Study on the Nonlinear Dynamic Behavior of Rattling Vibration in Gear Systems

Abstract

1. Introduction

1.1. Research on Rattling Vibration of Gear Pairs

1.2. Research on the Theory of Discontinuous Dynamical Systems

2. Materials and Methods

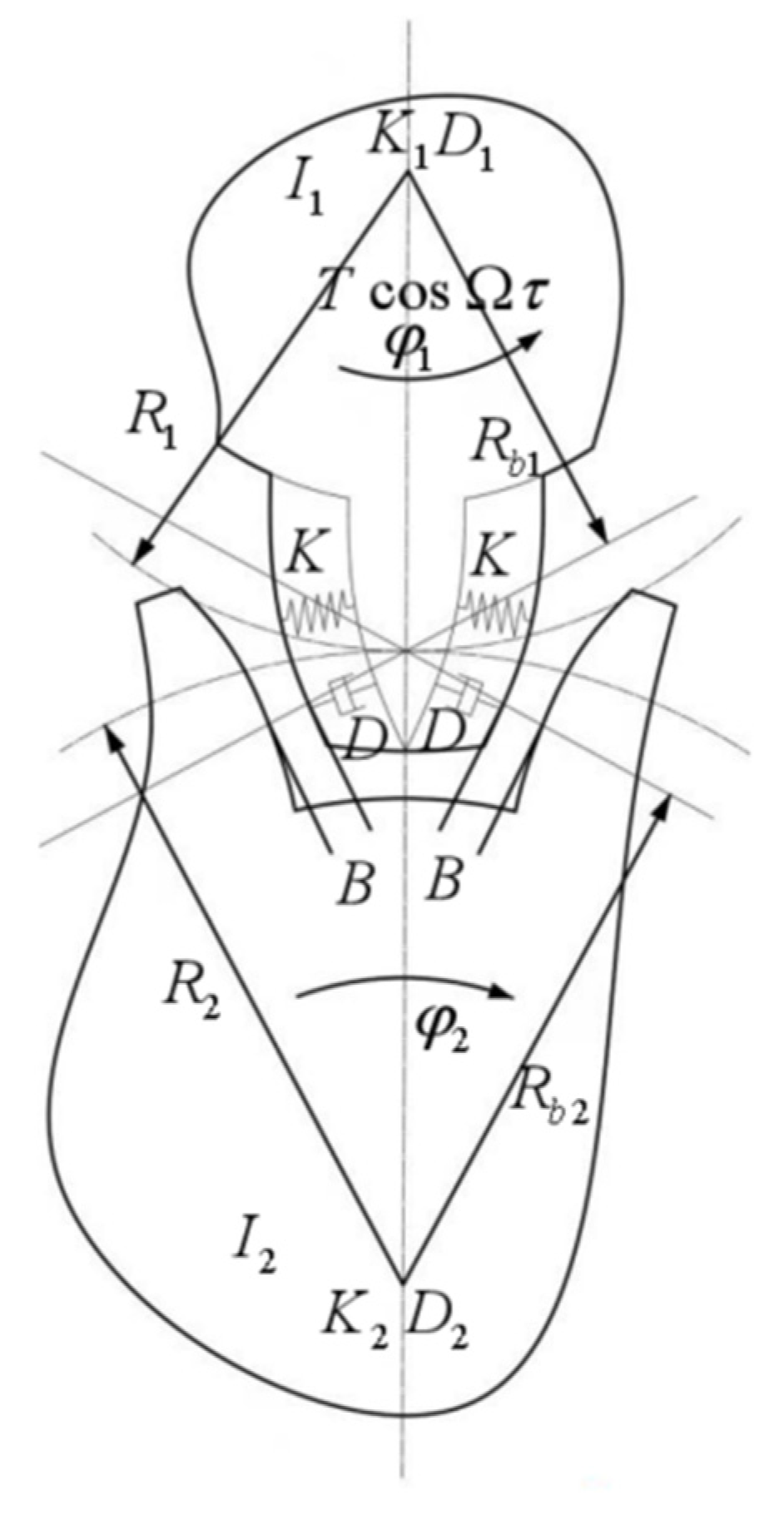

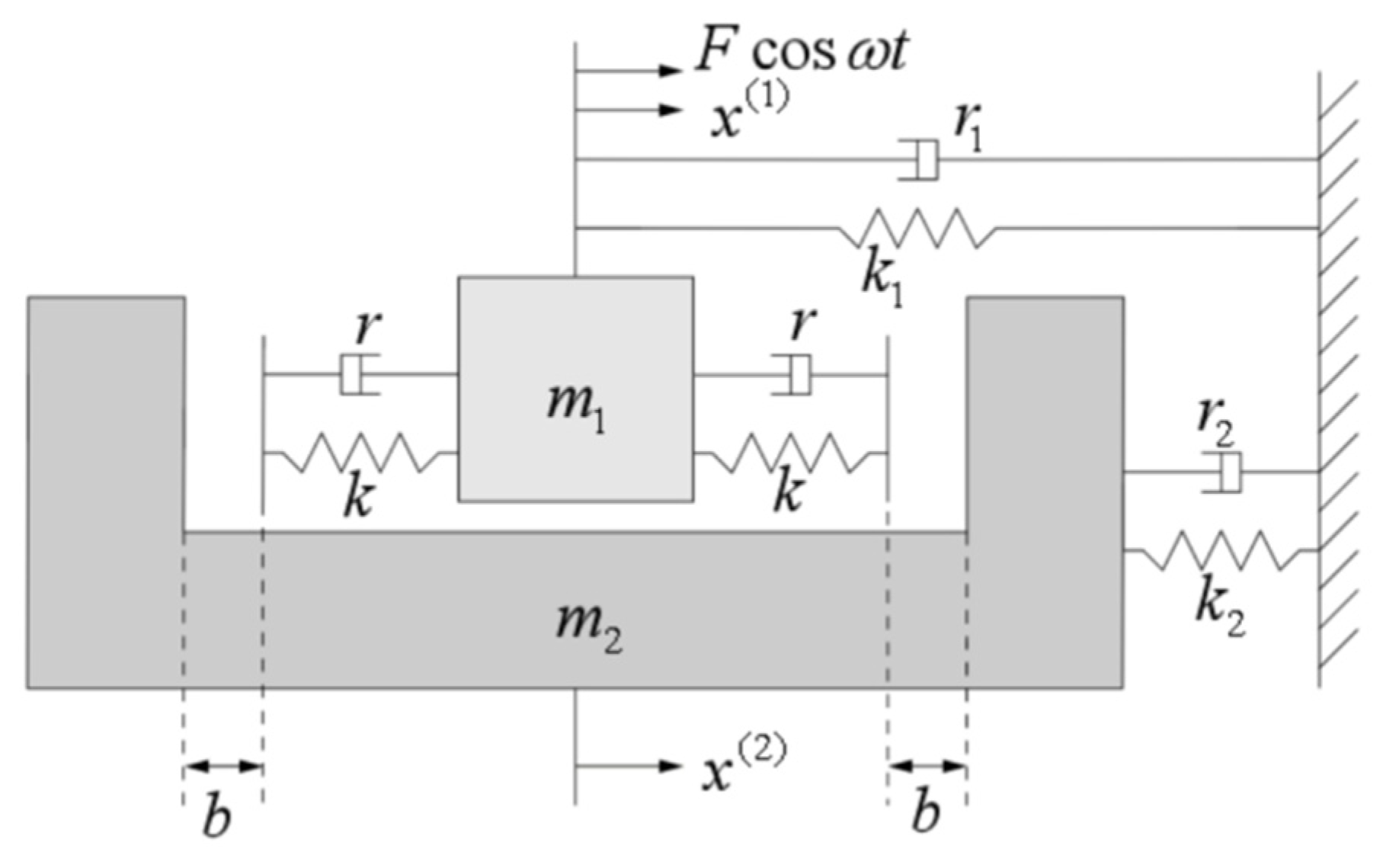

2.1. Discontinuous Model of Gear Pair with Backlash

2.1.1. Model Description

2.1.2. Discontinuous Boundary and Domain

2.1.3. Equations of Motion in Relative Coordinates

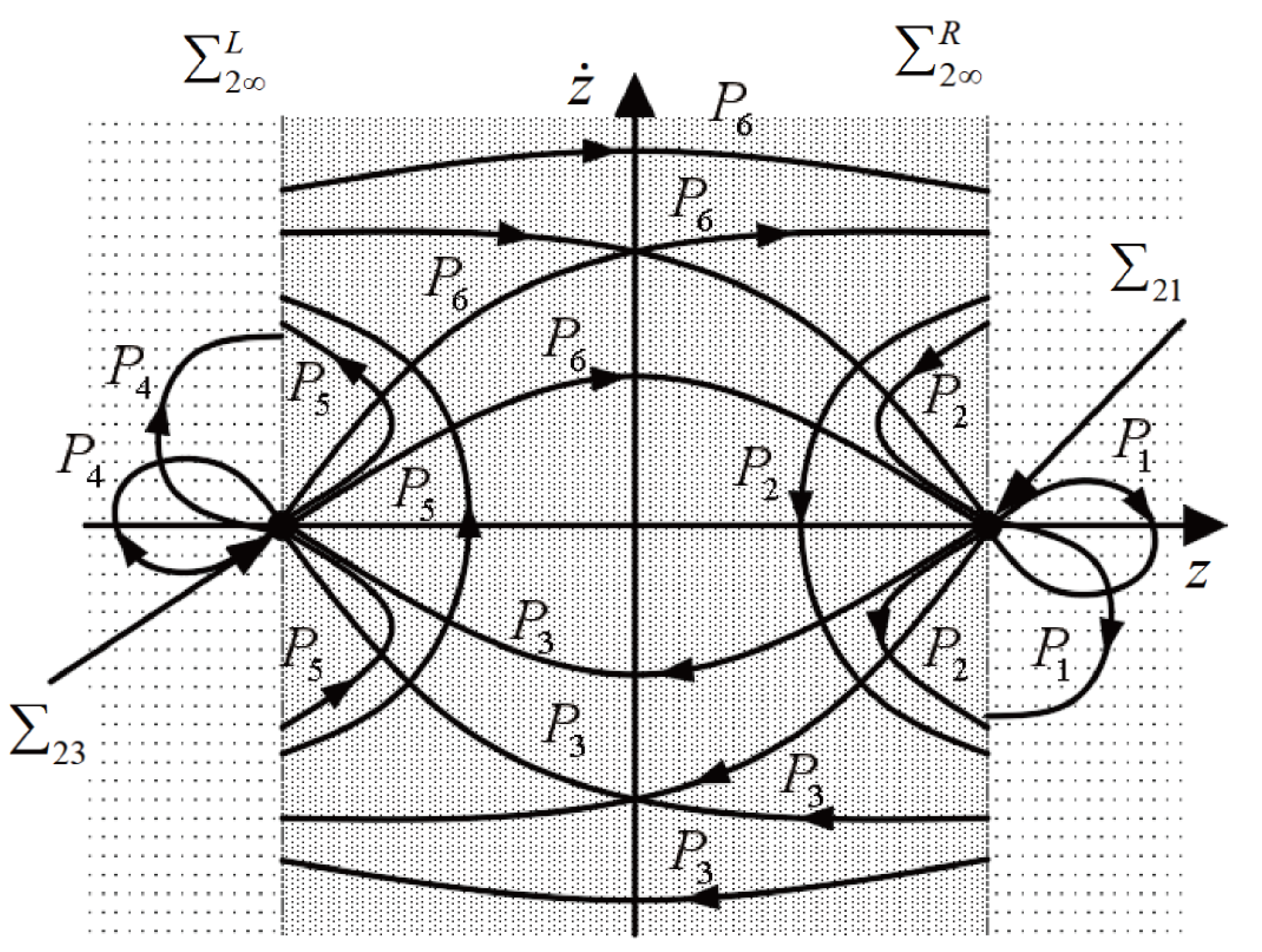

2.1.4. The Definition of Mapping Structures

2.2. The Theory of Flow Switchability

2.2.1. G Function

