Design of a Hydrostatic Spindle and Its Simulation Analysis with the Application to a High Precision Internal Grinding Machine

Abstract

1. Introduction

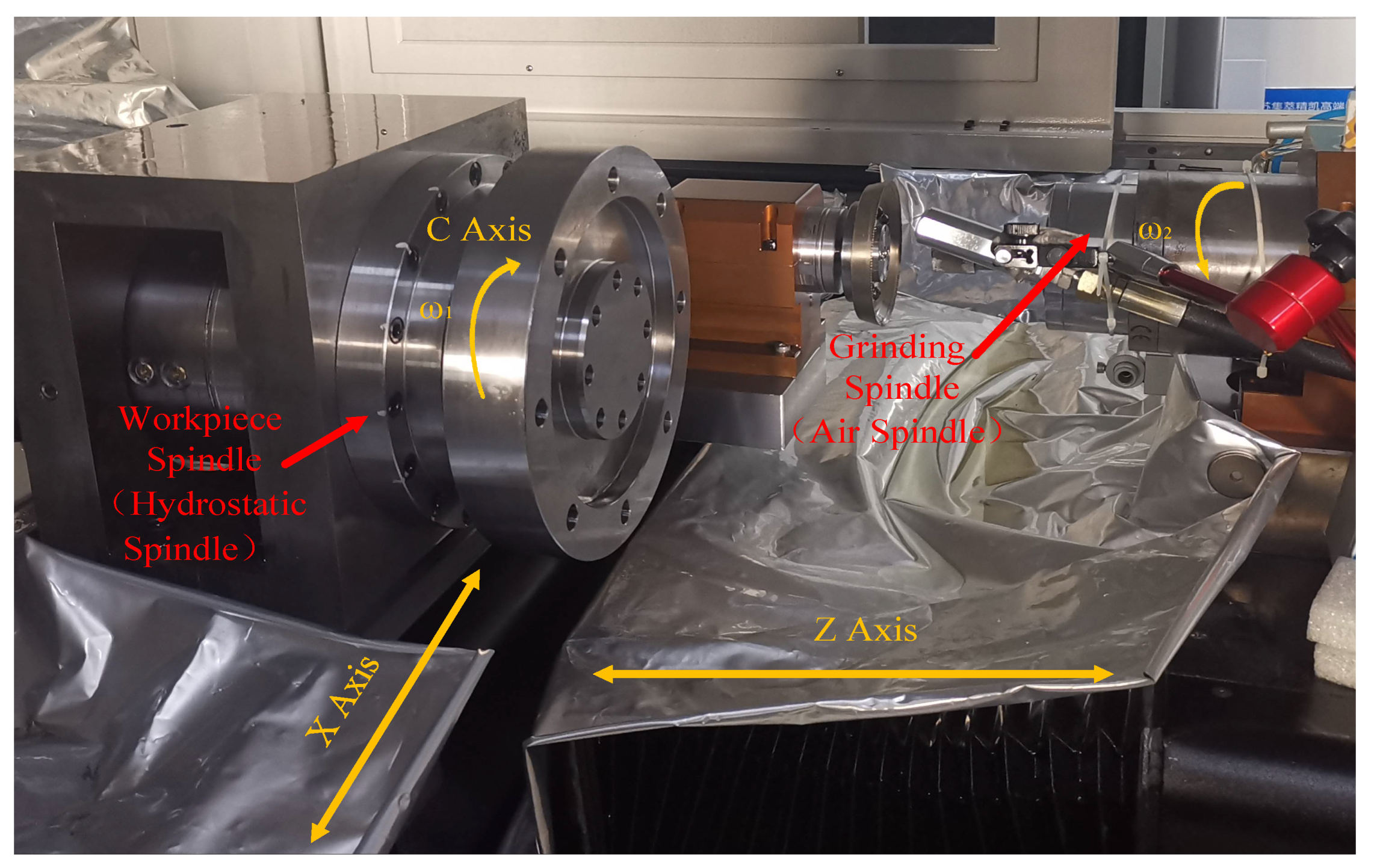

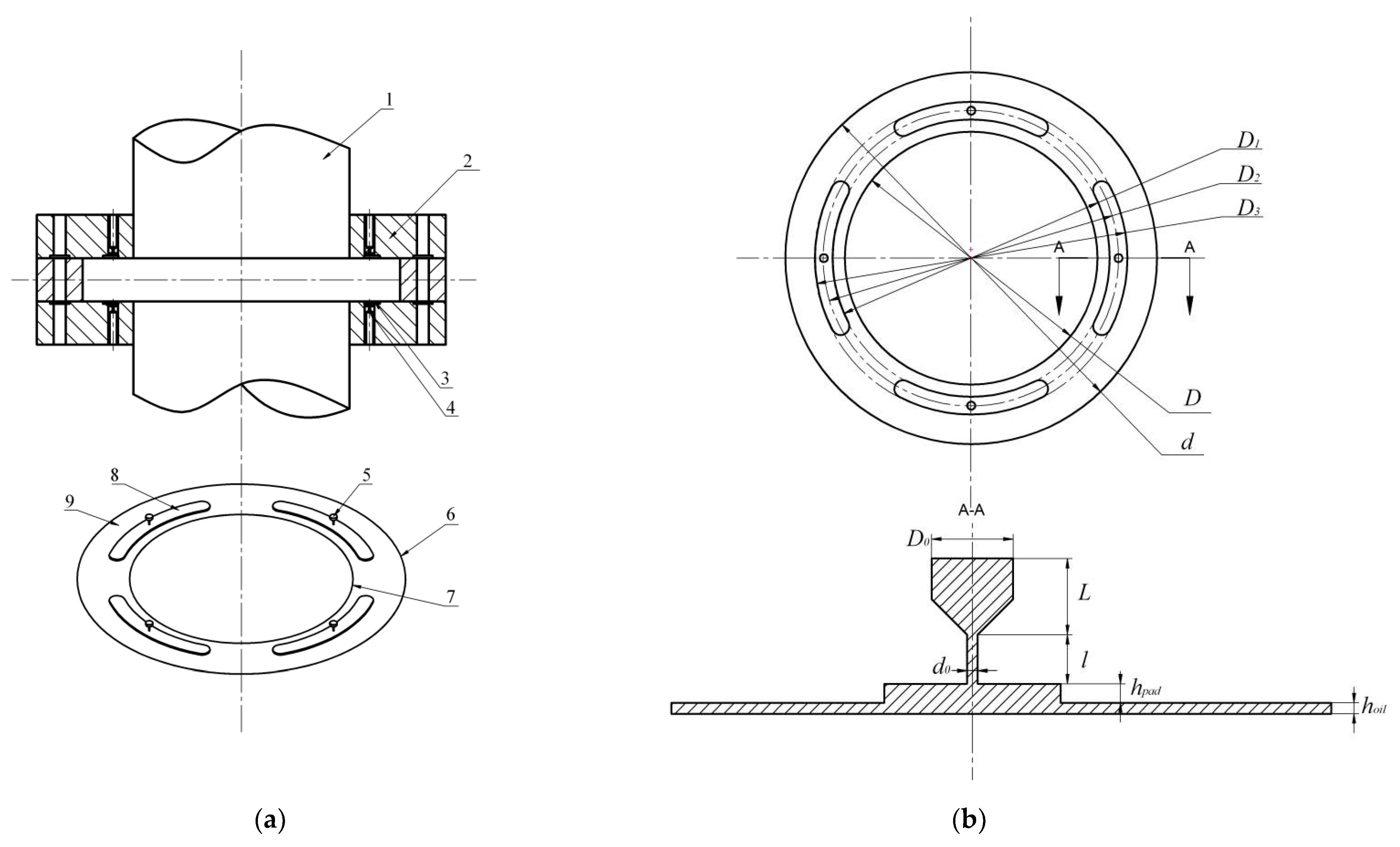

