Research and Experimental Analysis of Hydraulic Cylinder Position Control Mechanism Based on Pressure Detection

Abstract

:1. Introduction

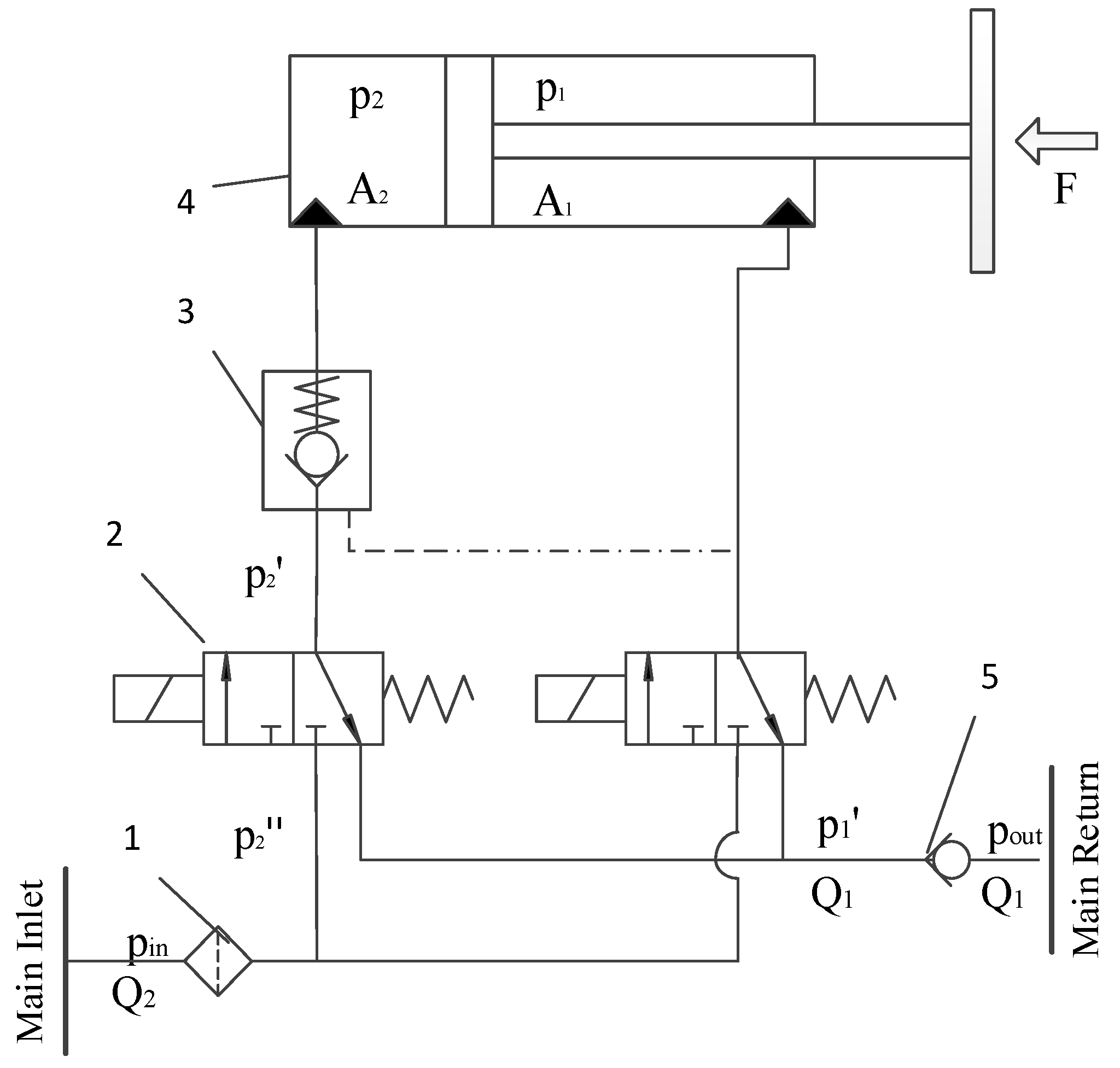

2. Mechanism Analysis of Hydraulic Support System

2.1. Hydraulic Cylinder Extension Model

2.2. Hydraulic Cylinder Retracted Model

3. Simulation and Experiment

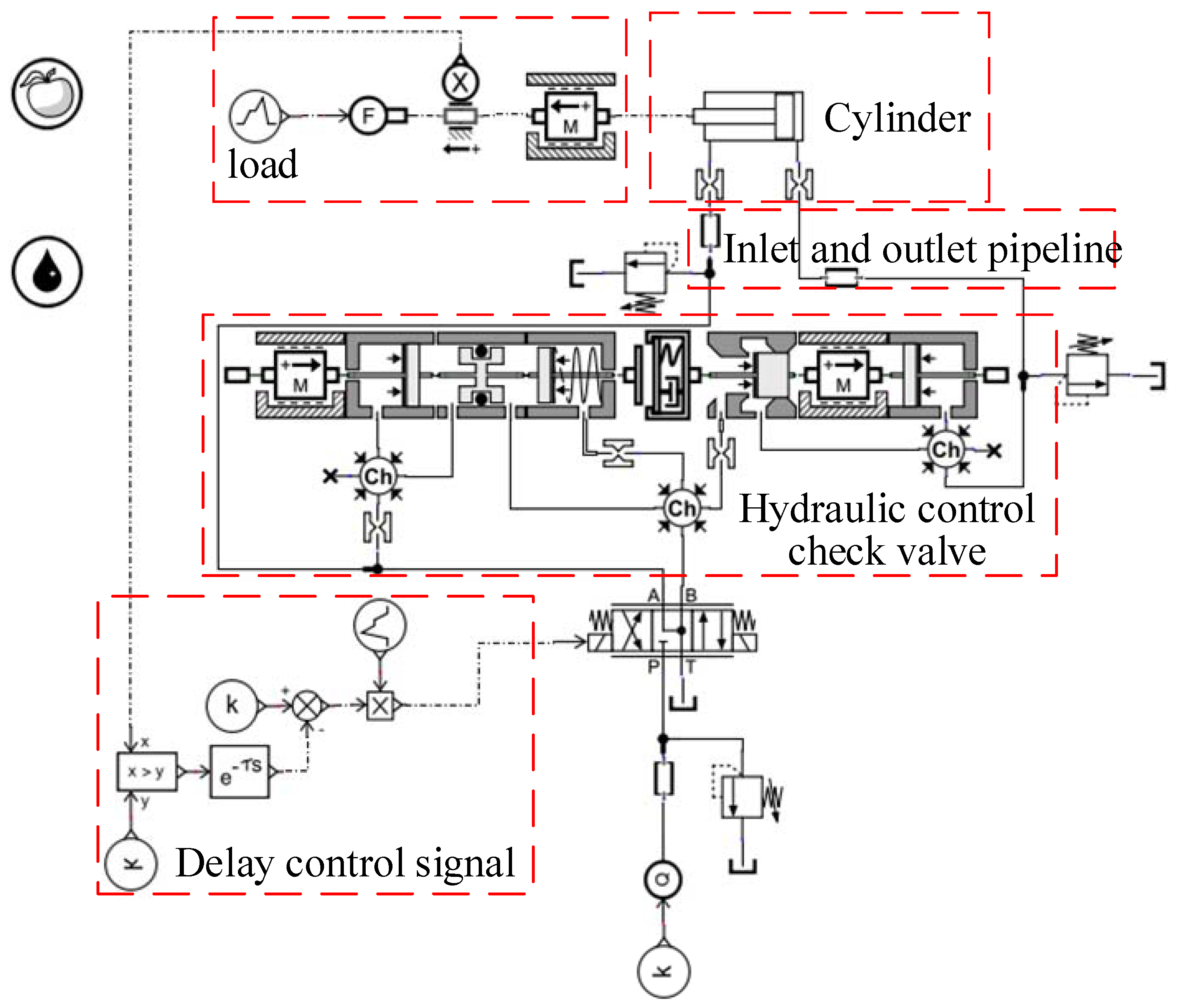