2.2.2. Conditions of Flow Switching

3. Results

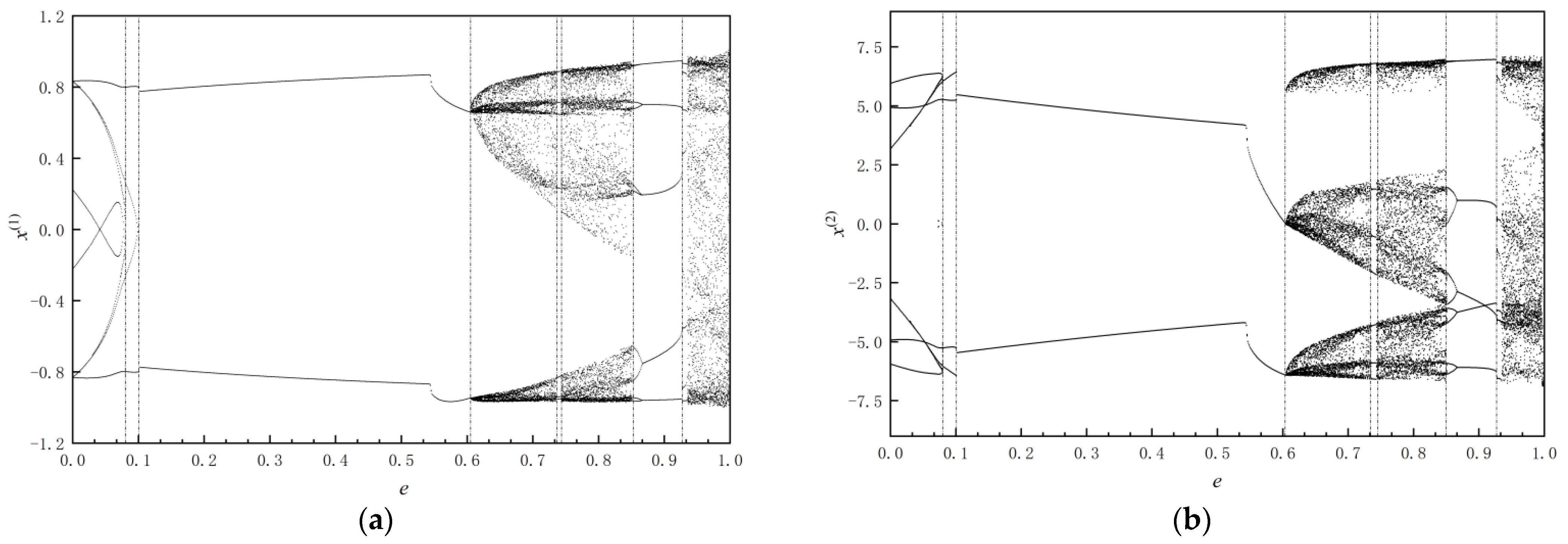

3.1. The Grazing Bifurcation

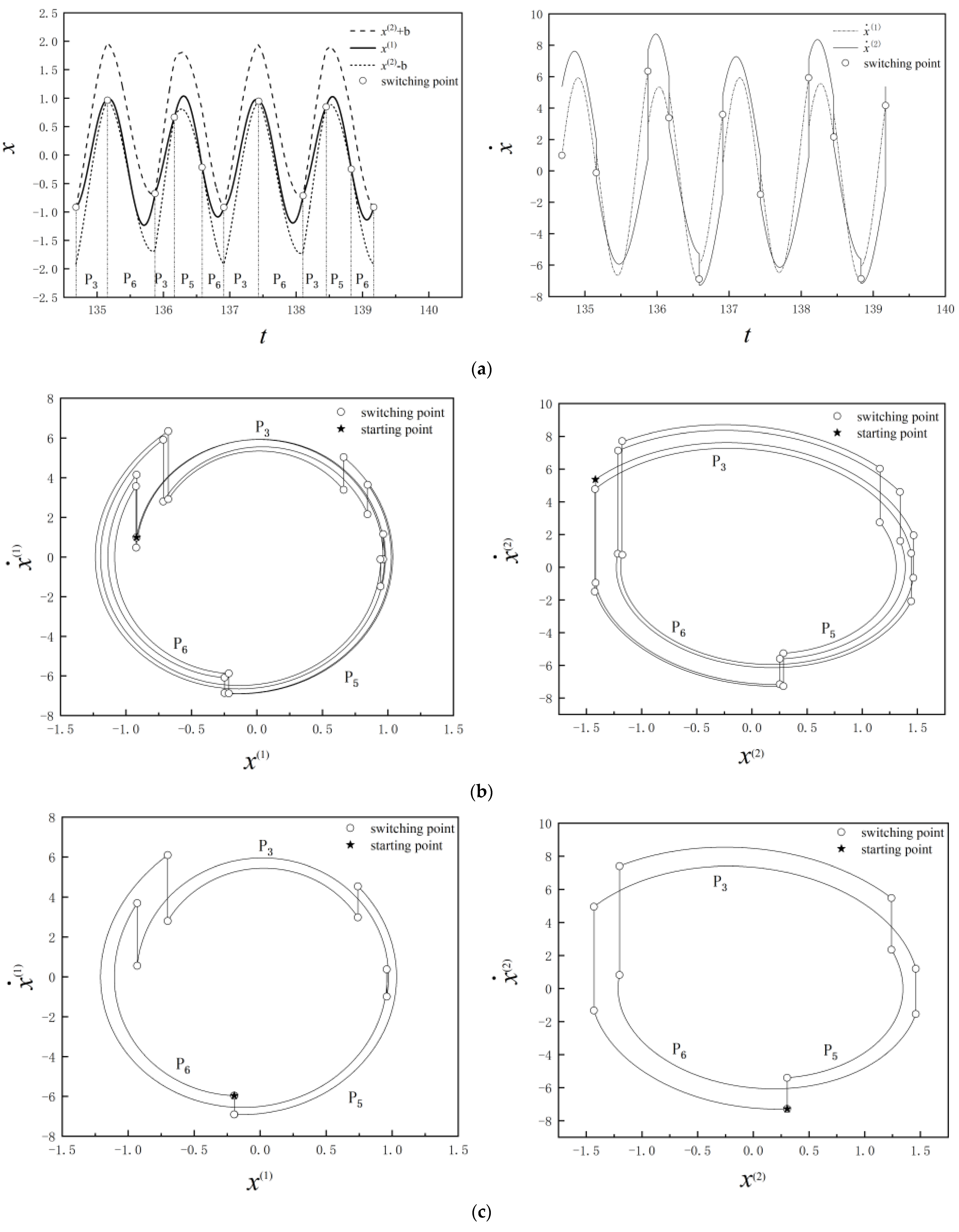

3.1.1. Periodic Structure Mutation Induced by Grazing Bifurcation

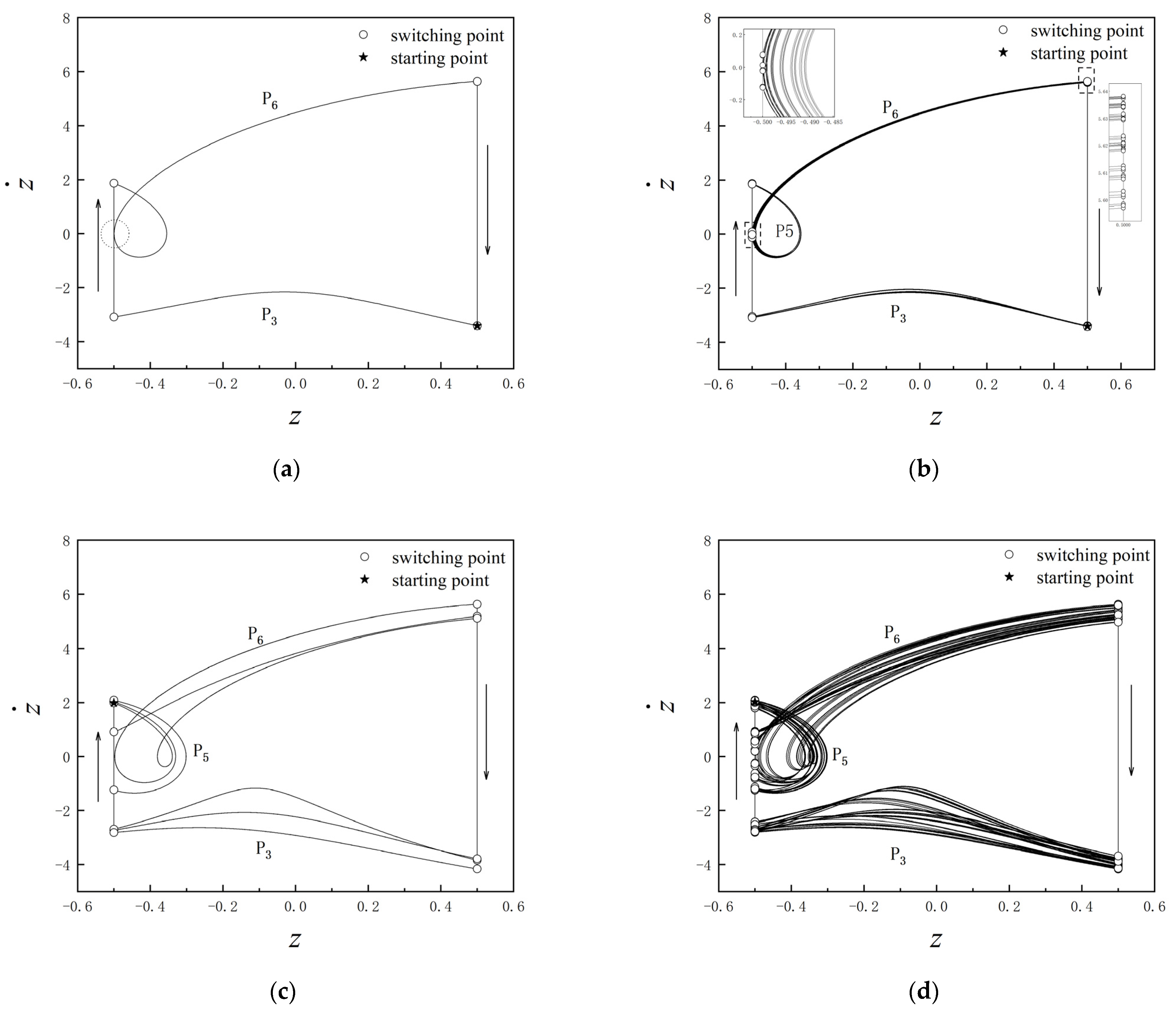

3.1.2. Chaotic Phenomena Induced by Grazing Bifurcation

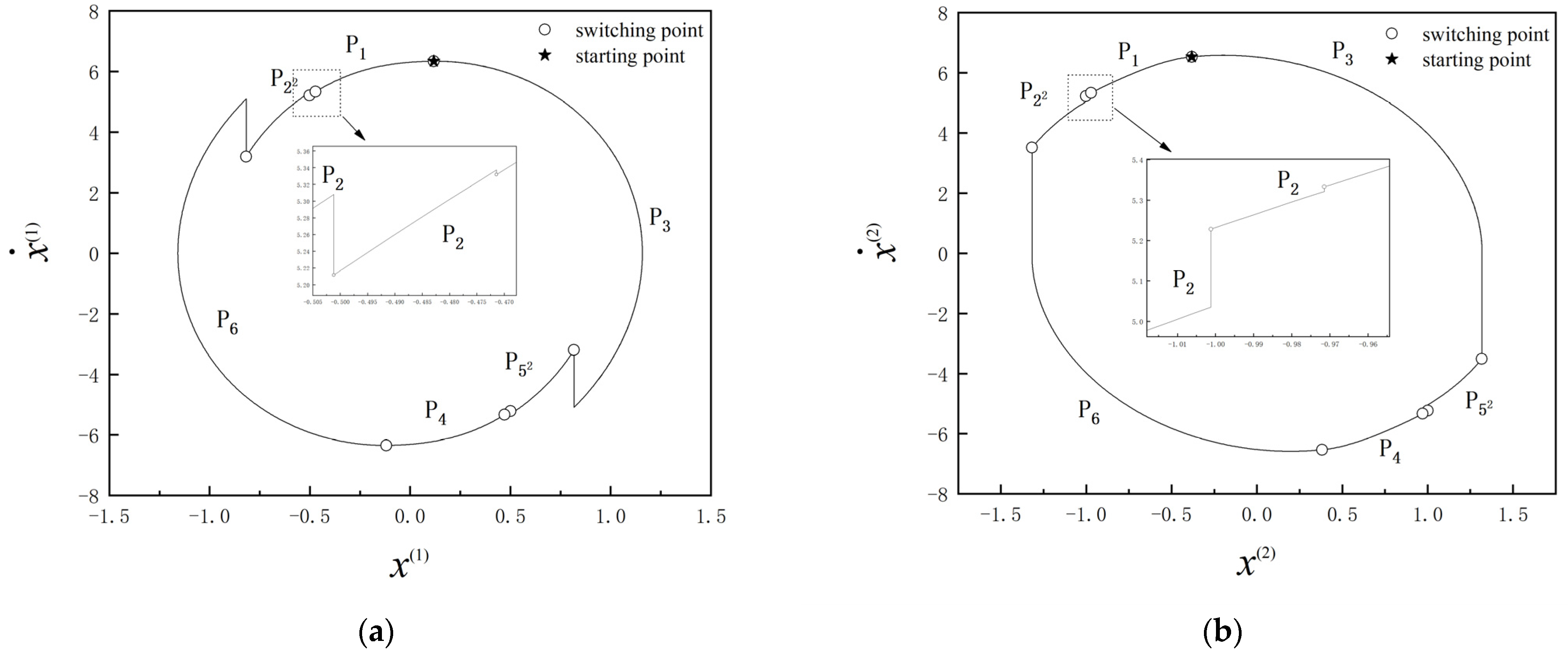

3.2. Inverse Bifurcation

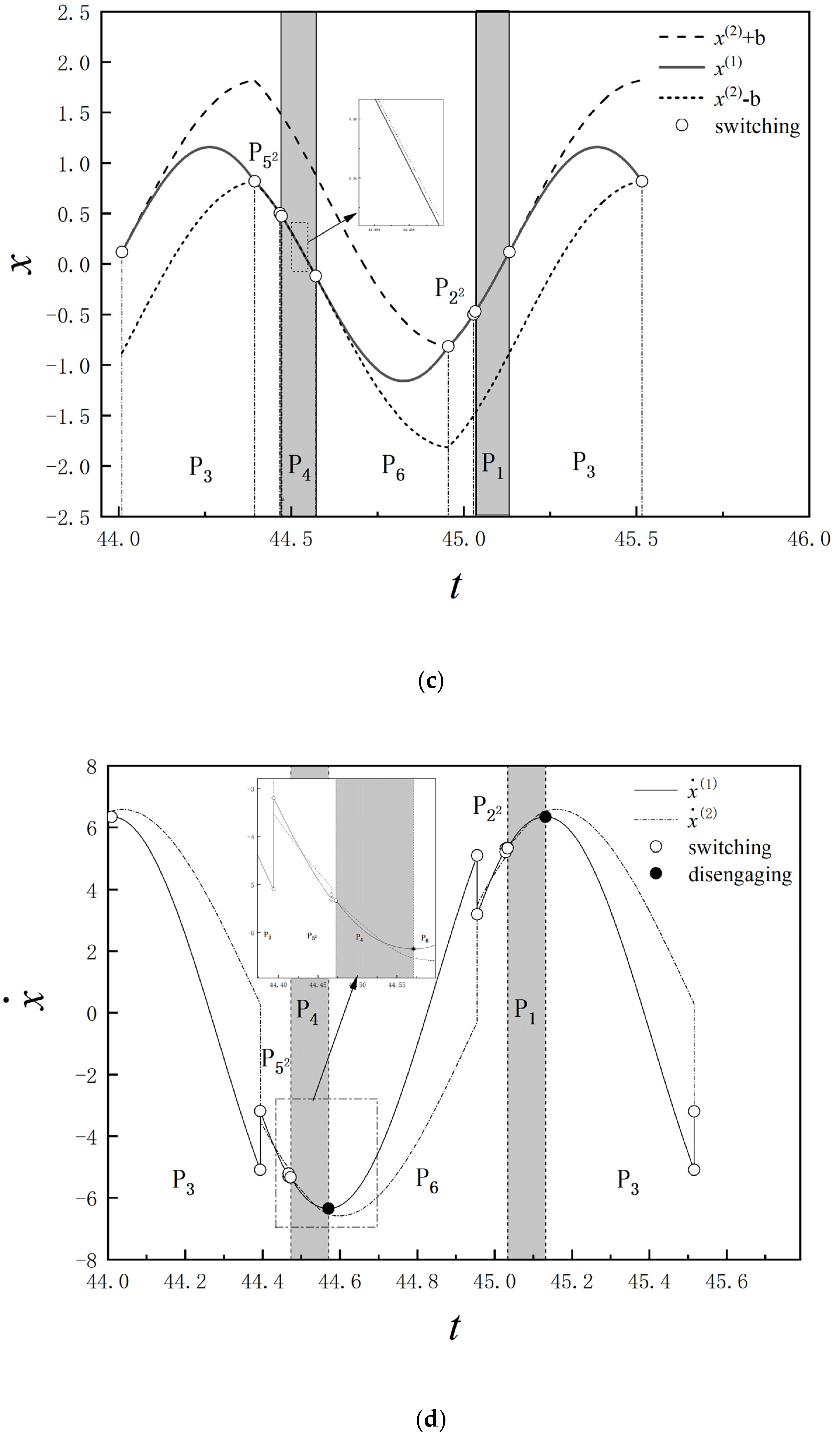

3.3. Impact-Meshing Motion

4. Conclusions

- As the coefficient of restitution changes, the grazing bifurcation occurs frequently. The phenomenon of grazing bifurcation in gear transmission system with backlash will lead