2. Design of the Hydrostatic Spindle for a High Precision Internal Grinding Machine

3. Modelling and Analysis of the Hydrostatic Bearing Spindle

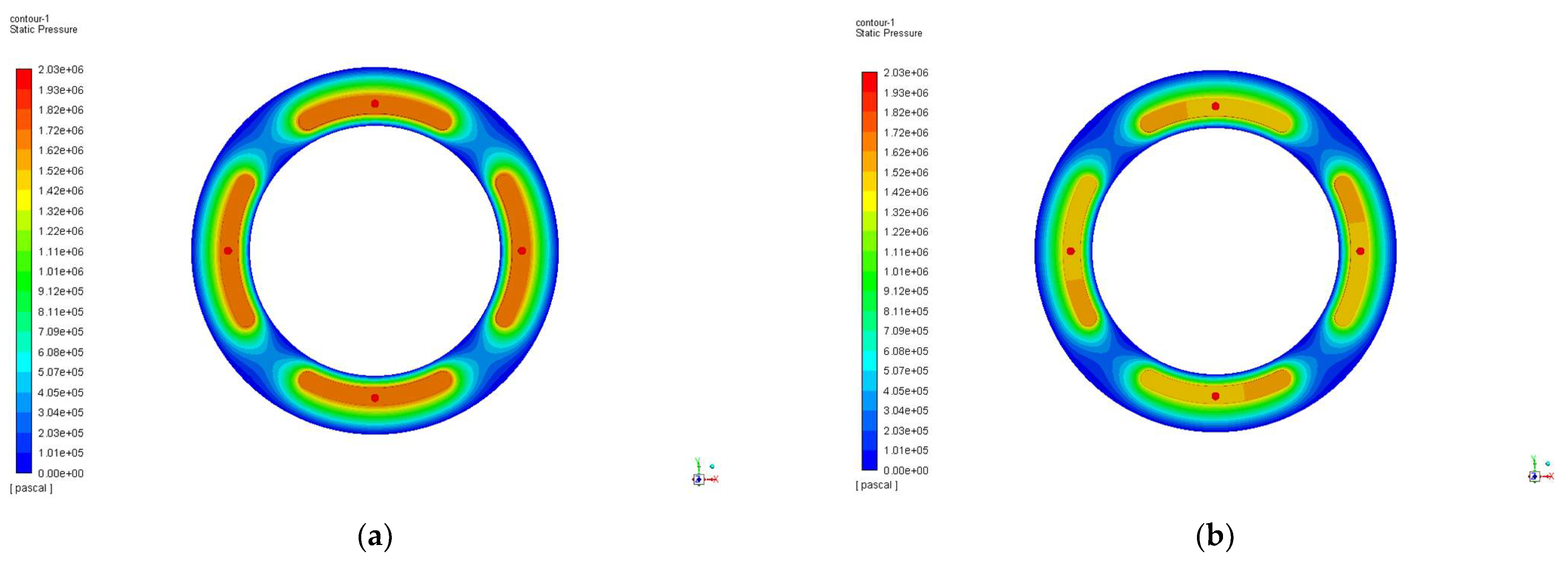

