1. Introduction

With the continuous development of remote sensing technology for Earth observation, the requirements for lightweight space camera and imaging quality are increasing. As an important part of the space camera optical system, the reflector greatly affects the imaging quality of the space camera. The reflector design indexes considered in the design stage of the reflector are the weight of the reflector, the mirror deformation of the reflector under the influence of gravity, and the stiffness of the reflector.

The weight of the reflector has an impact on the launch cost of the rocket, considering the launch capacity of the rocket. The reflector is affected by its own gravity during the manufacturing and testing process on the ground, and when the reflector is launched into the space operation orbit, the loss of gravity on the reflector will have an impact on the imaging quality. In addition, the reflector is disturbed by the vibration of the external environment during the rocket launch. In order to avoid the resonance phenomenon, the designers need to ensure that the reflector features sufficient stiffness to resist external disturbance. Therefore, it is a very important task to optimize the design of the reflector by fully considering several design criteria of the reflector in the design phase.

Researchers have carried out a significant amount of work on the optimal design of the reflector of space cameras. Topology optimization methods have been widely used in the optimal design of the reflector. Liu et al. completed a topology optimization design for the lightweight primary mirror [

1]. Liu et al. improved the imaging quality and reduced the weight of the primary mirror through topology optimization [

2]. Qu et al. integrate topology optimization and parameter optimization methods for the lightweight design of the reflector [

3]. Shao et al. analyzed the effect of mirror dimension parameters on mirror imaging and completed the lightweight optimization design of the mirror [

4]. Liu et al. used topology optimization and parameter optimization to optimize the mirror surface deformation and weight of the reflection [

5]. Li used topology optimization and integration analysis for the lightweight design and mounting of a 760 mm diameter SiC reflector [

6]. In addition to the above-mentioned topology optimization methods, intelligent algorithms and surrogate models have been applied to the optimal design of mechanical structures in recent years [

7,

8,

9,

10,

11,

12]. Kihm et al. used genetic algorithm to optimize the dimensional parameters of the mirror [

13]. Wang et al. used the response surface method to optimize the structure of the 2 m space reflector and reduced the mirror deformation error [

14]. Qin et al. developed a surrogate model with high prediction accuracy by fusing particle swarm algorithm, genetic algorithm, and backpropagation neural network for multi-aperture primary mirror [

15]. Wang et al. used the neural network method to establish the optimization objective prediction model of the primary mirror to optimize the mirror deformation, stiffness, and mass of the primary mirror [

16]. Ye et al. fused the Kriging approximation model and multi-objective genetic algorithm to optimize the mass and mirror accuracy of 2 m aperture SiC primary mirror [

17].

