Multi-Objective Optimization and Optimal Airfoil Blade Selection for a Small Horizontal-Axis Wind Turbine (HAWT) for Application in Regions with Various Wind Potential

Abstract

:1. Introduction

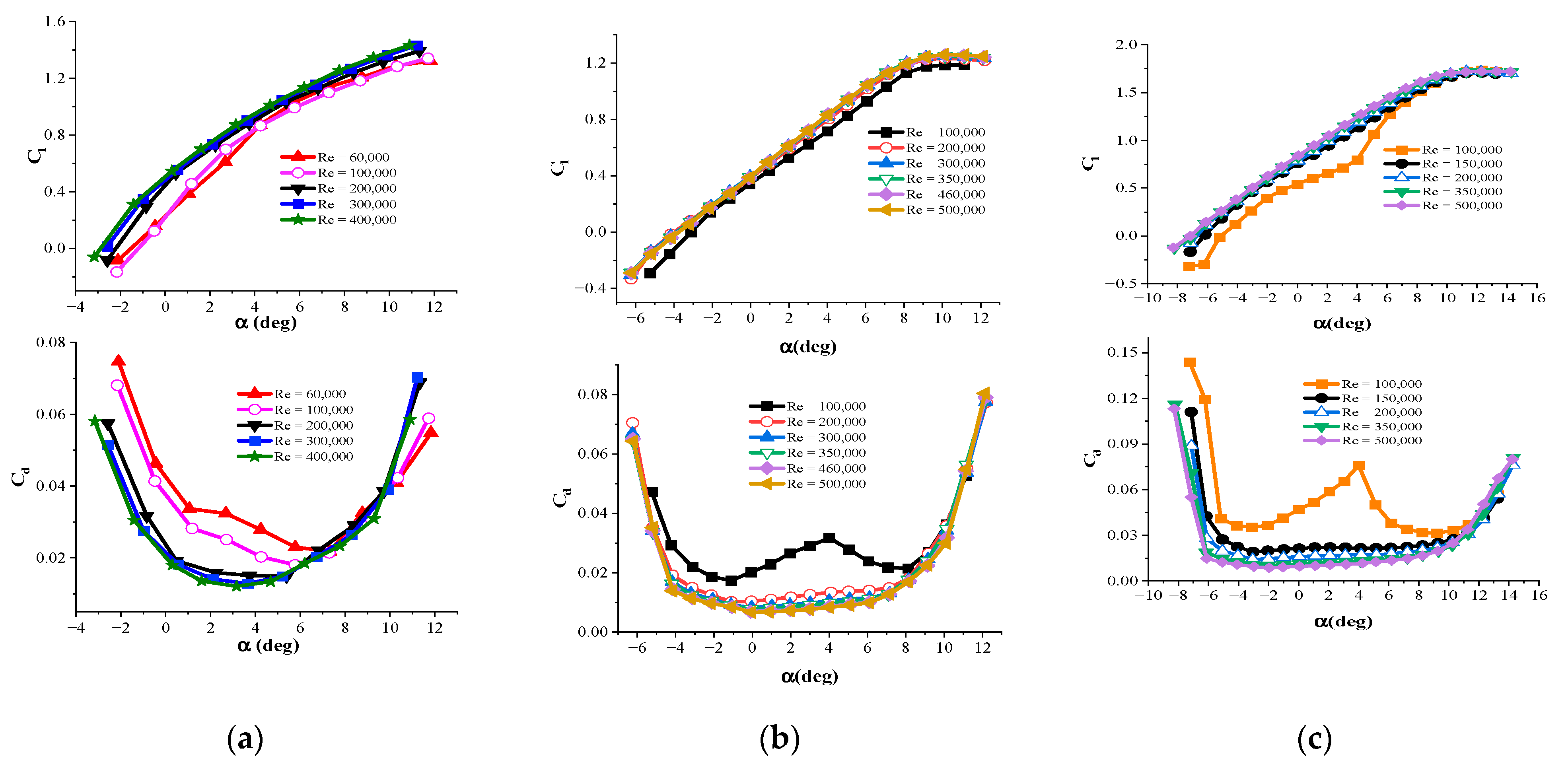

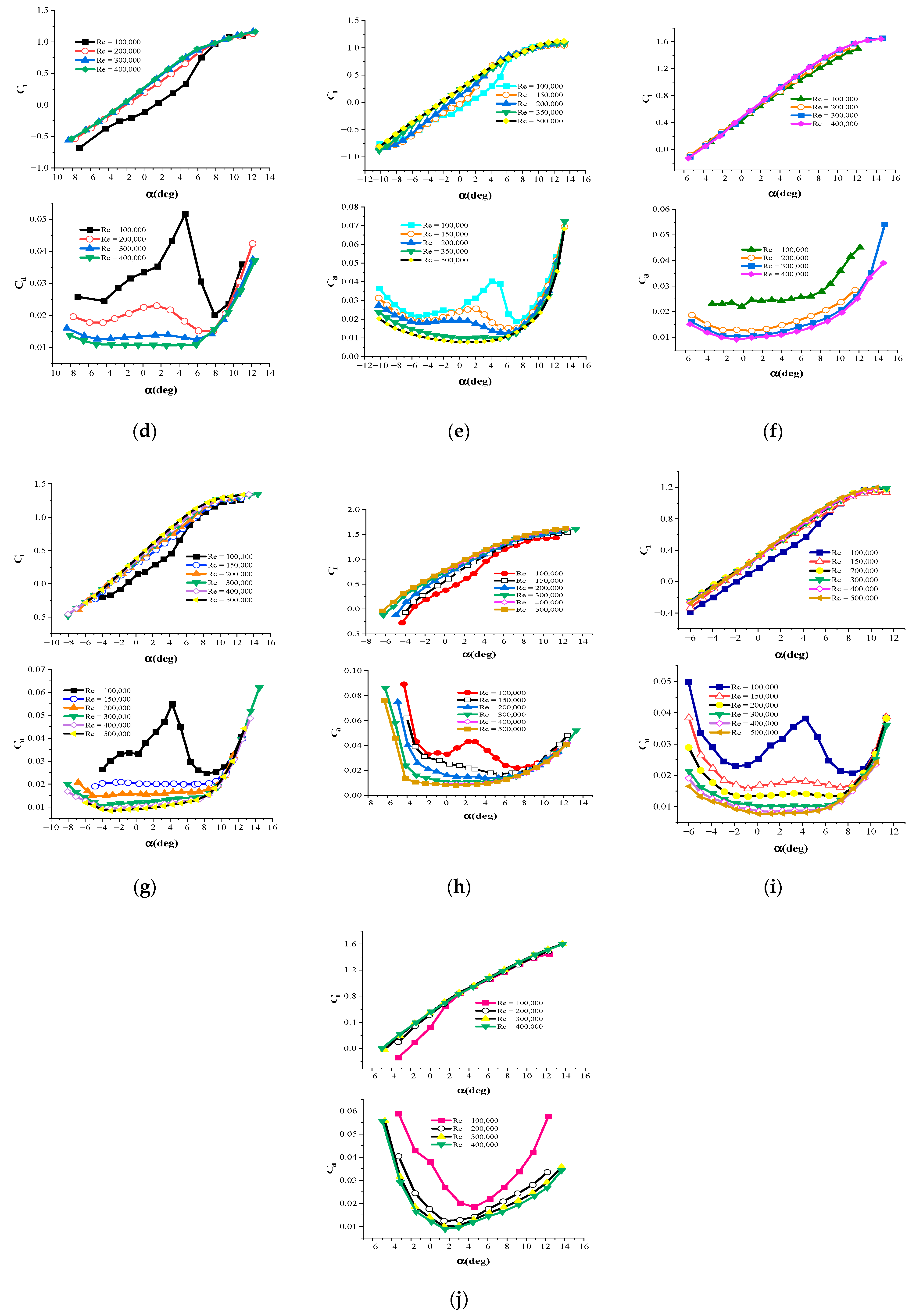

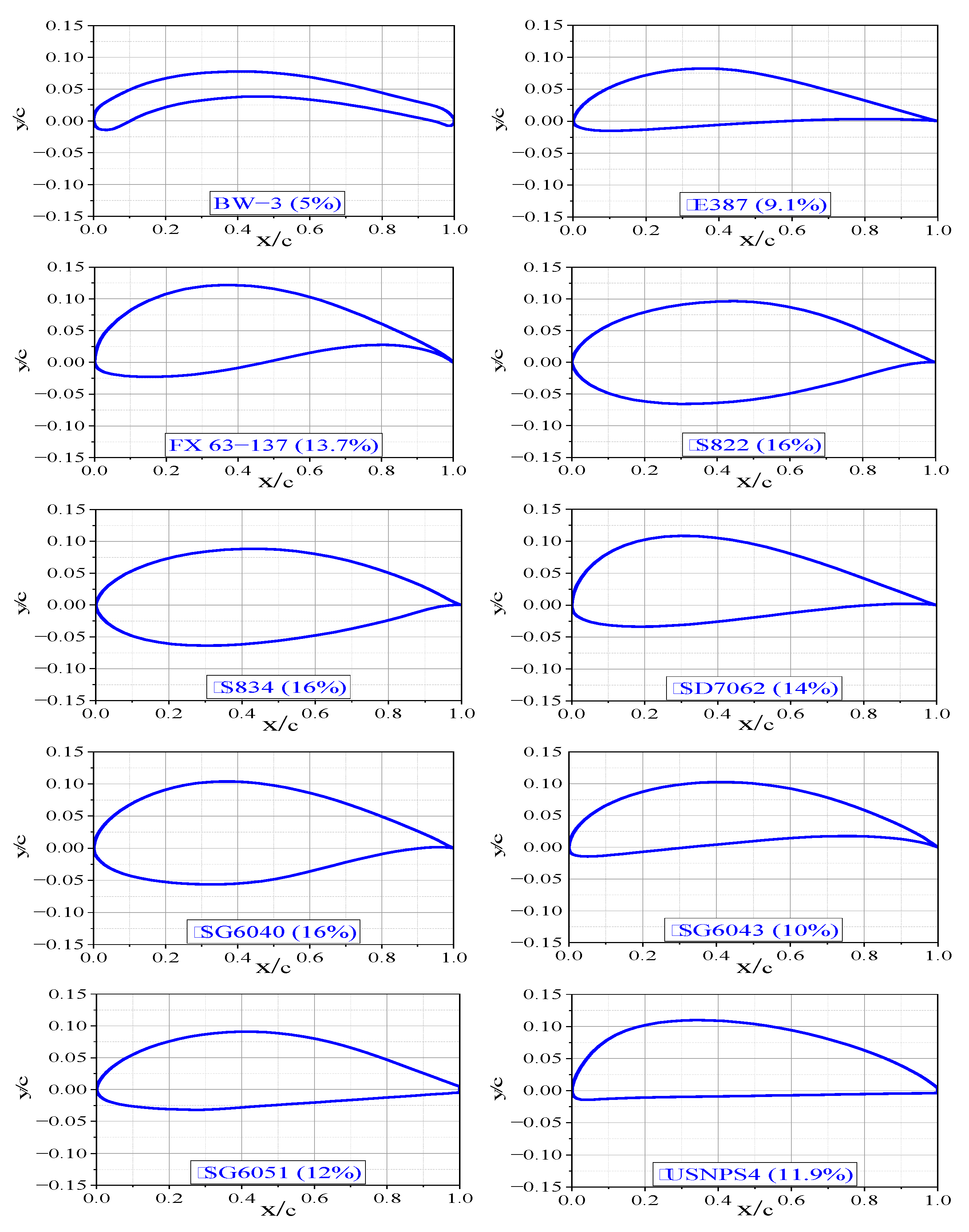

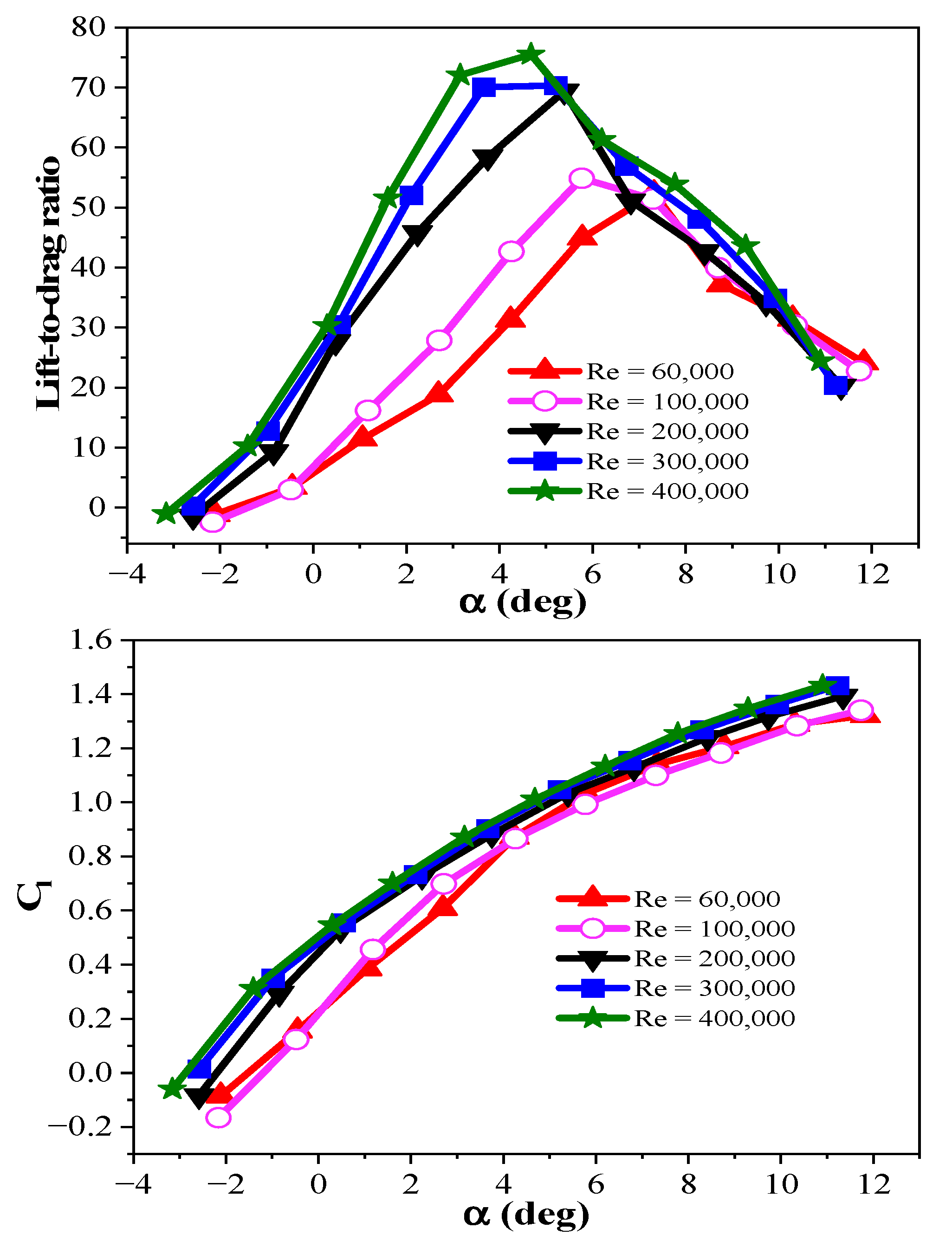

2. The Selected Airfoils

3. Numerical Procedure

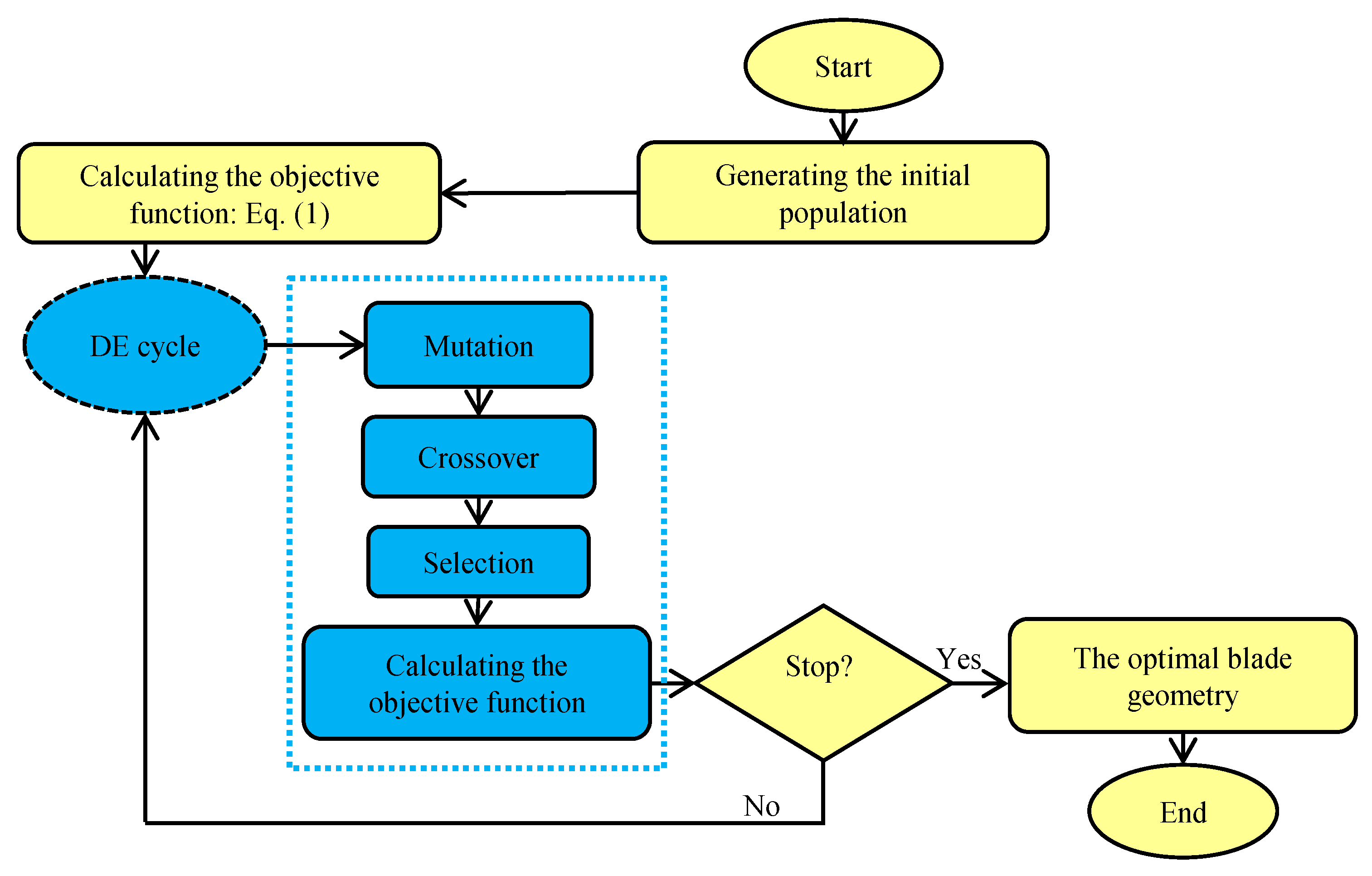

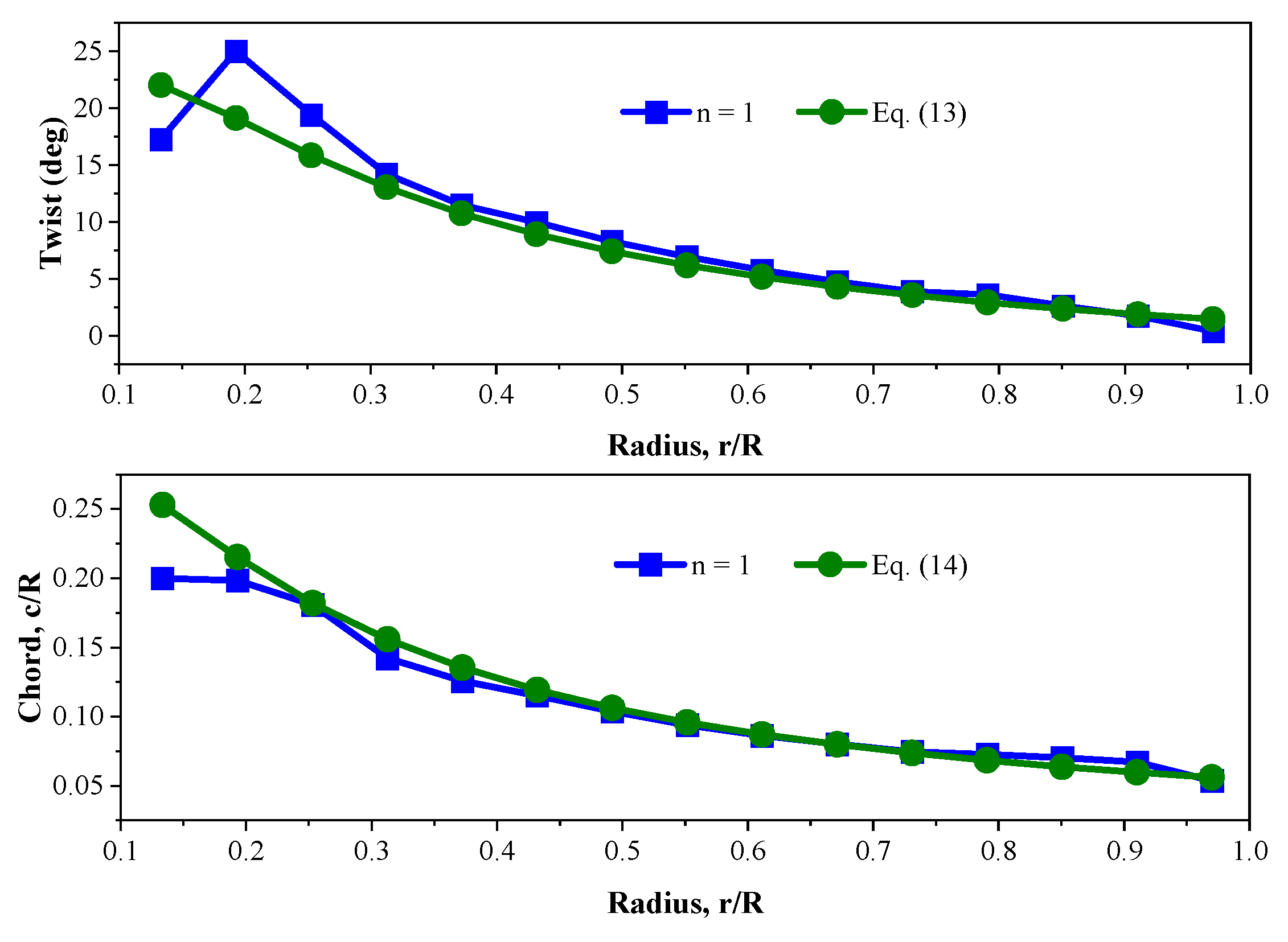

3.1. Multi-Objective Optimization

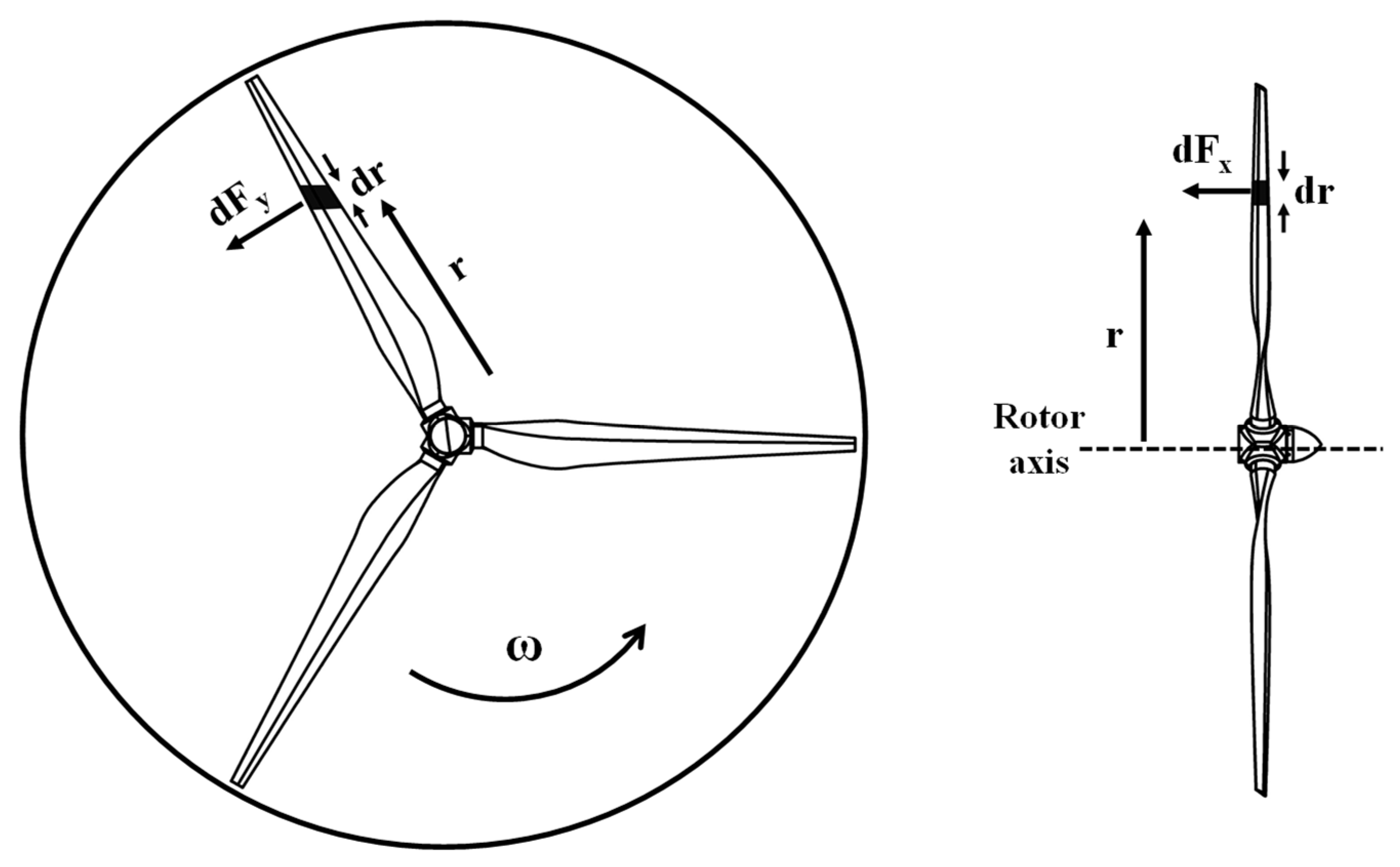