to complex dynamic behavior of the system, which will directly lead to bifurcations, new periodic mapping structure, and even chaos of the system. It is necessary to select appropriate coefficients to avoid this phenomenon, and the theory of discontinuous dynamical systems is quite suitable for gear systems.

- Gear pairs with low restitution coefficient are more likely to mesh, that is, gear materials with strong plasticity are more likely to mesh, and the number of impacts before engagement will be significantly reduced. With large restitution coefficient, the speed of the gear pair has difficulty reaching the meshing condition, so it is difficult to mesh. Reasonable selection of gear materials can increase the meshing opportunity as much as possible and reduce the rattling energy loss.

- Because the gear teeth are elastic-plastic, the introduction of gear meshing stiffness and impact restitution coefficient can more effectively represent the elastic deformation and energy loss in the process of gear impact-meshing motion, which provides a theoretical model for further gear transmission systems with flexible contact considering the more complex multi degree of freedom.

Author Contributions

Funding

Conflicts of Interest

References

- Pavelko, I.; Pavelko, V. Dynamic properties of aircraft components at real constraints. Aviation 2008, 12, 113–117. [Google Scholar] [CrossRef]

- Bruzzone, F.; Rosso, C. Sources of excitation and models for cylindrical gear dynamics: A review. Machines 2020, 8, 37. [Google Scholar] [CrossRef]

- Li, M.; Khonsari, M.; Yang, R. Dynamics analysis of torsional vibration induced by clutch and gear set in automatic transmission. Int. J. Automot. Technol. 2018, 19, 473–488. [Google Scholar] [CrossRef]

- Amin Al Hajj, M.; Quaglia, G.; Schulz, I.; Qin, Y. Condition-Based Monitoring on High-Precision Gearbox for Robotic Applications. Shock Vib. 2022, 2022, 6653723. [Google Scholar] [CrossRef]