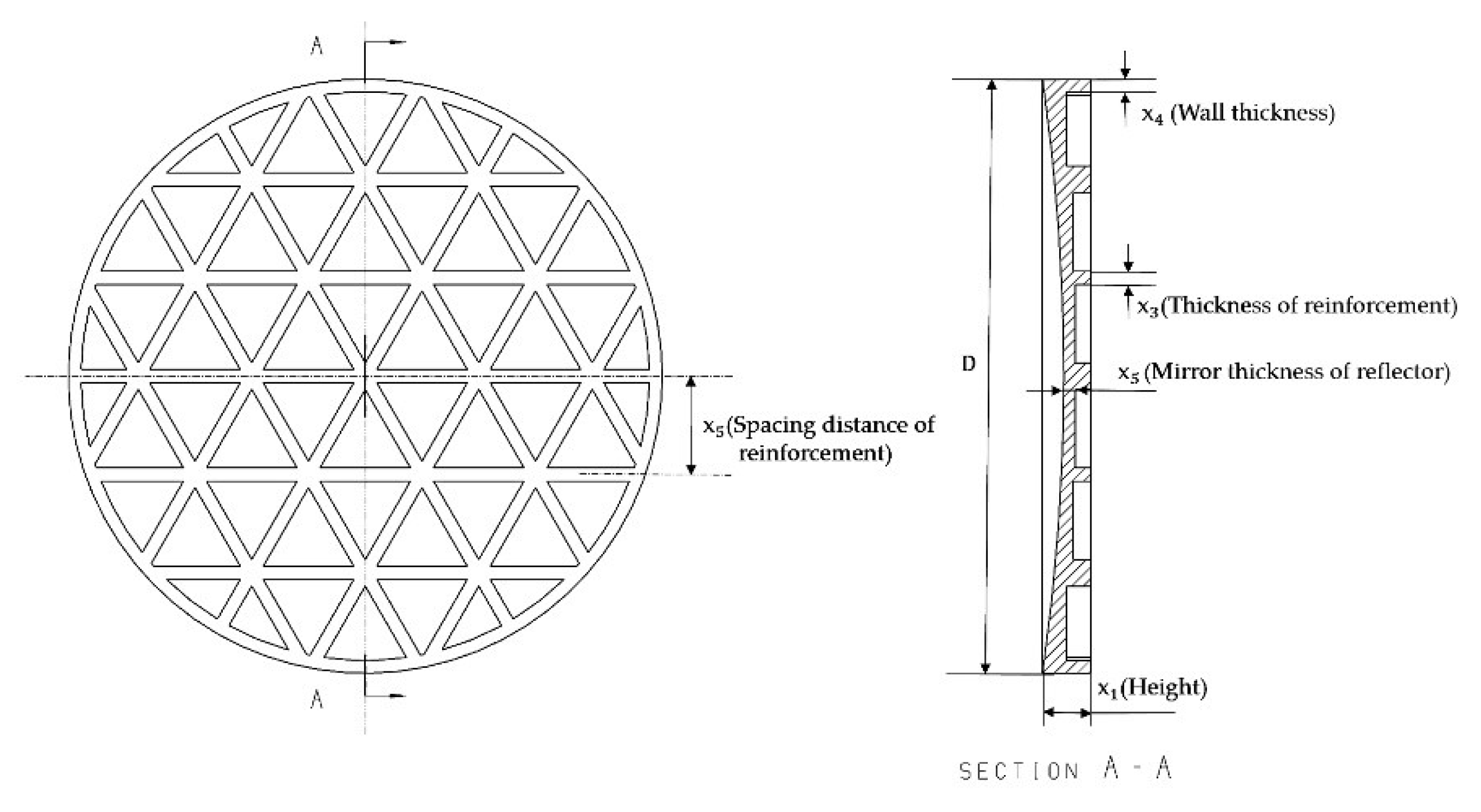

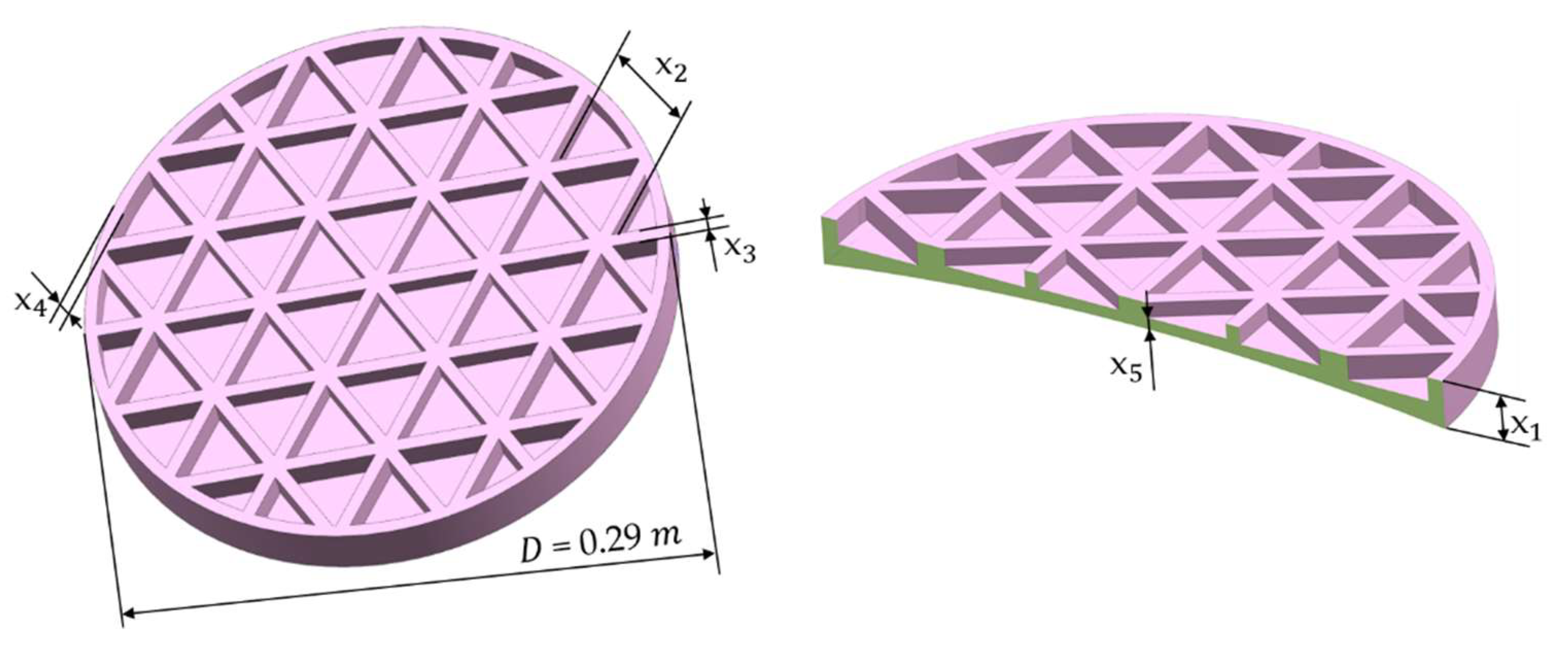

The reflector itself is a complex mechanical structure (as shown in

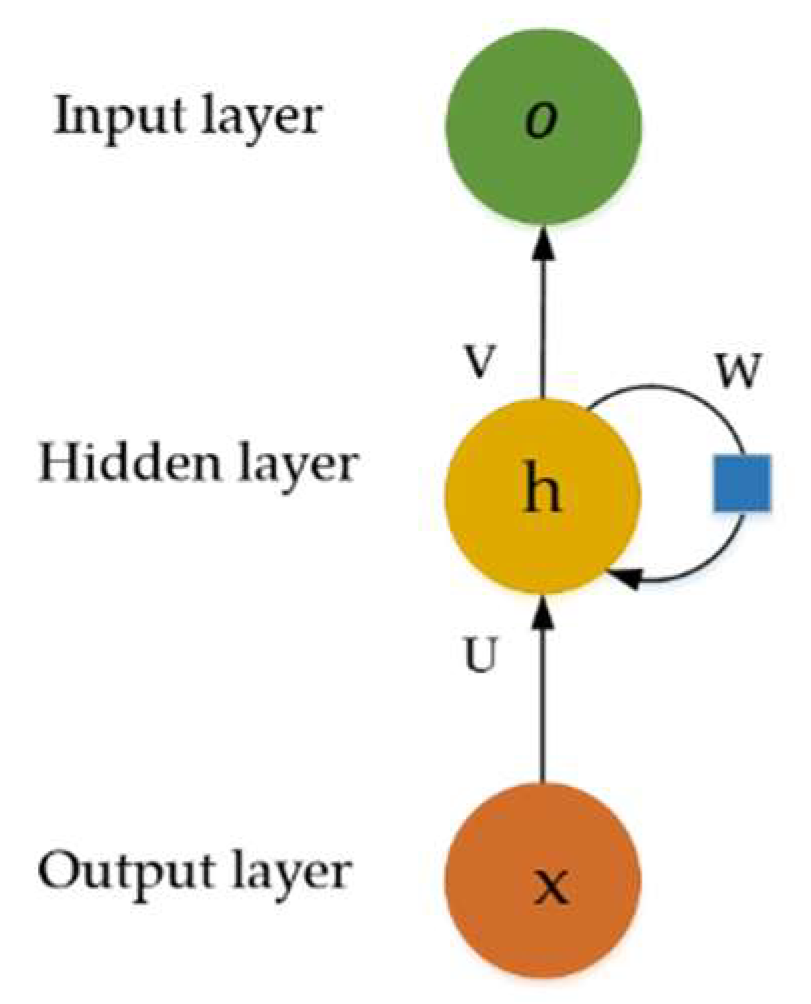

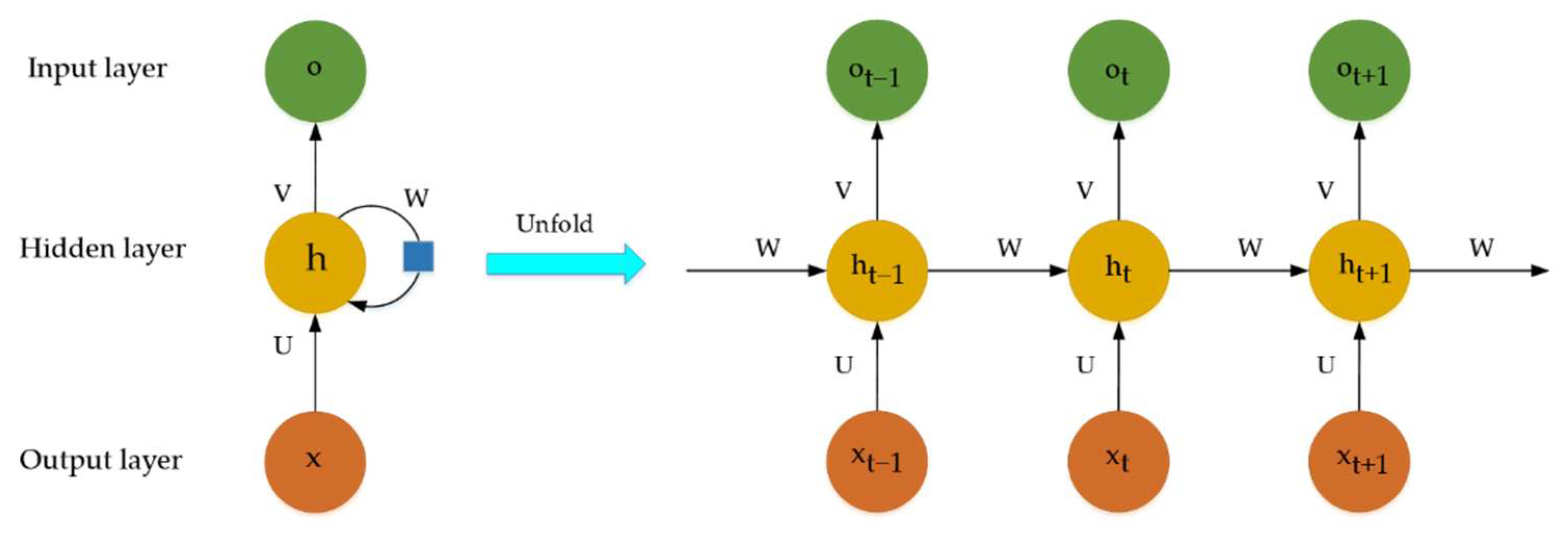

Figure 1), and there are complex nonlinear functional relationships between multiple dimensional parameters of the reflector and multiple optimization objectives. It is necessary to establish a prediction model with high prediction accuracy for the optimization objectives of the reflector to complete the optimal design of the reflector. The recurrent neural network (RNN) is suitable for fitting the nonlinear relationship between input and output variables. To improve the generalization ability of the recurrent neural network, the Bayesian regularization algorithm can optimize the weights of the recurrent neural network, which improves the generalization ability of the recurrent neural network [

