Fault Diagnosis of Rolling Element Bearings Based on Adaptive Mode Extraction

Abstract

:1. Introduction

- (1)

- A novel adaptive mode extraction method is established based on variational mode extraction (VME) method.

- (2)

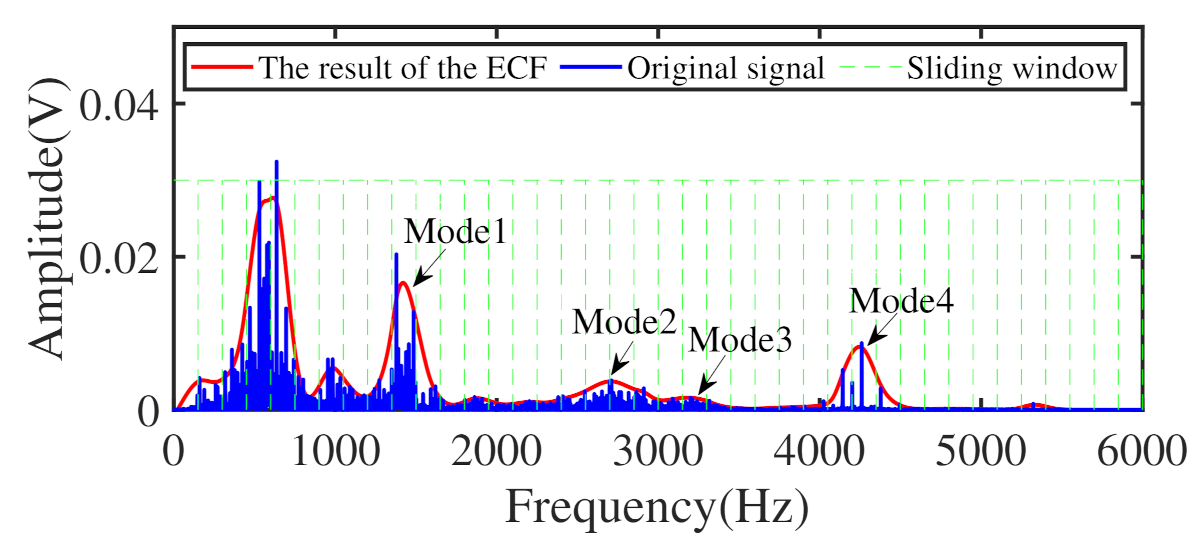

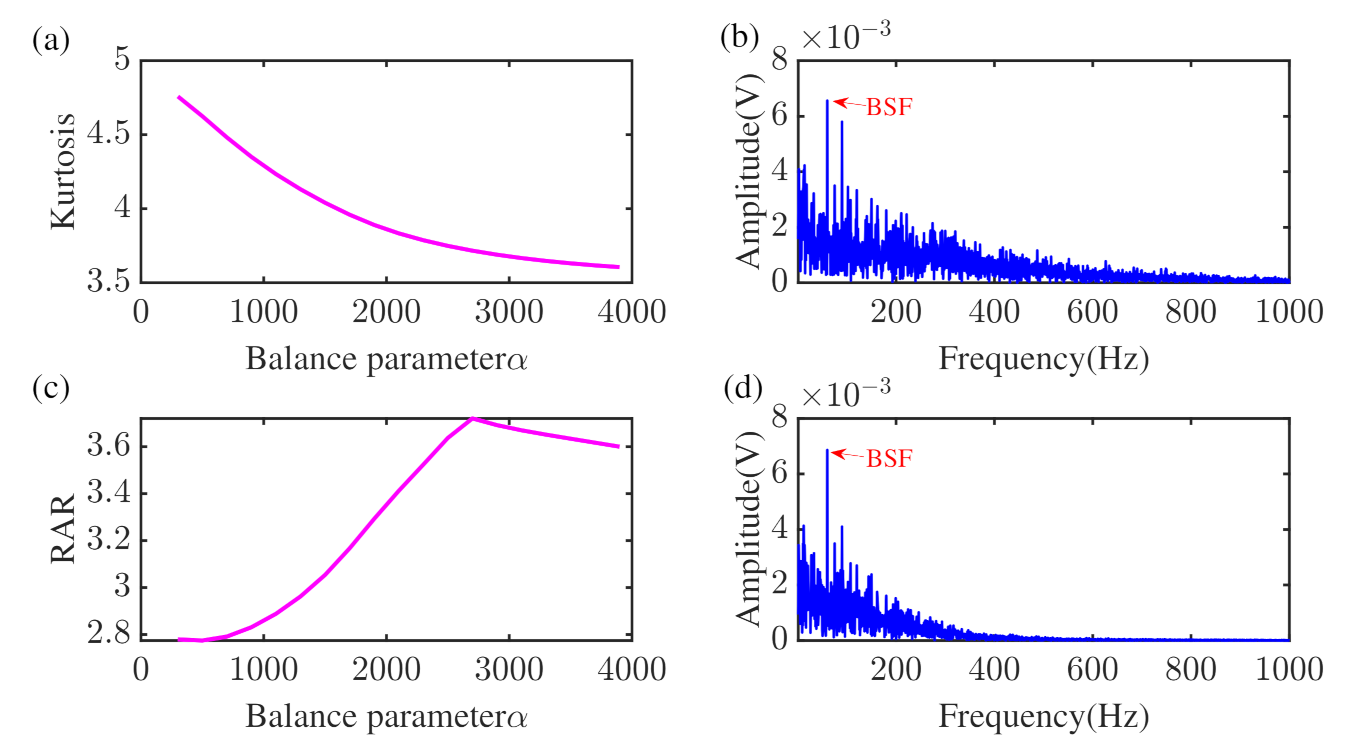

- A spectrum segmentation method called envelope curve fitting (ECF) is proposed to determine the initial center frequency of the VME method, and relative amplitude ratio (RAR) index is used to optimize the balance parameter.

- (3)

- The proposed method has been verified on different test benches and compared with other methods, which proves the effectiveness of the proposed method.

