Intelligent Mechatronics in the Measurement, Identification, and Control of Water Level Systems: A Review and Experiment

Abstract

1. Introduction

2. Software in the Research of Liquid Level Control Systems

2.1. MATLAB/Simulink Environment

2.2. LabVIEW Virtual Instruments

2.3. Other Programming Environments and Languages

3. Modern Techniques, Machines, and Sensor Solutions for Water Level Measurements

3.1. Capacitive-Type Sensing

3.2. Image-Based and Optical Sensing

3.3. Ultrasonic Sensing

4. Mathematical Modeling

- 1.

- A single-tank dynamical system (eventually, equipped with a reservoir—a basin of water), which is investigated in [39,60,61] (state-space approach, PI, PID), [22,37] (state-space representation in a discrete form), [2,7,19,26,62,63] (transfer function approach), [3,5,6,26,62,63,64,65] (FL, PSO), [22,37] (predictive control), [18,20,27] (geometry-varying tank: conical and spherical) and others [34,46];

- 2.

- A coupled or cascaded two-tank dynamical system, which is investigated in [17,66,67,68,69] (state-space approach, PI, PID), [11,12,23,25,30,36] (transfer function approach), [35,70,71] (FL, PSO, NN), [72] (autoregressive model), [73] (multidimensional regularization), [74] (model-predictive control of a geometry-varying conical tank), and [75,76] (SMC);

- 3.

- A coupled or cascaded dynamical system consisting of many tanks, which is investigated in [8,15,68,77,78,79,80,81,82] (state-space approach, PI, PID), [10,30,80] (transfer function approach), [14,16] (FL, NN), [9,10,15,78,83] (model-based or model-predictive control, state predictor), [8,16,79] (geometry-varying tank), [77,84] (SMC), and [80] (dead-time).

4.1. The Single-Tank Dynamical System

4.2. The Two-Tank Dynamical System

- (C1)

- (C2)

- (C3)

- (C4)