18,

19,

20,

21]. In order to solve the multi-objective optimization problem, Srinivas and Deb proposed the non-dominated sorting genetic algorithm (NSGA) in 1995 [

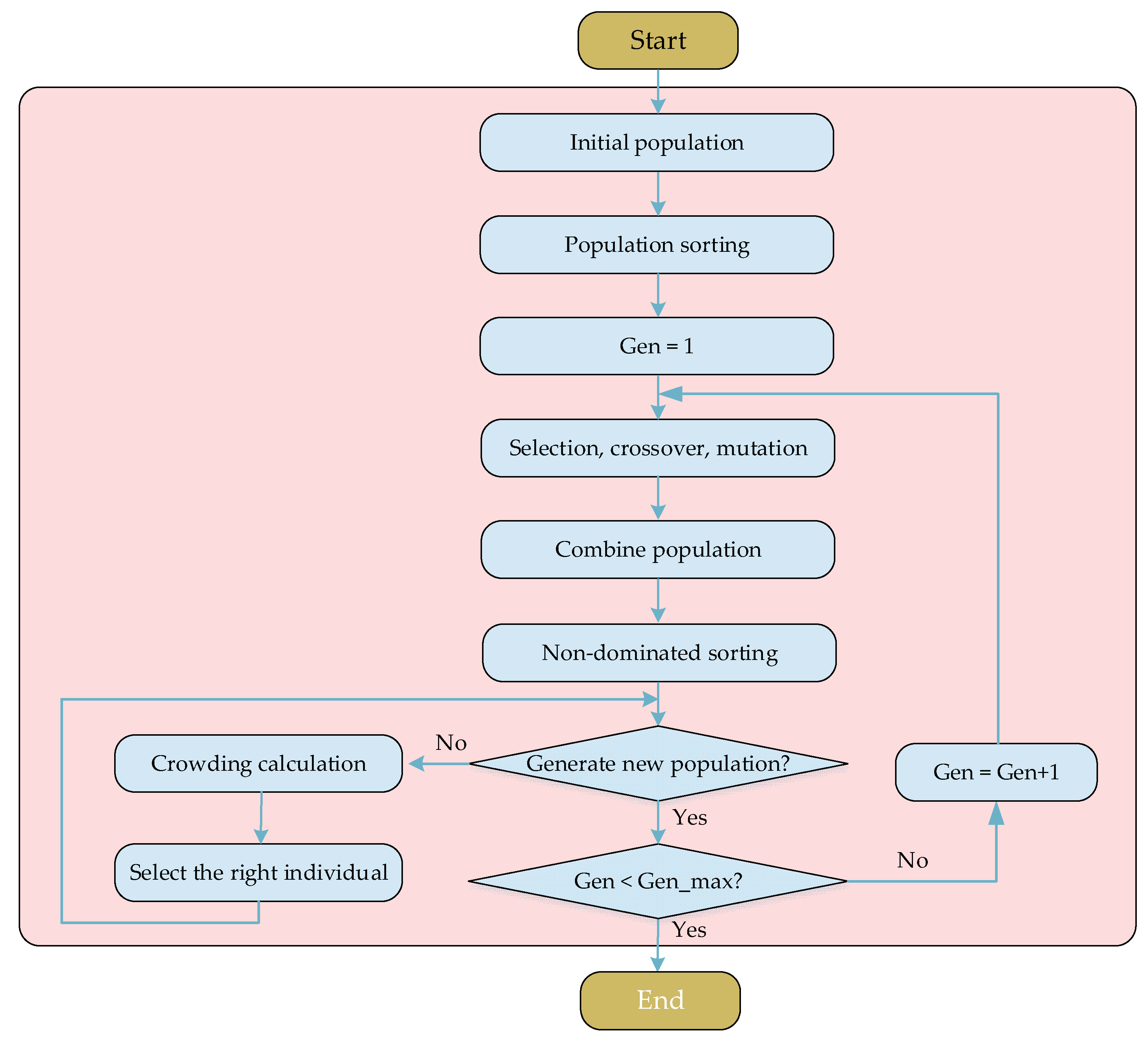

22]. Deb et al. proposed the non-dominated sorting genetic algorithm-II (NSGA-II) in 2000, which improved on the shortcomings of NSGA by adopting the fast non-dominated sorting approach, elitist approach, and parameter-less sharing approach [

23]. The NSGA-II method offers advantages of high efficiency and accuracy in solving multi-objective optimization problems [

23,

24,

25]. In this paper, we propose a recurrent neural network based on the Bayesian regularization algorithm and NSGA-II algorithm (BR-RNN-NSGA-II) to complete the optimal design of the reflector. The rest of the paper is organized as follows.

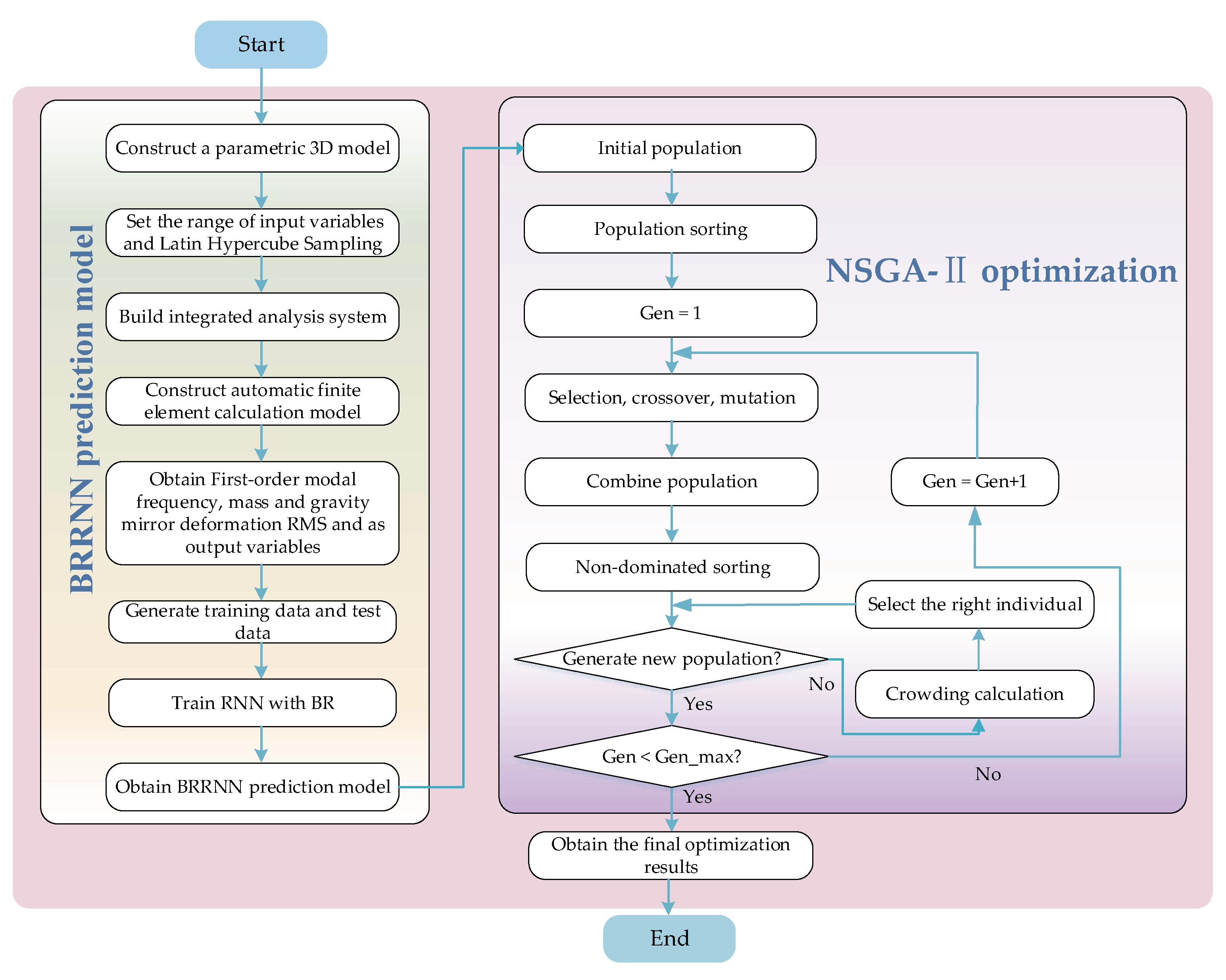

Section 2 discusses the theory of the recurrent neural network based on the Bayesian regularization algorithm and the theory of the NSGA-II method.

