Static Modelling and Analysis of a Novel Movable Tooth Drive with Logarithmic Spiral Tooth Profiles

Abstract

:1. Introduction

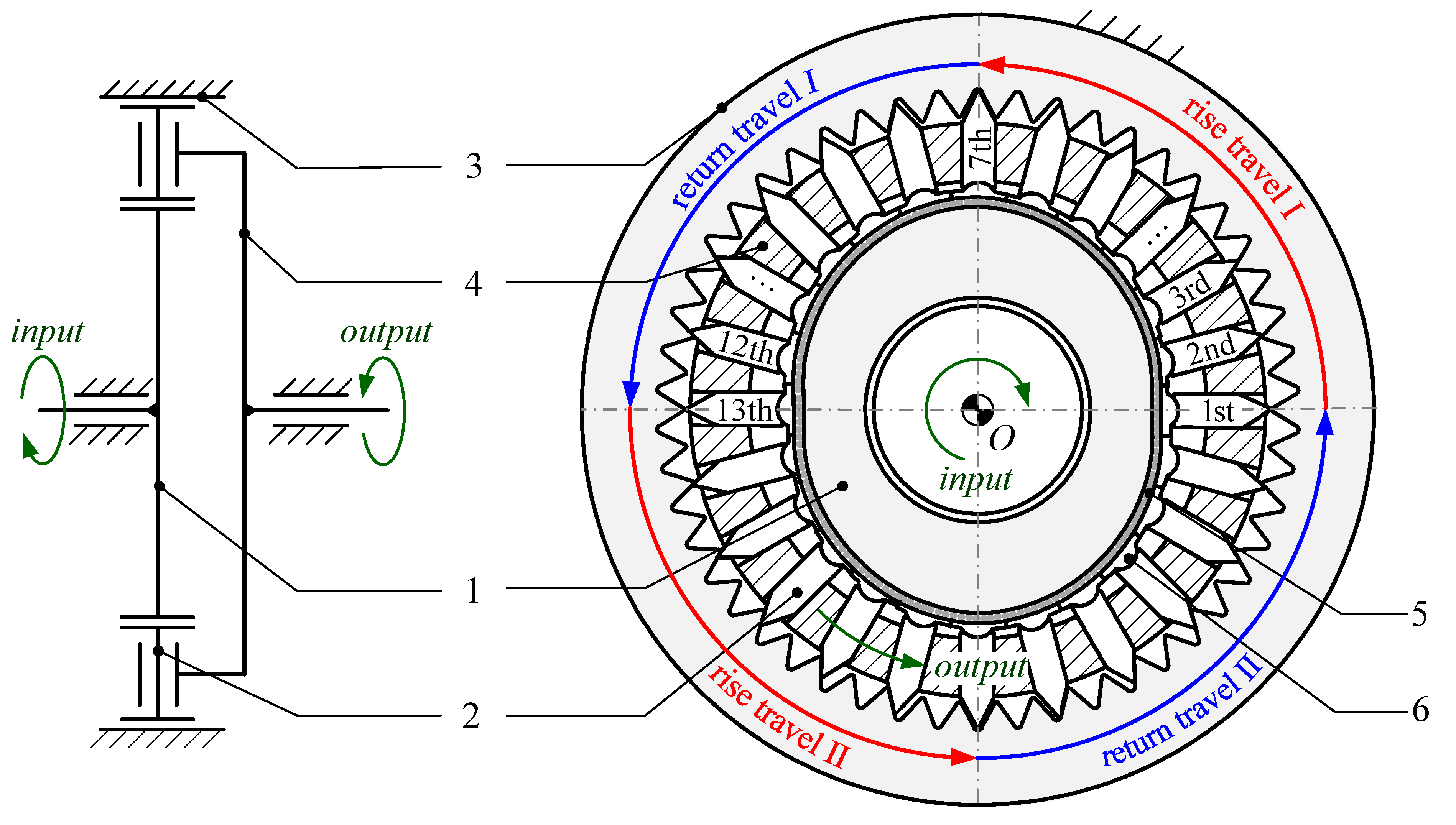

2. Structure and Transmission Principle

3. Profile Equations

3.1. Movable Tooth and Ring Gear

3.1.1. Geometric Properties of Logarithmic Spiral

- Equiangularity: the spiral angle between the tangent line and polar radius is equal at an arbitrary point;