3.1. Valve Control Cylinder Simulation Model

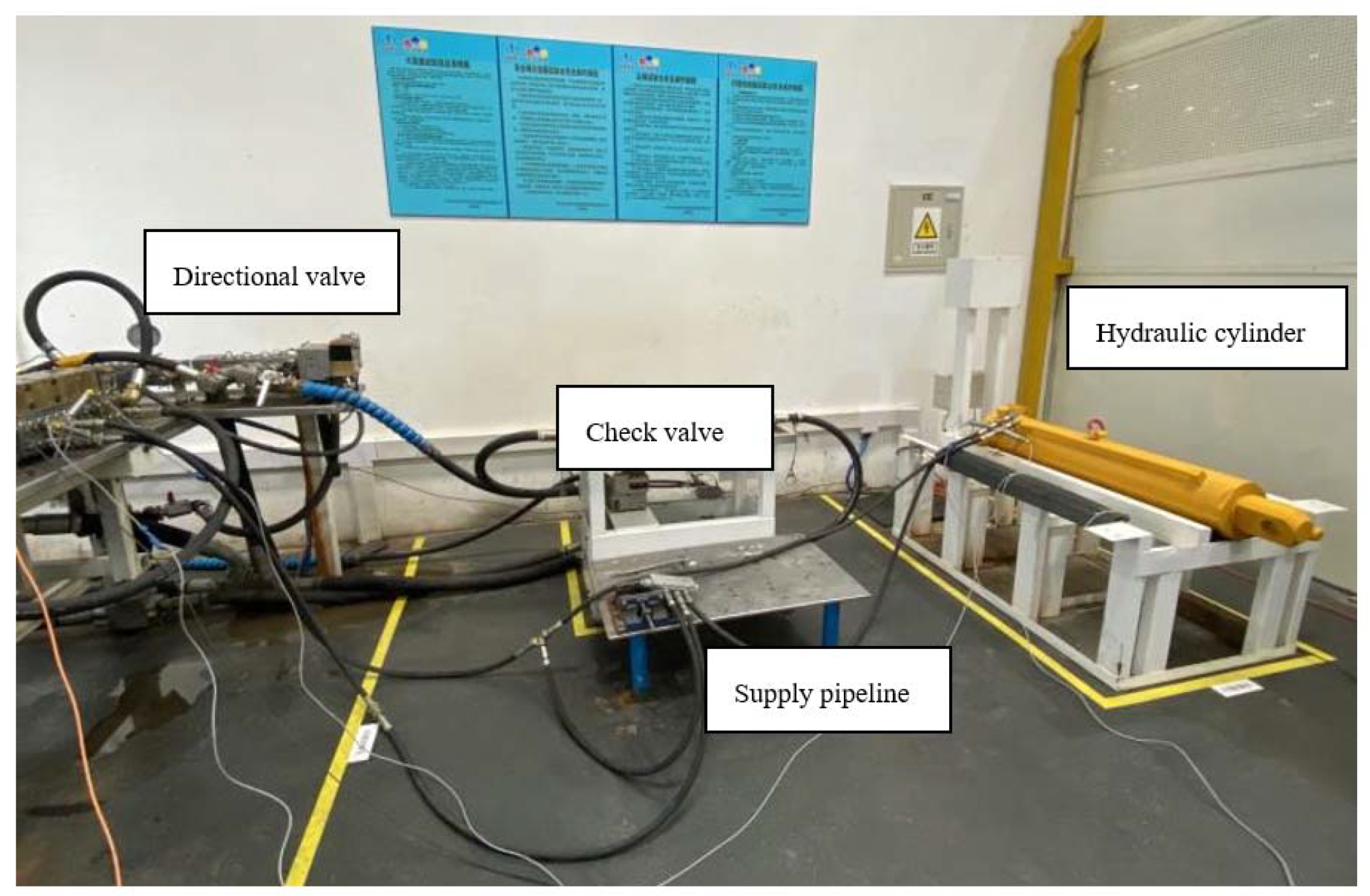

3.2. Valve Control Cylinder Test System

3.3. Experimental Method

4. Result and Discussion

4.1. Simulation Verification

4.2. Simulation Result Analysis

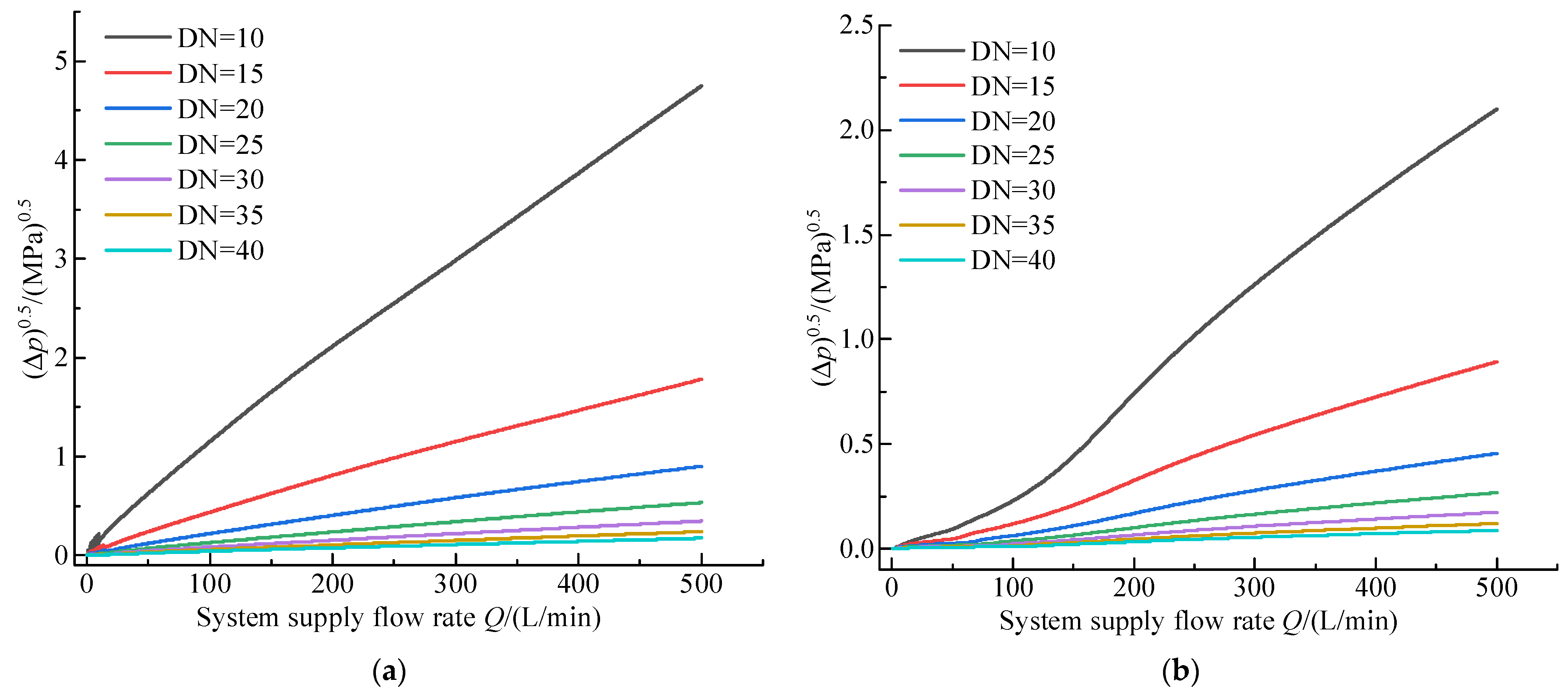

4.2.1. Relationship between Pressure Drop of Different Components and System Flow

4.2.2. Analysis of Pressure Drop Caused by Different Diameter of Liquid Supply Pipeline

4.2.3. Simulation Summary

4.3. Experimental Result Analysis

4.3.1. Relationship between Flow and Pressure Drop of Different Component

4.3.2. Relationship between Flow and Inlet and Outlet Pressure

4.4. Fitting Verification

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feng, H.; Ma, W.; Yin, C.; Cao, D. Trajectory control of electro-hydraulic position servo system using improved PSO-PID controller. Autom. Constr. 2021, 127, 103722. [Google Scholar] [CrossRef]

- Adnan, R.; Rahiman, M.H.F.; Samad, A.M. Model identification and controller design for real-time control of hydraulic cylinder. In Proceedings of the 2010 6th International Colloquium on Signal Processing & Its Applications (CSPA), Malacca, Malaysia, 21–23 May 2010. [Google Scholar]

