Industry 4.0-Oriented Turnkey Project: Rapid Configuration and Intelligent Operation of Manufacturing Systems

Abstract

1. Introduction

- In response to the growing demand for turnkey services of manufacturing systems under the trend of personalized manufacturing, key research on the configuration and operation of manufacturing systems is carried out around the construction and implementation of I4TP;

- Through the introduction of the I4TP, the core functional process of it is summarized into the configuration and the operation management of manufacturing systems, and the configuration view and the operation view are extracted and established, respectively, from RAMI4.0 to conceptually describe these two aspects;

- Guided by the configuration and operation views, a turnkey project platform is established in the Advanced Manufacturing Technology Center (AMTC), and the design, development, and application of key enabling tools for the configuration and operation of I4TP are introduced in detail through this platform case;

- The key function process of configuration and operation of the turnkey project platform is verified through product cases, which shows the feasibility of the platform and the good application prospects of the I4TP.

2. Related Work

- Manufacturing system configuration

- Manufacturing system operation

3. Industry 4.0-Oriented Turnkey Project and Its Configuration View and Operation View

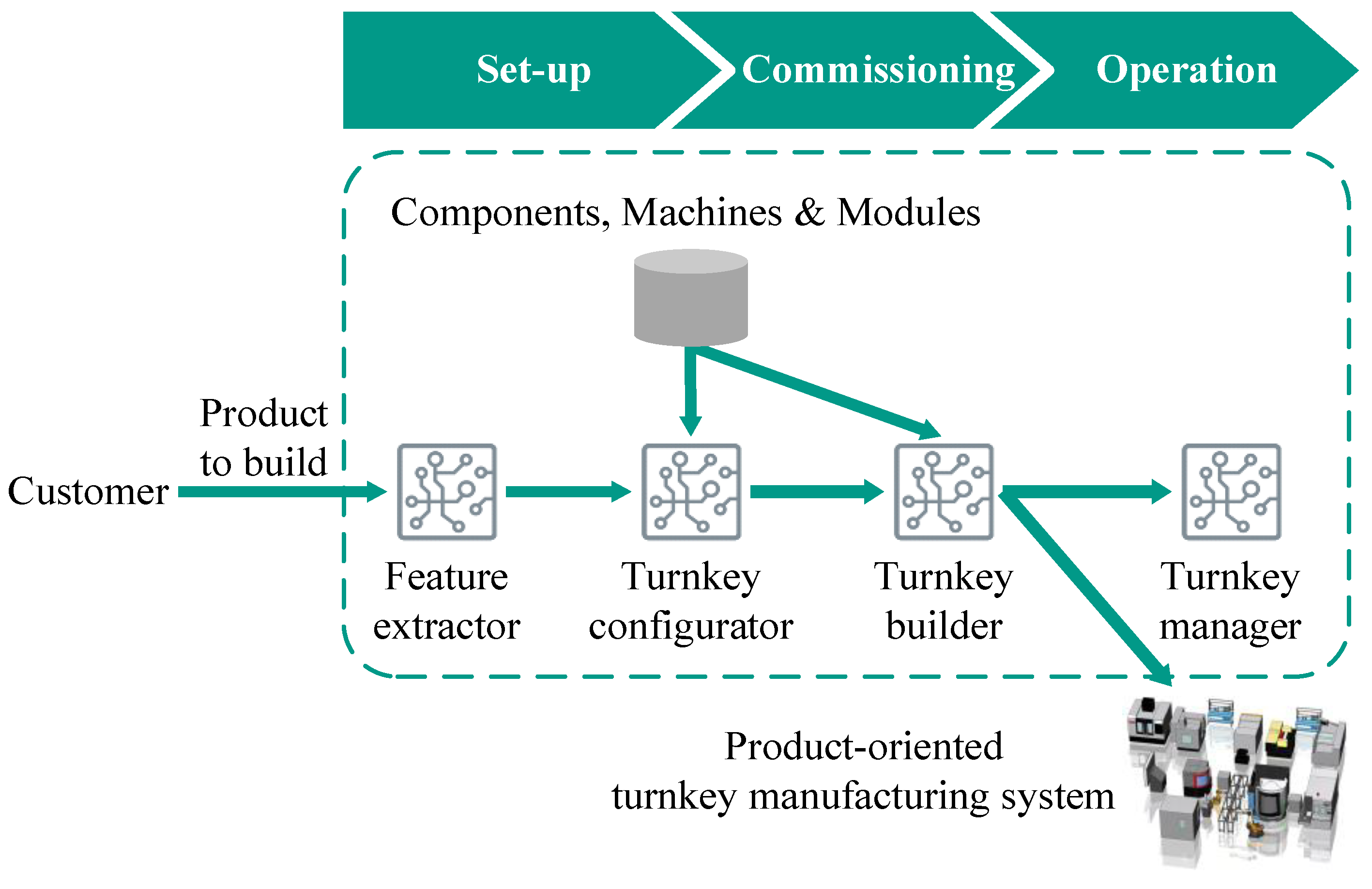

3.1. Introduction of the Industry 4.0-Oriented Turnkey Project

- Standardized turnkey service business process;

- Good coordination ability;

- Rapid information exchange capability;

- A mass of functional modules for automatic and intelligent operation;

- Standard modular functional components;

- Strong compatibility and scalability.