- Evolute: the curve generated by the curvature center of each point is the identical logarithmic spiral with a phase angle difference π/2;

- Similarity: the polar radii of any two sectors with the same angle θ are in same proportion eθ/tanβ.

3.1.2. Logarithmic Spiral Conjugate Tooth Profile

3.2. Wave Generator Cam

4. Static Model of the Mechanism

4.1. Load Distribution Characteristic of Multi-Tooth Meshing

4.2. Static Equilibrium Equations of Components

4.2.1. Ring Gear

4.2.2. Movable Tooth

4.2.3. Wave Generator and Tooth Carrier

5. Validation of the Model

5.1. Numerical Simulation

5.1.1. Forces of the Movable Tooth

5.1.2. Load Distribution Factor

5.2. FEM Simulation

6. Discussion

6.1. Self-Locking Analysis

6.1.1. Rise Travel

6.1.2. Return Travel

6.2. Force Transmission Characteristics

6.2.1. Pulsation Amplitude of Total Contact Force

6.2.2. Force Transmission Rate

6.3. Selection of Dimensional Parameters

6.3.1. Pitch Circle Radius Coefficient r0/R and Spiral Angle β

6.3.2. Radius Coefficients of the Outer and Inner Circles of the Tooth Carrier, ru/R and rl/R

7. Conclusions

- (1)

- The tooth profiles of movable tooth and ring gear can be designed by two pieces of curves taken from the same one logarithmic spiral. They are almost in full surface contact under the working condition because their curvatures are very close, different from the conventional involute or cycloidal tooth profiles creating a linear contact. Thus, the novel drive can bear more loads and has higher rigidity than the conventional ones, which can be applied in the fields with heavy load requirements, such as machine tools, petroleum drilling platforms, industrial robots, etc.;

- (2)

- The contact force between one tooth and ring gear is proportional to the curvature radius of the contact point, which increases exponentially and monotonically corresponding to the curvature radius of the logarithmic spiral tooth profile during the rise travel, and the load distribution of the teeth is determined according to the ratio of the curvature radius of their contact points;

- (3)

- The pulsations of total contact force appear periodically at the alternation of the teeth in the multi-tooth meshing condition, because the closer the tooth is to the tooth root of the ring gear, the larger its load ratio is, and the pulsation amplitude is related to the spiral angle, rise travel angle, and ring gear tooth number;

- (4)

- There may be self-locking between the tooth and ring gear in a meshing period because of the unreasonable parameter design, especially during the return travel; therefore it is recommended to select feasible ranges of the dimensional parameters, or equip the reset springs, to avoid the self-locking, and the comprehensive consideration of the pulsation amplitude and force transmission rate can further help the dimensional synthesis.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| z1, z2, and z3 | the number of the wave generator lobe, movable teeth, and ring gear teeth |

| θh | the rise travel angle |

| Δθ | the phase difference |

| R | the initial polar radius |

| β | the spiral angle |

| eiθ | the unit vector |

| r1, r2, and r3 | the vector equations of wave generator cam profile, the tooth profile of movable tooth and ring gear |

| O1-x1y1 | the fixed coordinate system located at the rotation center of the wave generator |

| O2-x2y2 | the follow-up coordinate system connected to the movable tooth. |

| θ | the tooth profile parameter |

| ϕ | the rotation angle of movable tooth |

| s | the radial displacement of movable tooth |

| the coordinate transformation matrix from O2-x2y2 to O1-x1y1 | |

| n12 and v | the common normal vector and relative velocity vector at the meshing point |

