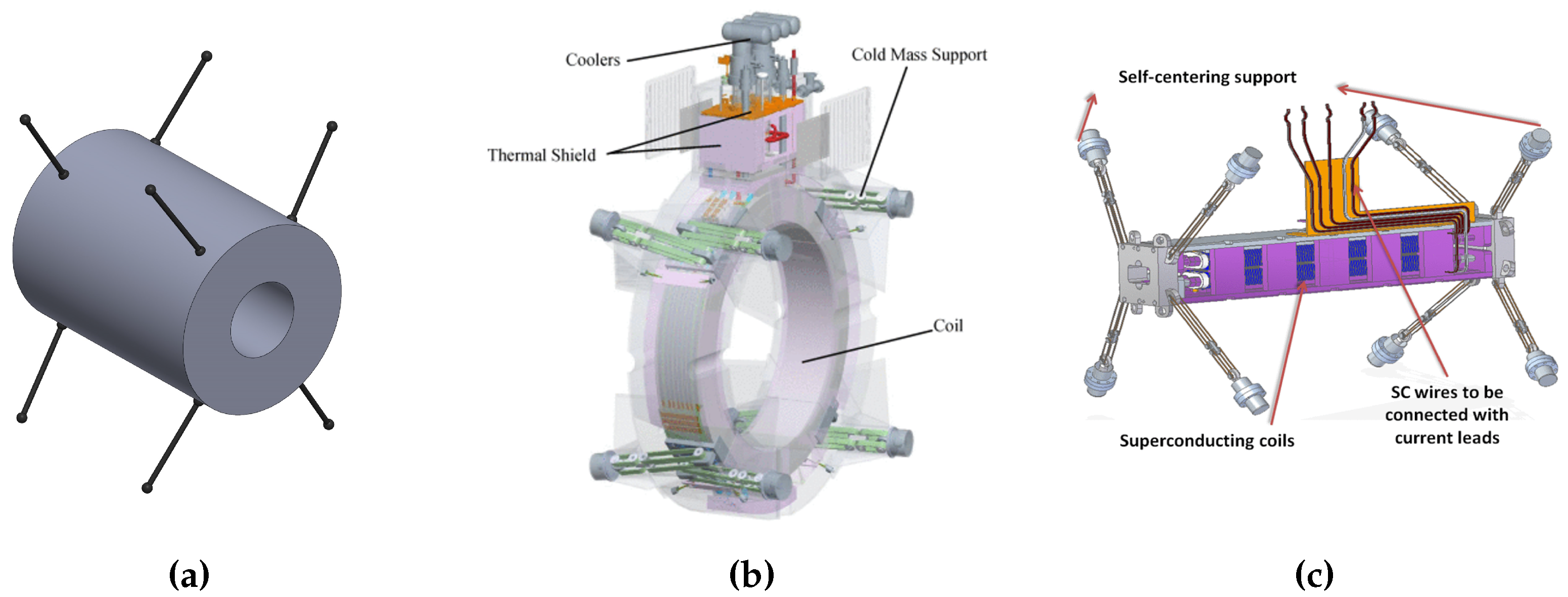

3.2. The “8-Support” Architecture and Geometry

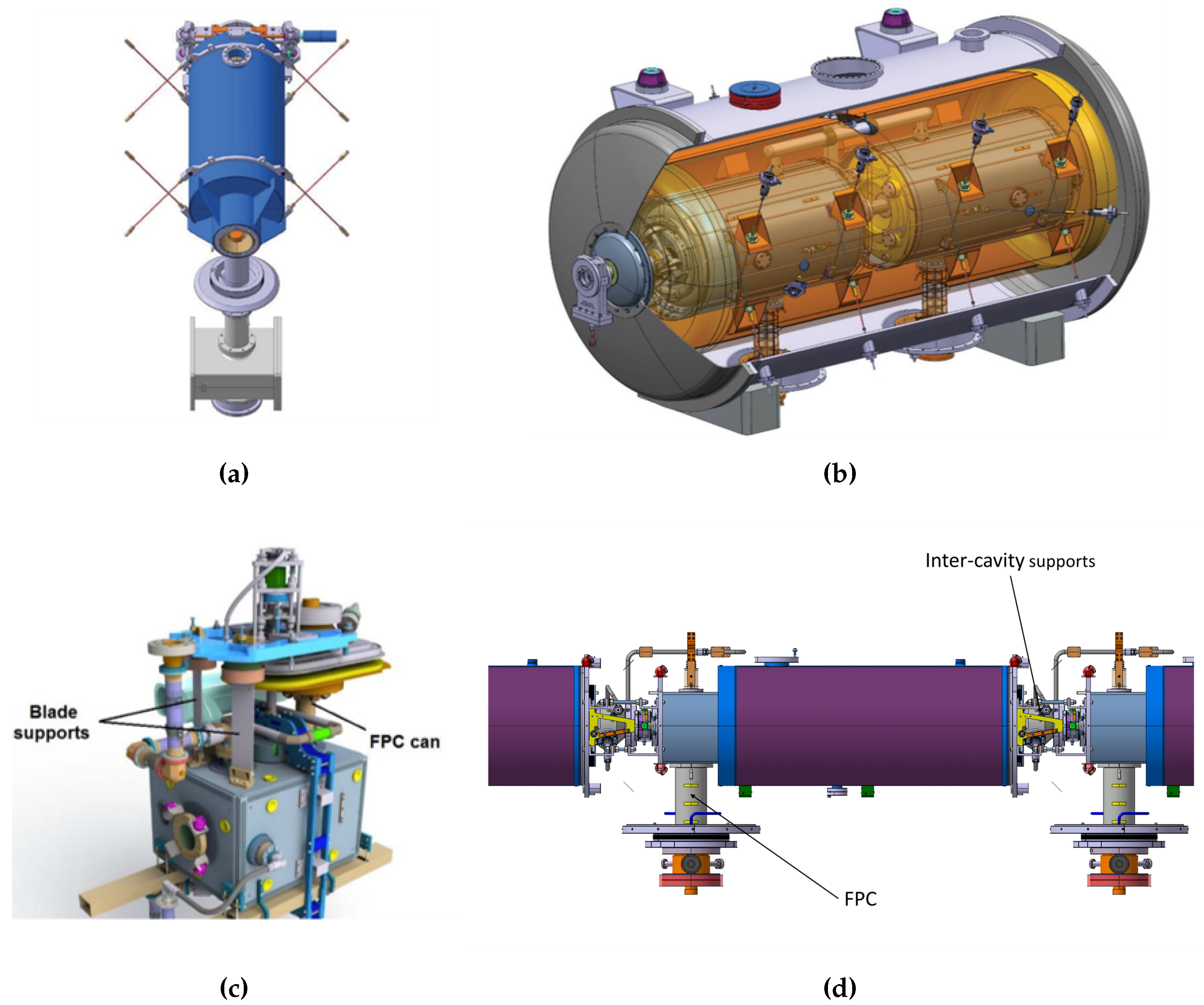

3.3. The Cavity Architecture and Geometry

3.4. Other Architectures

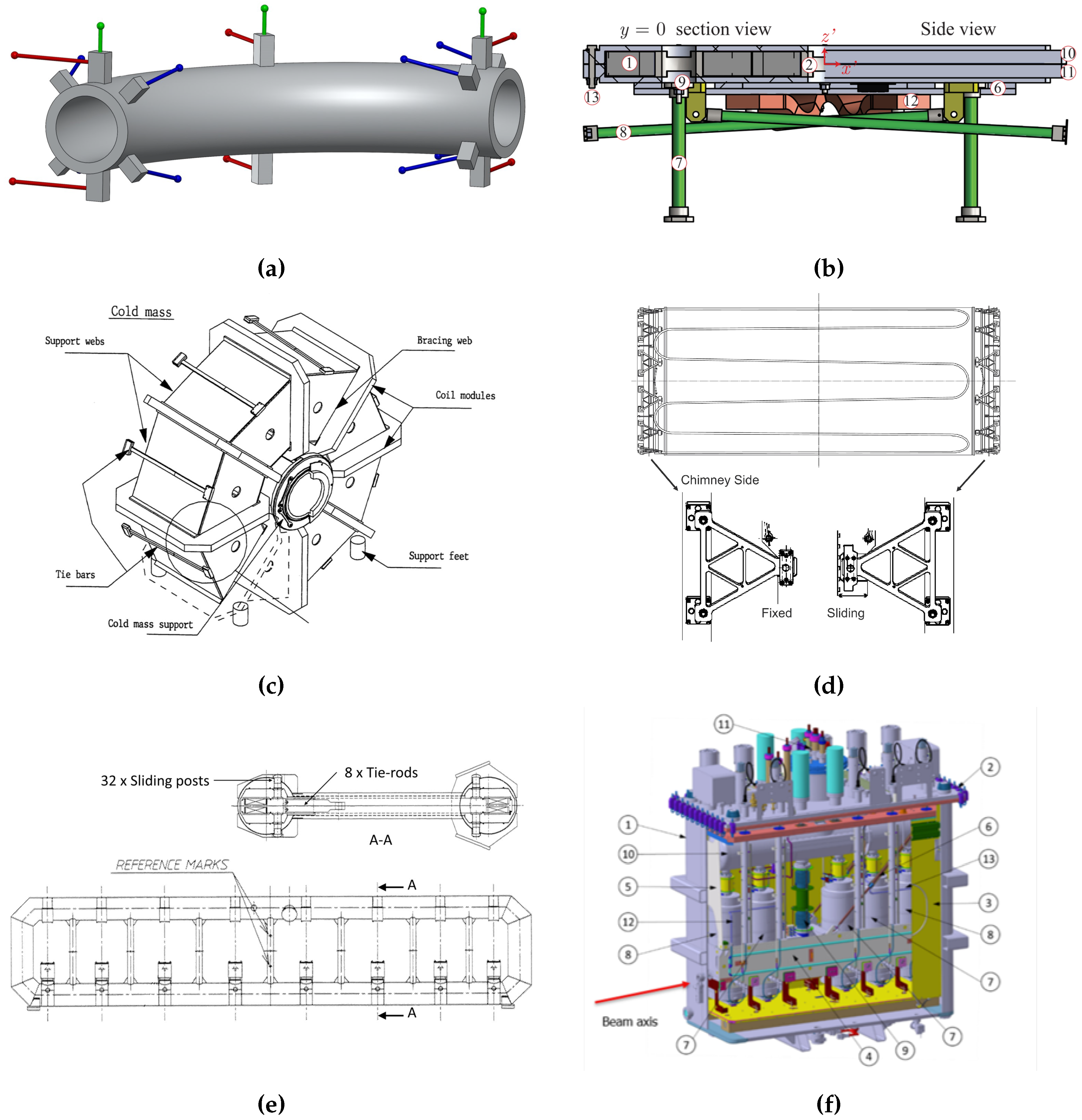

3.5. Intermediate Structural Elements: Common Girder and Space Frame

3.6. Other Remarks on Results

3.7. Materials Used for the Supports

- Metallic materials: Ti-6Al-4V, Ti 5AL 2.5Sn ELI, SS316L, SS 316LN, AISI 304, Inconel® 718;

- Composites: CFRP (Carbon Fibre Reinforced Polymer), G10, G11, G11CR, UFGE (Unidirectional FibreGlass Epoxy), GFRE (Glass Fibre Reinforced Epoxy), Ultem® 2100, SEl-GFN3 Noryl®.

