A Case Study in Social Manufacturing: From Social Manufacturing to Social Value Chain

Abstract

1. Introduction

2. Literature and Prior Work

2.1. Definition of Terms

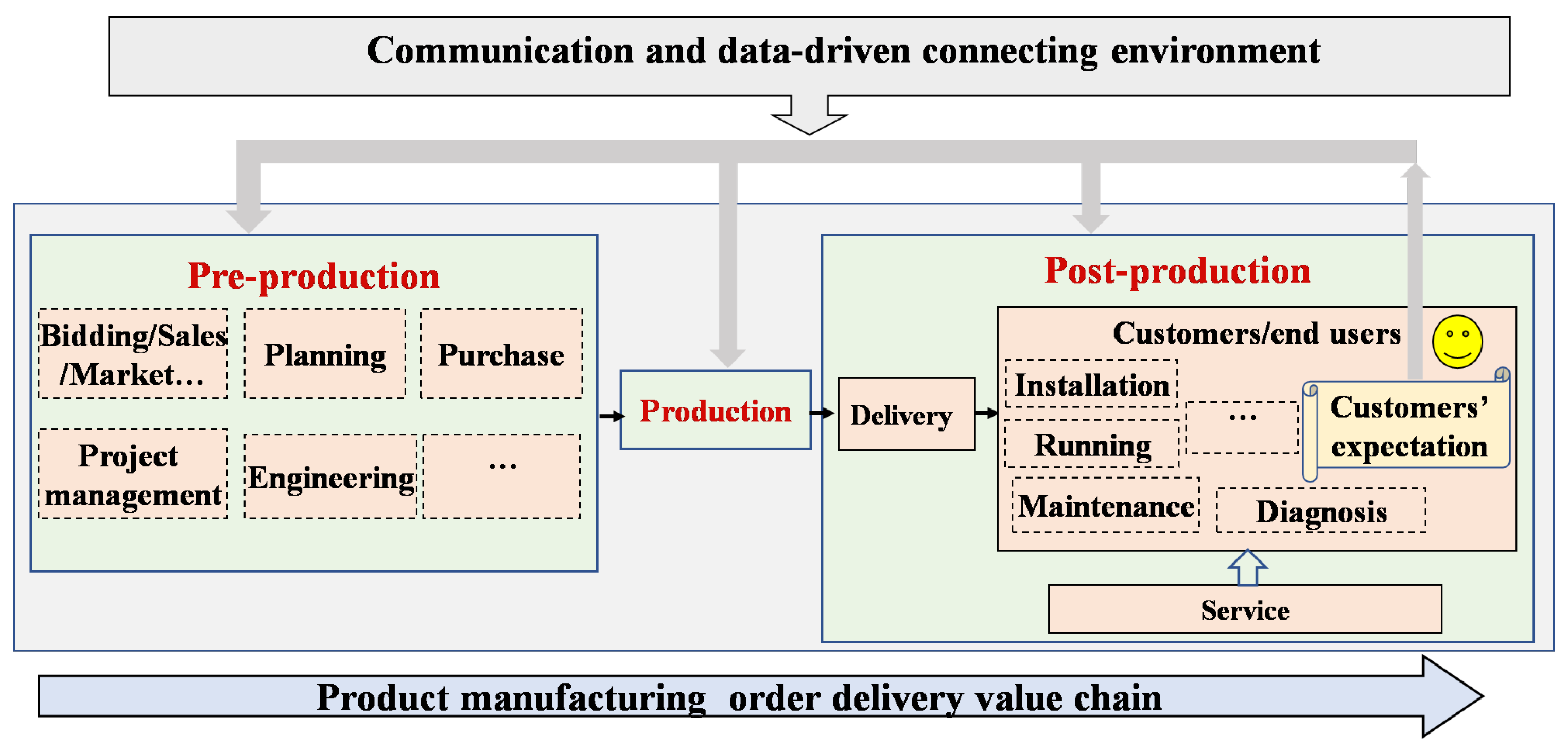

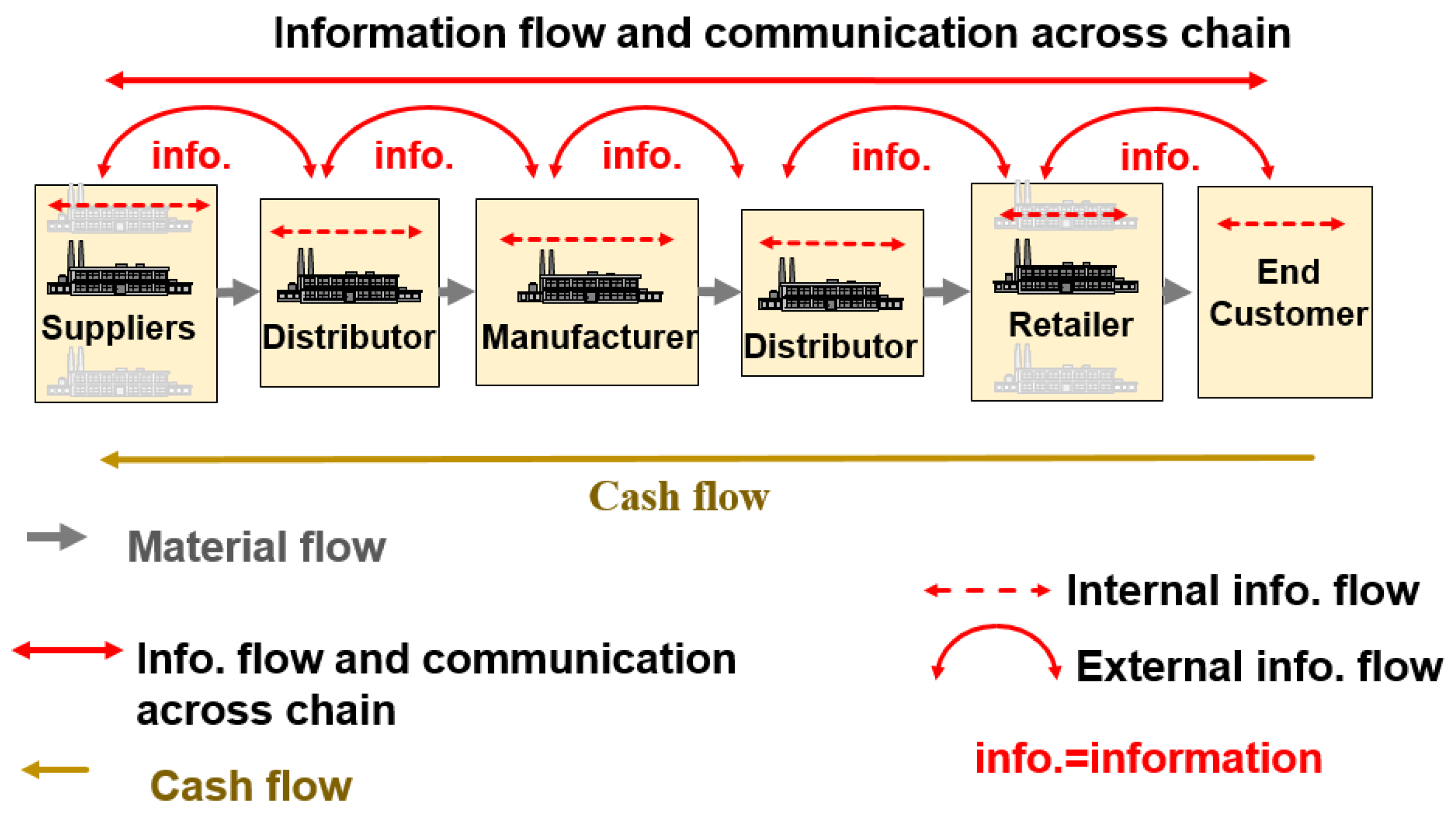

2.2. Evolution of Value Chain Concept

- -

- Sourcing issues: due to the limited capacity of sourcing in enterprises and the supply-side market, it is not easy to select qualified suppliers at reasonable cost. Therefore, waste is caused by sourcing or supplier issues.

- -

- Service issues: due to service having been considered a crucial factor in competitiveness in recent years, many enterprises must try to meet the requirements from customers. In particular, for the process of after-sales, such as installing, commissioning and maintenance on-site, service problems have existed for a long time, and in the normal mode are difficult to solve. For instance, the crane industry has suffered from timeliness, effectiveness, efficiency in after-sales service, such as delays, and declining productivity [30]. In particular, with an increased amount of customization and personalization, the demand for after-sales service or product maintenance has been increasing dramatically. Good service can provide more value-adding potential for enterprises; however, most enterprises lack effective service systems or appropriate service providers and support technology to meet the requirements through the normal mode.

- -

