Optimal Synthesis of Loader Drive Mechanisms: A Group Robust Decision-Making Rule Generation Approach

Abstract

:1. Introduction

2. The Process of Optimal Synthesis of Loader Manipulator Drive Mechanisms

- Phase 1: generation of variant solutions for mechanisms;

- Phase 2: the definition of the synthesis criteria;

- Phase 3: the evaluation and selection of the variant solutions for mechanisms using the proposed RDMR approach.

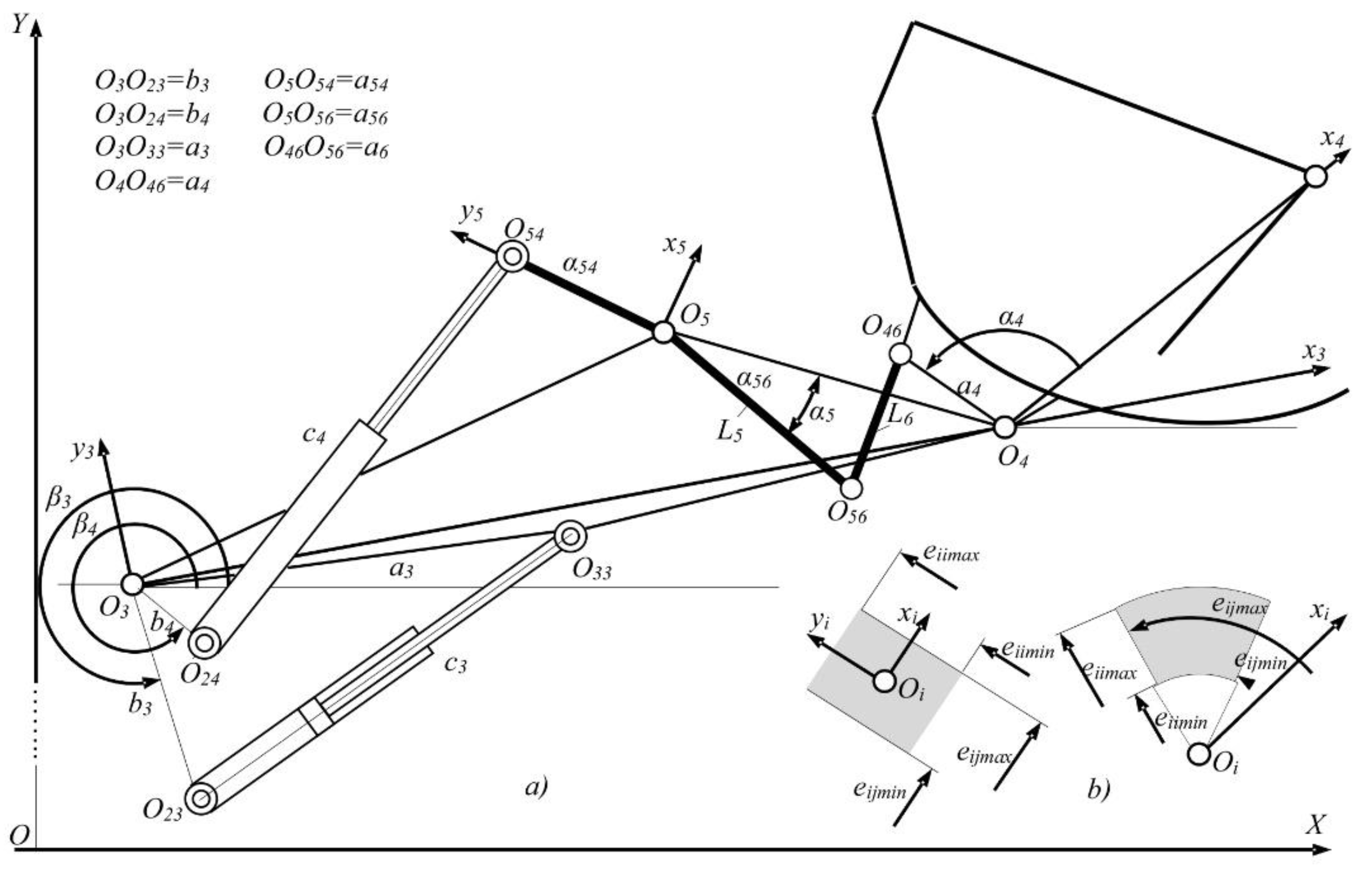

2.1. Generation of Variant Mechanism Solutions

2.1.1. Generation of Searching Area

- Continuous variables (transmission parameters): the coordinates of joints and lengths of mechanisms levers, which are included in the following sets:

- Discrete variables (executive parameters): the diameters of pistons and rods of hydraulic cylinders of manipulator drive mechanisms:

2.1.2. The Procedure of Variant Solutions Generation

2.1.3. Analysis of Generated Variant Solutions

2.2. Definition of Synthesis Criteria

- The kinematic criterion, C1, was defined with the aim of ensuring that during the operation of material transfer, when a full bucket with material is lifting from the transport to the unloading position, the bucket back angle in relation to the ground base deviates minimally from the given transport angle to prevent the spillage of bucket loaded material.

- The criterion of directed digging force, C2, was defined with the aim of achieving maximum digging forces in the zone of the manipulator working area harmonized with potential loader stability. As an indicator of the criteria, the directed digging force was defined based on the possible digging forces determined in the entire working area of the manipulator corrected by the loading position factor and direction factor of the digging force in relation to the cutting edge of the bucket.

- The tribological criterion, C3, is defined with the aim of minimizing energy losses caused by friction in the kinematic chain joints and manipulator drive mechanisms. It reflects the energy efficiency of the manipulator drive mechanisms. The indicator of the criterion is determined according to the power losses caused by the manipulation tasks of the loader in the entire working area of the manipulator.

- The time criterion, C4: The duration of the operation of the loading, transport, and unloading of material with a bucket is determined as an indicator of the criteria in order to achieve the maximum technical performance of the loader with the manipulator drive mechanisms. It is assumed that the hydraulic cylinders of the drive mechanisms of the manipulator are supplied by a hydraulic pump of variable specific flow with regulation of the hydraulic flow according to the criterion of constant hydraulic power.

- The manipulator mass criterion C5 was determined with the aim of ensuring that the mass of the members of the kinematic chain and the drive mechanisms of the manipulator are minimal. The indicators of the criteria are the relative mass of the actuators of the drive mechanisms and the nominal mass of the arm and the levers of the manipulator bucket mechanism, as determined by the transmission and executive parameters of the mechanisms.

- The dynamic criterion C6 refers to the influence of the parameters of the drive mechanisms of the manipulator on the dynamic stability of the loader. As an indicator of the criterion, the vertical movement of the support-moving member of the kinematic chain of the loader caused by the movement of the kinematic chain members of the manipulator in the loader dynamic model is taken. The hydraulic cylinders of the manipulator drive mechanisms are modeled as elastic-damping elements since they act as “hydraulic springs” under load.