2. Underlying Theory

2.1. Basic Principle of VME

2.2. Envelope Curve Fitting (ECF) and Relative Amplitude Ratio (RAR)

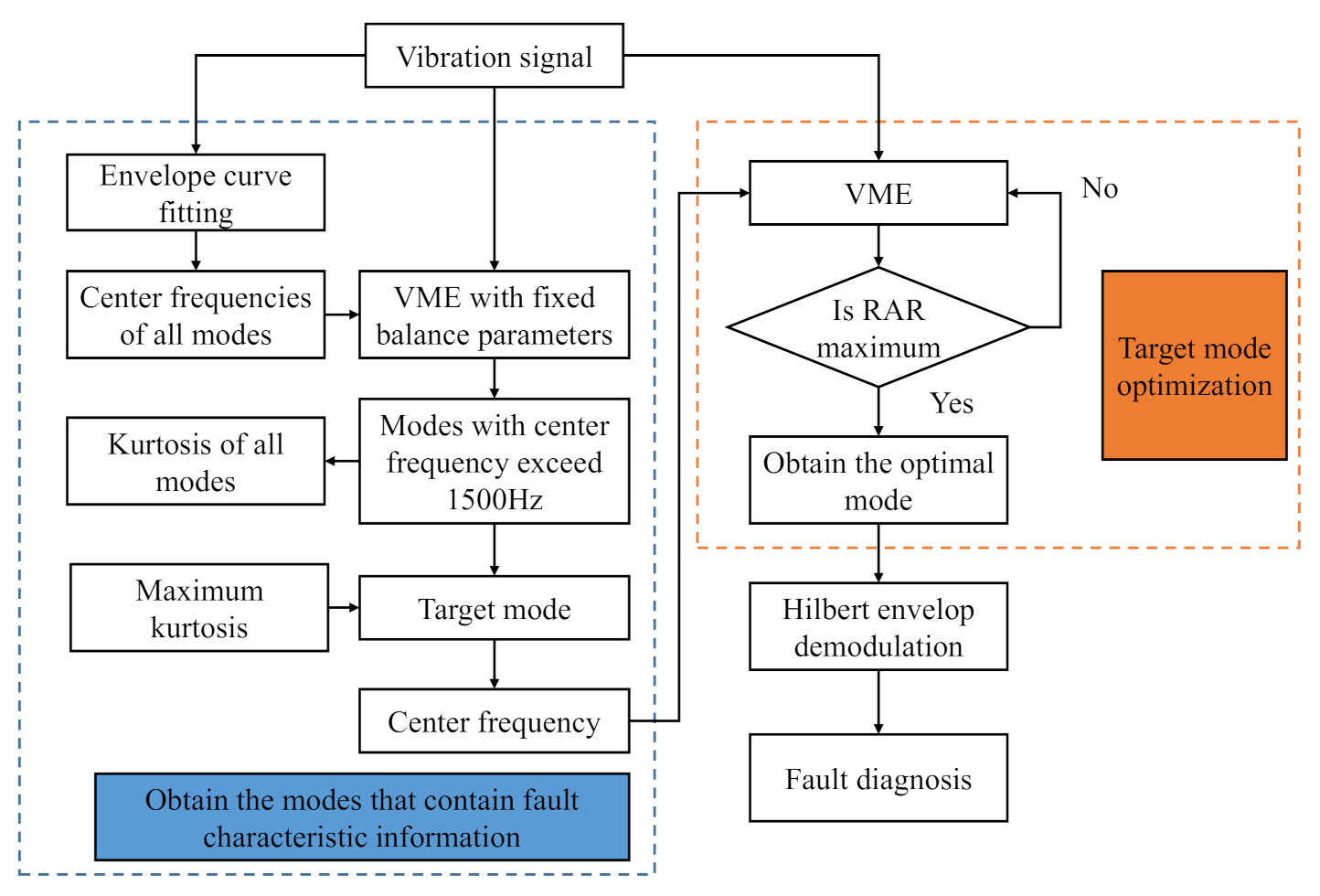

3. The Flow Chart of the Proposed Method

- (1)

