Experimental Study on the Response of Hand-Transmitted Vibration from an EVA Power Tool

Abstract

:1. Introduction

2. Theoretical Consideration

3. Materials and Methods

3.1. Test Procedure

3.2. Test Equipment

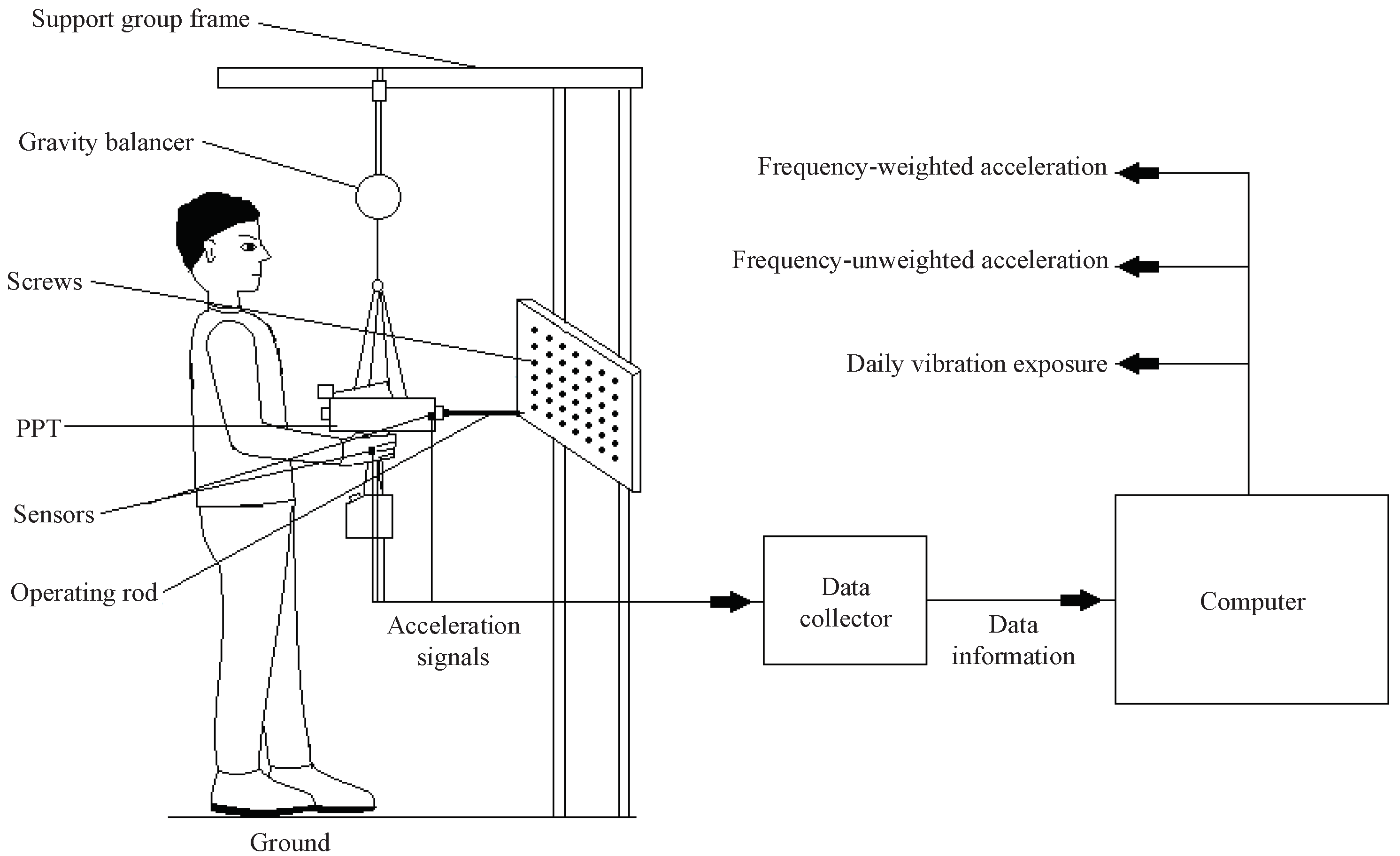

