1. Introduction

Coal deposit modeling and evaluation as well as the process of mineable reserves estimation are essential and very important aspects of mine planning. In this framework, the modeling and evaluation procedure for the estimation of mineable reserves of multi-seam coal deposits could be divided into three main stages: (1) geologic modeling, (2) spatial block modeling, and (3) estimation of mineable lignite reserves [

1]. Considering the spatial modeling of the deposits, quantitative understanding of the spatial variability of coal energy reserves helps to optimize mine exploitation and to reduce fluctuations in the quality of the fuel supplied to power plants [

2].

There are mining industry accepted methods for splitting a coal deposit into mine development sectors and optimizing the mine planning and design. The main issue is to optimize the mining operations that usually refer to the application of operations research models [

3,

4]. Although the three-dimensional description of the deposit is helpful for modeling purposes, its computational complexity is not easily handled. In addition, a primary segmentation of the deposit into sectors, according to quantitative and qualitative criteria, is usually desirable for mine planning and design purposes. The primary factor for such a segmentation is the tectonic structure of the deposit that mainly defines regions of different geometry. Based on drill-hole data, conventional methods including cross sections and contour maps of the quantitative and qualitative variables within each tectonic region could provide deposit segmentation, especially in deposits with horizontal layers. However, these methods are not adequate for coal deposits with a complicated structure.

In an attempt to address the topic of multi-seam coal deposit spatial modeling and evaluation in a contemporary and sufficient way, this research work proposes and presents the coupling of principal component analysis (PCA) and geographic information system (GIS) techniques.

PCA is a statistical method for reducing the dimensions of complex datasets, increasing interpretability, while at the same time minimizing information loss [

5]. In simpler words, it is used for converting a complex dataset of possibly correlated variables into a smaller collection of uncorrelated factors (known as principal components) that contain most of the information of the initial dataset.

In an integrated decision-making model, Roumpos et al. [

6] considered the main factors that influence the evaluation of a lignite deposit and the optimization of a combined project of mine exploitation and power plant operation for electricity generation. The application of the proposed model showed that the mineral deposit factor which is related to the deposit data in combination with the mining characteristics has a particular effect on the viability of the project.

Spatial analysis of deposit indicators, combined with GIS applications, can provide a useful tool for evaluating a coal deposit in the framework of the corresponding surface mine investment analysis [

7]. Furthermore, spatial analysis of coal energy reserves for exploitation planning and quality control can resolve variations of various properties at different scales and identify potentially useful correlations between variables [

2]. The determination of the geological and spatial variability of the parameters that affect initial planning and final mine design is an essential part of mine modeling. It also affects the strategic mine exploitation sequence, from the opening up of the mine to the end of its life [

4].

Statistics, and more specifically; geostatistics, are effective approaches to analyze mineral deposit parameters and to provide tools for evaluating mining processes, covering all aspects of the exploitation, from the preliminary pre-mining deposit research to the post-mining reclamation works. Recent examples of the previous arguments are the works of Lishchuk et al. [

8] and Carvalho and Dimitrakopoulos [

9]. The first paper deals with the construction of a “synthetic ore body model”, for simulating a mining value chain for data integration, by using a synthetic deposit, mine production, constrained by a mine plan, and a simulated beneficiation process. The second one incorporates geostatistical simulations with other techniques in an attempt to optimizing mining complexes operations.

Closer to the present paper is the work of Bhuiyan et al. [

10], where data analysis techniques (including the PCA method) are applied, for establishing relationships between the Bond Work Index (BWI) and geomechanical, geophysical and geochemical variables for the Paracatu gold orebody in Brazil.

PCA has been applied in several cases as a useful geostatistical modeling tool [

11] and for different purposes. For example, PCA has been applied in hydrochemistry data acquisition [

12,

13], in geotechnical properties of formations data [

14], in quality composition of geological formations and trace elements data [

15], etc. PCA is also implemented in various topics concerning mining activities and their impacts, especially coal mining, mainly regarding environmental and quality aspects [

16,

17,

18,

19,

20,

21].

According to Dowd et al. [

22], modeling, estimation and simulation of geometallurgical variables and their integration into resource and reserve estimation and mine planning present challenges during strategic mine planning and design.

The identification of the surface mining regions of certain economic importance considering physicochemical or geometrical characteristics of a multi-seam coal deposit, based on the available drill-hole data and geostatistical techniques, is an interesting research topic. Taking into account the large number of parameters, which are related to coal deposits for surface mine development, geostatistical modeling should be applied for the analysis of the large datasets derived from the primary deposit drill-hole survey.

The objective of this paper is to incorporate PCA and GIS modeling of a multi-seam coal deposit into the mine planning and design model for the development of a surface coal mine. Emphasis is placed on the segmentation of the deposit into sectors of different technical and economic characteristics for further mine planning and design purposes. In short, the main goal of this research is to present and test a new method for mine planning and development of multi-seam coal deposits.

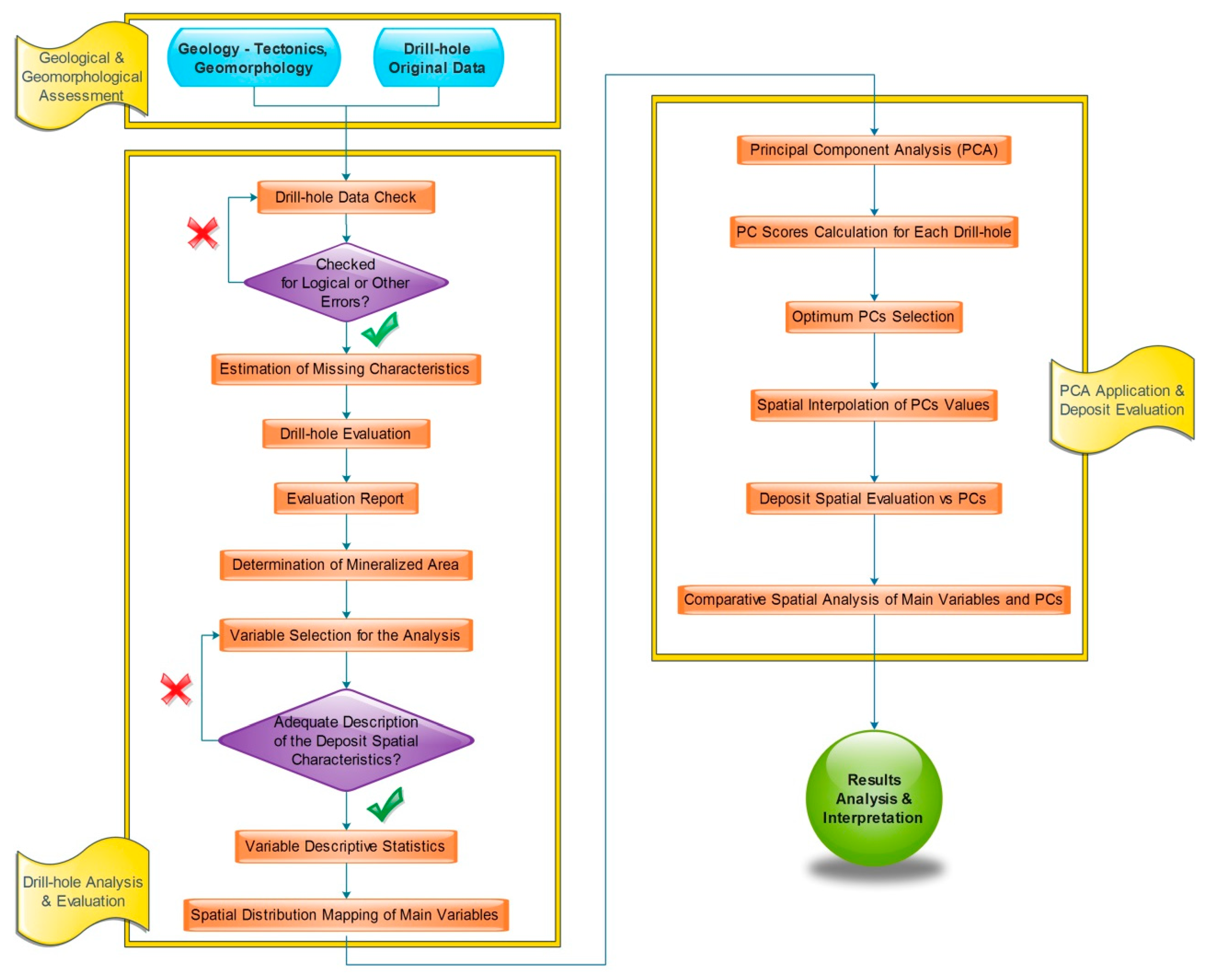

Figure 1 shows the flowchart of the research steps considering a multi-seam coal deposit, with frequently changing sequences of coal and waste layers.