3. Applied Methods and Proposed RDMR-G Approach

3.1. Applied Methods to Criteria Weights Determination

3.1.1. Fuzzy Analytic Hierarchy Process

3.1.2. Fuzzy Pivot Pairwise Relative Criteria Importance Assessment

3.1.3. Fuzzy Full Consistency Method

- (1)

- allows for the pairwise comparison of the evaluation criteria not only through the use of integers but also by utilizing decimal values,

- (2)

- uses a simple algorithm to determine the criteria weights,

- (3)

- and needs a smaller number of pairwise comparisons for deciding criteria weights.

3.1.4. Entropy Weighting Method

3.1.5. Criteria Importance through Intercriteria Correlation Method

3.1.6. Method based on the Removal Effects of Criteria

3.2. MCDM Method Used to Rank Alternatives of Loader Mechanisms

3.3. The Proposed Approach for Generating a Robust Decision Rule

4. Results and Discussion

Statistical Comparison of Complete Rankings using Kendall’s Tau-b and Spearman’s Rho Tests

5. Conclusions

- The proposed integrated RDMR-G approach was found to be very useful in the aggregation of different attitudes in decision-making processes by engineering groups. The RDMR-G approach is particularly applicable to cases where there is certain degree of inconsistency in the alternative final rankings obtained using different weighting methods.

- The conducted statistical comparison of complete rankings using Kendall’s tau-b and Spearman’s rho tests shows that the application of the RDMR-G approach provided the highest overall summary values, which indicates that this approach enables the highest level of stability of the final complete rankings.

- The process of the optimal synthesis of loader drive mechanisms using a three phase algorithm and the RDMR-G approach showed that the dominant characteristics of the best-rated variants of the mechanism are smaller pistons/connecting rod diameters of hydraulic cylinders and larger transmission lever lengths and coordinates of hydraulic cylinder connection joints.

- The proposed three phase algorithm has a general character and can be used for the synthesis of the lever mechanisms of manipulators and other mobile machines.

- Also, proposed RDMR-G approach has a general character and can be applied to any MCDM problem with group decisioning.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sen, P.; Yang, J.B. Multiple Criteria Decision Support in Engineering Design; Springer: New York, NY, USA, 1998. [Google Scholar]

- Hung, K.-C.; Julian, P.; Chien, T.; Jin, W.T.-H.; Julian, P. A decision support system for engineering design based on an enhanced fuzzy MCDM approach. Expert Syst. Appl. 2010, 37, 202–213. [Google Scholar] [CrossRef]

- Chen, S.J.; Hwang, C.L. Fuzzy Multiple Attribute Decision Making: Methods and Applications, Lecture Notes in Economics and Mathematical Systems; Springer: New York, NY, USA, 1992. [Google Scholar]

- Petrović, G.S.; Madić, M.; Antucheviciene, J. An approach for robust decision making rule generation: Solving transport and logistics decision making problems. Expert Syst. Appl. 2018, 106, 263–276. [Google Scholar] [CrossRef]

- Chen, C.-T. Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst. 2000, 114, 1–9. [Google Scholar] [CrossRef]

- Wu, J.; Cao, Q.-W. Same families of geometric aggregation operators with intuitionistic trapezoidal fuzzy numbers. Appl. Math. Model. 2013, 37, 318–327. [Google Scholar] [CrossRef] [Green Version]

- Dombi, J. A general class of fuzzy operators, the demorgan class of fuzzy operators and fuzziness measures induced by fuzzy operators. Fuzzy Sets Syst. 1982, 8, 149–163. [Google Scholar] [CrossRef]

- Bonferroni, C. Sulle medie multiple di potenze. Boll. Unione. Mat. Ital. 1950, 5, 267–270. [Google Scholar]

- Wang, W.; Liu, X. Intuitionistic fuzzy geometric aggregation operators based on einstein operations. Int. J. Intell. Syst. 2011, 26, 1049–1075. [Google Scholar] [CrossRef]

- Yager, R.R. The Power Average Operator. IEEE Trans. Syst. Man. Cyb. 2001, 31, 724–731. [Google Scholar] [CrossRef]

- Xu, Z.; Yager, R.R. Some geometric aggregation operators based on intuitionistic fuzzy sets. Int. J. Gen. Syst. 2006, 35, 417–433. [Google Scholar] [CrossRef]

- Pamučar, D.; Žižović, M.; Biswas, S.; Božanić, D. A new logarithm methodology of additive weights (LMAW) for multi-criteria decision-making: Application in logistics. Fact. Univ. Ser. Mech. Eng. 2021, 19, 361–380. [Google Scholar] [CrossRef]

- Liu, Y.; Eckert, C.M.; Earl, C. A review of fuzzy AHP methods for decision-making with subjective judgements. Expert Syst. Appl. 2020, 161, 113738. [Google Scholar] [CrossRef]

- Đalić, I.; Stević, Ž.; Ateljević, J.; Turskis, Z.; Zavadskas, E.K.; Mardani, A. A novel integrated MCDM-SWOT-TOWS model for the strategic decision analysis in transportation company. Fact. Univ. Ser. Mech. Eng. 2021, 19, 401–422. [Google Scholar] [CrossRef]

- Stević, Ž.; Stjepanović, Ž.; Božičković, Z.; Das, D.K.; Stanujkić, D. Assessment of Conditions for Implementing Information Technology in a Warehouse System: A Novel Fuzzy PIPRECIA Method. Symmetry 2018, 10, 586. [Google Scholar] [CrossRef] [Green Version]

- Pamučar, D.; Stević, Ž.; Sremac, S. A new model for determining weight coefficients of criteria in MCDM models: Full consistency method (FUCOM). Symmetry 2018, 10, 393. [Google Scholar] [CrossRef] [Green Version]

- Mukhametzyanov, I. Specific character of objective methods for determining weights of criteria in MCDM problems: Entropy, CRITIC and SD. Decis. Mak. Appl. Manag. Eng. 2021, 4, 76–105. [Google Scholar] [CrossRef]

- Žižović, M.; Miljković, B.; Marinković, D. Objective methods for determining criteria weight coefficients: A modification of the CRITIC method. Decis. Mak. Appl. Manag. Eng. 2020, 3, 149–161. [Google Scholar] [CrossRef]

- Keshavarz-Ghorabaee, M.; Amiri, M.; Zavadskas, E.; Turskis, Z.; Antucheviciene, J. Determination of Objective Weights Using a New Method Based on the Removal Effects of Criteria (MEREC). Symmetry 2021, 13, 525. [Google Scholar] [CrossRef]

- Sreeram, T.; Katti, V. A Multi-Criteria Decision Making Model for the Design of Machine Structures. In SAE Technical Paper Series 2007-01-1479; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Renzi, C.; Leali, F. A Multicriteria Decision-Making Application to the Conceptual Design of Mechanical Components. J. Multi-Criteria Decis. Anal. 2016, 23, 87–111. [Google Scholar] [CrossRef]

- Oladejo, K.A.; Adetan, D.A.; Adewale, M.D.; Malomo, B.O. Model for design concept evaluation using decision-matrix logic. Int. J. Multidiscip. Sci. Eng. 2016, 7, 6–14. [Google Scholar]