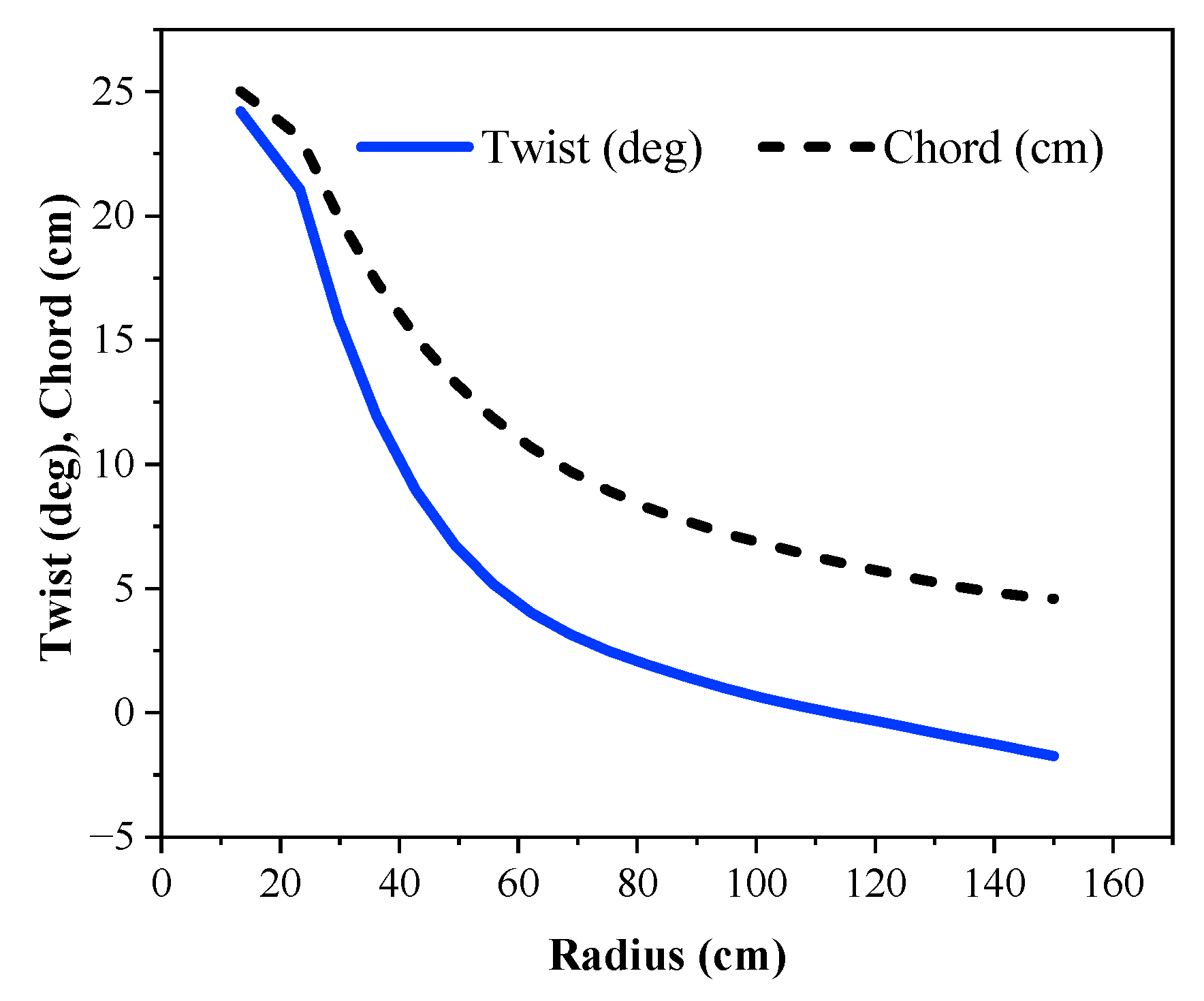

3.2. Calculating Design Goals

3.3. Adjusting the Input Parameters

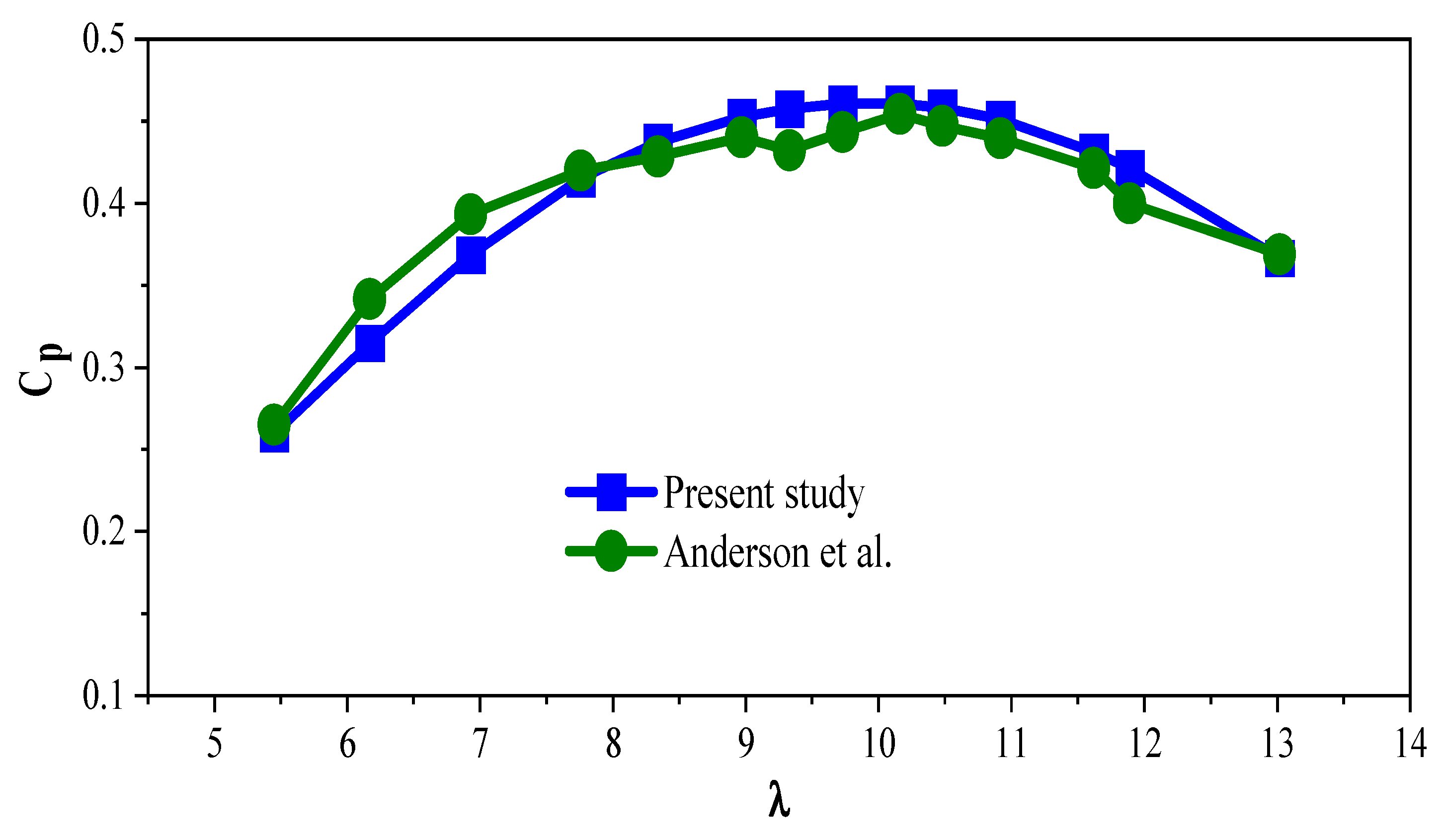

3.4. Validation of the BEM Code

3.5. Validation of the Optimization Code

4. Discussion of Results

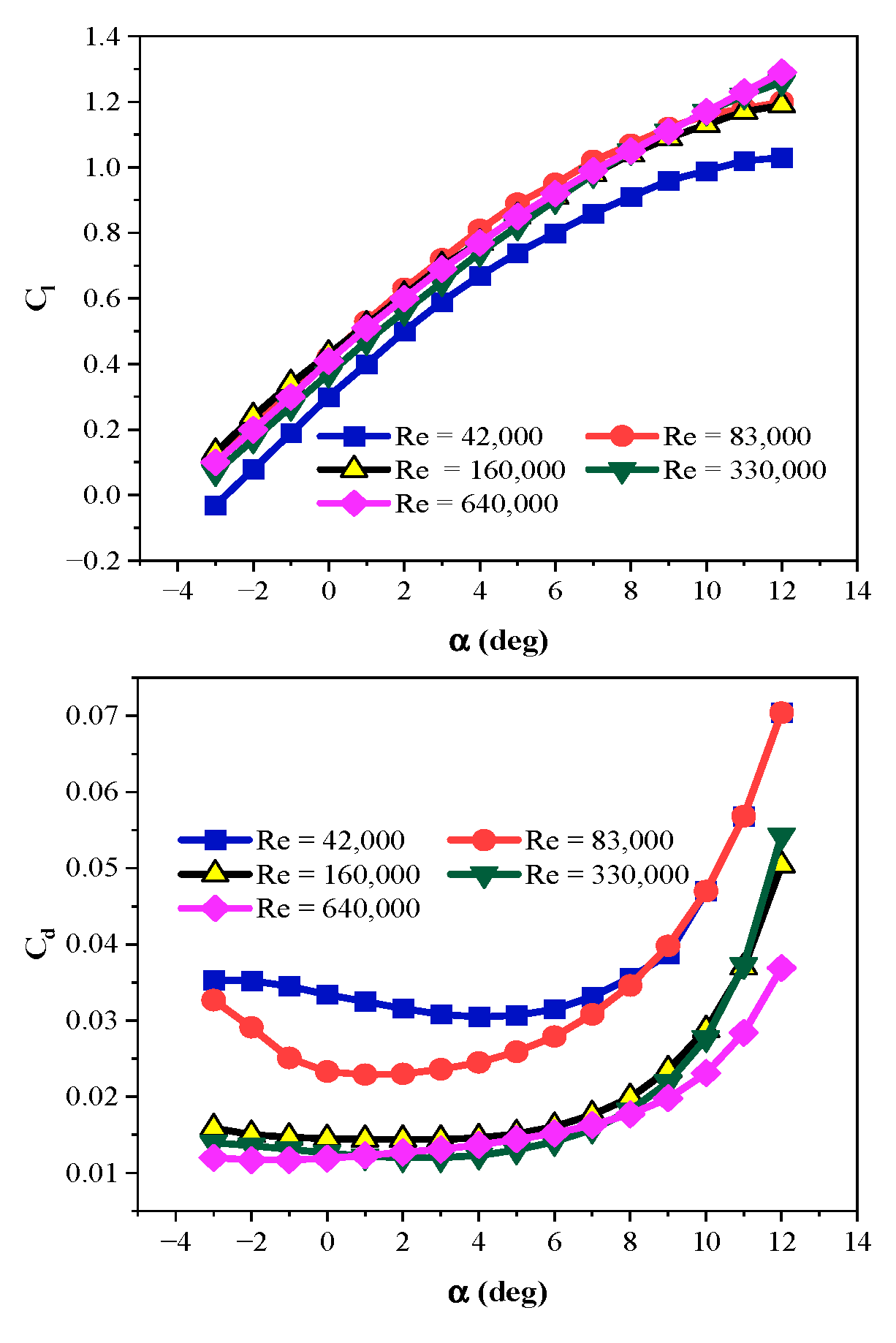

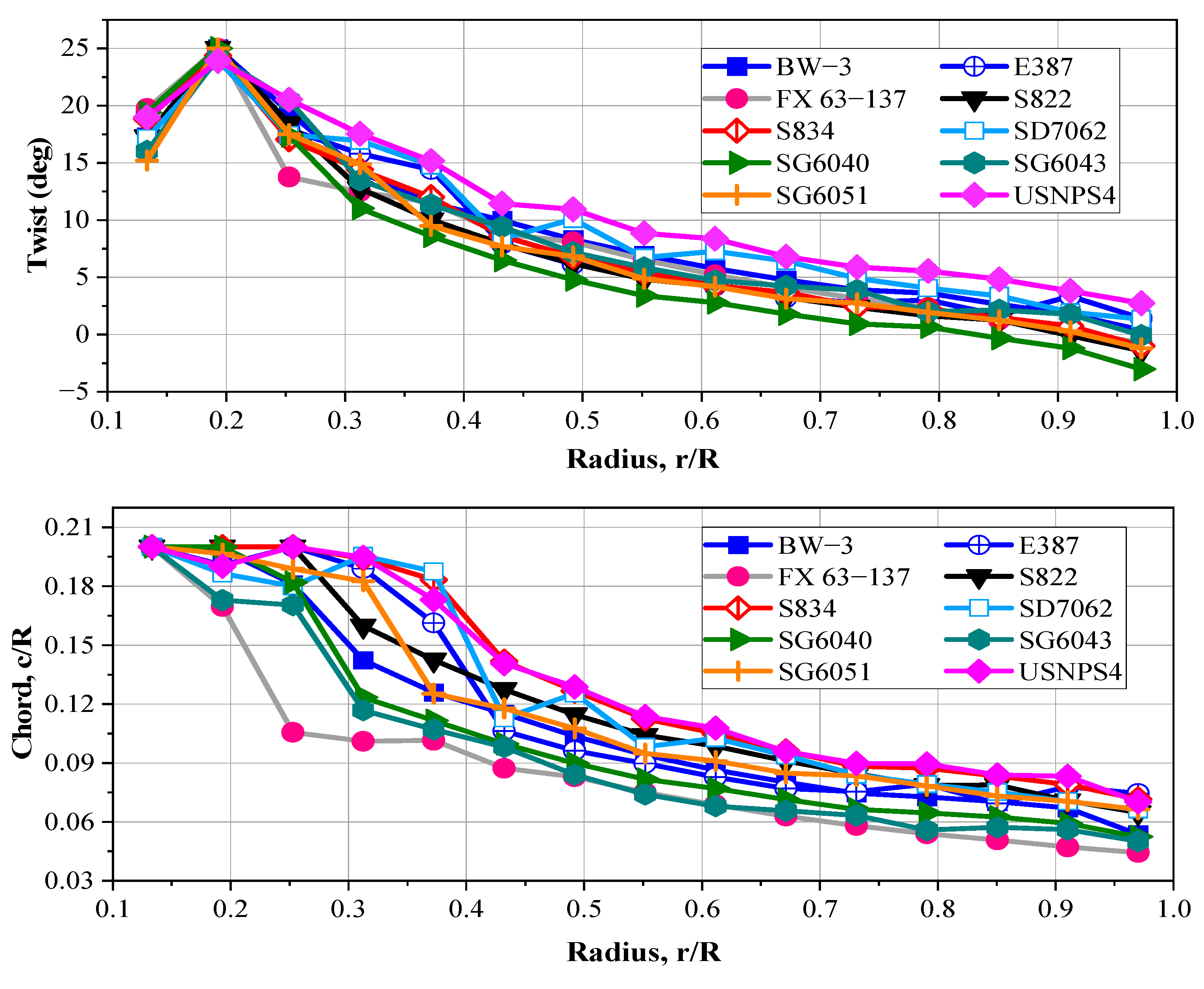

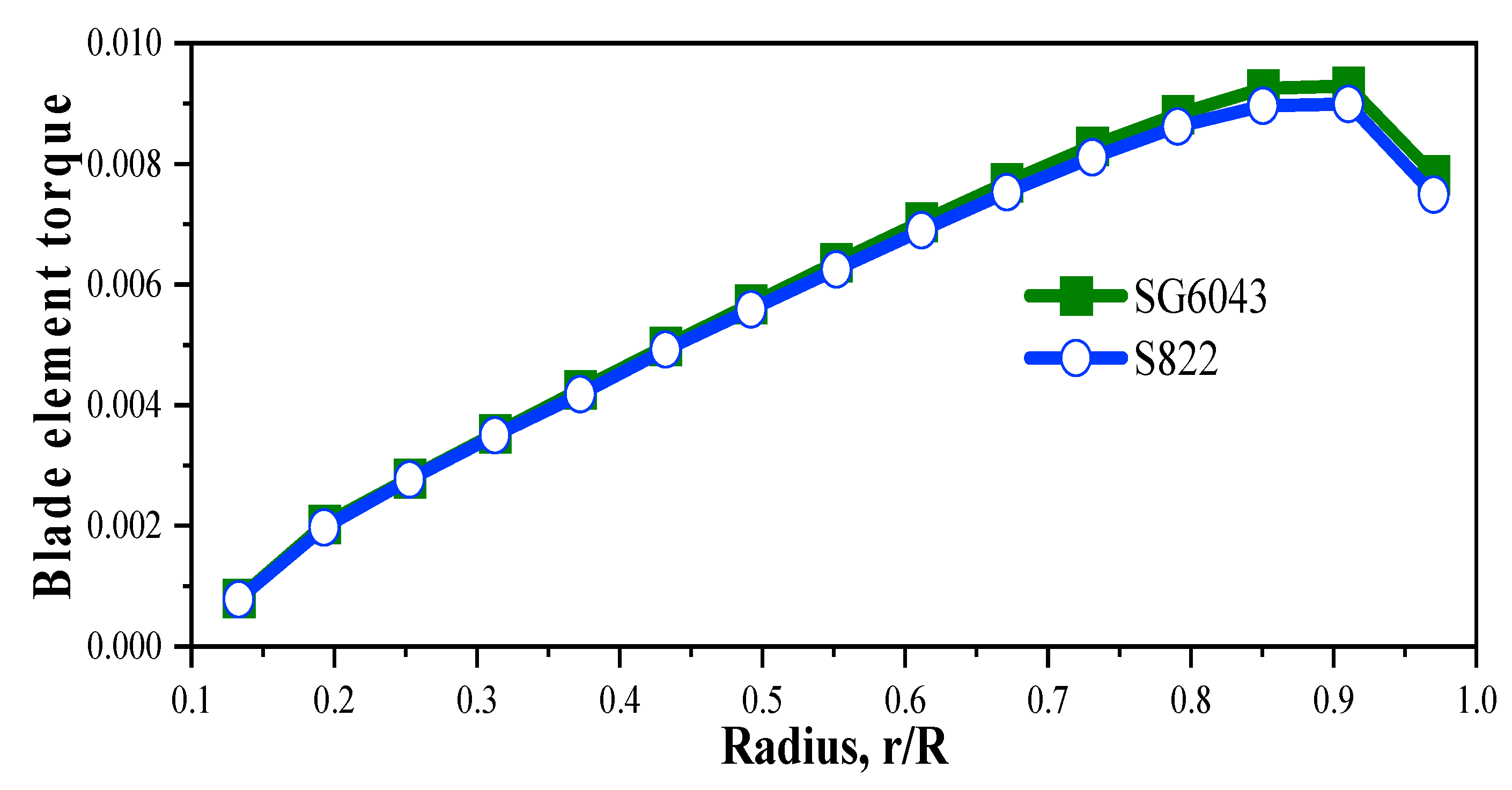

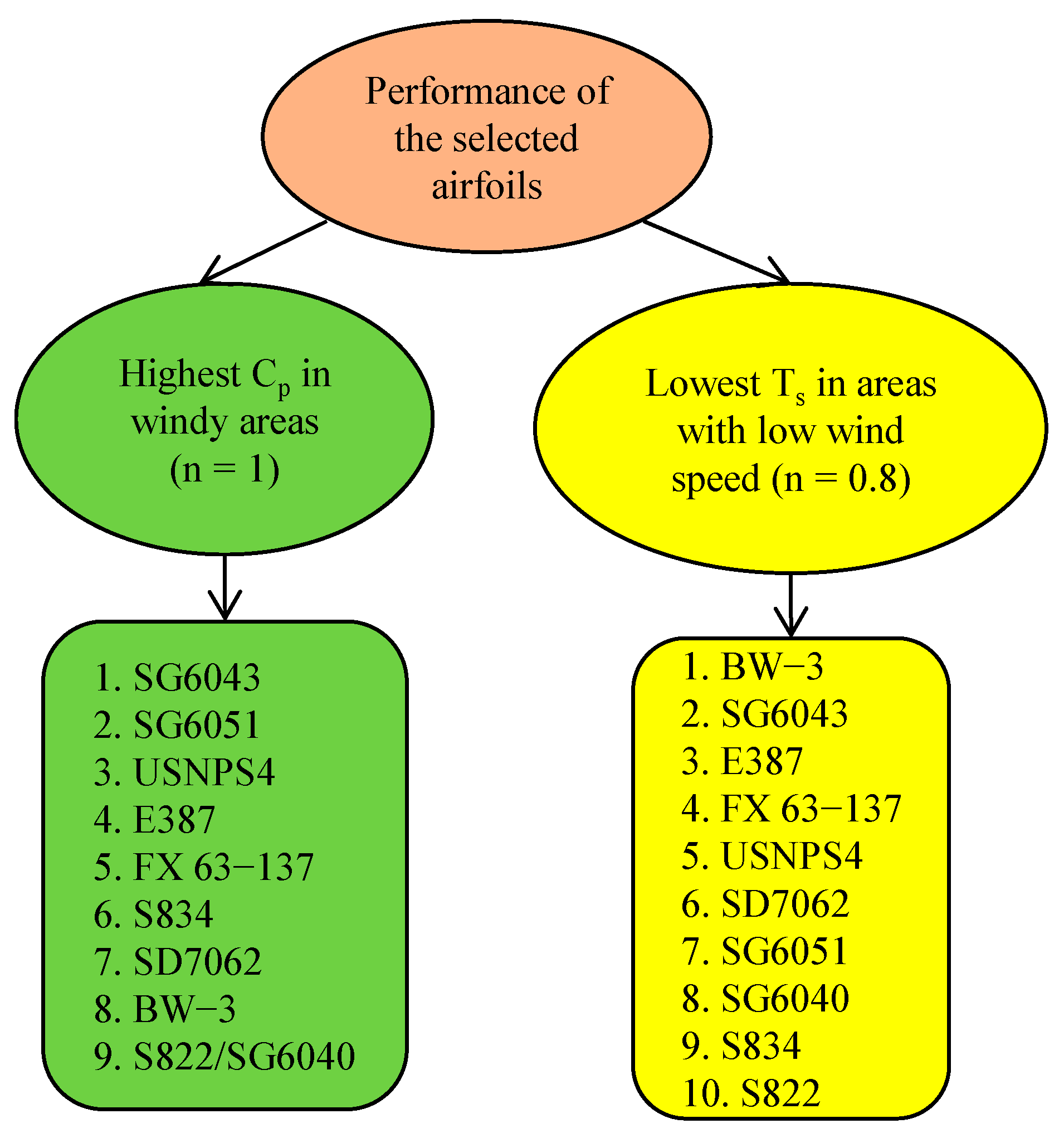

4.1. Investigating the Performance of Airfoils in Windy Areas

4.2. Investigating the Performance of Airfoils in Areas with Low Wind Speed

