1. Introduction

The low-pressure rotor of an aero-engine has an impact on the vibration response of the whole machine when it is rotating at high speed. Too much unbalance will make the low-pressure rotor rotate at high speed when the unbalance force rises, thus causing the whole machine to vibrate, and even lead to the blade touching to grind, and then affect the reliability and service life of the aero-engine operation [

1,

2,

3,

4]. Depending on statistics, about 60% of aero-engine vibrations are caused by rotor unbalance [

5]. Therefore, it is very important to control the unbalance of the low-pressure rotor.

The low-pressure rotor is composed of a disk and blades. It is a typical multistage disk structure. The unbalance is the result of the superposition of unbalance vectors distributed on every single piece [

6]. The changing and coupled assembly processes lead to the following difficulties in predicting low-pressure rotor unbalance during assembly:

Unbalance is associated across processes. The assembly process of low-pressure rotors is divided into three processes: three-disc assembly, second-stage blade assembly, and first and third-stage blade assembly. The participating parts in each process are different, and the factors that affect the imbalance are also different. The unbalanced amount of the current process is not only related to the influencing factors of the process but also related to the unbalance of the previous process, which has a certain cumulative effect;

Effect of blade assembly sequence on imbalance. The blade is an important part of the low-pressure rotor. The imbalance of the blade group will affect the imbalance of the rotor;

Many factors are influencing unbalance and they are coupled with each other. The unbalance is related to the quality of parts processing, the assembly process, and the assembly quality, and involves numerous influencing factors, which are dynamically changing and coupled with each other. It is difficult to establish the relationship model between influencing factors and unbalance through a mechanism under the synergistic action of multiple factors;

Assembly steps of low-pressure rotors are interrelated. Unbalance is formed after all the steps of a process are completed. The subsequent steps in the assembly process have not yet been carried out, the actual process parameters of the subsequent assembly steps cannot be obtained, and the prediction of unbalance in the assembly process cannot be realized. Additionally, the work steps are carried out step by step according to the process planning, with a certain time sequence relationship, and the assembly result of each work step not only has an impact on the unbalance of the process but also influences each other between the work steps. This requires that the unbalance prediction model can consider the influence of subsequent working steps on unbalancing while mining the temporal correlation.

In view of the above difficulties in predicting low-pressure rotor unbalance, this paper proposes a low-pressure rotor unbalance prediction method based on the fusion of mechanism and data drive, taking the low-pressure rotor of an engine model as the research object. Firstly, the blade assembly sequence optimization model is established through the mechanism analysis method to realize the blade assembly sequence optimization. Then, on the basis of determining the blade assembly sequence through the mechanism model, the actual assembly data of the assembled blade is combined with the design data of the unassembled blade to build a semi-physical simulation model based on the bidirectional recurrent neural network BRNN for predicting the unbalance in the assembly process while assembling, which provides data support for the subsequent optimization of unbalance.

2. Literature Review

2.1. Prediction Methods of Rotor Unbalance

Yue Chen et al. [

7] proposed an unbalance optimization method for multistage rotors in the assembly process. A multistage rotor assembly error propagation model was established considering the alignment process and the distribution of screw holes in adjacent rotors. Based on the geometric parameters of the rotor in discrete stages, the change of the coordinate value of any point in each rotor before and after assembly is predicted. Liu Yongmeng et al. [

8] propose a method to minimize stage-by-stage initial unbalance in the aero engine assembly of multistage rotors based on the connective assembly model. The process of the mass eccentric deviation propagation in the assembly is analyzed. The initial unbalance of the final assembly is improved by properly selecting the assembly orientations of multistage rotors. Chen Yue et al. [

9] proposed an optimization method for aero-engine multistage rotor assembly, which predicted assembly coaxiality and unbalance at each stage in the assembly process and gave the best assembly direction.. Yang Yi et al. [

10] proposed a method to predict the corresponding unbalance of the gear rotor system. Gohari M et al. [

11] investigated the application of vibration signals in the prediction of rotor imbalance parameters, including unbalanced position and unbalanced magnitude values. Abbasi A et al. [

12] proposed a hybrid algorithm detailing the salp group algorithm and the Nelder-Mead algorithm for determining the magnitude and phase of imbalance in rotor-bearing systems with rotational imbalance. Choudhury T et al. [

13] applied a method based on force and displacement minimization to determine the unbalance position, magnitude, and phase of a large flexible rotor.

The above studies have realized the prediction of inequality to a certain extent. Unbalance prediction based on the stack model is mainly to compute the offset of the centroid of each disk to obtain the unbalance of the rotor as a whole. However, this method only examines the characteristics of parts and ignores the influencing factors in the assembly process, so the prediction result has a large error. Deep learning can consider multiple elements or even all elements in the assembly process. Using actual assembly process data can bring us closer to the actual assembly process. Therefore, this paper tries to use the deep learning method to mine the relationship between the influencing factors and the imbalance in the assembly process and realize the prediction of the imbalance.