3.8. Cool-Down Effects and Adjustability

4. Summary

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martín-Martín, A.; Orduna-Malea, E.; Thelwall, M.; López-Cózar, E.D. Google Scholar, Web of Science, and Scopus: A systematic comparison of citations in 252 subject categories. J. Inf. 2018, 12, 1160–1177. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Wang, L.; Sun, S.; Wang, S.; Yin, L. Design of cold mass supports for a superconducting undulator prototype at SINAP. IEEE Trans. Appl. Supercond. 2014, 25, 4101004. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Guo, X.; Wang, S.; Li, M.; Sun, S. Development of a Test Cryostat for a Superconducting Undulator Prototype at the SSRF. IEEE Trans. Appl. Supercond. 2021, 31, 9500105. [Google Scholar] [CrossRef]

- Darve, C.; Bosland, P.; Devanz, G.; Olivier, G.; Renard, B.; Thermeau, J.P. The ESS elliptical cavity cryomodules. AIP Conf. Proceedings. Am. Inst. Phys. 2014, 1573, 639–646. [Google Scholar]

- Olivier, G.; Thermeau, J.; Bosland, P.; Darve, C. Ess cryomodules for elliptical cavities. In Proceedings of the 16th International Conference on RF Superconductivity, Paris, France, 23–27 September 2013. [Google Scholar]

- European Spallation Source. ESS Installs First Two Cryomodules in the Linac. Available online: https://europeanspallationsource.se/article/2023/03/15/ess-installs-first-two-cryomodules-linac (accessed on 20 February 2023).

- Monaco, L.; Bellandi, A.; Bertucci, M.; Bignami, A.; Bosotti, A.; Chen, J.; Michelato, P.; Paparella, R.; Sertore, D.; Pagani, C.; et al. Fabrication and treatment of the ESS medium beta prototype cavities. In Proceedings of the 8th International Particle Accelerator Conference, Copenhagen, Denmark, 14–19 May 2017; pp. 1003–1006. [Google Scholar]

- Carra, F.; Apeland, J.; Calaga, R.; Capatina, O.; Capelli, T.; Verdú-Andrés, S.; Zanoni, C. Assessment of thermal loads in the CERN SPS crab cavities cryomodule1. J. Phys. Conf. Ser. 2017, 874, 012005. [Google Scholar] [CrossRef]

- Jones, T.; Burt, G.; Artoos, K.; Calaga, R.; Capatina, O.; Capelli, T.; Sosin, M.; Swieszek, J.; Zanoni, C. Development of a Novel Supporting System for High Luminosity LHC SRF Crab Cavities. In Proceedings of the 18th International Conference on RF Superconductivity, Lanzhou, China, 17–21 July 2017; JACOW: Geneva, Switzerland, 2018; pp. 304–308. [Google Scholar]

- Pattalwar, S.; Burt, G.; Capatina, O.; Hall, B.; Jones, T.; May, A.; McIntosh, P.; Nicol, T.; Templeton, N.; Wheelhouse, A.; et al. Key Design Features of Crab-Cavity Cryomodule for HiLumi LHC. In Proceedings of the 5th International Particle Accelerator Conference, Dresden, Germany, 15–20 June 2014; pp. 2580–2582. Available online: https://cds.cern.ch/record/2003149/files/wepri045.pdf (accessed on 20 February 2023).

- Azevedo, P. SPL Short Cryomodule Design. In Indico, SPL Internal Meeting, CERN; CERN: Geneva, Switzerland, 2012. [Google Scholar]

- Parma, V.; Van Weelderen, R.; Schirm, K.; Chambrillon, J.; Vande Craen, A.; Vandoni, G.; Montesinos, E.; Capatina, O.; Bonomi, R. Status of the Superconducting Proton Linac (SPL) Cryo-Module. In Proceedings of the 16th International Conference on RF Superconductivity, Paris, France, 23–27 September 2013; pp. 345–348. [Google Scholar]

- Atieh, S.; Weingarten, W.; Arnau Izquierdo, G.; Renaglia, T.; Capatina, O.; Tardy, T.; Aviles Santillana, I.; Valverde Alonso, N. Mechanical Design and Fabrication Studies for SPL Superconducting RF Cavities. In Proceedings of the 2nd International Particle Accelerator Conference, San Sebastian, Spain, 4–9 September 2011; pp. 199–201. [Google Scholar]

- Reynet, D.; Brault, S.; Duthil, P.; Duchesne, P.; Olry, G.; Gandolfo, N.; Rampnoux, E.; Bousson, S. Design of the ESS Spoke cryomodule. In Proceedings of the SRF 2013, Paris, France, 23–27 September 2013; pp. 357–360. [Google Scholar]