5. Conclusions

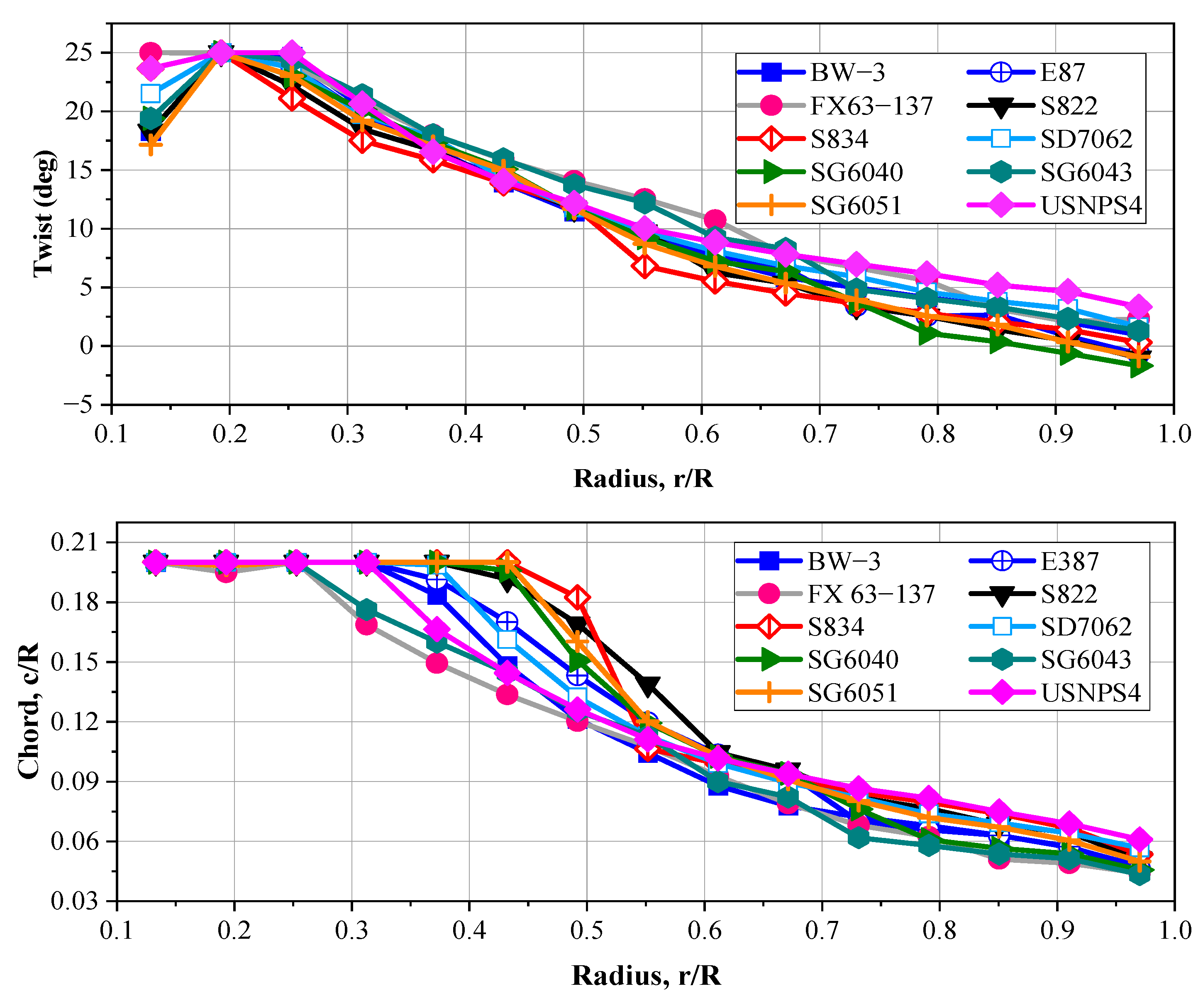

- Regardless of the type of airfoil, using ideal equations to determine the twist angle and chord length to maximize the power coefficient, raises the turbine startup time;

- The SG6043 airfoil has the highest power coefficient while the S822 and SG6040 airfoils have the lowest power coefficients. The reason for the superiority of SG6043 is its high lift-to-drag ratio. It is highly recommended to use this airfoil in windy areas where the purpose of designing small wind turbines is to achieve the maximum power coefficient;