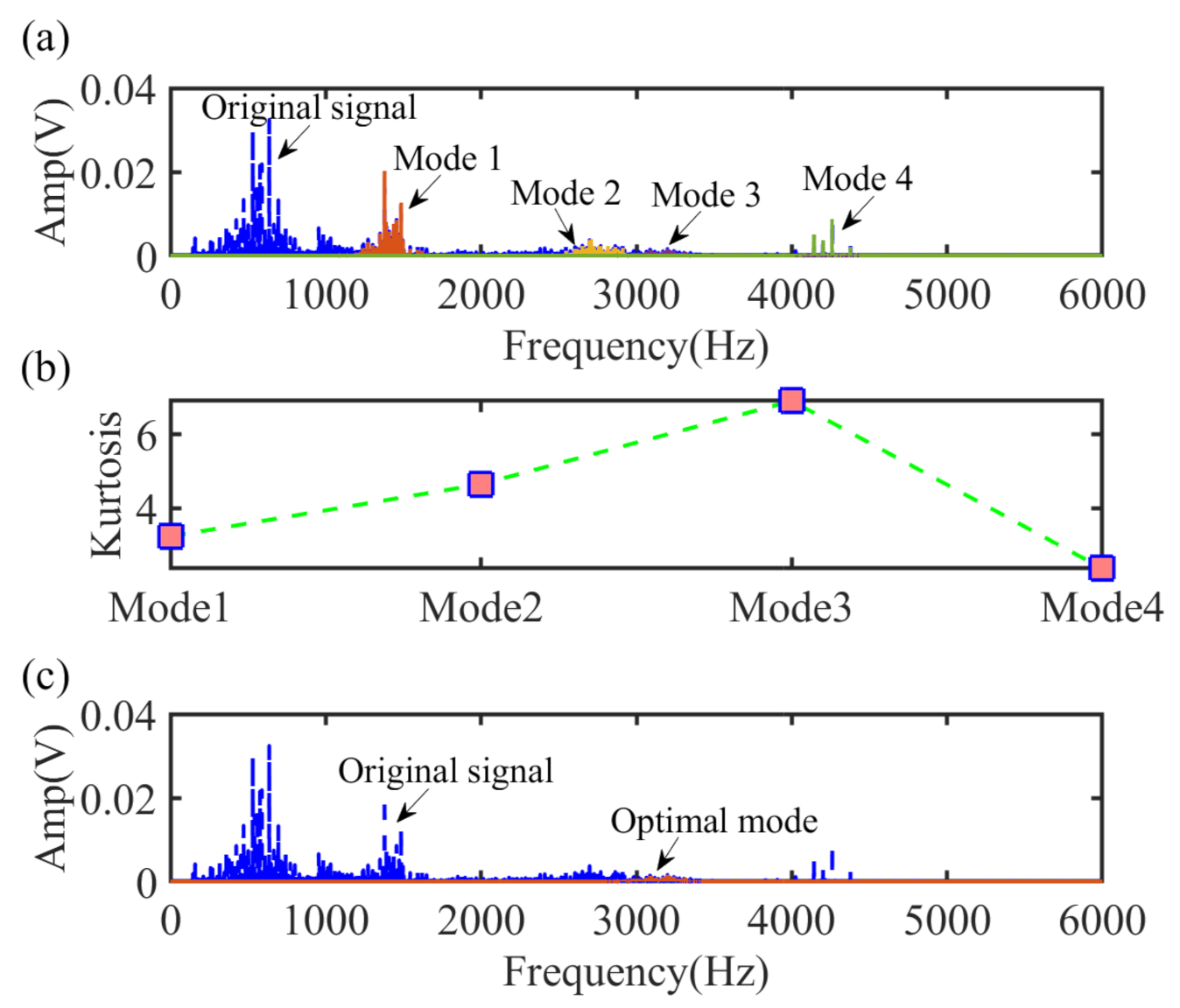

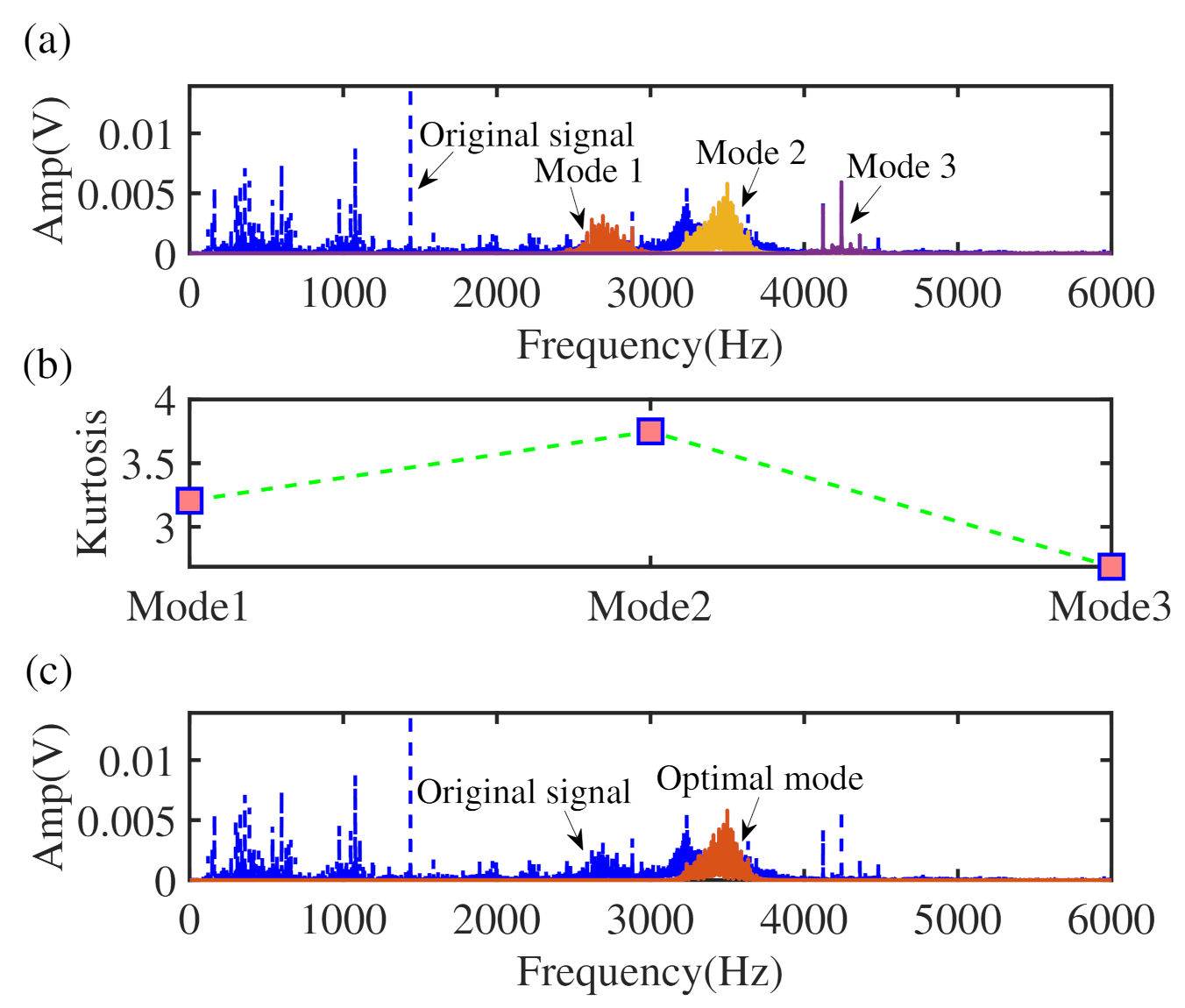

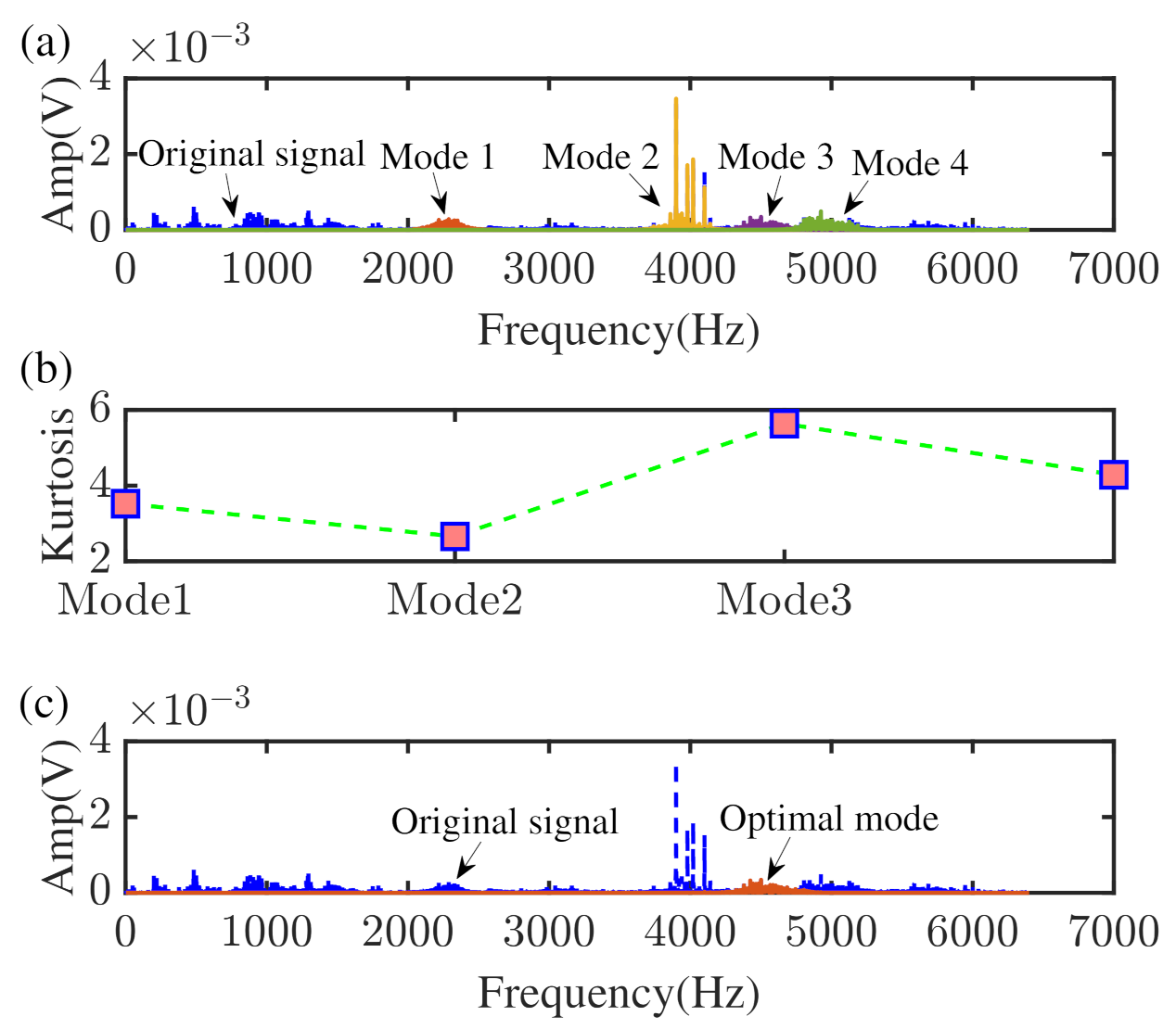

- Obtain the mode containing fault feature information. First, ECF is performed on the collected vibration data to obtain the center frequencies of principal modes above 1500 Hz. Next, with a fixed balance parameter, VME is used to extract modes that may contain fault feature information and choose the mode with the highest kurtosis value as the target mode.