2.2. Application of Semi-Physical Simulation Technology in The Assembly Field

Yi Tang et al. [

14] proposed a real-time semi-physical co-simulation platform scheme to develop control centers and hardware devices based on the grid simulation developed by Real Time Laboratory (RT-LAB) and the communication network simulation developed by OPNET to achieve real-world control behavior instead of digital simulation. Jamshidi, J. et al. [

15] integrated the measurement system into the assembly process and formed Measurement Assisted Assembly (MAA) technology, which provides guidance to the assembly process through continuous measurement of size and realizes the assembly size precision control technology. K. Cheng et al. [

16] propose a semi-physical simulation method for industrial software testing and evaluation based on digital twin-driven technology. By building a semi-physical simulation model of SMS, the reliability and robustness of software systems are quickly verified by running industrial software in various manufacturing scenarios. Bao Jinsong et al. [

17] proposed a hardware-in-kind virtual assembly model based on a fat model, which guided product preassembly, assembly analysis, and manufacturing decisions by combining the CAD model with point cloud data. Zhao Bin [

18] established a semi-physical simulation model of aero-engine vibration by combining a finite element model with experimental data to decrease the error of engine vibration analysis because of the complex structure of the aero-engine and the substantial error of vibration simulation analysis.

The above research shows that the semi-physical simulation technology can think of the context information in the assembly process and combine the theoretical data with the measured data. In the process of the rotor assembly, unbalance is formed only after the completion of a specified procedure. In the assembly process, the subsequent work steps have not been carried out, so the actual process parameters and assembly quality of the ensuing work steps cannot be obtained, so theoretical data should be used instead. Therefore, this paper intends to use the idea of semi-physical simulation to establish a prediction model for the unbalance of low-voltage rotors.

2.3. Application of BRNN Neural Network

Wennian Yu et al. [

19] proposed a sensor-based data-driven scheme that takes advantage of BRNN neural networks to correlate historical and future information, combined with similarity-based curve matching techniques to estimate the RUL of the system. Alvaro Peris et al. [

20] introduced bidirectional recurrent neural networks to capture forward and backward temporal relationships in video input frames. Cheng Z. Heng et al. [

21] used BRNN networks in the video snapshot compression imaging problem to improve the quality of reconstructed video by taking advantage of BRNN networks in time correlation to reconstruct subsequent frames of video in a sequential manner. Xianlong Tang et al. [

22] proposed a multilayer bidirectional recurrent neural network-based model for predicting short-term electricity load and validated it on two data sets. The experimental results show that the proposed method outperforms the competition winner in terms of prediction accuracy on the EUTN competition data.

In summary, the BRNN (bidirectional recurrent neural network) neural network can correlate not only historical information but also future information to achieve a two-way correlation in time sequence. During the assembly process of the rotor, the assembly result of the previous process will have an impact on the assembly process and assembly quality of the next process. The assembly result of the next process will also change the assembly result of the previous process, and the assembly process of the rotor has a two-way timing correlation. Therefore, BRNN can build the prediction model of the rotor’s unbalance to achieve the prediction of unbalance.

3. Influence Factors of Low-Pressure Rotor Unbalance

The low-pressure rotor is a three-stage disk structure. Each stage is composed of a disk and a certain number of blades. Different assembly processes are involved in the assembly of the parts and the process is not consistent, making the influence factors of each process different, so the influence factors of each process are analyzed separately.

3.1. Factors Affecting Unbalance of the Disc Assembly Process

3.1.1. Disk Processing Quality Influencing Factors

Due to the inevitable errors in the machining process, there will be an uneven mass distribution of the discs at all levels in the molding process, making the initial unbalance of the discs at all levels. The initial unbalance of the disc is an important factor affecting the unbalance of the disc assembly process.

When the two disks are bolted together, the shape and position errors lead to uneven force in all parts of the connecting surface after assembly [

2]. The form and position errors of all levels of disks are transmitted and accumulated along with the connecting surface of the joint, making all levels of disks produce eccentricity and deflection. The distribution of unbalance in the process is affected by adding another unbalance to the initial unbalance of the disk. Therefore, the shape and position error at the joint of the disk is the factor affecting the unbalance of the process [

23].

The surface roughness of the column and section at the disk connection stop will also affect the final unbalance. The surface roughness of the cylinder and end face will change the contact stiffness at the connecting surface of the disk. The part surface is composed of many peaks and valleys, and the contact between the mating surfaces is actually the contact of the peaks. The contact of the bump affects the contact stiffness of the mating part. The smaller the roughness value, the less the contact of the bump, the smaller the clearance of the mating surface, the better the contact stiffness of the part, and the smaller the deformation [

24,

25].

Based on the above analysis of the factors affecting the machining quality of the unbalance of the disk assembly process, the formal expression of the factors affecting the machining quality of the unbalance of this process is as follows:

In the formula is the influencing factor of unbalanced processing quality in the disk assembly process; ,,,,,,,,,, are the initial unbalance of the level i disk, the parallelism, runout, and surface roughness of the end face of the disk connection.

3.1.2. Disk Assembly Process Influencing Factors

The mounting angle between the two discs affects the transmission of the deviation, which in turn affects the mass eccentricity of the discs [

26]. The assembly process influences that affect unbalance in this process include the mounting angle between the discs, expressed formally as follows:

In the formula, is the set of factors influencing the unbalanced amount of the disk installation process; is the installation phase of the gradedisk.

3.1.3. Disk Assembly Quality Influencing Factors

Due to the manufacturing error of the single-stage disk, it makes the coaxiality error of the disk at all levels after the completion of assembly, and the existence of coaxiality error leads to the deviation of the disk inertia axis and rotation axis, which changes the eccentricity of the unbalanced mass [

27]. In addition, the roughness between the contact surfaces can lead to inconsistent preload on the bolts, which can further distort the disk connection surfaces and affect the rotor’s mass eccentricity. Therefore, the coaxiality between the discs of each level is the influencing factor for the unbalance of the disc assembly process, which is expressed formally as follows:

In the formula, is the set of factors affecting the assembly quality of the unbalance of the disk assembly process; is the coaxiality between two disks.