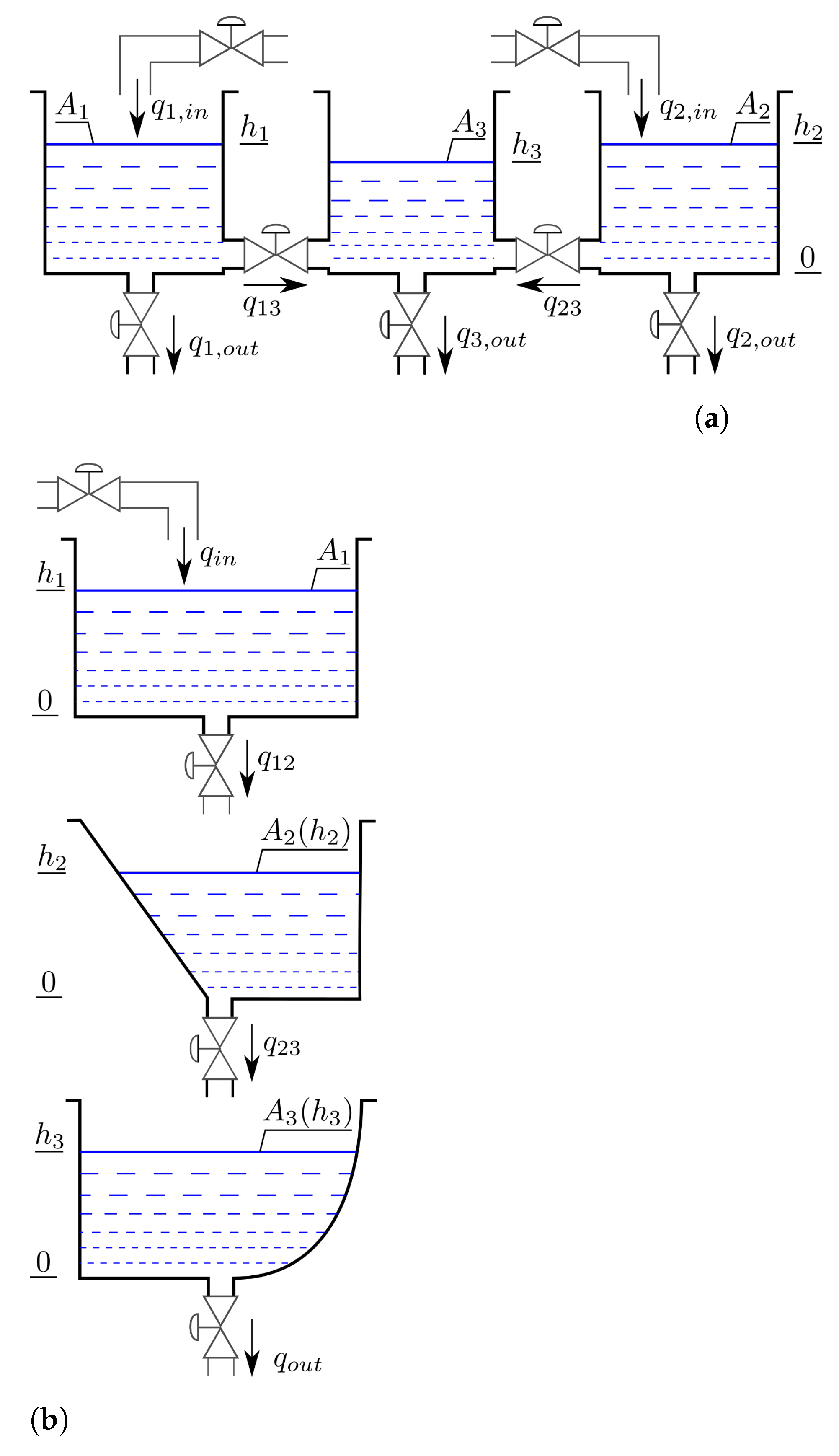

4.3. Multi-Tank Dynamical Systems

5. Model Analysis and Control Strategies

5.1. Traditional Approaches with Modern Inclusions

5.2. Experimental Identification and the Estimation of Model Parameters

5.3. Model Prediction

5.4. Time Effects

5.5. Sliding Mode Control

5.6. Fuzzy Logic Control

5.7. Special Approaches

6. Proportional Control with Correction Based on a Numerical Prediction of Water Level

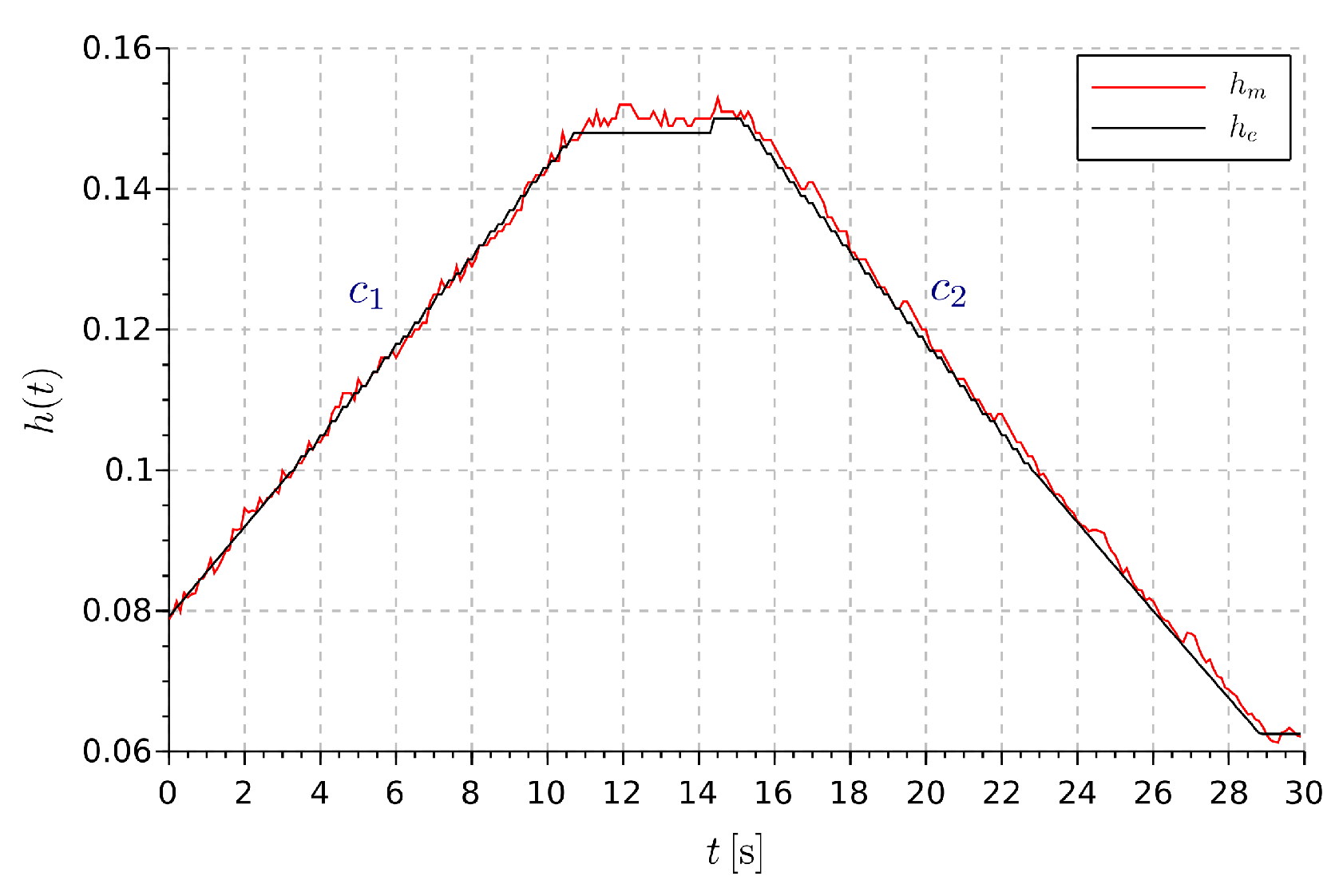

6.1. Identification of the Hydraulic System

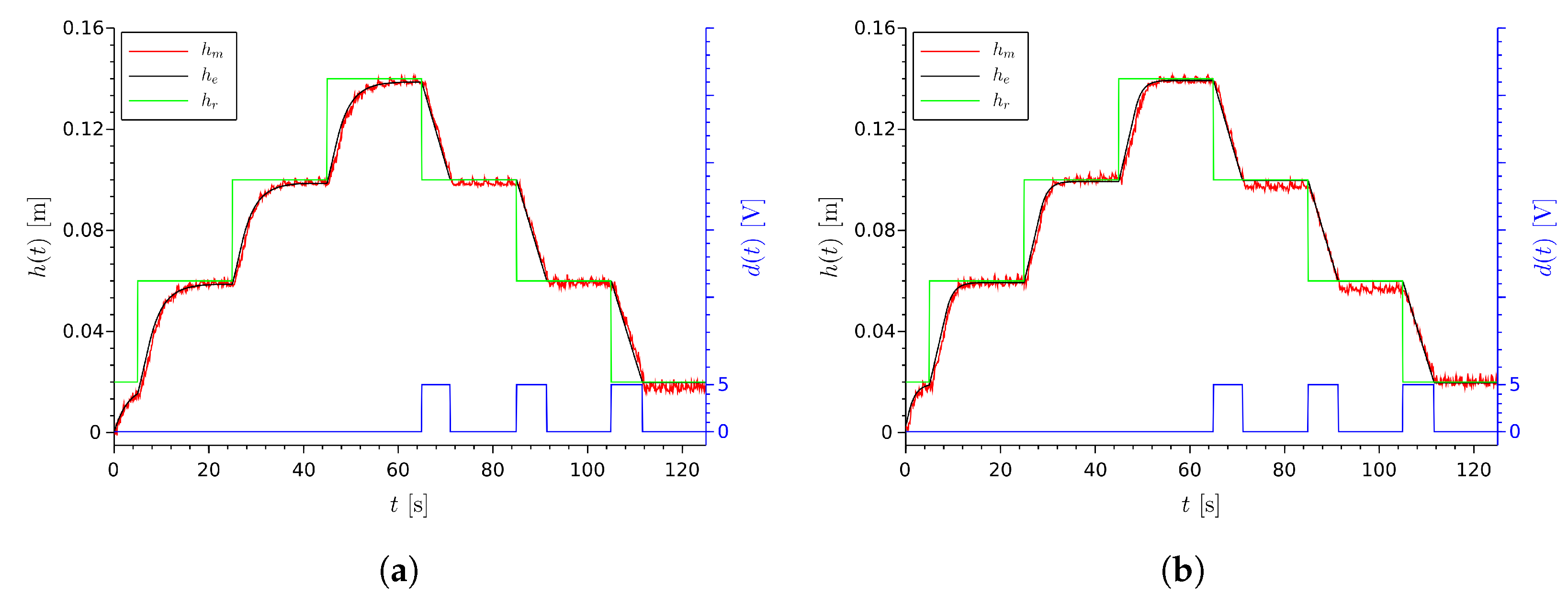

6.2. Control of the Experimental Test Station

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kunikowski, W.; Czerwiński, E.; Olejnik, P.; Awrejcewicz, J. An Overview of ATmega AVR Microcontrollers Used in Scientific Research and Industrial Applications. Pomiary Autom. Robot. 2015, 215, 15–20. [Google Scholar] [CrossRef]

- Mamur, H.; Atacak, I.; Korkmaz, F.; Bhuiyan, M. Modelling and Application of a Computer-Controlled Liquid Level Tank System. In Proceedings of the Seventh International Conference on Computer Science, Engineering and Applications (CCSEA-2017), Dubai, UAE, 28–29 January 2017. [Google Scholar] [CrossRef]

- Krivic, S.; Hujdur, M.; Mrzic, A.; Konjicija, S. Design and implementation of fuzzy controller on embedded computer for water level control. In Proceedings of the MIPRO, 2012 Proceedings of the 35th International Convention, Opatija, Croatia, 21–25 May 2012; pp. 1747–1751.