- Olabanji, O.M.; Mpofu, K. Hybridized fuzzy analytic hierarchy process and fuzzy weighted average for identifying optimal design concept. Heliyon 2020, 6, e03182. [Google Scholar] [CrossRef] [Green Version]

- Olabanji, O.M.; Mpofu, K. Appraisal of conceptual designs: Coalescing fuzzy analytic hierarchy process (F-AHP) and fuzzy grey relational analysis (F-GRA). Results Eng. 2021, 9, 100194. [Google Scholar] [CrossRef]

- Gomes, C.F.S.; Costa, H.G. Aplicação de métodos multicritério ao problema de escolha de modelos de pagamento eletrônico por cartão de crédito. Production 2015, 25, 54–68. [Google Scholar] [CrossRef]

- Brauers, W.K.M.; Zavadskas, E.K. Robustness of MULTIMOORA: A Method for Multi-Objective Optimization. Informatica 2012, 23, 1–25. [Google Scholar] [CrossRef]

- Pavlović, J.; Janošević, D.; Jovanović, V.; Petrović, N. Multy-criteria optimal synthesis of the loader manipulator drive mechanisms using genetic algorithm. In Proceedings of the Seventh International Conference Transport and Logistics (TIL 2019), Niš, Serbia, 6 December 2019. [Google Scholar]

- Shin, K.; Lee, S.; Shin, H.; Yoo, Y.; Kim, J. Coupled linkage system optimization for minimum power consumption. J. Mech. Sci. Technol. 2012, 26, 1099–1106. [Google Scholar] [CrossRef]

- Pavlović, J.; Đokić, R.; Petrović, N.; Despenić, N. Optimization of a loader drive mechanisms on the basis of the cycle time criterion. In Proceedings of the Eighth International Conference Transport and Logistics (TIL 2021), Niš, Serbia, 3 December 2021. [Google Scholar]

- Shen, J.; Wang, G.; Bi, Q.; Qu, J. A comprehensive genetic algorithm for design optimization of Z-bar loader working mechanism. J. Mech. Sci. Technol. 2013, 27, 3381–3394. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytical Hierarchy Process: Planning, Priority Setting, Resource Allocation; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Van Laarhoven, P.; Pedrycz, W. A fuzzy extension of Saaty’s priority theory. Fuzzy Sets Syst. 1983, 11, 229–241. [Google Scholar] [CrossRef]

- Buckley, J.J. Ranking alternatives using fuzzy numbers. Fuzzy. Set. Syst. 1985, 29, 145–153. [Google Scholar] [CrossRef]

- Chang, D.-Y. Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Mardani, A.; Jusoh, A.; Zavadskas, E.K. Fuzzy multiple criteria decision-making techniques and applications—Two decades review from 1994 to 2014. Expert Syst. Appl. 2015, 42, 4126–4148. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Turskis, Z.; Stević, Ž.; Mardani, A. Modelling Procedure for the Selection of Steel Pipes Supplier by Applying Fuzzy AHP Method. Oper. Res. Eng. Sci. Theory Appl. 2020, 3, 39–53. [Google Scholar] [CrossRef]

- Stanujkic, D.; Zavadskas, E.K.; Karabasevic, D.; Smarandache, F.; Turskis, Z. The use of the pivot pairwise relative criteria importance assessment method for determining the weights of criteria. Rom. J. Econ. Forecast. 2017, 20, 116–133. [Google Scholar]

- Pamucar, D.; Ecer, F.; Deveci, M. Assessment of alternative fuel vehicles for sustainable road transportation of United States using integrated fuzzy FUCOM and neutrosophic fuzzy MARCOS methodology. Sci. Total Environ. 2021, 788, 147763. [Google Scholar] [CrossRef] [PubMed]

- Fazlollahtabar, H.; Smailbašić, A.; Stević, Ž. FUCOM method in group decision-making: Selection of forklift in a warehouse. Decis. Mak. Appl. Manag. Eng. 2019, 2, 49–65. [Google Scholar] [CrossRef]

- Durmić, E.; Stević, Ž.; Chatterjee, P.; Vasiljević, M.; Tomašević, M. Sustainable supplier selection using combined FUCOM—Rough SAW model. Rep. Mech. Eng. 2020, 1, 34–43. [Google Scholar] [CrossRef]

- Pamučar, D.; Deveci, M.; Canıtez, F.; Bozanic, D. A fuzzy Full Consistency Method-Dombi-Bonferroni model for prioritizing transportation demand management measures. Appl. Soft Comput. 2020, 87, 105952. [Google Scholar] [CrossRef]

- Pamucar, D.; Ecer, F. Prioritizing the weights of the evaluation criteria under fuzziness: The fuzzy full consistency method—FUCOM-F. Fact. Univ. Ser. Mech. Eng. 2020, 18, 419–437. [Google Scholar] [CrossRef]

- Shannon, C.E. A mathematical theory of communication. Bell. Labs. Tech. J. 1948, 27, 379–423. [Google Scholar] [CrossRef] [Green Version]

- Zeleny, M. Multiple Criteria Decision Making; McGraw-Hill: New York, NY, USA, 1982. [Google Scholar]

- Diakoulaki, D.; Mavrotas, G.; Papayannakis, L. Determining objective weights in multiple criteria problems: The critic method. Comput. Oper. Res. 1995, 22, 763–770. [Google Scholar] [CrossRef]

- Madic, M.; Radovanović, M. Ranking of some most commonly used nontraditional machining processes using ROV and CRITIC methods. UPB Sci. Bull. Ser. D 2015, 77, 193–204. [Google Scholar]

- Hwang, C.L.; Yoon, K. Multiple Attribute Decision Making Methods and Applications; Springer: Berlin, Germany, 1981. [Google Scholar]

- Zolfani, S.H.; Yazdani, M.; Pamucar, D.; Zarate, P. A VIKOR and TOPSIS focused reanalysis of the MADM methods based on logarithmic normalization. Fact. Univ. Ser. Mech. Eng. 2020, 18, 341–355. [Google Scholar]

- Lin, Y.-H.; Lee, P.-C.; Chang, T.-P.; Ting, H.-I. Multi-attribute group decision making model under the condition of uncertain information. Autom. Constr. 2008, 17, 792–797. [Google Scholar] [CrossRef]

- Wang, Y.J.; Lee, H.S.; Lin, K. Fuzzy TOPSIS for multi-criteria decision-making. Int. Math. J. 2003, 3, 367–379. [Google Scholar]

