Identification of the Critical Factors for Global Supply Chain Management under the COVID-19 Outbreak via a Fusion Intelligent Decision Support System

Abstract

1. Introduction

2. Global Supply Chain Management Sustainability Factors

2.1. Productivity and Logistics

2.2. Raw Material Supply

2.3. Global Management Strategy

2.4. Cash Management and Information

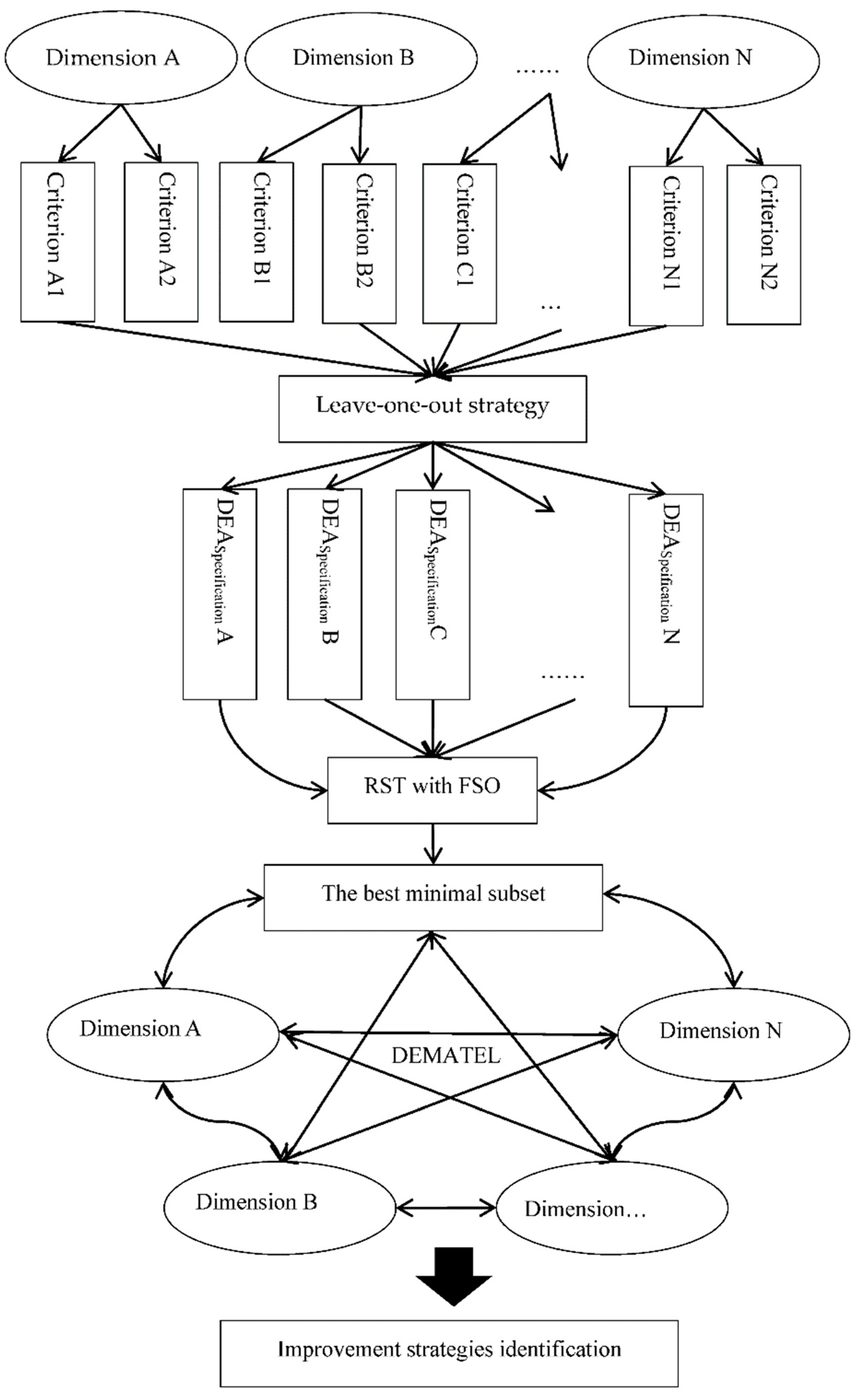

2.5. Fusion Intelligent Model

3. Methodologies

3.1. A Fusion Intelligent Decision Support System

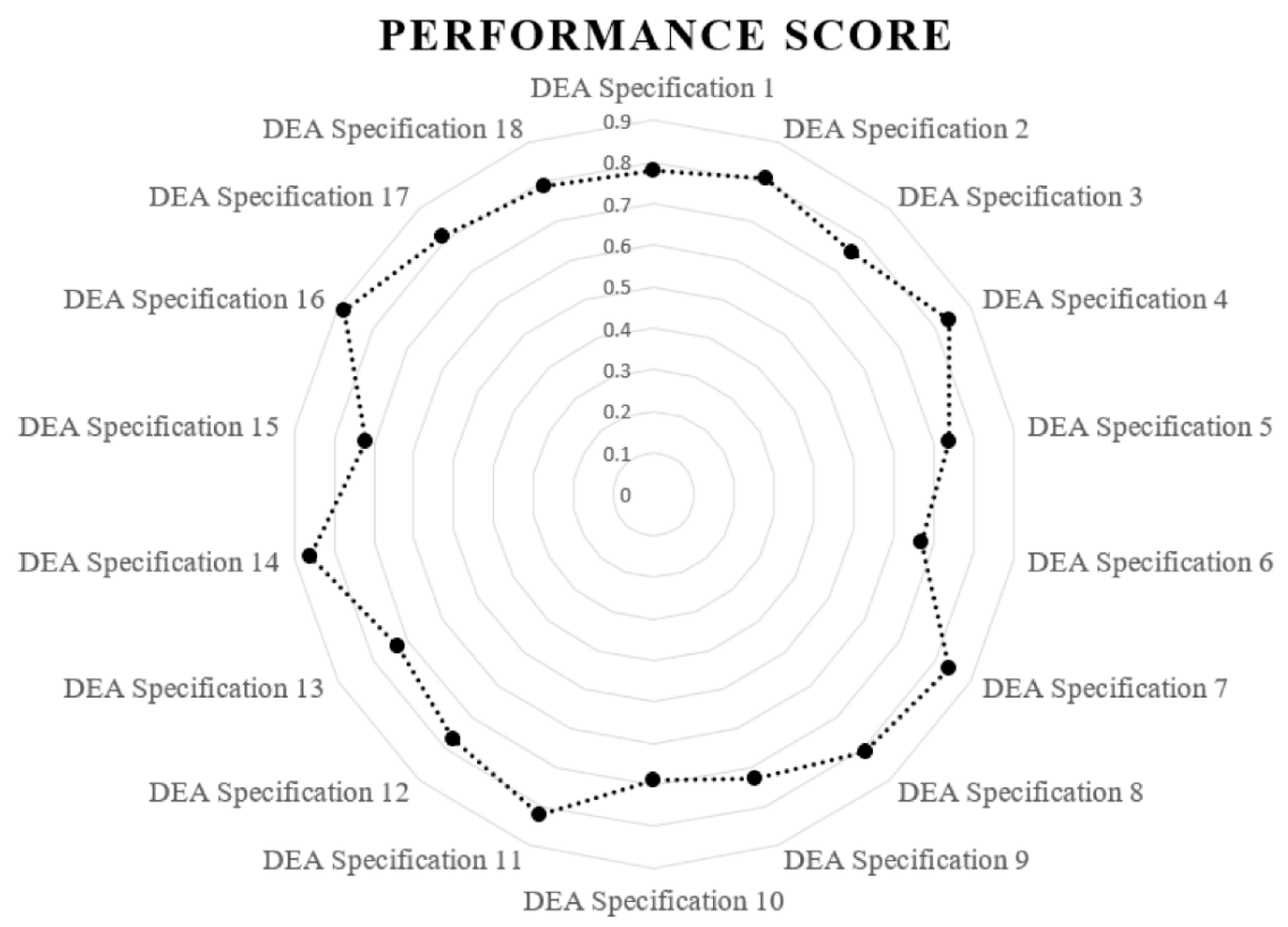

3.2. Data Envelopment Analysis (DEA)

3.3. Rough Set Theory with Fish Swarm Optimization (RST-FSO)

3.4. DEMATEL Method

4. Empirical Results

4.1. Questionnaire Design and Data Collection

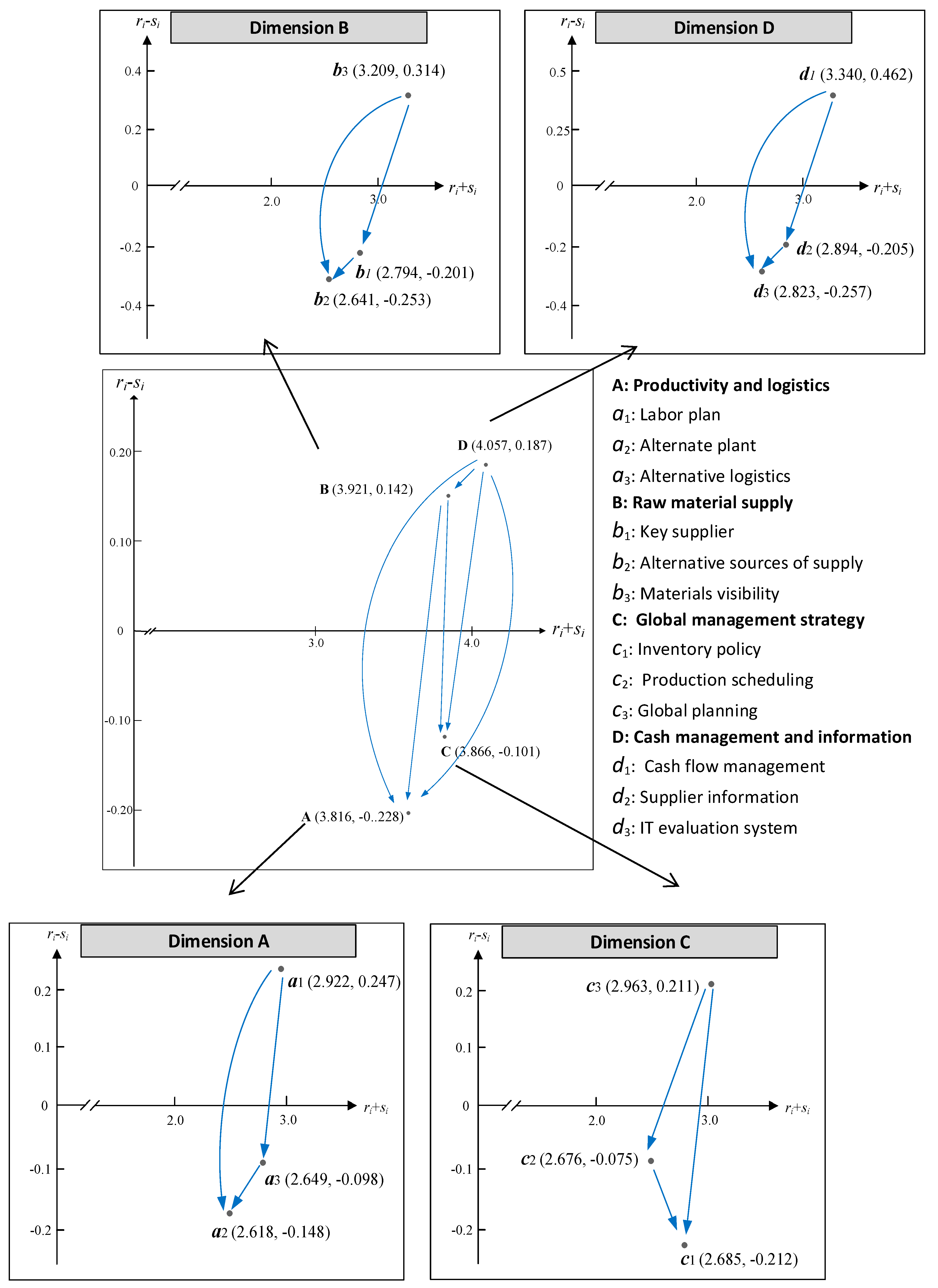

4.2. Key Criteria Acquisition Using the DEMATEL Technique

5. Discussion and Implication

6. Conclusions and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Harbour, L. The Coronavirus Impact on The Global Automotive Supply Chains. Available online: https://www.forbes.com/sites/laurieharbour1/2020/03/13/the-coronavirus-impact-on-the-global-automotive-supply-chain/185153c8444e (accessed on 10 April 2020).

