Sliding Mode Based Load Frequency Control and Power Smoothing of Power Systems with Wind and BESS Penetration

Abstract

:1. Introduction

- (1)

- A comprehensive control framework is proposed for interconnected thermal power systems with wind and BESS penetration to maintain frequency stability. In this framework, the BESS is utilized to provide frequency support for the thermal power system. Simultaneously, it reduces the power disturbance from the wind farm to the power system through wind power smoothing;

- (2)

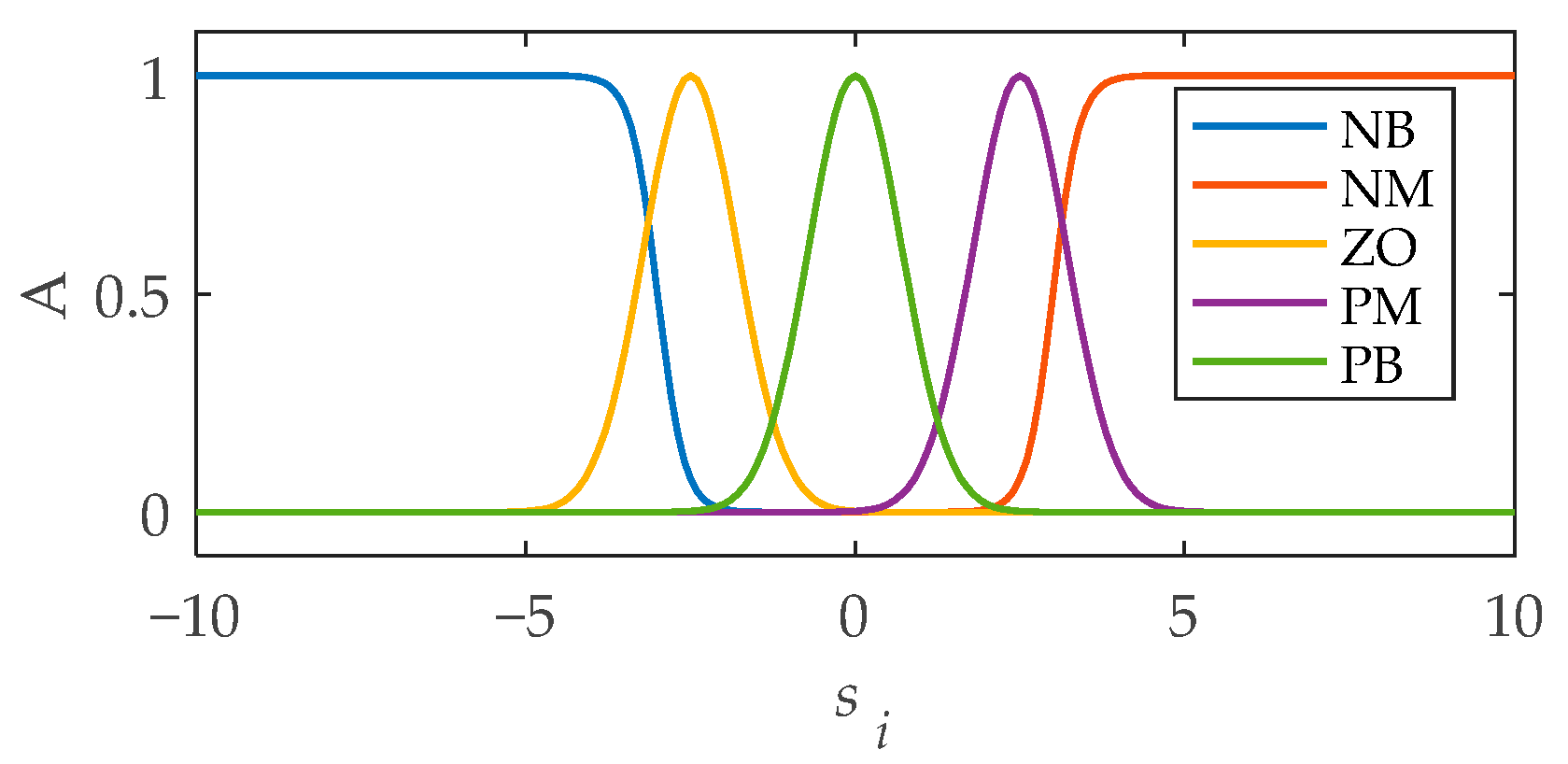

- AF-SSMC controllers are designed for the subsystems of a hybrid power system to realize precise control. Firstly, sliding functions and control laws are designed for the subsystems according to their relative degrees. Then, the super-twisting algorithm and the adaptive fuzzy control method are employed to suppress chattering and to adjust the control gains online, respectively;

- (3)

- The model of an interconnected two-area thermal power system with wind and BESS penetration is constructed for simulation analyses. The results indicate that the proposed control framework is effective in frequency regulation and wind power smoothing.