- Omijeh, B.; Ehikhamenle, M.; Elechi, P. Simulated Design of Water Level Control System. Comput. Eng. Intell. Syst. 2015, 6, 30–40. [Google Scholar]

- Turki, M.; Bouzaida, S.; Sakly, A. Identification of a water level system using ANFIS. In Proceedings of the Proceedings Engineering and Technology, International Conference on Control, Engineering and Information Technology (CEIT’13), Tlemcen, Algeria, 25–27 May 2014; Volume 3. [Google Scholar]

- Turki, M.; Sakly, A. Modelling of water level system using neurofuzzy tuned by PSO. In Proceedings of the 17th International Conference on Sciences and Techniques of Automatic Control and Computer Engineering—STA’2016, Sousse, Tunisia, 19–21 December 2016; pp. 54–60. [Google Scholar] [CrossRef]

- Tapak, P. Nonlinear Control of Liquid Level. IFAC Proc. Vol. 2012, 45, 218–223. [Google Scholar] [CrossRef]

- Rosinova, D.; Balko, P.; Puleva, T. Teaching multiloop control of nonlinear system: Three tanks case study. IFAC-PapersOnLine 2016, 49, 360–365. [Google Scholar] [CrossRef]

- Gouta, H.; Said, S.; Barhoumi, N.; Faouzi, M. Generalized predictive control for a coupled four tank MIMO system using a continuous-discrete time observer. ISA Trans. 2016, 67, 280–292. [Google Scholar] [CrossRef] [PubMed]

- Velswamy, K. Distributed multiparametric model predictive control design for a quadruple tank process. Measurement 2013, 47, 841–854. [Google Scholar] [CrossRef]

- Roy, P.; Roy, B. Fractional Order PI Control Applied to Level Control in Coupled Two Tank MIMO System with Experimental Validation. Control Eng. Pract. 2016, 48, 119–135. [Google Scholar] [CrossRef]

- Dulau, M.; Dulău, T.M. Multivariable System with Level Control. Procedia Technol. 2016, 22, 614–622. [Google Scholar] [CrossRef][Green Version]

- Terzic, E.; Nagarajah, R.; Alamgir, M. Capacitive sensor-based fluid level measurement in a dynamic environment using neural network. Eng. Appl. Artif. Intell. 2010, 23, 614–619. [Google Scholar] [CrossRef]

- Sahu, H.; Ayyagari, R. Interval Fuzzy Type-II Controller for the Level Control of a Three Tank System. IFAC-PapersOnLine 2016, 49, 561–566. [Google Scholar] [CrossRef]

- Cetin, M.; Iplikci, S. A novel auto-tuning PID control mechanism for nonlinear systems. ISA Trans. 2015, 58, 292–308. [Google Scholar] [CrossRef] [PubMed]

- Belikov, J.; Petlenkov, E. Model based control of a water tank system. IFAC Proc. Vol. 2014, 47, 10838–10843. [Google Scholar] [CrossRef]

- Relan, R.; Tiels, K.; Marconato, A.; Schoukens, J. An Unstructured Flexible Nonlinear Model for the Cascaded Water-tanks Benchmark. IFAC-PapersOnLine 2017, 50, 452–457. [Google Scholar] [CrossRef]

- Perez-Correa, J.; Lefranc, G.; Fernandez-Fernandez, M. A New Application of the Hill Repressor Function: Automatic Control of a Conic Tank Level and Local Stability Analysis. Math. Probl. Eng. 2015, 2015, 1–6. [Google Scholar] [CrossRef]

- Aljumaili, M.; Koh, S.; Chong, K.; Tiong, S.; Obaid, Z. Genetic Algorithm Tuning Based PID Controller for Liquid-Level Tank System. In Proceedings of the International Conference on Man-Machine Systems (ICoMMS), Pulau Pinang, Malaysia, 26–27 August 2009. [Google Scholar]

- Balochian, S.; Ebrahimi, E. Parameter Optimization via Cuckoo Optimization Algorithm of Fuzzy Controller for Liquid Level Control. J. Eng. 2013, 2013, 982354. [Google Scholar] [CrossRef]

- Mustapha Imam, A.; Tijjani, Y. PLC-Based Water Level Control. Afr. J. Sci. Res. 2016, 5, 65–67. [Google Scholar]

- Rossi, F.; Galvao, R. Robust Predictive Control of Water Level in an Experimental Pilot Plant with Uncertain Input Delay. Math. Probl. Eng. 2014, 2014, 1–10. [Google Scholar] [CrossRef]

- Tomera, M. Comparison analysis of three PID-type algorithms: Linear, fuzzy, neural. Automatyka Elektryka Zakłócenia 2011, 6, 1–19. [Google Scholar]

- Larsen, R.W. LabVIEW for Engineers; Prentice Hall: Hoboken, NJ, USA, 2011. [Google Scholar]