3.2. Configuration View and Operation View of the Turnkey Project

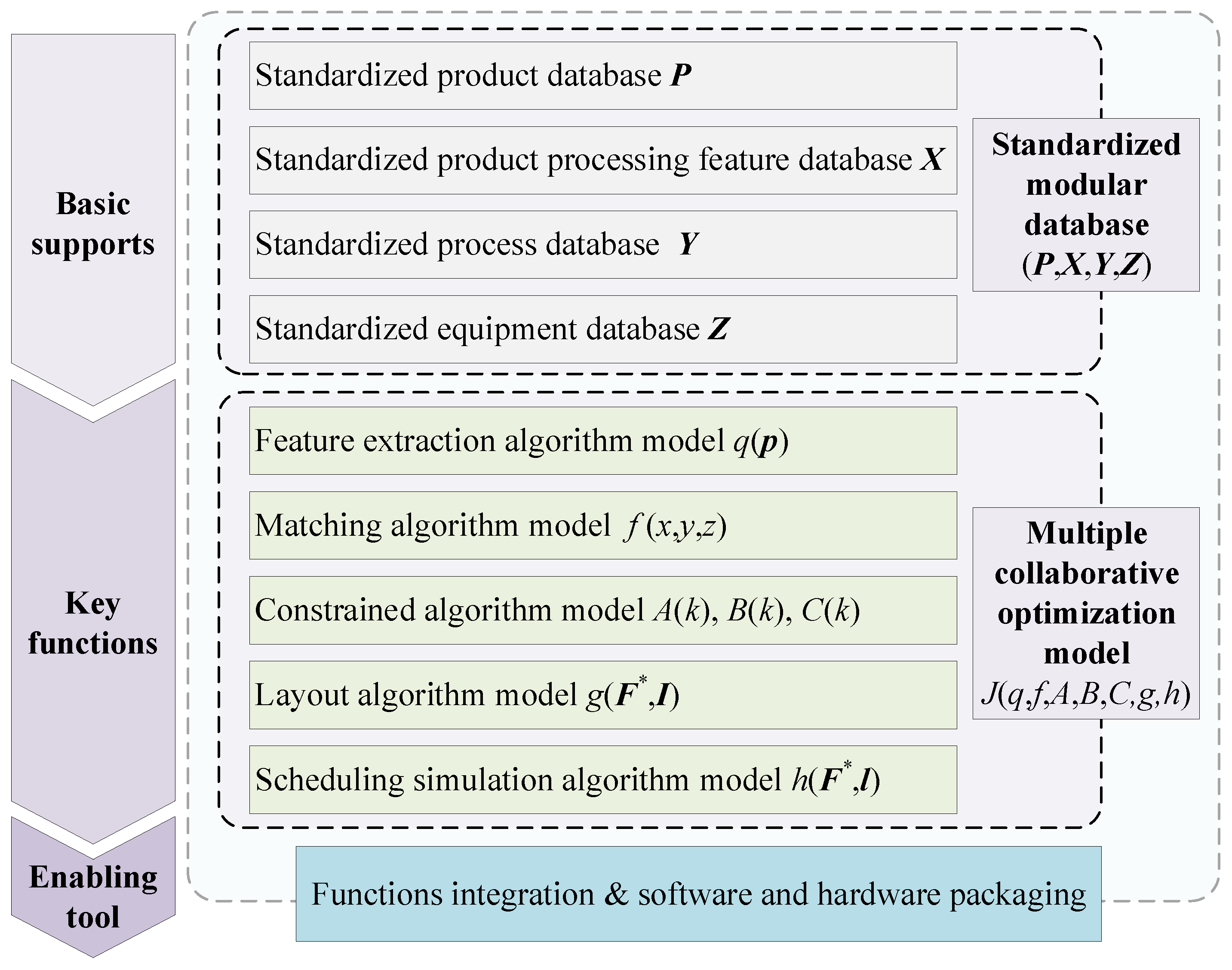

- Configuration view

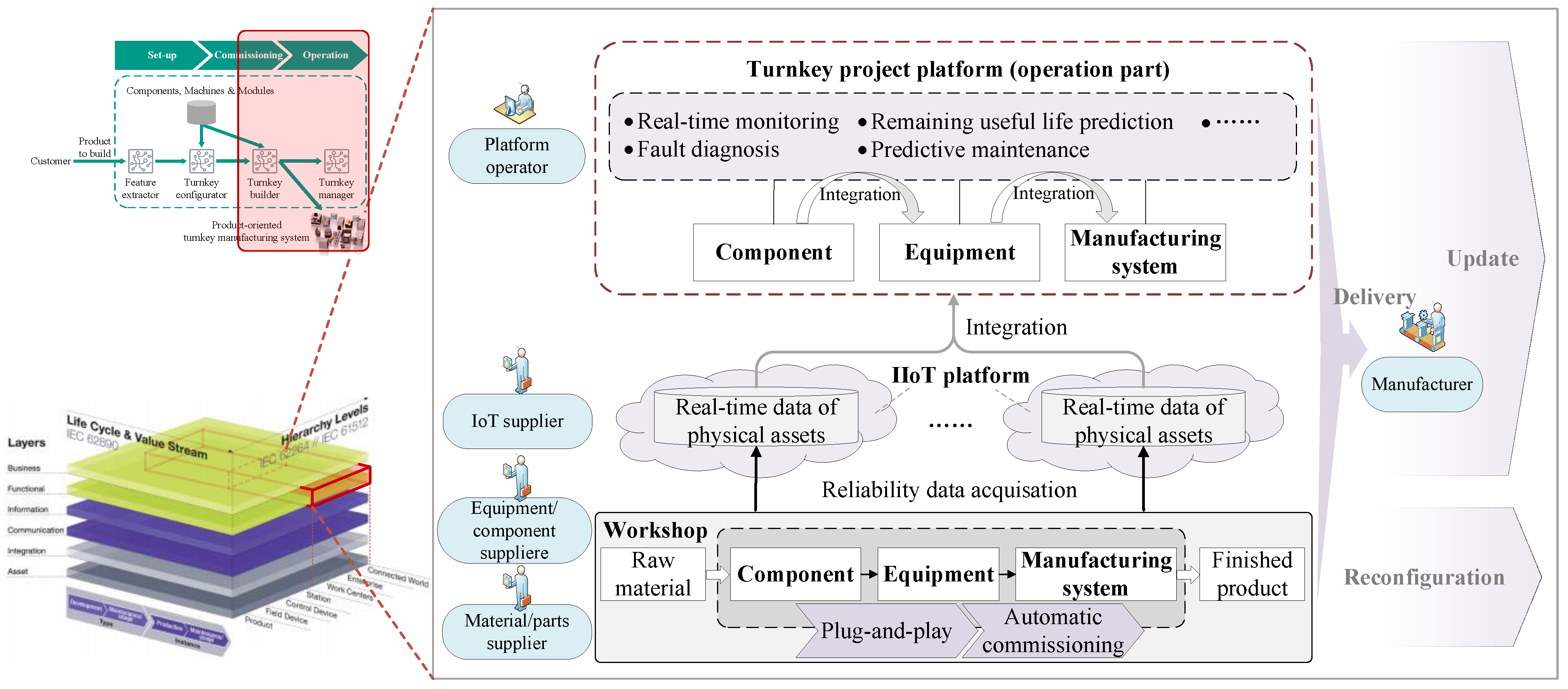

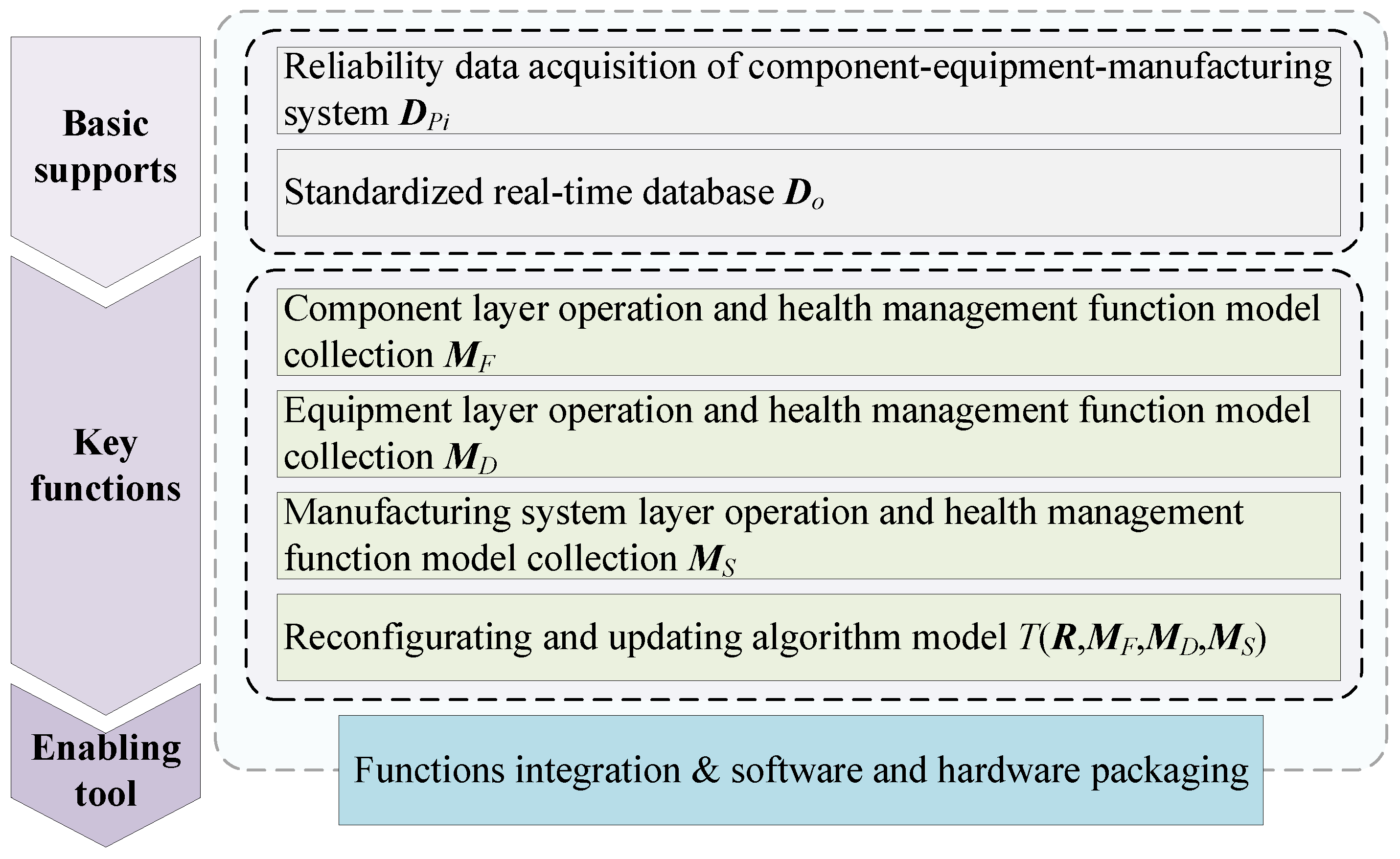