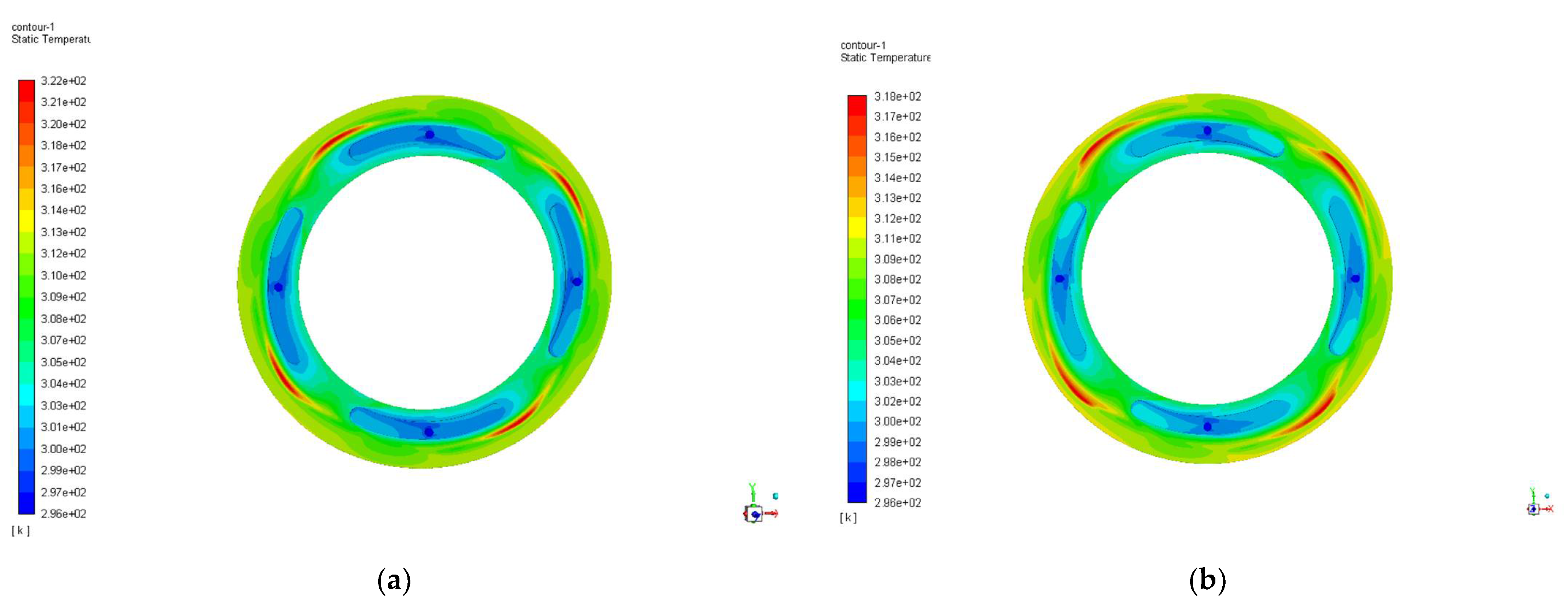

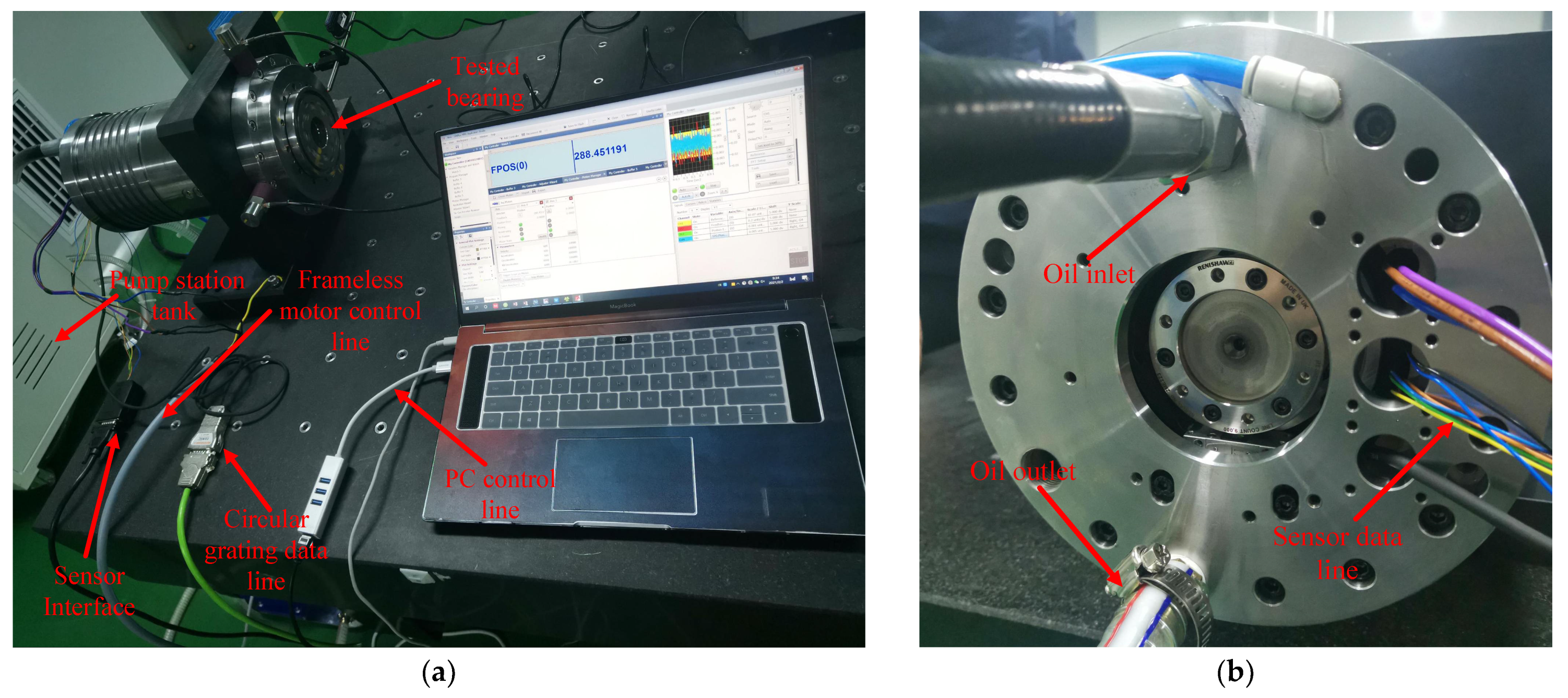

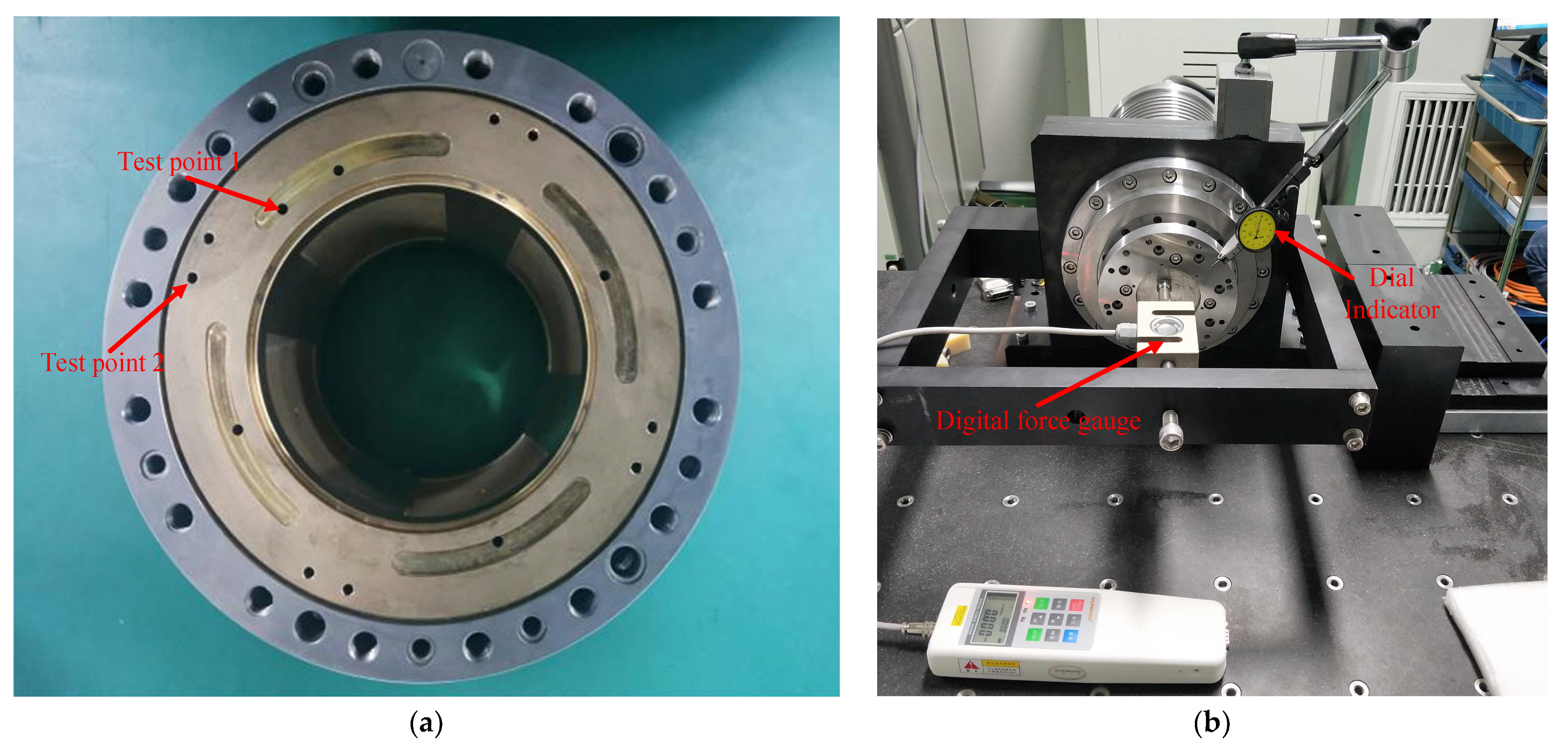

4. Simulation Development, Results and Discussion

5. Application Case Study

6. Conclusions

- (1)