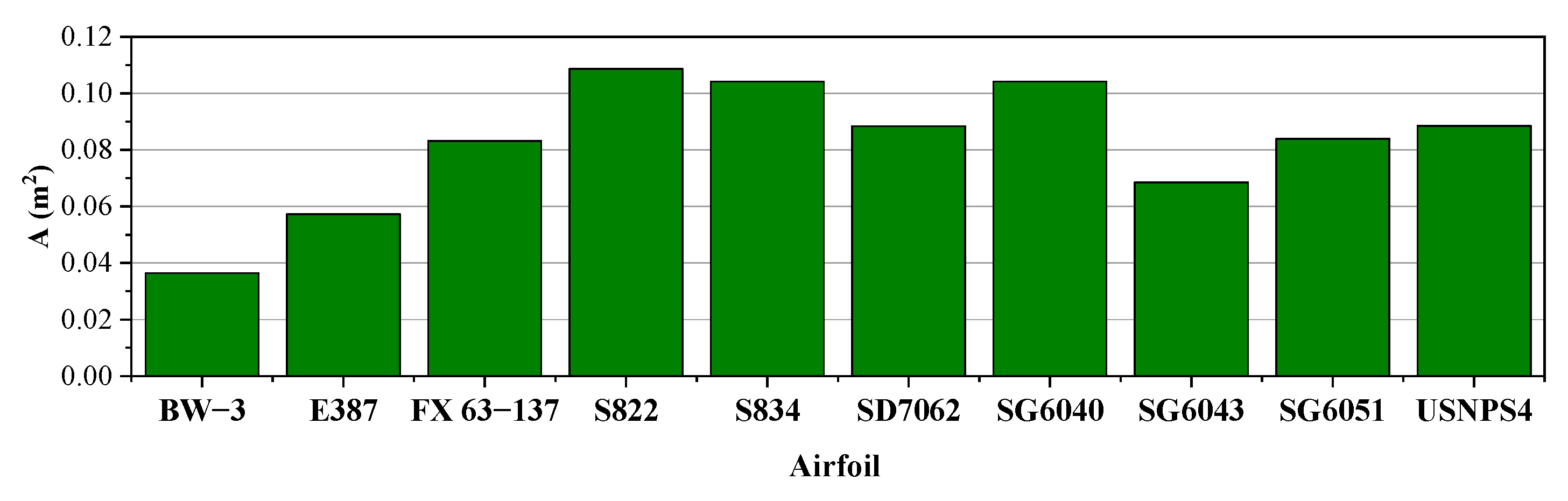

- Among the optimal blades for achieving the maximum power coefficient, the blades with the FX 63-137 and USNPS4 airfoils have the shortest and longest chord lengths, respectively. This has caused the power coefficient not to be as high as expected, despite the high lift-to-drag ratio of the FX 63-137 airfoil;

- Regardless of the airfoil type, raising the twist angle and chord length in the root section reduces the turbine startup time;