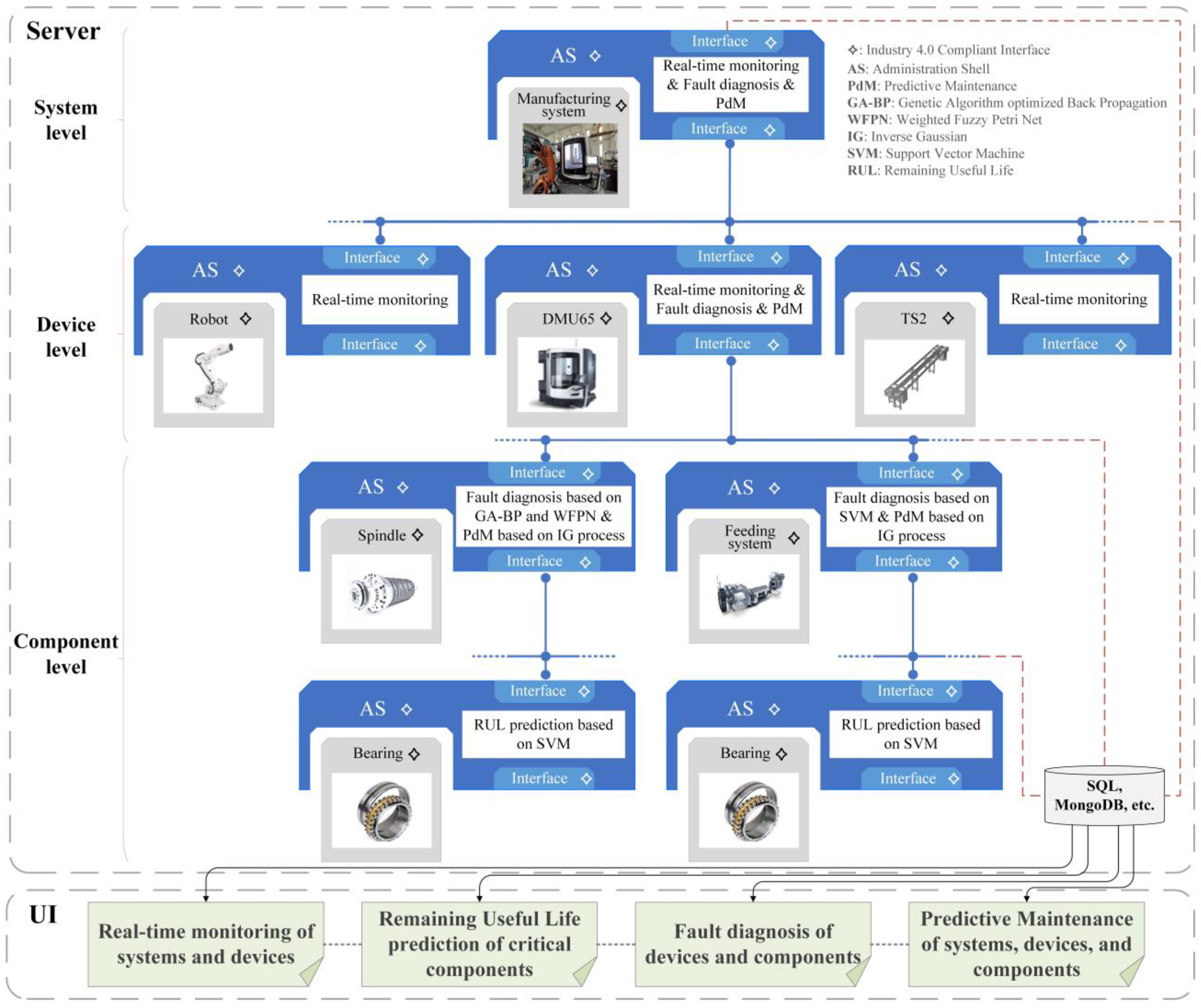

- Operation view

4. Design and Development of Key Enabling Tools for Manufacturing System Configuration and Operation: Taking AMTC as an Example