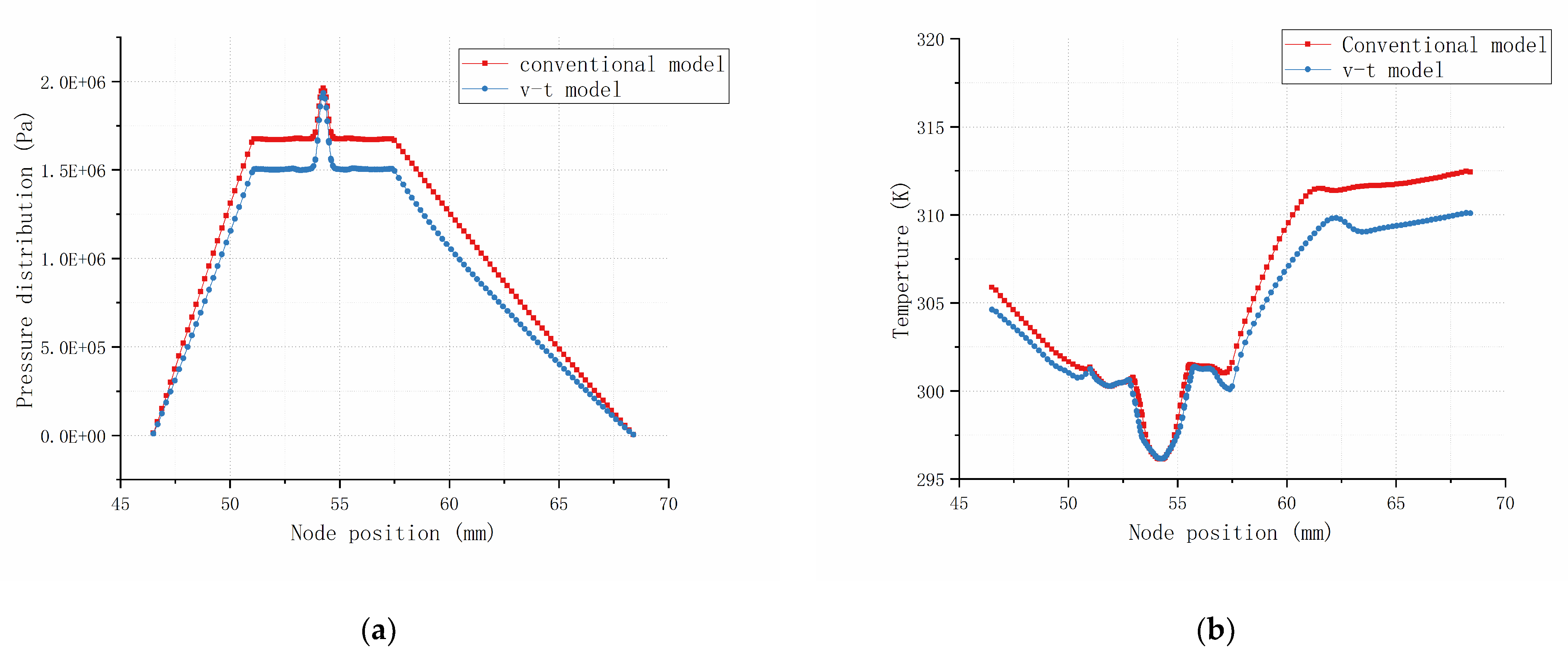

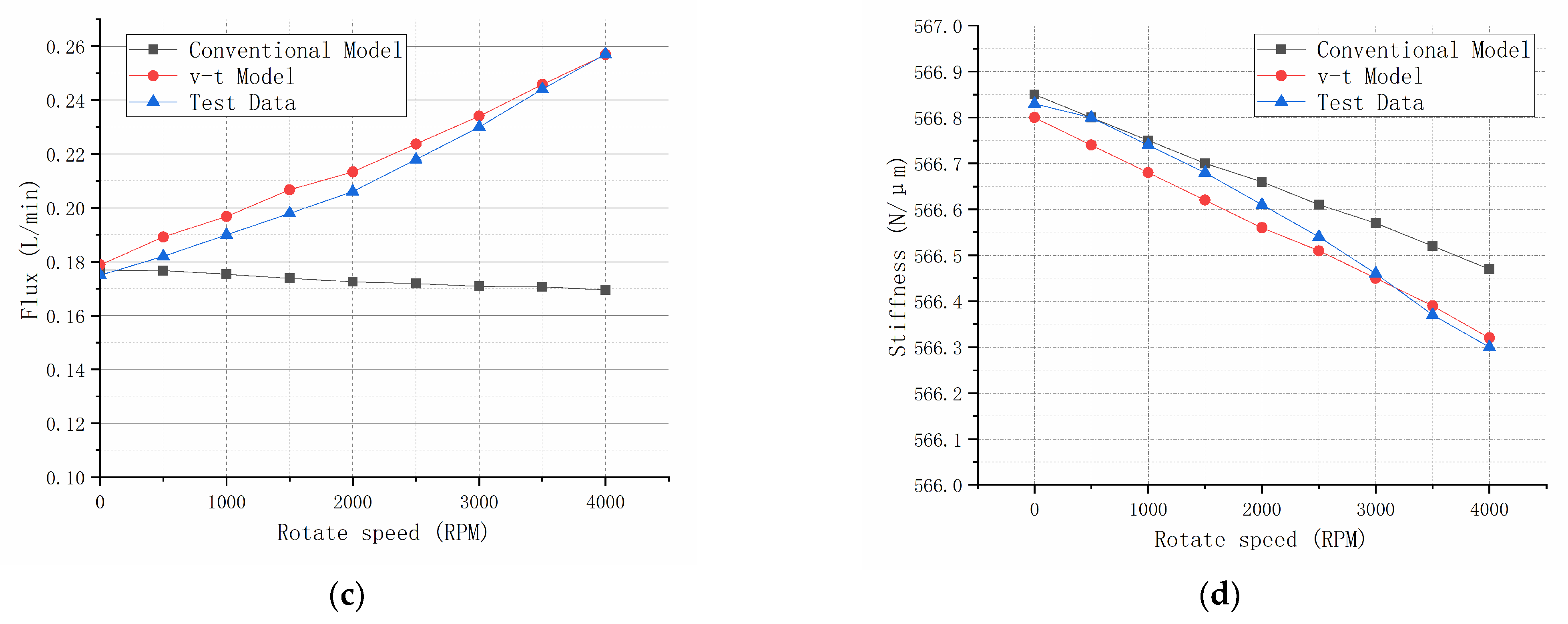

- The viscosity-temperature model plays a significant role in the accurate design and analysis of high pressure and high-speed hydrostatic bearings and the consequent spindle, particularly considering the oil supply pressure and speed are changed. The simulation results on the variation trend of temperature, bearing loading capacity and flow rate are consistent with those of the experiment.