- From the startup viewpoint, the BW-3 airfoil has the best performance among the selected airfoils. This is due to the low inertia of the blades fitted with this airfoil. Therefore, in areas with low wind speeds where having a low startup time is greatly important, the use of this airfoil is highly recommended;

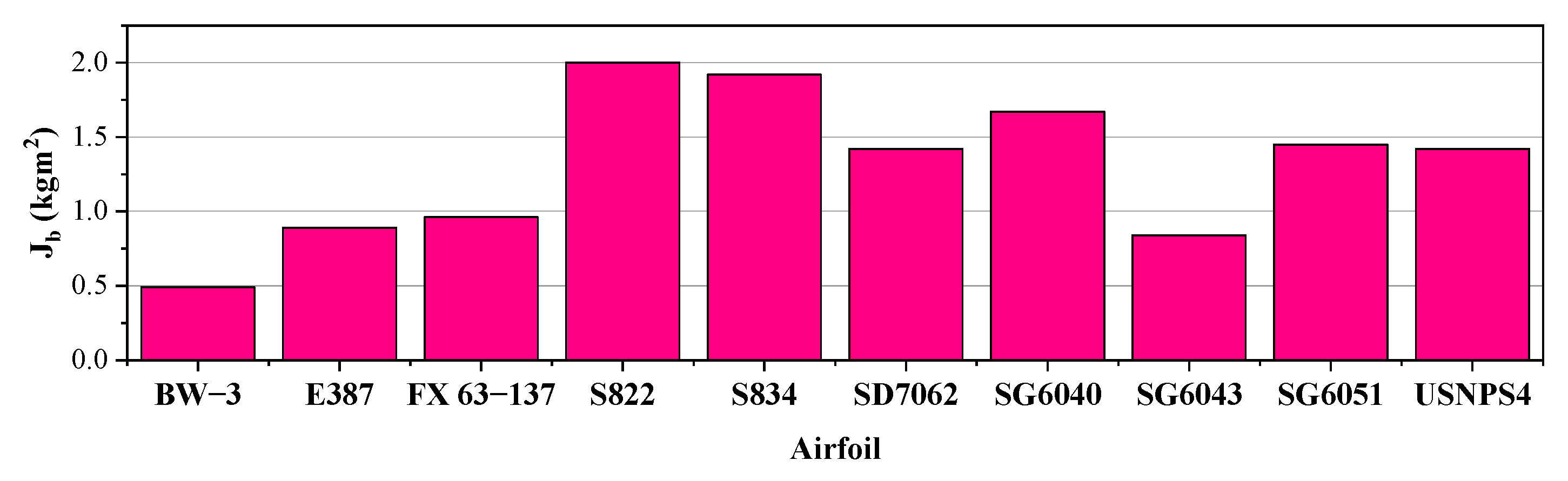

- The S822, S834, and SG6040 airfoils have the highest startup time. The common aspect of these three airfoils is their high surface area;

- Although the thinness of the airfoil is an advantage for reducing the blade moment of inertia and hence obtaining a better performance of the turbine at low wind speeds, the blade fitted with a thinner airfoil does not necessarily have a lower startup time than the blade with a thicker airfoil. This is because the airfoil type completely affects the distribution of twist angle and chord length. This is accompanied by fundamental changes in the startup torque and moment of inertia, both of which play an influential role in the startup process of the turbine;

- Regardless of the airfoil type, when the blade begins to rotate, the startup torque first decreases slightly and then starts to increase;