- Networking issues: from the perspective of connecting with customers, customer feedback is an integral part of the business. There is no scope for improvement if enterprises do not get to know what the customer likes and does not like. From the perspective of interacting and communicating among manufacturing resources, such as people-to-people, people-to-machine or machine-to-people, and machine-to-machine, the communicating and interacting mode has great room for improvement.

- -

- Mass customization (MC) issues: due to customized and personalized demand in markets becoming permanent trend, there is a lot of space to create value relevant to customized products and services. However, regardless of mass production, lean production, or other normal manufacturing mode, it has been increasingly difficult to satisfy increased individual requirements and specifications by means of normal VC.

- -

- Sharing issues: limited sharing of information on sourcing, capacity, and other resources among all participants in VC brings about huge waste through normal VC. For instance, enterprise A has excess capacity, while enterprise B in the same industry a lack of capacity, but enterprise B cannot utilize the excess capacity from A. Similar issues have widely existed in the context of normal manufacturing mode and VC.

- -

- Technical issues: lack of support technology limits the value-added capacity throughout the VC process Technical issues are also obstacles to the creating of value from enterprises to customers.

2.3. Evolution of SocialM

- Microlization and minimalization of manufacturing resources;

- Self-enterprise of socialized manufacturing resources;

- Virus-like propagation of enterprise structure;

- Sharing and competing capabilities and business benefits;

- Dynamically distributive infrastructure;

- Big-data driven decision-making and performance optimization;

- Industrial software model to be used.