- He, X.; Zhang, H. Dynamics modelling of transmission gear rattle and analysis on influence factors. IOP Conf. Ser. Mater. Sci. Eng. 2018, 307, 012050. [Google Scholar] [CrossRef]

- Dawei, L.; Zhenzhen, L.; Guohao, Z. Rattle dynamics of noncircular face gear under multifrequency parametric excitation. Mech. Sci. 2021, 12, 361–373. [Google Scholar]

- Rigaud, E.; Perret-Liaudet, J. Investigation of gear rattle noise including visualization of vibro-impact regimes. J. Sound Vib. 2020, 467, 115026. [Google Scholar] [CrossRef]

- Dong, G.; Yi, Z.; Yi, Z.; Yawen, W.; Fangchao, C.; Xiaohui, S. Numerical and experimental study of gear rattle based on a refined dynamic model. Appl. Acoust. 2022, 185, 108407. [Google Scholar]

- Mingxuan, L.; Ying, W.; Tian, Z. Optimization on nonlinear dynamics of gear rattle in automotive transmission system. Shock Vib. 2019, 2019, 4056204. [Google Scholar]

- Zhang, J.; Liu, D.; Yu, H. Experimental and numerical analysis for the transmission gear rattle in a power-split hybrid electric vehicle. Int. J. Veh. Des. 2017, 74, 1–18. [Google Scholar] [CrossRef]

- Dong, H.; Shen, Y.; Liu, X. Research on the rattling in gear system. In Proceedings of the International Conference on Mechanical Transmissions, Chongqing, China, 26–30 September 2006; Volume 1. [Google Scholar]