- Bousson, S.; Darve, C.; Duthil, P.; Elias, N.; Molloy, S.; Reynet, D.; Thermeau, J.P. The ESS spoke cavity cryomodules. AIP Conf. Proceedings. Am. Inst. Phys. 2014, 1573, 665–672. [Google Scholar]

- Duthil, P.; Reynet, D.; Olry, G.; Brault, S.; Duchesne, P.; Gandolfo, N.; Rampnoux, E.; Darve, C.; Ellas, N. Design and Prototyping of the Spoke Cyromodule for ESS. In Proceedings of the HB2016, Malmö, Sweden, 3–8 July 2016; pp. 416–421. [Google Scholar]

- Bhunia, U.; Agrawal, A.; Roy, A.; Nandi, C.; Khare, V.; Thakur, S.; Dey, M.; Bandyopadhyay, A. Development and performance evaluation of a conduction-cooled warm bore HTS steering magnet. Physica C 2023, 604, 1354191. [Google Scholar] [CrossRef]

- Zhang, J.; Song, Y.; Zhang, W.; Jiang, F. Magnetic and thermal design of HTS quadrupole magnet for newly developed superconducting proton cyclotron beam line. J. Supercond. Nov. Magn. 2019, 32, 529–538. [Google Scholar] [CrossRef]

- Kosse, J.; Wessel, W.; Zhou, C.; Dhallé, M.; Tomás, G.; Krooshoop, H.; Ter Brake, H.; Ten Kate, H. Mechanical design of a superconducting demonstrator for magnetic density separation. Supercond. Sci. Technol. 2021, 34, 115019. [Google Scholar] [CrossRef]

- Kadi, Y.; Fraser, M.A.; Papageorgiou-Koufidou, A. HIE-ISOLDE: Technical Design Report for the Energy Upgrade; CERN Yellow Reports: Monographs; CERN: Geneva, Switzerland, 2018. [Google Scholar] [CrossRef]

- Delruelle, N.; Leclercq, Y.; Pirotte, O.; Ramos, D.; Tibaron, P.; Vandoni, G.; Williams, L. The high Beta cryo-modules and the associated cryogenic system for the HIE-ISOLDE upgrade at CERN. AIP Conf. Proc. 2014, 1573, 811–818. [Google Scholar]

- Xu, M.F.; Zhang, X.Z.; Ye, R.; Chen, F.S.; Yang, X.C.; Zhao, T.X.; Li, S.P.; Sun, X.J.; Sun, L.R.; Ma, C.C.; et al. Design, assembly, and pre-commissioning of cryostat for 3W1 superconducting wiggler magnet. Nucl. Sci. Tech. 2020, 31, 113. [Google Scholar] [CrossRef]

- Hwang, C.; Chang, C.; Chen, H.; Lin, F.; Fan, T.; Huang, M.; Jan, J.; Hsu, K.; Chen, J.; Hsu, S.; et al. Superconducting wiggler with semi-cold beam duct at Taiwan light source. Nucl. Instruments Methods Phys. Res. Sect. Accel. Spectrometers, Detect. Assoc. Equip. 2006, 556, 607–615. [Google Scholar] [CrossRef]

- Chen, H.; Hwang, C.; Chang, C.; Jan, J.; Lin, F.; Huang, M.; Fan, T. Design of mechanical structure and cryostat for IASW superconducting wiggler at NSRRC. In Proceedings of the 2007 IEEE Particle Accelerator Conference (PAC), Albuquerque, NM, USA, 25–29 June 2007; pp. 374–376. [Google Scholar]

- Wang, L.; Wu, H.; Li, S.; Guo, X.; Pan, H.; Zheng, S.X.; Green, M.A. Design and analysis of a self-centered cold mass support for the MICE coupling magnet. IEEE Trans. Appl. Supercond. 2011, 21, 2259–2262. [Google Scholar] [CrossRef]

- Fischer, E.; Schnizer, P.; Sugita, K.; Meier, J.P.; Mierau, A.; Spiller, P.; Kester, O.; Khodzhibagiyan, H.; Trubnikov, G. Superconducting quadrupole module system for the sis100 synchrotron. In Proceedings of the Russian Particle Accelerator Conference 2012, Saint-Petersburg, Russia, 24–28 September 2012; pp. 143–145. [Google Scholar]

- Meier, J.; Bleile, A.; Fischer, E.; Hess, G.; Macavei, J.; Spiller, P. Cryo-technical design aspects of the superconducting SIS100 quadrupole doublet modules. AIP Conf. Proceedings. Am. Inst. Phys. 2014, 1573, 1519–1526. [Google Scholar]

- Ambrosio, G.; Andreev, N.; Cheban, S.; Coleman, R.; Dhanaraj, N.; Evbota, D.; Feher, S.; Kashikhin, V.; Lamm, M.; Lombardo, V.; et al. Challenges and design of the transport solenoid for the Mu2e experiment at Fermilab. IEEE Trans. Appl. Supercond. 2013, 24, 4101405. [Google Scholar] [CrossRef]

- Lopes, M.; Ambrosio, G.; Badgley, K.E.; Bradascio, F.; Brandt, J.; Evbota, D.; Hocker, A.; Lamm, M.; Lombardo, V.; Miller, J.; et al. Mu2e transport solenoid cold-mass alignment issues. IEEE Trans. Appl. Supercond. 2017, 27, 4500405. [Google Scholar] [CrossRef]