- (2)

- Target mode optimization. The balance parameter is adjusted by maximizing the RAR index to obtain the optimal mode.

- (3)

- Hilbert envelope demodulation. Demodulate the mode from the adaptive VME method and identify the practical fault characteristic frequency.

- (4)

- Fault diagnosis. The machine health state is judged by identifying the fault characteristic frequency.

4. Experimental Verification

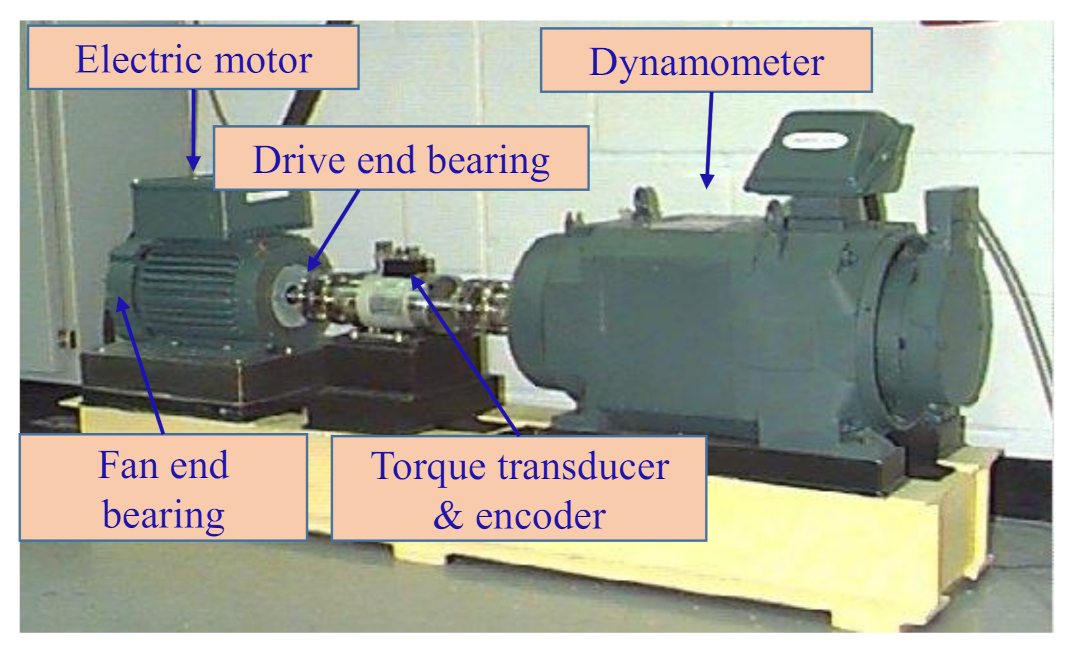

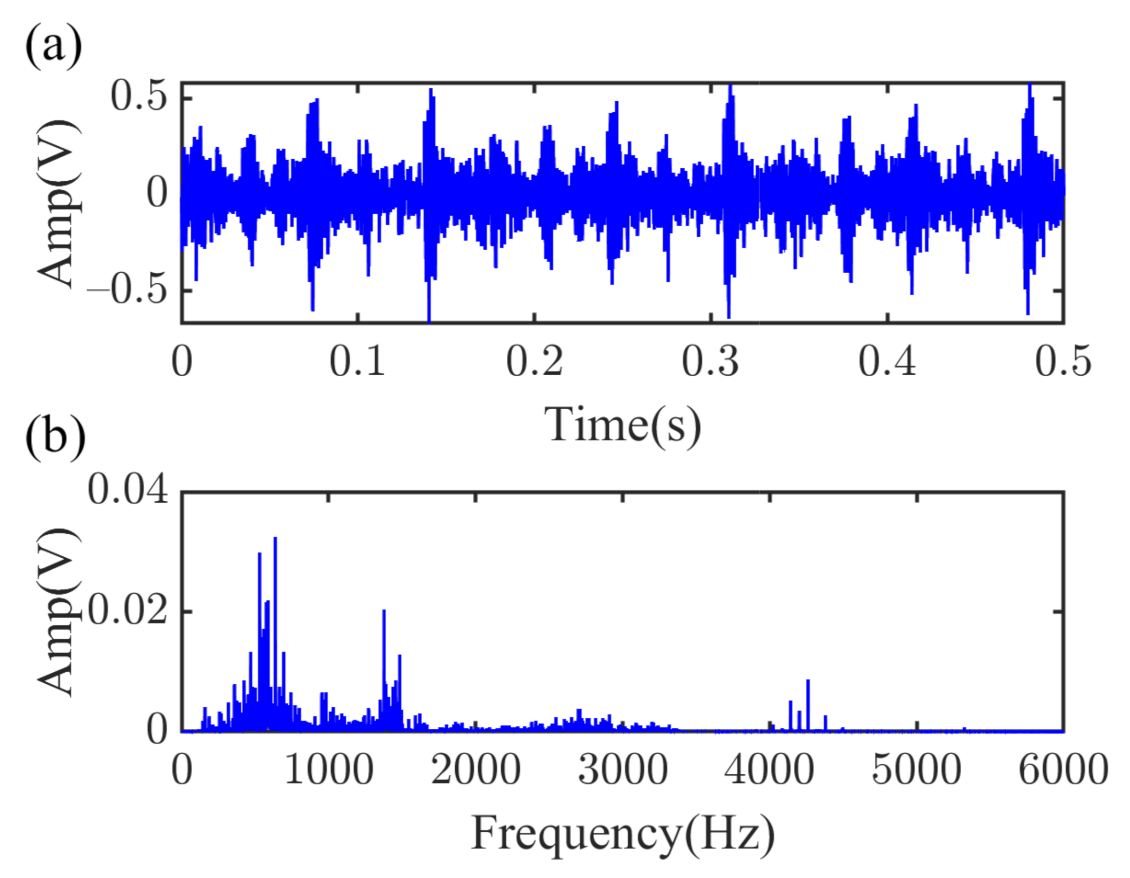

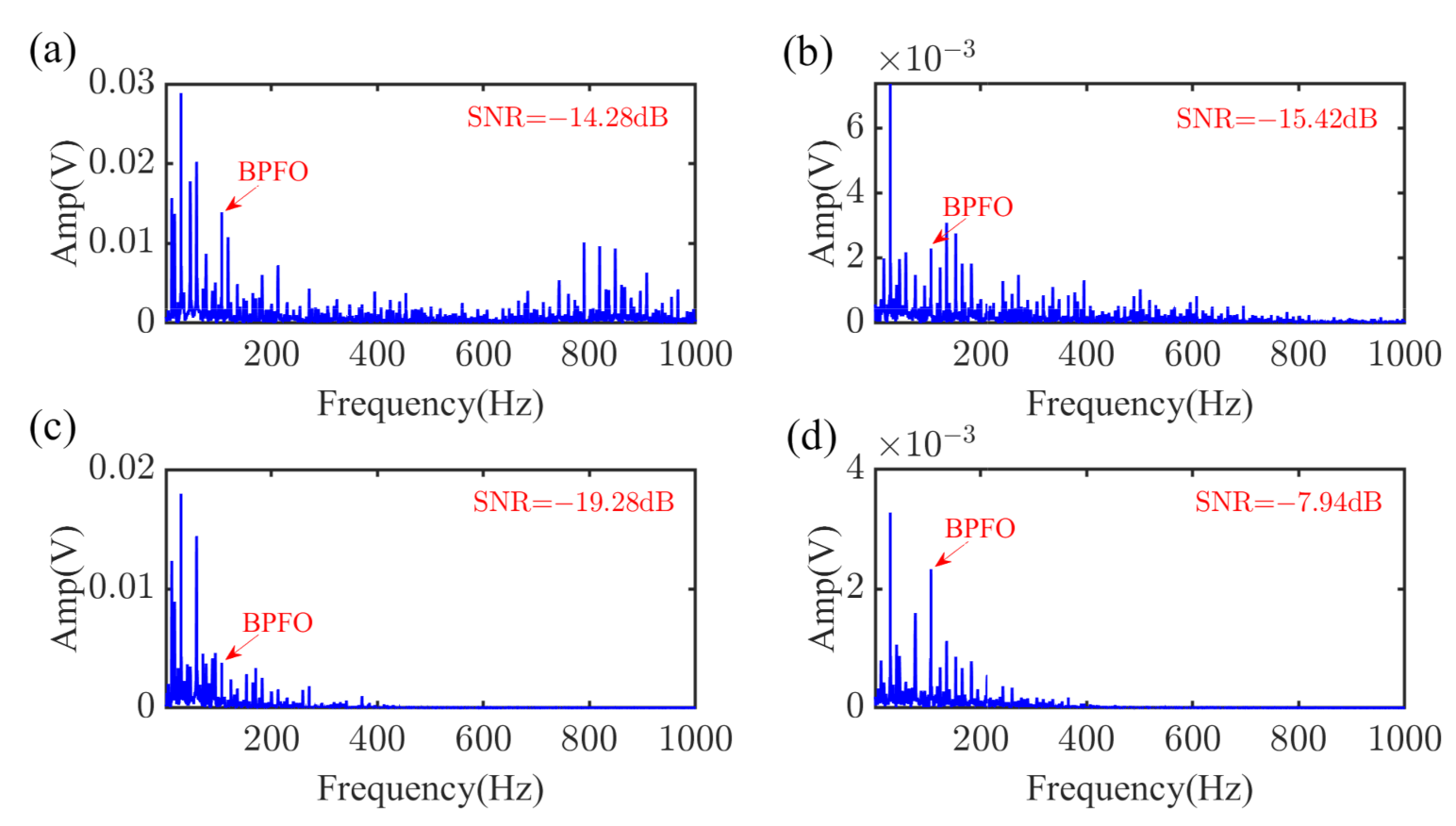

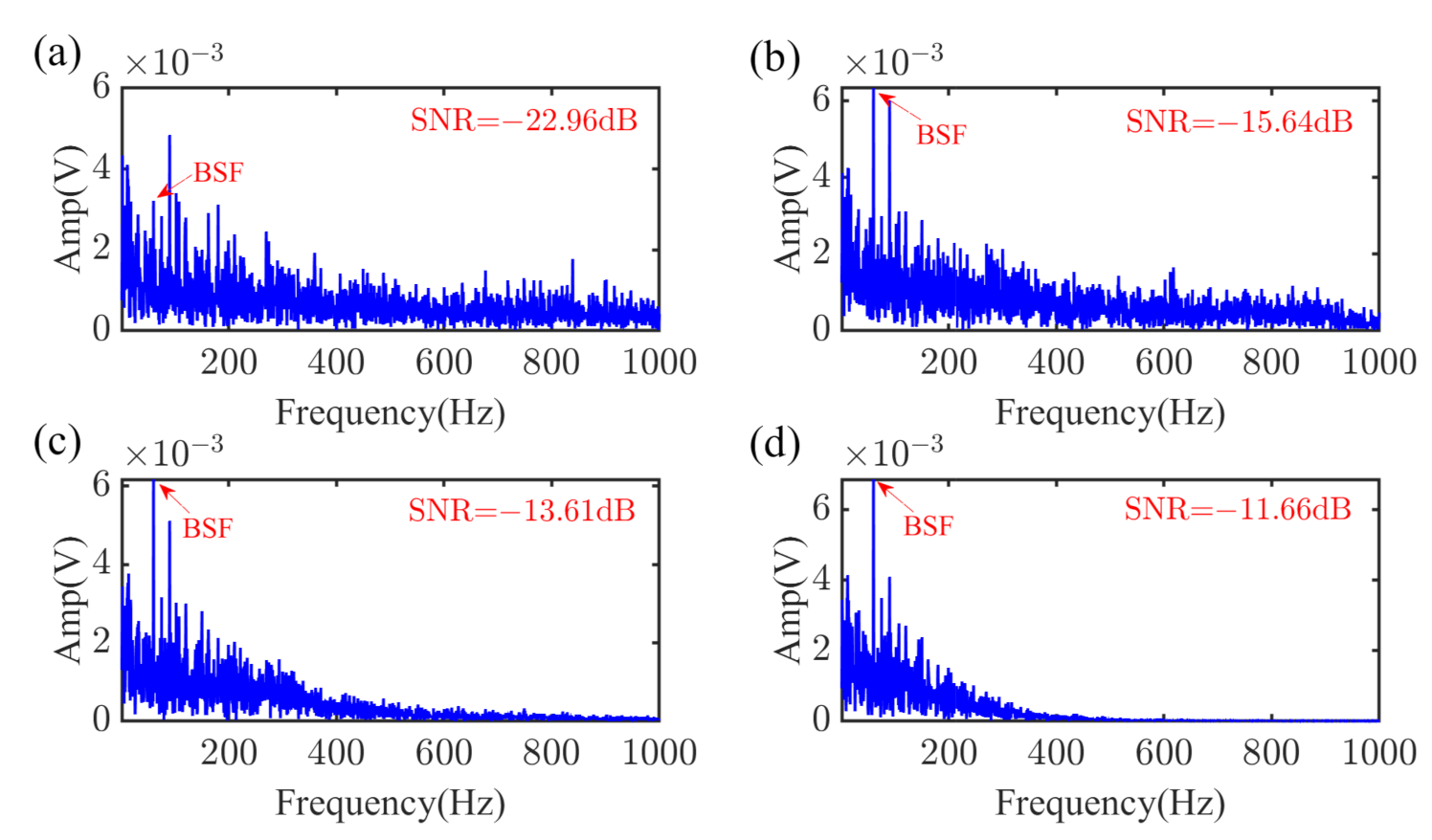

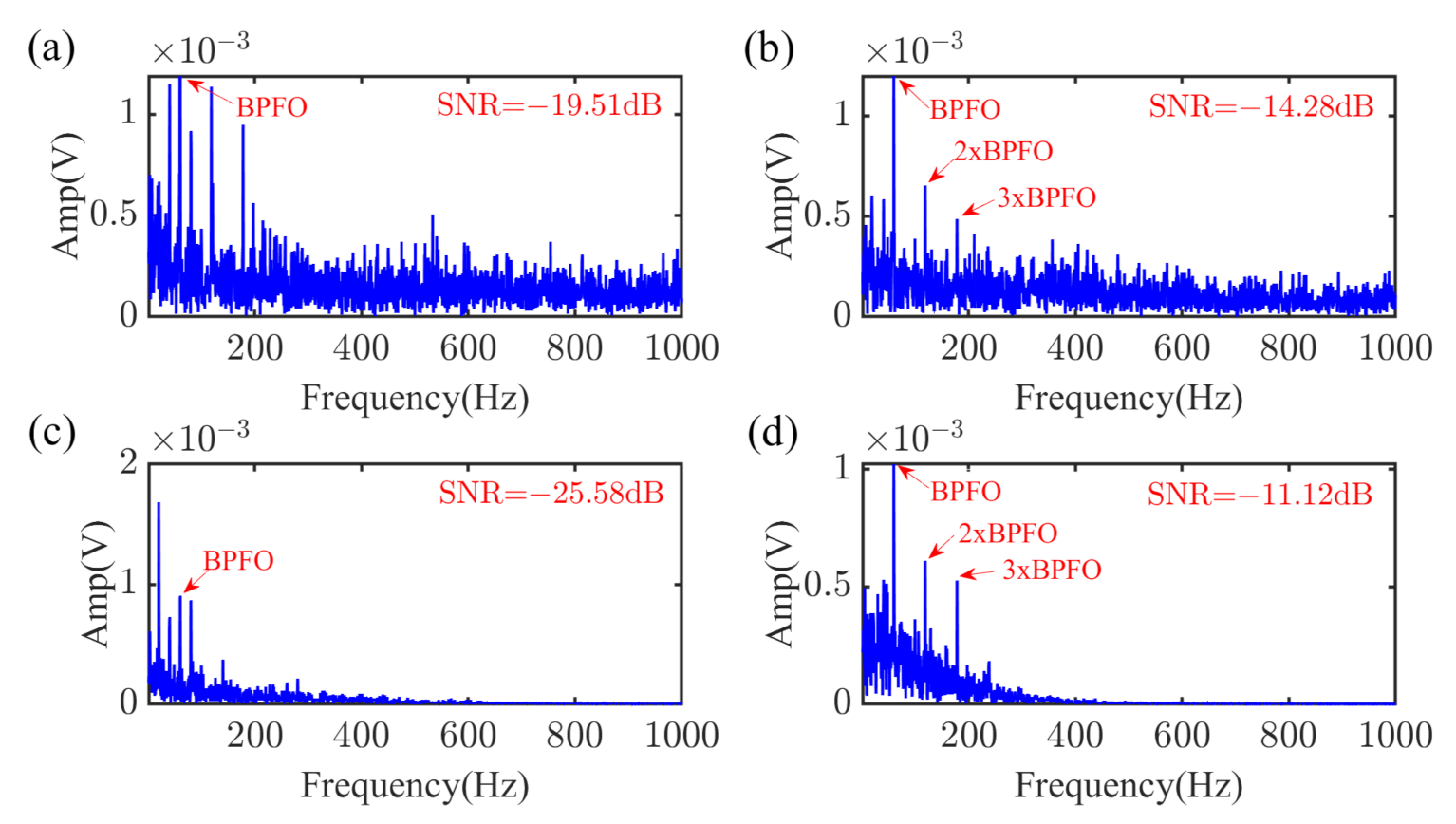

4.1. The Rolling Element Bearings Data from CWRU

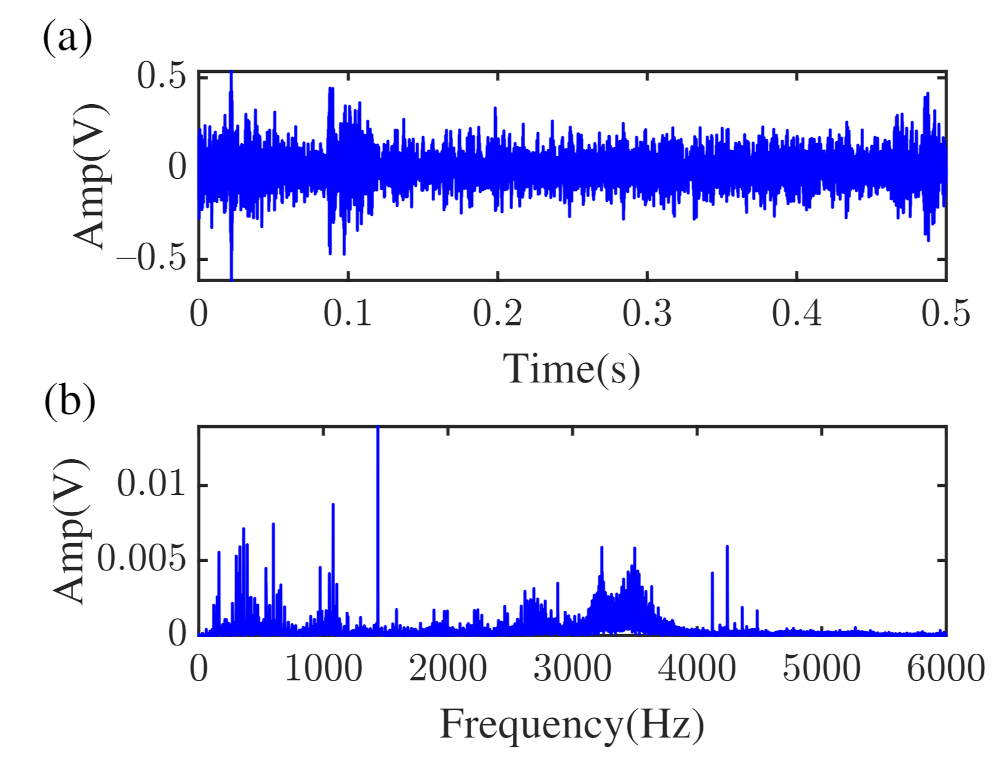

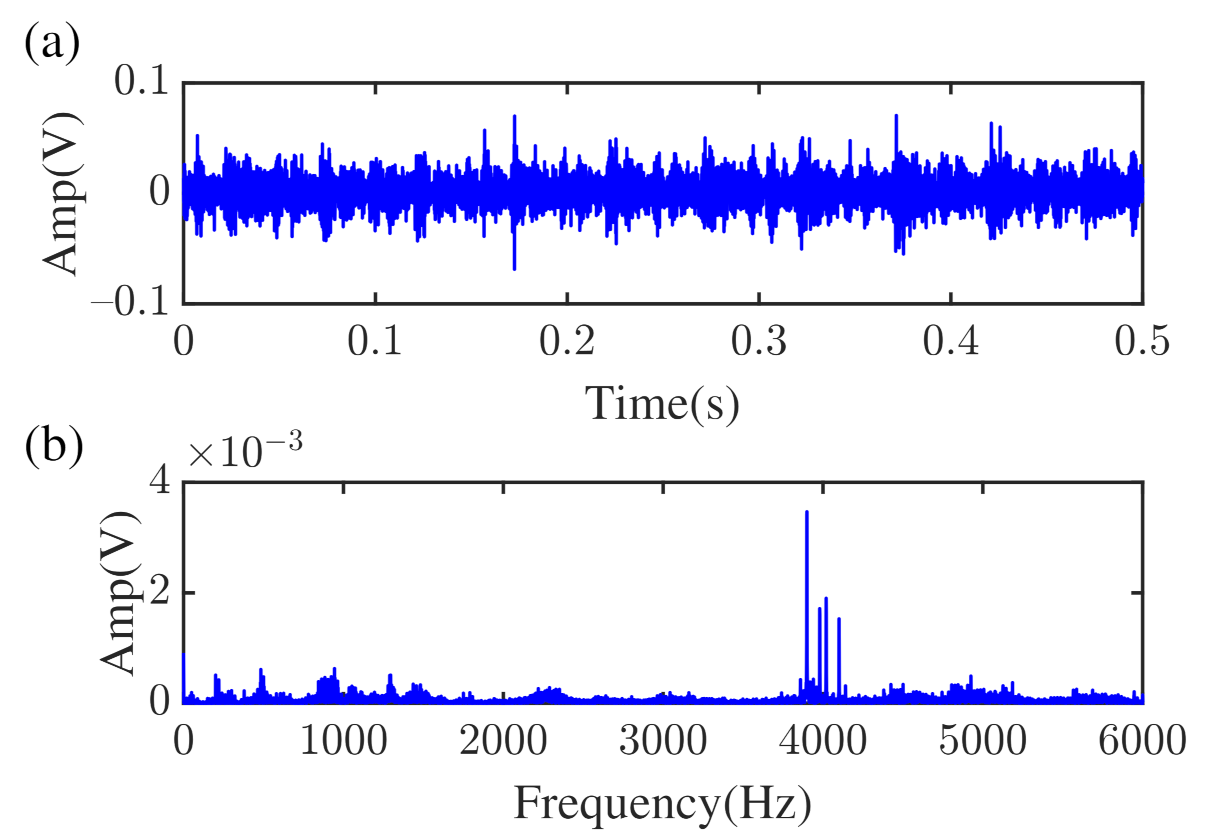

4.2. Vibration Data Collected from TRDT Test Stand

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| VME | Variational Mode Extraction |

| VMD | Variational Mode Decomposition |

| ECF | Envelope Curve Fitting |

| RAR | Relative Amplitude Ratio |

| CWRU | Case Western Reserve University |

| TRDT | Tail Rotor Drive Train |

| BPFI | Ball Pass Frequency, Inner Race |

| BPFO | Ball Pass Frequency, Outer Race |