3.2. Influencing Factors of Unbalanced Amount of Blade Assembly Process

3.2.1. Factors Affecting the Processing Quality of the Blade Installation Process

Due to the processing error making the blade weight moment deviation, different weight moments will appear in different blade group sorting ways. Different sorting methods of blade groups will produce different unbalance of blade groups. Therefore, the weight moment of the blade and the unbalance of the blade set are the main influencing factors on the unbalance of the low-pressure rotor. The formal expression of the factors influencing the processing quality of the unbalance of the process is as follows:

In the formula, is the unbalance of the blade installation process of grade ; is the unbalance after the assembly of the previous process. is the weight moment of the jth blade of the disk; is the unbalance of grade blade group.

3.2.2. Factors Influencing the Assembly Process of Blade Mounting Process

Different blade installation positions will have different blade unbalance. Therefore, the installation position of the blade is an influential factor affecting the amount of unbalance, expressed formally as follows.

In the formula, is the influencing factor of the assembly process of blade mounting process unbalance; is the jth blade installation position of grade i disk.

3.2.3. Factors Influencing Assembly Quality of Blade Mounting Process

In the process of the blade assembly, the clearance fit between blade and disk will affect the overall eccentricity of the rotor. Therefore, the assembly gap between blade and disk is the influencing factor of unbalance.

In the formula, is the influencing factor of assembly quality of blade mounting process unbalance; is the assembly clearance of the jth blade of the grade disk.

4. Overall Method Description

For the rotor unbalance prediction problem, this paper proposes a semi-physical simulation model framework for unbalance prediction based on the fusion of mechanism and data drive. Firstly, the blade assembly sequence optimization model is established through the mechanism analysis method to realize the blade assembly sequence optimization. Then, based on the bidirectional recurrent neural network BRNN, a semi-physical simulation model for rotor unbalance prediction is constructed. The actual data of the assembled part is fused with the theoretical design data of the unassembled part to achieve the prediction of rotor unbalance. The framework includes ranking optimization of blades, data enhancement based on adversarial self-encoder AAE (adversarial auto-encoder), and semi-physical simulation of unbalance prediction based on BRNN (bidirectional recurrent neural network). The semi-physical method of low-pressure rotor imbalance prediction is shown in

Figure 1 below.

Blade sequencing is based on the establishment of a blade sequencing optimization mechanism model, using reinforcement learning to optimize the blade sequencing so that the sum of blade group unbalance and disc initial unbalance is minimized, so as to obtain the optimal blade sequencing.

Data augmentation based on the AAE method is to learn the distribution of the original data by combining the generative adversarial network and the self-encoder. New sample data are generated based on the distribution of the original data to provide data support for the training imbalance prediction model.

The semi-physical simulation of imbalance prediction based on BRNN (bidirectional recurrent neural network) is divided into two parts: data fusion and imbalance prediction.

Data fusion is used to fuse theoretical data with actual data in order to construct inputs for the imbalance prediction model. Since the part to be assembled has been determined before assembly, the processing quality factors of each step are the actual value when predicting the imbalance amount. When the assembly of the tth working step is completed. The assembly process and assembly quality before this working step are actual values. The assembly process and assembly quality of the later steps are theoretical values. The data after fusion is. The data to before the tth working step are all actual data, . to are the theoretical values,.

The imbalance prediction is to input the fused data into the model to realize the prediction of the imbalance of the process step.

5. Blade Sorting Mechanism Model

The blade assembly sequence is the main factor affecting rotor unbalance. Existing methods usually divide the disc into several areas and control the difference in blade quality between the areas so that the imbalance of the blade group is small. In this process, the initial imbalance of the disk is not considered. Although the imbalance of the blade group is small, the overall imbalance after assembly still does not meet the requirements. Therefore, in this paper, based on the establishment of the blade sorting optimization mechanism model, reinforcement learning [

28] is used to optimize the blade sorting so that the sum of the unbalance of the blade sorting and the initial unbalance of the disk is minimized and the optimal blade sorting order is obtained.

The blade affects the unbalance of the rotor through the mass moment. The blade mass moment is composed of the mass and the distance from the center of mass to the blade tenon [

29]. The theoretical mass of blade

i is

, The theoretical radius of the rotation vector is

. The theoretical mass moment is as follows:

The mass moment of the blade is decomposed orthogonally, as shown in

Figure 2 below. Under ideal conditions, the vector sum of the mass moments of all blades with respect to the axis of rotation is zero. The centroid of the blade group coincides with the origin. Due to the machining error of the blade, the centroid of the blade group is deviated, which leads to unbalance.

Since the number of blades in each stage of the low-pressure rotor is fixed, so

. In the formula,

n is the number of blades, and

i is the

ith blade. After the mass moments of the blade set are orthogonally decomposed, the amount of unbalance of the blade set can be determined.

The initial unbalance of the disk is called

. By optimizing the blade sequence, the sum of the blade mass moments

and the initial unbalance

of the disk cancel each other as much as possible, to minimize the initial unbalance of the rotor.

There are n blades in the low-pressure rotor, and there are n! ways to arrange the blades. The calculation is large, and the exhaustive method is difficult to complete. In this paper, reinforcement learning is used to optimize the blade ordering, and the optimal blade ordering result is obtained to ensure that the unbalance of the rotor after blade assembly meets the requirements.

