Open-Switch Fault Detection Based on Open-Winding Five-Phase Fault-Tolerant Permanent-Magnet Motor Drives

Abstract

:1. Introduction

2. An Analysis of OW FPFTPM Motor Drives Suffering from the Open-Switch Fault

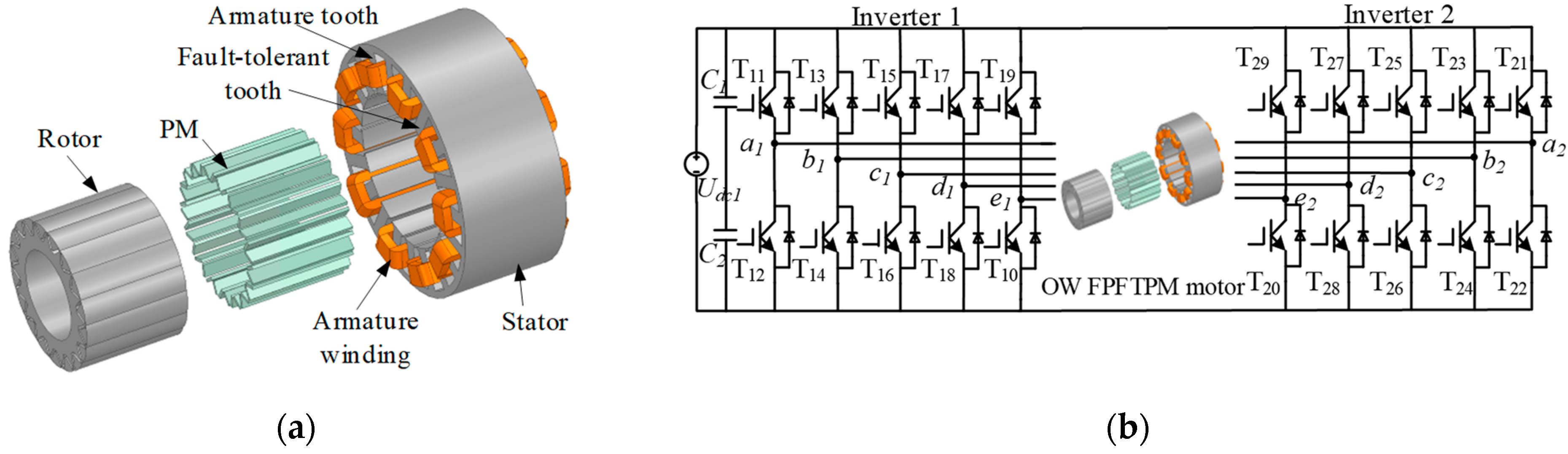

2.1. The Description of OW FPFTPM Motor Drives