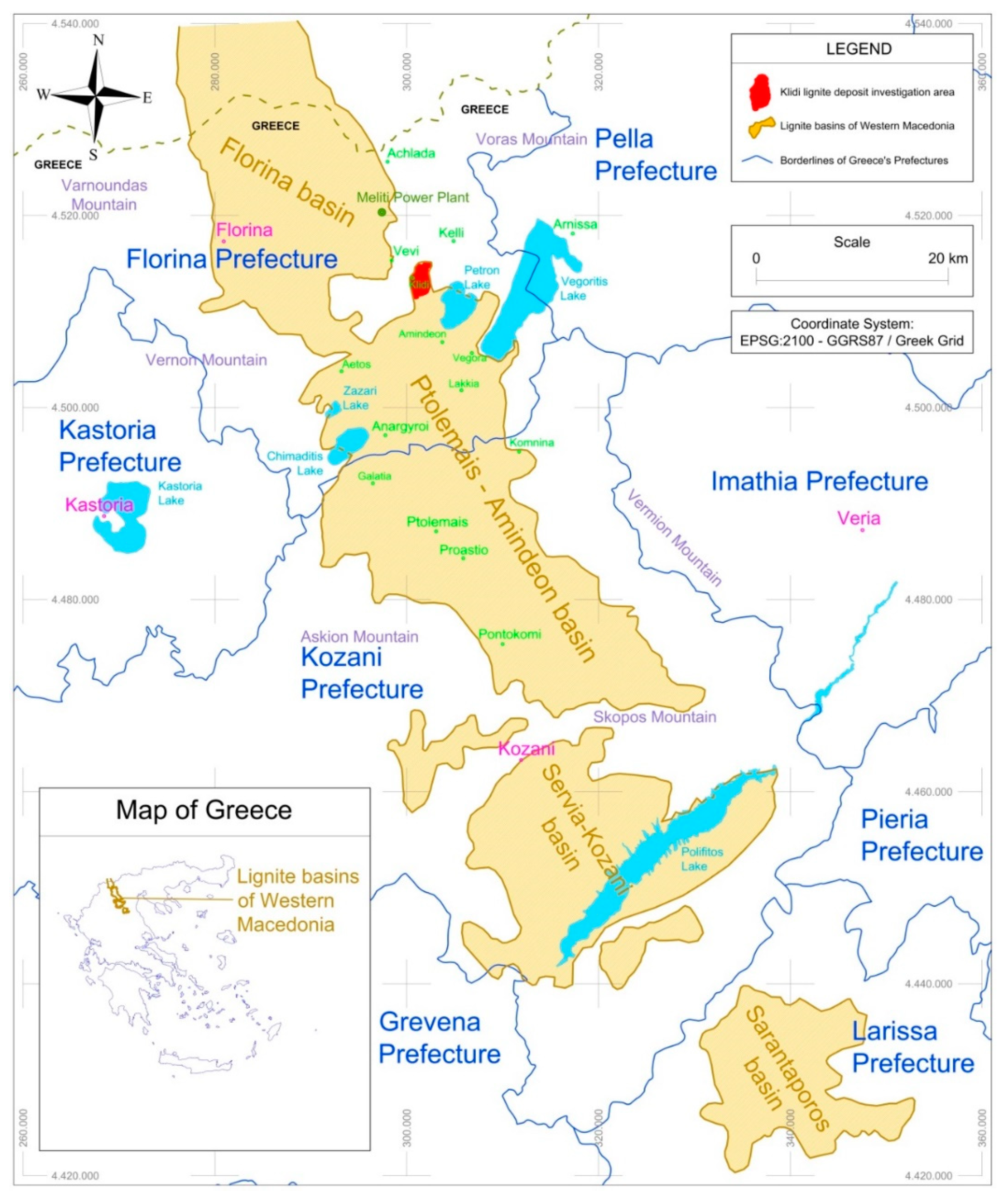

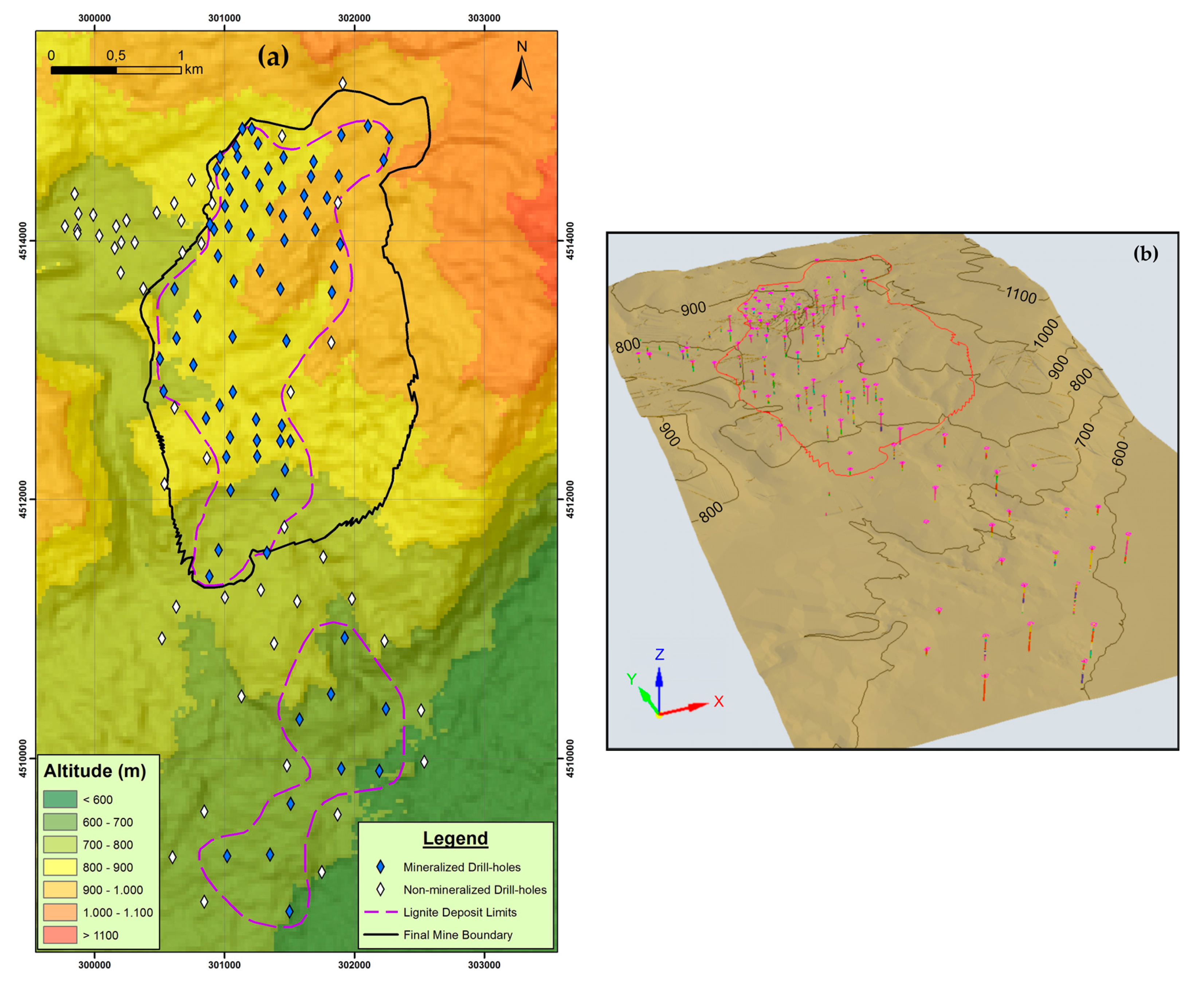

The methodology presented in this paper is applied to the Klidi lignite mining field, in the Northern part of Greece (West Macedonia) and specifically in the tectonic basin that extends along the axis Florina–Ptolemais–Kozani (

Figure 2). Specifically, it is located in the eastern-southeastern boundary of the entire Florina mining area, approximately 22 km east–southeast of the city of Florina. It extends approximately 3 km N–S and approximately 1.7 km E–W (

Figure 2).

This work provides the framework for a better understanding of multi-seam deposit characteristics and set solid directions for optimum mine exploitation planning. As will be discussed in the following sections, the applied analysis was justified by the results, which proved to be very useful, not only for establishing the foundations for the identification of the deposit structure and the optimum planning of mine development, but also for validating the methodological approach itself.

2. Coal Deposit Setting

Lignite is a type of low-rank coal, which is deposited on earth’s higher stratigraphic layers. Lignite is of particular significance for the power-generating branch of Greece as it covers about 30% of its