| BSF | Ball (Roller) Spin Frequency |

References

- Randall, R.B.; Antoni, J. Rolling element bearing diagnostics—A tutorial. Mech. Syst. Signal Process. 2011, 25, 485–520. [Google Scholar] [CrossRef]

- Duan, Z.; Wu, T.; Guo, S.; Shao, T.; Malekian, R.; Li, Z. Development and trend of condition monitoring and fault diagnosis of multi-sensors information fusion for rolling bearings: A review. Int. J. Adv. Manuf. Technol. 2018, 96, 803–819. [Google Scholar] [CrossRef] [Green Version]

- Cong, F.; Chen, J.; Dong, G.; Pecht, M. Vibration model of rolling element bearings in a rotor-bearing system for fault diagnosis. J. Sound Vib. 2013, 332, 2081–2097. [Google Scholar] [CrossRef]

- Zhang, B.; Miao, Y.; Lin, J.; Li, H. Weighted envelope spectrum based on the spectral coherence for bearing diagnosis. ISA Trans. 2021. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Yang, B.; Wang, X.; Zhang, L. Acoustic emission analysis for wind turbine blade bearing fault detection under time-varying low-speed and heavy blade load conditions. IEEE Trans. Ind. Appl. 2021, 57, 2791–2800. [Google Scholar] [CrossRef]