- The highest startup torque is produced by the blade fitted with the USNPS4 airfoil and the lowest startup torque is produced by the blade fitted with the BW-3 airfoil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Airfoil cross-sectional area [m2] | |

| Axial induction factor | |

| Rotational induction factor | |

| Drag coefficient | |

| Lift coefficient | |

| Power coefficient | |

| Blade chord [m] | |

| Prandtl tip loss factor | |

| Axial force [kg·m·s−2] | |

| Total tangential force [kg·m·s−2] | |

| Term in Prandtl tip loss factor | |

| Rotational inertia [kg·m2] | |

| Number of blades | |

| Weighting factor | |

| Power [kg·m2·s−3] | |

| Torque [kg·m2·s−2] | |

| Resistive torque [kg·m2·s−2] | |

| Startup torque [kg·m2·s−2] | |

| Startup torque at t = 0 [kg·m2·s−2] | |

| Blade tip radius [m] | |

| Reynolds number | |

| Radial coordinate along blade [m] | |

| Time [s] | |

| The swept area of the blades [m2] | |

| Startup time [s] | |

| Wind velocity [m·s−1] | |

| Wind velocity for rated power [m·s−1] | |

| Total velocity at blade element [m·s−1] | |

| Greek Symbols | |

| Angle of attack | |

| Blade twist angle | |

| Tip speed ratio | |

| Tip speed ratio for rated power | |

| Local tip speed ratio | |

| Density [kg·m−3] | |

| Blade inflow angle | |

| Angular velocity [s−1] | |

| Subscripts | |

| 1 | The upwind face of the rotor |

| b | Blade |

| G | Generator |

| h | Hub |

| s | Startup |

| Abbreviations | |

| BEM | Blade element momentum |

| DE | Differential evolution algorithm |

| HAWT | Horizontal-axis wind turbine |

| NACA | U.S. National Advisory Committee on Aeronautics |

Appendix A

Appendix B

| λ | Cp | ||||

|---|---|---|---|---|---|

| Current Numerical Code | Experimental Data [45] | Absolute Error | Squared Error | Error (%) | |

| 5.45 | 0.25960 | 0.26498 | 0.00538 | 2.89444 × 10−5 | 2.03 |

| 6.17 | 0.31963 | 0.34177 | 0.02214 | 0.00049018 | 6.47 |

| 6.93 | 0.36843 | 0.39325 | 0.02482 | 0.000616032 | 6.31 |

| 7.759 | 0.41506 | 0.41983 | 0.00477 | 2.27529 × 10−5 | 1.13 |

| 8.34 | 0.43715 | 0.42827 | −0.00888 | 7.88544 × 10−5 | −2.07 |

| 8.97 | 0.45241 | 0.44008 | −0.01233 | 0.000152029 | −2.80 |

| 9.329 | 0.45768 | 0.43207 | −0.02561 | 0.000655872 | −5.92 |

| 9.73 | 0.46076 | 0.44346 | −0.0173 | 0.00029929 | −3.90 |

| 10.16 | 0.46081 | 0.45443 | −0.00638 | 4.07044 × 10−5 | −1.40 |

| 10.48 | 0.45829 | 0.44726 | −0.01103 | 0.000121661 | −2.46 |

| 10.918 | 0.45114 | 0.43966 | −0.01148 | 0.00013179 | −2.61 |

| 11.62 | 0.43138 | 0.42152 | −0.00986 | 9.72196 × 10−5 | −2.33 |

| 11.89 | 0.42146 | 0.40000 | −0.02146 | 0.000460532 | −5.36 |

| 13.02 | 0.36678 | 0.36878 | 0.002 | 4 × 10−6 | 0.54 |

Appendix C

| Airfoil | A (m2) | n = 1 | n = 0.8 | n = 0.6 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cp | Ts (s) | Jb (kgm2) | QS0 (Nm) | Cp | Ts (s) | Jb (kgm2) | QS0 (Nm) | Cp | Ts (s) | Jb (kgm2) | QS0 (Nm) | ||

| BW-3 | 0.0364 | 0.496 | 2.78 | 0.438 | 1.165 | 0.486 | 1.82 | 0.494 | 1.651 | 0.435 | 1.33 | 0.364 | 1.673 |

| E387 | 0.0573 | 0.502 | 4.87 | 0.786 | 1.213 | 0.485 | 3.10 | 0.889 | 1.722 | 0.439 | 2.27 | 0.660 | 1.753 |

| FX 63-137 | 0.0831 | 0.499 | 8.44 | 0.584 | 0.795 | 0.489 | 3.26 | 0.964 | 1.757 | 0.449 | 2.59 | 0.760 | 1.749 |

| S822 | 0.1087 | 0.495 | 13.25 | 1.600 | 1.006 | 0.481 | 7.02 | 2.000 | 1.711 | 0.416 | 4.71 | 1.337 | 1.725 |

| S834 | 0.1042 | 0.498 | 11.54 | 1.872 | 1.193 | 0.483 | 6.87 | 1.921 | 1.682 | 0.411 | 4.37 | 1.137 | 1.641 |

| SD7062 | 0.0883 | 0.497 | 6.15 | 1.394 | 1.435 | 0.488 | 4.49 | 1.421 | 1.834 | 0.438 | 3.31 | 1.003 | 1.794 |

| SG6040 | 0.1042 | 0.495 | 15.67 | 1.105 | 0.817 | 0.480 | 6.02 | 1.678 | 1.695 | 0.429 | 4.31 | 1.233 | 1.726 |

| SG6043 | 0.0685 | 0.506 | 5.72 | 0.580 | 0.972 | 0.496 | 2.89 | 0.842 | 1.743 | 0.459 | 2.33 | 0.687 | 1.759 |

| SG6051 | 0.0839 | 0.504 | 9.80 | 1.253 | 1.118 | 0.490 | 5.13 | 1.456 | 1.708 | 0.428 | 3.45 | 0.950 | 1.689 |

| USNPS4 | 0.0884 | 0.503 | 5.36 | 1.586 | 1.731 | 0.493 | 4.22 | 1.423 | 1.919 | 0.443 | 3.14 | 0.987 | 1.836 |

References

- Afsharpanah, F.; Pakzad, K.; Mousavi Ajarostaghi, S.S.; Poncet, S.; Sedighi, K. Accelerating the Charging Process in a Shell and Dual Coil Ice Storage Unit Equipped with Connecting Plates. Int. J. Energy Res. 2022, 46, 7460–7478. [Google Scholar] [CrossRef]

- Shyu, C.-W. A Framework for ‘Right to Energy’ to Meet UN SDG7: Policy Implications to Meet Basic Human Energy Needs, Eradicate Energy Poverty, Enhance Energy Justice, and Uphold Energy Democracy. Energy Res. Soc. Sci. 2021, 79, 102199. [Google Scholar] [CrossRef]

- Karthikeyan, N.; Kalidasa Murugavel, K.; Arun Kumar, S.; Rajakumar, S. Review of Aerodynamic Developments on Small Horizontal Axis Wind Turbine Blade. Renew. Sustain. Energy Rev. 2015, 42, 801–822. [Google Scholar] [CrossRef]

- Afsharpanah, F.; Mousavi Ajarostaghi, S.S.; Arıcı, M. Parametric Study of Phase Change Time Reduction in a Shell-and-Tube Ice Storage System with Anchor-Type Fin Design. Int. Commun. Heat Mass Transf. 2022, 137, 106281. [Google Scholar] [CrossRef]

- Afsharpanah, F.; Cheraghian, G.; Hamedani, F.A.; Shokri, E.; Ajarostaghi, S.S.M. Utilization of Carbon-Based Nanomaterials and Plate-Fin Networks in a Cold PCM Container with Application in Air Conditioning of Buildings. Nanomaterials 2022, 12, 1927. [Google Scholar] [CrossRef] [PubMed]

- Afsharpanah, F.; Pakzad, K.; Mousavi Ajarostaghi, S.S.; Arıcı, M. Assessment of the Charging Performance in a Cold Thermal Energy Storage Container with Two Rows of Serpentine Tubes and Extended Surfaces. J. Energy Storage 2022, 51, 104464. [Google Scholar] [CrossRef]

- Lattieff, F.A.; Atiya, M.A.; Mahdi, J.M.; Majdi, H.S.; Talebizadehsardari, P.; Yaïci, W. Performance Analysis of a Solar Cooling System with Equal and Unequal Adsorption/Desorption Operating Time. Energies 2021, 14, 6749. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, D.; Wang, T.; Shen, W.; Liu, H.; Chen, M. A Review: Approaches for Aerodynamic Performance Improvement of Lift-Type Vertical Axis Wind Turbine. Sustain. Energy Technol. Assessments 2022, 49, 101789. [Google Scholar] [CrossRef]

- Soni, V.; Sharma, A.; Singh, V. A Critical Review on Nature Inspired Optimization Algorithms. In IOP Conference Series Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1099, p. 012055. [Google Scholar] [CrossRef]

- Tušar, T.; Filipič, B. Differential Evolution versus Genetic Algorithms in Multiobjective Optimization. In Proceedings of the International Conference on Evolutionary Multi-Criterion Optimization, Matsushima, Japan, 5–8 March 2007; Volume 4403, pp. 257–271. [Google Scholar] [CrossRef]

- Lilla, A.D.; Khan, M.A.; Barendse, P. Comparison of Differential Evolution and Genetic Algorithm in the Design of Permanent Magnet Generators. In Proceedings of the IEEE International Conference on Industrial Technology, Cape Town, South Africa, 25–28 February 2013; pp. 266–271. [Google Scholar] [CrossRef]

- IEC 61400.2; Wind Turbines-Design Requirements for Small Wind Turbines. British Standards European Norm: London, UK, 2013; pp. 61400–61402.

- Clausen, P.D.; Wood, D.H. Recent Advances in Small Wind Turbine Technology. Wind Eng. 2000, 24, 189–201. [Google Scholar] [CrossRef]

- Astolfi, D. A Study of the Impact of Pitch Misalignment on Wind Turbine Performance. Machines 2019, 7, 8. [Google Scholar] [CrossRef]

- Mostafaeipour, A. Economic Evaluation of Small Wind Turbine Utilization in Kerman, Iran. Energy Convers. Manag. 2013, 73, 214–225. [Google Scholar] [CrossRef]

- Castellani, F.; Astolfi, D.; Peppoloni, M.; Natili, F.; Buttà, D.; Hirschl, A. Experimental Vibration Analysis of a Small Scale Vertical Wind Energy System for Residential Use. Machines 2019, 7, 35. [Google Scholar] [CrossRef]

- Eltayesh, A.; Castellani, F.; Burlando, M.; Bassily Hanna, M.; Huzayyin, A.S.; El-Batsh, H.M.; Becchetti, M. Experimental and Numerical Investigation of the Effect of Blade Number on the Aerodynamic Performance of a Small-Scale Horizontal Axis Wind Turbine. Alex. Eng. J. 2021, 60, 3931–3944. [Google Scholar] [CrossRef]

- Worasinchai, S.; Ingram, G.L.; Dominy, R.G. Effects of Wind Turbine Starting Capability on Energy Yield. J. Eng. Gas Turbines Power 2012, 134, 042603. [Google Scholar] [CrossRef]

- Wood, D. Small Wind Turbines: Analysis, Design, and Application; Green Energy and Technology; Springer: London, UK, 2011; Volume 38, ISBN 9781849961745. [Google Scholar]

- Pourrajabian, A.; Dehghan, M.; Javed, A.; Wood, D. Choosing an Appropriate Timber for a Small Wind Turbine Blade: A Comparative Study. Renew. Sustain. Energy Rev. 2019, 100, 1–8. [Google Scholar] [CrossRef]