electricity generation needs. The confirmed lignite reserves of Greece amount to 3.5 billion tons, out of which 2.3 billion tons (66%) are economically recoverable reserves. These reserves are distributed in various regions of Greece [

23]. The vast majority of Greek lignite deposits are located in the Northern part of Greece (West Macedonia) and specifically in the tectonic basin that extends along the axis Florina–Ptolemais–Kozani (

Figure 1). The geological formation of Greek deposits is developed on many horizontal seams of small and changing thickness, alternating with intermediate waste beds of different lithological and petrographic content.

The Klidi mining area is hilly with surface elevations ranging between +750 m and +1100 m above sea level (a.s.l.). The area of the planned mine covers approximately 6 km

2, including the Klidi village in the west of the field [

24]. The lignite basin of the deposit progressively broadens from NW to SE with a decrease of surface altitudes. The mine is planned to contribute to the lignite demand of the 330 MW Meliti Power Plant, which is located 13 km NW from the mine (road distance).

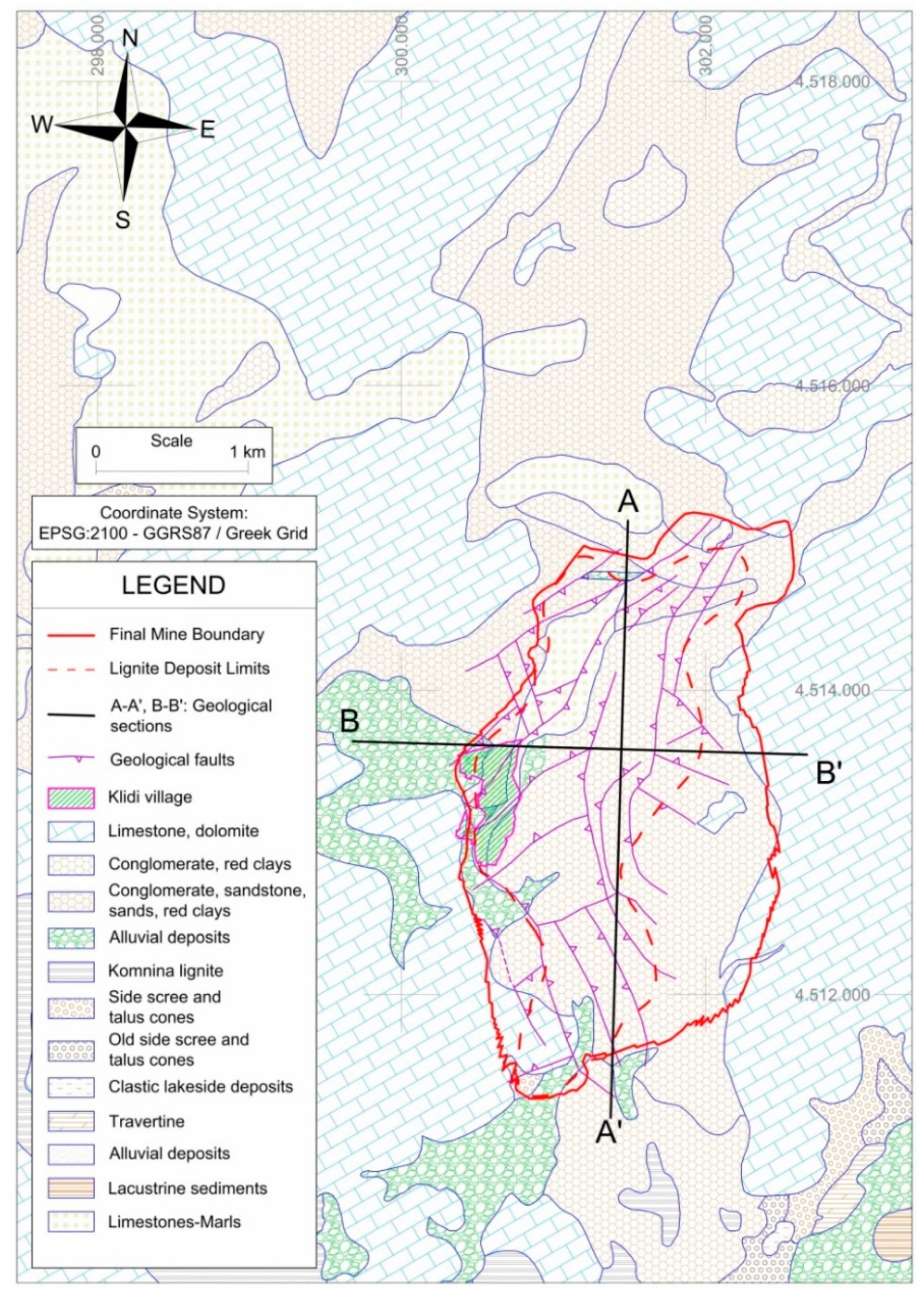

The deposit of the Klidi mine is divided into partly narrow blocks by several fault systems (