- Wanderer, P.; Muratore, J.; Anerella, M.; Ganetis, G.; Ghosh, A.; Greene, A.; Gupta, R.; Jain, A.; Kahn, S.; Kelly, E.; et al. Construction and testing of arc dipoles and quadrupoles for the Relativistic Heavy Ion Collider (RHIC) at BNL. Proc. Part. Accel. Conf. 1995, 2, 1293–1297. [Google Scholar]

- Sondericker, J.; Wolf, L. Alternative concepts for structurally supporting the cold mass of a superconducting accelerator magnet. In Supercollider 3; Nonte, J., Ed.; Springer: Boston, MA, USA, 1991; pp. 175–189. [Google Scholar] [CrossRef]

- Li, L.; Wang, Q.; Zhao, B.; Ni, Z.; Cui, C.; Wang, H. Theoretical model of a cold mass strap suspension system for superconducting magnets. IEEE Trans. Appl. Supercond. 2011, 21, 3640–3645. [Google Scholar] [CrossRef]

- Yamamoto, A.; Makida, Y.; Ruber, R.; Doi, Y.; Haruyama, T.; Haug, F.; Ten Kate, H.; Kawai, M.; Kondo, T.; Kondo, Y.; et al. The ATLAS central solenoid. Nucl. Instruments Methods Phys. Res. Sect. A 2008, 584, 53–74. [Google Scholar] [CrossRef]

- Devred, A.; Chapman, M.; Cortella, J.; Desportes, A.; DiMarco, J.; Kaugerts, J.; Schermer, R.; Tompkins, J.; Turner, J.; Cottingham, J.; et al. Quench Characteristics of Full-Length SSC R&D Dipole Magnets; Advances in Cryogenic Engineering, Volume 35; Springer: Boston, MA, USA, 1990. [Google Scholar] [CrossRef]

- Nicol, T.; Niemann, R.; Gonczy, J. SSC magnet cryostat suspension system design. In Advances in Cryogenic Engineering; Springer: A Cryogenic Engineering Conference Publication, Volume 33; Springer: Boston, MA, USA, 1988; pp. 227–234. [Google Scholar] [CrossRef]

- Galayda, J. The LCLS-II: A High Power Upgrade to the LCLS; SLAC National Accelerator Lab.: Menlo Park, CA, USA, 2018. [Google Scholar]

- Peterson, T.; Arkan, T.; Ginsburg, C.; He, Y.; Kaluzny, J.; McGee, M.; Orlov, Y. LCLS-II 1.3 GHz cryomodule design-modified tesla-style cryomodule for CW operation. In Proceedings of the 17th International Conference on RF Superconductivity, Whistler, Canada, 13–18 September 2015; pp. 1417–1421. [Google Scholar]

- Lu, K.; Song, Y.; Niu, E.; Zhou, T.; Wang, Z.; Chen, Y.; Zhu, Y. Evolution of the design of cold mass support for the ITER magnet feeder system. Plasma Sci. Technol. 2013, 15, 196. [Google Scholar] [CrossRef]

- Zhu, Y.; Song, Y.; Zhang, Y.; Wang, Z. Conceptual design and analysis of cold mass support of the CS3U feeder for the ITER. Plasma Sci. Technol. 2013, 15, 599. [Google Scholar] [CrossRef][Green Version]

- Dwivedi, J.; Kumar, A.; Parma, V.; Goswami, S.; Madhumurthy, V.; Soni, H. The Alignment Jacks of the LHC Cryomagnets. In Proceedings of the EPAC 2004, Lucerne, Switzerland, 5–9 July 2004; pp. 1687–1689. [Google Scholar]

- Castoldi, M.; Parma, V.; Pangallo, M.; Vandoni, G. Thermal Performance of the Supporting System for the Large Hadron Collider (LHC) Superconducting Magnets. In Proceedings of the Joint Cryogenic Engineering Conference and International Cryogenic Materials Conference, LHC project report 335, Montreal, Canada, 12–16 July 1999. [Google Scholar]

- Seyvet, F.; Jeanneret, J.B.; Poncet, A.; Tommasini, D.; Beauquis, J.; Cano, E.F.; Wildner, E. Improvement of the geometrical stability of the LHC cryodipoles when blocking the central support post. In Proceedings of the 2005 Particle Accelerator Conference, Knoxville, TN, USA, 16–20 May 2005; pp. 2675–2677. [Google Scholar]

- Mathieu, M.; Parma, V.; Renaglia, T.; Rohmig, P.; Williams, L. Supporting systems from 293 K to 1.9 K for the Large Hadron Collider (LHC) cryo-magnets. Adv. Cryog. Eng. 1998, 43, 427–434. [Google Scholar]

- Dudarev, A.; Rabbers, J.; Berriaud, C.; Junker, S.; Pengo, R.; Ravat, S.; Deront, L.; Sbrissa, E.; Olesen, G.; Arnaud, M.; et al. First full-size ATLAS barrel toroid coil successfully tested up to 22 kA at 4 T. IEEE Trans. Appl. Supercond. 2005, 15, 1271–1274. [Google Scholar] [CrossRef]

- Mayri, C.; Berriaud, C.; Cazaux, S.; Dudarev, A.; Foussat, A.; Pabot, Y.; Rey, J.; Reytier, M.; Ten Kate, H.; Sun, Z.; et al. Suspension system of the barrel toroid cold mass. IEEE Trans. Appl. Supercond. 2006, 16, 525–528. [Google Scholar] [CrossRef]

- Badiou, J.; Beltramelli, J.; Baze, J.; Belorgey, J. ATLAS Barrel Toroid: Technical Design Report; CERN cds; CERN: Geneva, Switzerland, 1997. [Google Scholar] [CrossRef]