2.2. Open-Switch Fault Analysis of OW FPFPTM Motor Drives

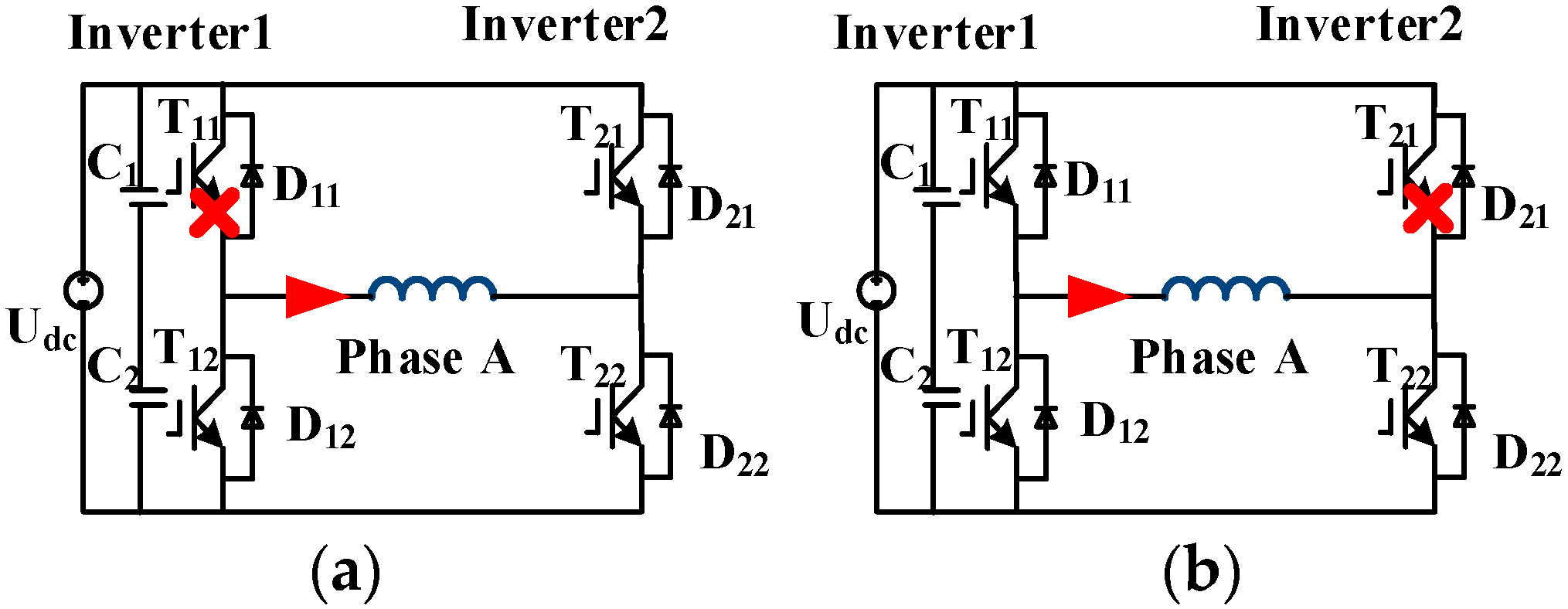

2.2.1. Open-Circuit Fault in the Single Switch

2.2.2. Open-Circuit Faults in Two Switches

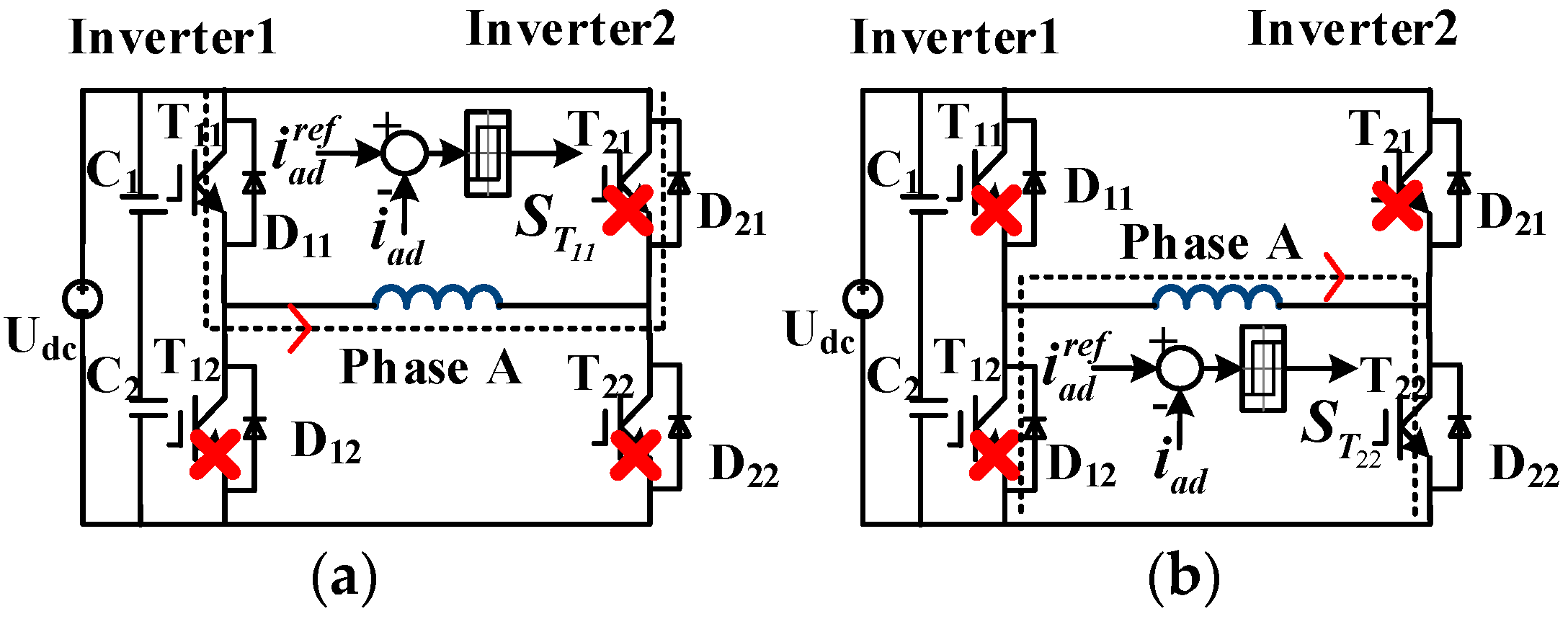

2.2.3. Open-Circuit Faults in Three and Four Switches

3. Detection Method for the Open-Switch Fault