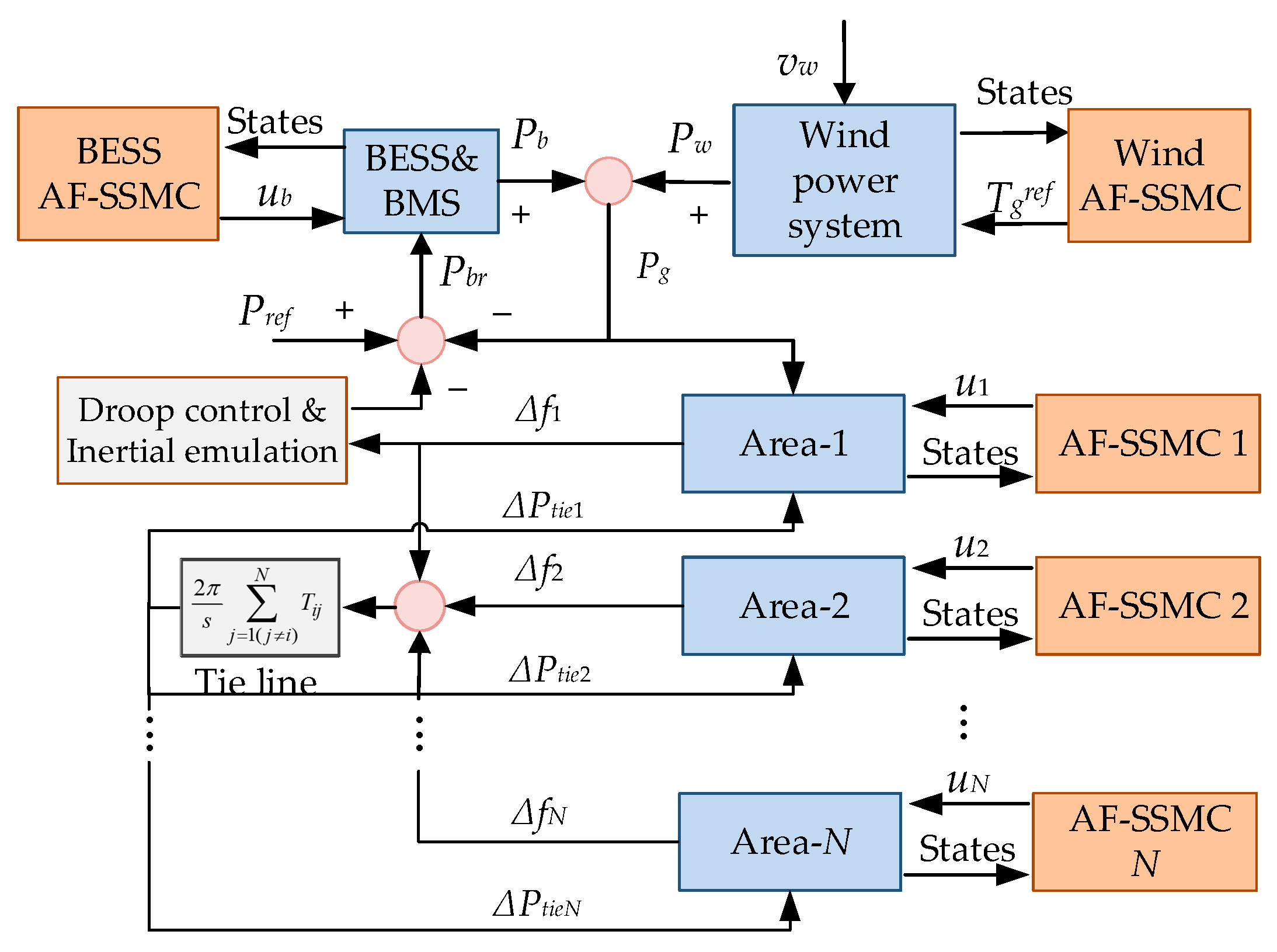

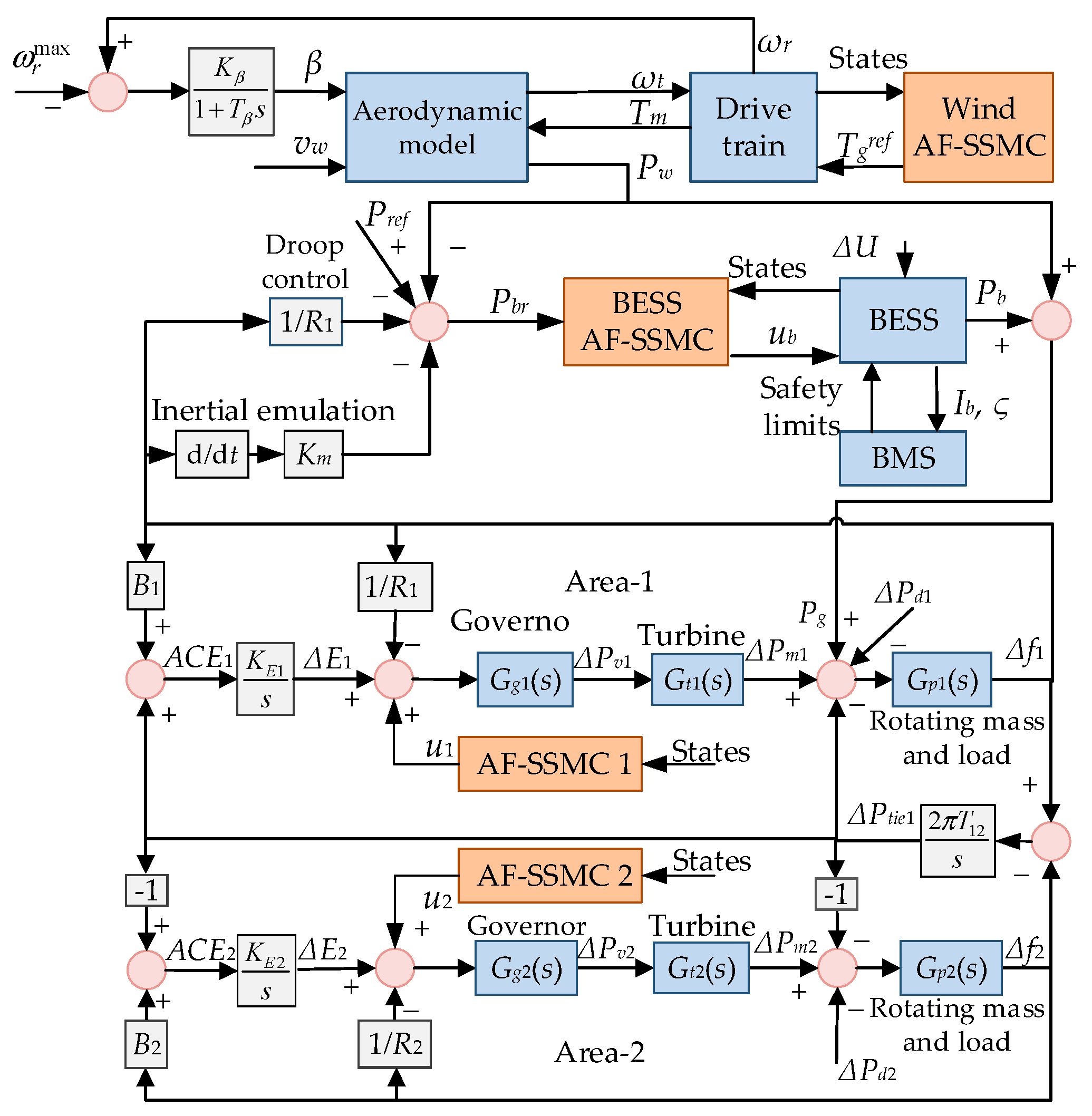

2. System Configuration

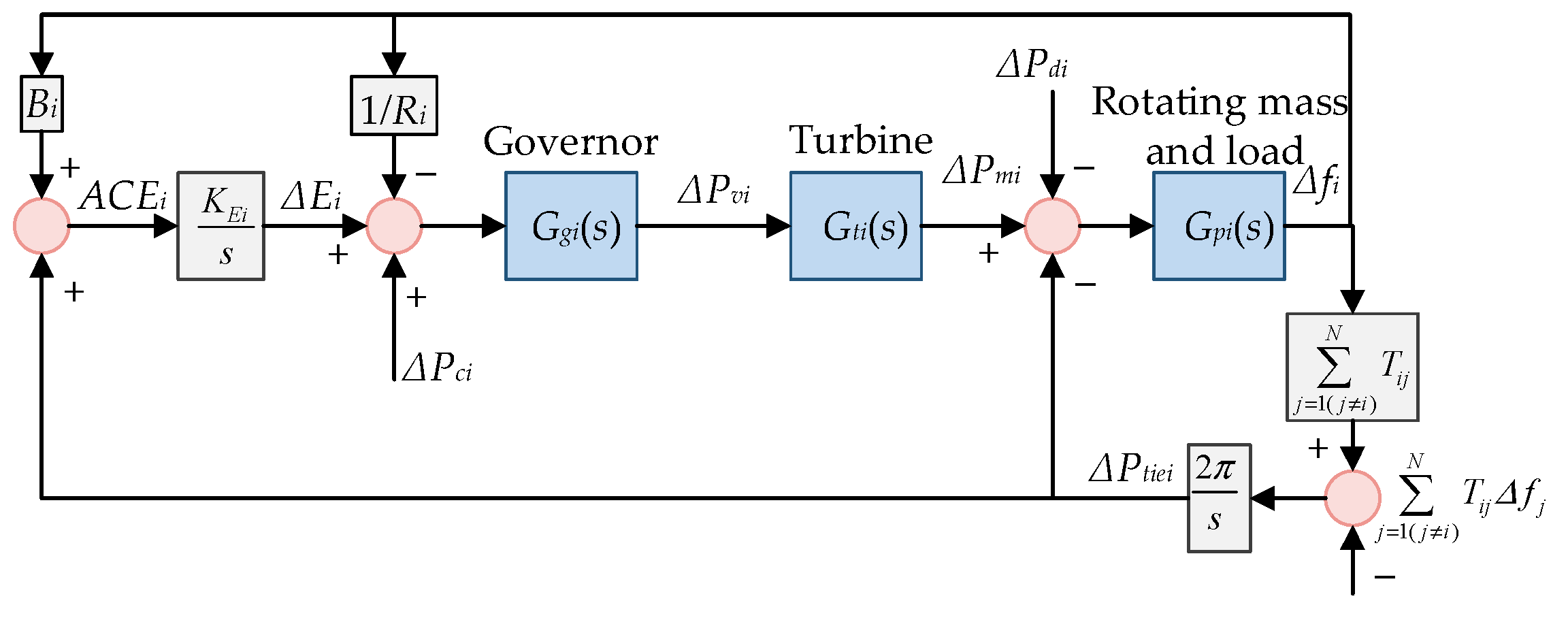

2.1. Power System

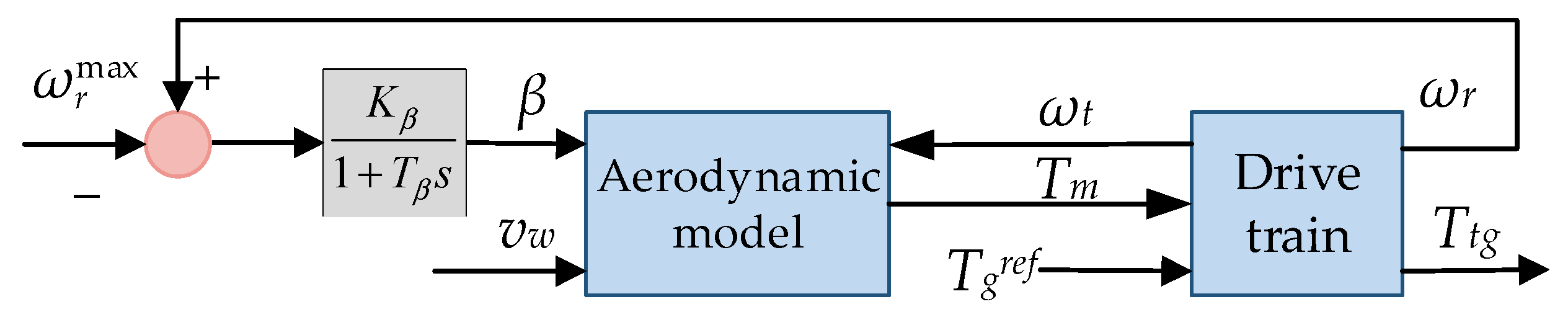

2.2. Wind Power System

2.3. Battery Energy Storage System

| Algorithm 1 Control logic of BMS |

| if SoC ∈[ςmin, ςmax] |

| Ib ∈[−, ] |