- Boulant, N.; Quettier, L. Commissioning of the Iseult CEA 11.7 T whole-body MRI: Current status, gradient–magnet interaction tests and first imaging experience. Magn. Reson. Mater. Phys. Biol. Med. 2023, 36, 175–189. [Google Scholar] [CrossRef]

- Nunio, F.; Berriaud, C.; Bredy, P.; Schild, T.; Scola, L.; Tellier, O.; Vedrine, P. Mechanical design of the Iseult 11.7 T whole body MRI magnet. IEEE Trans. Appl. Supercond. 2010, 20, 760–763. [Google Scholar] [CrossRef]

- Vedrine, P.; Maksoud, W.A.; Aubert, G.; Beaudet, F.; Belorgey, J.; Bermond, S.; Berriaud, C.; Bredy, P.; Bresson, D.; Donati, A.; et al. Latest progress on the Iseult/INUMAC whole body 11.7 T MRI magnet. IEEE Trans. Appl. Supercond. 2011, 22, 4400804. [Google Scholar] [CrossRef]

- Baynham, D.E.; Butterworth, J.; Carr, F.; Courthold, M.; Cragg, D.; Densham, C.; Evans, D.; Holtom, E.; Robertson, S.; Sole, D.; et al. Engineering design optimisation of the superconducting end cap toroid magnets for the ATLAS experiment at LHC. IEEE Trans. Appl. Supercond. 1999, 9, 856–859. [Google Scholar] [CrossRef]

- Baynham, D.; Carr, F.; Holtom, E.; Buskop, J.; Dudarev, A.; Vandoni, G.; Ruber, R.; Foussat, A.; Losasso, M.; Benoit, P.; et al. ATLAS end cap toroid final integration, test and installation. IEEE Trans. Appl. Supercond. 2008, 18, 391–394. [Google Scholar] [CrossRef]

- ATLAS, Magnet Project collaboration, End-Cap Toroid Group. ATLAS End-Cap Toroids: Technical Design Report; CERN cds; CERN: Geneva, Switzerland, 1997. [Google Scholar] [CrossRef]

- Levesy, B.; Gerwig, H.; Kircher, F.; Reytier, M. Design and test of the titanium alloy tie rods for the CMS coil suspension system. IEEE Trans. Appl. Supercond. 2002, 12, 403–406. [Google Scholar] [CrossRef]

- Mitchell, N.; Devred, A.; Libeyre, P.; Lim, B.; Savary, F. The ITER magnets: Design and construction status. IEEE Trans. Appl. Supercond. 2011, 22, 4200809. [Google Scholar] [CrossRef]

- Liao, M.; Li, P.; Hou, B.; Yang, S.; Fu, Y.; Gallix, R. Prototype engineering test platform of ITER magnet gravity support. Plasma Sci. Technol. 2013, 15, 192. [Google Scholar] [CrossRef]

- Corato, V.; Vorpahl, C.; Sedlak, K.; Anvar, V.; Bennet, J.; Biancolini, M.; Bonne, F.; Bonifetto, R.; Boso, D.; Brighenti, A.; et al. The DEMO magnet system–Status and future challenges. Fusion Eng. Des. 2022, 174, 112971. [Google Scholar] [CrossRef]

- Weisend, J., II. Cryostat Design; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar] [CrossRef]

- Lee, J.; Seo, G.; Mun, J.; Park, M.; Kim, S. Thermal and mechanical design for refrigeration system of 10 MW class HTS wind power generator. IEEE Trans. Appl. Supercond. 2020, 30, 5201905. [Google Scholar] [CrossRef]

- Tuvdensuren, O.; Go, B.; Sung, H.; Park, M. Design of an HTS module coil for a 750 kW-class superconducting wind power generator. J. Phys. Conf. Ser. 2019, 1293, 012077. [Google Scholar] [CrossRef]

- Tuvdensuren, O.; Sung, H.; Go, B.; Le, T.; Park, M.; Yu, I. Structural design and heat load analysis of a flux pump-based HTS module coil for a large-scale wind power generator. J. Phys. Conf. Ser. 2018, 1054, 012084. [Google Scholar] [CrossRef]

- Go, B.; Sung, H.; Park, M.; Yu, I. Structural design of a module coil for a 12-MW class HTS generator for wind turbine. IEEE Trans. Appl. Supercond. 2017, 27, 5202405. [Google Scholar] [CrossRef]

- Dam, M.; Battiston, R.; Burger, W.; Carpentiero, R.; Chesta, E.; Iuppa, R.; Rijk, G.; Rossi, L. Conceptual design of a high temperature superconducting magnet for a particle physics experiment in space. Supercond. Sci. Technol. 2020, 33, 044012. [Google Scholar] [CrossRef]

- Dam, M.; Burger, W.; Carpentiero, R.; Chesta, E.; Iuppa, R.; Rijk, G.; Rossi, L. Design and modeling of AMaSED-2: A high temperature superconducting demonstrator coil for the space spectrometer ARCOS. IEEE Trans. Appl. Supercond. 2022, 32, 4500105. [Google Scholar] [CrossRef]

- Dam, M.; Burger, W.; Carpentiero, R.; Chesta, E.; Iuppa, R.; Kirby, G.; Rijk, G.; Rossi, L. Manufacturing and testing of AMaSED-2: A no-insulation high-temperature superconducting demonstrator coil for the space spectrometer ARCOS. Supercond. Sci. Technol. 2022, 36, 014007. [Google Scholar] [CrossRef]