- Keogh, J.G. COVID-19. To Ensure the Supply of Food and Consumer Goods, We Must Change the Rules of the Game. Available online: www.foodincanada.com (accessed on 22 April 2020).

- Hong, J.; Zhang, Y.; Ding, M. Sustainable supply chain management practices, supply chain dynamic capabilities, and enterprise performance. J. Clean. Prod. 2018, 172, 3508–3519. [Google Scholar] [CrossRef]

- Kot, S.; Goldbach, I.R.; Ślusarczyk, B. Supply chain management in SMEs-Polish and Romanian approach. Econ. Soc. 2018, 11, 142. [Google Scholar] [CrossRef]

- Kot, S.; Haque, A.U.; Baloch, A. Supply chain management in SMEs: Global perspective. Monten. J. Econ. 2020, 16, 87–104. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Papadopoulos, T.; Childe, S.J.; Shibin, K.T.; Samuel, S.F. Sustainable supply chain management: Framework and further research directions. J. Clean. Prod. 2017, 142, 1119–1130. [Google Scholar] [CrossRef]

- Mehdikhani, R.; Valmohammadi, C. Strategic collaboration and sustainable supply chain management. J. Enterp. Inf. Manag. 2018, 32, 778–806. [Google Scholar] [CrossRef]

- Mesjasz-Lech, A. The use of IT systems supporting the realization of business processes in enterprises and supply chains in Poland. Pol. J. Manag. Stud. 2014, 10, 94–103. [Google Scholar]