6. Imbalance Data Enhancement Based on AAE Model

The low-voltage rotor is a single-piece small batch production mode, and the assembly data volume is small. While the existing deep learning model requires a large sample size, small sample data is difficult to ensure the accuracy and generalization ability of the prediction model. To achieve an accurate prediction of inequality, it is necessary to enhance the existing small sample data and expand the existing data set. An adversarial auto-encoder (AAE) is a generation network that can learn the distribution of original samples and generate new sample data without the guidance of human experience. Therefore, AAE is selected as the data enhancement model in this paper. The problem of low accuracy and poor generalization of the prediction model caused by the small amount of assembly data is solved by generating new sample data.

6.1. Imbalance Data Enhancement Network Design Based on AAE Model

The AAE model is composed of an autoencoder and an adversarial network. The basic structure is shown in

Figure 3 below. The AAE model matches the implicit coding of the encoder with the prior distribution by training on the target. In the application, the sampled data in the prior distribution is used as the input, and the decoder completed by training is used as the generating model to generate new data with the same distribution as the original data set.

In the above figure

represents the actual sample.

represents the implicit encoding of the autoencoder.

is the preset prior distribution. Each batch training of the AAE model is divided into two stages: sample reconstruction and regularization. In the sample reconstruction stage, the autoencoder updates the encoder and decoder to reduce the input reconstruction error. In the regularization stage, the adversarial network updates its discriminant network to distinguish real samples from generated samples and updates its generative network to confuse the discriminant network. When the training is completed, the decoder of the autoencoder can be used as a generative model to realize sample enhancement [

30].

The design of the AAE model includes the setting of model layers, input dimension, hidden coding dimension, prior distribution, and other parameters. The input dimension of the AAE model is the number of influencing factors included in the process. The optimal model depth and the number of neurons in each layer were obtained through multiple-model training. In the AAE model, prior distribution can be preset arbitrarily. Most of the influencing factors studied in this paper, including form and position tolerance, assembly process, and assembly quality, conform to the Gaussian distribution. Therefore, the Gaussian distribution is selected as the prior distribution required for the model. In addition, the sampling data of in the model training stage needs to be input into the discriminator at the same time as the encoder’s implicit code for antagonistic training. In the application phase, the preset is used as the input of the decoder to generate new data samples. Therefore, the dimension must be the same as the dimension of the encoder’s implicit code .

6.2. Implementation of Imbalanced Data Enhancement Network Based on AAE Model

This article uses the Python-based machine learning open-source platform TensorFlow to achieve unbalanced data enhancement. The following

Table 1 is a detailed introduction to AAE model training.

For each assembly process of a low-voltage rotor, the decoder weight and bias of the data generation model for each assembly process are obtained through the training of the above steps. Then, the data is sampled from the predefined a priori distribution and input to the decoder to obtain new sample data for each assembly process, so as to expand the data of each assembly process of the low-voltage rotor and lay the foundation for establishing the prediction of process unbalance.

7. Prediction of Inequality Based on BRNN

In the assembly process of a low-voltage rotor, the assembly result of the front installation process will affect the assembly process and assembly quality of the rear installation process. The assembly result of the following installation process will change the assembly result of the previous installation process, and the assembly process has a bi-directional temporal correlation. The relationship between process unbalance and its influencing factors is complex and the mechanism of action is not clear, so the mapping relationship between process unbalance and its influencing factors cannot be established by a mathematical formula. BRNN [

31] is a recurrent neural network. In addition to constructing nonlinear and complex mapping relationships, its special LSTM (Long-Short Term Memory) unit can not only associate historical information but also associate future information to realize bidirectional association in time sequence. Therefore, this paper adopts the BRNN network to establish the unbalance prediction model of the low-voltage rotor and realize the unbalance prediction of each process.

7.1. Parameter Design of Unbalanced Prediction Model Based on BRNN Network

Due to the different meanings and changes of each influencing factor, it is difficult to directly take each key influencing factor as the input of the prediction model. In this paper, the influencing factors are divided into the following two types of influencing factors: those that change with the process and those that change with the work step according to the changes of the influencing factors. Influencing factors that change with the process are factors that do not change in a given assembly process, such as the initial unbalance of the disk and its mounting angle at each level in the disk assembly process. The influence factor that changes with the work step is the factor that changes with the assembly work step repeatedly in a certain assembly process, for example, the weight moment of the blade at each level and its installation position in the blade assembly process. The input of the unbalance prediction model of each assembly process is a combination of the influencing factors that change with the process and the influencing factors that change with the work step. The input dimension is the number of influencing factors of the corresponding assembly process.

Each assembly process is composed of a number of assembly steps and has a certain degree of repeatability. The repeatability of assembly steps makes it possible to predict the unbalance of each process by using the BRNN network. Therefore, the number of repeated work steps in each assembly process is taken as the time step of BRNN when constructing the prediction model of the unbalance of each process.

Although this paper uses the AAE model to enhance the unbalance data of each process, the generated data still has some errors. To reduce the effect of data errors, the number of neurons contained in each LSTM unit is set to a lesser value.

To sum up, the input neurons of the BRNN unbalance prediction model are LSTM units. The number of units contained in each LSTM unit is determined according to different processes. The time step of the model is the number of working steps included in each process. The dimension of the time window is the number of influencing factors that change with the working procedure and working step.

7.2. Realization of Unbalance Prediction Model Based on BRNN Network

This paper uses TensorFlow, an open-source machine learning algorithm library based on Python, to build a prediction model of inequality based on the BRNN network. The training steps of the model are shown

Figure 4 and

Table 2.