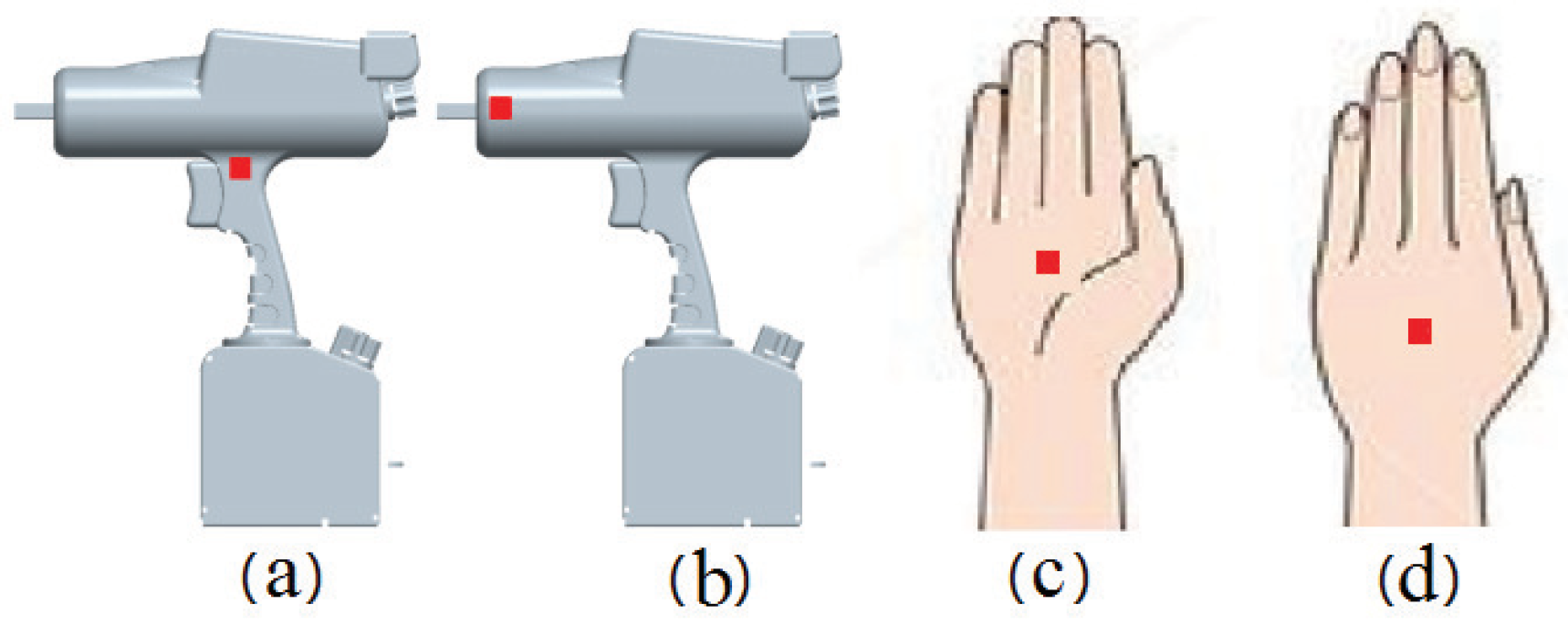

3.3. Vibration Measurement

3.4. Data Analysis

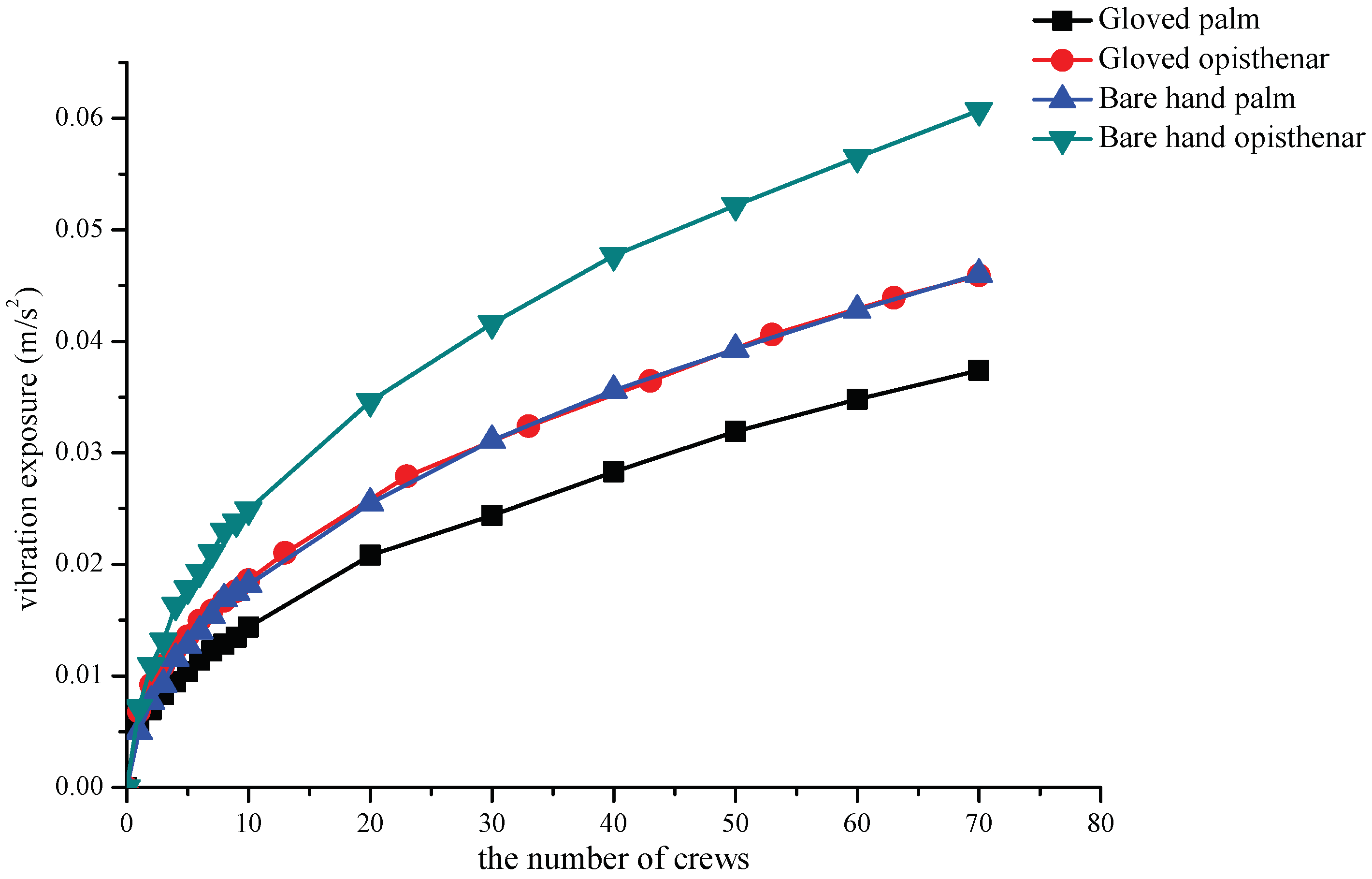

4. Experimental Results

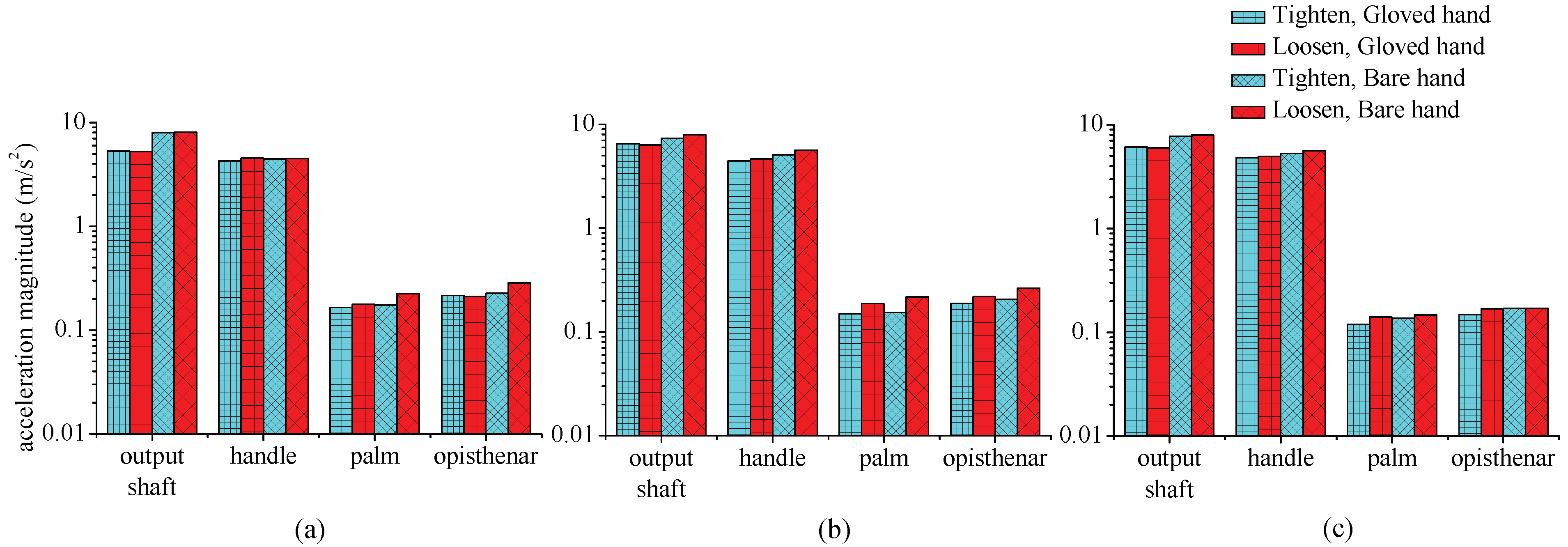

4.1. Vibration Characteristics in Different Operating States