- (2)

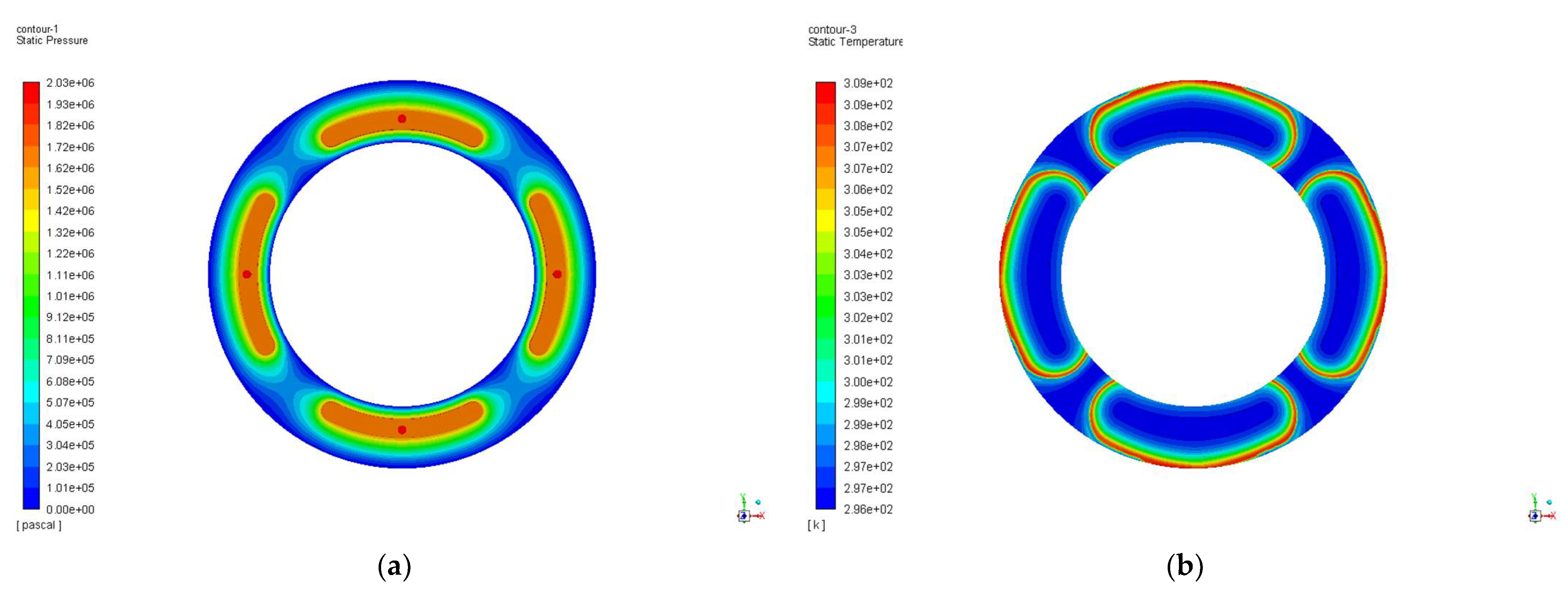

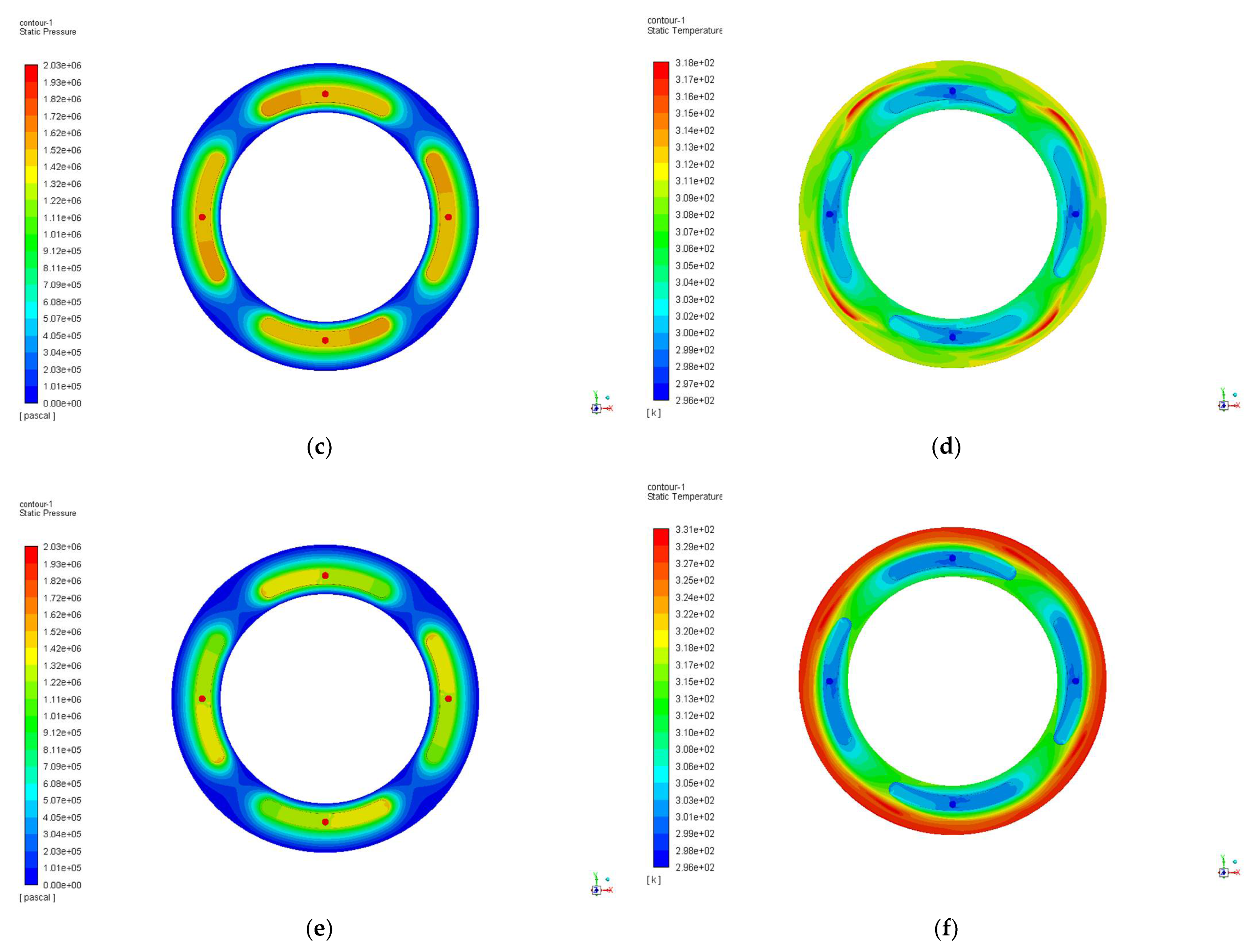

- From the overall pressure and temperature contours analysis, when the oil supply pressure is 2 MPa to change the rotating speed, the bearing capacity of the static thrust bearing deviates to one side of the oil cavity with the increase of the speed, and gradually decreases. The temperature increases with the increase of the rotating speed, and the highest temperature is generated in the outer ring of the oil outlet. When the rotating speed is 2000 r/min to change the oil supply pressure, the higher the oil supply pressure is, the more concentrated oil pressure in the oil pad increases.

- (3)