2.4. Contributions of the Research

- New thinking for enterprises in terms of having more opportunities to add value, as compared with the normal manufacturing mode;

- Establishing the social value chain system for all participants/enterprises across the chain by means of the value chain concept and SocialM mode with supporting technology;

- Considering a suitable performance measurement to monitor and evaluate whether the SocialVC system works efficiently.

3. Method

4. Results and Discussion

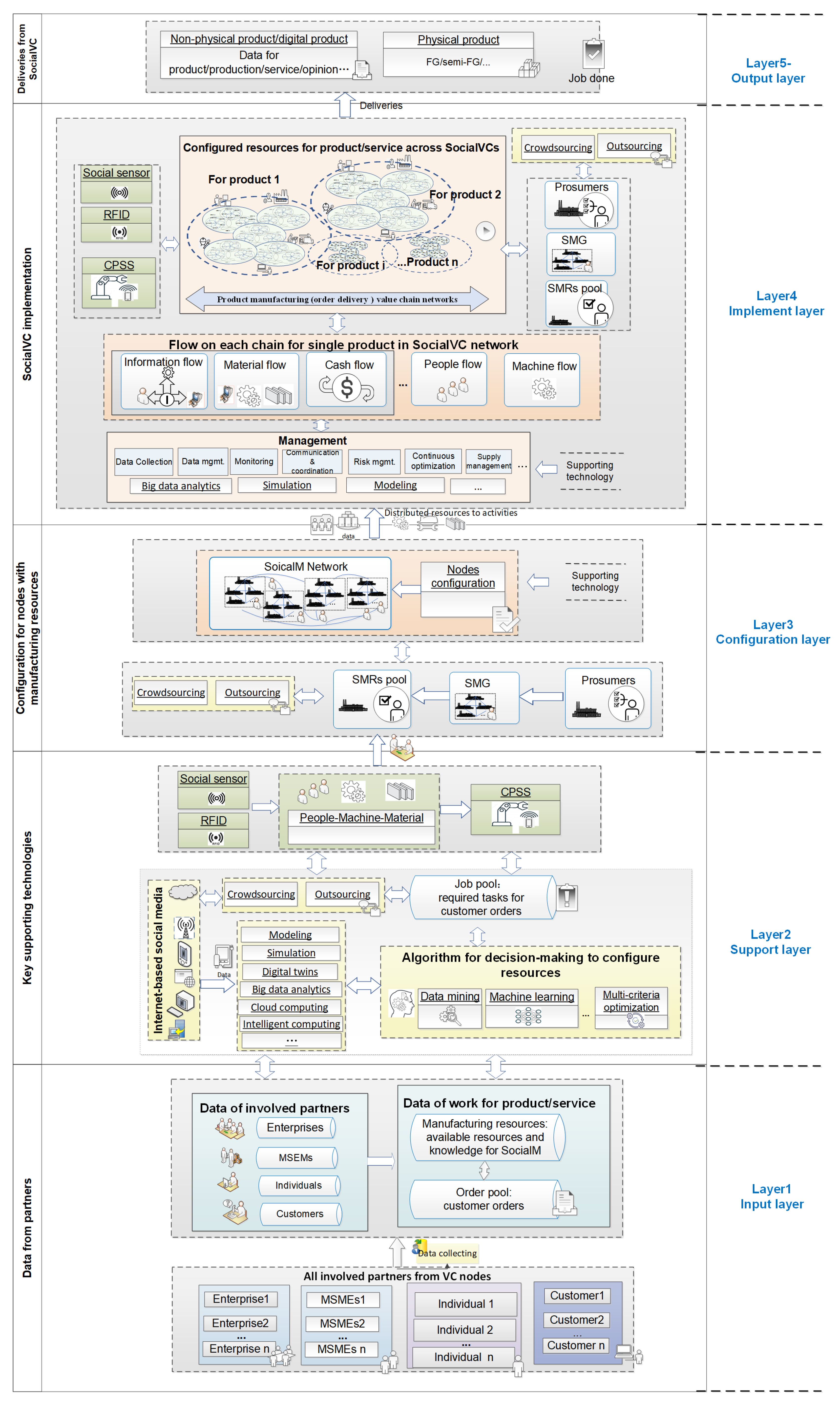

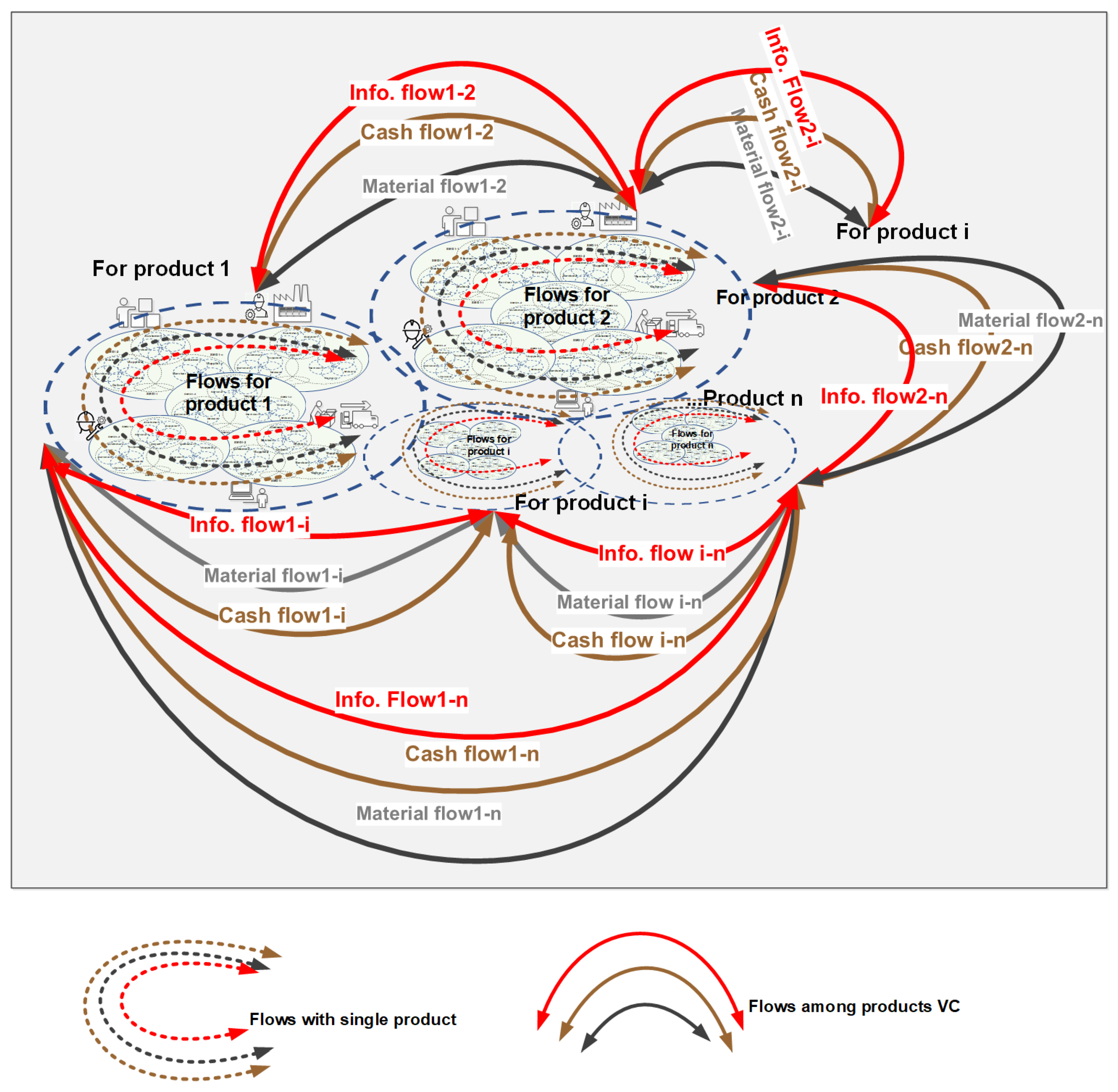

4.1. Establishing an Architecture of the SocialVC System

4.1.1. Layer1—Input Layer

4.1.2. Layer2—Support Layer

4.1.3. Layer3—Configuration Layer

4.1.4. Layer4—Implement Layer

4.1.5. Layer5—Output Layer

4.2. SocialVC Measurement Framework

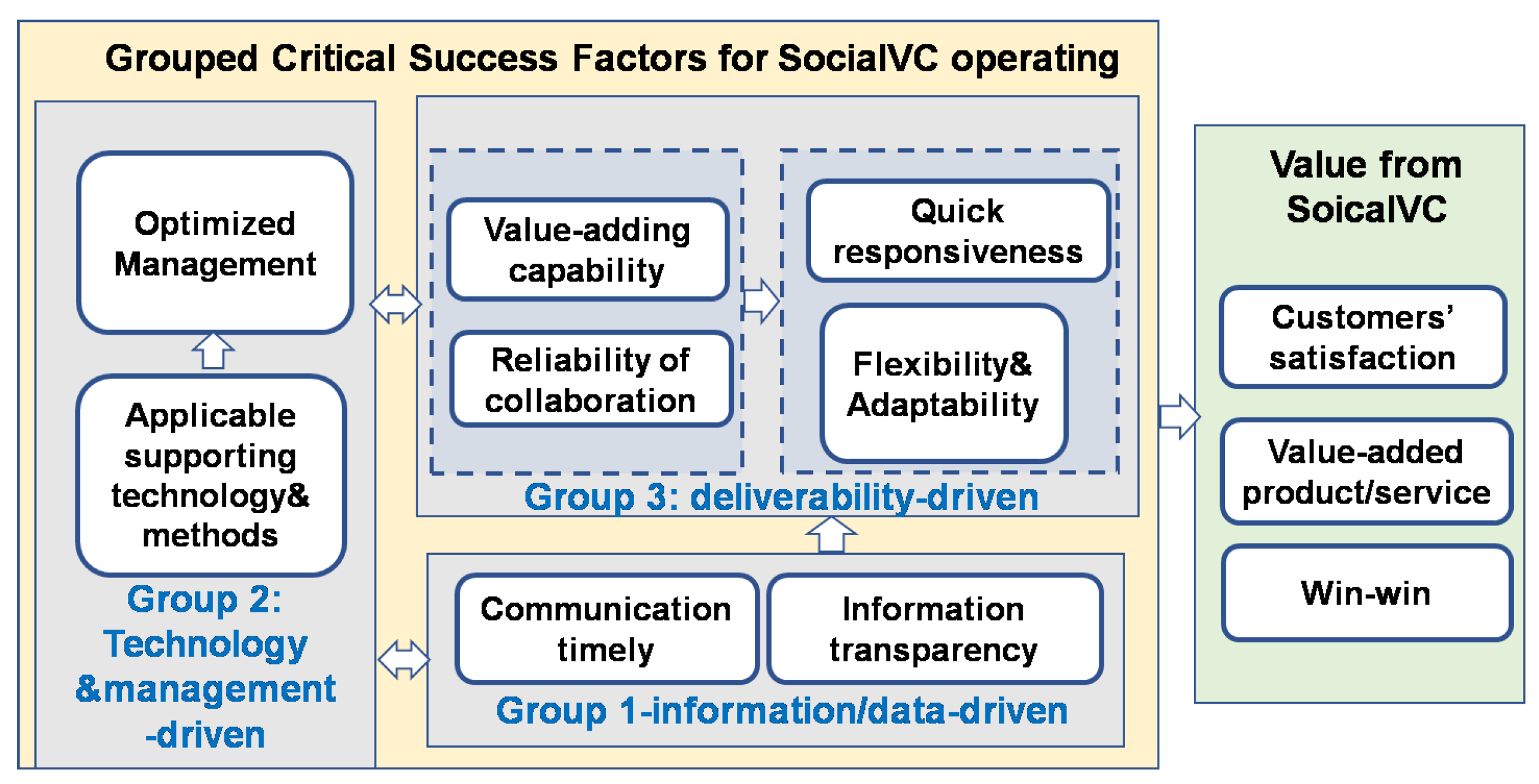

4.3. Critical Success Factors for SocialVC Operation

4.4. Performance Measurement Framework of VC

5. Conclusions and Future Research

5.1. Conclusions

5.2. Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Markillie, P. A Third Industrial Revolution. The Economist, 21 April 2012. [Google Scholar]

- Wang, F.Y. From social computing to social manufacturing: The coming industrial revolution and new frontier in cyber-physical-social space. Bull. Chin. Acad. Sci. 2012, 6, 658–669. [Google Scholar]