- Liu, H.; Wang, C.; Guo, X.; Zhao, B.; Huo, P. Active disturbance rejection control method for position servo system based on electro-hydraulic load sensing. J. Beijing Univ. Aeronaut. Astronaut. 2020, 46, 2131–2139. [Google Scholar]

- Shi, L.; Zhu, J.; Tang, F.; Wang, C. Multi-Disciplinary optimization design of axial-flow pump impellers based on the approximation model. Energies 2020, 13, 779. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Li, G.; Wang, R.; Tang, S.; Su, H.; Cao, K. Intelligent fault diagnosis of hydraulic piston pump combining improved lenet-5 and PSO hyperparameter optimization. Appl. Acoust. 2021, 183, 108336. [Google Scholar] [CrossRef]

- Tang, S.; Zhu, Y.; Yuan, S. An improved convolutional neural network with an adaptable learning rate towards multi-signal fault diagnosis of hydraulic piston pump. Adv. Eng. Inform. 2021, 50, 101406. [Google Scholar] [CrossRef]

- Wang, H.; Long, B.; Wang, C.; Han, C.; Li, L. Effects of the impeller blade with a slot structure on the centrifugal pump performance. Energies 2020, 13, 1628. [Google Scholar] [CrossRef]

- Wang, H.; Hu, Q.; Yang, Y.; Wang, C. Performance differences of electrical submersible pump under variable speed schemes. Int. J. Simul. Model. 2021, 20, 76–78. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, G.; Wang, R.; Tang, S.; Su, H.; Cao, K. Intelligent fault diagnosis of hydraulic piston pump based on wavelet analysis and improved AlexNet. Sensors 2021, 21, 549. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Zhao, M.; Wang, C.; Gao, Z. Optimal design of diversion piers of lateral intake pumping station based on orthogonal test. Shock Vib. 2021, 2021, 6616456. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, C.; Zhang, Y.; Xiang, W.; He, Z.; Shi, W. Numerical study of coupled flow in blocking pulsed jet impinging on a rotating wall. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 508. [Google Scholar] [CrossRef]

- Wang, H.; Qian, Z.; Zhang, D.; Wang, T.; Wang, C. Numerical study of the normal impinging water jet at different impinging height, based on Wray-Agarwal turbulence model. Energies 2020, 13, 1744. [Google Scholar] [CrossRef] [Green Version]

- Zhu, P.; Zou, S.; Xie, Y. Simulation research on electro-hydraulic proportional position control system of hydraulic excavator. Mech. Eng. Autom. 2019, 5, 104–106. [Google Scholar]

- Gao, Q.; Zhu, Y.; Luo, Z.; Wang, R.; Song, Y.; Chen, X. Hardware in the Loop Simulation for Position Control Hydraulic Cylinder Using High Speed on/of Valve. Trans. Beijing Inst. Technol. 2019, 39, 1091–1096. [Google Scholar]

- Sun, C.; Wu, L.; Xi, G. Design and Application of Electro-Hydraulic Servo Fuzzy PID Position Control System. Mach. Des. Manuf. 2016, 6, 155–157, 162. [Google Scholar] [CrossRef]

- Li, L.; Lin, Z.; Jiang, Y.; Yu, C.; Yao, J. Valve Deadzone/Backlash Compensation for Lifting Motion Control of Hydraulic Manipulators. Machines 2021, 9, 57. [Google Scholar] [CrossRef]

- Yin, L.; Deng, W.; Yang, X.; Yao, J. Finite-Time Output Feedback Control for Electro-Hydraulic Servo Systems with Parameter Adaptation. Machines 2021, 9, 214. [Google Scholar] [CrossRef]

- Ali, H.H.; Fales, R.C. A review of flow control methods. Int. J. Dyn. Control 2021, 9, 1847–1854. [Google Scholar] [CrossRef]

- Yang, H.; Guo, Y.; Zhang, H.; Wang, X.; Lin, B.; Dang, Y. Development of the hydraulic cylinder position control system based on electromagnetic directional valve. Mach. Des. Manuf. Eng. 2020, 49, 101–104. [Google Scholar]