- Valmohammadi, C. Investigating supply chain management practices in Iranian manufacturing organizations. Oper. Supply Chain Manag. 2013, 6, 36–42. [Google Scholar] [CrossRef]

- Kasim, E.S.; Daud, D.; Said, J.; Md Zin, N.; Kusrini, E. Supply disruption risk mitigation: A case study of automotive company. Pol. J. Manag. Stud. 2020, 22, 247–262. [Google Scholar]

- Damert, M.; Koep, L.; Guenther, E.; Morris, J. Stakeholders and socially responsible supply chain management: The moderating role of internationalization. Sust. Account. Manag. Policy J. 2020. ahead-of-print. [Google Scholar] [CrossRef]

- Gualandris, J.; Klassen, R.D. Emerging Discourse Incubator: Delivering transformational change: Aligning supply chains and stakeholders in non-governmental organizations. J. Supply Chain Manag. 2018, 54, 34–48. [Google Scholar] [CrossRef]

- Gualandris, J.; Klassen, R.D.; Vachon, S.; Kalchschmidt, M. Sustainable evaluation and verification in supply chains: Aligning and leveraging accountability to stakeholders. J. Oper. Manag. 2015, 38, 1–13. [Google Scholar] [CrossRef]

- Speier, C.; Whipple, J.M.; Closs, D.J.; Voss, M.D. Global supply chain design considerations: Mitigating product safety and security risks. J. Oper. Manag. 2011, 29, 721–736. [Google Scholar] [CrossRef]