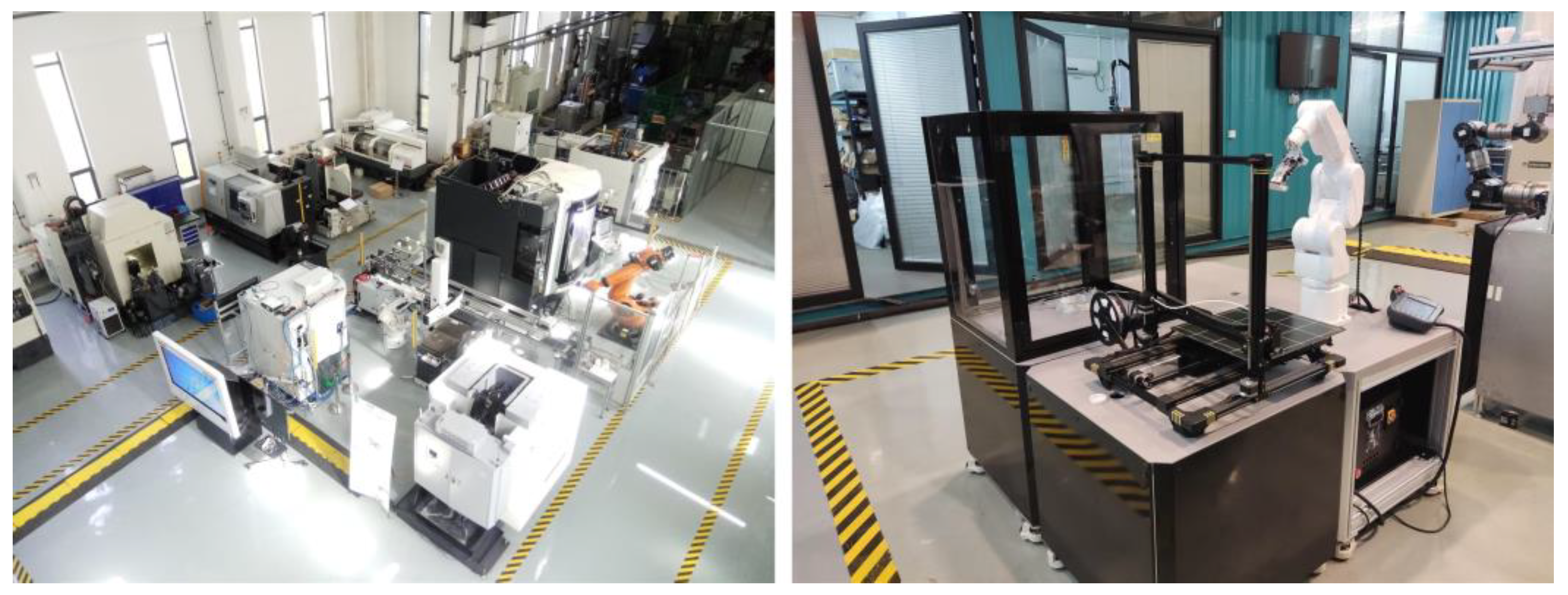

4.1. Development Background of the Turnkey Project Platform in AMTC

- Equipment supports

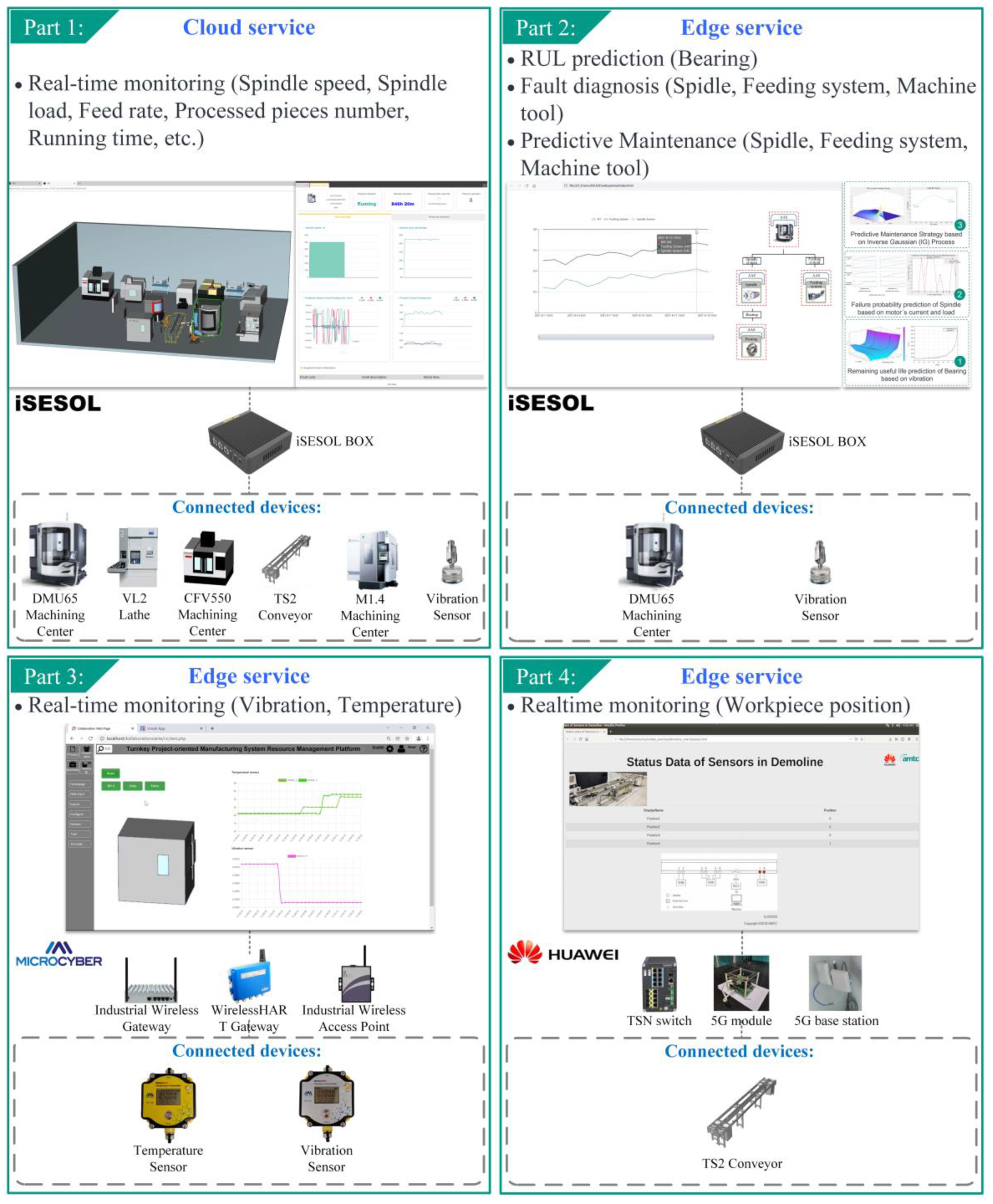

- Machine communication supports

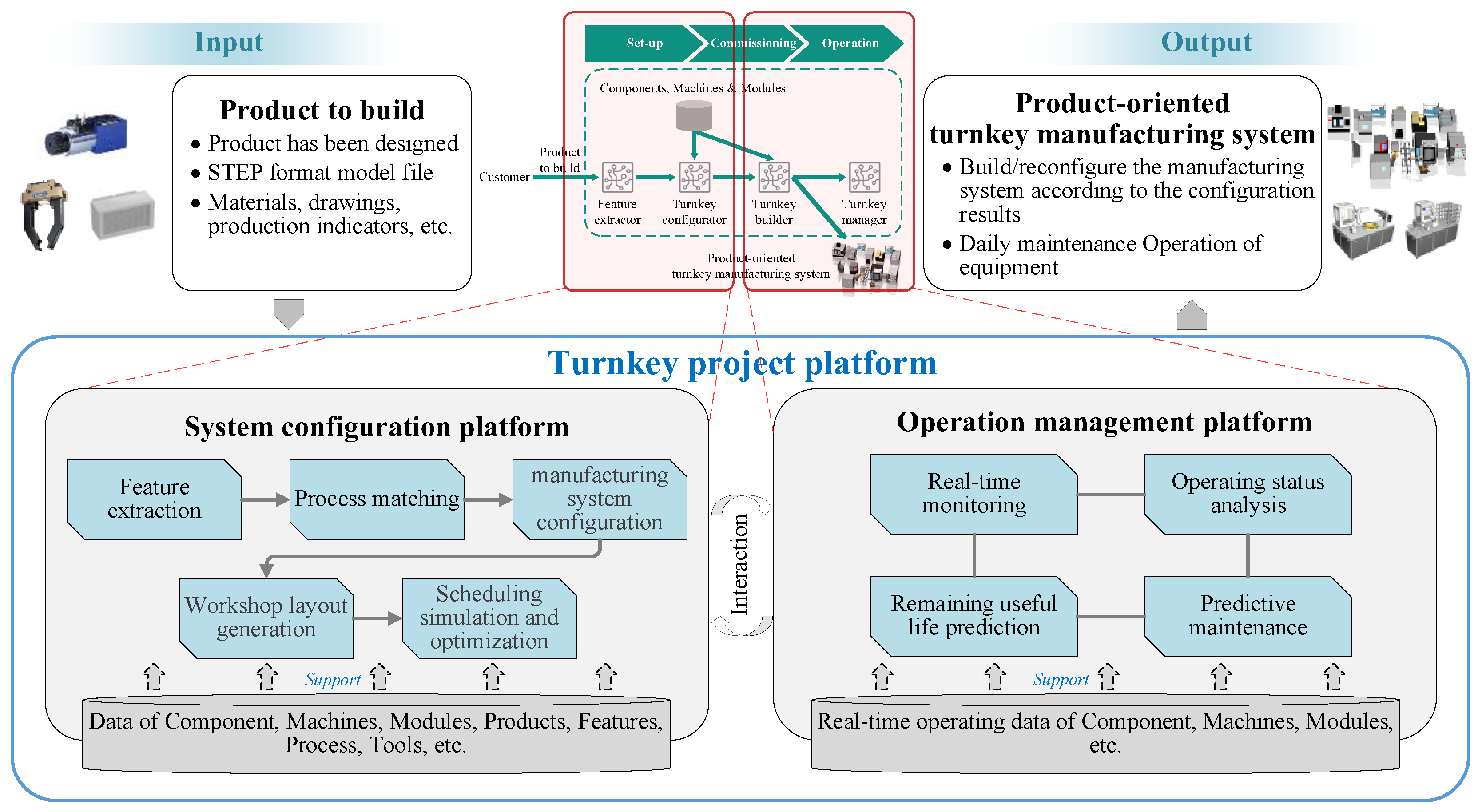