- Guo, X.L.; Wang, L.; Wang, J.; Wang, S.; Liu, Y.; Sun, S. Thermal and mechanical analysis on the cold mass support assembly of test cryomodule for IMP ADS-injector-II. AIP Conf. Proc. Am. Inst. Phys. 2014, 1573, 1341–1348. [Google Scholar]

- Yuan, J.; Ma, L.; He, Y.; Zhang, B.; Zhang, J.; Sun, G. Alignment and Deformation of the Cryostat in the CADS Injector II. In Proceedings of the 15th International Workshops on Accelerator Alignment, Fermilab, Batavia, NY, USA, 8–12 October 2018. [Google Scholar]

- Duthil, P. Material properties at low temperature. arXiv 2015, arXiv:1501.07100. [Google Scholar]

- National Institute of Standards and Technologies. Properties of Solid Materials from Cryogenic to Room-Temperatures. Available online: https://trc.nist.gov/cryogenics/materials/materialproperties.htm (accessed on 20 February 2023).

| Keyword | Description |

|---|---|

| FEA | Filters results in which the suspension system has been analyzed using Finite Element Analysis. |

| superconducting | Sets the search field to superconducting technologies. |

| cold mass | Highlights the interest in cold mass supports. |

| mechanical | Filters for mechanical analysis rather than just general physics analysis. |

| support | Sets the search field to the supports of a superconducting element. |

| suspension | Synonym for “support.” |

| ATLAS | Avoids repeated articles in the results citing one of the most well-known physics experiments (included manually afterwards). |

| CMS | Avoids repeated articles in the results citing one of the most well-known physics experiments (included manually afterwards). |

| LHC | Avoids the many publications related to LHC supports (included manually afterwards). |

| Ref. | Project | Element | SC Material | Mass | L1 a | L2 b | Architecture | Material | Cool-Down c | Applicability d | Adjustability e | Publication | Status f |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg | |||||||||||||

| [2,3] | SSRF | Magnet | NbTi wire | 160 | * | 8 bands | CFRP | E-SC | possible | SVI-P-R | 2014, 2021 | op. | |

| [4,5,6,7] | ESS | Cavity | Nb sheets | 210 | ca. | * | 8 rods + 1 post *** | Ti-6Al-4V (rod) + power-coupler | E-SC | possible | SVI-P-R | 2013, 2014 2017 2023 | const. |

| [8,9,10] | HL-LHC | Cavity | Nb bulk | 250 | * | 1 * | 2 blades + 1 post | SS 316L + power-coupler | N-AC | possible | VGI-P-NR * | 2014, 2017 2018 | dev. |

| [11,12,13] | SPL | Cavity | Nb bulk | * | * | 2 ICS + 1 post | N-AC | possible | VGI-P-NR * | 2011, 2012 2014 | ND | ||

| [6,14,15,16] | ESS (spoke) | Cavity | Nb sheets | * | 22 rods + 2 posts | Ti-6Al-4V (rod) + power-coupler | ND | possible | SVI-P-R | 2013, 2014, 2016, 2017 | const. | ||

| [17] | VECC | Magnet | Bi-2223 wire | * | 4 bands | G10 | N-AC | discouraged | VGI-P-NR | 2023 | op. | ||

| [18] | CAS | Magnet | YBCO tape | * | * | 8 pillars | G10 | E-SC | possible | SVI-P-R | 2019 | dev. | |

| [19] | MDS (UT) | Magnet | NbTi wire | 520 | 1 * | 4 posts + 4 rods | G11 | E-AC * | possible | Not relevant | 2021 | dev. | |

| [20,21] | HIE-ISOLDE | Frame | Cu sheets Nb coating | 850 | 2 | 1 * | 2 rods + 2 plates | N-AC | discouraged | SVI-P-NR | 2014, 2018 | op. | |

| [22] | IHEP | Magnet | 1400 | ca. | * | 8 bands | T300 (CFRP) | E-SC | possible | SVI-P-R | 2020 | op. | |

| [23,24] | TLS | Magnet | NbTi wire | * | 8 bands | UFGE | E-SC | possible | SVI-P-R | 2006, 2007 | op. | ||

| [25] | MICE | Magnet | NbTi wire | 1600 | 8 bands | UFGE | E-SC | possible | SVI-P-R | 2011 | op. | ||

| [26,27] | FAIR | Frame | NbTi wire | * | 8 rods | Ti-6Al-4V + AISI 304 | N-SC | possible | VGI-P-NR * | 2012, 2014 | const. | ||

| [28,29] | Mu2e | Magnet | NbTi wire | * | 3 springs + 14 rods | Inconel® 718 | ND | possible | SVI-P-R * | 2013, 2017 | const. | ||

| [30,31] | RHIC | Magnet | NbTi wire | 3605 | * | 3 posts | Ultem® 2100 or SEl-GFN3 Noryl® | N-AC | possible | VGI-P-NR * | 1991, 1995 | op. | |

| [32] | CAS | Magnet | 4000 | 8 bands | E-SC | possible | 2011 | res. | |||||

| [33] | ATLAS CS | Magnet | NbTi wire | 4700 | 24 struts | GFRE | N-AC | possible | SVI-P-R | 2007 | op. | ||

| [34,35] | SSC | Magnet | NbTi wire | 7700 | 17 | * | 5 posts | G11CR | N-AC | possible | VGI-P-NR * | 1988, 1990 | cancelled |