8. Case Study

8.1. Example Verification of Blade Sorting Mechanism Model

This paper studies a model of an aero-engine low-pressure rotor with three sets of blades. When assembling, the second-stage blades are assembled first, and then the overall unbalance of the rotor is measured. Then, the first-stage blades or the third-stage blades are assembled, and the overall unbalance is measured after the three sets of blades are assembled. It can be seen that the second-stage blades are a relatively important part of the low-pressure rotor. Therefore, this paper takes the second-stage blade arrangement as an example for verification. The constructed model is used to optimize the blade arrangement. The data for second-stage blades are shown in the following

Table 3.

The blade ordering model was constructed to optimize the blade ordering, and the results of the ordering graph were as follows:

Figure 5 and

Table 4.

The result of the blade sorting determines the overall assembly unbalance of the rotor. In order to verify the optimization effect of the method in this paper, several methods mentioned in the literature [

32,

33], simulated annealing algorithm SA, and particle swarm optimization algorithm PSO were used to sort the blades, and the results of unbalance and mass moment difference of the diagonal position of the blades were obtained, as shown in

Table 5.

As can be seen from

Table 5, the Weight Sorted and Sorting-1 (4 skip) methods have a serious excess of unbalance in the blade arrangement process, and the diagonal mass moment difference is too large. Work-shop, Sorting-2 (7 skip), Sorting-3, Sorting-4, and Sorting-5 have relatively small unbalance under the condition that the diagonal mass moment difference meets the requirements, but the unbalance is still greater than 100

, and the result is still not ideal. Next is a comparison of the three intelligent algorithms (SA, PSO, and GA) with traditional sorting methods. It can be seen from the table that the diagonal mass moment differences optimized by the intelligent algorithm all meet the requirements, and the calculated unbalance value is far less than that of the traditional sorting method.

In order to further explore the performance of each intelligent algorithm, MEAN, and root MEAN square error (RMSE) were used to evaluate the accuracy and robustness of each intelligent algorithm. The smaller the values of MEAN and RMSE, the higher the accuracy and the better the robustness of the algorithm.

From

Table 6, the MEAN and RMSE values of Q-learning are the smallest, with 9.24 and 3.33, respectively. The optimization effect and robustness of Q-learning are more suitable for the solution of aero-engine rotor blade sequencing optimization problems compared with SA and PSO algorithms. Additionally, the reinforcement learning algorithm can make the blade sorting model converge to the optimal value rapidly as the model is continuously trained.