- Ivanov, D. Predicting the impact of epidemic outbreaks on the global supply chains: A simulation-based analysis on the example of Coronavirus (COVID-19/SARS-CoV-2) case. Transp. Res. Part E 2020, 136, 101922. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef]

- Sheffi, Y.; Rice, J.B., Jr. A supply chain view of the resilient enterprise. MIT Sloan Manag. Rev. 2005, 47, 41–48. [Google Scholar]

- Hosseini, S.; Ivanov, D.; Dolgui, A. Review of quantitative methods for supply chain resilience analysis. Transp. Res. Part E 2019, 125, 285–307. [Google Scholar] [CrossRef]

- Lin, W.K.; Lin, S.J.; Yang, T.N. Integrated business prestige and artificial intelligence for corporate decision making in dynamic environments. Cyber Syst. 2007, 48, 303–324. [Google Scholar] [CrossRef]

- Lin, S.J.; Chang, T.M.; Hsu, M.F. An emerging online business decision making architecture in a dynamic economic environment. J. Intell. Fuzzy Syst. 2019, 37, 1893–1903. [Google Scholar] [CrossRef]

- Chen, F.H. Application of a hybrid dynamic MCDM to explore the key factors for the internal control of procurement circulation. Int. J. Prod. Res. 2015, 53, 2951–2969. [Google Scholar] [CrossRef]

- Hu, K.H.; Chen, F.H.; Tzeng, G.H. CPA firm’s cloud auditing provider for performance evaluation and improvement: An empirical case of China. Technol. Econ. Dev. Econ. 2018, 24, 2338–2373. [Google Scholar] [CrossRef]

- Hu, K.H.; Hsu, M.F.; Chen, F.H.; Liu, M.Z. Identifying the key factors of subsidiary supervision and management using an innovative hybrid architecture in a big data environment. Financ. Innov. 2021, 7, 10. [Google Scholar] [CrossRef]

- Hu, K.H.; Lin, S.J.; Hsu, M.F.; Chen, F.H. A dynamic network-based decision architecture for performance evaluation and improvement. J. Intell. Fuzzy Syst. 2020, 39, 4299–4311. [Google Scholar] [CrossRef]

- Lu, W.; Kweh, Q.L.; Wang, C. Integration and application of rough sets and data envelopment analysis for assessments of the investment trusts industry. Ann. Oper. Res. 2021, 296, 163–194. [Google Scholar] [CrossRef]

- Chang, T.M.; Hsu, M.F. Integration of incremental filter-wrapper selection strategy with artificial intelligence for enterprise risk management. Int. J. Mach. Learn. Cyber. 2018, 9, 477–489. [Google Scholar] [CrossRef]

- Hu, K.H.; Chen, F.H.; Hsu, M.F.; Tzeng, G.H. Identifying key factors for adopting artificial intelligence-enabled auditing techniques by joint utilization of fuzzy-rough set theory and MRDM technique. Technol. Econ. Dev. Econ. 2020, 27, 459–492. [Google Scholar] [CrossRef]

- Deloitte COVID-19: Managing Supply Chain Risk and Disruption. Available online: https://www2.deloitte.com/global/en/pages/risk/articles/covid-19-managing-supply-chain-risk-and-disruption.html (accessed on 25 April 2020).

- Hsu, C.C.; Tan, K.C.; Zailani, S.H.M. Strategic orientations, sustainable supply chain initiatives, and reverse logistics empirical evidence from an emerging market. Int. J. Oper. Prod. Manag. 2016, 36, 86–110. [Google Scholar] [CrossRef]

- Mönch, L.; Uzsoy, R.; Fowler, J.W. A survey of semiconductor supply chain models part I: Semiconductor supply chains, strategic network design, and supply chain simulation. Int. J. Prod. Res. 2018, 56, 4524–4545. [Google Scholar] [CrossRef]

- Lim, M.; Bassamboo, A.; Chopra, S.; Daskin, M.S. Flexibility and Fragility: Supply Chain Network Design with Disruption Risks; Northwestern University: Evanston, IL, USA, 2011. [Google Scholar]

- Karimi, B.; Niknamfar, A.H.; Hassan Gavyar, B.; Barzegar, M.; Mohtashami, A. Multi-objective multi-facility green manufacturing closed-loop supply chain under uncertain environment. Assem. Autom. 2019, 39, 58–76. [Google Scholar] [CrossRef]

- Trappey, C.V.; Trappey, A.J.C.; Lin, G.Y.P.; Liu, C.S. Business and logistics hub integration to facilitate global supply chain linkage. Proc. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 1221–1233. [Google Scholar] [CrossRef]

- Uluskan, M.; Godfrey, A.B. Business environment-supply chain framework and benchmarking supply chain structures Haiti versus China. Benchmark. Int. J. 2018, 25, 3021–3044. [Google Scholar] [CrossRef]

- Adewole, A. Developing a strategic framework for efficient and effective optimisation of information in the supply chains of the UK clothing manufacture industry. Supply Chain Manag. 2005, 10, 357–366. [Google Scholar] [CrossRef]

- Luomaranta, T.; Martinsuo, M. Supply chain innovations for additive manufacturing. Int. J. Phys. Distrib. Logist. Manag. 2020, 50, 54–79. [Google Scholar] [CrossRef]

