1. Introduction

In order to remove the materials on the surfaces of mechanical parts made of difficult-to-cut materials, research communities and industry have successfully applied electrical discharge machining (EDM), an advanced machining process. Additionally, EDM is also able to generate complicated geometrical shapes. This operation has shown its advantages compared to those of traditional machining processes such as grinding [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14]. In recent decades, EDM has been widely utilized in the automotive industry, aerospace, mold, and die made of conductive materials irrespective of the physical properties of machined materials. Nevertheless, it is noticed that the machinability of the EDM process is crucially limited by the low removing speed of materials or by the low material removal rate (MRR), bad surface quality, and the quick acceleration of tool wear. To solve the weakness of EDM, powder-mixed electrical discharge machining (PMEDM) has been proposed [

15,

16,

17,

18,

19,

20,

21]. In this context, fine powder is mixed with the dielectric to satisfy the properties of EDM, e.g., high precision, better surface quality, and improving material removal rate.

It has been proven that the added powder has a strong effect on the dielectric fluid increase in the MRR [

1,

6,

22]. W.S. Zhao et al. [

6] conducted the experimental evaluation to test the influences of PMEDM on machining efficiency compared with traditional EDM operation. The surface roughness and machining efficiency resulting from both PMEDM and traditional EDM were measured and compared. It was revealed that the machining efficiency of PMEDM was smaller than that of traditional EDM. Inversely, in terms of the surface roughness, PMEDM exhibited a much smaller value than that generated by traditional EDM. This can be explained by the fact that in the case of PMEDM, the discharge gaps and passage are normally bigger than those of EDM machining, hence pulse discharge energy is much lost in discharge gaps. Moreover, ejecting force of discharge on the melted materials is reduced by extended discharge gaps. Finally, these reasons significantly impact the lower efficiency of PMEDM machining when compared to that of traditional EDM. On the other hand, the similar discharge parameters, and evenly distributed and “large and shadow” shaped etched cavities make better machining quality of PMEDM. With a similar purpose, Jeswani et al. [

1] quantitatively investigated the effectiveness of mixing the powder into the traditional EDM process to increase MRR and reduce EWR. It has been found that adding 4 g of fine graphite powder per little of kerosene causes to augment MRR by 60%. This might be due to the reduction in the breakdown voltage of the kerosene dielectric generated by adding the powder. The advantages of PMEDM compared to traditional EDM machining have also been documented in other studies [

10,

17,

23].

It should be noticed that PMEDM and traditional EDM processes have different machining characteristics, some parameters may be suitable to the former, but unreasonable to the latter. Hence, in order to get the proper set of parameters that can much better improve the advantages of PMEDM, there have been research works dealing with the optimization process [

18,

20,

23,

24,

25]. Kanssal et al. [

21] applied the response surface method to plan and analyze the experiments for optimizing the process parameters such as pulse-on time, duty cycle, peak current, and concentration of the silicon powder. The responses in this study are minimizing surface roughness and maximizing the material removal rate. It shows that peak current factor and concentration are the most influential parameters on MRR and SR. The reliability of the proposed method is confirmed by a small error percentage between predictions and experiments. In another study [

20], the authors have similar conclusions about the most influential factors of the peak current and the concentration of the silicon powder. However, in this study, the responses selected were machining rate (MR), SR, and tool wear rate (TWR). The important impact of powder-mixed concentration was documented in some studies [

5,

17,

23]. Regarding the materials of mixed powder, some kinds have been adopted in the research community such as SiC, silicon carbide, titanium, and aluminum [

17,

20,

23,

25]. When comparing the effectiveness of each mixed powder material, Narumiya et al. [

2] reported that under suitably mastered machining conditions, surface quality resulting from aluminum and graphite powders is better than that generated by silicon powder in the dielectric. However, there have been few studies dealing with comparing the capability of each mixed powder material. The Taguchi method, analysis of variance (ANOVA), and response surface method have been widely adopted to optimize the process parameters in PMEDM machining [

17,

20,

21,

24] when single responses are required. However, in several studies, it is reported that the Taguchi method is combined with GRA [

15] to solve the multi-objective responses. Recently, there have been a few studies on PMEDM when processing cylindrically shaped parts [