8.2. Example Validation of The Model with Enhanced Inequality Data

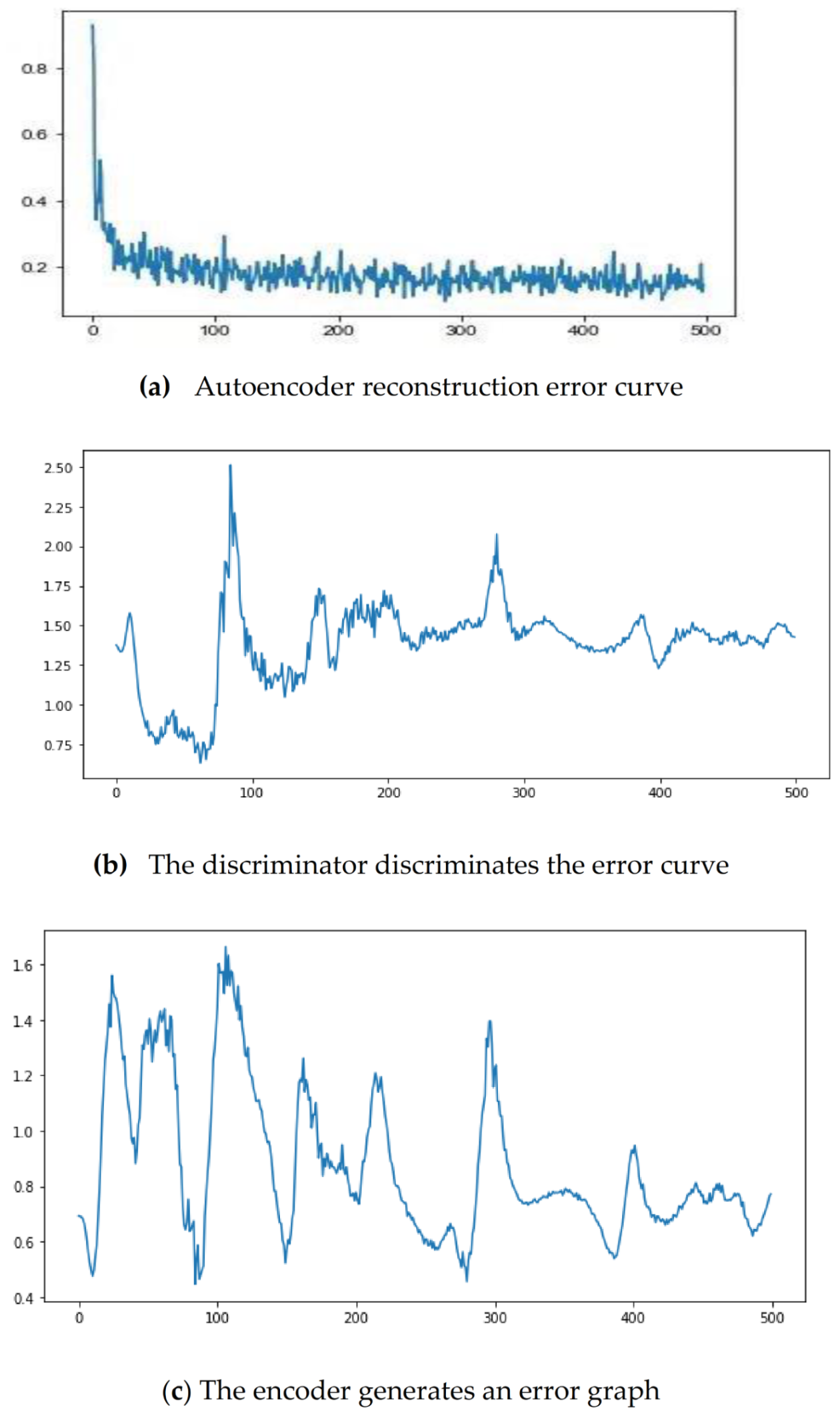

Taking the second-stage blade assembly process as an example, the actual data of the second-stage blade assembly process were input into the AAE model as the original samples. The weight of each part is optimized and updated by the Adma optimization algorithm. The model reconstruction error, discrimination error, and generation error are reduced. The variation trend of the above errors with the number of iterations of the training process is shown in

Figure 6 below.

According to

Figure 6 above, the reconstruction error of the autoencoder converges to 0.19 after 100 iterations. The discrimination error of the discriminator converges to 1.49 after 300 iterations. The generator error converges to 0.8 after 400 iterations. The decrease in reconstruction error indicates that the auto-encoder has a higher degree of feature fitting and that the decoder can reconstruct the original data well. The increase in discriminator error and the decrease in generator error indicate that the difference between the generated data and the real data decreases with the increase in training times. When the curve converges, it indicates that the model has reached equilibrium.

After the AAE model training is completed, 1000 groups of new data samples are generated using prior distribution as input and the decoder as the generation model. There are 183 columns in the sample. A partial sample is shown in

Table 7.

In total, 1000 groups of sample data generated by the AAE model were input into the BRNN network for training. After training, 20 groups of original data were input into the trained model to observe the error between the actual value and the predicted value of unbalance. The loss function curve and prediction results of the training process are shown in

Figure 7 below.

The trained BRNN network converges to 0.14 after 150 iterations. The prediction results show that the constructed prediction network can predict the unbalance of the assembly process better and the prediction effect is better. At the same time, it shows that the sample data generated by the model is distributed with the original data, which has a certain validity. The data generated based on the AAE model is only used for the training of the unbalance prediction model. In practice, data augmentation is not required and will not affect the runtime of the unbalance prediction model.

8.3. Example Verification of Unbalance Prediction Model

Take the second-stage blade assembly process as an example; there are 60 blades in this process, so the time step of the process prediction model is 60. The input of each time step is the initial unbalance of the disk, the unbalance of the secondary blade group, the weight moment of the blade, the installation position of the blade, and the blade assembly gap. In order to facilitate data reading and training, the generated

data storage format is changed to a

data format. Every 60 lines is a group of assembly data, and one line is a time step data. One set of data is as follows:

In order to evaluate the established unbalance prediction model, this paper compares the prediction results of the BRNN network with those of the LSTM network and BP neural network. The root mean square error (RMSE), mean absolute error (MAE), and R

2 are also selected as evaluation metrics to compare the accuracy and robustness of each algorithm. The comparison with the LSTM network method is performed to verify the advantages of the BRNN network in the problem of bidirectional timing correlation of rotor assembly, and the comparison with the BP [

34] network method is performed to compare with other methods from the literature.

In this paper, k-fold cross-validation is used for validation. The 1000 sets of data were sequentially divided into 5 copies of 200 sets each, and 4 of them were taken for training and 1 for testing each time. The loss function curves and test sample prediction curves for the training process of each model are shown in the following

Figure 8.

The prediction results of 10 randomly selected groups of prediction models are shown in

Table 8 below.

As can be seen from

Table 8, the maximum relative error of the BP neural network model is 11.59%, the minimum relative error is 6.96%, and the average relative error is 9.26%. The maximum relative error of the LSTM neural network is 12.21%, the minimum relative error is 2.11%, and the average relative error is 6.82%. The maximum relative error of the BRNN neural network is 9.74%, the minimum relative error is 4.08%, and the average relative error is 6.33%. In summary, the prediction results of the BRNN neural network are relatively balanced and the average relative error is minimal, which proves the effectiveness and accuracy of the proposed method.

Evaluated from the metrics of the prediction models, the RMSE, MAE, and R

2 values of each prediction model are shown in

Table 9.

From the above loss function curves, we can see that the BRNN network converges to 0.12 after 150 iterations, the LSTM converges to 0.16 after 200 iterations, and the BP network converges to 0.18 after 250 iterations, indicating that the BRNN network can fit better and faster. By comparing the RMSE, MAE, and R

2 of each model in

Table 9 above, it can be seen that the BRNN network has the smallest RMSE and MAE and the largest R

2, and the BRNN network proposed in this paper has better effectiveness and accuracy in the prediction of the unbalance.

After the above training and validation processes, the unbalance prediction model for the second stage blade assembly process is obtained. In order to validate the prediction model of unbalance using semi-physical ideas, the original data set is used as the test set, and it is tested by fusing the actual data with the theoretical data to form

sets of data. The theoretical values of the initial unbalance of the disk, the unbalance of the secondary blade set, the blade weight moment, and the assembly clearance are shown in the following

Table 10.