- Thomas, V.H.; Mahanty, B. Assessment of emergency sourcing strategy of a supply chain through dynamic simulation approach. J. Ind. Prod. Eng. 2020, 37, 56–69. [Google Scholar] [CrossRef]

- Aryal, A.; Liao, Y.; Nattuthurai, P.; Li, B. The emerging big data analytics and IoT in supply chain management: A systematic review. Supply Chain Manag. 2018, 25, 141–156. [Google Scholar] [CrossRef]

- Bag, S.; Gupta, C.; Foropon, C. Examining the role of dynamic remanufacturing capability on supply chain resilience in circular economy. Manag. Decis. 2019, 57, 863–885. [Google Scholar] [CrossRef]

- Huo, B.; Han, Z.; Chen, H.; Zhao, X. The effect of high-involvement human resource management practices on supply chain integration. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 716–746. [Google Scholar] [CrossRef]

- Alimardani, M.; Rafiei, H.; Rabbani, M. A novel approach toward coordinated inventory management of an agile multi-echelon multiproduct supply chain. Cogent Eng. 2015, 3, 1–26. [Google Scholar]

- Kobayashi, M.; Tomino, T.; Shintaku, J.; Park, Y.W. Demand fluctuation and supply chain integration: Case studies of Japanese firms. Persp. Glob. Dev. Technol. 2017, 16, 564–586. [Google Scholar] [CrossRef]

- Madhani, P.M. Supply chain strategy selection: A multi-criteria decision-making approach. IUP J. Supply Chain Manag. 2017, 14, 38–56. [Google Scholar]

- Kalir, A.A.; Grosbard, D.I. Global optimization of a semiconductor IC supply chain network. J. Serv. Sci. Manag. 2017, 10, 338–352. [Google Scholar] [CrossRef]

- Bay, B.K.; Tang, N.H.K.; Bennett, D. An empirical study of the imperatives for a supply chain implementation project in Seagate Technology International. Supply Chain Manag. 2004, 9, 331–340. [Google Scholar]

- Tsai, C.Y. On delineating supply chain cash flow under collection risk. Int. J. Prod. Econ. 2011, 129, 186–194. [Google Scholar] [CrossRef]

- Zhao, F.; Dash Wu, D.; Liang, L.; Dolgui, A. Cash flow risk in dual-channel supply chain. Int. J. Prod. Res. 2015, 53, 3678–3691. [Google Scholar] [CrossRef]

- Hmida, F.B.; Séguy, A.; Dupas, R. Multiagent simulation and evaluation of supply chain control architectures. IFAC Proc. 2012, 45, 781–786. [Google Scholar] [CrossRef]

- Villegas, M.A.; Pedregal, D.J. Automatic selection of unobserved components models for supply chain forecasting. Int. J. Forecast 2019, 35, 157–169. [Google Scholar] [CrossRef]

- Mani, V.; Gunasekaran, A.; Delgado, C. Supply chain social sustainability: Standard adoption practices in Portuguese manufacturing firms. Int. J. Prod. Econ. 2018, 198, 149–164. [Google Scholar] [CrossRef]

- Cragg, T.; McNamara, T. An ICT-based framework to improve global supply chain integration for final assembly SMES. J. Enterp. Inf. Manag. 2018, 31, 634–657. [Google Scholar] [CrossRef]

- Fitzpartrick, P.J. A comparison of ratios of successful industrial enterprises with those of failed companies. J. Account Res. 1932, 10, 598–605. [Google Scholar]

- Odom, M.; Sharda, R. A neural networks model for bankruptcy prediction. In Proceedings of the 1990 IJCNN International Joint Conference Neural Networks, San Diego, CA, USA, 17–21 June 1990; pp. 163–168. [Google Scholar]

- Hu, X.; Sun, B.; Chen, X. Double quantitative fuzzy rough set-based improved AHP method and application to supplier selection decision making. Int. J. Mach. Learn. Cyber. 2020, 11, 153–167. [Google Scholar] [CrossRef]

- Liu, D.; Yang, X.; Li, T. Three-way decisions: Beyond rough sets and granular computing. Int. J. Mach. Learn. Cyber. 2020, 11, 989–1002. [Google Scholar] [CrossRef]

- Karagoz, G.N.; Yazici, A.; Dokeroglu, T.; Cosar, A. A new framework of multi-objective evolutionary algorithms for feature selection and multi-label classification of video data. Int. J. Mach. Learn. Cyber. 2021, 12, 53–71. [Google Scholar] [CrossRef]

- Yi, Y.; Shi, Y.; Wang, W.; Lei, G.; Dai, J.; Zheng, H. Combining boundary detector and SND-SVM for fast learning. Int. J. Mach. Learn. Cyber. 2021, 12, 689–698. [Google Scholar] [CrossRef]

- Gu, X.; Chung, F.; Wang, S. Extreme vector machine for fast training on large data. Int. J. Mach. Learn. Cyber. 2020, 11, 33–53. [Google Scholar] [CrossRef]

- Feng, S.; Song, K.; Wang, D.; Gao, W.; Zhang, Y. InterSentiment: Combining deep neural models on interaction and sentiment for review rating prediction. Int. J. Mach. Learn. Cyber. 2021, 12, 477–488. [Google Scholar] [CrossRef]