- Zhou, C.; Wen, G.; Qing, X. Study of electro-hydraulic position control system using solenoid directional valve. Eng. J. Wuhan Univ. 2017, 50, 760–765. [Google Scholar]

- Jin, L. Study on the Precise Position Control of Hydraulic Cylinder Using Solenoid Operated Directional Control Valve. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2019. [Google Scholar]

- Jin, B.; Zhu, S.; Zhang, G.; Lin, J. Study on parallel conference control system. J. Mech. Eng. 2000, 36, 72–75+82. [Google Scholar] [CrossRef]

- Jiang, H. Research of Electro-Hydraulic Postion Control System Based on High Speed On-Of Valve. Master’s Thesis, Northeastern University, Shenyang, China, 2011. [Google Scholar]

- Zhao, R.; Liao, Y.; Lian, Z.; Li, R.; Guo, Y. Research on the performance of a novel electro-hydraulic proportional directional valve with position-feedback groove. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2021, 235, 1930–1944. [Google Scholar] [CrossRef]

- Shi, J.; Quan, L.; Zhang, X.; Xiong, X. Electro-hydraulic velocity and position control based on independent metering valve control in mobile construction equipment. Autom. Constr. 2018, 94, 73–84. [Google Scholar] [CrossRef]

- Saeedzadeh, A.; Rezaei, S.M.; Zareinejad, M. Energy-efficient position control of an actuator in a digital hydraulic system using on/off valve. In Proceedings of the International Conference on Robotics and Mechatronics, Tehran, Iran, 26–28 October 2016. [Google Scholar]

- Zhou, R.; Li, S.; Wei, W.; Zhang, L.; Wang, W. Study on coupling mechanism of pressure and flow in following hydraulic system of mining face. Coal Sci. Technol. 2020, 48, 129–136. [Google Scholar]

- Fu, X.; Wang, R.; Zhao, Y. Investigation of hydraulic system simulation and fluid feeding technology with steady pressure of working face supports. J. China Coal Soc. 2018, 43, 1471–1478. [Google Scholar]

- Li, S. Measurement & control and localisation for fully-mechanized working face alignment based on inertial naviga tion. Coal Sci. Technol. 2019, 47, 169–174. [Google Scholar]

- Song, Z. Application of LASC technology in mine’s automatic mining of fully mechanized mining face. Shenhua Sci. Technol. 2018, 16, 26–29. [Google Scholar]

- Wang, F. Research off precise pushing control scheme for hydraulic support and its application. Ind. Mine Autom. 2017, 43, 6–9. [Google Scholar]

- Li, S.; Li, S.; Zhang, S.; Wang, F. Key technology and application of intelligent perception and intelligent control in fully mechanized mining face. Coal Sci. Technol. 2021, 49, 28–39. [Google Scholar]

- Che, P.; Wu, Y.; Zhao, Y.; Zhao, Y. Pressure Loss Analysis of hydraulic support different feed liquid manner. Hydraul. Pneum. Seals 2013, 33, 69–72. [Google Scholar]

| Symbol | The Parameter Name | Magnitude |

|---|---|---|

| Q | Main System Flow/(L/min) | 400 |

| ρ | The emulsion density/(kg/m3) | 998 |

| E | Bulk modulus of elasticity of emulsion/MPa | 2010 |

| pset | Set pressure of system safety valve/MPa | 31.5 |

| D | Piston diameter of advancing hydraulic cylinder/mm | 180 |

| d | Diameter of piston rod of advancing hydraulic cylinder/mm | 120 |

| L | Stroke of advancing hydraulic cylinder/mm | 900 |

| dr | Inlet diameter of advancing hydraulic cylinder/mm | 11.2 |

| dc | Outlet diameter of advancing hydraulic cylinder/mm | 11.2 |

| m | Load mass/kg | 500 |

| F1 | Coulomb friction of advancing hydraulic cylinder/N | 7000 |

| F2 | Static friction of advancing hydraulic cylinder/N | 10,000 |

| hf | Flow resistance of electro-hydraulic control directional valve/(L min−1/MPa) | 250/5 |