15,

26,

27]. They have contributed to improving productivity and accuracy when machining tablet-shaped punches (

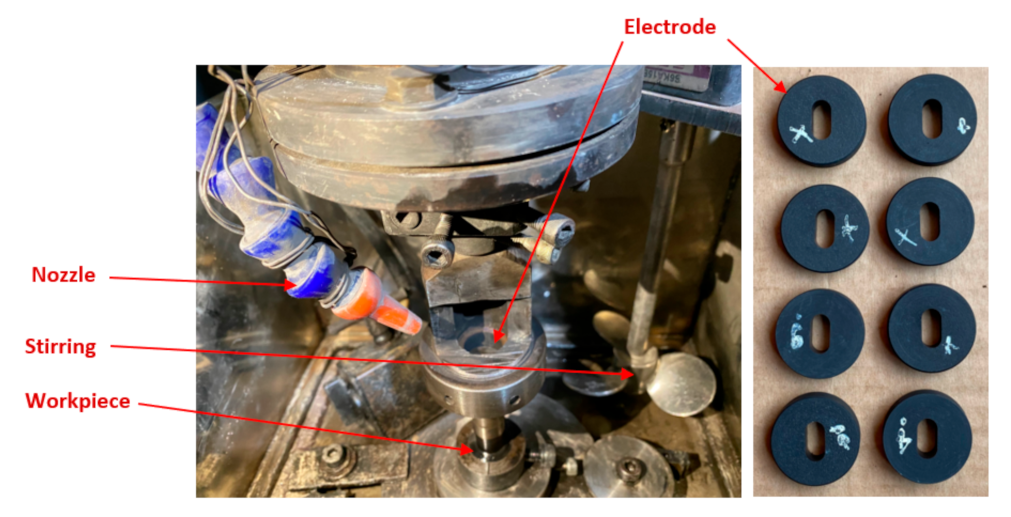

Figure 1).

From the above analysis, it can be seen that there have been many studies on PMEDM so far. However, there has been no research on the optimization of the PMEDM process when machining cylindrically shaped parts with the use of graphite electrodes. Moreover, solving PMEDM with the multi-objective function is a crucial requirement in practice, but there have been few studies dealing with this issue type until now. In this work, an optimization process will be conducted to find the set of optimal main process parameters which can minimize SR and EWR, and maximize MRR. The input parameters are the powder concentration, the pulse-on time, the pulse-off time, the pulse current, and the servo voltage. The PMEDM cylindrical-shaped workpiece and the gray relation analysis (GRA) method combined with the Taguchi method for simultaneously solving multi-objective functions with the support of Minitab R19 software are used to design the experiment and analyze the results. The materials of mixed powder to the dielectric are SiC. The optimal set of main process parameters will be confirmed by experiments.

3. Multi-Objective Optimization

The responses in this study are minimizing SR and EWR, and maximizing MRR. As previously mentioned, with the single utilization of the Taguchi method it is impossible to get the multi-objective optimization with three requirements, hence, the GRA method and Taguchi method will be applied to simultaneously optimize the three above-stated targets. According to this combination, firstly the

S/

N ratio of SR, EWR, and MRR should be determined:

The average values of

S/

N ratios of three responses are exhibited in

Table 3.

In order to analyze gray relation based on the

S/

N ratio, the value of this ratio should be converted into a series compared to unitless quantities. Hence, the data have to be normalized. The determined values of S/N ratios are normalized by using

Zi where 0 ≤

Zi ≤ 1 and:

where

n is the number of experimental runs (

n = 18). The calculated values of normalized

Zi are shown in

Table 4.

The gray relation coefficient

yj(

k) is identified by the following equation:

where

n is the number of tests (

n = 18); k is the number of output responses (

k = 3); Δ

i(k) is the absolute value of reference value determined by: Δ

i(k) = ||Z0(k) – Zi(k)||; it is the absolute value of the difference between

(reference value

Z0(k) = 1) and

) (Z-value of the

experiment of the

target). Δ

min(k) is the minimum value of

i(

k); max(k) is the maximum value of

i(

k); ζ is the discriminant coefficient, determined in the range 0 ≤ ζ ≤ 1, in experimental research ζ = 0.5.