4.2. The Overall Functional Design of the Turnkey Project Platform

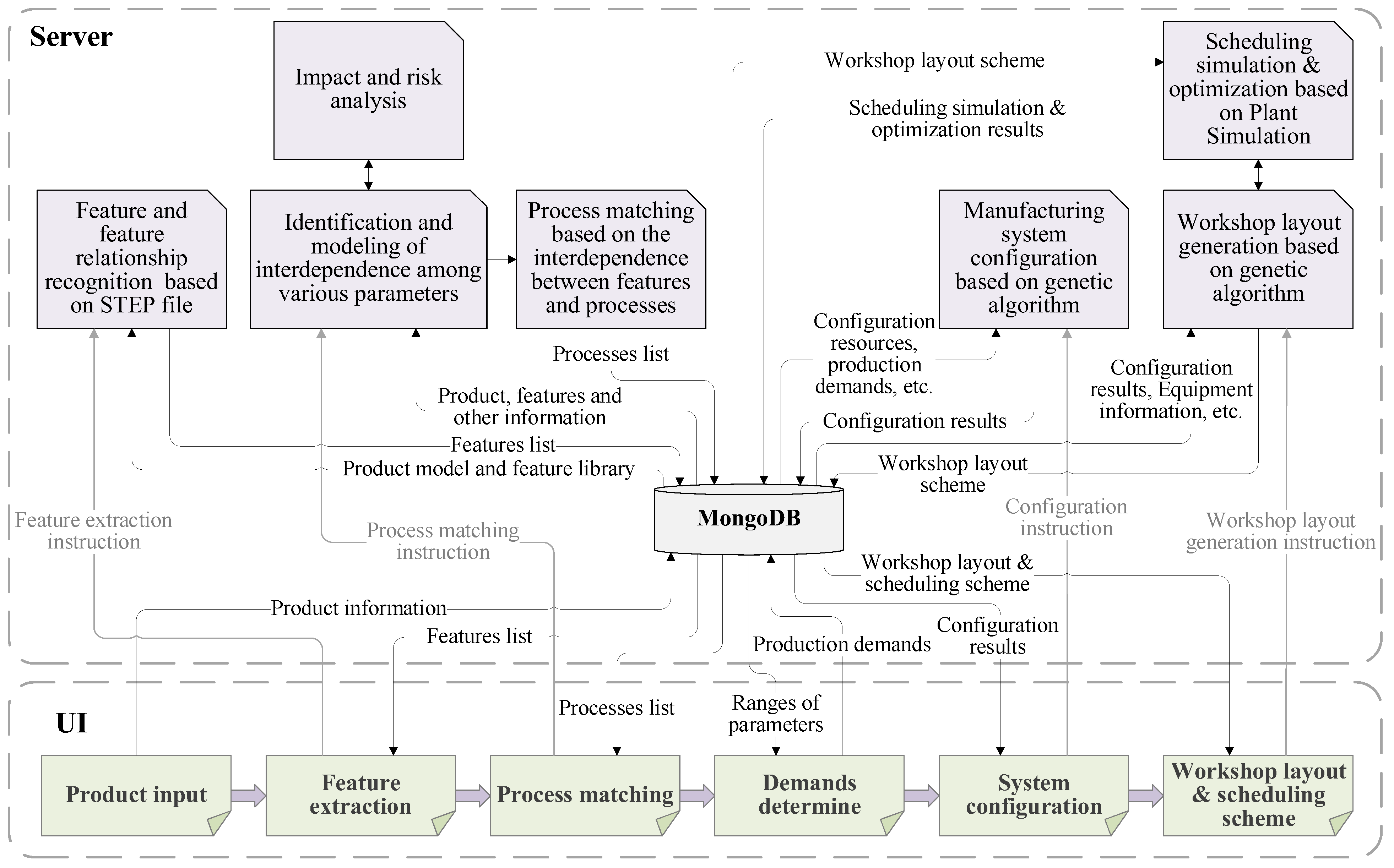

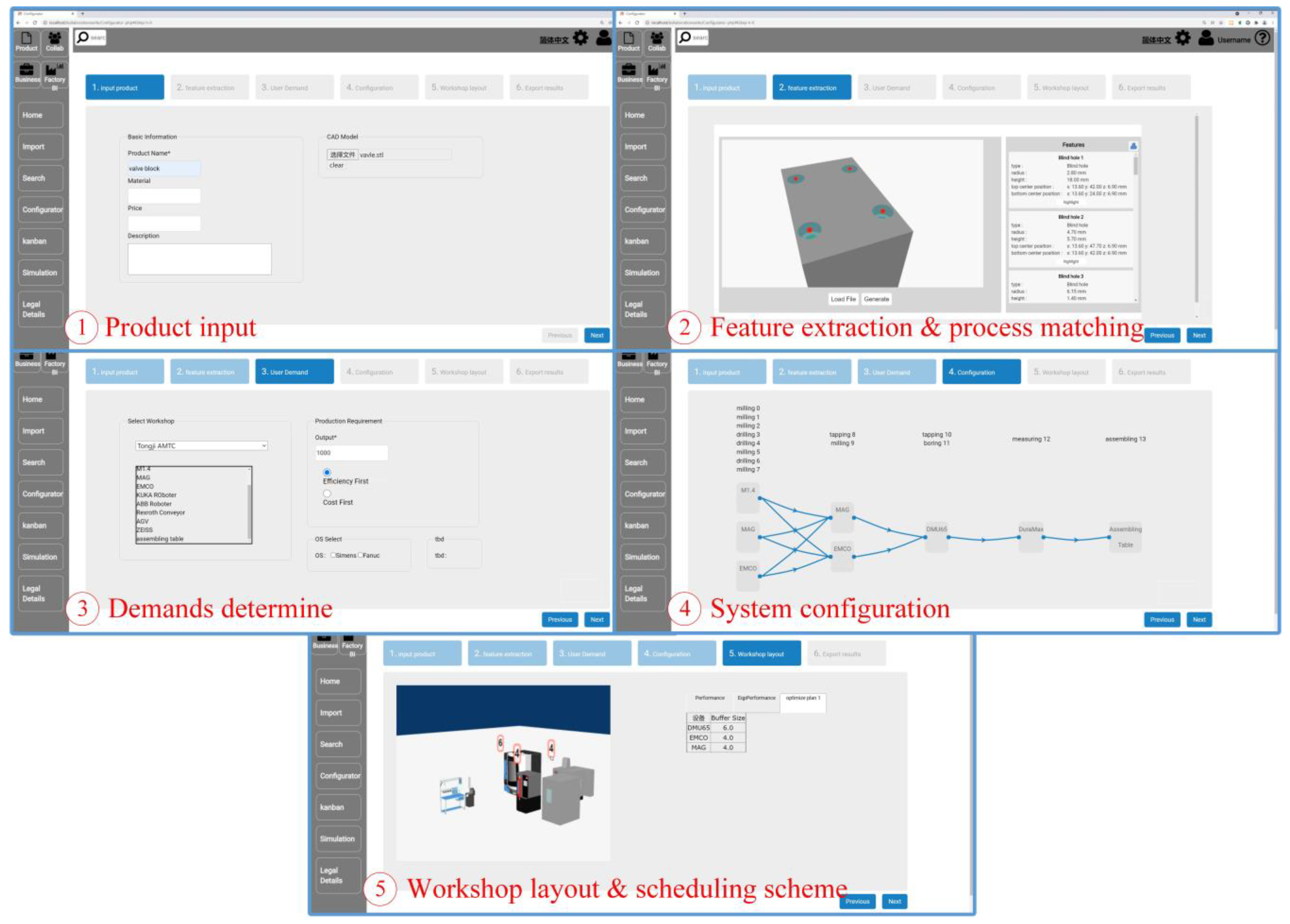

4.3. Design and Development of the System Configuration Platform

4.4. Design and Development of the Operation Management Platform

