Machining Quality Prediction of Marine Diesel Engine Block Based on Error Transmission Network

Abstract

:1. Introduction

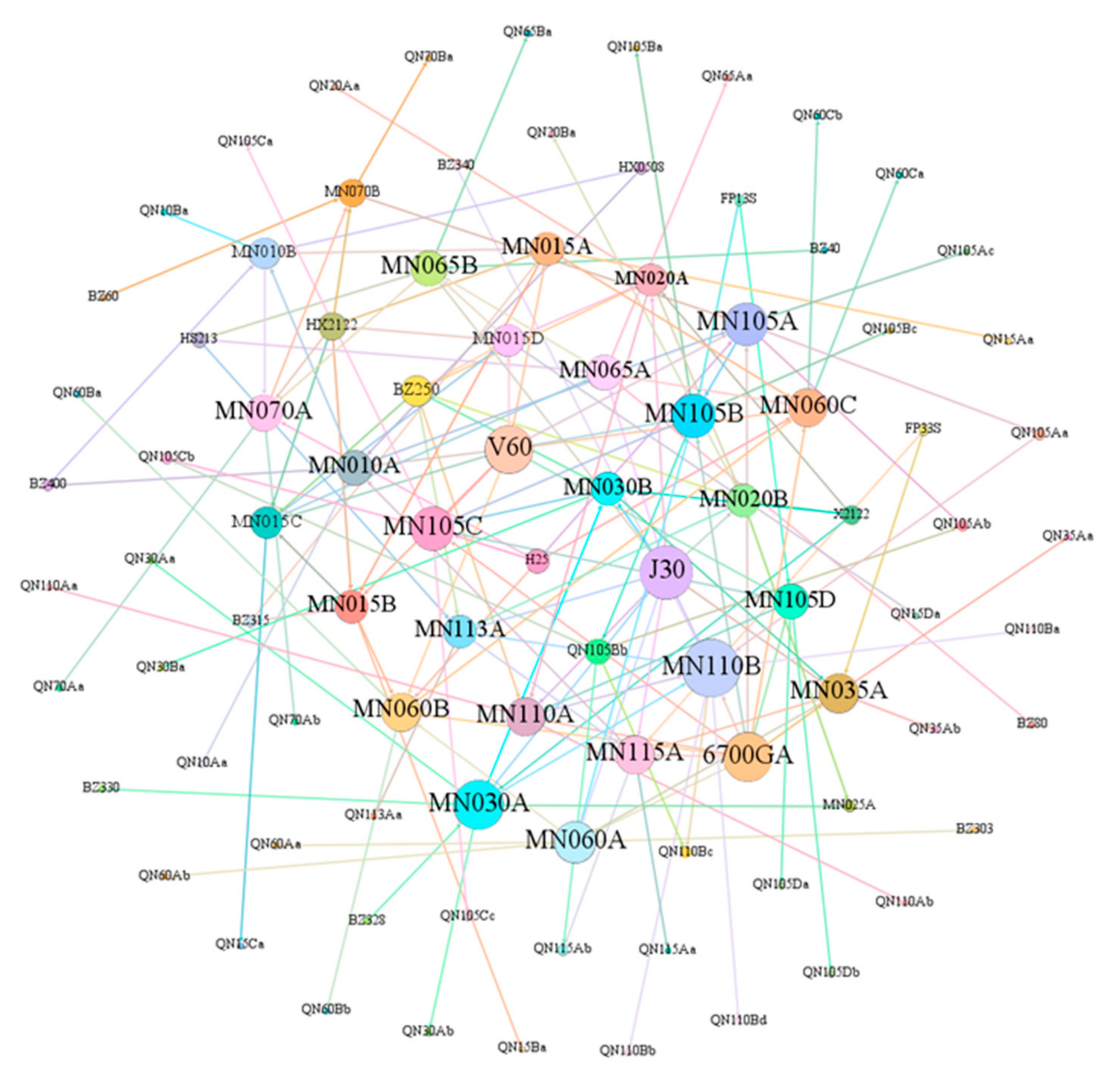

- Based on the transfer relationship between the processing features of the diesel engine body and between the processing features and processing elements, the processing error transfer network was established.

- Based on the PageRank algorithm and the calculation of the node degree value, the key quality control points and key quality features in the diesel engine body machining process were determined.

- Based on the error transfer relationship, the SVR algorithm parameters were optimized using a combination of the K-fold cross-validation method and the grid search method.