- Taguchi, G. Introduction to Quality Engineering; Asian Productivity Organization: Tokyo, Japan, 1986. [Google Scholar]

| Transmission Parameters 1–4 | Executive Parameters 5,6 | Additional Parameters | |||||||

|---|---|---|---|---|---|---|---|---|---|

| [mm] | [°] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [-] | |

| 3.001 | 524 | 269.7 | 1655 | −129 | 125 | 90 | 1340 | 2058 | 2 |

| 3.014 | 495 | 259.7 | 1498 | 55 | 125 | 80 | 1335 | 1945 | |

| 3.020 | 482 | 262.6 | 1614 | −15 | 125 | 80 | 1402 | 2028 | |

| 3.026 | 575 | 262.6 | 1602 | −28 | 110 | 80 | 1361 | 2097 | |

| 3.028 | 583 | 263.5 | 1682 | −81 | 110 | 80 | 1410 | 2172 | |

| 3.033 | 380 | 261.9 | 1604 | −16 | 140 | 90 | 1431 | 1930 | |

| 3.036 | 1633 | 262.3 | 512 | −109 | 125 | 90 | 1330 | 2031 | |

| 3.051 | 343 | 262.1 | 1612 | −26 | 150 | 100 | 1449 | 1904 | |

| 3.053 | 481 | 262.8 | 1655 | −23 | 125 | 90 | 1438 | 2066 | |

| 3.064 | 367 | 262.5 | 1662 | 0 | 140 | 90 | 1491 | 1976 | |

| 3.095 | 498 | 262.6 | 1628 | −16 | 125 | 90 | 1410 | 2056 | |

| 3.108 | 362 | 267.4 | 1360 | −86 | 150 | 100 | 1179 | 1618 | |

| 3.111 | 621 | 263.5 | 1691 | −91 | 110 | 80 | 1404 | 2213 | |

| 3.117 | 413 | 262.7 | 1667 | 0 | 140 | 90 | 1474 | 2018 | |

| 3.135 | 524 | 285.2 | 1764 | −115 | 125 | 90 | 1340 | 2073 | |

| 3.147 | 370 | 262,4 | 1658 | 0 | 140 | 90 | 1487 | 1974 | |

| 3.150 | 486 | 262.6 | 1633 | −19 | 125 | 90 | 1418 | 2049 | |

| 3.178 | 335 | 284.7 | 1434 | −78 | 150 | 100 | 1183 | 1629 | |

| 3.223 | 449 | 260.5 | 1538 | 27 | 125 | 80 | 1366 | 1936 | |

| 3.236 | 595 | 263,1 | 1657 | −7 | 110 | 80 | 1390 | 2161 | |

| 3.245 | 338 | 262.4 | 1668 | 12 | 150 | 100 | 1511 | 1958 | |

| 3.267 | 482 | 260,3 | 1526 | 36 | 125 | 80 | 1353 | 1956 | |

| 3.271 | 614 | 263,4 | 1686 | −95 | 110 | 80 | 1401 | 2202 | |

| 3.278 | 587 | 263.3 | 1689 | −78 | 110 | 80 | 1418 | 2184 | |

| 3.290 | 475 | 262.5 | 1750 | −150 | 125 | 90 | 1508 | 2145 | |

| 3.295 | 475 | 262.5 | 1750 | 150 | 125 | 90 | 1585 | 2182 | |

| Transmission Parameters 1–10 | Executive Parameters 11,12 | Additional Parameters | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [mm/°] | [mm] | [mm] | [mm/°] | [mm] | [mm/°] | [mm] | [mm] | [mm] | [mm] | [mm] | [-] | |

| 4.001 | 293/314.6 | 1703 | 577 | 369/88 | 720 | 751/15.1 | 756 | 150 | 100 | 1340 | 1897 | 1 |

| 4.014 | 252/341.3 | 1742 | 632 | 270/84.2 | 764 | 784/10.7 | 643 | 160 | 100 | 1440 | 1815 | |

| 4.020 | 325/342.8 | 1748 | 614 | 348/85.8 | 700 | 735/16.2 | 757 | 140 | 90 | 1349 | 1818 | |

| 4.026 | 259/340.7 | 1739 | 631 | 287/84.1 | 763 | 814/10.9 | 631 | 170 | 115 | 1412 | 1798 | |

| 4.028 | 235/350.1 | 1622 | 657 | 253/86.4 | 834 | 849/11.7 | 676 | 180 | 115 | 1329 | 1688 | |

| 4.033 | 251/347.9 | 1627 | 637 | 267/86.3 | 839 | 853/11.8 | 675 | 160 | 110 | 1299 | 1675 | |

| 4.036 | 300/342.5 | 1750 | 633 | 320/85 | 749 | 779/13.7 | 690 | 150 | 100 | 1385 | 1822 | |

| 4.051 | 250/342.5 | 1725 | 633 | 270/85 | 763 | 793/10 | 650 | 170 | 110 | 1433 | 1803 | |

| 4.053 | 275/342.5 | 1650 | 527 | 295/90 | 720 | 750/10 | 730 | 150 | 100 | 1241 | 1647 | |

| 4.064 | 300/342.5 | 1700 | 607 | 320/90 | 820 | 850/11.8 | 650 | 150 | 100 | 1297 | 1736 | |

| 4.095 | 325/342.5 | 1775 | 620 | 345/85 | 706 | 736/15.6 | 730 | 140 | 100 | 1379 | 1849 | |

| 4.108 | 250/340.6 | 1703 | 577 | 300/95 | 647 | 840/6.1 | 637 | 180 | 125 | 1397 | 1727 | |

| 4.111 | 250/342.5 | 1675 | 633 | 270/85 | 806 | 836/10 | 650 | 170 | 115 | 1372 | 1742 | |

| 4.117 | 400/342.5 | 1675 | 607 | 445/85 | 763 | 793/11.8 | 850 | 125 | 90 | 1258 | 1840 | |

| 4.135 | 293/314.6 | 1703 | 577 | 355/88 | 720 | 751/15.1 | 756 | 150 | 100 | 1393 | 1862 | |

| 4.147 | 250/342.5 | 1650 | 567 | 270/90 | 791 | 821/11.8 | 650 | 160 | 100 | 1238 | 1615 | |

| 4.150 | 275/342.5 | 1650 | 553 | 295/90 | 791 | 821/10 | 670 | 160 | 100 | 1231 | 1640 | |

| 4.178 | 295/325 | 1695 | 570 | 360/88 | 740 | 850/15.1 | 663 | 150 | 100 | 1411 | 1706 | |

| 4.223 | 300/342.5 | 1675 | 607 | 320/85 | 763 | 793/15.6 | 730 | 150 | 100 | 1258 | 1699 | |

| 4.236 | 263/347.9 | 1635 | 626 | 278/86 | 826 | 858/11.9 | 667 | 170 | 110 | 1271 | 1656 | |

| 4.245 | 345/342.2 | 1750 | 608 | 366/86.3 | 718 | 746/16.1 | 759 | 140 | 90 | 1326 | 1825 | |

| 4.267 | 250/351.6 | 1600 | 660 | 270/85 | 806 | 836/11.8 | 730 | 170 | 115 | 1314 | 1687 | |

| 4.271 | 350/351.6 | 1675 | 660 | 370/90 | 806 | 836/19.3 | 750 | 140 | 100 | 1212 | 1719 | |

| 4.278 | 275/342.5 | 1775 | 647 | 295/85 | 734 | 764/17.5 | 670 | 160 | 100 | 1406 | 1813 | |

| 4.290 | 250/351.6 | 1600 | 687 | 270/85 | 820 | 850/17.5 | 730 | 160 | 100 | 1271 | 1648 | |