- Park, J.M.; Kim, B.S. Review of social manufacturing technology on product life cycle management (PLM) base. J. Korean Inst. Ind. Eng. 2013, 39, 156–162. [Google Scholar]

- Shang, X.; Liu, X.; Xiong, G.; Cheng, C.; Ma, Y.; Nyberg, T.R. Social manufacturing cloud service platform for the mass customization in apparel industry. In Proceedings of the 2013 IEEE International Conference on Service Operations and Logistics, and Informatics, Dongguan, China, 28–30 July 2013; pp. 220–224. [Google Scholar]

- Xiong, G.; Chen, Y.; Shang, X.; Liu, X.; Nyberg, T.R. AHP fuzzy comprehensive method of supplier evaluation in social manufacturing mode. In Proceedings of the 11th World Congress on Intelligent Control and Automation, Shenyang, China, 29 June–4 July 2014; pp. 3594–3599. [Google Scholar]

- Mohajeri, B.; Nyberg, T.; Karjalainen, J.; Tukiainen, T.; Nelson, M.; Shang, X.; Xiong, G. The impact of social manufacturing on the value chain model in the apparel industry. In Proceedings of the 2014 IEEE International Conference on Service Operations and Logistics, and Informatics, Beijing, China, 12–15 October 2014; pp. 378–381. [Google Scholar]

- Mohajeri, B. Paradigm Shift from Current Manufacturing to Social Manufacturing. Master’s Thesis, Aalto University, Espoo, Finland, 2015. [Google Scholar]