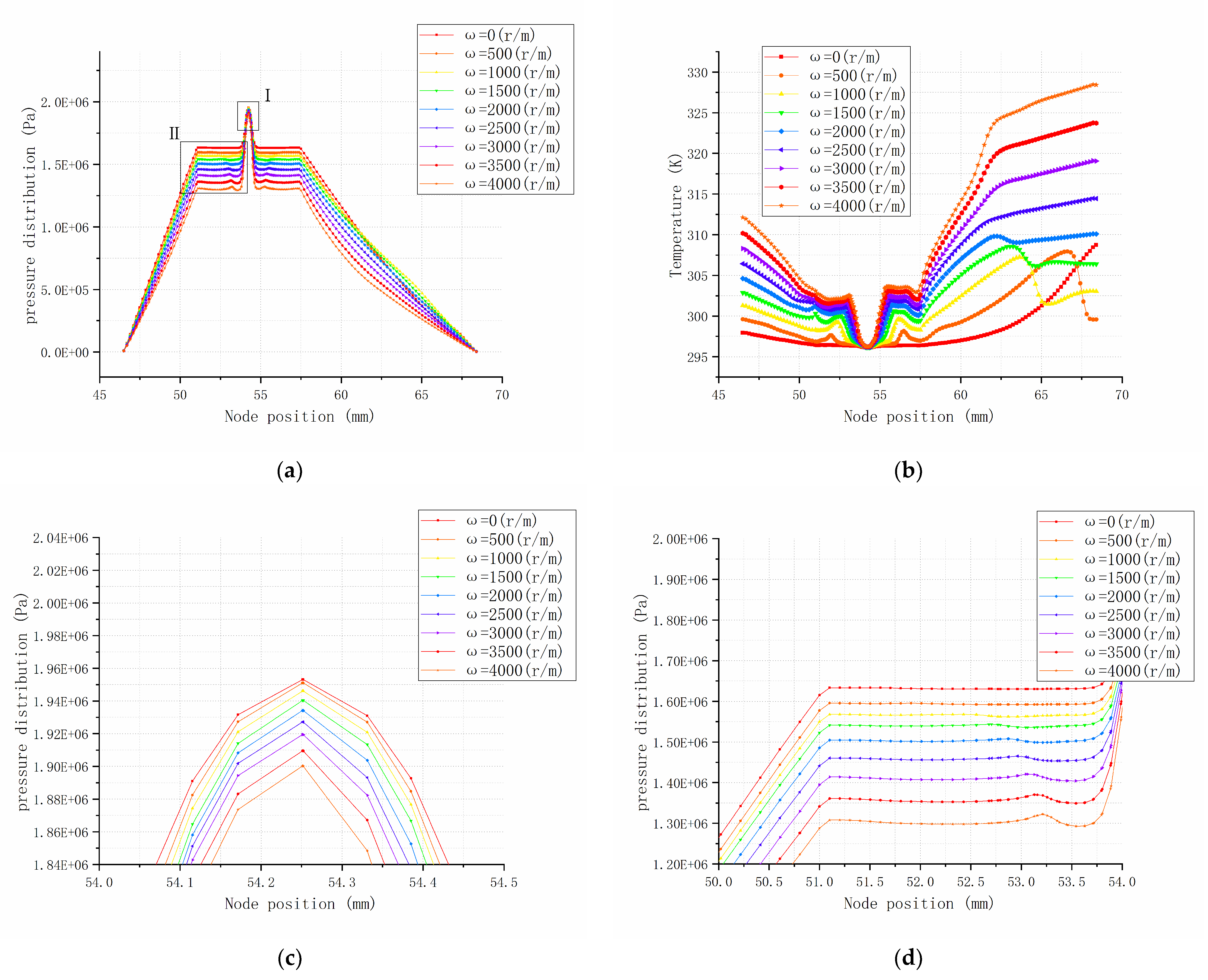

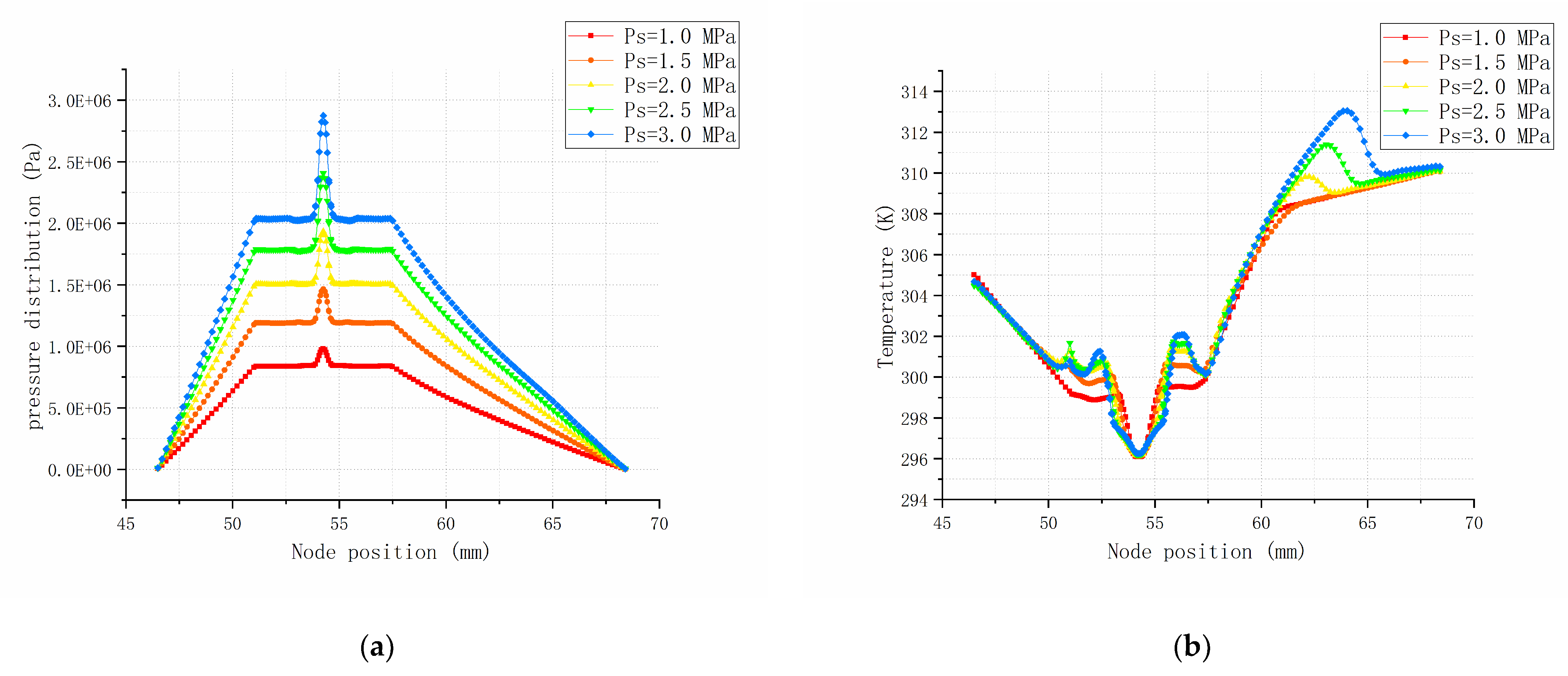

- Analysis from the A-A profile, when the oil supply pressure is 2 MPa to change the rotating speed, the pressure distribution decreases gradually from the oil orifice position through the oil pad. The higher the rotating speed, the more obvious the pressure fluctuation is near the oil pad. When the bearing spindle rotating speed is varied from 0 to 2000 r/min, the oil temperature at the outlet position has obvious fluctuation; when the rotating speed is varied from 2000 to 4000 r/min, the temperature curve tends to change gently, although the bearing working temperature increases significantly.

- (4)

- When the bearing spindle rotating speed is at 2000 r/min while changing oil supply pressure, the pressure near the orifice increases obviously, but the average pressure in the oil pad does not increase significantly. When the oil supply pressure is at 0.5 to 1.5 MPa, the bearing temperature rises gently; when the oil supply pressure is greater than 2 MPa, the temperature will fluctuate significantly at the outlet, this is the main reason for causing the decrease of oil viscosity and bearing capacity.

- (5)

- According to the position fluctuation at the oil inlet hole, four different configurations of the orifice are analyzed. Taper hole type has the lowest turbulence intensity. It can effectively reduce the pressure fluctuation, the bearing spindle temperature and improve the carrying capacity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Brinksmeier, E.; Mutlugünes, Y.; Klocke, F.; Aurich, J.C.; Shore, P.; Ohmori, H. Ultra-precision grinding. CIRP Ann. 2010, 59, 652–671. [Google Scholar] [CrossRef]

- Rowe, W.B. Hydrostatic, Aerostatic and Hybrid Bearing Design; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Chen, S.; Yang, S.; Liao, Z.; Cheung, C.F.; Jiang, Z.; Zhang, F. Curvature effect on surface topography and uniform scallop height control in normal grinding of optical curved surface considering wheel vibration. Opt Express 2021, 29, 8041. [Google Scholar] [CrossRef] [PubMed]

- Gupta, M.K.; Khan, A.M.; Song, Q.; Liu, Z.; Khalid, Q.S.; Jamil, M.; Kuntoğlu, M.; Usca, Ü.A.; Sarıkaya, M.; Pimenov, D.Y. A review on conventional and advanced minimum quantity lubrication approaches on performance measures of grinding process. Int. J. Adv. Manuf. Technol. 2021, 117, 729–750. [Google Scholar] [CrossRef]