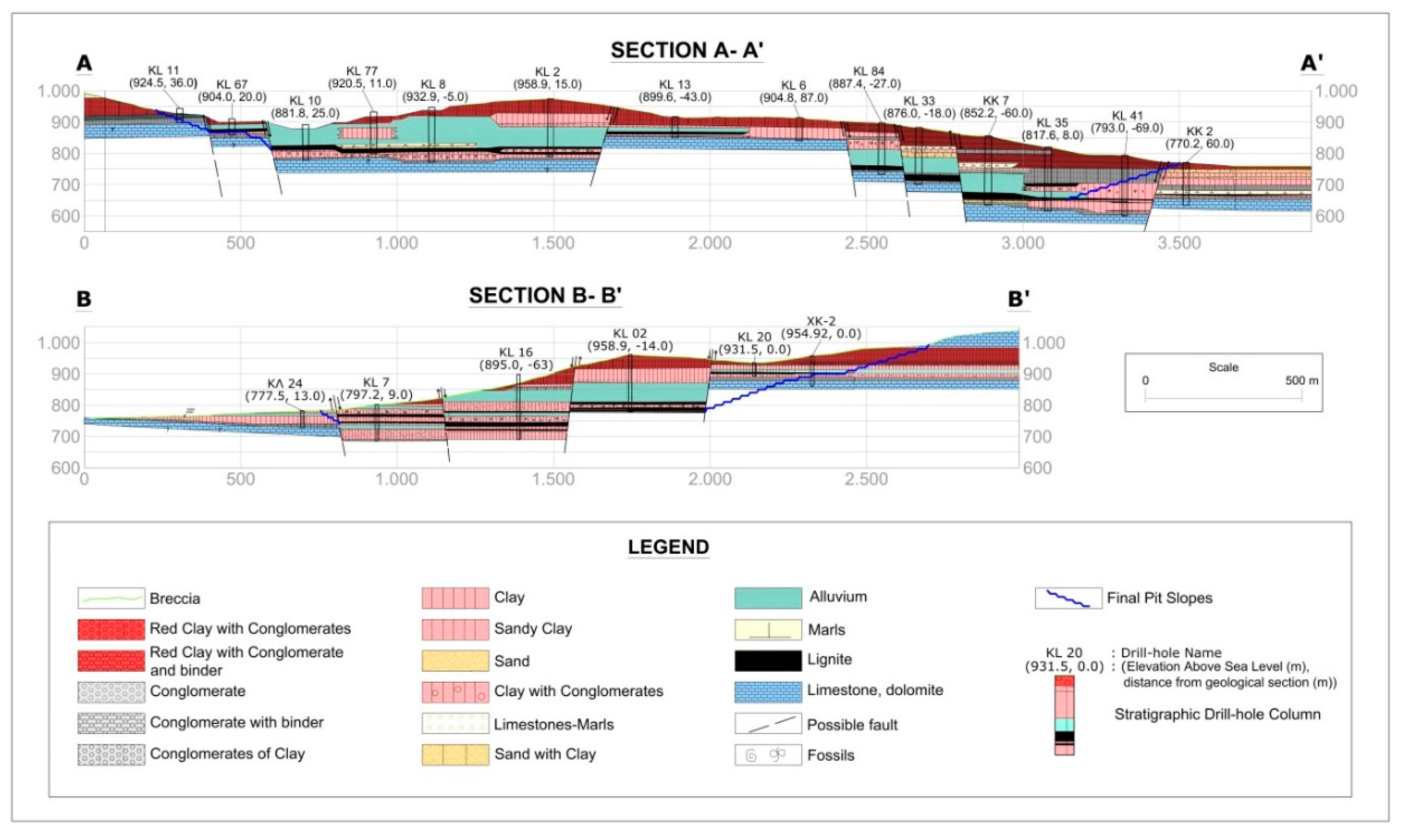

Figure 3), which mainly strike in a NW–SE, NE–SW and N–S direction and mostly consist of normal and, to a lesser extent, of reverse faults with slight faulting in the underlying seams. The effect of these faults on the stratigraphy is shown in sections A-A´ and B-B´ (

Figure 4).

The overlying strata thickness ranges from approximately 3 m up to 100 m. The layer series is composed of finely clastic, sandy clays and calcareous clayey marls with coarsely clastic, marly sands, sandy gravels and pebbles (

Figure 4). Furthermore, overlying strata locally incorporate consolidated layers, the so-called Klidi formation, which may impede mining operations. This formation is distributed in high percentage over the mining area and predominantly consists of consolidated conglomerates with gravels and disk-shaped stones. The excavation of this formation may require blasting. The overall thickness of the lignite-bearing series (including intermediate seams) ranges between approximately 3 and 50 m [

24,

25].