| df | Valve spool diameter of hydraulic control check valve/mm | 33 |

| dspool | Diameter of control piston of hydraulic control check valve/mm | 13 |

| dgan | Ejector rod diameter of hydraulic control check valve/mm | 7 |

| Equipment | Parameter | Model |

|---|---|---|

| Emulsion pump | Nominal flow 400 L/min, nominal pressure 31.5 MPa | BRW400/37.5 |

| Pressure sensor | Measurement range 0–40 MPa, measurement accuracy 0.5% | KYB18G10M1PXCX-II |

| Return circuit breaker | Nominal flow 400 L/min, nominal pressure 16 MPa | FD400/16 |

| Directional valve | Nominal flow 400 L/min, nominal pressure 31.5 MPa | FHS400/31.5 |

| Hydraulic control check valve | Nominal flow 400 L/min, nominal pressure 50 MP a | FDYA400/31.5 |

| Magnetostrictive displacement sensor | Measurement range 900 mm, precision 0.1% | TMDXC(GUC1200/900/L).00 |

| Laser displacement sensor | Measurement 1600 mm, | DAN-10-150 |

| Advancing hydraulic cylinder | Cylinder/rod diameter 180/120 mm, stroke 900 mm | TMQTC(100/70*440)SL |

| Flowmeter | Nominal flow 400 L/min, precision 0.5% | FD-Q 50C |

| (MPa) | (L/min) | |||

|---|---|---|---|---|

(Directional Valve) | (Pipeline) | (Check Valve) | ||

| 6 | 21.57 | 1.71 | 0.14 | 0.61 |

| 10.5 | 41.50 | 1.87 | 0.50 | 2.25 |

| 17 | 64.20 | 0.78 | 1.18 | 5.31 |

| 21.4 | 72.99 | 1.23 | 1.52 | 6.84 |

| 26.8 | 83.81 | 1.35 | 2.01 | 9.00 |

| 31 | 92.48 | 0.63 | 2.50 | 10.93 |

| (MPa) | (L/min) | |||

|---|---|---|---|---|

(Directional Valve) | (Pipeline) | (Check Valve) | ||

| 6 | 20.62 | 1.72 | 0.41 | 1.91 |

| 10.5 | 35.08 | 1.75 | 1.15 | 5.01 |

| 17 | 49.94 | 1.52 | 2.29 | 9.75 |

| 21.4 | 56.65 | 1.97 | 2.94 | 12.40 |

| 26.8 | 64.84 | 2.60 | 3.83 | 16.07 |

| 31 | 70.23 | 3.08 | 4.48 | 18.72 |

| (MPa) | (L/min) | |||

|---|---|---|---|---|

(Directional Valve) | (Pipeline) | (Check Valve) | ||

| 5.2 | 71.22 | 1.15 | 0.15 | 0.28 |

| 11.5 | 179.74 | 0.91 | 0.97 | 1.79 |

| 16 | 222.15 | 0.90 | 1.48 | 2.73 |

| 22 | 266.95 | 1.30 | 2.14 | 3.95 |

| 25.8 | 291.09 | 1.51 | 2.54 | 4.67 |

| 30.6 | 316.37 | 1.77 | 3.00 | 5.48 |

| (MPa) | (L/min) | |||

|---|---|---|---|---|

(Directional Valve) | (Pipeline) | (Check Valve) | ||

| 5.2 | 77.61 | 1.08 | 0.18 | 1.26 |

| 11.5 | 134.60 | 3.09 | 0.54 | 3.36 |

| 16 | 159.10 | 4.28 | 0.76 | 4.67 |

| 22 | 187.64 | 5.95 | 1.05 | 6.44 |

| 25.8 | 202.95 | 6.91 | 1.23 | 7.58 |

| 30.6 | 216.28 | 7.83 | 1.40 | 8.60 |

| Hydraulic Cylinder Extends | Hydraulic Cylinder Retracts | |||||||

|---|---|---|---|---|---|---|---|---|

| Flow (L/min) | Inlet Pressure | Return Pressure | (N)0.5 | Flow (L/min) | Inlet Pressure | Return Pressure | (N)0.5 | |