2. Establishment of Machining Error Transmission Network of Diesel Engine Block and Analysis of Quality Prediction Scheme

3. Establishment and Analysis of Machining Error Transmission Network of the Diesel Engine Block

3.1. The Establishment of the Transmission Network for the Machining Error of the Diesel Engine Block

3.1.1. Definition of Error Propagation Network Nodes

- (1)

- Machine error: During the machining process of the machine body, the spindle runout of the machine tool will have a direct impact on its rotary accuracy. In this regard, the spindle vibration degree of the machine tool is selected to characterize the machining state of the machine tool. The machine spindle vibration degree classification is shown in Table 1.

- (2)

- Fixture error: Fixtures are generally composed of components such as positioning elements and clamping devices. For the modeling of fixture error, the main consideration in this paper is the error of the positioning element. According to the actual process of the diesel engine body, the positioning elements used for body machining are divided into the V-block and angle iron, so the fixture error in the body machining process is defined as:

- (3)

- Tool error: Tool wear plays a very important role in tool deformation, and the tool error is expressed by the amount of tool wear . The specific formula is:

- (4)

- Operating error: Operating error is defined as the difference in the worker’s operating level caused by the worker’s experience and thinking time. There is an exponential relationship between human behavioral performance and the physical stimuli to which they are exposed, as follows:

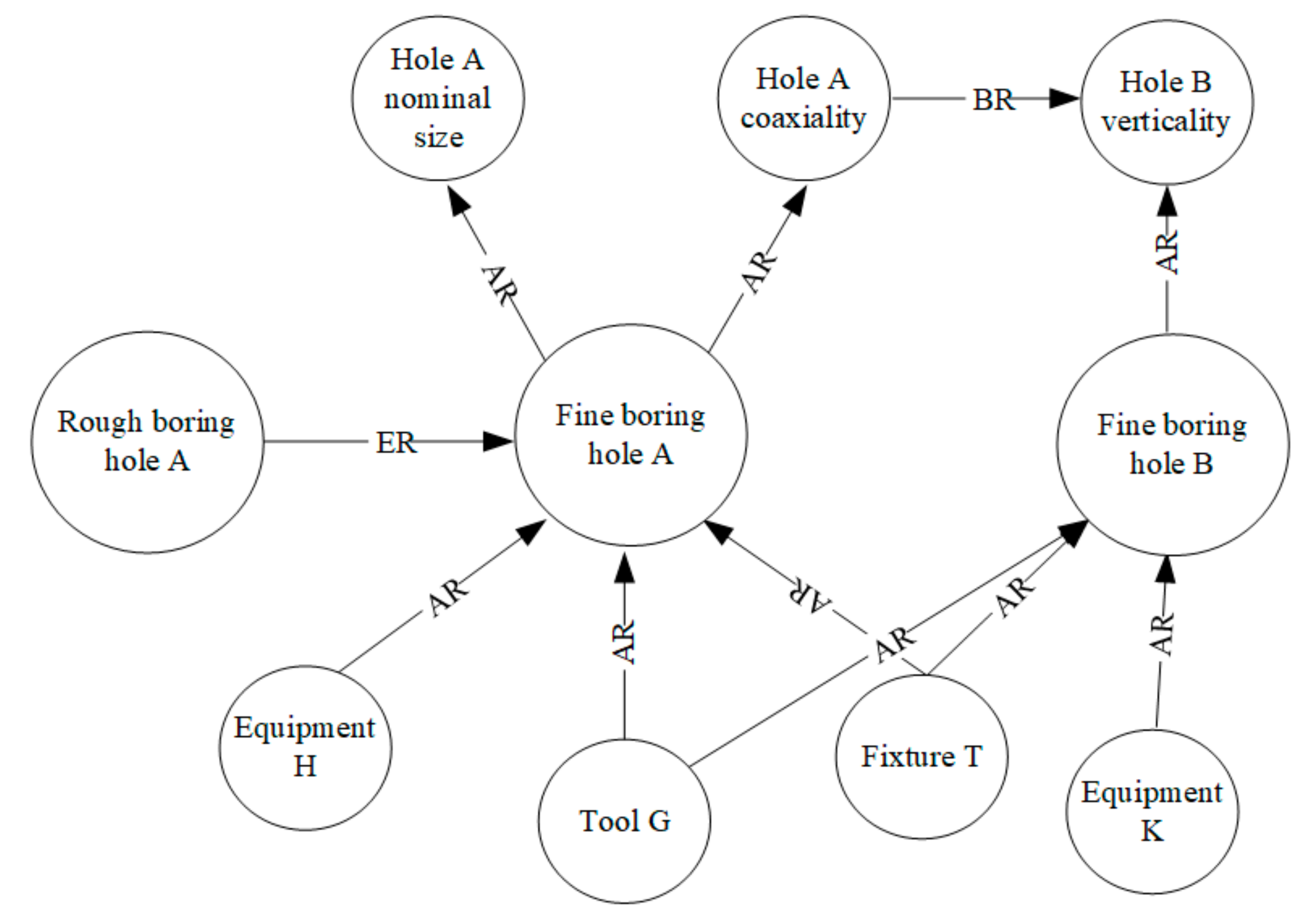

3.1.2. Definition of Edge Relationship of Processing Error Transfer Network

- Evolutionary relationship

- 2.

- Benchmark relationship

- 3.

- Sequential relationship

- 4.