- Shang, X.; Shen, Z.; Xiong, G.; Wang, F.Y.; Liu, S.; Nyberg, T.R.; Wu, H.; Guo, C. Moving from mass customization to social manufacturing: A footwear industry case study. Int. J. Comput. Integr. Manuf. 2019, 32, 194–205. [Google Scholar] [CrossRef]

- Hamalainen, M.; Karjalainen, J. Social manufacturing: When the maker movement meets interfirm production networks. Bus. Horizons 2017, 60, 795–805. [Google Scholar] [CrossRef]

- Cao, W.; Jiang, P.Y. Cloud machining community for social manufacturing. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Baech, Switzerland, 2012; Volume 220, pp. 61–64. [Google Scholar]

- Cao, W.; Jiang, P.; Jiang, K. Demand-based manufacturing service capability estimation of a manufacturing system in a social manufacturing environment. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 1275–1297. [Google Scholar] [CrossRef]

- Jiang, P.; Ding, K.; Leng, J. Towards a cyber-physical-social-connected and service-oriented manufacturing paradigm: Social Manufacturing. Manuf. Lett. 2016, 7, 15–21. [Google Scholar] [CrossRef]

- Jiang, P.; Leng, J. The configuration of social manufacturing: A social intelligence way toward service-oriented manufacturing. Int. J. Manuf. Res. 2017, 12, 4–19. [Google Scholar] [CrossRef]

- Jiang, P. Social Manufacturing: Fundamentals and Applications; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- ASCM. Association for Supply Chain Management. Available online: https://www.ascm.org/ (accessed on 20 March 2022).