- Golafshan, R.; Sanliturk, K.Y. Svd and hankel matrix based de-noising approach for ball bearing fault detection and its assessment using artificial faults. Mech. Syst. Signal Process. 2016, 70–71, 36–50. [Google Scholar] [CrossRef]

- Miao, Y.; Wang, J.; Zhang, B.; Li, H. Practical framework of gini index in the application of machinery fault feature extraction. Mech. Syst. Signal Process. 2022, 165, 108333. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhang, Y.; Tang, J.; Lin, J.; He, L.; Yi, C. Blind deconvolution technique based on improved correlated generalized lp/lq norm for extracting repetitive transient feature. IEEE Trans. Instrum. Meas. 2021, 70, 1–21. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, J.; Du, W.; Lei, Y.; Wang, J. Bearing fault diagnosis method based on adaptive maximum cyclostationarity blind deconvolution. Mech. Syst. Signal Process. 2022, 162, 108018. [Google Scholar] [CrossRef]

- Ni, Q.; Ji, J.; Feng, K.; Halkon, B. A novel correntropy-based band selection method for the fault diagnosis of bearings under fault-irrelevant impulsive and cyclostationary interferences. Mech. Syst. Signal Process. 2021, 153, 107498. [Google Scholar] [CrossRef]

- Schmidt, S.; Gryllias, K.C. Combining an optimisation-based frequency band identification method with historical data for novelty detection under time-varying operating conditions. Measurement 2021, 169, 108517. [Google Scholar] [CrossRef]

- Schmidt, S.; Mauricio, A.; Heyns, P.S.; Gryllias, K.C. A methodology for identifying information rich frequency bands for diagnostics of mechanical components-of-interest under time-varying operating conditions. Mech. Syst. Signal Process. 2020, 142, 106739. [Google Scholar] [CrossRef]

- Zhou, W.; Feng, Z.; Xu, Y.; Wang, X.; Lv, H. Empirical fourier decomposition: An accurate signal decomposition method for nonlinear and non-stationary time series analysis. Mech. Syst. Signal Process. 2022, 163, 108155. [Google Scholar] [CrossRef]

- He, X.; Zhou, X.; Yu, W.; Hou, Y.; Mechefske, C.K. Adaptive variational mode decomposition and its application to multi-fault detection using mechanical vibration signals. ISA Trans. 2021, 111, 360–375. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Cheng, X.; Li, Q.; Meng, Z. Adaptive energy-constrained variational mode decomposition based on spectrum segmentation and its application in fault detection of rolling bearing. Signal Process. 2021, 183, 108025. [Google Scholar] [CrossRef]