| r0 | the pitch circle radius of the wave generator |

| n | the normal wave generator profile |

| α | the acute angle between n and v |

| I | the speed ratio of the mechanism |

| M3 | the torque applied to the ring gear |

| N3i and δi | the contact force and elastic deformation between the i-th tooth and ring gear |

| Δτ | the small rotation angle of the tooth carrier |

| r3i | the distance from the contact point to the rotation center O |

| ρi | the curvature radius of the ring gear tooth profile at the contact point |

| k | the contact stiffness of the teeth and ring gear |

| Ki | the load distribution factor |

| li | the arm of contact force |

| Li | the coefficient matrix |

| F1i and F3i | the total reaction forces of the wave generator and ring gear to the teeth |

| F2 | the total reaction forces of the tooth carrier to the teeth |

| Fki, Fri, and Fci | the inertial forces acting on the centroid |

| φ1, φ2, and φ3 | the friction angles |

| h and b | the full tooth height and width of the tooth |

| r1i and αi | the radius and meshing angle at the hinge point |

| ru and rl | the radii of the outer and inner circles of the tooth carrier |

| M1 and M2 | the input torque and output torque |

| Fx and Fy | the components of force of the frame on the wave generator along x and y directions |

| ϕi | the angle between the centerline of the i-th tooth and x-axis |

| δF | the pulsation amplitude of total contact force |

| αc | the critical meshing angle |

| [αc] | the allowable meshing angle |

| αmax | the maximum meshing angle |

| r0/R | the pitch circle radius coefficient |

| ηF | the force transmission rate |

| ru/R and rl/R | the radius coefficients of the outer and inner circles of the tooth carrier |

References

- Pham, A.D.; Ahn, H.J. High precision reducers for industrial robots driving 4th industrial revolution: State of arts, analysis, design, performance evaluation and perspective. Int. J. Precis. Eng. Manufact.-Green Technol. 2018, 5, 519–533. [Google Scholar] [CrossRef]

- Kudrijavcev, V.N. Planetary Gear Train; Mechanical Engineering: Leningrad, Russian, 1966. [Google Scholar]

- Malhotra, S.K.; Parameswaran, M.A. Analysis of a cycloid speed reducer. Mech. Mach. Theory 1983, 18, 491–499. [Google Scholar] [CrossRef]

- Xuan, L.; Xie, C.; Guan, T.M.; Lei, L.; Jiang, H. Research on dynamic modeling and simulation verification of a new type of FT pin-cycloid transmission. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 6276–6288. [Google Scholar] [CrossRef]

- Gorla, C.; Davoli, P.; Rosa, F.; Longoni, C.; Chiozzi, F.; Samarani, A. Theoretical and experimental analysis of a cycloidal speed reducer. ASME J. Mech. Des. 2008, 130, 112604. [Google Scholar] [CrossRef]

- Li, X.; Li, C.Y.; Wang, Y.W.; Chen, B.K.; Lim, T.C. Analysis of a cycloid speed reducer considering tooth profile modification and clearance-fit output mechanism. ASME J. Mech. Des. 2017, 139, 033303. [Google Scholar] [CrossRef]

- Hidaka, T.; Wang, H.Y.; Ishida, T. Rotational transmission error of K-H-V planetary gears with cycloid gear (1st Report, Analytical method of the rotational transmission error). Trans. Jpn. Soc. Mech. Eng. Ser. C 1994, 60, 645–653. [Google Scholar] [CrossRef]

- Meng, Y.H.; Wu, C.L.; Ling, L.P. Mathematical modelling of the transmission performance of 2K-H pin cycloid planetary mechanism. Mech. Mach. Theory 2007, 42, 776–790. [Google Scholar] [CrossRef]

- Hsieh, C.F. Dynamics analysis of cycloidal speed reducers with pinwheel and nonpinwheel designs. ASME J. Mech. Des. 2014, 136, 091008. [Google Scholar] [CrossRef]