- Huotari, T.; Savolainen, J.; Collan, M. Deep reinforcement learning agent for S&P 500 stock selection. Axioms 2020, 9, 130. [Google Scholar]

- Lin, S.J. Integrated artificial intelligence and visualization technique for enhanced management decision in today’s turbulent business environments. Cybern. Syst. 2021, 52, 274–292. [Google Scholar] [CrossRef]

- Romanov, A.; Voronina, V.; Guskov, G.; Moshkina, I.; Yarushkina, N. Discrete and fuzzy models of time series in the tasks of forecasting and diagnostics. Axioms 2020, 9, 49. [Google Scholar] [CrossRef]

- Zhao, J.; Du, W.-S. New generalized Ekeland’s variational principle, critical point theorems and common fuzzy fixed point theorems induced by Lin-Du’s abstract maximal element principle. Axioms 2021, 10, 11. [Google Scholar] [CrossRef]

- Muhiuddin, G.; Al-Kadi, D.; Balamurugan, M. Anti-intuitionistic fuzzy soft a-ideals applied to BCI-algebras. Axioms 2020, 9, 79. [Google Scholar] [CrossRef]

- Pramanik, S.; Dey, P.P.; Smarandache, F.; Ye, J. Cross entropy measures of bipolar and interval bipolar neutrosophic sets and their application for multi-attribute decision-making. Axioms 2018, 7, 21. [Google Scholar] [CrossRef]

- Ma, X.A. Fuzzy entropies for class-specific and classification-based attribute reducts in three-way probabilistic rough set models. Int. J. Mach. Learn. Cyber. 2021, 12, 433–457. [Google Scholar] [CrossRef]

- Pal, P.; Tiwari, S.P.; Singh, S. L-fuzzy rough automaton: A mathematical model for natural languages. Int. J. Mach. Learn. Cyber. 2021. [Google Scholar] [CrossRef]

- Chen, C.Y.; Tzeng, G.H.; Huang, J.J. Generalized DEMATEL technique with centrality measurements. Technol. Econ. Dev. Econ. 2018, 24, 600–614. [Google Scholar] [CrossRef]

- Chen, F.H.; Tzeng, G.H.; Chang, C.C. Evaluating the enhancement of corporate social responsibility websites quality based on a new hybrid MADM model. Int. J. Inf. Technol. Decis. Mak. 2015, 14, 697–724. [Google Scholar] [CrossRef]

- Bakir, S.; Khan, S.; Ahsan, K.; Rahman, S. Exploring the critical determinants of environmentally oriented public procurement using the DEMATEL method. J. Environ. Manag. 2018, 225, 325–335. [Google Scholar] [CrossRef] [PubMed]

- Gardas, B.B.; Raut, R.D.; Narkhede, B. Evaluating critical causal factors for post-harvest losses (PHL) in the fruit and vegetables supply chain in India using the DEMATEL approach. J. Clean. Prod. 2018, 199, 47–61. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision Making with Dependence and Feedback: The Analytic Network Process; RWS Publications: Pittsburgh, PA, USA, 1996. [Google Scholar]

- García-Alcaraz, J.L.; Sánchez-Ramírez, C.; Avelar-Sosa, L.; Alor-Hernández, G. Techniques, Tools and Methodologies Applied to Global Supply Chain Ecosystems; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Hu, K.H.; Wei, J.; Tzeng, G.H. Risk factor assessment improvement for China’s cloud computing auditing using a new hybrid MADM model. Int. J. Inform. Tech. Decis. Mak. 2017, 16, 737–777. [Google Scholar] [CrossRef]

- Raghavan, N.R.S.; Mishra, V.K. Short-term financing in a cash-constrained supply chain. Int. J. Prod. Econ. 2011, 134, 407–412. [Google Scholar] [CrossRef]

- Kulchania, M.; Thomas, S. Cash reserves as a hedge against supply-chain risk. J. Financ. Quant. Anal. 2017, 52, 1951–1988. [Google Scholar] [CrossRef]

- Bertel, S.; Fenies, P.; Roux, O. Optimal cash flow and operational planning in a company supply chain. Int. J. Comput. Integr. Manuf. 2008, 21, 440–454. [Google Scholar] [CrossRef]

- Kazi, Y.; Mitra, S.R. Supply chain collaboration—Next steps and beyond. J. Supply Chain Manag. Syst. 2017, 6, 1–16. [Google Scholar]

- Eckstein, D.; Goellner, M.; Blome, C.; Henke, M. The performance impact of supply chain agility and supply chain adaptability: The moderating effect of product complexity. Int. J. Prod. Res. 2015, 53, 3028–3046. [Google Scholar] [CrossRef]

- Tukamuhabwa, B.R.; Stevenson, M.; Busby, J.; Zorzini, M. Supply chain resilience: Definition, review and theoretical foundations for further study. Int. J. Prod. Res. 2015, 53, 5592–5623. [Google Scholar] [CrossRef]

- Chau, K.Y.; Tang, Y.M.; Liu, X.; Ip, Y.K.; Tao, Y. Investigation of critical success factors for improving supply chain quality management in manufacturing. Enterp. Inf. Syst. 2021, 1, 1–20. [Google Scholar] [CrossRef]