| DN10 pipeline | 20.62 | 6 | 0.62 | 0.121 | 21.57 | 6 | 0.62 | 0.073 |

| 35.08 | 10.5 | 0.74 | 0.162 | 41.5 | 10.5 | 0.53 | 0.103 | |

| 49.94 | 17 | 0.82 | 0.207 | 64.2 | 17 | 0.53 | 0.135 | |

| 56.65 | 21.4 | 0.89 | 0.233 | 72.99 | 21.4 | 0.54 | 0.152 | |

| 64.84 | 26.8 | 0.83 | 0.261 | 83.81 | 26.8 | 0.57 | 0.171 | |

| 70.23 | 31 | 0.91 | 0.281 | 92.48 | 31 | 0.65 | 0.184 | |

| DN20 pipeline | 77.61 | 5.2 | 0.75 | 0.112 | 71.22 | 5.2 | 0.37 | 0.071 |

| 134.60 | 11.5 | 0.65 | 0.170 | 179.74 | 11.5 | 1.18 | 0.101 | |

| 159.10 | 16 | 0.91 | 0.201 | 222.15 | 16 | 1.84 | 0.117 | |

| 187.64 | 22 | 1.22 | 0.235 | 266.95 | 22 | 2.63 | 0.136 | |

| 202.95 | 25.8 | 1.46 | 0.255 | 291.09 | 25.8 | 3.19 | 0.146 | |

| 216.28 | 30.6 | 1.67 | 0.277 | 316.37 | 30.6 | 3.67 | 0.160 | |

| System Pressure (MPa) | 5 | 10 | 15 | 20 | 25 | 30 | |

|---|---|---|---|---|---|---|---|

| Hydraulic cylinder extends under DN10 pipeline | Actual flow (L/min) | 20.62 | 35.08 | 49.94 | 56.65 | 64.84 | 70.23 |

| Fitting flow (L/min) | 23.16 | 39.04 | 49.89 | 56.15 | 62.90 | 67.72 | |

| Relative error (%) | 12.32 | 11.29 | 0.11 | 0.88 | 2.99 | 3.57 | |

| Hydraulic cylinder retracts under DN10 pipeline | Actual flow (L/min) | 21.57 | 41.5 | 64.2 | 72.99 | 83.81 | 92.48 |

| Fitting flow (L/min) | 25.894 | 47.234 | 64.53 | 72.656 | 81.738 | 87.952 | |

| Relative error (%) | 20.05 | 13.82 | 0.51 | 0.46 | 2.47 | 4.90 | |

| Hydraulic cylinder extends under DN20 pipeline | Actual flow (L/min) | 77.61 | 134.60 | 159.10 | 187.64 | 202.95 | 216.28 |

| Fitting flow (L/min) | 88.70 | 134.64 | 159.19 | 186.12 | 201.96 | 219.38 | |

| Relative error (%) | 14.29 | 0.03 | 0.06 | 0.81 | 0.49 | 1.44 | |

| Hydraulic cylinder retracts under DN20 pipeline | Actual flow (L/min) | 71.22 | 179.74 | 222.15 | 266.95 | 291.09 | 316.37 |

| Fitting flow (L/min) | 79.83 | 191.80 | 222.18 | 258.26 | 277.25 | 303.84 | |

| Relative error (%) | 12.09 | 6.71 | 0.01 | 3.25 | 4.75 | 3.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, R.; Meng, L.; Yuan, X.; Qiao, Z. Research and Experimental Analysis of Hydraulic Cylinder Position Control Mechanism Based on Pressure Detection. Machines 2022, 10, 1. https://doi.org/10.3390/machines10010001

Zhou R, Meng L, Yuan X, Qiao Z. Research and Experimental Analysis of Hydraulic Cylinder Position Control Mechanism Based on Pressure Detection. Machines. 2022; 10(1):1. https://doi.org/10.3390/machines10010001

Chicago/Turabian StyleZhou, Rulin, Lingyu Meng, Xiaoming Yuan, and Zishi Qiao. 2022. "Research and Experimental Analysis of Hydraulic Cylinder Position Control Mechanism Based on Pressure Detection" Machines 10, no. 1: 1. https://doi.org/10.3390/machines10010001

APA StyleZhou, R., Meng, L., Yuan, X., & Qiao, Z. (2022). Research and Experimental Analysis of Hydraulic Cylinder Position Control Mechanism Based on Pressure Detection. Machines, 10(1), 1. https://doi.org/10.3390/machines10010001