Section 3 builds the prediction model of the optimization objective of the reflector and then completes the multi-objective optimization design using the NSGA-II method.

Section 4 takes the reflector of a space camera as an example to complete the optimization design of the reflector and verify the effectiveness of the method proposed in this paper.

Section 5 summarizes the research work of this paper and concludes.

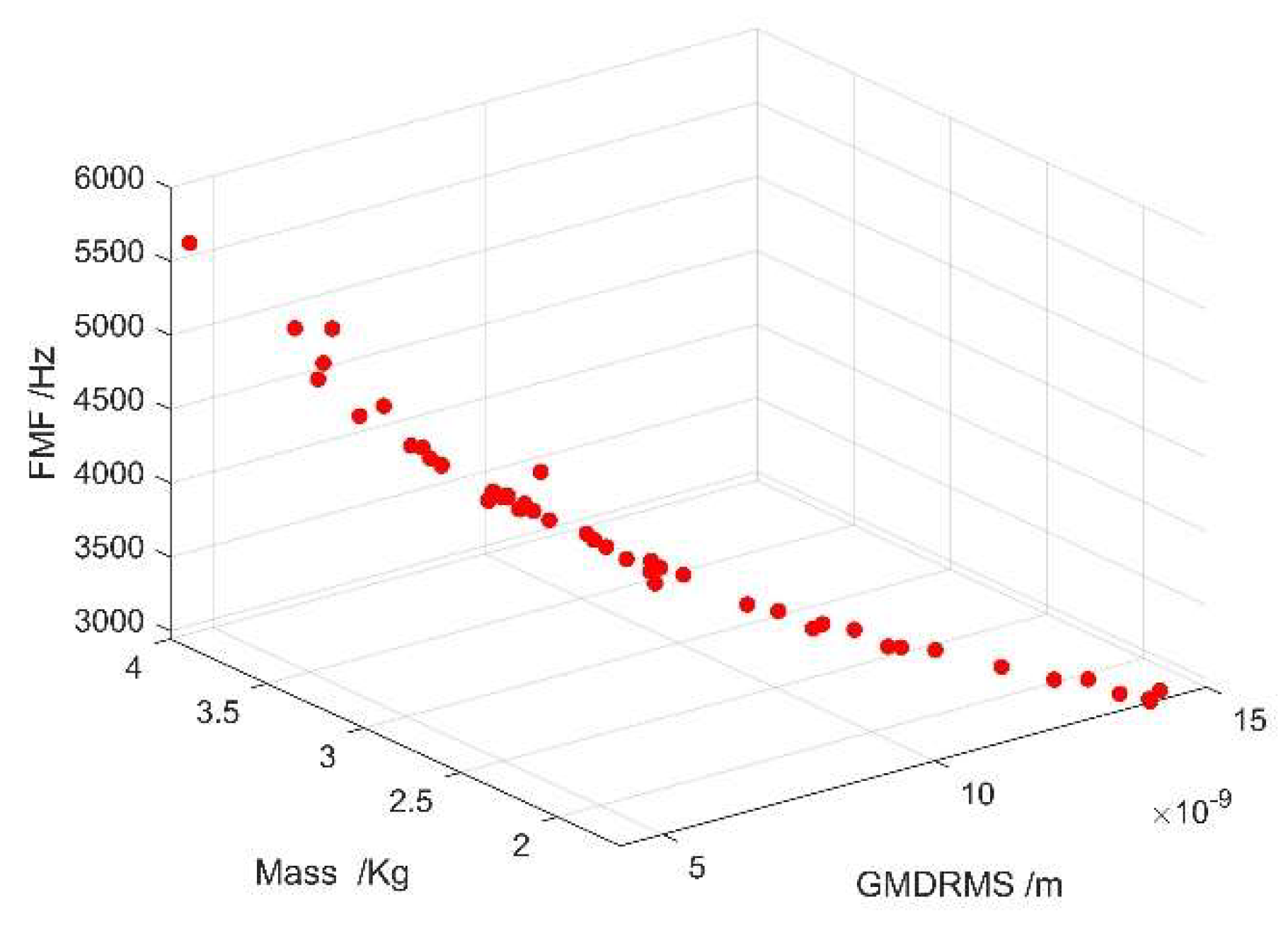

3. Optimal Design Model of Reflector

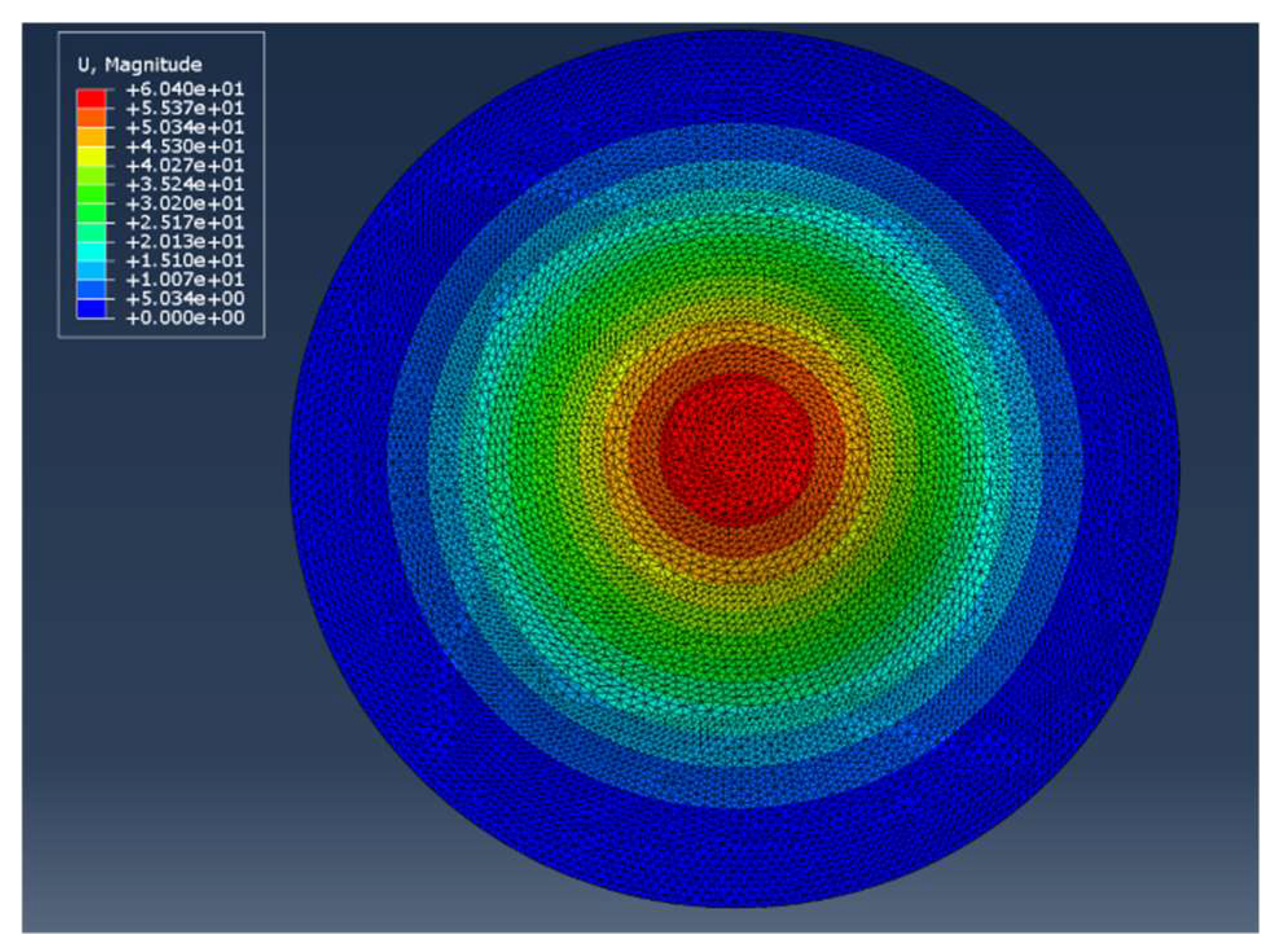

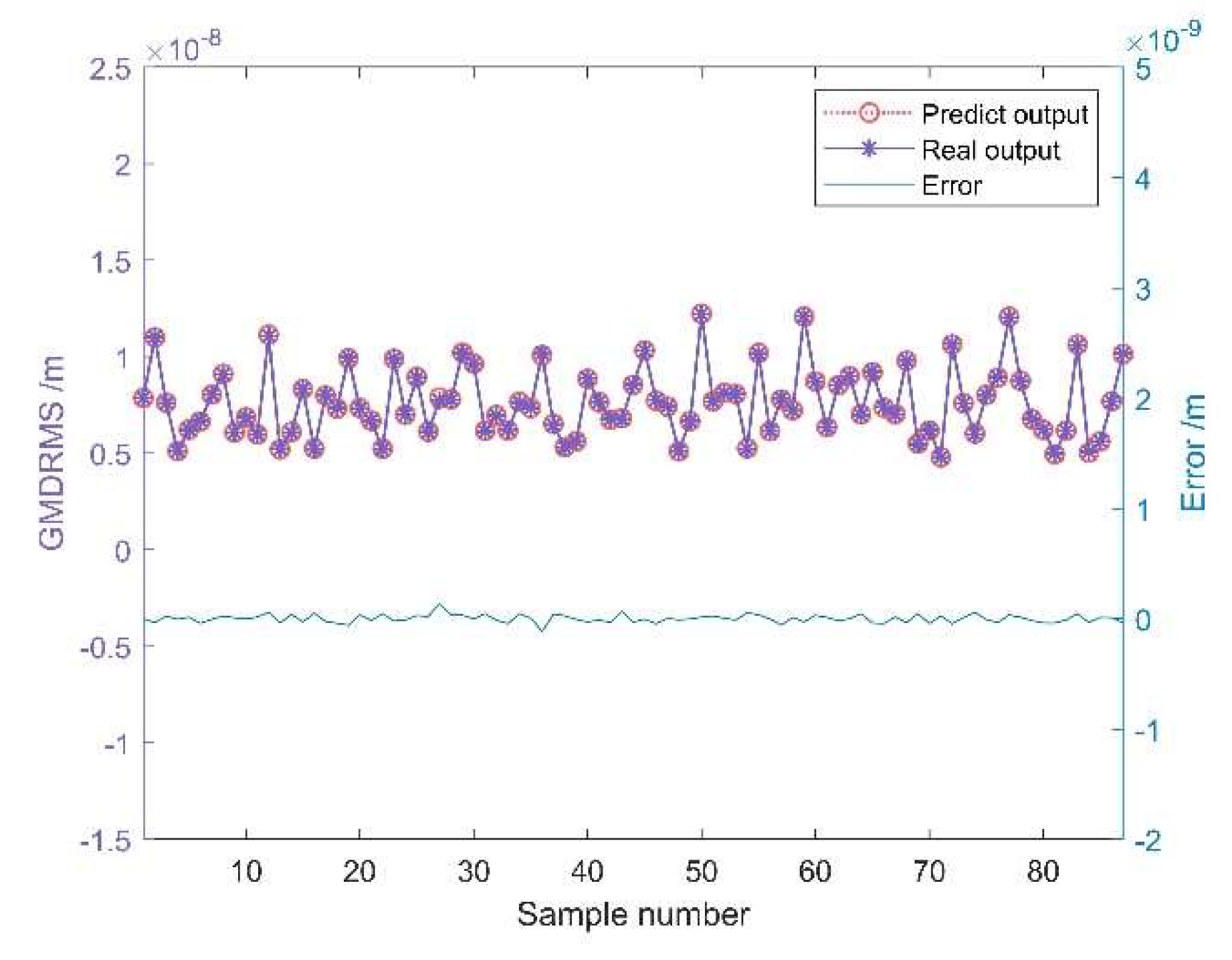

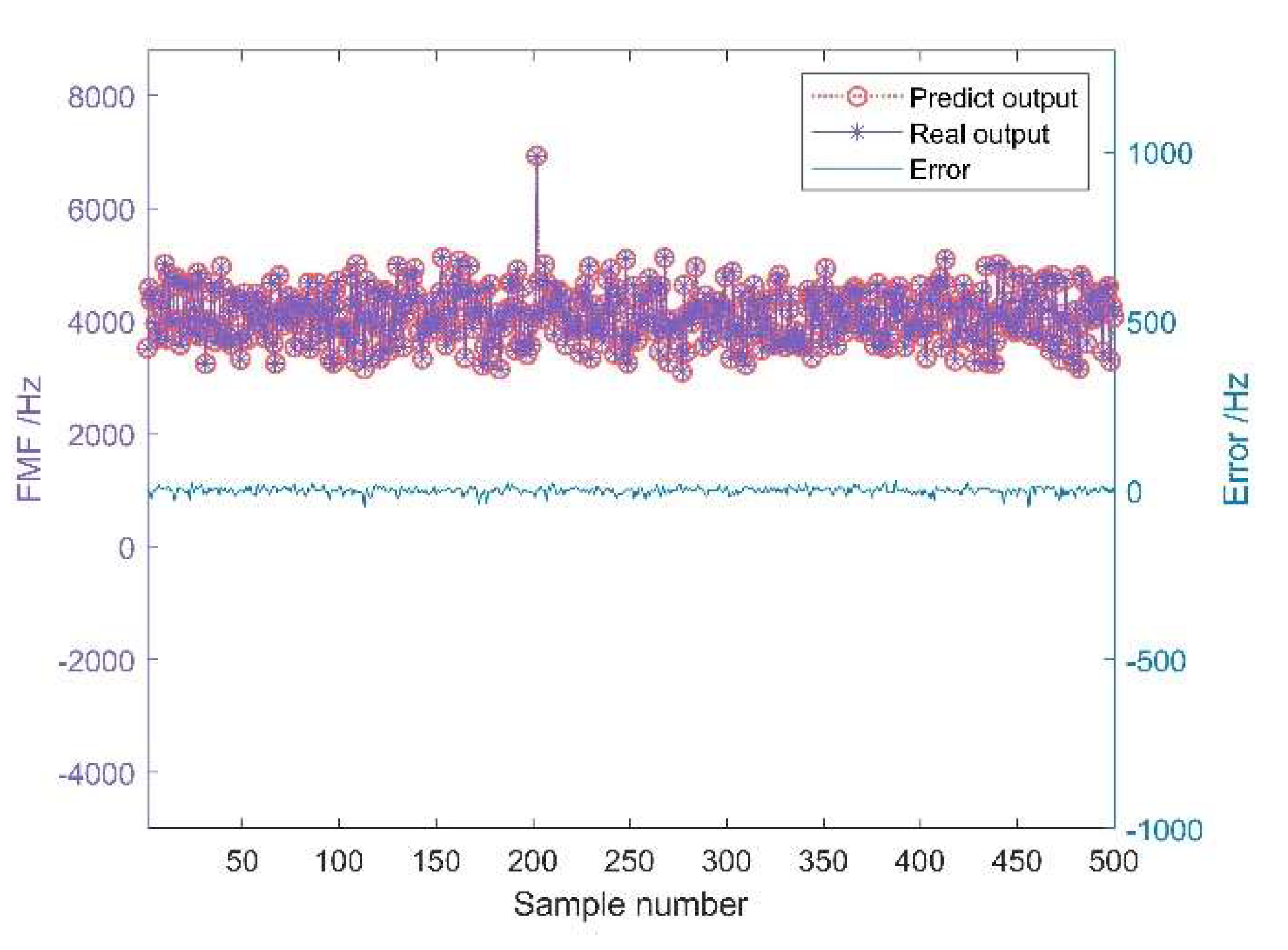

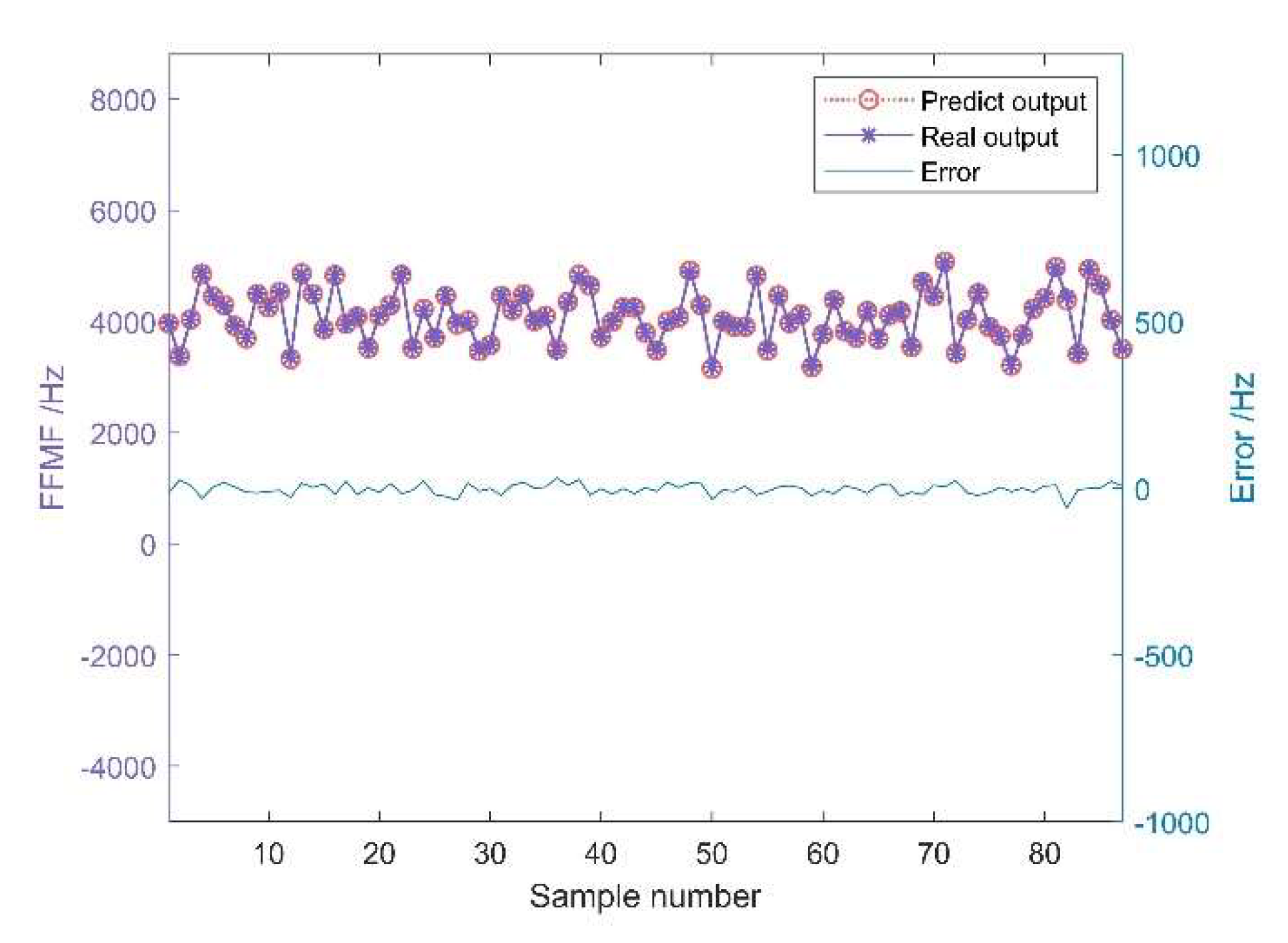

During the ground fabrication and test phase, the reflector image quality is affected by the influence of gravity. In order to avoid resonance of the reflector during the launch, it is necessary to ensure that the reflector features a certain stiffness to resist external interference. In order to reduce the launch cost, the mass of the mirror needs to be reduced as much as possible. In summary, the root mean square value of gravitational mirror deformation root mean square (GMDRMS) is selected to characterize the effect of gravity on the imaging quality of the mirror, the first-order modal frequency (FMF) of the mirror is selected to characterize the stiffness of the mirror, and mass is selected to characterize the mass of the mirror. This paper uses GMDRMS, FMF, and mass as the optimization objectives of the reflector.

3.1. Obtain Sample Data for the Reflector

The shape of the lightweight hole at the back of the reflector are triangular, quadrilateral, hexagonal, circular and scalloped. The triangular hole was chosen for this paper because of its high stability compared to other shaped holes. There are five dimension parameters to be optimized for the reflector, which are the height of the reflector (x

1), the spacing distance of the reinforcement (x

2), the thickness of the reinforcement (x

3), the wall thickness of the outer ring of the reflector (x

4) and the minimum thickness of the mirror surface of the reflector (x

5). The schematic diagram of the reflector structure is shown in

Figure 5.