The degree of gray relation can be calculated through the average gray relation value of the output objectives:

where

is the gray relation value of the

output aims in the

experiment. The determined results of gray relation value

and the average gray relation value

of the experiments are shown in

Table 5.

4. Result and Discussions

In order to ensure consistency among the output parameters, the average gray relation values should be higher-the-better. Therefore, the multi-objective function can be considered as a single objective function with the output being the average gray relation values. Taguchi method is applied to estimate the effects of the PMEDM process parameters on the average gray relation values. For that reason, the S/N ratio of

can be calculated by Equations (1) and (2), and this series is analyzed by the ANOVA shown in

Table 6.

There is the fact that the influencing degree of each parameter is represented by its

p-value shown in

Table 6. This means that one parameter has static significance when its

p-value is minor to a confidence level of 0.05. Based on the results presented in

Table 6, it is seen that P-values of IP, T

off, T

on, SV, and C

p are 0.000, 0.012, 0.014, 0.02, and 0.118, respectively. Except for the case of C

p having a

p-value higher than 0.05, the remainder have static significance. The influencing order of process parameters on the average gray relation values

is peak current (IP) of 74.18% (with the strongest influence), pulse-off time (T

off) of 7.88%, pulse-on time (T

on) of 7.59%, servo voltage (SV) of 3.64%, and finally powder concentration (C

P) of 2.78%, which can be considered as non-static significance. This influencing order can be shown in tabular form as in

Table 7.

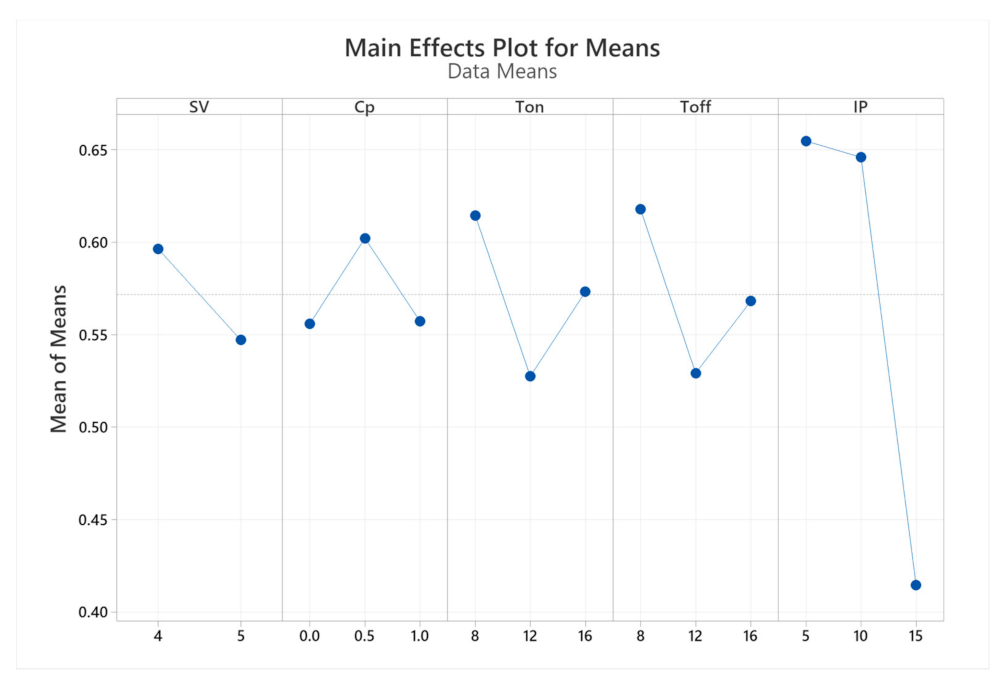

It is realized that from

Table 7 the influence order of input parameters on the average gray relation values are IP, T

off, T

on, SV, and Cp. Moreover, this influence can be graphically described by using the main effects plot for means as exhibited in

Figure 3.