5. Product-Oriented Manufacturing System Configuration and Operation Cases

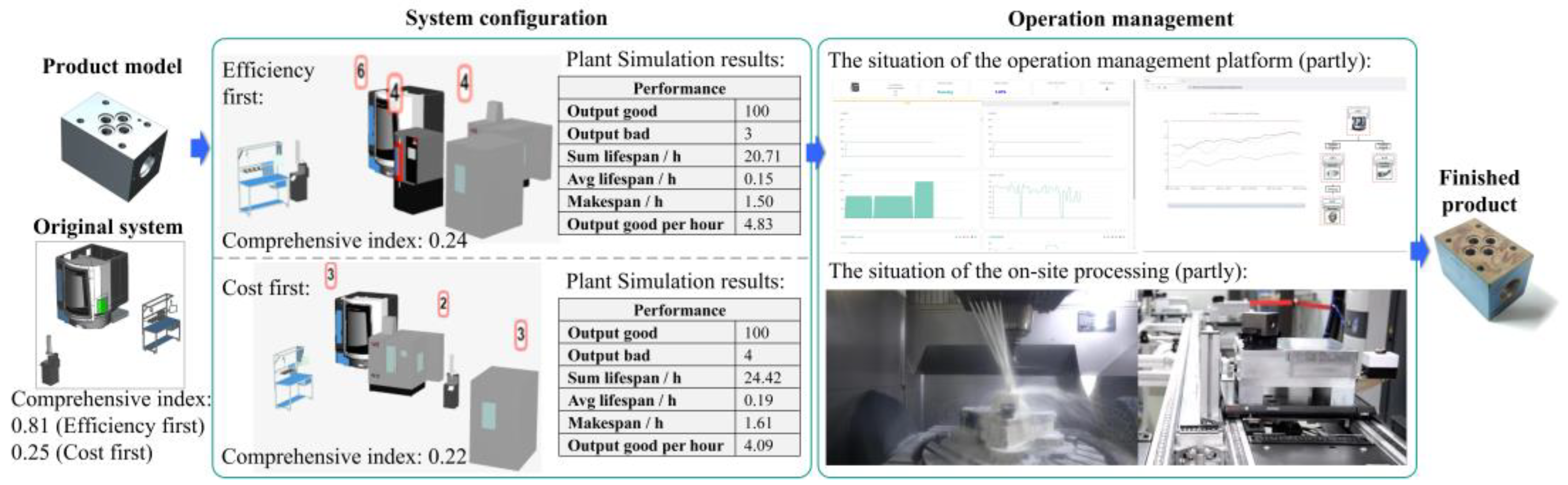

- Hydraulic valve block

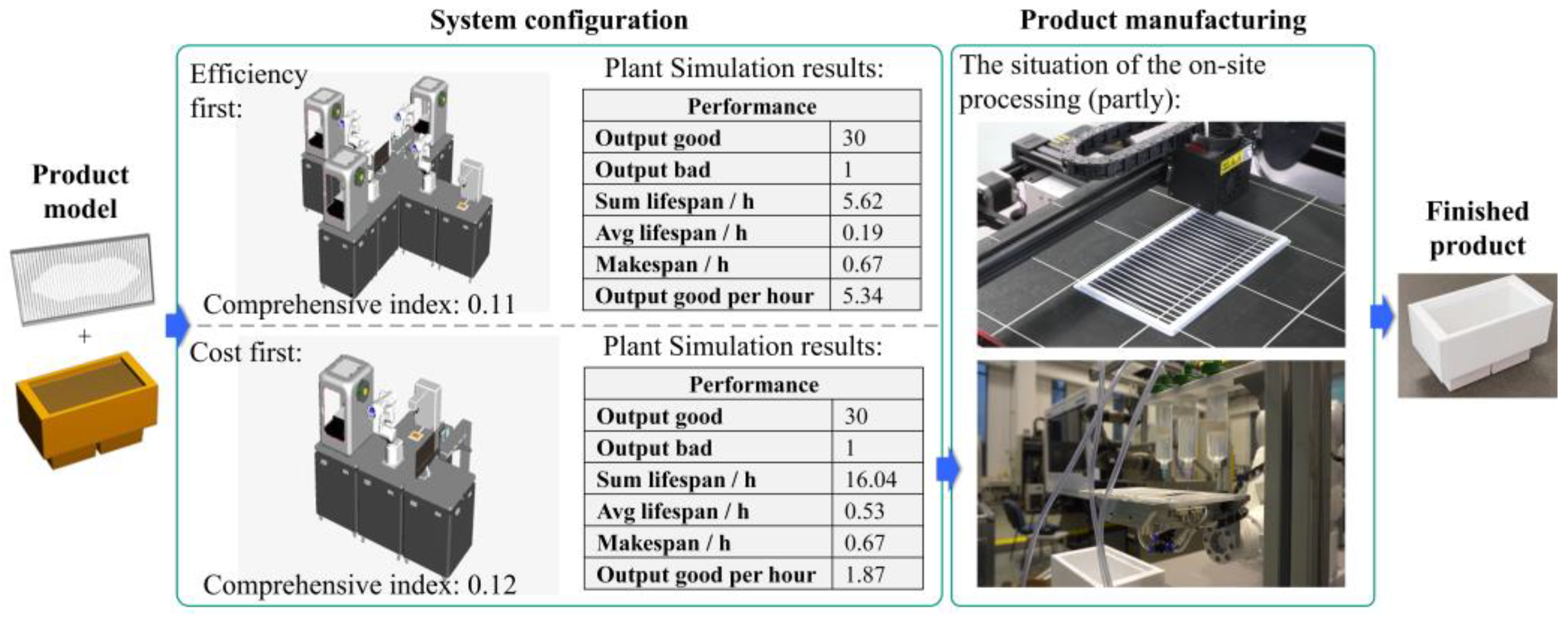

- Gripper base

- Automotive fuel cell (model)