- Zieliński, B.; Kapłonek, W.; Sutowska, M.; Nadolny, K. Analysis of a Feasibility Study of a Precision Grinding Process for Industrial Blades Used in the Cutting of Soft Tissues by a Prototype 5-Axis CNC Grinding Machine. Appl. Sci. 2019, 9, 3883. [Google Scholar] [CrossRef]

- Wu, M.; Guo, B.; Zhao, Q.; He, P. Precision grinding of a microstructured surface on hard and brittle materials by a microstructured coarse-grained diamond grinding wheel. Ceram. Int. 2018, 44, 8026–8034. [Google Scholar] [CrossRef]

- He, C.L.; Zong, W.J.; Zhang, J.J. Influencing factors and theoretical modeling methods of surface roughness in turning process: State-of-the-art. Int. J. Mach. Tools Manuf. 2018, 129, 15–26. [Google Scholar] [CrossRef]

- Urreta, H.; Aguirre, G.; Kuzhir, P.; Lopez De Lacalle, L.N. Actively lubricated hybrid journal bearings based on magnetic fluids for high-precision spindles of machine tools. J. Intell. Mater. Syst. Struct. 2019, 30, 2257–2271. [Google Scholar] [CrossRef]

- Hanoca, P.; Ramakrishna, H.V. To Investigate the Effect of Oil Film Thickness at the Entrance of the Infinitely Long Slider Bearing Using CFD Analysis. Procedia Eng. 2015, 127, 447–454. [Google Scholar] [CrossRef][Green Version]

- Zha, J.; Chen, Y.; Zhang, P. Precision design of hydrostatic thrust bearing in rotary table and spindle. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 2044–2053. [Google Scholar] [CrossRef]

- Kashchenevsky, L.; Johnson, D. Theoretical Analysis of Rotational Accuracy for Thrust Hydrostatic Bearings. In Proceedings of ASPE Summer Topical Meeting on Precision Bearings and Spindles, State College, PA, USA, 11–12 June 2007; pp. 7–9. [Google Scholar]

- Chen, D.; Gao, X.; Zha, C.; Pan, R.; Fan, J. Tilt Angle of Hydrostatic Spindle Influenced by Microscale Effects. Tribol. Trans. 2020, 63, 28–37. [Google Scholar] [CrossRef]

- Yadav, S.K.; Sharma, S.C. Performance of hydrostatic tilted thrust pad bearings of various recess shapes operating with non-Newtonian lubricant. Finite Elem. Anal. Des. 2014, 87, 43–55. [Google Scholar] [CrossRef]

- Hanawa, N.; Kuniyoshi, M.; Miyatake, M.; Yoshimoto, S. Static characteristics of a water-lubricated hydrostatic thrust bearing with a porous land region and a capillary restrictor. Precis. Eng. 2017, 50, 293–307. [Google Scholar] [CrossRef]