- Yun, Y.J.; Iljae, L. Nonlinear analysis of Vibro-Impacts for unloaded gear pairs with various excitations and system parameters. J. Vib. Acoust. 2014, 136, 031010. [Google Scholar] [CrossRef]

- Han, R.; Luo, A.; Deng, W. Chaotic motion of a horizontal impact pair. J. Sound Vib. 1995, 181, 231–250. [Google Scholar] [CrossRef]

- Luo, A.; Menon, S. Global chaos in a periodically forced, linear system with a dead-zone restoring force. Chaos Soliton. Fract. 2004, 19, 1189–1199. [Google Scholar] [CrossRef]

- Luo, A. A theory for non-smooth dynamic systems on the connectable domains. Commun. Nonlinear Sci. Numer. Simul. 2005, 10, 1–55. [Google Scholar] [CrossRef]

- Luo, A.C.J.; Rapp, B.M. Flow switchability and periodic motions in a periodically forced, discontinuous dynamical system. Nonlinear Anal. Real World Appl. 2008, 10, 3028–3044. [Google Scholar] [CrossRef]

- Luo, A.; O’Connor, D. Impacting chatter and stick in a transmission system with two oscillators. J. Multi-Body Dyn. 2009, 223, 159–188. [Google Scholar] [CrossRef]

- Guo, S.; Luo, A. An analytical prediction of periodic motions in a discontinuous dynamical system. J. Vib. Test. Syst. Dyn. 2020, 4, 377–388. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, Z.; Luo, A.C.J. On bifurcation trees of period-1 to period-2 motions in a nonlinear Jeffcott rotor system. Int. J. Mech. Sci. 2019, 160, 429–450. [Google Scholar] [CrossRef]

- Yeyin, X.; Luo, A.C.J. Period-1 to period-8 motions in a nonlinear jeffcott rotor system. J. Comput. Nonlin. Dyn. 2020, 15, 091012. [Google Scholar]

- Xu, Y.; Chen, Z.; Luo, A.C.J. Period-1 motion to chaos in a nonlinear flexible rotor system. Int. J. Bifurcat. Chaos 2020, 30, 2050077. [Google Scholar] [CrossRef]

- Guo, S.; Luo, A.C.J. On existence and bifurcations of periodic motions in discontinuous dynamical systems. Int. J. Bifurcat. Chaos 2021, 31, 2150063. [Google Scholar] [CrossRef]

- Luo, A.; Liu, C. Analytical dynamics of a discontinuous dynamical system with a hyperbolic boundary. J. Vib. Test. Syst. Dyn. 2021, 5, 285–319. [Google Scholar] [CrossRef]

- Luo, A. The mapping dynamics of periodic motions for a three-piecewise linear system under a periodic excitation. J. Sound Vib. 2005, 283, 723–748. [Google Scholar] [CrossRef]

- Luo, A.C. On the differential geometry of flows in nonlinear dynamical systems. J. Comput. Nonlinear Dyn. 2008, 3, 021104. [Google Scholar]

- Yin, S.; Shen, Y.; Wen, G.; Xu, H. Analytical determination for degenerate grazing bifurcation points in the single-degree-of-freedom impact oscillator. Nonlinear Dynam. 2017, 90, 443–456. [Google Scholar] [CrossRef]

| Dimensionless Coefficients | Symbol | Value |

|---|---|---|

| Equivalent mass of gear 1 | 2 | |

| Equivalent mass of gear 2 | 1 | |

| Support damping of gear 1 | 0.6 | |

| Support damping of gear 2 | 0.6 | |

| Meshing damping | 1 | |

| Support stiffness of gear 2 | 30 | |

| Support stiffness of gear 2 | 20 | |

| Meshing stiffness | 1000 | |

| Amplitude of driving force | 50 | |

| Excitation frequency | 5.6 | |

| Backlash of gear pair | 2b | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Jiao, Y.; Qi, S.; Yu, G.; Du, M. Study on the Nonlinear Dynamic Behavior of Rattling Vibration in Gear Systems. Machines 2022, 10, 1112. https://doi.org/10.3390/machines10121112

Liu Y, Jiao Y, Qi S, Yu G, Du M. Study on the Nonlinear Dynamic Behavior of Rattling Vibration in Gear Systems. Machines. 2022; 10(12):1112. https://doi.org/10.3390/machines10121112

Chicago/Turabian StyleLiu, Yang, Yinghou Jiao, Shiyuan Qi, Guangbin Yu, and Mengdi Du. 2022. "Study on the Nonlinear Dynamic Behavior of Rattling Vibration in Gear Systems" Machines 10, no. 12: 1112. https://doi.org/10.3390/machines10121112

APA StyleLiu, Y., Jiao, Y., Qi, S., Yu, G., & Du, M. (2022). Study on the Nonlinear Dynamic Behavior of Rattling Vibration in Gear Systems. Machines, 10(12), 1112. https://doi.org/10.3390/machines10121112