6. Conclusions and Summary

- According to the basic process of generating the turnkey scheme and the characteristics of the turnkey project, the configuration view and the operation view of the turnkey project are proposed based on RAMI4.0. The configuration and operation processes are described in the form of mathematical models, and the key function development processes of configuration and operation enabling tools are given;

- Guided by the configuration and operation views, relying on AMTC’s equipment and machine communication network support, the overall functional design of the turnkey project platform is carried out according to actual needs. The functional structure design and application development of the system configuration platform and the operation management platform are focused on. Various functions of configuration and operation are integrated into the servers, and simple and easy-to-use UIs are provided. This provides users with turnkey services for the rapid configuration of manufacturing systems and intelligent operation management;

- The developed turnkey project platform is verified by taking three products as case studies. The results show that the system configuration and operation management functions of the turnkey project platform can operate normally, and they have achieved good application results, which can meet the rapid configuration and efficient operation management requirements of the manufacturing system.

Author Contributions

Funding

Conflicts of Interest

References

- Mehrabi, M.G.; Ulsoy, A.G.; Koren, Y.; Heytler, P. Trends and perspectives in flexible and reconfigurable manufacturing systems. J. Intell. Manuf. 2002, 13, 135–146. [Google Scholar] [CrossRef]

- Bortolini, M.; Galizia, F.G.; Mora, C. Reconfigurable manufacturing systems: Literature review and research trend. J. Manuf. Syst. 2018, 49, 93–106. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Liu, A.; Kusiak, A. Data-driven smart manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar] [CrossRef]

- Gönnheimer, P.; Kimmig, A.; Mandel, C.; Stürmlinger, T.; Yang, S.; Schade, F.; Ehrmann, C.; Klee, B.; Behrendt, M.; Schlechtendahlc, J.; et al. Methodical approach for the development of a platform for the configuration and operation of turnkey production systems. Procedia CIRP 2019, 84, 880–885. [Google Scholar] [CrossRef]

- DIN SPEC 91345:2016-04; Reference Architecture Model Industrie 4.0 (RAMI4.0). Beuth: Berlin, Germany, 2016.

- Pisching, M.A.; Pessoa, M.A.; Junqueira, F.; dos Santos Filho, D.J.; Miyagi, P.E. An architecture based on RAMI 4.0 to discover equipment to process operations required by products. Comput. Ind. Eng. 2018, 125, 574–591. [Google Scholar] [CrossRef]

- Fast Radius. The Biggest Revolution in Manufacturing since the Assembly Line. Available online: https://www.fastradius.com/capabilities/cloud-manufacturing/ (accessed on 27 September 2022).

- Phoenixcontact. Digital Factory Now. Available online: https://www.phoenixcontact.com/zh-cn/industries/digital-factory (accessed on 27 September 2022).

- Rold. Discover Smartfab. Available online: https://www.rold.com/rold-smartfab-bring-company-4-0-universe/ (accessed on 27 September 2022).

- Instrumentation Technology and Economy Institute, PR. China. Intelligent Manufacturing Comprehensive Test Platform. Available online: http://www.itei.cn/imct.html (accessed on 27 September 2022).

- Schneider Electric. EcoStruxure Platform. Available online: https://www.se.com/ww/en/work/campaign/innovation/platform.jsp (accessed on 27 September 2022).

- Pal Singh, P.; Madan, J.; Singh, H. Composite performance metric for product flow configuration selection of reconfigurable manufacturing system (RMS). Int. J. Prod. Res. 2020, 59, 3996–4016. [Google Scholar] [CrossRef]

- Sabioni, R.C.; Daaboul, J.; Le Duigou, J. Concurrent optimisation of modular product and Reconfigurable Manufacturing System configuration: A customer-oriented offer for mass customisation. Int. J. Prod. Res. 2022, 60, 2275–2291. [Google Scholar] [CrossRef]

- Eynaud, A.B.D.; Klement, N.; Roucoules, L.; Gibaru, O.; Durville, L. Framework for the design and evaluation of a reconfigurable production system based on movable robot integration. Int. J. Adv. Manuf. Technol. 2022, 118, 2373–2389. [Google Scholar] [CrossRef]

- Khan, A.S.; Homri, L.; Dantan, J.Y.; Siadat, A. An analysis of the theoretical and implementation aspects of process planning in a reconfigurable manufacturing system. Int. J. Adv. Manuf. Technol. 2022, 119, 5615–5646. [Google Scholar] [CrossRef]

- Demir, L.; Koyuncuoğlu, M.U. The impact of the optimal buffer configuration on production line efficiency: A VNS-based solution approach. Expert Syst. Appl. 2021, 172, 114631. [Google Scholar] [CrossRef]

- Guo, D.R.; Zhong, Y.; Ling, S.; Rong, Y.; Huang, G.Q. A roadmap for Assembly 4.0: Self-configuration of fixed-position assembly islands under Graduation Intelligent Manufacturing System. Int. J. Prod. Res. 2020, 58, 4631–4646. [Google Scholar] [CrossRef]

- Hou, S.X.; Gao, J.; Wang, C. Design for mass customisation, design for manufacturing, and design for supply chain: A review of the literature. IET Collab. Intell. Manuf. 2022, 4, 1–16. [Google Scholar] [CrossRef]

- Sabioni, R.C.; Daaboul, J.; le Duigou, J. An integrated approach to optimize the configuration of mass-customized products and reconfigurable manufacturing systems. Int. J. Adv. Manuf. Technol. 2021, 115, 141–163. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, D.B.; Zhu, H.H.; Li, S.P.; Nie, Q.W. A flexible configuration method of distributed manufacturing resources in the context of social manufacturing. Comput. Ind. 2021, 132, 103511. [Google Scholar] [CrossRef]

- Khettabi, I.; Benyoucef, L.; Boutiche, M.A. Sustainable reconfigurable manufacturing system design using adapted multi-objective evolutionary-based approaches. Int. J. Adv. Manuf. Technol. 2021, 115, 3741–3759. [Google Scholar] [CrossRef]

- Liu, Q.; Leng, J.; Yan, D.; Zhang, D.; Wei, L.; Yu, A.; Zhao, R.; Zhang, H.; Chen, X. Digital twin-based designing of the configuration, motion, control, and optimization model of a flow-type smart manufacturing system. J. Manuf. Syst. 2021, 58, 52–64. [Google Scholar] [CrossRef]