- The Smiling Curve, “Wikipedia”. 2017. Available online: https://en.wikipedia.org/wiki/Smiling_curve#cite_note-1 (accessed on 15 January 2022).

- Pettersen, J. Defining lean production: Some conceptual and practical issues. TQM J. 2009, 21, 127–142. [Google Scholar] [CrossRef]

- Ritzer, G.; Dean, P.; Jurgenson, N. The coming of age of the prosumer. Am. Behav. Sci. 2012, 56, 379–398. [Google Scholar] [CrossRef]

- Brabham, D.C. Crowdsourcing as a model for problem solving: An introduction and cases. Convergence 2008, 14, 75–90. [Google Scholar] [CrossRef]

- Porter, M.E. How competitive forces shape strategy. Harv. Bus. Rev. 1979, 57, 137–145. [Google Scholar]

- Porter, M.E. Techniques for Analysing Industries and Competitors. In Competitive Strategy; Free: New York, NY, USA, 1980. [Google Scholar]

- Hopkins, T.K.; Wallerstein, I. Commodity Chains in the World-Economy Prior to 1800; Research Foundation of State University of New York: Albany, NY, USA, 1986; Volume 10, pp. 157–170. [Google Scholar]

- Gereffi, G. The organization of buyer-driven global commodity chains: How US retailers shape overseas production networks. In Commodity Chains and Global Capitalism; ABC-CLIO: Santa Barbara, CA, USA, 1994; pp. 95–122. [Google Scholar]

- Kaplinsky, R.; Morris, M. A Handbook for Value Chain Research Brighton; Institute for Development Studies: Brighton, UK, 2001. [Google Scholar]

- Ohno, T. Toyota Production System on Audio Tape: Beyond Large Scale Production; Productivity Press: New York, NY, USA, 2001. [Google Scholar]

- Womack, J.P.; Jones, D.T. From lean production to lean enterprise. Harv. Bus. Rev. 1994, 72, 93–103. [Google Scholar]

- Krafcik, J.F. Triumph of the lean production system. Sloan Manag. Rev. 1988, 30, 41–52. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean Thinking; Simon & Schuster: London, UK, 2005. [Google Scholar]

- Xiong, G.; Wu, H.; Helo, P.; Shang, X.; Xiong, G.; Qin, R.; Wang, F.Y. A Kind of Change Management Method for Global Value Chain Optimization and Its Case Study. IEEE Trans. Comput. Soc. Syst. 2021, 9, 1060–1074. [Google Scholar] [CrossRef]

- Rajnoha, R.; Sujová, A.; Dobrovič, J. Management and economics of business processes added value. Procedia-Soc. Behav. Sci. 2012, 62, 1292–1296. [Google Scholar] [CrossRef][Green Version]

- WTO. World Trade Report 2021: Economic Resilience and Trade. 2021. Available online: https://www.wto.org/english/res_e/booksp_e/wtr21_e/00_wtr21_e.pdf (accessed on 15 July 2022).

- Olearczyk, J.; Lei, Z.; Ofrim, B.; Han, S.; Al-Hussein, M. Intelligent Crane Management Algorithm for Construction Operation. In Proceedings of the 2015 32nd ISARC, Oulu, Finland, 15–18 June 2015. [Google Scholar]

- Acquier, A.; Daudigeos, T.; Pinkse, J. Promises and paradoxes of the sharing economy: An organizing framework. Technol. Forecast. Soc. Chang. 2017, 125, 1–10. [Google Scholar] [CrossRef]

- Mont, O.; Palgan, Y.V.; Bradley, K.; Zvolska, L. A decade of the sharing economy: Concepts, users, business and governance perspectives. J. Clean. Prod. 2020, 269, 122215. [Google Scholar] [CrossRef]

- Zervas, G.; Proserpio, D.; Byers, J.W. The rise of the sharing economy: Estimating the impact of Airbnb on the hotel industry. J. Mark. Res. 2017, 54, 687–705. [Google Scholar] [CrossRef]

- RepRap Community. Available online: http://reprap.org (accessed on 15 May 2022).

- Juracz, L.; Lattmann, Z.; Levendovszky, T.; Hemingway, G.; Gaggioli, W.; Netterville, T.; Pap, G.; Smyth, K.; Howard, L. VehicleFORGE: A Cloud-Based Infrastructure for Collaborative Model-Based Design. In MDHPCL@ MoDELS; Citeseer: Princeton, NJ, USA, 2013; pp. 25–36. [Google Scholar]

- Zhou, J.; Yao, X. Hybrid teaching–learning-based optimization of correlation-aware service composition in cloud manufacturing. Int. J. Adv. Manuf. Technol. 2017, 91, 3515–3533. [Google Scholar] [CrossRef]

- VehicleFORGE. Available online: http://www.vehicleforge.org (accessed on 8 April 2022).