- Hsieh, C.F. Traditional versus improved designs for cycloidal speed reducers with a small tooth difference: The effect on dynamics. Mech. Mach. Theory 2015, 86, 15–35. [Google Scholar] [CrossRef]

- Kumar, N.; Kosse, V.; Oloyede, A. A new method to estimate effective elastic torsional compliance of single-stage cycloidal drives. Mech. Mach. Theory 2016, 105, 185–198. [Google Scholar] [CrossRef]

- Xu, L.X. A dynamic model to predict the number of pins to transmit load in a cycloidal reducer with assembling clearance. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4247–4269. [Google Scholar] [CrossRef]

- Xu, L.X.; Chen, B.K.; Li, C.Y. Dynamic modelling and contact analysis of bearing-cycloid-pinwheel transmission mechanisms used in joint rotate vector reducers. Mech. Mach. Theory 2019, 137, 432–458. [Google Scholar] [CrossRef]

- Kim, K.H.; Lee, C.S.; Ahn, H.J. Torsional rigidity of a cycloid drive considering finite bearing and hertz contact stiffness. In Proceedings of the ASME International Design Engineering Technical Conferences/Computers and Information in Engineering Conference, San Diego, CA, USA, 30 August–2 September 2009. [Google Scholar]

- Li, S.T. Design and strength analysis methods of the trochoidal gear reducers. Mech. Mach. Theory 2014, 81, 140–154. [Google Scholar] [CrossRef]

- Blagojevic, M.; Marjanovic, N.; Djordjevic, Z.; Stojanovic, B.; Disic, A. A new design of a two-stage cycloidal speed reducer. ASME J. Mech. Des. 2011, 133, 085001. [Google Scholar] [CrossRef]

- Xu, L.X.; Yang, Y.H. Dynamic modelling and contact analysis of a cycloid-pin gear mechanism with a turning arm cylindrical roller bearing. Mech. Mach. Theory 2016, 104, 327–349. [Google Scholar] [CrossRef]

- Dong, H.M.; Wang, D.L.; Ting, K.L. Kinematic effect of the compliant cup in harmonic drives. ASME J. Mech. Des. 2011, 133, 051004. [Google Scholar] [CrossRef]

- Kayabasi, O.; Erzincanli, F. Shape optimization of tooth profile of a flexspline for a harmonic drive by finite element modelling. Mater. Des. 2007, 28, 441–447. [Google Scholar] [CrossRef]

- Li, X.Z.; Song, C.S.; Yang, Y.; Zhu, C.C.; Liao, D.L. Optimal design of wave generator profile for harmonic gear drive using support function. Mech. Mach. Theory 2020, 152, 103941. [Google Scholar] [CrossRef]

- Zhu, C.Z.; Wang, X.J.; Li, Z.L.; Jun, L.; Zheng, J.Q. Research on static and dynamics mechanical characteristics of flexible bearing in harmonic reducer. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420919953. [Google Scholar]

- Pacana, J. The impact of the structural form on the stress distribution in a flexspline of a hermetic harmonic drive. J. Theor. Appl. Mech. 2020, 58, 1049–1060. [Google Scholar] [CrossRef]

- Tjahjowidodo, T.; Al-Bender, F.; Van Brussel, H. Theoretical modelling and experimental identification of nonlinear torsional behaviour in harmonic drives. Mechatronics 2013, 23, 497–504. [Google Scholar] [CrossRef]

- Ma, D.H.; Wu, J.N.; Liu, T.; Yan, S.Z. Deformation analysis of the flexspline of harmonic drive gears considering the driving speed effect using laser sensors. Sci. China. Technol. Sci. 2017, 60, 1175–1187. [Google Scholar] [CrossRef]

- Ma, J.F.; Li, C.; Luo, Y.C.; Cui, L.L. Simulation of meshing characteristics of harmonic reducer and experimental verification. Adv. Mech. Eng. 2018, 10, 1–9. [Google Scholar] [CrossRef]