- Bastida, H.; Ponce, P.; Ramirez-Mendoza, R.A.; Molina, A. Model and Control for Coupled Tanks Using Labview. In Proceedings of the IEEE 2013 International Conference on Mechatronics, Electronics and Automotive Engineering (ICMEAE), Morelos, Mexico, 19–22 November 2013. [Google Scholar] [CrossRef]

- Sabri, L.; Al-mshat, H. Implementation of Fuzzy and PID Controller to Water Level System using LabView. Int. J. Comput. Appl. 2015, 116, 6–10. [Google Scholar] [CrossRef]

- Meenatchi Sundaram, S.; Purohit, A. Stiction Compensated Fuzzy Controller Design For Non Linear Spherical Tank Level System Using Labview. Int. J. Pure Appl. Math. 2018, 20, 2023–2031. [Google Scholar]

- Vasistha, V. Remote Access for Fully Automatic Multi-Input Multi-Output Water Level Control System Using SCCT in LabVIEW Environment. IOSR J. Electron. Commun. Eng. 2014, 9, 42–45. [Google Scholar] [CrossRef]

- Nurdiansyah, E.; Hasani, C.; Faruq, A. Application Monitoring Design of Water Tank Volume and Clarity System using LabView NI MYRIO. Kinet. Game Technol. Inf. Syst. Comput. Netw. Comput. Electron. Control 2017, 2, 309. [Google Scholar] [CrossRef][Green Version]

- Rúa Pérez, S.; Zuluaga, C.; Posada, N.; Hernandez, F.; Vasquez, R. Development of the supervision/control software for a multipurpose three-tank system. IFAC-PapersOnLine 2016, 49, 156–161. [Google Scholar] [CrossRef]

- Sohn, K.R.; Shim, J.H. Liquid-level monitoring sensor systems using fiber Bragg grating embedded in cantilever. Sens. Actuators A Phys. 2009, 152, 248–251. [Google Scholar] [CrossRef]

- Wang, W.; Li, F. Large-range liquid level sensor based on an optical fibre extrinsic Fabry-Perot interferometer. Opt. Lasers Eng. 2014, 52, 201–205. [Google Scholar] [CrossRef]

- Terzic, J.; Nagarajah, C.R.; Alamgir, M. Fluid level measurement in dynamic environments using a single ultrasonic sensor and Support Vector Machine (SVM). Sens. Actuators A Phys. 2010, 161, 278–287. [Google Scholar] [CrossRef]

- Azeez, H.; Chen, S.-C. Automatic water level control using LabVIEW. Kurd. J. Appl. Res. 2017, 3, 369–375. [Google Scholar] [CrossRef]

- Owa, K.; Sharma, S.; Sutton, R. A wavelet neural network based non-linear model predictive controller for a multi-variable coupled tank system. Int. J. Autom. Comput. 2014, 12, 156–170. [Google Scholar] [CrossRef]

- Alvaro, R.; Maria, A.; David, F. Level control in a system of tanks in interacting mode using Xcos software. Contemp. Eng. Sci. 2018, 11, 63–70. [Google Scholar] [CrossRef]

- Hedjar, R.; Messaoud, B. Wireless model predictive control: Application to water-level system. Adv. Mech. Eng. 2016, 8, 1–13. [Google Scholar] [CrossRef]

- Gafar Abdullah, A.; Putra, A. Water Level Measurement Altitude Trainer Integrated With Human Machine Interface. Indones. J. Sci. Technol. 2017, 2, 197. [Google Scholar] [CrossRef][Green Version]

- Galan, D.; Heradio, R.; de la Torre Cubillo, L.; Dormido, S.; Esquembre, F. Virtual Control Labs Experimentation: The Water Tank System. IFAC PapersOnLine 2016, 49, 87–92. [Google Scholar] [CrossRef]

- Lai, C.W.; Lo, Y.L.; Yur, J.P.; Liu, W.F.; Chuang, C.H. Application of Fabry-Pérot and fiber Bragg grating pressure sensors to simultaneous measurement of liquid level and specific gravity. Measurement 2012, 45, 469–473. [Google Scholar] [CrossRef]

- Guilin, Z.; Zong, H.; Zhuan, X.; Wang, L. High-Accuracy Surface-Perceiving Water Level Gauge With Self-Calibration for Hydrography. Sen. J. IEEE 2011, 10, 1893–1900. [Google Scholar] [CrossRef]

- Bande, V.; Pitica, D.; Ciascai, I. Multi—Capacitor sensor algorithm for water level measurement. In Proceedings of the 2012 35th International Spring Seminar on Electronics Technology, Bad Aussee, Austria, 9–13 May 2012; pp. 286–291. [Google Scholar] [CrossRef]

- Mou, C.; Zhou, K.; Yan, Z.; Fu, H.; Zhang, L. Liquid level sensor based on an excessively tilted fibre grating. Opt. Commun. 2013, 305, 271–275. [Google Scholar] [CrossRef]