- Wang, F.Y.; Yuan, Y.; Wang, X.; Qin, R. Societies 5.0: A new paradigm for computational social systems research. IEEE Trans. Comput. Soc. Syst. 2018, 5, 2–8. [Google Scholar] [CrossRef]

- Gladden, M.E. Who will be the members of Society 5.0? Towards an anthropology of technologically posthumanized future societies. Soc. Sci. 2019, 8, 148. [Google Scholar] [CrossRef]

- Ding, K.; Jiang, P.; Su, S. RFID-enabled social manufacturing system for inter-enterprise monitoring and dispatching of integrated production and transportation tasks. Robot. Comput.-Integr. Manuf. 2018, 49, 120–133. [Google Scholar] [CrossRef]

- Wang, S.; Wang, J.; Wang, X.; Qiu, T.; Yuan, Y.; Ouyang, L.; Guo, Y.; Wang, F.Y. Blockchain-powered parallel healthcare systems based on the ACP approach. IEEE Trans. Comput. Soc. Syst. 2018, 5, 942–950. [Google Scholar] [CrossRef]

- Ding, K.; Jiang, P.Y. Social sensors (S2ensors): A kind of hardware-software-integrated mediators for social manufacturing systems under mass individualization. Chin. J. Mech. Eng. 2017, 30, 1150–1161. [Google Scholar] [CrossRef]

- Insight Ningbo. Available online: http://news.cnnb.com.cn/system/2022/01/19/030322900.shtml (accessed on 25 June 2022).

- Jiang, P.; Leng, J.; Ding, K. Social manufacturing: A survey of the state-of-the-art and future challenges. In Proceedings of the 2016 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI), Sydney, Australia, 24–27 July 2016; pp. 12–17. [Google Scholar]

- Xiong, G.; Wang, F.Y.; Nyberg, T.R.; Shang, X.; Zhou, M.; Shen, Z.; Li, S.; Guo, C. From mind to products: Towards social manufacturing and service. IEEE/CAA J. Autom. Sin. 2017, 5, 47–57. [Google Scholar] [CrossRef]

- Xiong, G.; Shang, X.; Xiong, G.; Nyberg, T.R. A kind of lean approach for removing wastes from non-manufacturing process with various facilities. IEEE/CAA J. Autom. Sin. 2019, 6, 307–315. [Google Scholar] [CrossRef]

- Xiong, G.; Tamir, T.S.; Shen, Z.; Shang, X.; Wu, H.; Wang, F.Y. A Survey on Social Manufacturing: A Paradigm Shift for Smart Prosumers. IEEE Trans. Comput. Soc. Syst. 2022; Early Access. [Google Scholar] [CrossRef]

- Guo, W.; Li, P.; Yang, M.; Liu, J.; Jiang, P. Social Manufacturing: What are its key fundamentals? IFAC-PapersOnLine 2020, 53, 65–70. [Google Scholar] [CrossRef]

- Wang, F.Y.; Shang, X.; Qin, R.; Xiong, G.; Nyberg, T.R. Social manufacturing: A paradigm shift for smart prosumers in the era of societies 5.0. IEEE Trans. Comput. Soc. Syst. 2019, 6, 822–829. [Google Scholar] [CrossRef]

- Rosen, R.; Von Wichert, G.; Lo, G.; Bettenhausen, K.D. About the importance of autonomy and digital twins for the future of manufacturing. IFAC-Papersonline 2015, 48, 567–572. [Google Scholar] [CrossRef]

- Ding, K.; Jiang, P.; Leng, J.; Cao, W. Modeling and analyzing of an enterprise relationship network in the context of social manufacturing. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 752–769. [Google Scholar] [CrossRef]

- Wang, F.Y. Parallel system methods for management and control of complex systems. Control Decis. 2004, 19, 485–489. [Google Scholar]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the digital twin for design and production engineering. CIRP Ann. 2017, 66, 141–144. [Google Scholar] [CrossRef]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.Y.; Nee, A.Y. Digital twin-driven product design framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y. Digital twin in industry: State-of-the-art. IEEE Trans. Ind. Inf. 2018, 15, 2405–2415. [Google Scholar] [CrossRef]

- Leng, J.; Jiang, P. A deep learning approach for relationship extraction from interaction context in social manufacturing paradigm. Knowl.-Based Syst. 2016, 100, 188–199. [Google Scholar] [CrossRef]

- Xue, X.; Wang, S.; Zhang, L.; Feng, Z.; Guo, Y. Social learning evolution (SLE): Computational experiment-based modeling framework of social manufacturing. IEEE Trans. Ind. Inf. 2018, 15, 3343–3355. [Google Scholar] [CrossRef]

- European Union Commission. Commission recommendation of 6 May 2003 concerning the definition of micro, small and medium-sized enterprises. Off. J. Eur. Union 2003, 46, 36–41. [Google Scholar]