| 4.295 | 275/342.5 | 1675 | 567 | 295/90 | 777 | 807/13.7 | 670 | 150 | 100 | 1232 | 1642 | |

| Alternative-Variants of the Drive Mechanisms Ev | C1 [°] | C2 [kN] | C3 [W] | C4 [s] | C5 [kg] | C6 [m] |

|---|---|---|---|---|---|---|

| Min | Max | Min | Min | Min | Min | |

| V.001 | 4.089 | 22.652 | 425.137 | 8.504 | 971.621 | 0.0142 |

| V.014 | 0.183 | 22.653 | 541.580 | 8.113 | 1085.811 | 0.0120 |

| V.020 | 0.734 | 22.591 | 446.604 | 7.828 | 900.815 | 0.0123 |

| V.026 | 1.368 | 21.718 | 473.667 | 8.003 | 1048.561 | 0.0103 |

| V.028 | 0.155 | 21.974 | 513.465 | 8.523 | 1099.590 | 0.0102 |

| V.033 | 0.108 | 22.553 | 634.874 | 7.910 | 1218.694 | 0.0162 |

| V.036 | 0.332 | 23.658 | 424.215 | 7.910 | 1084.033 | 0.0115 |

| V.051 | 0.154 | 23.217 | 708.934 | 8.227 | 1319.761 | 0.0156 |

| V.053 | 0.538 | 22.580 | 498.660 | 7.899 | 912.036 | 0.0148 |

| V.064 | 0.385 | 22.055 | 598.755 | 7.794 | 1101.295 | 0.0153 |

| V.095 | 0.416 | 22.909 | 448.396 | 7.648 | 952.286 | 0.0117 |

| V.108 | 3.429 | 23.416 | 674.644 | 7.832 | 1391.960 | 0.0165 |

| V.111 | 0.254 | 22.709 | 470.975 | 8.063 | 974.863 | 0.0095 |

| V.117 | 0.495 | 23.036 | 476.138 | 7.578 | 904.988 | 0.0142 |

| V.135 | 3.979 | 22.732 | 425.254 | 8.105 | 903.912 | 0.0130 |

| V.147 | 0.458 | 22.227 | 641.743 | 8.112 | 1064.816 | 0.0162 |

| V.150 | 0.408 | 22.861 | 515.947 | 8.155 | 1075.259 | 0.0125 |

| V.178 | 2.260 | 21.535 | 602.219 | 7.749 | 1122.245 | 0.0154 |

| V.223 | 0.227 | 21.484 | 509.715 | 7.853 | 971.883 | 0.0134 |

| V.236 | 0.487 | 22.054 | 476.795 | 8.187 | 967.528 | 0.0134 |

| V.245 | 0.441 | 22.777 | 615.591 | 7.885 | 1092.325 | 0.0144 |

| V.267 | 0.288 | 22.455 | 559.207 | 8.196 | 1172.175 | 0.0124 |

| V.271 | 0.414 | 22.478 | 372.014 | 7.750 | 812.676 | 0.0086 |

| V.278 | 0.474 | 22.064 | 444.064 | 8.131 | 1008.867 | 0.0100 |

| V.290 | 0.300 | 22.587 | 524.807 | 8.196 | 1071.200 | 0.0128 |

| V.295 | 0.520 | 22.247 | 516.179 | 7.821 | 961.929 | 0.0135 |

| Criteria Weights | W1 | W2 | W3 | W4 | W5 | W6 | ||

|---|---|---|---|---|---|---|---|---|

| F-AHP | Expert 1 | 0.108 | 0.087 | 0.178 | 0.146 | 0.258 | 0.224 | |

| Expert 2 | 0.295 | 0.363 | 0.117 | 0.117 | 0.107 | 0.000 | ||

| Expert 3 | 0.084 | 0.099 | 0.243 | 0.287 | 0.178 | 0.109 | ||

| Expert 4 | 0.208 | 0.256 | 0.215 | 0.215 | 0.106 | 0.000 | ||

| Expert 5 | 0.270 | 0.258 | 0.210 | 0.129 | 0.062 | 0.071 | ||

| F-PIPRECIA | Expert 1 | l | 0.081 | 0.081 | 0.127 | 0.106 | 0.162 | 0.196 |

| m | 0.095 | 0.095 | 0.162 | 0.150 | 0.249 | 0.249 | ||

| u | 0.121 | 0.114 | 0.247 | 0.192 | 0.356 | 0.377 | ||

| d | 0.097 | 0.096 | 0.171 | 0.149 | 0.253 | 0.262 | ||

| Expert 2 | l | 0.153 | 0.182 | 0.131 | 0.131 | 0.107 | 0.093 | |

| m | 0.212 | 0.227 | 0.145 | 0.145 | 0.135 | 0.135 | ||

| u | 0.269 | 0.345 | 0.196 | 0.190 | 0.149 | 0.129 | ||

| d | 0.211 | 0.239 | 0.151 | 0.151 | 0.133 | 0.127 | ||

| Expert 3 | l | 0.083 | 0.083 | 0.139 | 0.163 | 0.137 | 0.137 | |

| m | 0.105 | 0.105 | 0.205 | 0.205 | 0.190 | 0.190 | ||

| u | 0.128 | 0.128 | 0.294 | 0.335 | 0.261 | 0.248 | ||

| d | 0.105 | 0.105 | 0.209 | 0.220 | 0.193 | 0.191 | ||

| Expert 4 | l | 0.165 | 0.165 | 0.160 | 0.123 | 0.087 | 0.059 | |

| m | 0.216 | 0.216 | 0.198 | 0.167 | 0.122 | 0.081 | ||

| u | 0.382 | 0.368 | 0.311 | 0.214 | 0.141 | 0.080 | ||

| d | 0.235 | 0.233 | 0.210 | 0.167 | 0.119 | 0.077 | ||

| Expert 5 | l | 0.202 | 0.202 | 0.151 | 0.123 | 0.090 | 0.110 | |

| m | 0.215 | 0.215 | 0.172 | 0.158 | 0.115 | 0.125 | ||

| u | 0.289 | 0.275 | 0.204 | 0.160 | 0.106 | 0.136 | ||

| d | 0.225 | 0.223 | 0.174 | 0.153 | 0.109 | 0.124 | ||

| F-FUCOM | Expert 1 | l | 0.043 | 0.051 | 0.091 | 0.039 | 0.124 | 0.122 |

| m | 0.136 | 0.106 | 0.209 | 0.135 | 0.246 | 0.268 | ||

| u | 0.169 | 0.106 | 0.209 | 0.135 | 0.246 | 0.268 | ||