- Attribute relationship

3.1.3. Construction of Processing Error Transfer Network

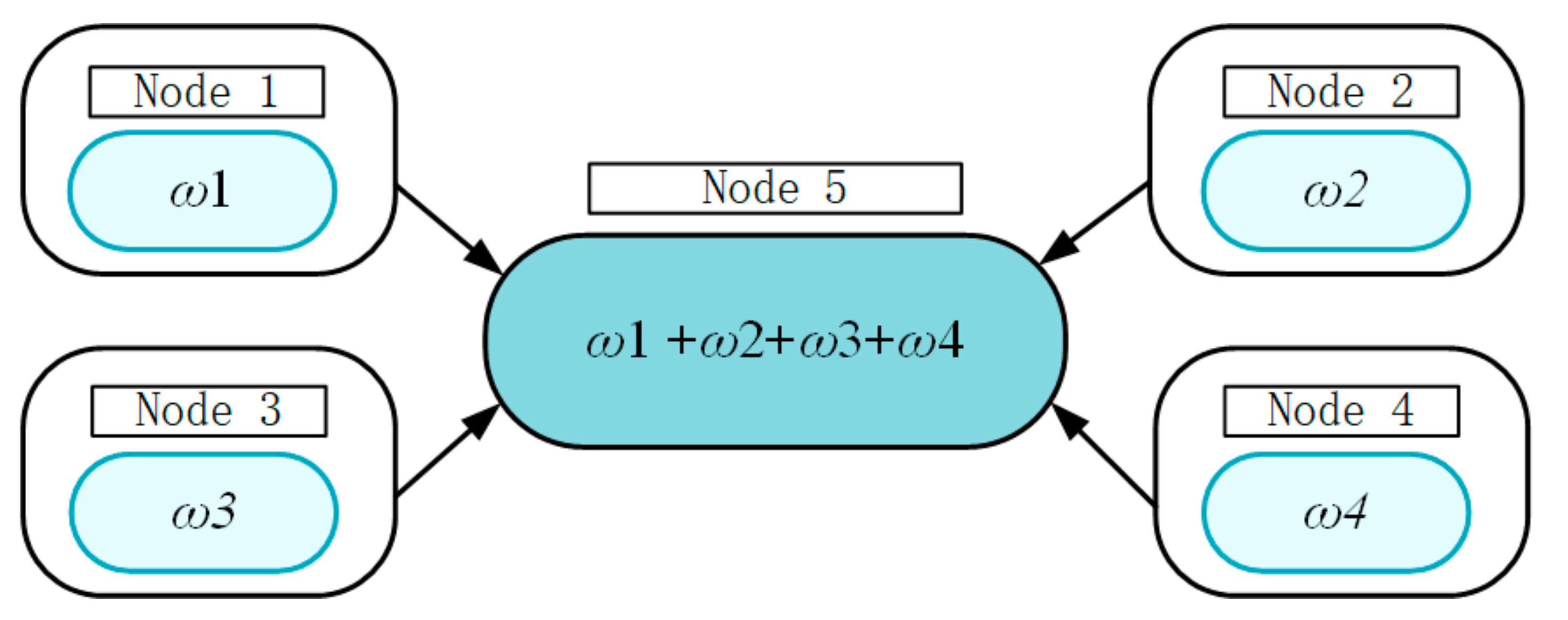

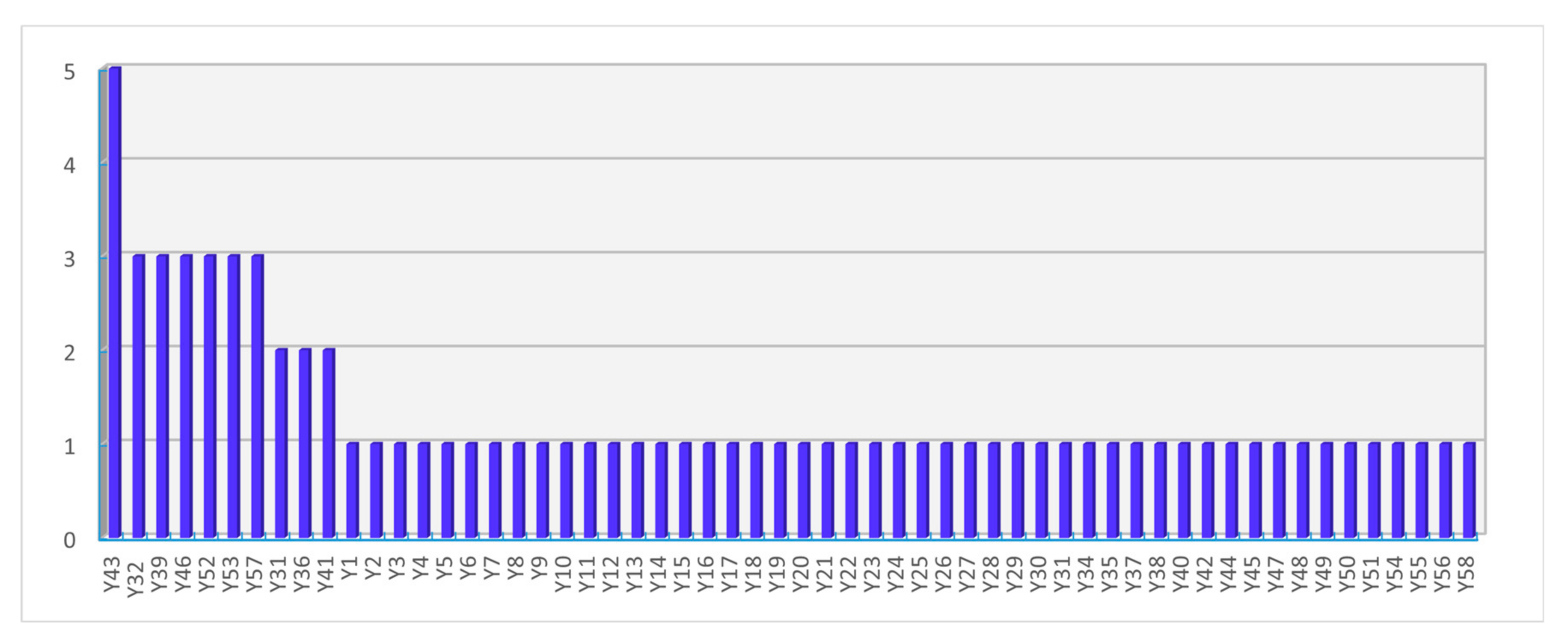

3.2. Analysis of Key Nodes of Error Transfer Network Based on Complex Network Theory

4. Diesel Engine Body Machining Quality Prediction

4.1. Modeling of Diesel Engine Body Machining Quality Prediction

4.1.1. Collection of Training Set Samples

4.1.2. Support Vector Machine Regression Algorithm and Its Parameter Optimization

4.2. Instance Verification

5. Conclusions

- Based on the transmission relationship between the processing features of the diesel engine block and the processing features and the processing elements, the processing error transmission network of the diesel engine block was established.

- Based on the PageRank algorithm and the calculation of nodal degree values, the key quality control points and key quality features in the diesel engine body machining process were determined. The key quality control points were: “Fine-milling Haff surface”, “Fine-boring crankshaft bore”, “Fine-boring camshaft bore”, “Rough boring camshaft bore”, “Fine Boring of Cylinder Bore”, “Rough Boring of Cylinder Bore”, “V Block”, “Machine 4”, and “Tool 1”. The key quality features were: “Cylinder bore verticality”, “Crankshaft bore coaxially”, and “Camshaft bore coaxially”.