- Tamir, T.S.; Xiong, G.; Dong, X.; Fang, Q.; Liu, S.; Lodhi, E.; Shen, Z.; Wang, F.Y. Design and Optimization of a Control Framework for Robot Assisted Additive Manufacturing Based on the Stewart Platform. Int. J. Control Autom. Syst. 2022, 20, 968–982. [Google Scholar] [CrossRef]

- Tamir, T.S.; Xiong, G.; Fang, Q.; Dong, X.; Shen, Z.; Wang, F.Y. A feedback-based print quality improving strategy for FDM 3D printing: An optimal design approach. Int. J. Adv. Manuf. Technol. 2022, 120, 2777–2791. [Google Scholar] [CrossRef]

- Henao, R.; Sarache, W.; Gomez, I. Social Performance Metrics for Manufacturing Industry. In Proceedings of the 24th EurOMA Conference, Edinburgh, Scotland, 1–5 July 2017; Volume 10. [Google Scholar]

- ASCM. Structure of SCOR. Available online: https://www.ascm.org/learning-development/certifications-credentials/scor-p/ (accessed on 15 July 2022).

- Bullen, C.V.; Rockart, J.F. A primer on critical success factors. In The Rise of Managerial Computing: The Best of the Center for Information Systems Research; Massachusetts Institute of Technology, Sloan School of Management: Cambridge, MA, USA, 1981. [Google Scholar]

- Zhu, Q.; Liu, A.; Li, Z.; Yang, Y.; Miao, J. Sustainable Supplier Selection and Evaluation for the Effective Supply Chain Management System. Systems 2022, 10, 166. [Google Scholar] [CrossRef]

- Liu, D.; Wu, D.; Wu, S. A Graph Matching Model for Designer Team Selection for Collaborative Design Crowdsourcing Tasks in Social Manufacturing. Machines 2022, 10, 776. [Google Scholar] [CrossRef]

| No. | Metrics | Definitions | Examples |

|---|---|---|---|

| 1 | Level of data/information supportability | Measurement that focuses on how effectively the relevance data system/process/program/activity behaves in data management towards the business goal, such as data collection, data analysis, sharing, etc. across the value chain | Accuracy, Completeness, Timeliness of data collection, Consistency of data, Revise timely, Quality of data analysis, Traceability, data/information richness for carrying out required tasks/delivery, Level of privacy & security of data |

| 2 | Level of cooperating-ability | Measurement that focuses on how effectively communication/coordination is carried out among participants (prosumers/SMRs/SMGs) across the value chain | Supporting data/information, Timeliness of responses and feedback, Efficiency of interaction process/techniques/social media/channels for communication/coordination/sharing |

| 3 | Level of technology supportability | Measurement that focuses on how the defined support technology supports relevant goals of process/management/prosumers | Convenience, Stability, Maintainability, Connectivity of multiple techniques, Connectivity for requirement, Enableability, Compatibility |

| 4 | Level of Management | Measurement that focuses on how defined management system with relevant process/role effectively to achieve relevant management goal | Achievement of goal, Maturity of management process, Development of people’s skills, method of CI (continuous improvement) for optimization |

| 5 | Service level of delivery | Measurement that focuses on operational factors across the value chain to achieve both satisfaction of customers/prosumers, and win–win for all participants/prosumers of the value chain | Responsiveness to customer, Flexibility and adaptability to change, Rate of perfect order fulfillment |

| 6 | Value-adding capability | Measurement that focuses on the ability from all participants/prosumers across the value chain to carry out value-adding activity/task on product/service to meet the expectations of customers/prosumers | Total cash-to-cash cycle time, Total order delivery cost, Total of asset utilization of prosumers, Value of customer/prosumer; perceived value of product/service, Ability of innovation to create value for both customers and prosumers |

| 7 | Maturity of SocialVC | Measurement that focuses on how SocialVC operates in a resilient, stable, and healthy manner to deliver a product/service. Sl VC may define different maturity assessment models according to different management systems/processes with specific goals towards value-adding and win–win across the value chain | Maturity of data/information, Maturity of management/process across the chain, Maturity of overall cooperation/commitment of all prosumers/SMRs/SMGs |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, G.-Y.; Helo, P.; Ekstrom, S.; Tamir, T.S. A Case Study in Social Manufacturing: From Social Manufacturing to Social Value Chain. Machines 2022, 10, 978. https://doi.org/10.3390/machines10110978

Xiong G-Y, Helo P, Ekstrom S, Tamir TS. A Case Study in Social Manufacturing: From Social Manufacturing to Social Value Chain. Machines. 2022; 10(11):978. https://doi.org/10.3390/machines10110978

Chicago/Turabian StyleXiong, Guang-Yu, Petri Helo, Steve Ekstrom, and Tariku Sinshaw Tamir. 2022. "A Case Study in Social Manufacturing: From Social Manufacturing to Social Value Chain" Machines 10, no. 11: 978. https://doi.org/10.3390/machines10110978

APA StyleXiong, G.-Y., Helo, P., Ekstrom, S., & Tamir, T. S. (2022). A Case Study in Social Manufacturing: From Social Manufacturing to Social Value Chain. Machines, 10(11), 978. https://doi.org/10.3390/machines10110978