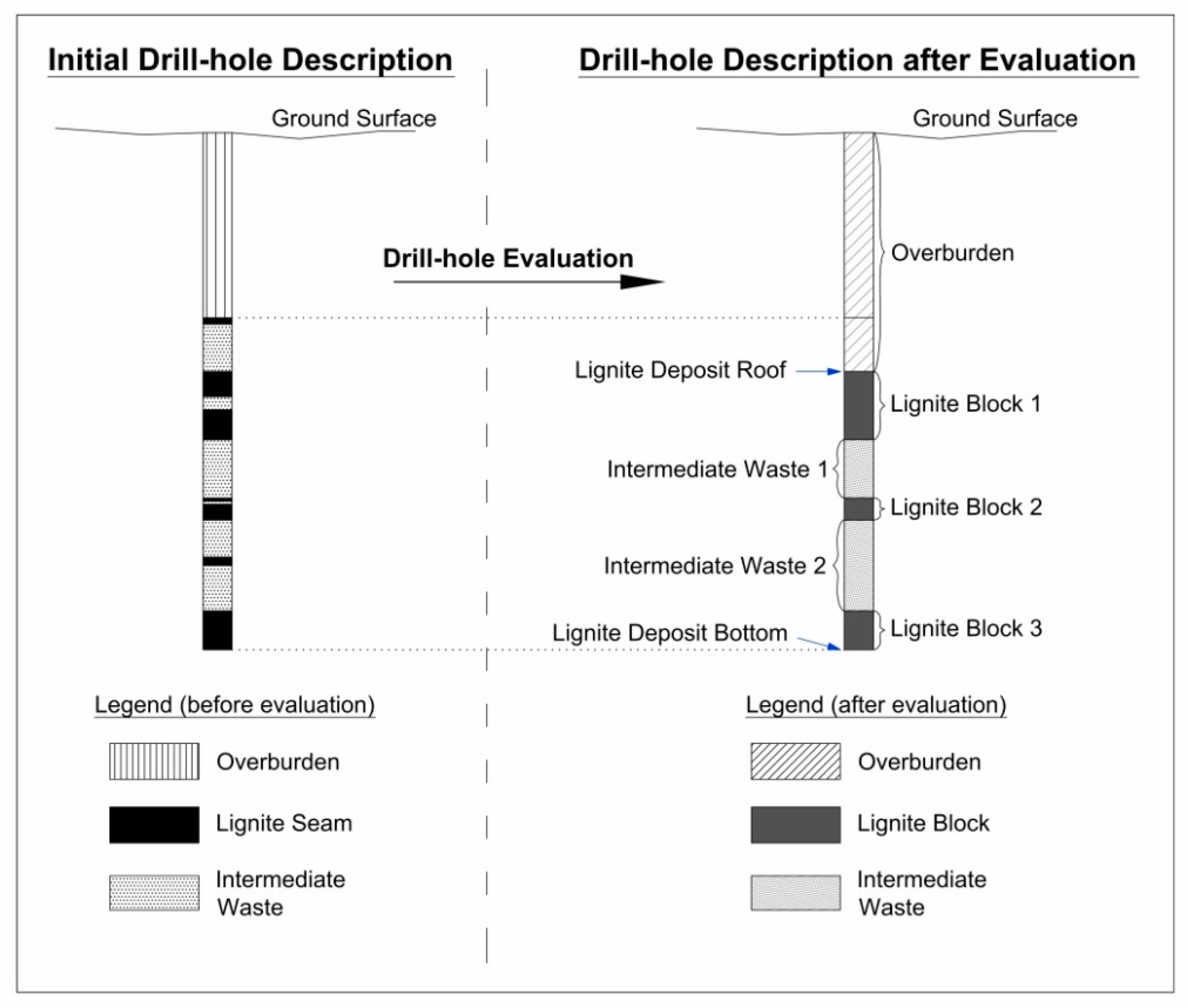

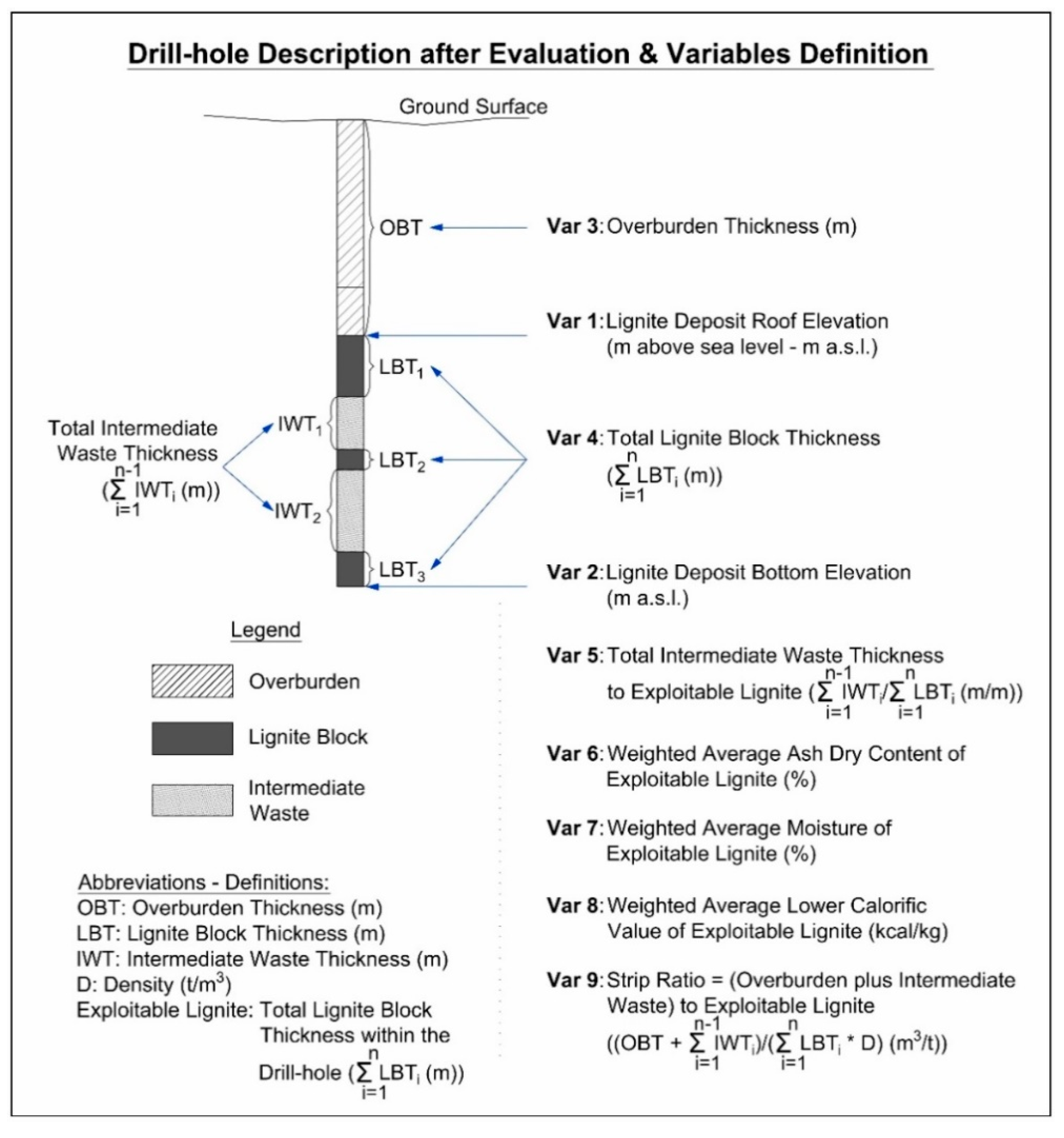

6. Discussion

From

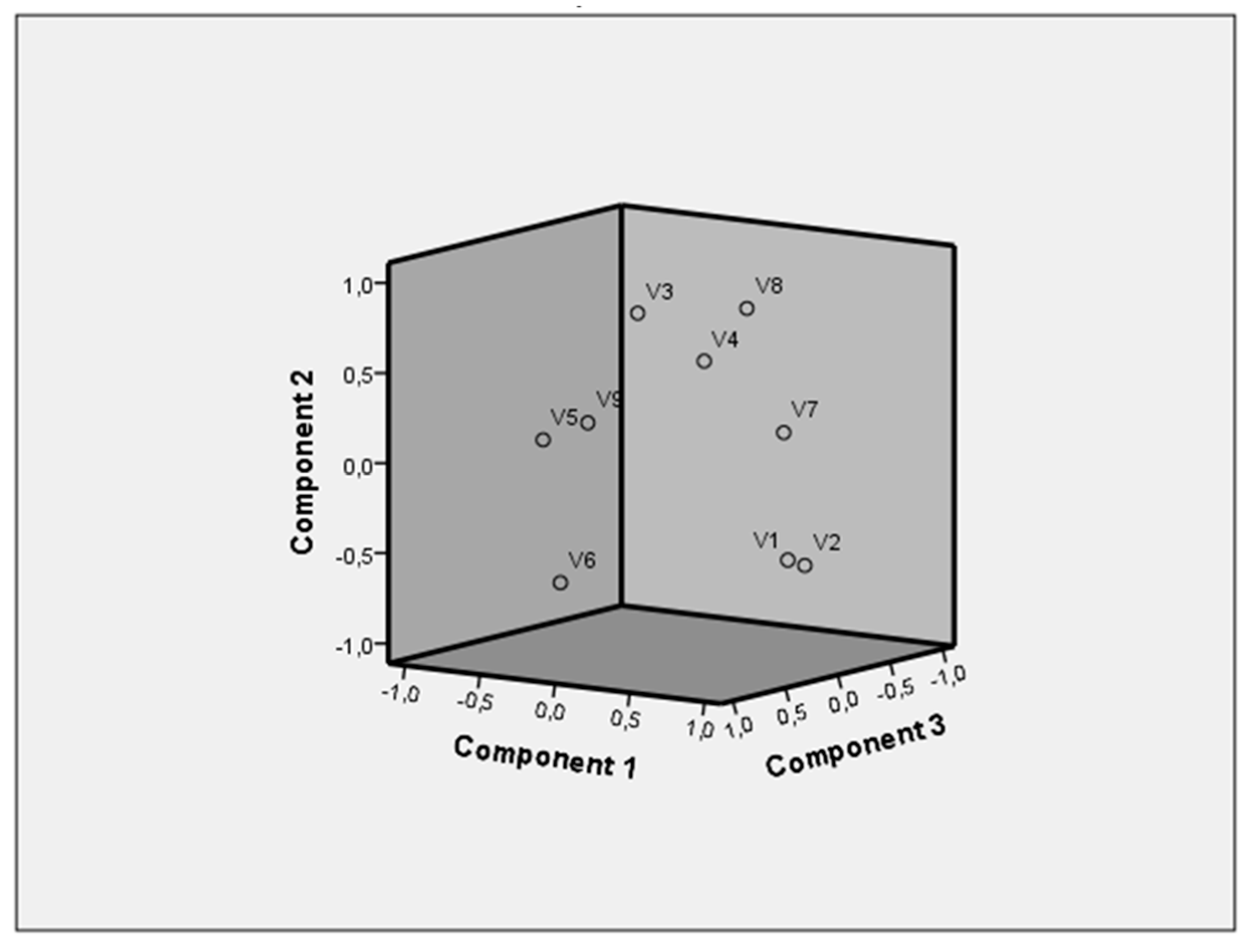

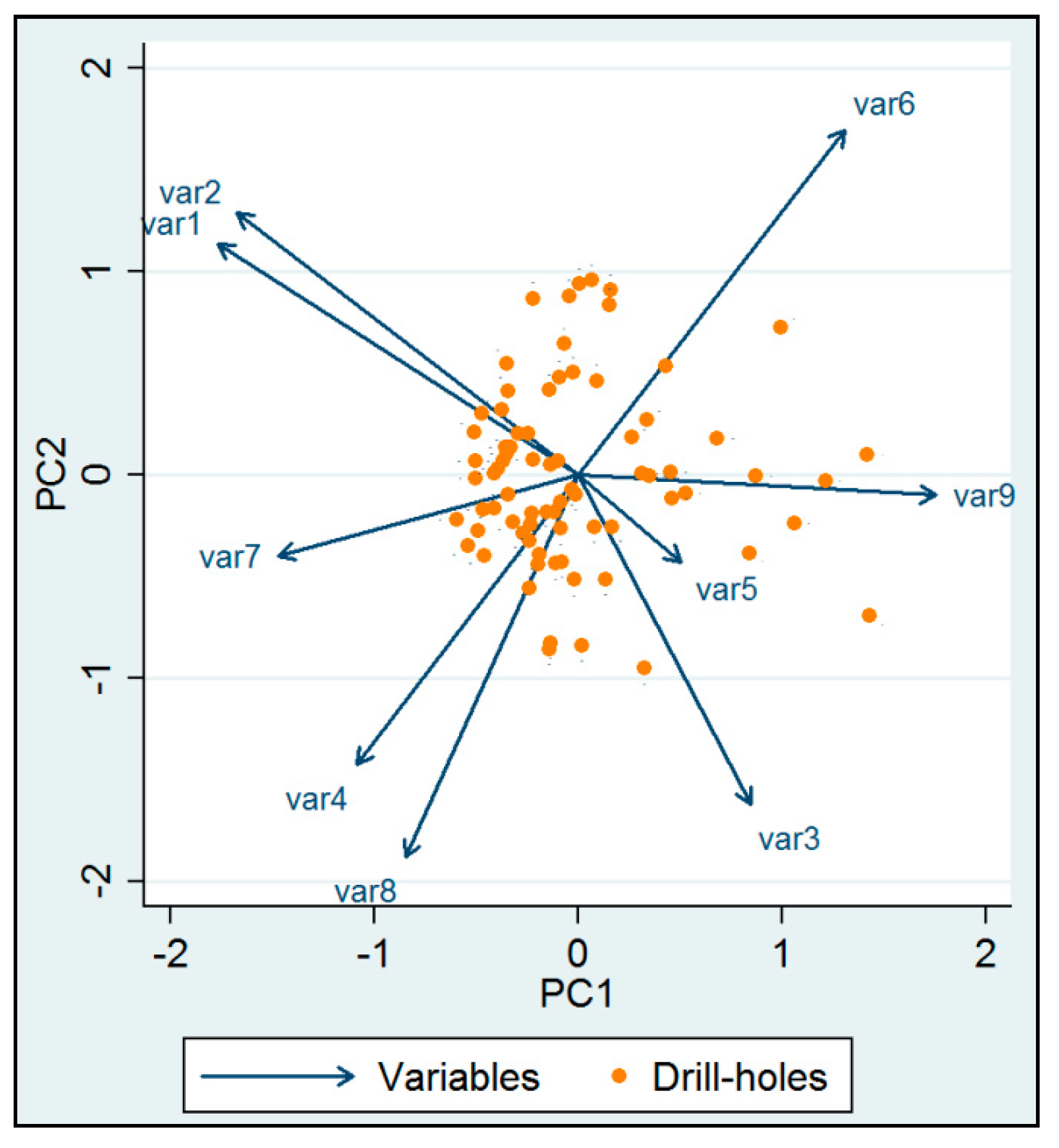

Figure 10 it can be deduced, as far as the variables of the Klidi deposit are concerned, that the strong positive correlation between lignite deposit roof elevation (Var 1) and lignite deposit bottom elevation (Var 2) is associated with the formation of the lignite deposit and the lignite-bearing sequence in relation to the sedimentation in the basin. A positive correlation also exists between the total lignite block thickness (Var 4) and the weighted average lower calorific value of exploitable lignite (Var 8), indicating the coexistence of these two main parameters that contribute to the exploitability of the deposit. In contrast, the weighted average lower calorific value of exploitable lignite (Var 8) and the weighted average ash dry content of exploitable lignite (Var 6) are negatively correlated indicating low fluctuations of moisture content within the deposit. In this context, a low total intermediate waste thickness to exploitable lignite (Var 5) is negatively correlated with the lignite deposit roof elevation (Var 1) and the lignite deposit bottom elevation (Var 2). Furthermore, the lignite deposit bottom elevation (Var 2) and the weighted average ash dry content of exploitable lignite (Var 6) are not correlated. This result is related to the structure of the deposit. A similar result is also obtained for the lignite deposit bottom elevation (Var 2) and the total lignite block thickness (Var 4). In conclusion, the initially expected correlations among the variables are confirmed by the biplot, a fact that verifies the accuracy of the primary data and the effective application of a PCA.