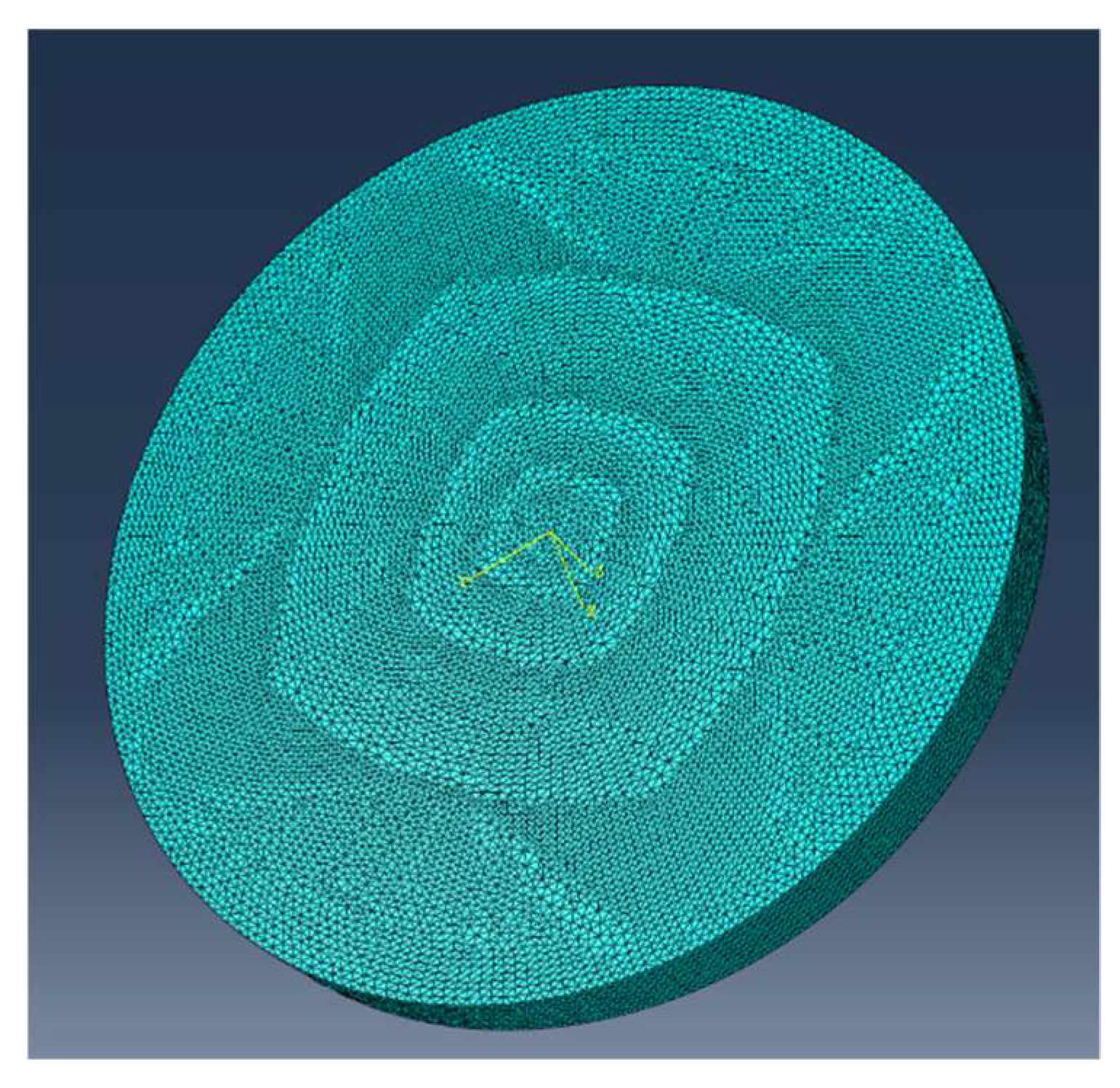

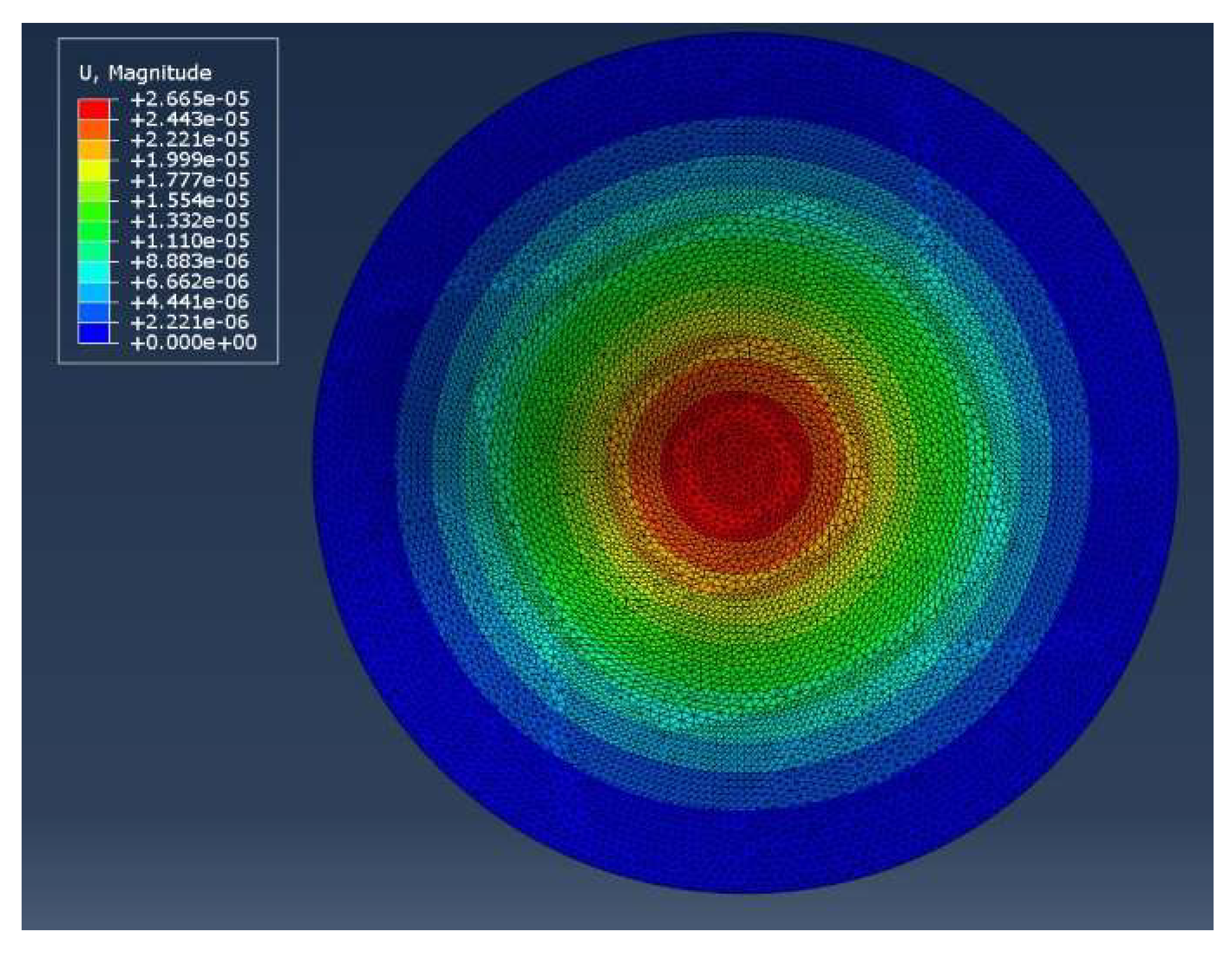

Firstly, five-dimension parameters of the reflector are extracted to build a parametric 3D model. Secondly, the GMDRMS, FMF, and mass of the reflector are calculated by the finite element method. The schematic diagram of the reflector after dividing the grid is shown in

Figure 6. Thirdly, the Latin square sampling is used to sample the dimensional parameters of the reflector to obtain several sets of sample input data. Finally, an integrated analysis platform is built to calculate the output data corresponding to each set of sample data of the reflector separately.