In order to achieve a clearer understanding of the evolution of input parameters and the average gray relation values, the next part discusses the results presented in

Figure 3. It is noticed that when SV is increased from 4 V to 5 V, the values of

are reduced. For the powder concentration parameter, compared to unmixed powder (traditional EDM) the powder concentration of 0.5 g/L leads to an increase in

. Nevertheless,

is reduced when the powder concentration reaches 1 g/L. Regarding the two parameters of T

on and T

off, both have a similar varying tendency, e.g., when they are increased from 8 µs to 12 µs,

lessens. However,

increases when T

on and T

off come to 16 µs. Finally, for Pear current parameter,

slightly decreases when IP is varied from 5 A to 10 A, and

significantly declines when IP reaches 15 A. This is the factor with the strongest impact on

.

It is noted that to determine the optimal set of process parameters, the effects of noise through the values of the S/N ratio should be considered. As the objective function of this study, in order to achieve the largest average gray relation value, the largest S/N value for each input parameter means that at that survey level it is less affected. The influence of the input parameters on the S/N ratio is described in

Table 8.

As in the earlier analysis, the parameters have a statistical significance when their P-values are bigger than the confidence level of 0.05. Similarly, the influence order of parameters is identically observed as those presented in

Table 6 where except for Cp, the others have statistical significance on the response. According to the analysis results in

Table 8, IP parameters also have the greatest influence on the S/N ratio with 81.19%, followed by the influence of the following parameters: T

off (6.39%), T

on (5.34%), SV (2.4%), and C

p (1.66%), respectively. The influence order of the input parameters and the S/N ratio at the survey levels are shown in

Table 9.

Table 9 also shows that the influence order of input parameters is IP, T

off, T

on, SV, and Cp, respectively. At the same time, the S/N ratio of the input parameters through the survey levels is also clearly shown in

Figure 4. From this chart in

Figure 4, it is possible to determine the S/N value of each survey level of the input parameters and determine the maximum S/N value.

As analyzed above, the parameter set with the highest S/N value

for each input parameter is the most reasonable set of parameters. From the chart in

Figure 4, the trend of influence of each input parameter on the S/N value is shown and the multi-objective optimal parameter set is determined, specifically in

Table 10.

4.1. Validating the Optimal Set of Main Process Parameters

In order to confirm the optimal values of input parameters, experiments were conducted. The experimental values of SR, MRS, and EWR are presented in

Table 11. It is observed that the error percents showing variation between predictions and experiments are small. For example, for SR the predicted and experimental values are 2.456 μm and 2.324 μm, respectively. This difference corresponds to the error percent of 5.38. The highest error percent belongs to EWR by 6.62%. For these results, it can be concluded that the suggested model is significantly confirmed and reliable.