- Chen, X.X.; Liu, Y.S.; Xing, J.Z.; Lin, S.Z.; Ma, M. A novel method based on mechanical analysis for the stretch of the neutral line of the flexspline cup of a harmonic drive. Mech. Mach. Theory 2014, 76, 1–19. [Google Scholar] [CrossRef]

- Xiong, Y.; Zhu, Y.S.; Yan, K. Load analysis of flexible ball bearing in a harmonic reducer. ASME J. Mech. Des. 2020, 142, 022302. [Google Scholar] [CrossRef]

- Mahanto, B.S.; Sahoo, V.; Maiti, R. Effect of cam insertion on stresses in harmonic drive in industrial robotic joints. Procedia Comput Sci. 2018, 133, 432–439. [Google Scholar] [CrossRef]

- Yague-Spaude, E.; Gonzalez-Perez, I.; Fuentes-Aznar, A. Stress analysis of strain wave gear drives with four different geometries of wave generator. Meccanica 2020, 55, 2285–2304. [Google Scholar] [CrossRef]

- Xu, L.Z.; Liang, Y.L. Output torque for electromagnetic harmonic drive. Adv. Mech. Eng. 2015, 7, 721543. [Google Scholar] [CrossRef]

- Xu, L.Z.; Liang, Y.L. Torque for an electromagnetic harmonic movable tooth drive system. Mech. Mach. Theory 2016, 98, 190–198. [Google Scholar] [CrossRef]

- Zhou, G.C.; Yang, Y.H.; Xie, R.; Tao, S.Y. A design method for a novel movable tooth drive with logarithmic spiral conjugated tooth profiles. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 9527–9542. [Google Scholar] [CrossRef]

| Dimensional Parameter | Value |

|---|---|

| Initial polar radius R (mm) | 65 |

| Pitch circle radius of the wave generator r0 (mm) | 35 |

| Radius of the outer circle of the tooth carrier ru (mm) | 63 |

| Radius of the inner circle of the tooth carrier rl (mm) | 47 |

| Spiral angle β (°) | 30 |

| Width of the tooth b (mm) | 6 |

| Duty Parameters | Case 1 | Case 2 |

|---|---|---|

| Number of wave generator lobe z1 | 1 | 2 |

| Number of the teeth z2 | 24 | 24 |

| Number of ring gear teeth z3 | 25 | 50 |

| Sequence of the teeth in the rise travel | 1st~12th | 1st~6th, 13th~18th |

| Speed ratio I | 24 | |

| Input torque M1 | 20 Nm | |

| Rotation Angle θ2 | 1/6θh | 1/3θh | 1/2θh | 2/3θh | 5/6θh | θh |

|---|---|---|---|---|---|---|

| Analytical model (N) | 278.1 | 283.2 | 288.4 | 293.7 | 299.1 | 304.5 |

| FEM model (N) | 272.2 | 276.8 | 281.1 | 286.0 | 291.2 | 295.9 |

| Relative error | 2.2% | 2.3% | 2.6% | 2.7% | 2.7% | 2.9% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, G.; Yang, Y. Static Modelling and Analysis of a Novel Movable Tooth Drive with Logarithmic Spiral Tooth Profiles. Machines 2022, 10, 837. https://doi.org/10.3390/machines10100837

Zhou G, Yang Y. Static Modelling and Analysis of a Novel Movable Tooth Drive with Logarithmic Spiral Tooth Profiles. Machines. 2022; 10(10):837. https://doi.org/10.3390/machines10100837

Chicago/Turabian StyleZhou, Guocheng, and Yuhu Yang. 2022. "Static Modelling and Analysis of a Novel Movable Tooth Drive with Logarithmic Spiral Tooth Profiles" Machines 10, no. 10: 837. https://doi.org/10.3390/machines10100837

APA StyleZhou, G., & Yang, Y. (2022). Static Modelling and Analysis of a Novel Movable Tooth Drive with Logarithmic Spiral Tooth Profiles. Machines, 10(10), 837. https://doi.org/10.3390/machines10100837