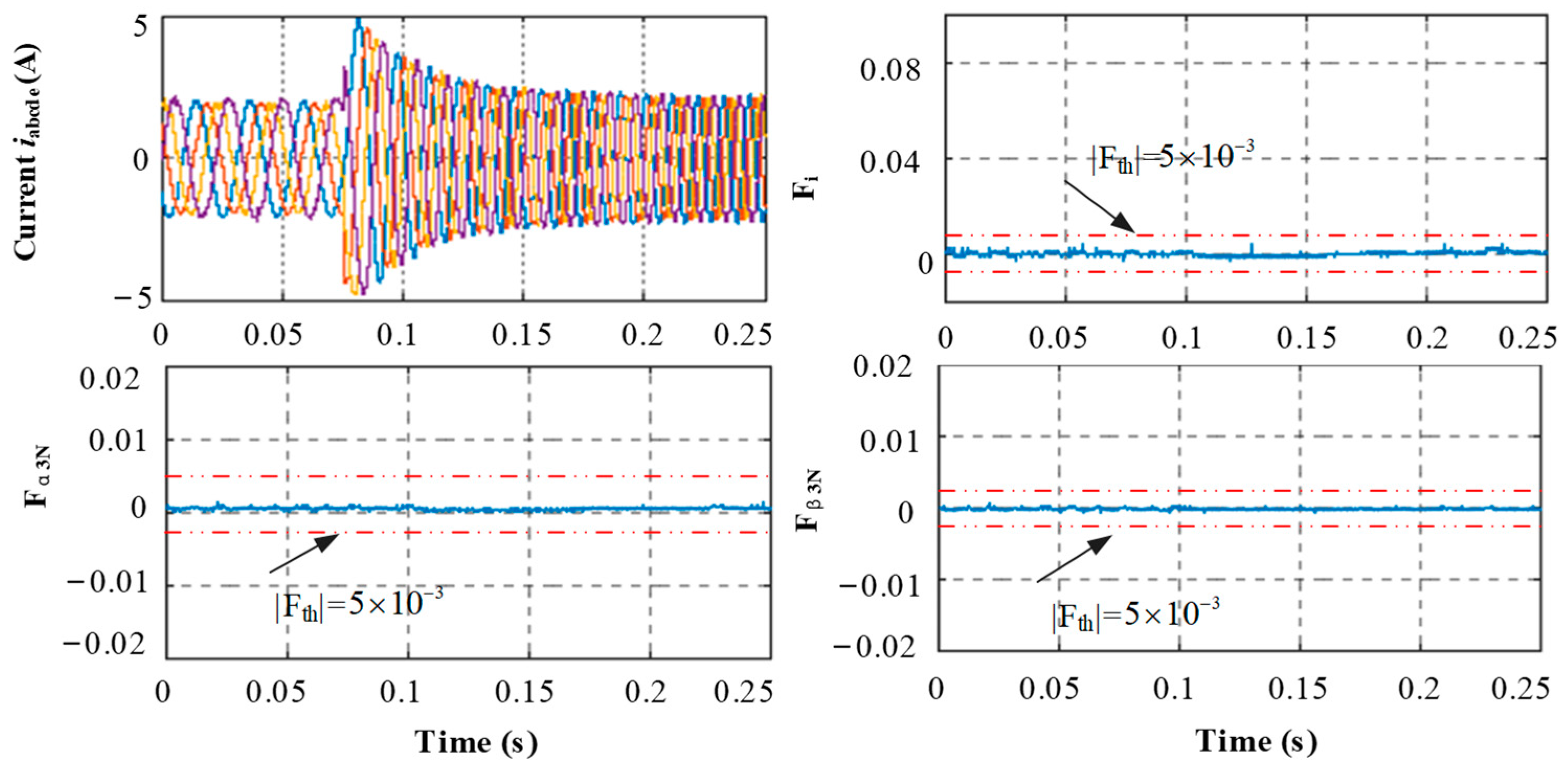

3.1. Determination of the Faulty Phase

3.2. Identification of the Faulty Switch within the H-Bridge Power Cell

4. Experimental Results and Discussion

4.1. Experimental Test Bench

4.2. Results and Discussion

4.3. Key Findings of the Detection Method

- (1)