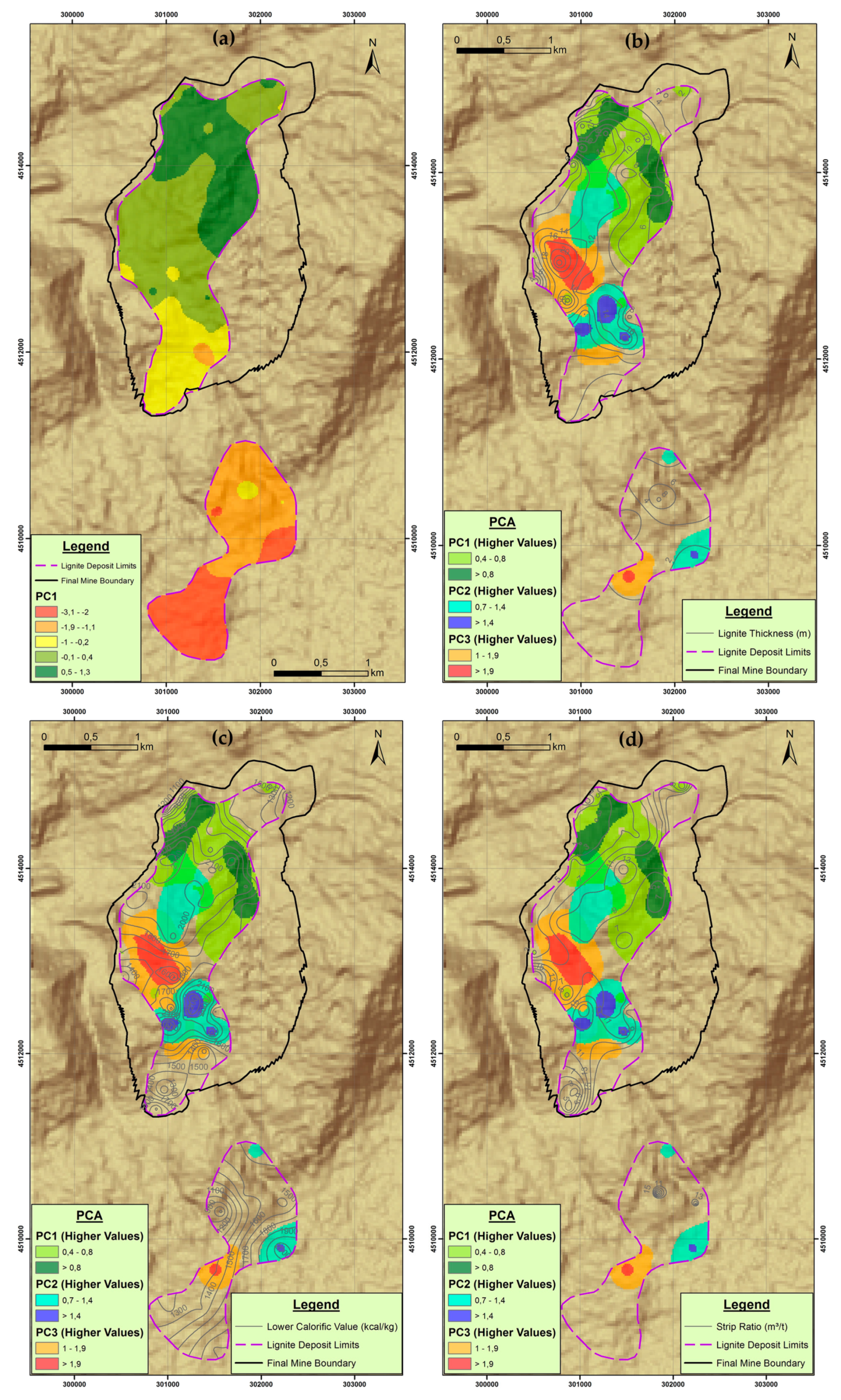

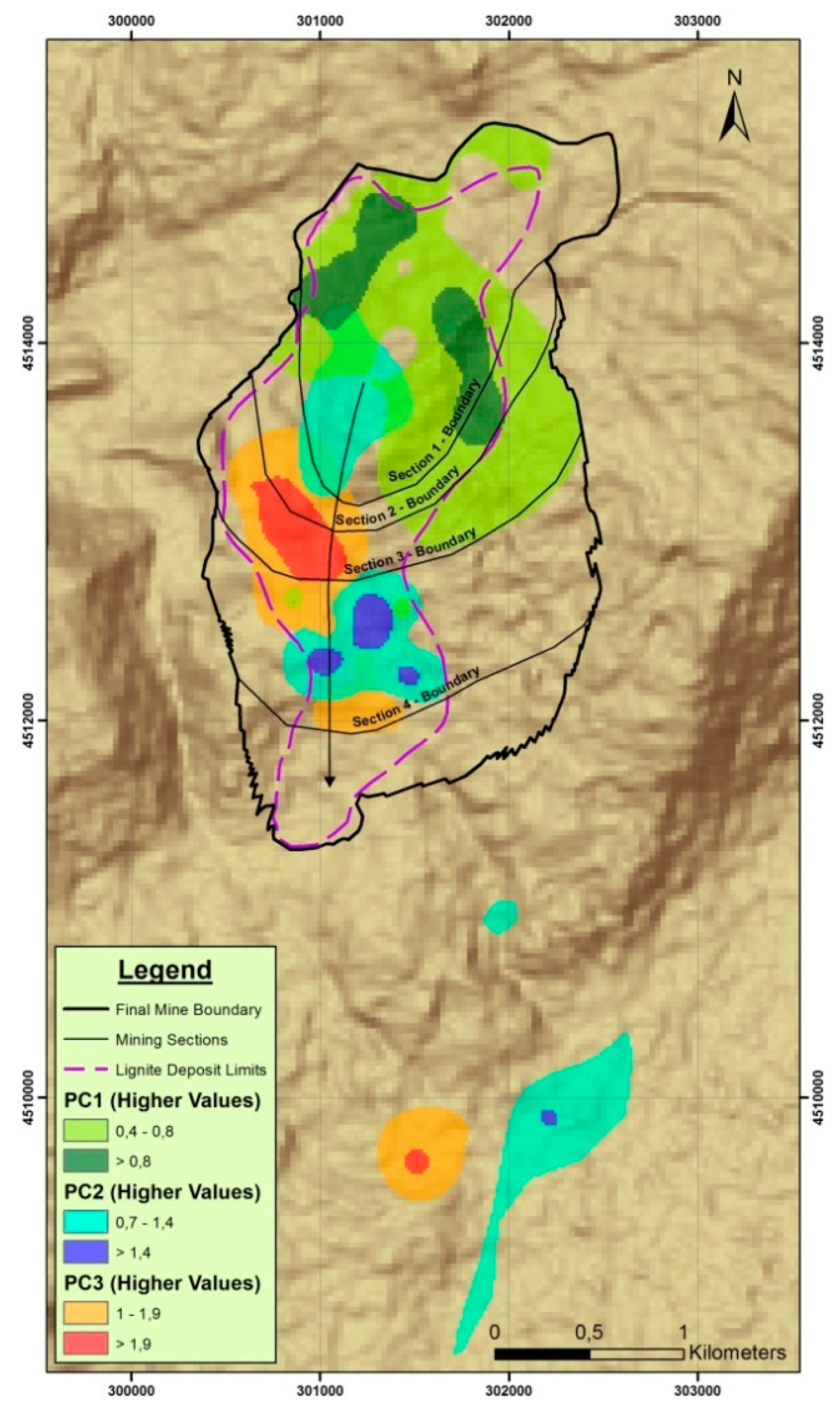

PC1 higher values are dominant in the mineralized area, which is located in the northeast part of the deposit (

Figure 11). This area is defined by the NE–SW oriented major faults. The higher values of PC1 are positively related to high elevation of the lignite deposit roof (Var 1), high elevation of the lignite deposit bottom (Var 2), high total lignite block thickness (Var 4) and high moisture content of exploitable lignite (Var 7) in combination with high lower calorific value (Var 8). The negative values of PC1 in the component score coefficient matrix (

Table 9) are related to low overburden thickness (Var 3), low total intermediate waste thickness to exploitable lignite (Var 5), low ash dry content of exploitable lignite (Var 6) and low strip ratio (Var 9). All these characteristics correspond to favorable conditions that increase the deposit exploitability. Therefore, this area is suitable for the location of the box cut and the initial opening phase of the mine (Sector 1 in

Figure 12). Considering the mine investment analysis, this area is characterized by lower mining operating cost, increased annual lignite production, earlier start of lignite production, as well as better quality of the orebody comparing with the rest part of the lignite deposit.