- Based on the error transfer relationship, the machining quality prediction model of the diesel engine body was established by using the SVR algorithm after parameter optimization. The validity of the method was finally verified by an example.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, S.Y.; Yu, J.B.; Liu, H.Q.; Cheng, F.; Sun, X.W.; Wu, H.H. Modeling and analysis of adaptive weighted deviation transfer network for hybrid multi-stage machining process. J. Mech. Eng. 2018, 54, 179–191. [Google Scholar] [CrossRef]

- Dong, H.; Feng, Y. Intelligent prediction model of body size assembly quality based on XG Boost. Ind. Eng. 2021, 24, 77–82. [Google Scholar]

- Lu, Z.; Dai, W.; Zhao, Y. Reliability evaluation and analysis of grinding process based on machining physics. Mater. Res. Innov. 2015, 19 (Suppl. S5), s5-1065–s5-1069. [Google Scholar] [CrossRef]

- Selvakumar, S.; Arulshri, K.P.; Padmanaban, K.P. Machining Fixture Layout Optimization Using Genetic Algorithm and Artificial Neural Network. Int. J. Manuf. Res. 2013, 8, 171–195. [Google Scholar] [CrossRef]

- Mo, D.S.; He, Y.; Yu, Y.Y. Quality control and prediction of injection molding based on RBF neural network and genetic algorithm. Plast. Ind. 2020, 48, 71–76. [Google Scholar]

- Hertlein, N.; Deshpande, S.; Venugopal, V.; Kumar, M.; Anand, S. Prediction of selective laser melting part quality using hybrid Bayesian network. Addit. Manuf. 2020, 32, 101089. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, F.P.; Yan, Y.; Zhang, T.H.; Zhou, J.H.; Guo, F.Y. Multi-process manufacturing quality modeling based on statistical quantification of process factors. J. Mil. Eng. 2020, 41, 1408–1416. [Google Scholar]

- Huang, J.D.; Wang, L.S.; Li, G.F. A least squares support vector machine based on surface roughness prediction system for cylindrical grinding. Opt. Precis. Eng. 2010, 18, 2407–2412. [Google Scholar]

- Ashtiani, H.R.R.; Shahsavari, P.A. Comparative Study on the Phenomenological and Artificial Neural Network Models to Predict Hot Deformation Behavior of Al-Cu-Mg-Pb Alloy. J. Alloy Compd. 2016, 687, 263–273. [Google Scholar] [CrossRef]

- Portillo, E.; Marcos, M.; Cabanes, I.; Zubizarreta, A. Recurrent ANN for monitoring degraded behaviors in a range of workpiece thicknesses. Eng. Appl. Artif. Intell. 2009, 22, 1270–1283. [Google Scholar] [CrossRef]

- Lu, C. Study on prediction of surface quality in machining process. J. Mater. Process Technol. 2008, 205, 439–450. [Google Scholar] [CrossRef]

- Zheng, W.; Zhou, M.; Zhou, L. Influence of process parameters on surface topography in ultrasonic vibration assisted end grinding of SiCp/Al composites. Int. J. Adv. Manuf. Technol. 2017, 91, 2347–2358. [Google Scholar] [CrossRef]

- Tirkel, I. Cycle time prediction in wafer fabrication line by applying data mining methods. In Proceedings of the 2011 IEEE/SEMI Advanced Semiconductor Manufacturing Conference, Saratoga Springs, NY, USA, 16–18 May 2011. [Google Scholar]

- Zajac, J.; Hatala, M.; Duplák, J.; Dupláková, D.; Steranka, J. Experimental high speed milling of the selected thin-walled component. TEM J. 2017, 6, 678. [Google Scholar]

- Duplak, J.; Duplakova, D.; Hatala, M.; Radchenko, S.; Sukic, E. Surveying the topography and examining the quality of the machined surface of selected hardened steels in the milling process. J. Eng. Res. 2021, 9, 285–301. [Google Scholar] [CrossRef]

- Li, K.; Wu, W.; Liu, F.S.; Chen, G.H.; Chen, S.H. Important node assessment of weapon and equipment system based on PageRank algorithm. Firepower Command. Control 2017, 42, 34–37+42. [Google Scholar]

- Han, D.; Zheng, J.R. Approximate modeling techniques in engineering optimal design. J. East China Univ. Sci. Technol. (Nat. Sci. Ed.) 2012, 38, 762–768. [Google Scholar]

- Lu, J.; Zhang, Z.K.; Wu, Z.Q.; Ma, J.Y.; Liao, X.P.; Hu, S.S. Surface roughness prediction of creeping graphite cast iron based on support vector machine. Surf. Technol. 2020, 49, 339–346. [Google Scholar]