- Chen, H.; Daugherty, P.J.; Landry, T.D. Supply chain process integration: A theoretical framework. J. Bus. Logist. 2009, 30, 27–46. [Google Scholar] [CrossRef]

- Xu, L.D. Information architecture for supply chain quality management. Int. J. Prod. Res. 2011, 49, 183–198. [Google Scholar] [CrossRef]

- Enagi, M.A.; Van Belle, J.P. Information searching and satisficing process for IT decision making process of SMEs. Afr. J. Inf. Syst. 2019, 11, 99–116. [Google Scholar]

- Vargas, M.A.; Comuzzi, M. A multi-dimensional model of enterprise resource planning critical success factors. Enterp. Inf. Syst. 2020, 14, 38–57. [Google Scholar] [CrossRef]

- Raut, R.D.; Narkhede, B.; Gardas, B.B. To Identify the critical success factors of sustainable supply chain management practices in the context of oil and gas industries: ISM approach. Renew. Sust. Energ. Rev. 2017, 68, 33–47. [Google Scholar] [CrossRef]

- Zhong, S.-h.; Huang, X.; Xiao, Z. Fine-art painting classification via two-channel dual path networks. Int. J. Mach. Learn. Cyber. 2020, 11, 137–152. [Google Scholar] [CrossRef]

- Martínez Torres, J.; Iglesias Comesaña, C.; García-Nieto, P.J. Review: Machine learning techniques applied to cybersecurity. Int. J. Mach. Learn. Cyber. 2019, 10, 2823–2836. [Google Scholar] [CrossRef]

| Dimensions | Criteria |

|---|---|

| Productivity and logistics | A1: Labor/workforce plan |

| A2: Alternate plant | |

| A3: Alternative workforce | |

| A4: Alternative logistics | |

| Raw material supply | B1: Key supplier |

| B2: Second supplier | |

| B3: Alternative sources of supply | |

| B4: Materials visibility | |

| B5: Relationship with suppliers | |

| Global management strategy | C1: Inventory policy C2: Production scheduling |

| C3: Global planning | |

| C4: Local and national policies | |

| Cash management and information | D1: Cash flow management |

| D2: Supplier information | |

| D3: Home country regulation of cooperative manufacturers | |

| D4: IT evaluation system | |

| D5: Information of competitors |

| Status | Selected Criteria | Forecasting Preciseness | Rule Coverage | SPRC |

|---|---|---|---|---|

| K = 2 | a1, a2, a3, a4, b1, b2, b3, b5, c1, c3, d3, d5 | 0.87 | 0.86 | 1.73 |

| K = 3 | a1, a2 a3, b1, b2, b3, c1, c2, c3, d1, d2, d3 | 0.88 | 0.89 | 1.77 |

| K = 4 | a1, a3, a4, b2, b4, c3, c4, d1, d4 | 0.82 | 0.85 | 1.67 |

| K = 5 | a1, a2, a4, b1, b3, c1, c2, d1, d3, d5 | 0.81 | 0.84 | 1.65 |

| K = 6 | a2 a3, b1, b4, b5, c3, c4, d2, d4, d5 | 0.78 | 0.86 | 1.64 |

| K = 7 | a1, a2, b2, b4, c1, c2, c4, d1, d3, d5 | 0.75 | 0.84 | 1.59 |

| K = 8 | a1, a2 a4, b2, b3, c1, c3, c4, d2, d4 | 0.71 | 0.82 | 1.53 |

| K = 9 | a1, a3, b1, b4, b5, c2, d1, d3, d5 | 0.68 | 0.81 | 1.49 |

| K = 10 | a2 a3, b1, b3, b5, c2, c3, c4, d2, d4, d5 | 0.66 | 0.79 | 1.45 |

| Dimensions/Criteria | Definitions | Sources |

| Productivity and logistics (A) | ||

| Labor/workforce plan () | Labor demand to maintain production. | Hsu et al. [29]; Mönch et al. [30] |

| Alternate plant () | Preparation for alternative factories when the legacy factory cannot engage in production. | Lim et al. [31]; Karimi et al. [32] |

| Alternative logistics () | Alternative transportation projects from interruption of the original logistics system. | Trappey et al. [33] |

| Raw material supply (B) | ||

| Key supplier () | Main suppliers of raw materials. | Uluskan and Godfrey [34] |

| Alternative sources of supply () | Alternative sources of supply for other available raw materials. | Luomaranta and Martinsuo [36]; Thomas and Mahanty [37] |

| Materials visibility () | Ability to fully and effectively grasp the status of raw materials engaged in production. | Aryal et al. [38]; Bag et al. [39] |

| Global management strategy (C) | ||

| Inventory policy () | Flexible dynamic inventory strategy. | Alimardani et al. [41]; Huo et al. [40] |

| Production scheduling () | Agile production scheduling strategy. | Kobayashi et al. [42]; Madhani [43] |

| Global planning () | Multi-channel global production planning. | Bay et al. [45]; Kalir and Grosbard [44] |

| Cash management and information (D) | ||

| Cash flow management () | Maintain a certain cash flow at any time. | Tsai [46]; Zhao et al. [47] |

| Supplier information () | Fully grasp the information of upstream and downstream suppliers. | Cragg and McNamara [51]; |