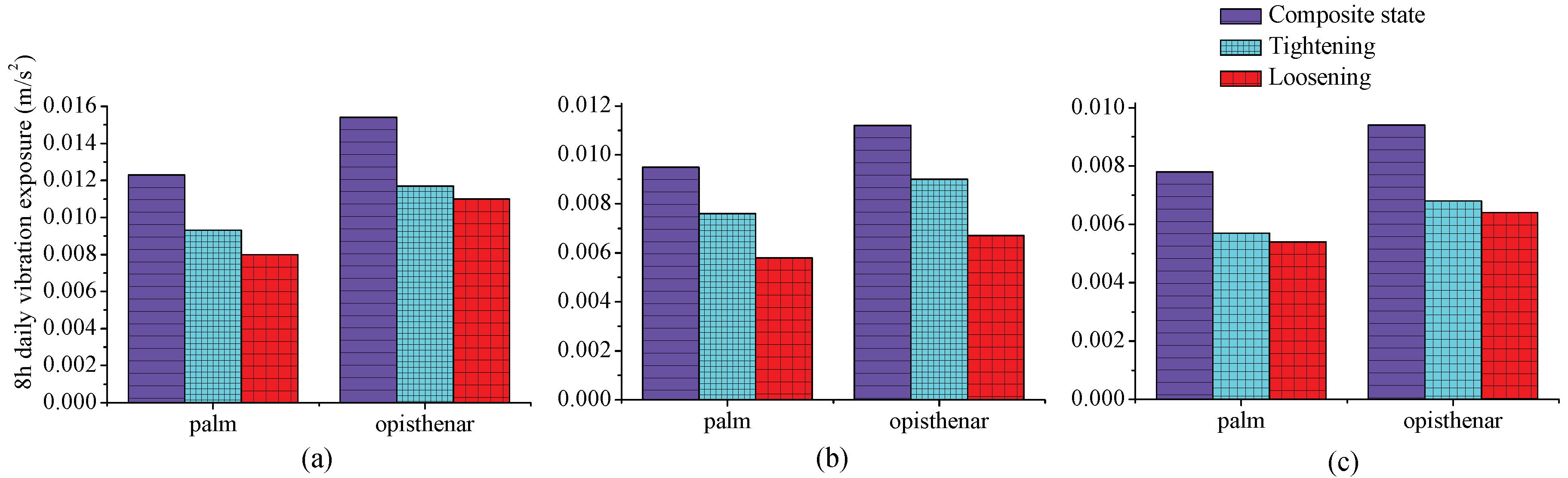

4.2. Transmission Characteristics of Vibration

5. Discussion

5.1. Analysis of Test Results

5.2. Other Factors Affecting Measurement Uncertainty

5.3. Vibration Suppression of Power Tools

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shayler, D.J.; Harland, D.M. Enhancing Hubble’s Vision; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Shayler, D.J.; Harland, D.M. The Hubble Space Telescope; Praxis: New York, NY, USA, 2016. [Google Scholar]