- The back EMF can be used as the power supply. Combined with the characteristics of the OW structure, the current injection test can be used to identify the open-switch fault;

- (2)

- Compared with the conventional detection method, the proposed method can extract detailed open-switch fault information online within one half-current cycle, including the fault phase, the fault current type, and the fault switch position. Based on the extracted information, the drives can easily realize fault-tolerant control under the open-switch fault;

- (3)

- The detection method uses the residual of the third harmonic current for fault detection, so it is not affected by the variable of motor load. Furthermore, this method does not require additional sensors and additional circuits, thus reducing the detection cost, which is suitable for engineering applications.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Notations

| inref | The reference current |

| inm | The measured feedback current |

| fn | The residual current of each phase |

| fα-β | The residual current in the α-β plane |

| fα3-β3 | The residual current in the α3-β3 plane |

| iαβref | The reference current in the α3-β3 plane |

| iα3β3m | The measured current in the α3-β3 plane |

| i0ref | The reference zero-sequence current |

| i0m | The measured zero-sequence current |

| The amplitude of the reference current in the stationary reference frame | |

| The amplitude of the feedback current in the stationary reference frame | |

| fα3N | The fault feature in α3-axis |

| fβ3N | The fault feature in β3-axis |

| Fi | Magnitude of the fault feature in the α3-β3 plane |

| Hk | The input data |

| yk | The output data |

| Pk | The covariance |

| Kk | The gain coefficient |

| λ | The forgetting factor |

| FPH | The angle of the faulty phase |

| Fα3N | The average value of fα3N |

| Fβ3N | The average value of fβ3N |

| The reference current amplitude of the faulty phase |

References

- Kim, H.; Lee, C. Shape parameters design for improving energy efficiency of IPM traction motor for EV. IEEE Trans. Veh. Technol. 2021, 70, 6662–6673. [Google Scholar] [CrossRef]

- Razi, M.; Murgovski, N.; McKelvey, T.; Wik, T. Design and comparative analyses of optimal feedback controllers for hybrid electric vehicles. IEEE Trans. Veh. Technol. 2021, 70, 2979–2993. [Google Scholar] [CrossRef]

- Jung, S.; Ko, J.J. Study on regenerative energy recovery of electric vehicle through voltage control using switched capacitor. IEEE Trans. Veh. Technol. 2021, 70, 4324–4339. [Google Scholar] [CrossRef]

- Shi, Z.; Sun, X.; Cai, Y.; Yang, Z. Robust design optimization of a five-phase PM hub motor for fault-tolerant operation based on taguchi method. IEEE Trans. Energy Convers. 2020, 35, 2036–2044. [Google Scholar] [CrossRef]

- Lin, H.; Zhao, F.; Kwon, B. Analysis and control of the permanent magnet synchronous motor with auxiliary modular design. IEEE Trans. Magn. 2018, 54, 8208206. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, X.; Gao, J.; Mao, Y. Design and analysis of new five-phase flux-intensifying fault-tolerant interior-permanent-magnet motor for sensorless operation. IEEE Trans. Ind. Electron. 2020, 67, 6055–6065. [Google Scholar] [CrossRef]

- Zhou, H.; Zhou, C.; Tao, W.; Wang, J.; Liu, G. Virtual-stator-flux-based direct torque control of five-phase fault-tolerant permanent-magnet motor with open-circuit fault. IEEE Trans. Power Electron. 2020, 35, 5007–5017. [Google Scholar] [CrossRef]

- Priestley, M.; Fletcher, J.; Tan, C. Space-vector PWM technique for five-phase open-end winding PMSM drive operating in the overmodulation region. IEEE Trans. Ind. Electron. 2018, 65, 6816–6827. [Google Scholar] [CrossRef]

- Belkhode, S.; Jain, S. Optimized switching PWM technique with common-mode current minimization for five-Phase open-end winding induction motor drives. IEEE Trans. Power Electron. 2019, 34, 8971–8980. [Google Scholar] [CrossRef]