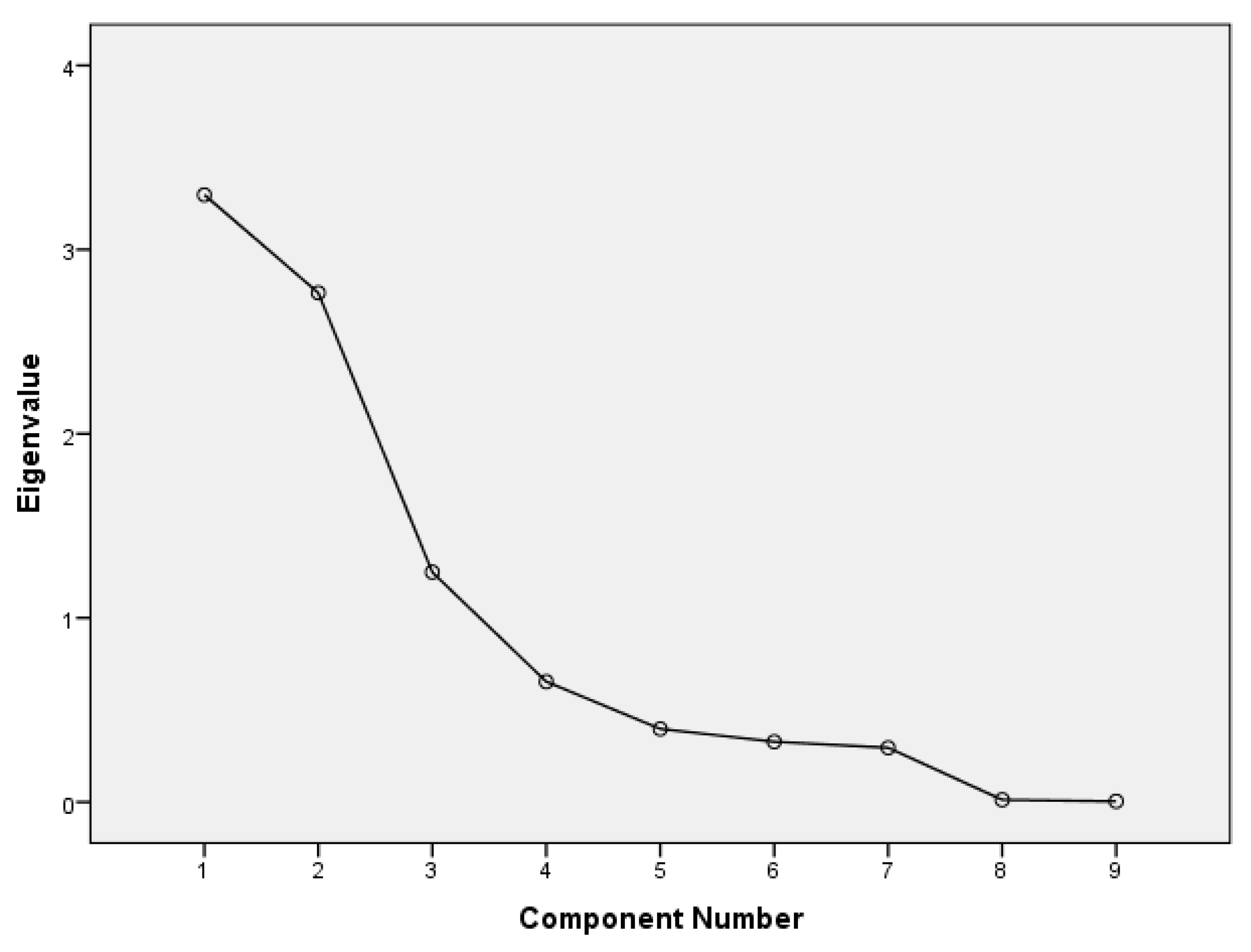

The second component PC2 involves increased overburden thickness (Var 3), the total lignite block thickness (Var 4) and the total intermediate waste thickness to exploitable lignite (Var 5) in combination with increased lower calorific value (Var 8), corresponding to a less financially efficient mineralized area. PC2 higher values are dominant in the drill-holes which are mainly located in the eastern part of the deposit, next to mountain Voras and in the southeast part of the deposit next to Petron Lake.

The third component PC3 is positively related to high total lignite block thickness (Var 4), high total intermediate waste thickness to exploitable lignite (Var 5), high ash dry content of exploitable lignite (Var 6), low lignite deposit bottom elevation (Var 2), the overburden thickness (Var 3), the low calorific value (Var 8), as well as low strip ratio (Var 9). PC3 higher values are dominant mainly in the central part of the deposit and characterize a low financially efficient mineralized area. The remaining principal components are considered insignificant, since each explains less than 8% of the total sampling cloud variance.

Based on the above results of PCA, the revealed spatial relationships of PC1, PC2 and PC3 permit a better understanding of the deposit structure regarding the spatial variability of the geometrical characteristics of the deposit, as well as of the lignite quality parameters. Furthermore, they are related to the mineralization pattern of the deposit (lignite deposit limits in

Figure 11 and

Figure 12) in combination with the orientation of the major faults (

Figure 3 and

Figure 4). The results also indicate that PCA can be a useful tool for orebody modeling and evaluation of multi-seam coal deposits.

In this framework, the results also highlighted that PCA can be used to efficiently analyze the spatial variability of specific deposit parameters that affect the cash flows of the mining project, estimate uncertainties, and optimize mine exploitation. In this way, the method can add value to mine planning. Taking into account that the design and scheduling phase in mine-planning is a multi-criteria, region and application-specific process, a scenario approach for the selection of the operation mode (direction of mine development and a parallel or a slewing pattern or a combination of both) could be based on the spatial distribution of the three principal components that were identified.

Considering the PCA results in relation to mine planning and design of the Klidi mine, the final mine boundary as well as the strategic mine development according to the successive excavation Sectors 1–4 (

Figure 12) is completely justified. The separated mineralized zone in the south is not significant according to the results of drill-holes evaluation. Considering the mine boundary according to the mine design shown in

Figure 12 the exploitable lignite reserves of the Klidi mine amount to 42 million tons with an average Strip Ratio of 10 m

3 of waste per ton of lignite and an average lower calorific value of 1750 kcal/kg.

This sequence of mine exploitation phases is mainly related to the following two objectives regarding the geologic model of the mineral deposit:

- (a)

Optimization of the mine operation and the lignite production schedule in relation to the time and spatial evolution of the strip ratio, based on discounted cash flow analysis, and

- (b)

Minimization of waste outside dumping volume

Compared to previously published results which also employed a PCA process, the results obtained in the present work refer to the application of a PCA for exploratory data analysis of multi-seam deposits and revealed the contribution of a PCA to a quantitative understanding and an efficient analysis of the spatial variations regarding critical parameters for mine planning purposes.

For an integrated approach, the mineral deposit model is combined with suitable geotechnical and hydrogeological analysis, as well as with an environmental impact assessment and the corresponding financial analysis [

36].

From the above analysis, it is obvious that a PCA can provide useful results considering the structural analysis of multi-seam coal deposits. Furthermore, it can be used to increase the efficiency of mine planning and design.

7. Conclusions

The implementation of principal component analysis on evaluated drill-hole data and its synergetic use with GIS spatial modeling techniques can become a very useful tool for mine planning and deposit structure identification. This integrated methodology can set the required criteria for optimum deposit segmentation, in terms of exploitation sequence, based on financial and other mining efficient parameters. This argument was proven in the present study, where the applied methodology in the Klidi area lignite deposit resulted in a productively suitable segmentation that was used for the exploitation planning and the progress of the mining works.

The revealed spatial relationships of the three principal components that were identified permit a better understanding of the deposit structure regarding the spatial variability of the geometrical characteristics of the deposit, as well as of the lignite quality parameters. Furthermore, they are related to the mineralization pattern of the deposit in combination with the orientation of the major faults. Therefore, the results are important for interpreting the geological characteristics of the mine site.

As a technique, a PCA can describe the variability of primary data and interpret their fluctuations and interrelationships, leading thus to the decrease of the initial dimensions of the studied phenomenon, in a way that no significant information is lost and at the same time the best understanding of the researched subject is deduced. This ability of this method along with GIS spatial analysis techniques, as was highlighted in the results of this study, is a well-suited approach for multi-seam deposit analysis, especially when big datasets (e.g., numerous records of drill-hole data) need to be processed, analyzed and evaluated. In parallel, in a more research perspective, this proposed methodology offers an alternative approach that can address the lack of analysis techniques when multi-seam deposits are concerned.

Compared with more traditional methods for the visualization of subsurface geology in multi-seam deposits based on drill-hole sequences and the data interpretation, a PCA can provide a deeper understanding of the related geological spatial variables. The principal advantage of the method lies in its ability to identify the dominant patterns among the variables and the deposit structure, contributing to the optimum planning of mine development.