| d | 0.126 | 0.097 | 0.189 | 0.119 | 0.226 | 0.244 | ||

| Expert 2 | l | 0.141 | 0.194 | 0.151 | 0.053 | 0.049 | 0.048 | |

| m | 0.246 | 0.194 | 0.246 | 0.133 | 0.149 | 0.101 | ||

| u | 0.246 | 0.194 | 0.251 | 0.133 | 0.164 | 0.101 | ||

| d | 0.229 | 0.194 | 0.231 | 0.120 | 0.135 | 0.092 | ||

| Expert 3 | l | 0.049 | 0.048 | 0.141 | 0.194 | 0.151 | 0.053 | |

| m | 0.149 | 0.101 | 0.246 | 0.194 | 0.246 | 0.133 | ||

| u | 0.164 | 0.101 | 0.246 | 0.194 | 0.251 | 0.133 | ||

| d | 0.135 | 0.092 | 0.229 | 0.194 | 0.231 | 0.120 | ||

| Expert 4 | l | 0.194 | 0.141 | 0.151 | 0.053 | 0.049 | 0.048 | |

| m | 0.194 | 0.246 | 0.246 | 0.133 | 0.149 | 0.101 | ||

| u | 0.194 | 0.246 | 0.251 | 0.133 | 0.164 | 0.101 | ||

| d | 0.194 | 0.229 | 0.231 | 0.120 | 0.135 | 0.092 | ||

| Expert 5 | l | 0.181 | 0.120 | 0.118 | 0.088 | 0.030 | 0.038 | |

| m | 0.181 | 0.238 | 0.241 | 0.202 | 0.088 | 0.130 | ||

| u | 0.181 | 0.238 | 0.259 | 0.202 | 0.098 | 0.130 | ||

| d | 0.181 | 0.218 | 0.223 | 0.183 | 0.080 | 0.115 | ||

| EWM | 0.125 | 0.191 | 0.154 | 0.153 | 0.111 | 0.268 | ||

| CRITIC | 0.353 | 0.126 | 0.131 | 0.153 | 0.134 | 0.102 | ||

| MEREC | 0.702 | 0.014 | 0.099 | 0.020 | 0.090 | 0.074 | ||

| Alternatives-Variants of the Drive Mechanisms Ev | F-AHP | F-PIPECIA | F-FUCOM | EWM | CRITIC | MEREC | S/N Ratio | RDMR-G | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E1 | E2 | E3 | E4 | E5 | E1 | E2 | E3 | E4 | E5 | E1 | E2 | E3 | E4 | E5 | ||||||

| V.001 | 25 | 26 | 25 | 25 | 26 | 25 | 26 | 25 | 25 | 26 | 25 | 25 | 25 | 25 | 25 | 25 | 26 | 26 | −28.075 | 25 |

| V.014 | 9 | 2 | 15 | 9 | 7 | 8 | 6 | 10 | 10 | 6 | 8 | 8 | 14 | 10 | 8 | 7 | 4 | 2 | −18.696 | 8 |

| V.020 | 7 | 21 | 6 | 16 | 19 | 7 | 19 | 7 | 7 | 19 | 7 | 16 | 8 | 16 | 16 | 10 | 21 | 21 | −23.330 | 14 |

| V.026 | 17 | 22 | 16 | 22 | 22 | 15 | 22 | 17 | 17 | 22 | 17 | 22 | 21 | 22 | 22 | 17 | 22 | 22 | −26.025 | 20 |

| V.028 | 6 | 3 | 11 | 6 | 4 | 5 | 4 | 6 | 6 | 4 | 6 | 5 | 10 | 6 | 6 | 4 | 2 | 1 | −15.236 | 5 |

| V.033 | 21 | 10 | 20 | 18 | 16 | 21 | 17 | 20 | 20 | 16 | 20 | 18 | 19 | 18 | 18 | 20 | 11 | 4 | −24.911 | 18 |

| V.036 | 5 | 5 | 5 | 2 | 2 | 6 | 3 | 5 | 5 | 3 | 5 | 3 | 5 | 3 | 2 | 5 | 5 | 9 | −13.358 | 3 |

| V.051 | 22 | 15 | 22 | 21 | 20 | 22 | 21 | 22 | 22 | 20 | 22 | 21 | 22 | 21 | 21 | 21 | 16 | 6 | −26.111 | 21 |

| V.053 | 15 | 19 | 10 | 13 | 15 | 17 | 15 | 15 | 15 | 15 | 16 | 14 | 11 | 13 | 15 | 16 | 19 | 20 | −23.734 | 16 |

| V.064 | 19 | 13 | 18 | 17 | 17 | 19 | 16 | 19 | 19 | 17 | 19 | 17 | 17 | 17 | 17 | 19 | 14 | 10 | −24.636 | 17 |

| V.095 | 4 | 8 | 2 | 4 | 6 | 4 | 5 | 4 | 4 | 5 | 4 | 4 | 3 | 4 | 4 | 6 | 9 | 13 | −15.178 | 4 |

| V.108 | 26 | 24 | 26 | 26 | 24 | 26 | 24 | 26 | 26 | 24 | 26 | 26 | 26 | 26 | 26 | 26 | 24 | 24 | −28.080 | 26 |

| V.111 | 2 | 1 | 3 | 3 | 1 | 2 | 1 | 2 | 2 | 1 | 2 | 2 | 2 | 2 | 3 | 2 | 1 | 5 | −7.132 | 1 |

| V.117 | 11 | 14 | 7 | 8 | 13 | 14 | 13 | 11 | 11 | 13 | 13 | 11 | 6 | 8 | 11 | 15 | 15 | 18 | −21.696 | 12 |

| V.135 | 24 | 25 | 24 | 24 | 25 | 24 | 25 | 24 | 24 | 25 | 24 | 24 | 24 | 24 | 24 | 24 | 25 | 25 | −27.726 | 24 |

| V.147 | 20 | 20 | 21 | 20 | 21 | 20 | 20 | 21 | 21 | 21 | 21 | 20 | 20 | 20 | 20 | 22 | 20 | 16 | −26.131 | 22 |

| V.150 | 13 | 11 | 13 | 12 | 10 | 11 | 10 | 12 | 12 | 10 | 11 | 12 | 15 | 12 | 12 | 8 | 10 | 12 | −21.246 | 11 |

| V.178 | 23 | 23 | 23 | 23 | 23 | 23 | 23 | 23 | 23 | 23 | 23 | 23 | 23 | 23 | 23 | 23 | 23 | 23 | −27.235 | 23 |

| V.223 | 8 | 4 | 9 | 5 | 5 | 9 | 8 | 8 | 8 | 7 | 9 | 7 | 7 | 7 | 7 | 12 | 3 | 3 | −17.324 | 7 |

| V.236 | 10 | 16 | 8 | 11 | 12 | 10 | 12 | 9 | 9 | 12 | 10 | 10 | 9 | 9 | 10 | 13 | 13 | 17 | −21.110 | 10 |

| V.245 | 18 | 17 | 19 | 19 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 19 | 18 | 19 | 19 | 18 | 17 | 14 | −25.096 | 19 |