- Priestley, M.; Farshadnia, M.; Fletcher, J. FOC transformation for single open-phase faults in the five-phase open-end winding topology. IEEE Trans. Ind. Electron. 2020, 67, 842–851. [Google Scholar] [CrossRef]

- Jlassi, I.; Cardoso, A. A single method for multiple IGBT, current, and speed sensor faults diagnosis in regenerative PMSM drives. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 2583–2599. [Google Scholar] [CrossRef]

- Mazzoletti, M.; Bossio, G.; Angelo, C.; Espinoza-Trejo, D. A model-based strategy for interturn short-circuit fault diagnosis in PMSM. IEEE Trans. Ind. Electron. 2017, 64, 7218–7228. [Google Scholar] [CrossRef]

- Gonz’alez-Prieto, I.; Duran, M.; Rios-Garcia, N.; Barrero, F.; Mart´ın, C. Open-switch fault detection in five-phase induction motor drives using model predictive control. IEEE Trans. Ind. Electron. 2018, 65, 3045–3055. [Google Scholar] [CrossRef]

- Khil, S.; Jlassi, I.; Cardoso, A.; Estima, J.; Mrabet-Bellaaj, N. Diagnosis of open-switch and current sensor faults in PMSM drives through stator current analysis. IEEE Trans. Ind. Appl. 2019, 55, 5925–5937. [Google Scholar] [CrossRef]

- Shi, T.; He, Y.; Wang, T.; Tong, J.; Li, B.; Deng, F. An improved open-switch fault diagnosis technique of a PWM voltage source rectifier based on current distortion. IEEE Trans. Power Electron. 2019, 34, 12212–12225. [Google Scholar] [CrossRef]

- Cheng, Y.; Sun, Y.; Li, X.; Dan, H.; Lin, J.; Su, M. Active common-mode voltage-based open-switch fault diagnosis of inverters in IM-drive systems. IEEE Trans. Ind. Electron. 2021, 68, 103–115. [Google Scholar] [CrossRef]

- Hang, J.; Zhang, J.; Cheng, M.; Ding, S. Detection and discrimination of open-phase fault in permanent magnet synchronous motor drive system. IEEE Trans. Power Electron. 2016, 31, 4697–4709. [Google Scholar] [CrossRef]

- Lamb, J.; Mirafzal, B. Open-circuit IGBT fault detection and location isolation for cascaded multilevel converters. IEEE Trans. Ind. Electron. 2017, 64, 4846–4856. [Google Scholar] [CrossRef]

- Wu, X.; Chen, C.; Chen, T.; Cheng, S.; Mao, Z.; Yu, T.; Li, K. A fast and robust diagnostic method for multiple open-circuit faults of voltage-source inverters through line voltage magnitudes analysis. IEEE Trans. Power Electron. 2020, 35, 5205–5220. [Google Scholar] [CrossRef]

- Shahin, A.; Martin, J.; Pierfederici, S. Zero-sequence current based diagnostic method for open-switch fault detection in parallel inverters system. IEEE Trans. Power Electron. 2019, 34, 3750–3764. [Google Scholar] [CrossRef]

- Guo, H.; Guo, S.; Xu, J.; Tian, X. Power switch open-circuit fault diagnosis of six-phase fault tolerant permanent magnet synchronous motor system under normal and fault-tolerant operation conditions using the average current park’s vector approach. IEEE Trans. Power Electron. 2021, 36, 2641–2660. [Google Scholar] [CrossRef]

- Kong, J.; Wang, K.; Zhang, J.; Zhang, H. Multiple open-switch fault diagnosis for five-phase permanent magnet machine utilizing currents in stationary reference frame. IEEE Trans. Energy Convers. 2021, 36, 314–324. [Google Scholar] [CrossRef]

- Salehifar, M.; Arashloo, R.; Equilaz, J.; Sala, V.; Romeral, L. Fault detection and fault tolerant operation of a five phase PM motor drive using adaptive model identification approach. IEEE J. Emerg. Sel. Top. Power Electron 2014, 2, 212–223. [Google Scholar] [CrossRef]

- Trabelsi, M.; Semail, E.; Nguyen, N. Experimental investigation of inverter open-circuit fault diagnosis for biharmonic five-phase permanent magnet drive. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 339–351. [Google Scholar] [CrossRef]