| elseif SoC < ςmin Ib ∈[0, ] |

| elseif SoC > ςmax |

| Ib ∈[−, 0] |

| end |

2.4. Hybrid Power System for Case Study

3. Control Design

3.1. Control Design for the Power System

3.2. Control Design for the Wind Power System

3.3. Control Design for the BESS

4. Numerical Simulations

4.1. Control Properties with/without Super-Twisting Algorithm

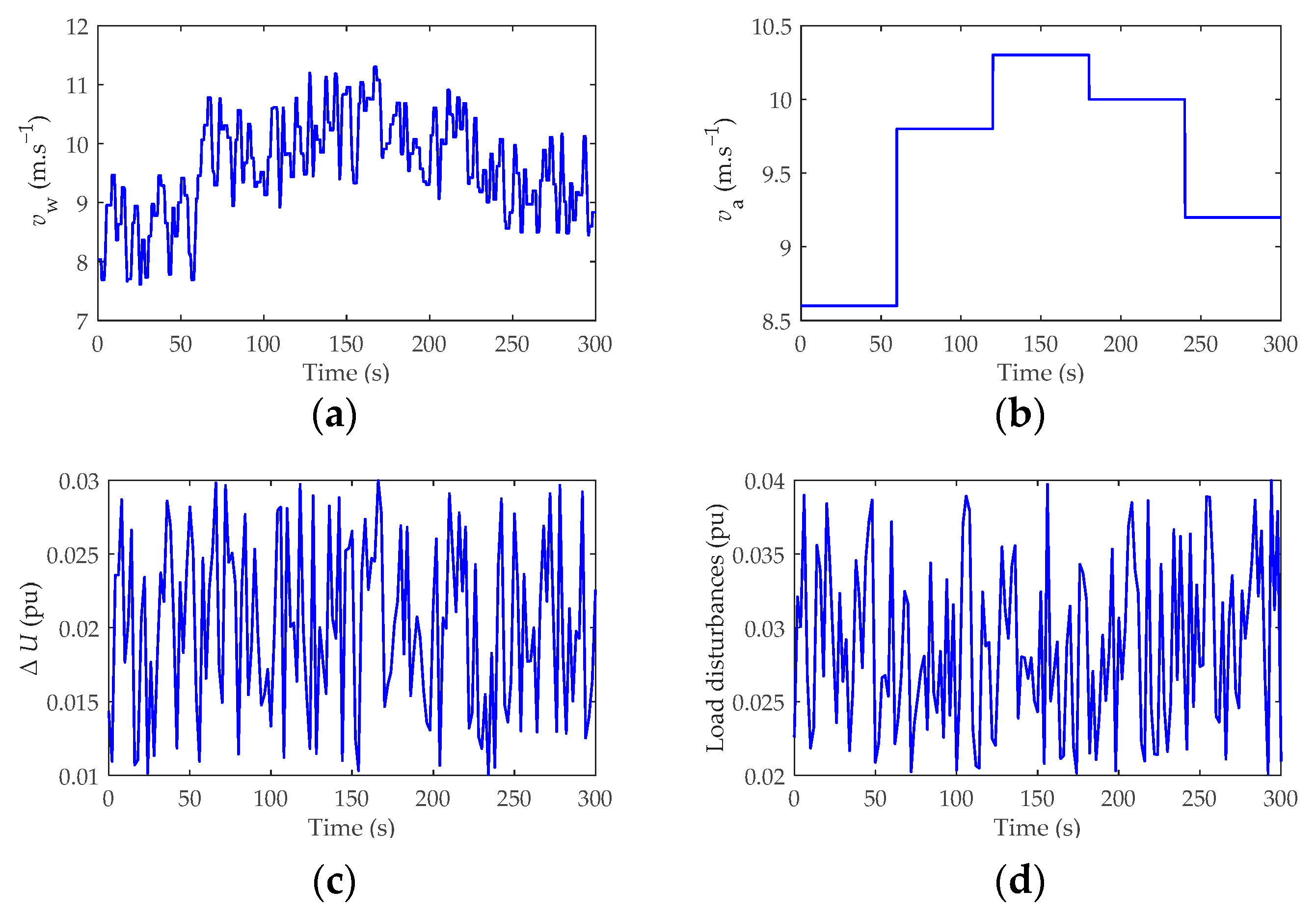

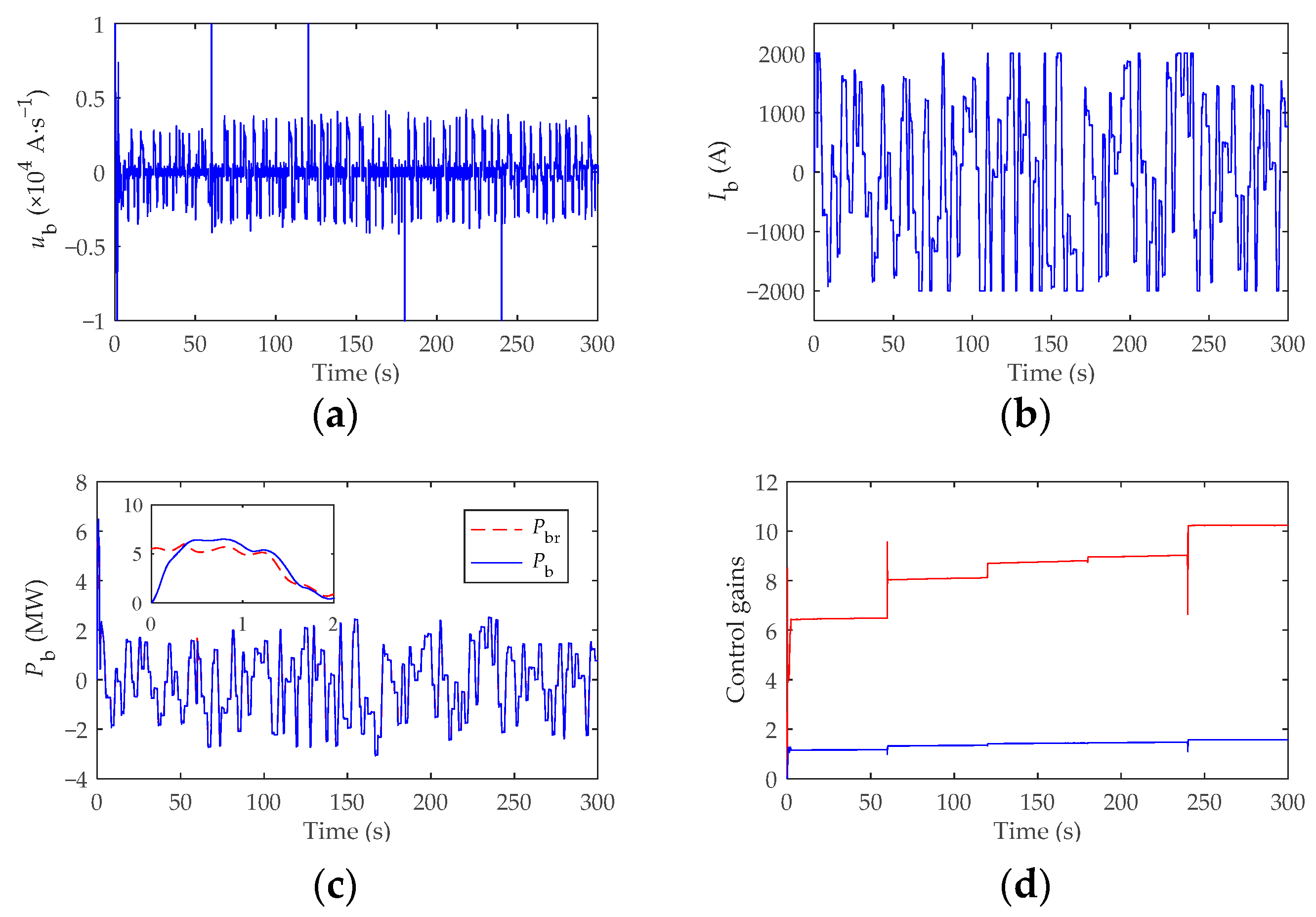

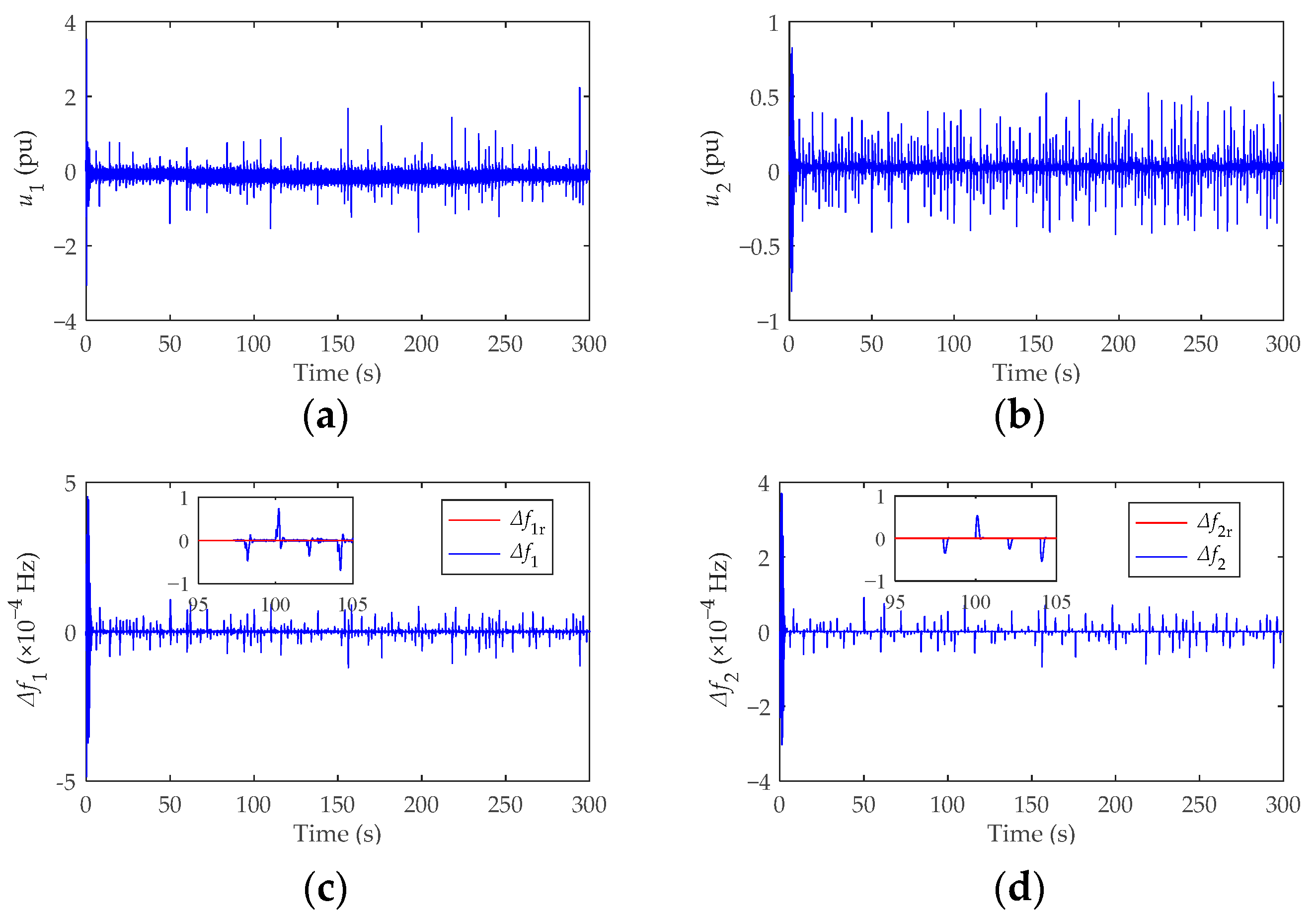

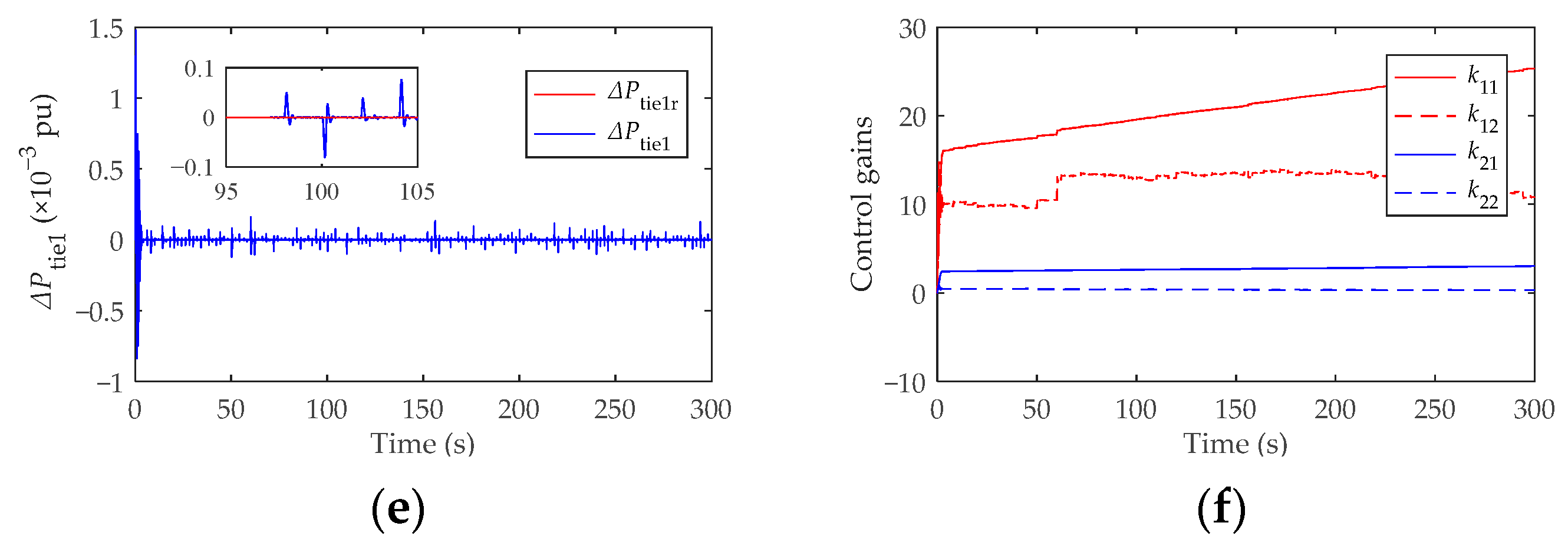

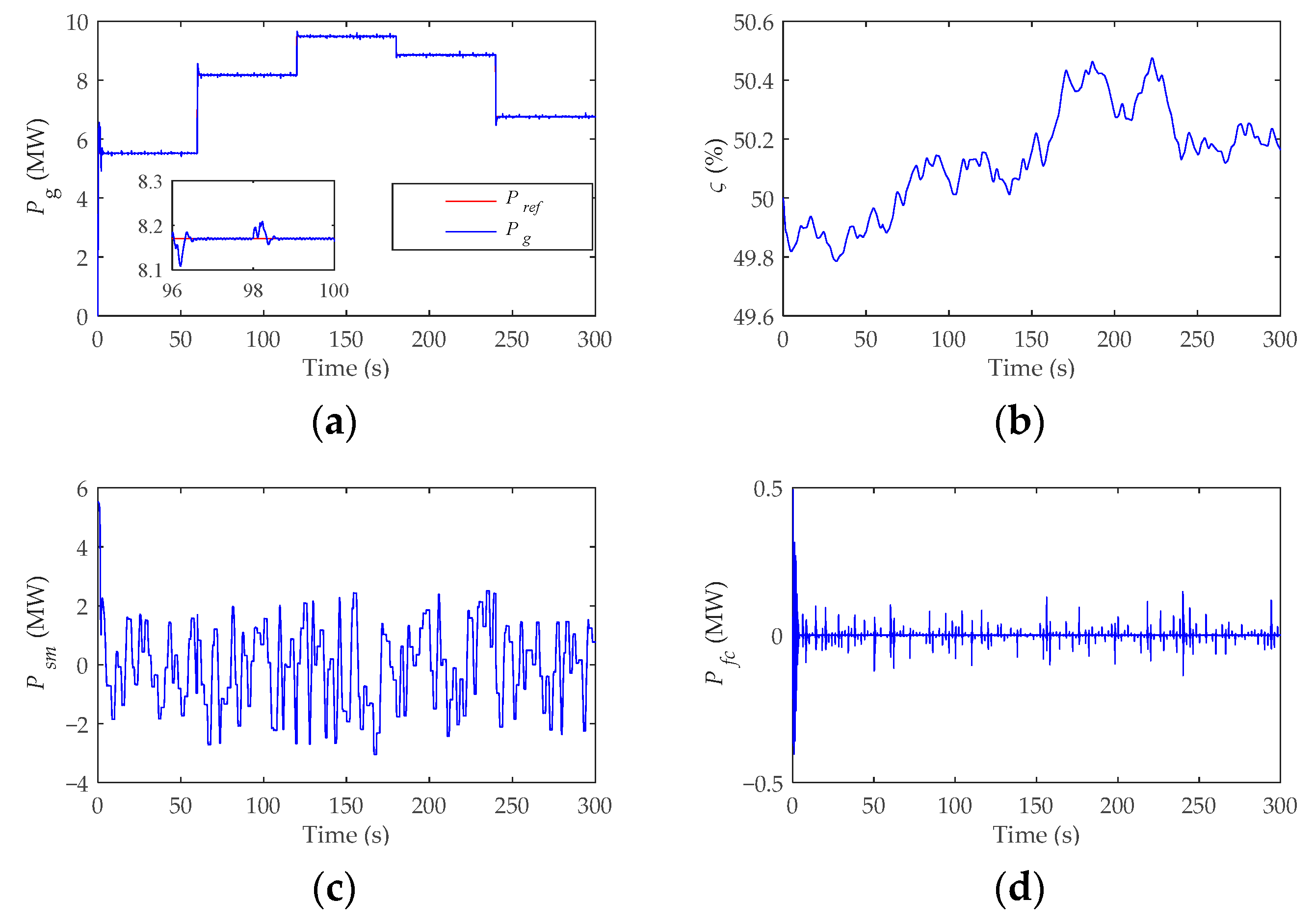

4.2. Dynamic Analysis on Frequency Regulation and Wind Power Smoothing

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. System Matrices

Appendix B. System Parameters

References

- Khalid, M.; Aguilera, R.P.; Savkin, A.V.; Agelidis, V.G. On maximizing profit of wind-battery supported power station based on wind power and energy price forecasting. Appl. Energy 2018, 211, 764–773. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, M.; Xin, B.; Zhao, X.; Watada, J. Analysis of operation cost and wind curtailment using multi-objective unit commitment with battery energy storage. Energy 2019, 178, 101–114. [Google Scholar] [CrossRef]

- Nguyen, N.; Mitra, J. An Analysis of the Effects and Dependency of Wind Power Penetration on System Frequency Regulation. IEEE Trans. Sustain. Energy 2016, 7, 354–363. [Google Scholar] [CrossRef]