- Zha, J.; Chen, Y.; Zhang, P.; Chen, R. Effect of design parameters and operational conditions on the motion accuracy of hydrostatic thrust bearing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 1481–1491. [Google Scholar] [CrossRef]

- Ferron, J.; Frene, J.; Boncompain, R. A Study of the Thermohydrodynamic Performance of a Plain Journal Bearing Comparison between Theory and Experiments. J. Lubr. Technol. 1983, 105, 422–428. [Google Scholar] [CrossRef]

- Zouzoulas, V.; Papadopoulos, C.I. 3-D thermohydrodynamic analysis of textured, grooved, pocketed and hydrophobic pivoted-pad thrust bearings. Tribol. Int. 2017, 110, 426–440. [Google Scholar] [CrossRef]

- Horvat, F.E.; Braun, M.J. Comparative Experimental and Numerical Analysis of Flow and Pressure Fields Inside Deep and Shallow Pockets for a Hydrostatic Bearing. Tribol. Trans. 2011, 54, 548–567. [Google Scholar] [CrossRef]

- Fouflias, D.G.; Charitopoulos, A.G.; Papadopoulos, C.I.; Kaiktsis, L.; Fillon, M. Performance comparison between textured, pocket, and tapered-land sector-pad thrust bearings using computational fluid dynamics thermohydrodynamic analysis. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 376–397. [Google Scholar] [CrossRef]

- Chen, X.; He, X. The effect of the recess shape on performance analysis of the gas-lubricated bearing in optical lithography. Tribol. Int. 2006, 39, 1336–1341. [Google Scholar] [CrossRef]

- Gao, S.; Cheng, K.; Chen, S.; Ding, H.; Fu, H. CFD based investigation on influence of orifice chamber shapes for the design of aerostatic thrust bearings at ultra-high speed spindles. Tribol. Int. 2015, 92, 211–221. [Google Scholar] [CrossRef]

- Gao, S.; Shang, Y.; Gao, Q.; Lu, L.; Zhu, M.; Sun, Y.; Yu, W. CFD-Based Investigation on Effects of Orifice Length–Diameter Ratio for the Design of Hydrostatic Thrust Bearings. Appl. Sci. 2021, 11, 959. [Google Scholar] [CrossRef]

- Sharma, S.C.; Rajput, A.K. Effect of geometric imperfections of journal on the performance of micropolar lubricated 4-pocket hybrid journal bearing. Tribol. Int. 2013, 60, 156–168. [Google Scholar] [CrossRef]

- Sharma, S.C.; Yadav, S.K. A comparative study of full and partial textured hybrid orifice compensated circular thrust pad bearing system. Tribol. Int. 2016, 95, 170–180. [Google Scholar] [CrossRef]

- Eleshaky, M.E. CFD investigation of pressure depressions in aerostatic circular thrust bearings. Tribol. Int. 2009, 42, 1108–1117. [Google Scholar] [CrossRef]

- Belforte, G.; Raparelli, T.; Trivella, A.; Viktorov, V.; Visconte, C. CFD Analysis of a Simple Orifice-Type Feeding System for Aerostatic Bearings. Tribol. Lett. 2015, 58, 25. [Google Scholar] [CrossRef]

- Shao, J.; Liu, G.; Yu, X.; Zhang, Y.; Meng, X.; Jiang, H. Effect of recess depth on lubrication performance of annular recess hydrostatic thrust bearing by constant rate flow. Ind. Lubr. Tribol. 2018, 70, 68–75. [Google Scholar] [CrossRef]

- Gropper, D.; Harvey, T.J.; Wang, L. A numerical model for design and optimization of surface textures for tilting pad thrust bearings. Tribol. Int. 2018, 119, 190–207. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Hafezi, M.; Hua, M.; Dong, G. A distribution design for circular concave textures on sectorial thrust bearing pads. Tribol. Int. 2020, 149, 105733. [Google Scholar] [CrossRef]

- Cicone, T.; Marinescu, A.A.; Sorohan, S. A simple analytical model for an elastohydrostatic thrust bearing. IOP Conf. Ser. Mater. Sci. Eng. 2020, 724, 12041. [Google Scholar] [CrossRef]

- Aguirre, G.; Al-Bender, F.; Van Brussel, H. A multiphysics model for optimizing the design of active aerostatic thrust bearings. Precis. Eng. 2010, 34, 507–515. [Google Scholar] [CrossRef]

- Shang, Y.; Cheng, K.; Ding, H.; Chen, S. Multiscale Modelling and Analysis on the Heavy-duty Hydrostatic Journal Bearing for a Precision Press Machine. IOP Conf. Ser. Mater. Sci. Eng. 2020, 825, 12010. [Google Scholar] [CrossRef]

- Sharma, S.C.; Jain, S.C.; Bharuka, D.K. Influence of recess shape on the performance of a capillary compensated circular thrust pad hydrostatic bearing. Tribol. Int. 2002, 35, 347–356. [Google Scholar] [CrossRef]

- Li, Y.; Ding, H. Influences of the geometrical parameters of aerostatic thrust bearing with pocketed orifice -type restrictor on its performance. Tribol. Int. 2007, 40, 1120–1126. [Google Scholar] [CrossRef]

- Kozdera, M.; Drábková, S.; Bojko, M. Experimental equipment for measuring physical properties of the annular hydrostatic thrust bearing. EPJ Web Conf. 2014, 67, 2058. [Google Scholar] [CrossRef]

- Yu, X.; Fu, X.; Meng, X.; Liu, D.; Zhang, Y.; Wang, W. Experimental and Numerical Study on the Temperature Performance of High-Speed Circular Hydrostatic Thrust Bearing. J. Comput. Theor. Nanosci. 2015, 12, 1540–1545. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, Y.; Cheng, K.; Ding, H.; Chen, S. Design of a Hydrostatic Spindle and Its Simulation Analysis with the Application to a High Precision Internal Grinding Machine. Machines 2022, 10, 127. https://doi.org/10.3390/machines10020127

Shang Y, Cheng K, Ding H, Chen S. Design of a Hydrostatic Spindle and Its Simulation Analysis with the Application to a High Precision Internal Grinding Machine. Machines. 2022; 10(2):127. https://doi.org/10.3390/machines10020127

Chicago/Turabian StyleShang, Youyun, Kai Cheng, Hui Ding, and Shijin Chen. 2022. "Design of a Hydrostatic Spindle and Its Simulation Analysis with the Application to a High Precision Internal Grinding Machine" Machines 10, no. 2: 127. https://doi.org/10.3390/machines10020127

APA StyleShang, Y., Cheng, K., Ding, H., & Chen, S. (2022). Design of a Hydrostatic Spindle and Its Simulation Analysis with the Application to a High Precision Internal Grinding Machine. Machines, 10(2), 127. https://doi.org/10.3390/machines10020127