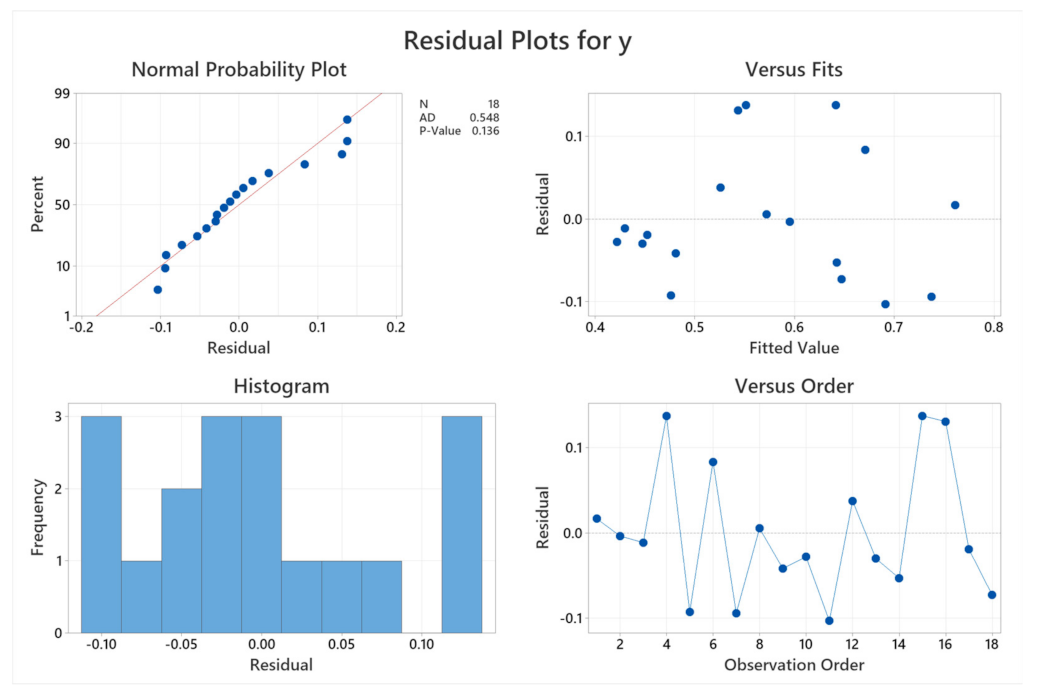

4.2. Evaluating the Reliability of the Proposed Experimental Method

The experimental model is evaluated through error distribution charts as shown in

Figure 5. It can be seen that in the normal distribution error distribution chart, the errors of the experimental points corresponding to the blue points on the distribution chart around the normal distribution line (red solid color line) indicate that the error is small. Histogram reveals the frequency of errors shows that the errors appear in the range −0.1 to 0.1, accounting for a large proportion. The remaining two graphs show the random distribution of experimental errors, which means that the built model is largely influenced by the selected input parameters and is not affected by the order of the experiment.

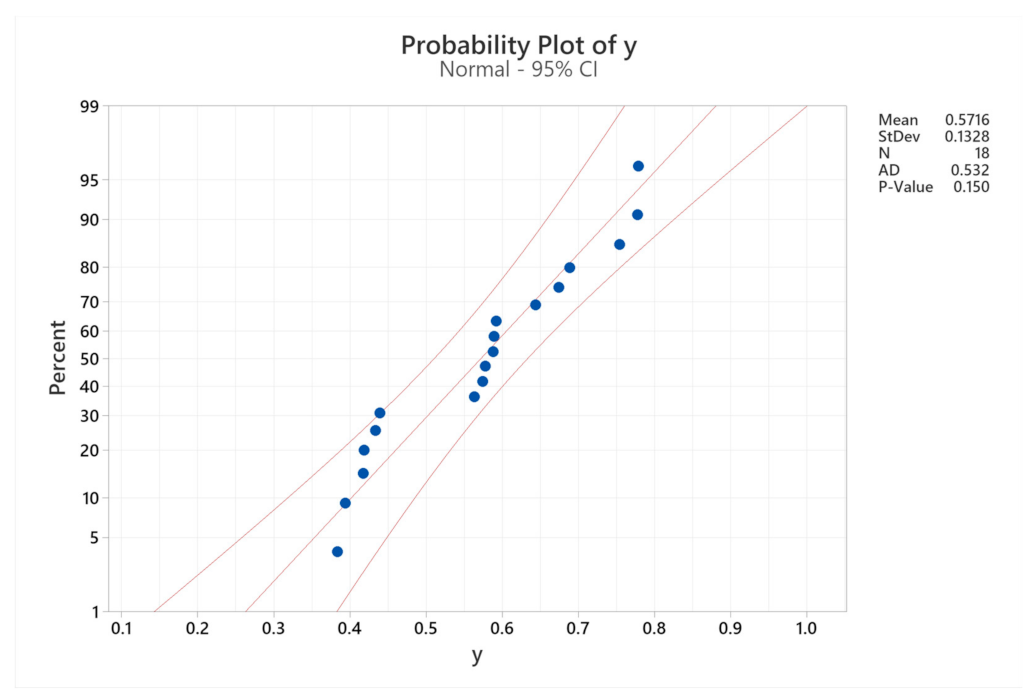

4.3. Evaluation of Mode Fit

The appropriateness of the experimental model verified by the Anderson–Darling method in

Figure 6 shows that the data corresponding to the experimental points (blue dots) are in the region bounded by two upper and lower bounds with the standard deviation of 95%. The P-value of 0.150 is greater than the value of α = 0.05. This indicates that the applied experimental model is suitable.