- Latif, A.; Hussain, S.M.S.; Das, D.C.; Ustun, T.S. State-of-the-art of controllers and soft computing techniques for regulated load frequency management of single/multi-area traditional and renewable energy based power systems. Appl. Energy 2020, 266, 114858. [Google Scholar] [CrossRef]

- Ansari, J.; Reza Abbasi, A.; Bahmani Firouzi, B. Decentralized LMI-based event-triggered integral sliding mode LFC of power systems with disturbance observer. Int. J. Electr. Power Energy Syst. 2022, 138, 107971. [Google Scholar] [CrossRef]

- Pradhan, C.; Bhende, C.N.; Samanta, A.K. Adaptive virtual inertia-based frequency regulation in wind power systems. Renew. Energy 2018, 115, 558–574. [Google Scholar] [CrossRef]

- Kumar, N.K.; Gopi, R.S.; Kuppusamy, R.; Nikolovski, S.; Teekaraman, Y.; Vairavasundaram, I.; Venkateswarulu, S. Fuzzy Logic-Based Load Frequency Control in an Island Hybrid Power System Model Using Artificial Bee Colony Optimization. Energies 2022, 15, 2199. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Liu, Y. Dynamic load frequency control for high-penetration wind power considering wind turbine fatigue load. Int. J. Electr. Power Energy Syst. 2020, 117, 105696. [Google Scholar] [CrossRef]

- Behera, A.; Panigrahi, T.K.; Ray, P.K.; Sahoo, A.K. A Novel Cascaded PID Controller for Automatic Generation Control Analysis With Renewable Sources. IEEE/CAA J. Autom. Sin. 2019, 6, 1438–1451. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Y.; Wei, Z.; Sun, G.; Wu, X. Robust H∞ load frequency control of multi-area power system with time delay: A sliding mode control approach. IEEE/CAA J. Autom. Sin. 2018, 5, 610–617. [Google Scholar] [CrossRef]

- Anand, S.; Dev, A.; Sarkar, M.K. Generalized proportional integral observering mode control approach. IEEE/CAA J. Autom. Sin. 2018, 5, 610–617, IEEE/CAA J. Autom. Sin.2019, 6, 1438–1451. [Google Scholar]

- Guo, J. Application of full order sliding mode control based on different areas power system with load frequency control. ISA Trans. 2019, 92, 23–34. [Google Scholar] [CrossRef] [PubMed]

- Jena, N.K.; Sahoo, S.; Sahu, B.K.; Ranjan Nayak, J.; Mohanty, K.B. Fuzzy adaptive selfish herd optimization based optimal sliding mode controller for frequency stability enhancement of a microgrid. Eng. Sci. Technol. 2022, 33, 101071. [Google Scholar] [CrossRef]

- Lamsal, D.; Sreeram, V.; Mishra, Y.; Kumar, D. Output power smoothing control approaches for wind and photovoltaic generation systems: A review. Renew. Sustain. Energy Rev. 2019, 113, 109245. [Google Scholar] [CrossRef]

- Xue, Y.; Tai, N. Review of contribution to frequency control through variable speed wind turbine. Renew. Energy 2011, 36, 1671–1677. [Google Scholar]

- Abouzeid, S.I.; Guo, Y.; Zhang, H.-C. Cooperative control framework of the wind turbine generators and the compressed air energy storage system for efficient frequency regulation support. Int. J. Electr. Power Energy Syst. 2021, 130, 106844. [Google Scholar] [CrossRef]

- De Siqueira, L.M.S.; Peng, W. Control strategy to smooth wind power output using battery energy storage system: A review. J. Energy Storage 2021, 35, 102252. [Google Scholar] [CrossRef]

- Datta, U.; Kalam, A.; Shi, J. The relevance of large-scale battery energy storage (BES) application in providing primary frequency control with increased wind energy penetration. J. Energy Storage 2019, 23, 9–18. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, Q.; Hu, S.; Xu, H.; Rasmussen, C.N. Review of energy storage system for wind power integration support. Appl. Energy 2015, 137, 545–553. [Google Scholar] [CrossRef]

- Hauer, I.; Balischewski, S.; Ziegler, C. Design and operation strategy for multi-use application of battery energy storage in wind farms. J. Energy Storage 2020, 31, 101572. [Google Scholar] [CrossRef]

- Lamsal, D.; Sreeram, V.; Mishra, Y.; Kumar, D. Smoothing control strategy of wind and photovoltaic output power fluctuation by considering the state of health of battery energy storage system. IET Renew. Power Gener. 2019, 13, 578–586. [Google Scholar] [CrossRef]

- Cao, M.; Xu, Q.; Qin, X.; Cai, J. Battery energy storage sizing based on a model predictive control strategy with operational constraints to smooth the wind power. Int. J. Electr. Power Energy Syst. 2020, 115, 105471. [Google Scholar] [CrossRef]

- Wan, C.; Qian, W.; Zhao, C.; Song, Y.; Yang, G. Probabilistic Forecasting Based Sizing and Control of Hybrid Energy Storage for Wind Power Smoothing. IEEE Trans. Sustain. Energy 2021, 12, 1841–1852. [Google Scholar] [CrossRef]

- Khalid, M.; Savkin, A.V. Minimization and control of battery energy storage for wind power smoothing: Aggregated, distributed and semi-distributed storage. Renew. Energy 2014, 64, 105–112. [Google Scholar] [CrossRef]

- Guo, J. Application of a novel adaptive sliding mode control method to the load frequency control. Eur. J. Control. 2021, 57, 172–178. [Google Scholar] [CrossRef]

- Lv, X.; Sun, Y.; Wang, Y.; Dinavahi, V. Adaptive event-triggered load frequency control of multi-area power systems under networked environment via sliding mode control. IEEE Access 2020, 8, 86585. [Google Scholar] [CrossRef]

- Prasad, S.; Purwar, S.; Kishor, N. Non-linear sliding mode control for frequency regulation with variable-speed wind turbine systems. Int. J. Electr. Power Energy Syst. 2019, 107, 19–33. [Google Scholar] [CrossRef]

- Deng, Z.; Xu, C. Frequency Regulation of Power Systems with a Wind Farm by Sliding-Mode-Based Design. IEEE/CAA J. Autom. Sin. 2022, 9, 1980–1989. [Google Scholar] [CrossRef]