| [36,37] | LCLS-II | HE pipe | Nb sheets | 8600 | 12 | * | 3 posts (hung) | G10 | N-AC * | discouraged | SVI-P-NR + VGI-P-NR | 2015, 2018 | op. |

| [38,39] | ITER | Feeder | 10,000 ca. | ca. | * | 2 posts | SS 316LN | N-AC * | possible | Not relevant | 2013 | const. | |

| [40,41,42,43] | LHC | Magnet | NbTi wire | 25,000 ** | 16 ** | 3 posts ** | GFRE | N-AC | possible | VGI-P-NR | 1998, 1999 2004, 2005 | op. | |

| [44,45,46] | ATLAS BT | Magnet | NbTi wire | 45,000 | 25 | 5 | 8 rods + 32 stops | Ti 5Al 2.5 Sn ELI GFRE | D-SC * | possible | VGI-P-R | 1997, 2005 2006 | op. |

| [47,48,49] | NeuroSpin | Magnet | NbTi wire | 132,000 | 5 | 4 | 8 rods | Ti-6Al-4V | E-SC | possible | SVI-P-R * | 2010, 2011 2023 | comm. |

| [50,51,52] | ATLAS ECT | Magnet | NbTi wire | 160,000 | 5 | 20 rods | stainless steel | ND | possible | SVI-P-R | 1999, 2008 | op. | |

| [53] | CMS CS | Magnet | NbTi wire | 225,000 | 6 ca. | 30 rods | Ti 5Al 2.5Sn ELI | E-SC | possible | SVI-P-R * | 2002 | op. | |

| [54,55] | ITER | Magnet | Nb3Sn and NbTi | 24 | 30 | 18 multi- blades | stainless steel | E-AC | possible | VGI-P-NR * | 2011, 2013 | const. | |

| [56] | DEMO | Magnet | Nb3Sn, NbTi and RE-123 | 36 ca. | 45 ca. | 16 multi- blades | stainless steel | E-AC | possible | VGI-P-NR * | 2022 | dev. |

| Parameter | Description |

|---|---|

| Ref | Relevant references related to suspension architecture design and description. |

| Project | Name of the project. |

| Element | Classification of the suspended cold mass. |

| SC material | Superconducting material and its raw shape used for the analyzed design. |

| Mass | Mass of the supported cold mass. |

| L1 | First major dimension of the cold mass, generally in the longitudinal direction (curvilinear for Mu2e or height for tokamaks). |

| L2 | Second major dimension of the cold mass, generally diameter. |

| Architecture | Suspension system elements and their classification based on geometry (i.e., post, band, rod, etc.). |

| Material | Material of the suspension elements. |

| Cool-down | Classification of the behavior of the support system during the cool-down, specifically related to the possibility of extra stress appearing in the supporting elements and to the influence of the thermal contraction on the misalignment of the cold mass. |

| Applicability | Evaluation of the possibility to apply the suspension architecture to support a cold mass that needs to be rotated. |

| Adjustability | Classification of the adjustment/alignment system, based on its position in the assembly, the way of adjustment (passive or actuated) and the evaluation of its applicability to rotating cold masses. |

| Publication | Years of publication of the references. |

| Status | Status of the project at the moment of the publication of this article. |

| Parameter | Abbreviation | Description |

|---|---|---|

| Cool-down | E | Extra stress appears in the suspension system element due to cool-down |

| N | No extra stress appears in the suspension system element due to cool-down | |

| D | The system gets de-stressed from an initial condition of pre-tensioned suspension system | |

| AC | The cool-down affects the position and orientation of the supported body in an asymmetric way, the architecture is not self-centering | |

| SC | The architecture is self centering during cool-down, there is no change in position and orientation of the cold mass | |

| ND | Not easily Deducible by these authors | |

| Adjustability | SVI | The adjustment/alignment system is placed at the interface between the suspension system and the vacuum vessel |

| VGI | The adjustment/alignment system is placed at the interface between the vacuum vessel and the ground | |

| A | The adjustment/alignment system is actuated | |

| P | The adjustment/alignment system is passive | |

| R | The adjustment/alignment system can be applied directly on a rotating machine with little R&D | |

| NR | The adjustment/alignment system cannot be applied directly on a rotating machine without R&D | |

| Status | dev. | The system is in development |

| const. | The system is in the construction phase | |

| comm. | The system is in the commissioning phase | |

| op. | The system is operational | |

| res. | The system is related to research, analytical calculations |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piacentini, L.; Dassa, L.; Perini, D.; Ratkus, A.; Torims, T.; Uberti, S. Literature Review of Suspension Systems for Superconducting Elements. Machines 2023, 11, 929. https://doi.org/10.3390/machines11100929

Piacentini L, Dassa L, Perini D, Ratkus A, Torims T, Uberti S. Literature Review of Suspension Systems for Superconducting Elements. Machines. 2023; 11(10):929. https://doi.org/10.3390/machines11100929

Chicago/Turabian StylePiacentini, Luca, Luca Dassa, Diego Perini, Andris Ratkus, Toms Torims, and Stefano Uberti. 2023. "Literature Review of Suspension Systems for Superconducting Elements" Machines 11, no. 10: 929. https://doi.org/10.3390/machines11100929

APA StylePiacentini, L., Dassa, L., Perini, D., Ratkus, A., Torims, T., & Uberti, S. (2023). Literature Review of Suspension Systems for Superconducting Elements. Machines, 11(10), 929. https://doi.org/10.3390/machines11100929