- Yu, C.; Zhang, C.; Bai, Y.; Huang, C. A Liquid Level Measuring Device for a Tank Based on Image Senor. Adv. Mater. Res. 2012, 443–444, 418–423. [Google Scholar] [CrossRef]

- Okhaifoh, J.E.; Igbinoba, C.; Eriaganoma, K. Microcontroller Based Automatic Control for Water Pumping Machine With Water Level Indicators Using Ultrasonic Sensor. Niger. J. Technol. 2016, 35, 579. [Google Scholar] [CrossRef][Green Version]

- Loizou, K.; Koutroulis, E. Water level sensing: State of the art review and performance evaluation of a low-cost measurement system. Measurement 2016, 89, 204–214. [Google Scholar] [CrossRef]

- Jin, B.; Zhang, Z.; Zhang, H. Structure design and performance analysis of a coaxial cylindrical capacitive sensor for liquid-level measurement. Sens. Actuators A Phys. 2015, 223, 84–90. [Google Scholar] [CrossRef]

- Reverter, F.; Li, X.; Meijer, G.C.M. Liquid-level measurement system based on a remote grounded capacitive sensor. Sens. Actuators A Phys. 2007, 138, 1–8. [Google Scholar] [CrossRef]

- Bera, S.C.; Mandal, H.; Saha, S.; Dutta, A. Study of a Modified Capacitance-Type Level Transducer for Any Type of Liquid. Instrum. Meas. IEEE Trans. 2014, 63, 641–649. [Google Scholar] [CrossRef]

- Qurthobi, A.; Iskandar, R.; Krisnatal, A.; Weldzikarvina. Design of capacitive sensor for water level measurement. J. Phys. Conf. Ser. 2016, 776, 012118. [Google Scholar] [CrossRef]

- Chetpattananondh, K.; Tapoanoi, T.; Phukpattaranont, P.; Jindapetch, N. A self-calibration water level measurement using an interdigital capacitive sensor. Sens. Actuators A Phys. 2014, 209, 175–182. [Google Scholar] [CrossRef]

- Reza, S.A.; Riza, N.A. Agile lensing-based non-contact liquid level optical sensor for extreme environments. Opt. Commun. 2010, 283, 3391–3397. [Google Scholar] [CrossRef]

- Wang, T.H.; Lu, M.C.; Hsu, C.C.; Chen, C.C.; Tan, J.D. Liquid-level measurement using a single digital camera. Measurement 2009, 42, 604–610. [Google Scholar] [CrossRef]

- Lorenz, M.G.; Mengibar-Pozo, L.; Izquierdo-Gil, M.A. High resolution simultaneous dual liquid level measurement system with CMOS camera and FPGA hardware processor. Sens. Actuators A Phys. 2013, 201, 468–476. [Google Scholar] [CrossRef]

- Jiang, Y.; Jiang, W.; Jiang, B.; Rauf, A.; Qin, C.; Zhao, J. Precise measurement of liquid-level by fiber loop ring-down technique incorporating an etched fiber. Opt. Commun. 2015, 351, 30–34. [Google Scholar] [CrossRef]

- Li, C.; Ning, T.; Zhang, C.; Li, J.; Wen, X.; Pei, L.; Gao, X.; Lin, H. Liquid level measurement based on a no-core fiber with temperature compensation using a fiber Bragg grating. Sens. Actuators A Phys. 2016, 245, 49–53. [Google Scholar] [CrossRef]

- Lin, Y.T.; Lin, Y.C.; Han, J.Y. Automatic water-level detection using single-camera images with varied poses. Measurement 2018, 127, 167–174. [Google Scholar] [CrossRef]

- Jatmiko, S.; Mutiara, A.; Indriati, M. Prototype of water level detection system with wireless. J. Theor. Appl. Inf. Technol. 2012, 37, 52–59. [Google Scholar]

- Matsuya, I.; Honma, Y.; Mori, M.; Ihara, I. Measuring Liquid-Level Utilizing Wedge Wave. Sensors 2017, 18, 2. [Google Scholar] [CrossRef] [PubMed]

- Boiko, I. Variable-structure PID controller for level process. Control Eng. Pract. 2013, 21, 700–707. [Google Scholar] [CrossRef]

- Reyes-Lúa, A.; Backi, C.J.; Skogestad, S. Improved PI control for a surge tank satisfying level constraints. IFAC-PapersOnLine 2018, 51, 835–840. [Google Scholar] [CrossRef]

- Sadeghi, M.S.; Safarinejadian, B.; Farughian, A. Parallel distributed compensator design of tank level control based on fuzzy Takagi-Sugeno model. Appl. Soft Comput. 2014, 21, 280–285. [Google Scholar] [CrossRef]