- Zhou, H.; Yang, W.; Sun, L.; Jing, X.; Li, G.; Cao, L. Reliability optimization of process parameters for marine diesel engine block hole system machining using improved PSO. Sci. Rep. 2021, 11, 21983. [Google Scholar] [CrossRef] [PubMed]

| Spindle Vibration Level | Evaluation |

|---|---|

| 0 | Vibration-free |

| 0.1~0.3 | Light vibration, machine in finishing condition |

| 0.4~0.6 | Medium vibration, the machine is in rough machining, vibration is high, but in fair condition |

| 0.7~0.9 | Heavy vibration, serious machine vibration, and poor running conditions should be avoided as much as possible |

| 1 | Severe vibration should be stopped immediately |

| Serial Number | Input | Output | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Pre-Mass Features | “Fine Boring of Cylinder Bores” Processing Element Error | Process Parameters | Quality Characteristics | ||||||

| Coaxial of Crankshaft Bore | Machine Tool Error | Clamp Error | Tool Error | Operating Errors | Rotational Speed (r/min) | Feed Rate (mm/min) | Cutting Depth (mm) | Cylinder Hole Verticality | |

| 1 | 0.0718 | 0.1 | 0.11 | 0.094 | 0.069 | 130.2 | 19.5 | 0.54 | 0.0186 |

| 2 | 0.0722 | 0.2 | 0.091 | 0.089 | 0.07 | 124 | 19.1 | 0.52 | 0.0189 |

| 3 | 0.0664 | 0.1 | 0.086 | 0.093 | 0.071 | 138.8 | 19.4 | 0.42 | 0.0168 |

| 4 | 0.0749 | 0.1 | 0.085 | 0.078 | 0.072 | 145.3 | 18.1 | 0.51 | 0.0187 |

| 5 | 0.0756 | 0.1 | 0.094 | 0.088 | 0.062 | 126.9 | 21.7 | 0.57 | 0.0188 |

| … | |||||||||

| 21 | 0.0735 | 0.1 | 0.086 | 0.079 | 0.069 | 131.9 | 21.4 | 0.35 | 0.0169 |

| 22 | 0.0708 | 0.1 | 0.102 | 0.073 | 0.071 | 144.2 | 17.1 | 0.4 | 0.0173 |

| 23 | 0.0756 | 0.2 | 0.11 | 0.073 | 0.066 | 124.6 | 23.3 | 0.45 | 0.0187 |

| 24 | 0.078 | 0.1 | 0.094 | 0.079 | 0.071 | 122.4 | 21.5 | 0.49 | 0.0193 |

| 25 | 0.0761 | 0.1 | 0.113 | 0.068 | 0.062 | 126.1 | 20.4 | 0.62 | 0.0188 |

| 26 | 0.0756 | 0.1 | 0.084 | 0.093 | 0.071 | 133.4 | 19.3 | 0.56 | 0.0194 |

| 27 | 0.0708 | 0.1 | 0.106 | 0.061 | 0.065 | 129.3 | 15.6 | 0.45 | 0.0163 |

| 28 | 0.0751 | 0.1 | 0.082 | 0.086 | 0.063 | 121.4 | 17.5 | 0.42 | 0.017 |

| 29 | 0.0723 | 0.2 | 0.083 | 0.088 | 0.069 | 117 | 21 | 0.59 | 0.0194 |

| 30 | 0.0704 | 0.1 | 0.098 | 0.068 | 0.07 | 127.7 | 24.4 | 0.65 | 0.0191 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, L.; Ren, X.; Zhou, H.; Li, G.; Yang, W.; Zhao, J.; Liu, Y. Machining Quality Prediction of Marine Diesel Engine Block Based on Error Transmission Network. Machines 2022, 10, 1081. https://doi.org/10.3390/machines10111081

Sun L, Ren X, Zhou H, Li G, Yang W, Zhao J, Liu Y. Machining Quality Prediction of Marine Diesel Engine Block Based on Error Transmission Network. Machines. 2022; 10(11):1081. https://doi.org/10.3390/machines10111081

Chicago/Turabian StyleSun, Li, Xiaodie Ren, Honggen Zhou, Guochao Li, Weibin Yang, Junjie Zhao, and Yinfei Liu. 2022. "Machining Quality Prediction of Marine Diesel Engine Block Based on Error Transmission Network" Machines 10, no. 11: 1081. https://doi.org/10.3390/machines10111081

APA StyleSun, L., Ren, X., Zhou, H., Li, G., Yang, W., Zhao, J., & Liu, Y. (2022). Machining Quality Prediction of Marine Diesel Engine Block Based on Error Transmission Network. Machines, 10(11), 1081. https://doi.org/10.3390/machines10111081