Among the above influencing factors, the initial unbalance of the disk and the unbalance of the secondary blade set are influencing factors that change with the process. Blade weight moment and mounting position are determined before blade assembly. The only undetermined influencing factor is the assembly clearance between the blade and the disk. Therefore, the theoretical data for this process is only the assembly gap. After the first step is completed, the actual data is fused with the theoretical data to form one of the data sets as follows. Each subsequent step replaces the corresponding process data in the input. Input the above data into the model to predict inequality, and some specific prediction results are shown in the following

Table 11:

The above prediction results show that the unbalance prediction model of the two-stage blade assembly process can realize the unbalance prediction in the assembly process. The maximum relative error is 13.4%, and the minimum relative error is 2.35%. Based on the above case verification, the proposed semi-physical simulation method of mechanism and data-driven fusion for low-voltage rotor unbalance prediction is effective, which can realize the unbalance prediction in the assembly process. The accuracy of the unbalance prediction model is affected by the blade sequencing results and the model training data, and the above example validation results also demonstrate again the effectiveness of the AAE-based generated data and the blade sequencing mechanism model.

9. Conclusions

In order to solve the problem of multiple assemblies and trials caused by the over-uniformity and low success rate of one-time assembly, this paper proposes a mechanism and data-driven fusion of a low-pressure rotor unbalance prediction method. Firstly, a blade sequencing mechanism model is established, and reinforcement learning is used to achieve blade sequencing optimization. Secondly, the actual data of the assembled blades are combined with the theoretical data of the blades that have not been assembled, and a semi-physical simulation framework of unbalance prediction with a BRNN network as the core is constructed to realize the imbalance prediction during the assembly process. Finally, the effectiveness of the method is demonstrated by comparing it with the BP neural network method and the LSTM neural network method. The method can be extended to other rotary multi-stage equipment assembly areas, such as turbine assembly. However, in this paper, the construction of the prediction model is completed by the samples generated by the AAE model, and there will be a gap between the generated samples and the actual samples. With the accumulation of real data, how to conduct incremental learning of the model is the next research direction.

Author Contributions

H.Z. has made contributions to the analysis of blade sorting problems, the determination of solutions to blade sorting problems, experimental design, experimental data processing, and paper writing. M.W. (Mingwei Wang) and J.Z. gave guidance on the overall methodology of the paper; L.L., X.M. and L.Y. contributed to the figures, tables, and English translation of the paper; M.W. (Manxian Wang) provided the 3D model of the rotor. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Key R&D Program of China (No. 2019YFB1703802).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw/processed data needed to reproduce these findings cannot be shared at this time because they are confidential.

Acknowledgments

Thanks to Enming Li and Changsen Yang for compiling the experimental data.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shi, H. Aero-Engine Assembly Process Technology; Beihang University Press: Beijing, China, 2015. [Google Scholar]

- Liu, X. Assembly Accuracy Prediction and Stacking of Aeroengine Rotor; Dalian University of Technology: Dalian, China, 2020. [Google Scholar]

- Ju, Y.; Wu, F.; Jin, B.; Wei, X.; Zu, J. Structure assembly technique of multi-stage disc rotor based on rotor runout and unbalance optimization. J. Aeroengine 2018, 44, 83–90. [Google Scholar]

- Li, P.; Wang, J.; Zhao, H. Research on the control method of aeroengine rotor static and couple unbalance. J. Aeronaut. Sci. Technol. 2019, 30, 13–18. [Google Scholar]

- Li, M. Analysis of rotor Dynamic balance of civil aero engine. J. Intern. Combust. Engine Parts 2018, 13, 73–75. [Google Scholar] [CrossRef]

- Chen, D. Research on Vibration Suppression Method of Aero-Engine Rotor Based on Stack Assembly Optimization; Harbin Institute of Technology: Harbin, China, 2019. [Google Scholar]

- Yue, C.; Ji, C.; Xun, S. An unbalance optimization method for a multi-stage rotor based on an assembly error propagation model. J. Appl. Sci. 2021, 11, 887. [Google Scholar]

- Liu, Y.; Zhang, M.; Sun, C.; Hu, M.; Chen, D.; Tan, J. A method to minimize stage-by-stage initial unbalance in the aero engine assembly of multistage rotors. J. Aerosp. Sci. Technol. 2019, 85, 270–276. [Google Scholar] [CrossRef]

- Chen, Y.; Cui, J.; Sun, X.; Cui, S. Research on multistage rotor assembly optimization methods for aeroengine based on the genetic algorithm. J. Complex. 2021, 2021. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, J.; Wang, X.; Dai, P. A general method to predict unbalance responses of geared rotor systems. J. Sound Vib. 2016, 381, 246–263. [Google Scholar] [CrossRef]

- Gohari, M.; Kord, A.; Jalali, H. Unbalance rotor parameters detection based on artificial neural network: Development of test rig. J. Vib. Eng. Technol. 2022, 1–9. [Google Scholar] [CrossRef]

- Abbasi, A.; Firouzi, B.; Sendur, P.; Ranjan, G.; Tiwari, R. Identification of unbalance characteristics of rotating machinery using a novel optimization-based methodology. J. Soft Comput. 2022, 26, 4831–4862. [Google Scholar] [CrossRef]

- Choudhury, T.; Viitala, R.; Kurvinen, E.; Viitala, R.; Sopanen, J. Unbalance estimation for a large flexible rotor using force and displacement minimization. J. Mach. 2020, 8, 39. [Google Scholar] [CrossRef]