- Loewenthal, S.; Allmon, C.; Reznik, C.; McFatter, J.; Davis, R.E. Space station solar array joint repair. Mater. Perform. Charact. 2015, 4, 200–208. [Google Scholar] [CrossRef] [Green Version]

- Fitts, R.H.; Riley, D.R.; Widrick, J.J. Physiology of a microgravity environment invited review: Microgravity and skeletal muscle. J. Appl. Physiol. 1985, 89, 823–839. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- O’Hara, J.; Briganti, M.; Cleland, J.; Winfield, D. Extravehicular Activities Limitations Study. Volume II: Establishment of Physiological and Performance Criteria for EVA Gloves; NASA: Bethpage, NY, USA, 1988. [Google Scholar]

- Burström, L.; Lundström, R.; Hagberg, M.; Nilsson, T. Comparison of different measures for hand–arm vibration exposure. Saf. Sci. 1998, 28, 3–14. [Google Scholar] [CrossRef]

- Xu, X.S.; Welcome, D.E.; McDowell, T.W.; Warren, C.; Service, S.; Lin, H.; Chen, Q.; Dong, R.G. An investigation of the effectiveness of vibration-reducing gloves for controlling vibration exposures during grinding handheld workpieces. Appl. Ergon. 2021, 95, 103454. [Google Scholar] [CrossRef] [PubMed]

- Marchetti, E.; Sisto, R.; Lunghi, A.; Sacco, F.; Sanjust, F.; Di Giovanni, R.; Botti, T.; Morgia, F.; Tirabasso, A. An investigation on the vibration transmissibility of the human elbow subjected to hand-transmitted vibration. Int. J. Ind. Ergon. 2017, 62, 82–89. [Google Scholar] [CrossRef]

- Vergara, M.; Sancho, J.L.; Rodríguez, P.; Pérez-González, A. Hand-transmitted vibration in power tools: Accomplishment of standards and users’ perception. Int. J. Ind. Ergon. 2008, 38, 652–660. [Google Scholar] [CrossRef]

- Lindenmann, A.; Uhl, M.; Gwosch, T.; Matthiesen, S. The influence of human interaction on the vibration of hand-held human-machine systems—The effect of body posture, feed force, and gripping forces on the vibration of hammer drills. Appl. Ergon. 2021, 95, 103430. [Google Scholar] [CrossRef] [PubMed]

- Dewangan, K.N.; Tewari, V.K. Characteristics of hand-transmitted vibration of a hand tractor used in three operational modes. Int. J. Ind. Ergon. 2009, 39, 239–245. [Google Scholar] [CrossRef]

- Dong, R.G.; Welcome, D.E.; McDowell, T.W.; Wu, J.Z. Biodynamic Response of Human Fingers in a Power Grip Subjected to a Random Vibration. J. Biomech. Eng. 2004, 126, 447–457. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.G.; Dong, J.H.; Wu, J.Z.; Rakheja, S. Modeling of biodynamic responses distributed at the fingers and the palm of the human hand-arm system. J. Biomech. 2007, 40, 2335–2340. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.G.; Welcome, D.E.; McDowell, T.W.; Wu, J.Z. Methods for deriving a representative biodynamic response of the hand–arm system to vibration. J. Sound Vib. 2009, 325, 1047–1061. [Google Scholar] [CrossRef]

- Dong, R.G.; Welcome, D.E.; McDowell, T.W.; Wu, J.Z. Modeling of the biodynamic responses distributed at the fingers and palm of the hand in three orthogonal directions. J. Sound Vib. 2013, 332, 1125–1140. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dong, R.G.; McDowell, T.W.; Welcome, D.E.; Rakheja, S.; Caporali, S.A.; Schopper, A.W. Effectiveness of a Transfer Function Method for Evaluating Vibration Isolation Performance of Gloves When Used with Chipping Hammers. J. Low Freq. Noise Vib. Act. Control 2002, 21, 141–155. [Google Scholar] [CrossRef]