| V.267 | 16 | 9 | 17 | 14 | 11 | 16 | 11 | 16 | 16 | 11 | 15 | 13 | 16 | 15 | 13 | 11 | 8 | 7 | −22.541 | 13 |

| V.271 | 1 | 7 | 1 | 1 | 3 | 1 | 2 | 1 | 1 | 2 | 1 | 1 | 1 | 1 | 1 | 1 | 6 | 11 | −11.158 | 2 |

| V.278 | 3 | 12 | 4 | 7 | 9 | 3 | 7 | 3 | 3 | 8 | 3 | 6 | 4 | 5 | 5 | 3 | 12 | 15 | −17.123 | 6 |

| V.290 | 12 | 6 | 14 | 10 | 8 | 12 | 9 | 13 | 13 | 9 | 12 | 9 | 13 | 11 | 9 | 9 | 7 | 8 | −20.401 | 9 |

| V.295 | 14 | 18 | 12 | 15 | 14 | 13 | 14 | 14 | 14 | 14 | 14 | 15 | 12 | 14 | 14 | 14 | 18 | 19 | −23.331 | 15 |

| F-AHP | F-PIPECIA | F-FUCOM | EWM | CRITIC | MEREC | RDMR-G | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E1 | E2 | E3 | E4 | E5 | E1 | E2 | E3 | E4 | E5 | E1 | E2 | E3 | E4 | E5 | |||||||

| F-AHP | E1 | 1.00 | 0.53 | 0.85 | 0.82 | 0.74 | 0.94 | 0.77 | 0.98 | 0.98 | 0.75 | 0.96 | 0.84 | 0.85 | 0.85 | 0.85 | 0.86 | 0.57 | 0.33 | 0.85 | |

| 1.00 | 0.72 | 0.96 | 0.94 | 0.88 | 0.99 | 0.90 | 1.00 | 1.00 | 0.90 | 1.00 | 0.95 | 0.96 | 0.95 | 0.95 | 0.96 | 0.75 | 0.46 | 0.96 | |||

| E2 | 0.53 | 1.00 | 0.43 | 0.66 | 0.80 | 0.54 | 0.77 | 0.53 | 0.53 | 0.78 | 0.56 | 0.68 | 0.50 | 0.64 | 0.67 | 0.61 | 0.95 | 0.77 | 0.68 | ||

| 0.72 | 1.00 | 0.59 | 0.85 | 0.93 | 0.72 | 0.91 | 0.72 | 0.72 | 0.92 | 0.74 | 0.86 | 0.67 | 0.82 | 0.86 | 0.80 | 0.99 | 0.91 | 0.86 | |||

| E3 | 0.85 | 0.43 | 1.00 | 0.75 | 0.62 | 0.82 | 0.65 | 0.86 | 0.86 | 0.63 | 0.83 | 0.74 | 0.93 | 0.78 | 0.73 | 0.74 | 0.45 | 0.21 | 0.74 | ||

| 0.96 | 0.59 | 1.00 | 0.90 | 0.80 | 0.93 | 0.82 | 0.96 | 0.96 | 0.81 | 0.94 | 0.89 | 0.98 | 0.92 | 0.89 | 0.87 | 0.61 | 0.30 | 0.89 | |||

| E4 | 0.82 | 0.66 | 0.75 | 1.00 | 0.85 | 0.77 | 0.87 | 0.82 | 0.82 | 0.86 | 0.80 | 0.96 | 0.83 | 0.96 | 0.95 | 0.77 | 0.69 | 0.45 | 0.91 | ||

| 0.94 | 0.85 | 0.90 | 1.00 | 0.97 | 0.91 | 0.97 | 0.94 | 0.94 | 0.97 | 0.93 | 0.99 | 0.94 | 0.99 | 0.99 | 0.91 | 0.86 | 0.60 | 0.98 | |||

| E5 | 0.74 | 0.80 | 0.62 | 0.85 | 1.00 | 0.72 | 0.96 | 0.73 | 0.73 | 0.98 | 0.75 | 0.88 | 0.69 | 0.83 | 0.88 | 0.78 | 0.83 | 0.59 | 0.88 | ||

| 0.88 | 0.93 | 0.80 | 0.97 | 1.00 | 0.88 | 0.99 | 0.88 | 0.88 | 1.00 | 0.89 | 0.98 | 0.85 | 0.95 | 0.97 | 0.92 | 0.95 | 0.72 | 0.97 | |||

| F-PIPECIA | E1 | 0.94 | 0.54 | 0.82 | 0.77 | 0.72 | 1.00 | 0.76 | 0.94 | 0.94 | 0.74 | 0.97 | 0.81 | 0.79 | 0.80 | 0.82 | 0.90 | 0.56 | 0.34 | 0.83 | |

| 0.99 | 0.72 | 0.93 | 0.91 | 0.88 | 1.00 | 0.90 | 0.99 | 0.99 | 0.89 | 1.00 | 0.93 | 0.92 | 0.92 | 0.93 | 0.97 | 0.75 | 0.47 | 0.95 | |||

| E2 | 0.77 | 0.77 | 0.65 | 0.87 | 0.96 | 0.76 | 1.00 | 0.76 | 0.76 | 0.98 | 0.79 | 0.91 | 0.72 | 0.86 | 0.91 | 0.82 | 0.79 | 0.56 | 0.90 | ||

| 0.90 | 0.91 | 0.82 | 0.97 | 0.99 | 0.90 | 1.00 | 0.90 | 0.90 | 1.00 | 0.91 | 0.98 | 0.86 | 0.96 | 0.98 | 0.94 | 0.93 | 0.69 | 0.98 | |||

| E3 | 0.98 | 0.53 | 0.86 | 0.82 | 0.73 | 0.94 | 0.76 | 1.00 | 1.00 | 0.74 | 0.97 | 0.83 | 0.85 | 0.86 | 0.84 | 0.87 | 0.56 | 0.32 | 0.85 | ||

| 1.00 | 0.72 | 0.96 | 0.94 | 0.88 | 0.99 | 0.90 | 1.00 | 1.00 | 0.89 | 1.00 | 0.94 | 0.96 | 0.95 | 0.94 | 0.95 | 0.74 | 0.46 | 0.96 | |||

| E4 | 0.98 | 0.53 | 0.86 | 0.82 | 0.73 | 0.94 | 0.76 | 1.00 | 1.00 | 0.74 | 0.97 | 0.83 | 0.85 | 0.86 | 0.84 | 0.87 | 0.56 | 0.32 | 0.85 | ||

| 1.00 | 0.72 | 0.96 | 0.94 | 0.88 | 0.99 | 0.90 | 1.00 | 1.00 | 0.89 | 1.00 | 0.94 | 0.96 | 0.95 | 0.94 | 0.95 | 0.74 | 0.46 | 0.96 | |||

| E5 | 0.75 | 0.78 | 0.63 | 0.86 | 0.98 | 0.74 | 0.98 | 0.74 | 0.74 | 1.00 | 0.77 | 0.90 | 0.70 | 0.85 | 0.89 | 0.81 | 0.81 | 0.58 | 0.90 | ||

| 0.90 | 0.92 | 0.81 | 0.97 | 1.00 | 0.89 | 1.00 | 0.89 | 0.89 | 1.00 | 0.91 | 0.98 | 0.86 | 0.96 | 0.98 | 0.93 | 0.94 | 0.71 | 0.98 | |||