- Cheng, H.; Kong, X.; Chen, G.; Wang, Q.; Wang, R. Transferable convolutional neural network based remaining useful life prediction of bearing under multiple failure behaviors. Measurement 2021, 168, 108286. [Google Scholar] [CrossRef]

- Lu, S.; He, Q.; Wang, J. A review of stochastic resonance in rotating machine fault detection. Mech. Syst. Signal Process. 2018, 116, 230–260. [Google Scholar] [CrossRef]

- Chen, X.H.; Cheng, G.; Shan, X.L.; Hu, X.; Guo, Q.; Liu, H.G. Research of weak fault feature information extraction of planetary gear based on ensemble empirical mode decomposition and adaptive stochastic resonance. Measurement 2015, 73, 55–67. [Google Scholar] [CrossRef]

- Li, J.; Li, M.; Zhang, J. Rolling bearing fault diagnosis based on time-delayed feedback monostable stochastic resonance and adaptive minimum entropy deconvolution. J. Sound Vib. 2017, 401, 139–151. [Google Scholar] [CrossRef]

- Dhamande, L.S.; Chaudhari, M.B. Compound gear-bearing fault feature extraction using statistical features based on time-frequency method. Measurement 2018, 125, 63–77. [Google Scholar] [CrossRef]

- Feng, Z.; Liang, M.; Chu, F. Recent advances in time–frequency analysis methods for machinery fault diagnosis: A review with application examples. Mech. Syst. Signal Process. 2013, 38, 165–205. [Google Scholar] [CrossRef]

- Dong, G.; Chen, J.; Zhao, F. A frequency-shifted bispectrum for rolling element bearing diagnosis. J. Sound Vib. 2015, 339, 396–418. [Google Scholar] [CrossRef]

- Chen, B.; Yin, P.; Gao, Y.; Peng, F. Use of the correlated eemd and time-spectral kurtosis for bearing defect detection under large speed variation—Sciencedirect. Mech. Mach. Theory 2018, 129, 162–174. [Google Scholar] [CrossRef]

- Mohanty, S.; Gupta, K.K.; Raju, K.S. Hurst based vibro-acoustic feature extraction of bearing using emd and vmd. Measurement 2017, 117, 200–220. [Google Scholar] [CrossRef]

- Li, Y.; Xu, M.; Wang, R.; Huang, W. A fault diagnosis scheme for rolling bearing based on local mean decomposition and improved multiscale fuzzy entropy. J. Sound Vib. 2016, 360, 277–299. [Google Scholar] [CrossRef]

- Sun, J.; Xiao, Q.; Wen, J.; Zhang, Y. Natural gas pipeline leak aperture identification and location based on local mean decomposition analysis. Measurement 2016, 79, 147–157. [Google Scholar] [CrossRef]

- Yang, Y.; Pan, H.; Ma, L.; Cheng, J. A roller bearing fault diagnosis method based on the improved itd and rrvpmcd. Measurement 2014, 55, 255–264. [Google Scholar] [CrossRef]

- He, D.; Liu, C.; Jin, Z.; Ma, R.; Chen, Y.; Shan, S. Fault diagnosis of flywheel bearing based on parameter optimization variational mode decomposition energy entropy and deep learning. Energy 2022, 239, 122108. [Google Scholar] [CrossRef]

- Dragomiretskiy, K.; Zosso, D. Variational mode decomposition. IEEE Trans. Signal Process. 2013, 62, 531–544. [Google Scholar] [CrossRef]

- Duan, J.; Wang, P.; Ma, W.; Tian, X.; Fang, S.; Cheng, Y.; Chang, Y.; Liu, H. Short-term wind power forecasting using the hybrid model of improved variational mode decomposition and correntropy long short-term memory neural network. Energy 2021, 214, 118980. [Google Scholar] [CrossRef]

- Li, H.; Liu, T.; Wu, X.; Chen, Q. An optimized vmd method and its applications in bearing fault diagnosis. Measurement 2020, 166, 108185. [Google Scholar] [CrossRef]

- Chen, G.; Yan, C.; Meng, J.; Wang, H.; Wu, L. Improved vmd-frft based on initial center frequency for early fault diagnosis of rolling element bearing. Meas. Sci. Technol. 2021, 32, 115024. [Google Scholar] [CrossRef]

- Jiang, X.; Shen, C.; Shi, J.; Zhu, Z. Initial center frequency-guided vmd for fault diagnosis of rotating machines. J. Sound Vib. 2018, 435, 36–55. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, X.; Guo, W.; Shi, J.; Zhu, Z. An enhanced vmd with the guidance of envelope negentropy spectrum for bearing fault diagnosis. Complexity 2020, 2020, 5162916. [Google Scholar] [CrossRef]

- Nazari, M.; Sakhaei, S.M. Variational mode extraction: A new efficient method to derive respiratory signals from ecg. IEEE J. Biomed. Health Inform. 2017, 22, 1059–1067. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, C.; Fu, W.; Liu, J.; Chen, H. A modified variational mode decomposition method based on envelope nesting and multi-criteria evaluation. J. Sound Vib. 2019, 468, 115099. [Google Scholar] [CrossRef]

- Li, J.; Chen, X.; He, Z. Adaptive stochastic resonance method for impact signal detection based on sliding window. Mech. Syst. Signal Process. 2013, 36, 240–255. [Google Scholar] [CrossRef]

- Yang, J.; Huang, D.; Zhou, D.; Liu, H. Optimal imf selection and unknown fault feature extraction for rolling bearings with different defect modes. Measurement 2020, 157, 107660. [Google Scholar] [CrossRef]

- Pang, B.; Nazari, M.; Tang, G. Recursive variational mode extraction and its application in rolling bearing fault diagnosis. Mech. Syst. Signal Process. 2022, 165, 108321. [Google Scholar] [CrossRef]

- Smith, W.A.; Randall, R.B. Rolling element bearing diagnostics using the case western reserve university data: A benchmark study. Mech. Syst. Signal Process. 2015, 64–65, 100–131. [Google Scholar] [CrossRef]

| Bearings Type | Pitch Diameter D/mm | Roller Diameter d/mm | Number of Roller | Contact Angle |

|---|---|---|---|---|

| 6200 | 20 | 5 | 8 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Tan, J.; Huang, Z. Fault Diagnosis of Rolling Element Bearings Based on Adaptive Mode Extraction. Machines 2022, 10, 260. https://doi.org/10.3390/machines10040260

Liu C, Tan J, Huang Z. Fault Diagnosis of Rolling Element Bearings Based on Adaptive Mode Extraction. Machines. 2022; 10(4):260. https://doi.org/10.3390/machines10040260

Chicago/Turabian StyleLiu, Chuliang, Jianping Tan, and Zhonghe Huang. 2022. "Fault Diagnosis of Rolling Element Bearings Based on Adaptive Mode Extraction" Machines 10, no. 4: 260. https://doi.org/10.3390/machines10040260

APA StyleLiu, C., Tan, J., & Huang, Z. (2022). Fault Diagnosis of Rolling Element Bearings Based on Adaptive Mode Extraction. Machines, 10(4), 260. https://doi.org/10.3390/machines10040260