- Erguzel, T. A hybrid PSO-PID approach for trajectory tracking application of a liquid level control process. Int. J. Optim. Control. Theor. Appl. 2015, 5, 63–73. [Google Scholar] [CrossRef]

- Basci, A.; Derdiyok, A. Implementation of an adaptive fuzzy compensator for coupled tank liquid level control system. Measurement 2016, 91, 12–18. [Google Scholar] [CrossRef]

- Valdez, F.; Vázquez, J.; Gaxiola, F. Fuzzy Dynamic Parameter Adaptation in ACO and PSO for Designing Fuzzy Controllers: The Cases of Water Level and Temperature Control. Adv. Fuzzy Syst. 2018, 2018, 1–19. [Google Scholar] [CrossRef]

- Alam, M.T.; Charan, P.; Khan, Z.; Ansari, M. Water Level Control of Coupled Tanks System with ISMC. Int. J. Sci. Adv. Res. Technol. 2015, 1, 91–95. [Google Scholar]

- Bieda, R.; Blachuta, M.; Grygiel, R. A New Look at Water Tanks Systems as Control Teaching Tools. IFAC-PapersOnLine 2017, 50, 13480–13485. [Google Scholar] [CrossRef]

- Cartes, D.; Wu, L. Experimental evaluation of adaptive three-tank level control. ISA Trans. 2005, 44, 283–293. [Google Scholar] [CrossRef]

- Abukhadra, F. Active Disturbance Rejection Control of a Coupled-Tank System. J. Eng. 2018, 2018, 1–6. [Google Scholar] [CrossRef]

- Ponce, H.; Ponce, P.; Bastida, H.; Molina, A. A Novel Robust Liquid Level Controller for Coupled-Tanks Systems Using Artificial Hydrocarbon Networks. Expert Syst. Appl. 2015, 42, 8858–8867. [Google Scholar] [CrossRef]

- Taoyan, Z.H.A.O.; Ping, L.I.; Jiangtao, C.A.O. Study of Interval Type-2 Fuzzy Controller for the Twin-tank Water Level System. Chin. J. Chem. Eng. 2012, 20, 1102–1106. [Google Scholar] [CrossRef]

- Giordano, G.; Sjoberg, J. Black- and white-box approaches for cascaded tanks benchmark system identification. Mech. Syst. Signal Process. 2018, 108, 387–397. [Google Scholar] [CrossRef]

- Birpoutsoukis, G.; Zoltán Csurcsia, P.; Schoukens, J. Nonparametric Volterra Series Estimate of the Cascaded Water Tanks Using Multidimensional Regularization. IFAC-PapersOnLine 2017, 50, 476–481. [Google Scholar] [CrossRef]

- Ravi, V.R.; Thyagarajan, T.; Maheshwaran, G.U. Dynamic Matrix Control of a Two Conical Tank Interacting Level System. Procedia Eng. 2012, 38, 2601–2610. [Google Scholar] [CrossRef]

- Khan, M.K.; Spurgeon, S.K. Robust MIMO water level control in interconnected twin-tanks using second order sliding mode control. Control Eng. Pract. 2006, 14, 375–386. [Google Scholar] [CrossRef]

- abu khadra, F.; Abu Qudeiri, J.E. Second Order Sliding Mode Control of the Coupled Tanks System. Math. Probl. Eng. 2015, 2015, 1–9. [Google Scholar] [CrossRef]

- Smida, F.; Said, S.; Faouzi, M. Robust High-Gain Observers Based Liquid Levels and Leakage Flow Rate Estimation. J. Control Sci. Eng. 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Huang, C.; Canuto, E.; Novara, C. The four-tank control problem: Comparison of two disturbance rejection control solutions. ISA Trans. 2017, 71, 252–271. [Google Scholar] [CrossRef]

- Yang, Z.J.; Sugiura, H. Robust Nonlinear Control of a Three-Tank System in the Presence of Mismatched Uncertainties. IFAC-PapersOnLine 2017, 50, 4088–4093. [Google Scholar] [CrossRef]

- Shneiderman, D.; Palmor, Z.J. Properties and control of the quadruple-tank process with multivariable dead-times. J. Process Control 2010, 20, 18–28. [Google Scholar] [CrossRef]

- Yakubu, G.; Olejnik, P.; Awrejcewicz, J. Modeling, Simulation, and Analysis of a Variable-Length Pendulum Water Pump. Energies 2021, 14, 8064. [Google Scholar] [CrossRef]

- Olejnik, P.; Wiądzkowicz, F.; Awrejcewicz, J. Experimental Dynamical Analysis of a Mechatronic Analogy of the Human Circulatory System. In Springer Proceedings in Mathematics & Statistics; Springer International Publishing: Cham, Switzerland, 2021; pp. 173–185. [Google Scholar] [CrossRef]