- Rahgozar, S.; Pourrajabian, A.; Kazmi, S.A.A.; Kazmi, S.M.R. Performance Analysis of a Small Horizontal Axis Wind Turbine under the Use of Linear/Nonlinear Distributions for the Chord and Twist Angle. Energy Sustain. Dev. 2020, 58, 42–49. [Google Scholar] [CrossRef]

- Clifton-Smith, M.J. Aerodynamic Noise Reduction for Small Wind Turbine Rotors. Wind Eng. 2010, 34, 403–420. [Google Scholar] [CrossRef]

- Andrew Ning, S.; Damiani, R.; Moriarty, P.J. Objectives and Constraints for Wind Turbine Optimization. J. Sol. Energy Eng. 2014, 136, 041010. [Google Scholar] [CrossRef]

- Natarajan, K.; Suthakar, T. Insight Aerodynamic Analysis on Small-Scale Wind Turbines Airfoils for Low Reynolds Number Applications. Environ. Prog. Sustain. Energy 2022, 41, e13807. [Google Scholar] [CrossRef]

- Bai, C.-J.; Wang, W.-C. Review of Computational and Experimental Approaches to Analysis of Aerodynamic Performance in Horizontal-Axis Wind Turbines (HAWTs). Renew. Sustain. Energy Rev. 2016, 63, 506–519. [Google Scholar] [CrossRef]

- Pourrajabian, A.; Dehghan, M.; Rahgozar, S. Genetic Algorithms for the Design and Optimization of Horizontal Axis Wind Turbine (HAWT) Blades: A Continuous Approach or a Binary One? Sustain. Energy Technol. Assess. 2021, 44, 101022. [Google Scholar] [CrossRef]

- Elizondo, J.; Martínez, J.; Probst, O. Experimental Study of a Small Wind Turbine for Low-and Medium-wind Regimes. Int. J. Energy Res. 2009, 33, 309–326. [Google Scholar] [CrossRef]

- Singh, R.K.; Ahmed, M.R. Blade Design and Performance Testing of a Small Wind Turbine Rotor for Low Wind Speed Applications. Renew. Energy 2013, 50, 812–819. [Google Scholar] [CrossRef]

- Giguere, P.; Selig, M.S. New Airfoils for Small Horizontal Axis Wind Turbines. J. Sol. Energy Eng. 1998, 120, 108–114. [Google Scholar] [CrossRef]

- Selig, M.S.; McGranahan, B.D. Wind Tunnel Aerodynamic Tests of Six Airfoils for Use on Small Wind Turbines. J. Sol. Energy Eng. 2004, 126, 986–1001. [Google Scholar] [CrossRef]

- Lyon, C.A.; Broeren, A.P.; Giguere, P.; Gopalarathnam, A.; Selig, M.S. Summary of Low-Speed Airfoil Data, Vol. 3.; Soartech: Virginia Beach, VA, USA, 1997; ISBN 0-9646747-3-4. [Google Scholar]

- Selig, M.; McGranahan, B.; Broughton, B. UIUC Low-Speed Airfoil Tests; University of Illinois at Urbana-Champaign: Champaign, IL, USA, 2001. [Google Scholar]

- Storn, R.; Price, K. Differential Evolution—A Simple and Efficient Heuristic for Global Optimization over Continuous Spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Ahmad, M.F.; Isa, N.A.M.; Lim, W.H.; Ang, K.M. Differential Evolution: A Recent Review Based on State-of-the-Art Works. Alex. Eng. J. 2022, 61, 3831–3872. [Google Scholar] [CrossRef]

- Stokes, Z.; Mandal, A.; Wong, W.K. Using Differential Evolution to Design Optimal Experiments. Chemom. Intell. Lab. Syst. 2020, 199, 103955. [Google Scholar] [CrossRef]

- Jureczko, M.; Mrówka, M. Multiobjective Optimization of Composite Wind Turbine Blade. Materials 2022, 15, 4649. [Google Scholar] [CrossRef]

- Spera, D.A. Wind Turbine Technology; ASME Publishing: New York, NY, USA, 1994. [Google Scholar]

- Glauert, H. Airplane Propellers. In Aerodynamic Theory; Springer: Berlin/Heidelberg, Germany, 1935; pp. 169–360. [Google Scholar]

- Hau, E. Wind Turbines: Fundamentals, Technologies, Application, Economics; Springer Science & Business Media: Berlin, Germany, 2013; Volume 9783642271, ISBN 9783642271519. [Google Scholar]

- Castellani, F.; Astolfi, D.; Natili, F.; Mari, F. The Yawing Behavior of Horizontal-Axis Wind Turbines: A Numerical and Experimental Analysis. Machines 2019, 7, 15. [Google Scholar] [CrossRef]

- Wood, D.H. A Blade Element Estimation of the Cut-in Wind Speed of a Small Turbine. Wind Eng. 2001, 25, 125–130. [Google Scholar] [CrossRef]

- Sessarego, M.; Wood, D. Multi-Dimensional Optimization of Small Wind Turbine Blades. Renew. Wind. Water Sol. 2015, 2, 9. [Google Scholar] [CrossRef]

- Clifton-Smith, M.J.; Wood, D.H. Further Dual Purpose Evolutionary Optimization of Small Wind Turbine Blades. In The Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2007; Volume 75, p. 12017. [Google Scholar]

- Pourrajabian, A.; Ebrahimi, R.; Mirzaei, M. Applying Micro Scales of Horizontal Axis Wind Turbines for Operation in Low Wind Speed Regions. Energy Convers. Manag. 2014, 87, 119–127. [Google Scholar] [CrossRef]

- Anderson, M.B.; Milborrow, D.J.; Ross, J.N. Performance and Wake Measurements on a 3 M Diameter Horizontal Axis Wind Turbine. Comparison of Theory, Wind Tunnel and Field Test Data. In Proceedings of the Papers Presented at the International Symposium on Wind Energy Systems, Cambridge, UK, 21–24 September 1982; Volume 2, pp. 113–135. [Google Scholar]

- Burton, T.; Jenkins, N.; Sharpe, D.; Bossanyi, E. Wind Energy Handbook; John Wiley & Sons: Hoboken, NJ, USA, 2011; ISBN 111999392X. [Google Scholar]

- Selig, M. UIUC Applied Aerodynamics Group, Department of Aerospace Engineering. Available online: https://m-selig.ae.illinois.edu/ (accessed on 5 August 2022).

- Wang, L.; Xu, J.; Luo, W.; Luo, Z.; Xie, J.; Yuan, J.; Tan, A.C.C. A Deep Learning-Based Optimization Framework of Two-Dimensional Hydrofoils for Tidal Turbine Rotor Design. Energy 2022, 253, 124130. [Google Scholar] [CrossRef]

- Gupta, P.; Tyagi, P.; Singh, R.K. Analysis of Generative Adversarial Networks for Data-Driven Inverse Airfoil Design. Lect. Notes Netw. Syst. 2022, 350, 251–261. [Google Scholar] [CrossRef]

- Duru, C.; Alemdar, H.; Baran, O.U. A Deep Learning Approach for the Transonic Flow Field Predictions around Airfoils. Comput. Fluids 2022, 236, 105312. [Google Scholar] [CrossRef]

- Wang, S.; Sun, G.; Chen, W.; Zhong, Y. Database Self-Expansion Based on Artificial Neural Network: An Approach in Aircraft Design. Aerosp. Sci. Technol. 2018, 72, 77–83. [Google Scholar] [CrossRef]

| Parameter | Minimum | Maximum |

|---|---|---|

| Twist, θ(°) | −5 | 25 |

| Chord, c/R | 0.01 | 0.2 |

| Parameters | Values/Settings |

|---|---|

| Population | 2000 |

| Number of generations | 500 |

| Mutation strategy | DE/rand/1 |

| Mutation weighting factor | 0.8 |

| Crossover operator | Uniform |

| Crossover constant | 0.1 |

| Parameters | Values and Units | Parameters | Values and Units |

|---|---|---|---|

| Airfoil | Windy Areas (n = 1) | Low Wind Areas (n = 0.8) | ||

|---|---|---|---|---|

| Cp | Ts (s) | Cp | Ts (s) | |

| BW-3 | 0.496 | 2.78 | 0.486 | 1.82 |

| E387 | 0.502 | 4.87 | 0.485 | 3.10 |

| FX 63-137 | 0.499 | 8.44 | 0.489 | 3.26 |

| S822 | 0.495 | 13.25 | 0.481 | 7.02 |

| S834 | 0.498 | 11.54 | 0.483 | 6.87 |

| SD7062 | 0.497 | 6.15 | 0.488 | 4.49 |

| SG6040 | 0.495 | 15.67 | 0.480 | 6.02 |

| SG6043 | 0.506 | 5.72 | 0.496 | 2.89 |

| SG6051 | 0.504 | 9.8 | 0.490 | 5.13 |

| USNPS4 | 0.503 | 5.36 | 0.493 | 4.22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akbari, V.; Naghashzadegan, M.; Kouhikamali, R.; Afsharpanah, F.; Yaïci, W. Multi-Objective Optimization and Optimal Airfoil Blade Selection for a Small Horizontal-Axis Wind Turbine (HAWT) for Application in Regions with Various Wind Potential. Machines 2022, 10, 687. https://doi.org/10.3390/machines10080687

Akbari V, Naghashzadegan M, Kouhikamali R, Afsharpanah F, Yaïci W. Multi-Objective Optimization and Optimal Airfoil Blade Selection for a Small Horizontal-Axis Wind Turbine (HAWT) for Application in Regions with Various Wind Potential. Machines. 2022; 10(8):687. https://doi.org/10.3390/machines10080687

Chicago/Turabian StyleAkbari, Vahid, Mohammad Naghashzadegan, Ramin Kouhikamali, Farhad Afsharpanah, and Wahiba Yaïci. 2022. "Multi-Objective Optimization and Optimal Airfoil Blade Selection for a Small Horizontal-Axis Wind Turbine (HAWT) for Application in Regions with Various Wind Potential" Machines 10, no. 8: 687. https://doi.org/10.3390/machines10080687

APA StyleAkbari, V., Naghashzadegan, M., Kouhikamali, R., Afsharpanah, F., & Yaïci, W. (2022). Multi-Objective Optimization and Optimal Airfoil Blade Selection for a Small Horizontal-Axis Wind Turbine (HAWT) for Application in Regions with Various Wind Potential. Machines, 10(8), 687. https://doi.org/10.3390/machines10080687