- Teleke, S.; Baran, M.E.; Bhattacharya, S.; Huang, A.Q. Optimal Control of Battery Energy Storage for Wind Farm Dispatching. IEEE Trans. Energy Convers. 2010, 25, 787–794. [Google Scholar] [CrossRef]

- Liu, K.; Wei, Z.; Zhang, C.; Shang, Y.; Teodorescu, R.; Han, Q.-L. Towards long lifetime battery: AI-based manufacturing and management. IEEE/CAA J. Autom. Sin. 2022, 9, 1139–1165. [Google Scholar] [CrossRef]

- Li, J.; Liu, K.; Zhou, Q.; Meng, J.; Ge, Y.; Xu, H. Electrothermal Dynamics-Conscious Many-Objective Modular Design for Power-Split Plug-in Hybrid Electric Vehicles. IEEE/ASME Trans. Mechatron. 2022, 1–11. [Google Scholar]

- Gohari, H.D.; Zarastvand, M.R.; Talebitooti, R.; Loghmani, A.; Omidpanah, M. Radiated sound control from a smart cylinder subjected to piezoelectric uncertainties based on sliding mode technique using self-adjusting boundary layer. Aerosp. Sci. Technol. 2020, 106, 106141. [Google Scholar] [CrossRef]

- Chen, D.; Zhang, J.; Li, Z. A Novel Fixed-Time Trajectory Tracking Strategy of Unmanned Surface Vessel Based on the Fractional Sliding Mode Control Method. Electronics 2022, 11, 726. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, Y.; Zhang, X.; Liang, J. A New Reaching Law for Antidisturbance Sliding-Mode Control of PMSM Speed Regulation System. IEEE Trans. Power Electron. 2020, 35, 4117–4126. [Google Scholar] [CrossRef]

- Wang, D.; Wang, D.; Zhou, W.; Niu, L. Research on PMSM Sliding-mode Vector Combined Speed Controller Based on Improved Exponential Reaching Law. J. Phys. Conf. Ser. IOP Publ. 2022, 2260, 012024. [Google Scholar] [CrossRef]

- Guo, J. The Load Frequency Control by Adaptive High Order Sliding Mode Control Strategy. IEEE Access 2022, 10, 25392–25399. [Google Scholar] [CrossRef]

- Mirzaei, M.J.; Hamida, M.A.; Plestan, F.; Taleb, M. Super-twisting sliding mode controller with self-tuning adaptive gains. Eur. J. Control. 2022, 68, 100690. [Google Scholar] [CrossRef]

- Fei, J.; Feng, Z. Adaptive Fuzzy Super-Twisting Sliding Mode Control for Microgyroscope. Complexity 2019, 2019, 6942642. [Google Scholar] [CrossRef]

- Li, M.; Li, Y.; Wang, Q. Adaptive fuzzy backstepping super-twisting sliding mode control of nonlinear systems with unknown hysteresis. Asian J. Control. 2021, 24, 1726–1743. [Google Scholar] [CrossRef]

- Ren, H.; Zhang, L.; Su, C. Tracking control of an uncertain heavy load robot based on super twisting sliding mode control and fuzzy compensator. Asian J. Control. 2021, 24, 3190–3199. [Google Scholar] [CrossRef]

- Luo, W.; Zhao, T.; Li, X.; Wang, Z.; Wu, L. Adaptive super-twisting sliding mode control of three-phase power rectifiers in active front end applications. IET Control. Theory Appl. 2019, 13, 1483–1490. [Google Scholar] [CrossRef]

- Shen, J.; Dong, X.; Zhu, J.; Liu, C.; Wang, J. HOSMD and neural network based adaptive super-twisting sliding mode control for permanent magnet synchronous generators. Energy Rep. 2022, 8, 5987–5999. [Google Scholar] [CrossRef]

- Zaare, S.; Soltanpour, M.R. Adaptive fuzzy global coupled nonsingular fast terminal sliding mode control of n-rigid-link elastic-joint robot manipulators in presence of uncertainties. Mech. Syst. Signal Process. 2022, 163, 108165. [Google Scholar] [CrossRef]

- Ayas, M.S.; Altas, I.H. Fuzzy logic based adaptive admittance control of a redundantly actuated ankle rehabilitation robot. Control. Eng. Pract. 2017, 59, 44–54. [Google Scholar] [CrossRef]

- Li, P.; Jiao, X.; Li, Y. Adaptive real-time energy management control strategy based on fuzzy inference system for plug-in hybrid electric vehicles. Control. Eng. Pract. 2021, 107, 104703. [Google Scholar] [CrossRef]

- Rosewater, D.M.; Copp, D.A.; Nguyen, T.A.; Byrne, R.H.; Santoso, S. Battery Energy Storage Models for Optimal Control. IEEE Access 2019, 7, 178357–178391. [Google Scholar] [CrossRef]

- Chiu, C.-S. Derivative and integral terminal sliding mode control for a class of MIMO nonlinear systems. Automatica 2012, 48, 316–326. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Z.; Xu, C.; Huo, Z.; Han, X.; Xue, F. Sliding Mode Based Load Frequency Control and Power Smoothing of Power Systems with Wind and BESS Penetration. Machines 2022, 10, 1225. https://doi.org/10.3390/machines10121225

Deng Z, Xu C, Huo Z, Han X, Xue F. Sliding Mode Based Load Frequency Control and Power Smoothing of Power Systems with Wind and BESS Penetration. Machines. 2022; 10(12):1225. https://doi.org/10.3390/machines10121225

Chicago/Turabian StyleDeng, Zhiwen, Chang Xu, Zhihong Huo, Xingxing Han, and Feifei Xue. 2022. "Sliding Mode Based Load Frequency Control and Power Smoothing of Power Systems with Wind and BESS Penetration" Machines 10, no. 12: 1225. https://doi.org/10.3390/machines10121225

APA StyleDeng, Z., Xu, C., Huo, Z., Han, X., & Xue, F. (2022). Sliding Mode Based Load Frequency Control and Power Smoothing of Power Systems with Wind and BESS Penetration. Machines, 10(12), 1225. https://doi.org/10.3390/machines10121225