- Radac, M.B.; Precup, R.E.; Roman, R.C. Data-driven model reference control of MIMO vertical tank systems with model-free VRFT and Q-Learning. ISA Trans. 2018, 73, 227–238. [Google Scholar] [CrossRef] [PubMed]

- Sutha, S.; Lakshmi, P.; Sankaranarayanan, S. Fractional-Order Sliding Mode Controller Design for a Modified Quadruple Tank Process via Multi-Level Switching. Comput. Electr. Eng. 2015, 45, 10–21. [Google Scholar] [CrossRef]

- Awrejcewicz, J.; Lewandowski, D.; Olejnik, P. Dynamics of Mechatronics Systems: Modeling, Simulation, Control, Optimization and Experimental Investigations; World Scientific Publishing: Singapore, 2017. [Google Scholar] [CrossRef]

- Pintelon, R.; Schoukens, J. System Identification: A Frequency Domain Approach; John Wiley & Sons, IEEE Press: New York, NY, USA, 2012. [Google Scholar]

- Overschee, P.V.; Moor, B.D. Subspace Identification for Linear Systems. Theory, Implementation, Applications; Kluwer Academic Publishers Group: Dordrecht, Netherlands, 1996. [Google Scholar] [CrossRef]

- Alvarado, I.; Limon, D.; Muñoz de la Pena, D.; Maestre, J.M.; Ridao, M.A.; Scheu, H.; Marquardt, W.; Negenborn, R.R.; De Schutter, B.; Valencia, F.; et al. A comparative analysis of distributed MPC techniques applied to the HD-MPC four-tank benchmark. J. Process Control 2011, 21, 800–815. [Google Scholar] [CrossRef]

- Nirmala, S.; Abirami, B.; Manamalli, D. Design of Model Predictive Controller for a Four-Tank Process Using Linear State Space Model and Performance Study for Reference Tracking under Disturbances. In Proceedings of the Proceedings of 2011 International Conference on Process Automation, Control and Computing, PACC 2011, Coimbatore, India, 20–22 July 2011. [Google Scholar] [CrossRef]

- Xiao, M.; Huang, T.; Li, C.; Zhou, X. Fast gradient-based distributed optimisation approach for model predictive control and application in four-tank benchmark. IET Control Theory Appl. 2015, 9, 1579–1586. [Google Scholar] [CrossRef]

- Gouta, H.; Said, S.; Faouzi, M. Model-Based Predictive and Backstepping controllers for a state coupled four-tank system with bounded control inputs: A comparative study. J. Frankl. Inst. 2015, 352, 4864–4889. [Google Scholar] [CrossRef]

- Boubakir, A.; Boudjema, F.; Labiod, S. A neuro-fuzzy-sliding mode controller using nonlinear sliding surface applied to the coupled tanks system. Int. J. Autom. Comput. 2009, 6, 72–80. [Google Scholar] [CrossRef]

- Aydin, S.; Tokat, S. Sliding mode control of a coupled tank system with a state varying sliding surface parameter. In Proceedings of the 10th IEEE International Workshop on Variable Structure Systems (VSS’08), Antalya, Turkey, 8–10 June 2008; pp. 355–360. [Google Scholar] [CrossRef]

- Li, Q.; Fang, Y.; Song, J.; Wang, J. The Application of Fuzzy Control in Liquid Level System. In Proceedings of the International Conference on Measuring Technology and Mechatronics Automation, Changsha, China, 13–14 March 2010; Volume 3, pp. 776–778. [Google Scholar] [CrossRef]

- Olejnik, P.; Awrejcewicz, J. A mechatronic experimental system for control of fluid level in LabVIEW. In Proceedings of the 2019 20th International Carpathian Control Conference (ICCC), Wieliczka, Poland, 26–29 May 2019. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olejnik, P.; Awrejcewicz, J. Intelligent Mechatronics in the Measurement, Identification, and Control of Water Level Systems: A Review and Experiment. Machines 2022, 10, 960. https://doi.org/10.3390/machines10100960

Olejnik P, Awrejcewicz J. Intelligent Mechatronics in the Measurement, Identification, and Control of Water Level Systems: A Review and Experiment. Machines. 2022; 10(10):960. https://doi.org/10.3390/machines10100960

Chicago/Turabian StyleOlejnik, Paweł, and Jan Awrejcewicz. 2022. "Intelligent Mechatronics in the Measurement, Identification, and Control of Water Level Systems: A Review and Experiment" Machines 10, no. 10: 960. https://doi.org/10.3390/machines10100960

APA StyleOlejnik, P., & Awrejcewicz, J. (2022). Intelligent Mechatronics in the Measurement, Identification, and Control of Water Level Systems: A Review and Experiment. Machines, 10(10), 960. https://doi.org/10.3390/machines10100960