- Tang, Y.; Tai, W.; Liu, Z.; Li, M.; Wang, Q.; Yun, L.; Huang, L. A hardware-in-the-loop based co-simulation platform of cyber-physical power systems for wide area protection applications. J. Appl. Sci. 2017, 7, 1279. [Google Scholar] [CrossRef]

- Jamshidi, J.; Kayani, A.; Iravani, P.; Maeopoulos, P.; Summers, M. Manufacturing and assembly automation by integrated metrology systems for aircraft wing fabrication. J. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 25–36. [Google Scholar] [CrossRef]

- Cheng, K.; Wang, Q.; Yang, D.; Dai, Q.; Wang, M. Digital-twins-driven semi-physical simulation for testing and evaluation of industrial software in a smart manufacturing system. J. Mach. 2022, 10, 388. [Google Scholar] [CrossRef]

- Bao, J.; Li, Q.; Xiang, Q.; Wu, D.; Zheng, X. The modeling, evolutionary and application of quasi-physical virtual assembly. J. Mech. Eng. 2018, 54, 61–69. [Google Scholar] [CrossRef]

- Zhao, B. Study on a Semi-Physical Simulation Model for the Whole Aero-engine Vibration. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2015. [Google Scholar]

- Yu, W.; Kim, I.; Mechefske, C. Remaining useful life estimation using a bidirectional recurrent neural network based autoencoder scheme. J. Mech. Syst. Signal Process. 2019, 129, 764–780. [Google Scholar] [CrossRef]

- Peris, Á.; Bolaños, M.; Radeva, P.; Francisco, C. Video description using bidirectional recurrent neural networks. In Proceedings of the International Conference on Artificial Neural Networks, Barcelona, Spain, 6–9 September 2016; Springer: Cham, Switzerland, 2016; pp. 3–11. [Google Scholar]

- Cheng, Z.; Lu, R.; Wang, Z.; Zhang, H.; Chen, B.; Meng, Z.; Yuan, X. BIRNAT: Bidirectional recurrent neural networks with adversarial training for video snapshot compressive imaging. In Proceedings of the European Conference on Computer Vision, Glasgow, UK, 23–28 August 2020; Springer: Cham, Switzerland, 2020; pp. 258–275. [Google Scholar]

- Tang, X.; Dai, Y.; Wang, T.; Wang, T.; Chen, Y. Short-term power load forecasting based on multi-layer bidirectional recurrent neural network. J. IET Gener. Transm. Distrib. 2019, 13, 3847–3854. [Google Scholar] [CrossRef]

- Li, Z. Research on Rotor Assembly Method Based on Axial Compression; Harbin Institute of Technology: Harbin, China, 2018. [Google Scholar]

- Shen, J. Characteristic Research and Statistical Test of Fractal Parameters of Machine Joint Interfaces. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2019. [Google Scholar]

- Li, W. Study on Micro-contact and Tribological Properties between Rough Surfaces under Cyclic Loading. Ph.D. Thesis, Northwestern Polytechnical University, Xi’an, China, 2018. [Google Scholar]

- Zhang, H.; Wang, M.; Deng, W.; Zhou, J.; Liu, L.; Li, J.; Li, R. Identification of Key Factors and Mining of Association Relations in Complex Product Assembly Process. Int. J. Aerosp. Eng. 2022, 2022, 583437. [Google Scholar] [CrossRef]

- Phadatare, H.; Pratiher, B. Nonlinear modeling, dynamics, and chaos in a large deflection model of a rotor–disk–bearing system under geometric eccentricity and mass unbalance. J. Acta Mech. 2020, 231, 907–928. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, M.; Li, Z.; Zhou, J.; Zhang, K.; Ma, X.; Wang, M. Semi-Physical Simulation of Fan Rotor Assembly Process Optimization for Unbalance Based on Reinforcement Learning. J. Aerosp. 2022, 9, 342. [Google Scholar] [CrossRef]

- Xu, G.; Bai, Y.; Sun, H.; Fu, X.; Zhang, G.; Peng, Q.; Chang, Z. Optimizing Blade Arrangement for Aero-Engine Rotor Based on Random Equiprobability Algorithm. J. Aeronaut. Manuf. Technol. 2020, 63, 52–56. [Google Scholar]

- Xia, L.; Wang, H.; Guo, W. Gait recognition based on Wasserstein generating adversarial image inpainting network. J. Cent. South Univ. 2019, 26, 2759–2770. [Google Scholar] [CrossRef]

- Lokesh, S.; Malarvizhi, K.; Ramya, D.; Parthasarathy, P.; Goukulnath, C. An automatic tamil speech recognition system by using bidirectional recurrent neural network with self-organizing map. J. Neural Comput. Appl. 2019, 31, 1521–1531. [Google Scholar] [CrossRef]

- Li, S.; Lv, Y. Optimal sequencing of high-pressure compressor blades based on improved ant colony algorithm. J. Mech. Eng. Autom. 2020, 3, 60–62. [Google Scholar] [CrossRef]

- Pan, W.; Zhang, M.; Tang, G. Blade arrangement optimization for mistuned bladed disk based on gaussian process regression and genetic algorithm. J. Eng. Gas Turbines Power 2020, 142, 021008. [Google Scholar] [CrossRef]

- Liu, Z. Double Objective Optimation Assembly Method of Coaxiality and Initial Unbalance for Aero-Engine Rotors; Harbin Institute of Technology: Harbin, China, 2019. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).