| IT evaluation system () | IT system to evaluate supply chain production activities. | Hmida et al. [48]; Villegas and Pedregal [49] |

| Criterion | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.472 | 0.559 | 0.554 | 0.546 | 0.526 | 0.489 | 0.572 | 0.554 | 0.514 | 0.508 | 0.538 | 0.540 | |

| 0.424 | 0.372 | 0.438 | 0.425 | 0.409 | 0.364 | 0.422 | 0.417 | 0.394 | 0.396 | 0.420 | 0.421 | |

| 0.442 | 0.452 | 0.381 | 0.432 | 0.413 | 0.378 | 0.446 | 0.432 | 0.419 | 0.405 | 0.432 | 0.439 | |

| 0.481 | 0.492 | 0.488 | 0.404 | 0.464 | 0.429 | 0.491 | 0.463 | 0.440 | 0.439 | 0.473 | 0.460 | |

| 0.452 | 0.463 | 0.456 | 0.440 | 0.364 | 0.390 | 0.462 | 0.440 | 0.421 | 0.415 | 0.437 | 0.435 | |

| 0.657 | 0.669 | 0.669 | 0.653 | 0.619 | 0.489 | 0.677 | 0.659 | 0.611 | 0.604 | 0.644 | 0.633 | |

| 0.450 | 0.462 | 0.453 | 0.437 | 0.423 | 0.379 | 0.392 | 0.432 | 0.423 | 0.420 | 0.437 | 0.438 | |

| 0.458 | 0.461 | 0.459 | 0.440 | 0.428 | 0.400 | 0.476 | 0.387 | 0.437 | 0.434 | 0.454 | 0.449 | |

| 0.560 | 0.589 | 0.568 | 0.571 | 0.534 | 0.496 | 0.580 | 0.557 | 0.450 | 0.523 | 0.549 | 0.546 | |

| 0.694 | 0.712 | 0.709 | 0.694 | 0.665 | 0.615 | 0.725 | 0.684 | 0.645 | 0.550 | 0.677 | 0.674 | |

| 0.494 | 0.505 | 0.503 | 0.480 | 0.470 | 0.437 | 0.512 | 0.491 | 0.457 | 0.453 | 0.413 | 0.478 | |

| 0.464 | 0.472 | 0.468 | 0.454 | 0.436 | 0.408 | 0.482 | 0.462 | 0.434 | 0.436 | 0.459 | 0.388 |

| Dimensions/Criteria | Row Sum () | Column Sum () | ||

|---|---|---|---|---|

| Productivity and logistics (A) | 1.816 | 2.045 | 3.861 | −0.228 |

| Labor/workforce plan () | 1.584 | 1.338 | 2.922 | 0.247 |

| Alternate plant () | 1.235 | 1.383 | 2.618 | −0.148 |

| Alternative logistics () | 1.275 | 1.374 | 2.649 | −0.098 |

| Raw material supply (B) | 2.032 | 1.889 | 3.921 | 0.142 |

| Key supplier () | 1.296 | 1.497 | 2.794 | −0.201 |

| Alternative sources of supply () | 1.194 | 1.447 | 2.641 | −0.253 |

| Materials visibility () | 1.762 | 1.447 | 3.209 | 0.314 |

| Global management strategy (C) | 1.883 | 1.983 | 3.866 | −0.101 |

| Inventory policy () | 1.236 | 1.449 | 2.685 | −0.212 |

| Production scheduling () | 1.300 | 1.376 | 2.676 | −0.075 |

| Global planning () | 1.587 | 1.376 | 2.963 | 0.211 |

| Cash management and information (D) | 2.122 | 1.935 | 4.057 | 0.187 |

| Cash flow management () | 1.901 | 1.439 | 3.340 | 0.462 |

| Supplier information () | 1.345 | 1.549 | 2.894 | −0.205 |

| IT evaluation system () | 1.283 | 1.540 | 2.823 | −0.257 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, K.-H.; Chen, F.-H.; Hsu, M.-F.; Yao, S.; Hung, M.-C. Identification of the Critical Factors for Global Supply Chain Management under the COVID-19 Outbreak via a Fusion Intelligent Decision Support System. Axioms 2021, 10, 61. https://doi.org/10.3390/axioms10020061

Hu K-H, Chen F-H, Hsu M-F, Yao S, Hung M-C. Identification of the Critical Factors for Global Supply Chain Management under the COVID-19 Outbreak via a Fusion Intelligent Decision Support System. Axioms. 2021; 10(2):61. https://doi.org/10.3390/axioms10020061

Chicago/Turabian StyleHu, Kuang-Hua, Fu-Hsiang Chen, Ming-Fu Hsu, Shuyi Yao, and Ming-Chin Hung. 2021. "Identification of the Critical Factors for Global Supply Chain Management under the COVID-19 Outbreak via a Fusion Intelligent Decision Support System" Axioms 10, no. 2: 61. https://doi.org/10.3390/axioms10020061

APA StyleHu, K.-H., Chen, F.-H., Hsu, M.-F., Yao, S., & Hung, M.-C. (2021). Identification of the Critical Factors for Global Supply Chain Management under the COVID-19 Outbreak via a Fusion Intelligent Decision Support System. Axioms, 10(2), 61. https://doi.org/10.3390/axioms10020061