- Ahmadian, H.; Hassan-Beygi, S.R.; Ghobadian, B.; Najafi, G. ANFIS modeling of vibration transmissibility of a power tiller to operator. Appl. Acoust. 2018, 138, 39–51. [Google Scholar] [CrossRef]

- Bointon, P.; Todhunter, L.; Clare, A.; Leach, R. Performance verification of a flexible vibration monitoring system. Machines 2020, 8, 3. [Google Scholar] [CrossRef] [Green Version]

- Tian, Y.; Zhang, H.; Wang, L.; Ding, L.; Li, D. Effects of EVA glove on hand dexterity at low temperature and low pressure. Appl. Ergon. 2018, 70, 98–103. [Google Scholar] [CrossRef] [PubMed]

- Abramov, I.P.; Pozdnyakov, S.S.; Severin, G.I.; Stoklitsky, A.Y. Main problems of the Russian Orlan-M space suit utilization for EVAs on the ISS. Acta Astronaut. 2001, 48, 265–273. [Google Scholar] [CrossRef]

- Musgrave, G.E.; Larsen, A.S.M.; Sgobba, T. (Eds.) Safety Design for Space Systems; Butterworth-Heinemann: Oxford, UK, 2009. [Google Scholar]

- Villalba, R.T.; Ramírez, H.M.; Águila Estrada, H. Classification of Design Methodologies to Minimize Vibrations in Gears and Bearings in the 21st Century: A Review. Machines 2021, 9, 212. [Google Scholar] [CrossRef]

| Working Condition | Hand State | Length of Operating Rods | Operation |

|---|---|---|---|

| Condition 1 | Gloved hand | 200 mm | Tighten |

| Condition 2 | Loosen | ||

| Condition 3 | 300 mm | Tighten | |

| Condition 4 | Loosen | ||

| Condition 5 | 400 mm | Tighten | |

| Condition 6 | Loosen | ||

| Condition 10 | Bare hand | 200 mm | Tighten |

| Condition 20 | Loosen | ||

| Condition 30 | 300 mm | Tighten | |

| Condition 40 | Loosen | ||

| Condition 50 | 400 mm | Tighten | |

| Condition 60 | Loosen |

| Mean Vibration Total Value (m/s2) | Mean Daily Vibration Exposure (m/s2) | ||||||

|---|---|---|---|---|---|---|---|

| Operating Conditions | Bare Hand | Gloved Hand | Operating Conditions | Bare Hand | Gloved Hand | ||

| 200 mm operating rod | Palm | 0.137 | 0.119 | 200 mm operating rod | Palm | 0.0105 | 0.0093 |

| Opisthenar | 0.170 | 0.149 | Opisthenar | 0.0126 | 0.0110 | ||

| 300 mm operating rod | Palm | 0.156 | 0.150 | 300 mm operating rod | Palm | 0.0138 | 0.0112 |

| Opisthenar | 0.208 | 0.189 | Opisthenar | 0.0174 | 0.0147 | ||

| 400 mm operating rod | Palm | 0.174 | 0.165 | 400 mm operating rod | Palm | 0.0144 | 0.0130 |

| Opisthenar | 0.228 | 0.216 | Opisthenar | 0.0184 | 0.0157 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, H.; Jin, M.; Yu, Y.; Chen, Y.; Zheng, P. Experimental Study on the Response of Hand-Transmitted Vibration from an EVA Power Tool. Machines 2022, 10, 307. https://doi.org/10.3390/machines10050307

Fu H, Jin M, Yu Y, Chen Y, Zheng P. Experimental Study on the Response of Hand-Transmitted Vibration from an EVA Power Tool. Machines. 2022; 10(5):307. https://doi.org/10.3390/machines10050307

Chicago/Turabian StyleFu, Hao, Minghe Jin, Yang Yu, Yang Chen, and Peng Zheng. 2022. "Experimental Study on the Response of Hand-Transmitted Vibration from an EVA Power Tool" Machines 10, no. 5: 307. https://doi.org/10.3390/machines10050307

APA StyleFu, H., Jin, M., Yu, Y., Chen, Y., & Zheng, P. (2022). Experimental Study on the Response of Hand-Transmitted Vibration from an EVA Power Tool. Machines, 10(5), 307. https://doi.org/10.3390/machines10050307