- Trabelsi, M.; Nguyen, N.; Semail, E. Real-time switches fault diagnosis based on typical operating characteristics of five-phase permanent-magnetic synchronous machines. IEEE Trans. Ind. Electron. 2016, 63, 4683–4694. [Google Scholar] [CrossRef]

- Li, Z.; He, Y.; Gao, Y.; Zhang, X.; Wang, B.; Ma, H. A Model-Data-Hybrid-Driven diagnosis method for Open-Switch faults in power converters. IEEE Trans. Power Electron. 2021, 36, 4965–4970. [Google Scholar] [CrossRef]

- Abari, I.; Hamouda, M.; Sleiman, M.; Slama, H.; Kanaan, Y.; AI-Haddad, K. Open-Circuit fault detection and isolation method for Five-Level PUC inverter based on the Wavelet Packet Transform of the radiated magnetic field. IEEE Trans. Instrum. Meas. 2022, 71, 3502611. [Google Scholar] [CrossRef]

- Yan, H.; Xu, Y.; Cai, F.; Zhang, H.; Zhao, W.; Gerada, C. PWM-VSI fault diagnosis for a PMSM drive based on the fuzzy logic approach. IEEE Trans. Power Electron. 2019, 34, 759–768. [Google Scholar] [CrossRef]

| Detection Methods | Fault Feature | Shortfalls |

|---|---|---|

| voltage-based | common-mode voltage zero-sequence voltage collector–emitter voltage | require additional detection circuits, sensors, or observers |

| current-based | fundamental current low-order harmonic current zero-sequence current | vulnerable to load, focus on the star-connected inverter |

| intelligent algorithm | neural network wavelet analysis fuzzy logic | require a large amount of training data, high computational complexity, focus on the star-connected inverter |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Rated-phase voltage | 100 V | d-axis inductance Ld | 13.7 mH |

| Rated current | 4.7 A | q-axis inductance Lq | 15.9 mH |

| Stator resistance | 0.5 Ω | Rated speed | 1500 r/min |

| Pole pair | 9 | DC bus voltage | 250 V |

| Faulty Phase | Fα3N | Fβ3N | Faulty Phase Current Type |

|---|---|---|---|

| Fα3N = 0 | Fβ3N = 0 | Null current | |

| A | Fα3N < 0 | Fβ3N = 0 | Negative half-cycle current |

| Fα3N > 0 | Fβ3N = 0 | Positive half-cycle current | |

| Fα3N=0 | Fβ3N = 0 | Null current | |

| B | Fα3N > 0 | Fβ3N > 0 | Negative half-cycle current |

| Fα3N < 0 | Fβ3N < 0 | Positive half-cycle current | |

| Fα3N = 0 | Fβ3N = 0 | Null current | |

| C | Fα3N < 0 | Fβ3N < 0 | Negative half-cycle current |

| Fα3N > 0 | Fβ3N > 0 | Positive half-cycle current | |

| Fα3N = 0 | Fβ3N = 0 | Null current | |

| D | Fα3N < 0 | Fβ3N > 0 | Negative half-cycle current |

| Fα3N > 0 | Fβ3N < 0 | Positive half-cycle current | |

| Fα3N = 0 | Fβ3N = 0 | Null current | |

| E | Fα3N < 0 | Fβ3N > 0 | Negative half-cycle current |

| Fα3N > 0 | Fβ3N < 0 | Positive half-cycle current |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, R.; Yu, S.; Li, S. Open-Switch Fault Detection Based on Open-Winding Five-Phase Fault-Tolerant Permanent-Magnet Motor Drives. Machines 2022, 10, 829. https://doi.org/10.3390/machines10100829

Cui R, Yu S, Li S. Open-Switch Fault Detection Based on Open-Winding Five-Phase Fault-Tolerant Permanent-Magnet Motor Drives. Machines. 2022; 10(10):829. https://doi.org/10.3390/machines10100829

Chicago/Turabian StyleCui, Ronghua, Shangshang Yu, and Shengquan Li. 2022. "Open-Switch Fault Detection Based on Open-Winding Five-Phase Fault-Tolerant Permanent-Magnet Motor Drives" Machines 10, no. 10: 829. https://doi.org/10.3390/machines10100829

APA StyleCui, R., Yu, S., & Li, S. (2022). Open-Switch Fault Detection Based on Open-Winding Five-Phase Fault-Tolerant Permanent-Magnet Motor Drives. Machines, 10(10), 829. https://doi.org/10.3390/machines10100829