| F-FUCOM | E1 | 0.96 | 0.56 | 0.83 | 0.80 | 0.75 | 0.97 | 0.79 | 0.97 | 0.97 | 0.77 | 1.00 | 0.84 | 0.82 | 0.83 | 0.85 | 0.90 | 0.58 | 0.35 | 0.86 | |

| 1.00 | 0.74 | 0.94 | 0.93 | 0.89 | 1.00 | 0.91 | 1.00 | 1.00 | 0.91 | 1.00 | 0.95 | 0.94 | 0.94 | 0.95 | 0.97 | 0.77 | 0.49 | 0.96 | |||

| E2 | 0.84 | 0.68 | 0.74 | 0.96 | 0.88 | 0.81 | 0.91 | 0.83 | 0.83 | 0.90 | 0.84 | 1.00 | 0.81 | 0.95 | 0.98 | 0.82 | 0.72 | 0.48 | 0.95 | ||

| 0.95 | 0.86 | 0.89 | 0.99 | 0.98 | 0.93 | 0.98 | 0.94 | 0.94 | 0.98 | 0.95 | 1.00 | 0.93 | 0.99 | 1.00 | 0.94 | 0.88 | 0.62 | 0.99 | |||

| E3 | 0.85 | 0.50 | 0.93 | 0.83 | 0.69 | 0.79 | 0.72 | 0.85 | 0.85 | 0.70 | 0.82 | 0.81 | 1.00 | 0.86 | 0.80 | 0.72 | 0.53 | 0.29 | 0.80 | ||

| 0.96 | 0.67 | 0.98 | 0.94 | 0.85 | 0.92 | 0.86 | 0.96 | 0.96 | 0.86 | 0.94 | 0.93 | 1.00 | 0.95 | 0.93 | 0.87 | 0.69 | 0.39 | 0.92 | |||

| E4 | 0.85 | 0.64 | 0.78 | 0.96 | 0.83 | 0.80 | 0.86 | 0.86 | 0.86 | 0.85 | 0.83 | 0.95 | 0.86 | 1.00 | 0.94 | 0.78 | 0.67 | 0.43 | 0.90 | ||

| 0.95 | 0.82 | 0.92 | 0.99 | 0.95 | 0.92 | 0.96 | 0.95 | 0.95 | 0.96 | 0.94 | 0.99 | 0.95 | 1.00 | 0.99 | 0.92 | 0.84 | 0.56 | 0.98 | |||

| E5 | 0.85 | 0.67 | 0.73 | 0.95 | 0.88 | 0.82 | 0.91 | 0.84 | 0.84 | 0.89 | 0.85 | 0.98 | 0.80 | 0.94 | 1.00 | 0.82 | 0.71 | 0.47 | 0.94 | ||

| 0.95 | 0.86 | 0.89 | 0.99 | 0.97 | 0.93 | 0.98 | 0.94 | 0.94 | 0.98 | 0.95 | 1.00 | 0.93 | 0.99 | 1.00 | 0.94 | 0.87 | 0.61 | 0.99 | |||

| EWM | 0.86 | 0.61 | 0.74 | 0.77 | 0.78 | 0.90 | 0.82 | 0.87 | 0.87 | 0.81 | 0.90 | 0.82 | 0.72 | 0.78 | 0.82 | 1.00 | 0.63 | 0.40 | 0.85 | ||

| 0.96 | 0.80 | 0.87 | 0.91 | 0.92 | 0.97 | 0.94 | 0.95 | 0.95 | 0.93 | 0.97 | 0.94 | 0.87 | 0.92 | 0.94 | 1.00 | 0.82 | 0.56 | 0.96 | |||

| CRITIC | 0.57 | 0.95 | 0.45 | 0.69 | 0.83 | 0.56 | 0.79 | 0.56 | 0.56 | 0.81 | 0.58 | 0.72 | 0.53 | 0.67 | 0.71 | 0.63 | 1.00 | 0.76 | 0.72 | ||

| 0.75 | 0.99 | 0.61 | 0.86 | 0.95 | 0.75 | 0.93 | 0.74 | 0.74 | 0.94 | 0.77 | 0.88 | 0.69 | 0.84 | 0.87 | 0.82 | 1.00 | 0.89 | 0.88 | |||

| MEREC | 0.33 | 0.77 | 0.21 | 0.45 | 0.59 | 0.34 | 0.56 | 0.32 | 0.32 | 0.58 | 0.35 | 0.48 | 0.29 | 0.43 | 0.47 | 0.40 | 0.76 | 1.00 | 0.48 | ||

| 0.46 | 0.91 | 0.30 | 0.60 | 0.72 | 0.47 | 0.69 | 0.46 | 0.46 | 0.71 | 0.49 | 0.62 | 0.39 | 0.56 | 0.61 | 0.56 | 0.89 | 1.00 | 0.62 | |||

| RDMR-G | 0.85 | 0.68 | 0.74 | 0.91 | 0.88 | 0.83 | 0.90 | 0.85 | 0.85 | 0.90 | 0.86 | 0.95 | 0.80 | 0.90 | 0.94 | 0.85 | 0.72 | 0.48 | 1.00 | ||

| 0.96 | 0.86 | 0.89 | 0.98 | 0.97 | 0.95 | 0.98 | 0.96 | 0.96 | 0.98 | 0.96 | 0.99 | 0.92 | 0.98 | 0.99 | 0.96 | 0.88 | 0.62 | 1.00 | |||

| Sum | 15.3 | 12.6 | 13.6 | 15.5 | 15.2 | 15.0 | 15.5 | 15.3 | 15.3 | 15.4 | 15.4 | 15.9 | 14.3 | 15.7 | 15.9 | 15.0 | 13.1 | 9.1 | 15.9 | ||

| 17.2 | 15.6 | 16.0 | 17.6 | 17.4 | 17.0 | 17.5 | 17.2 | 17.2 | 17.5 | 17.3 | 17.8 | 16.6 | 17.6 | 17.7 | 17.2 | 15.9 | 11.5 | 17.8 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrović, G.; Pavlović, J.; Madić, M.; Marinković, D. Optimal Synthesis of Loader Drive Mechanisms: A Group Robust Decision-Making Rule Generation Approach. Machines 2022, 10, 329. https://doi.org/10.3390/machines10050329

Petrović G, Pavlović J, Madić M, Marinković D. Optimal Synthesis of Loader Drive Mechanisms: A Group Robust Decision-Making Rule Generation Approach. Machines. 2022; 10(5):329. https://doi.org/10.3390/machines10050329

Chicago/Turabian StylePetrović, Goran, Jovan Pavlović, Miloš Madić, and Dragan Marinković. 2022. "Optimal Synthesis of Loader Drive Mechanisms: A Group Robust Decision-Making Rule Generation Approach" Machines 10, no. 5: 329. https://doi.org/10.3390/machines10050329

APA StylePetrović, G., Pavlović, J., Madić, M., & Marinković, D. (2022). Optimal Synthesis of Loader Drive Mechanisms: A Group Robust Decision-Making Rule Generation Approach. Machines, 10(5), 329. https://doi.org/10.3390/machines10050329