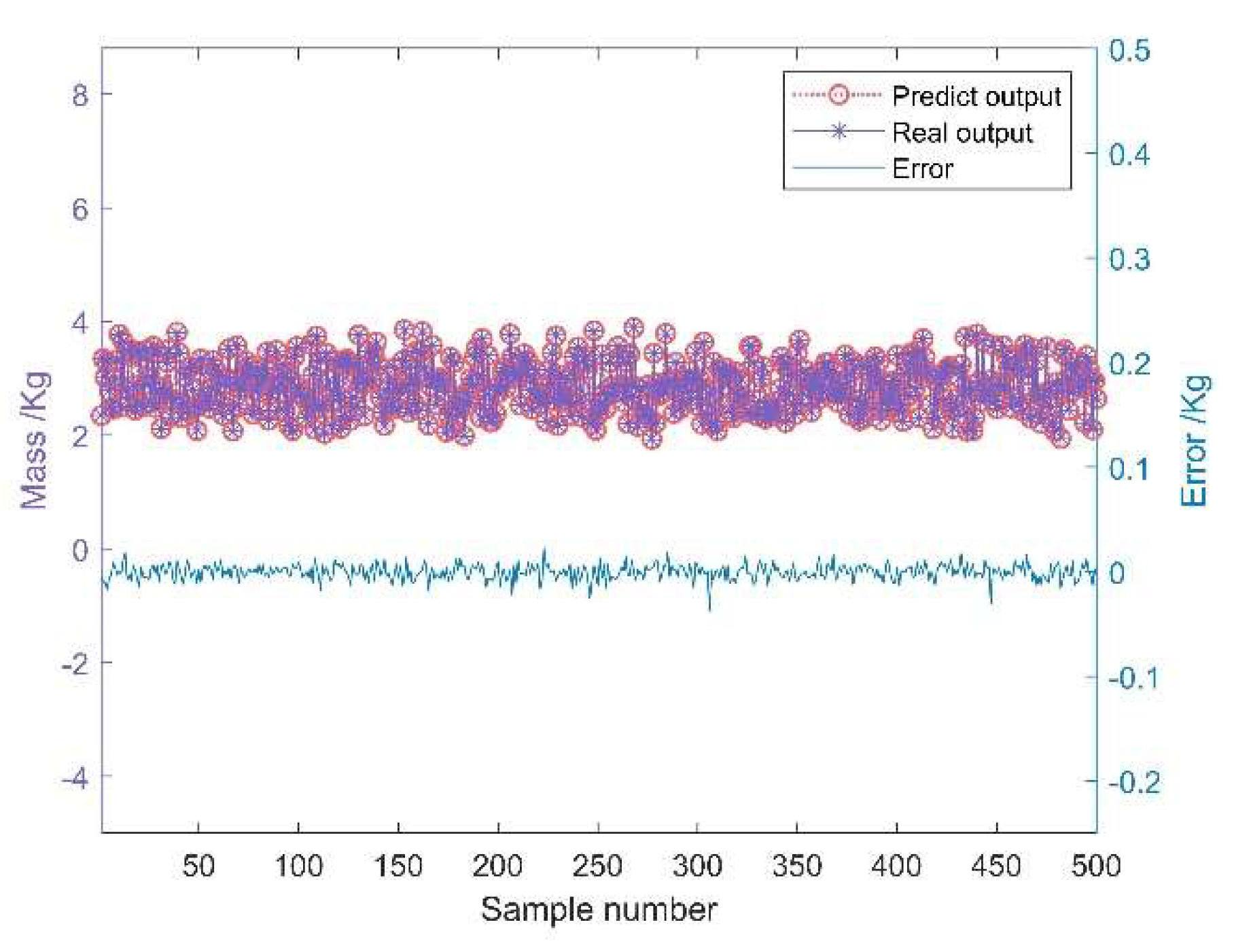

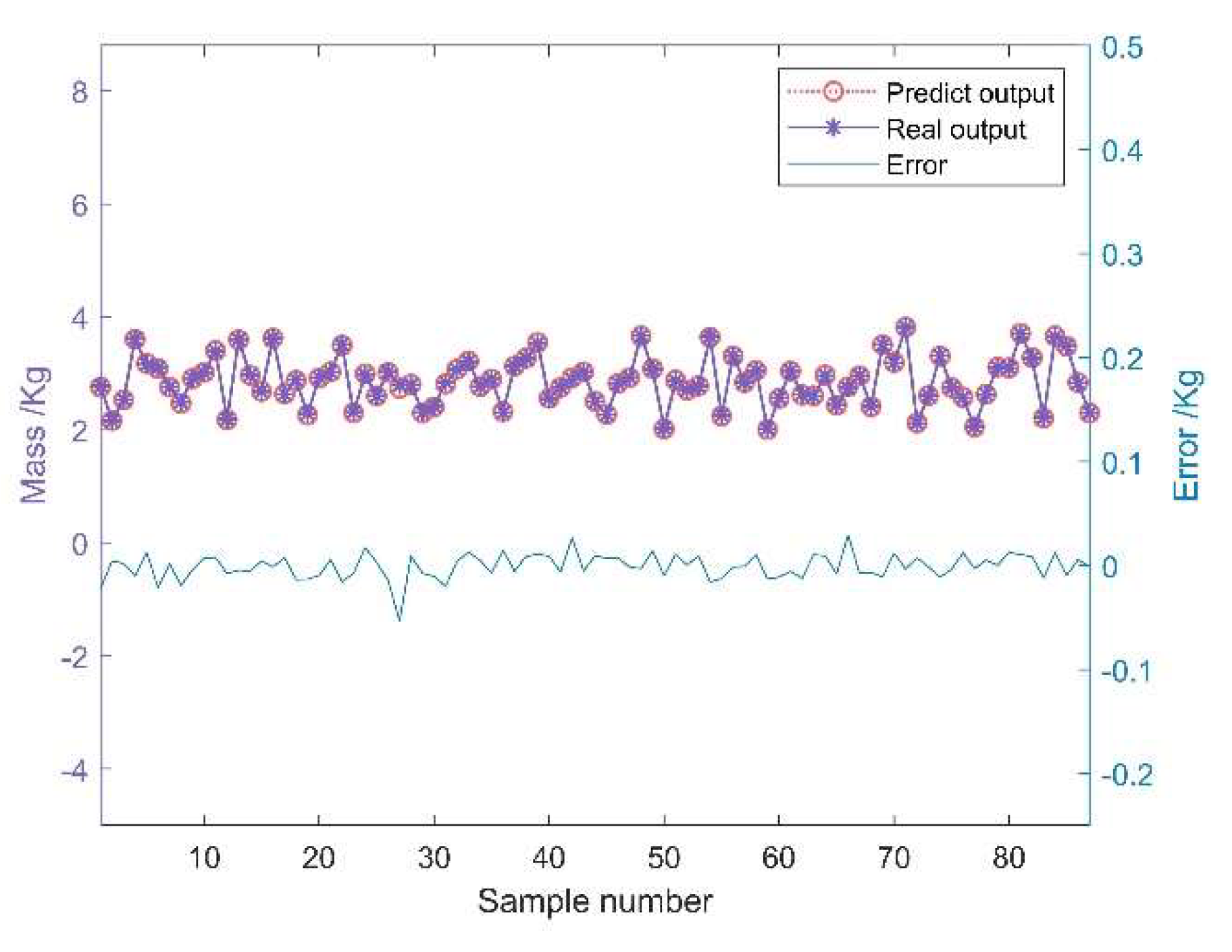

3.2. Develop a Prediction Model for the Reflector Design Indexes

First, the sample data obtained in part 3.1 are randomly divided into training and test sets according to a certain ratio. Next, the training set is trained using the first step in BR-RNN-NSGA-II and validated with the test set to obtain a reflector design indexes prediction model with high prediction accuracy.

3.3. Multi-Objective Optimization of the Reflector

First, the optimization objective of the reflector and the parameters to be optimized are determined. Next, the boundary conditions and other constraints of the parameters to be optimized are set. Finally, the second step of BR-RNN-NSGA-II is used to perform the global optimization of the reflector design indexes and obtain the best optimization results.

3.4. Reflector Optimization Design Flow Chart

The flow chart of the optimized design of the reflector is shown in

Figure 7.