- Xia, K.; Sacco, C.; Kirkpatrick, M.; Saidy, C.; Nguyen, L.; Kircaliali, A.; Harik, R. A digital twin to train deep reinforcement learning agent for smart manufacturing plants: Environment, interfaces and intelligence. J. Manuf. Syst. 2021, 58, 210–230. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, Y.; Cheng, Y.; Ren, J.; Wang, D.; Qi, Q.; Li, P. Digital twin and blockchain enhanced smart manufacturing service collaboration and management. J. Manuf. Syst. 2022, 62, 903–914. [Google Scholar] [CrossRef]

- Li, L.; Lei, B.; Mao, C. Digital twin in smart manufacturing. J. Ind. Inf. Integr. 2022, 26, 100289. [Google Scholar] [CrossRef]

- Wang, P.; Luo, M. A digital twin-based big data virtual and real fusion learning reference framework supported by industrial internet towards smart manufacturing. J. Manuf. Syst. 2021, 58, 16–32. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Ye, Y.; Zhang, C.; Wei, Y. A hybrid predictive maintenance approach for CNC machine tool driven by Digital Twin. Robot. Comput. Integr. Manuf. 2020, 65, 101974. [Google Scholar] [CrossRef]

- Liu, C.; le Roux, L.; Korner, C.; Tabaste, O.; Lacan, F.; Bigot, S. Digital Twin-enabled Collaborative Data Management for Metal Additive Manufacturing Systems. J. Manuf. Syst. 2022, 62, 857–874. [Google Scholar] [CrossRef]

- Ahola, T.; Laitinen, E.; Kujala, J.; Wikström, K. Purchasing strategies and value creation in industrial turnkey projects. Int. J. Proj. Manag. 2008, 26, 87–94. [Google Scholar] [CrossRef]

- Brady, T.; Davies, A.; Gann, D.M. Creating value by delivering integrated solutions. Int. J. Proj. Manag. 2005, 23, 360–365. [Google Scholar] [CrossRef]

- Gönnheimer, P.; Kimmig, A.; Ehrmann, C.; Schlechtendahl, J.; Güth, J.; Fleischer, J. Concept for the Configuration of Turnkey Production Systems. Procedia CIRP 2019, 86, 234–238. [Google Scholar] [CrossRef]

- Adolphs, P.; Ulrich, E. Reference Architecture Model Industrie 4.0 (RAMI4.0); VDI/VDE & ZVEI: Berlin, Germany, 2015. [Google Scholar]

- Bangemann, T.; Bauer, C.; Bedenbender, H.; Diesner, M.; Epple, U.I.; Elmas, F.; Jens, F.; Grüner, S. Industrie 4.0—Technical Assets—Basic Terminology Concepts, Life Cycles and Administration Models; VDI/VDE & ZVEI: Berlin, Germany, 2016. [Google Scholar]

- Dorst, W.; Glohr, C.; Hahn, T.; Knafla, F.; Loewen, U.; Rosen, R.; Schiemann, T.; Vollmar, F.; Winterhalter, C.; Diegner, B.; et al. Implementation Strategy Industrie 4.0: Report on the Results of the Industrie 4.0 Platform; Bitkom, VDMA & ZVEI: Berlin, Germany, 2016. [Google Scholar]

- D’Agostino, N.; Annacondia, E.; Bentkus, A.; Bianchi, G.; Briant, J.; Heidel, R.; Hoffmeister, M.; Lamboley, P.; Lensi, R.; Rossi, G.; et al. The Structure of the Administration Shell: Trilateral Perspectives from France, Italy and Germany; Plattform Industrie 4.0 & Piano Nazionale Impresa 4.0; Ministry of Economy and Finances: Paris, France; Federal Ministry for Economic Affairs and Energy (BMWi): Berlin, Germany; Ministero dello Sviluppo Economico: Rome, Italy, 2018.

- Bader, S.; Barnstedt, E.; Bedenbender, H.; Billmann, M.; Boss, B.; Braunmandl, A.; Clauer, E.; Deppe, T.; Diedrich, C.; Flubacher, B.; et al. Details of the Asset Administration Shell: Part 1—The Exchange of Information between Partners in the Value Chain of Industrie 4.0 (Version 3.0RC01); Plattform Industrie 4.0; ZVEI: Berlin, Germany, 2020. [Google Scholar]

- Bedenbender, H.; Billmann, M.; Epple, U.; Hadlich, T.; Hankel, M.; Heidel, R.; Hillermeier, O.; Hoffmeister, M.; Huhle, H.; Jochem, M.; et al. White Paper: Examples of the Asset Administration Shell for Industrie 4.0 Components—Basic Part; ZVEI: Berlin, Germany, 2017. [Google Scholar]

- DIN SPEC 16593-1; Reference Model for Industrie 4.0 Service Architectures—Part 1: Basic Concepts of an Interaction-Based Architecture. Beuth: Berlin, Germany, 2018.

- Bedenbender, H.; Bentkus, A.; Epple, U.; Hadlich, T.; Heidel, R.; Hillermeier, O.; Hoffmeister, M.; Huhle, H.; Kiele-Dunsche, M.; Koziolek, H.; et al. Industrie 4.0 Plug-and-Produce for Adaptable Factories: Example Use Case Definition, Models, and Implementation; Plattform Industrie 4.0; ZWEI: Berlin, Germany, 2017. [Google Scholar]

- Billmann, M.; Boss, B.; Epple, U.I.; Garrels, K.; Hadlich, T.; Hankel, M.; Heidel, R.; Hillermeier, O.; Jochem, M.; Hoffmeister, M.; et al. Which Criteria Do Industrie 4.0 Products Need to Fulfil? Guideline 2019; Plattform Industrie 4.0; ZVEI: Berlin, Germany, 2019. [Google Scholar]

- Angeli, C.; Boss, B.; Braunmandl, A.; Brost, G.; Claus, M.; Dressel, O.; Förder, T.; Garrels, K.; Hoffmeister, M.; Houdeau, D.; et al. Plattform Industrie 4.0. Access Control for Industrie 4.0 Components for Application by Manufacturers, Operators and Integrators; Federal Ministry for Economic Affairs and Energy (BMWi): Berlin, Germany, 2019.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, S.; Zhang, W.; Xue, F.; Li, D.; Liu, Y.; Fleischer, J.; Ehrmann, C. Industry 4.0-Oriented Turnkey Project: Rapid Configuration and Intelligent Operation of Manufacturing Systems. Machines 2022, 10, 983. https://doi.org/10.3390/machines10110983

Xie S, Zhang W, Xue F, Li D, Liu Y, Fleischer J, Ehrmann C. Industry 4.0-Oriented Turnkey Project: Rapid Configuration and Intelligent Operation of Manufacturing Systems. Machines. 2022; 10(11):983. https://doi.org/10.3390/machines10110983

Chicago/Turabian StyleXie, Shulian, Weimin Zhang, Feng Xue, Dongdong Li, Yangbokun Liu, Jürgen Fleischer, and Christopher Ehrmann. 2022. "Industry 4.0-Oriented Turnkey Project: Rapid Configuration and Intelligent Operation of Manufacturing Systems" Machines 10, no. 11: 983. https://doi.org/10.3390/machines10110983

APA StyleXie, S., Zhang, W., Xue, F., Li, D., Liu, Y., Fleischer, J., & Ehrmann, C. (2022). Industry 4.0-Oriented Turnkey Project: Rapid Configuration and Intelligent Operation of Manufacturing Systems. Machines, 10(11), 983. https://doi.org/10.3390/machines10110983