Utilisation of Water-Washing Pre-Treated Phosphogypsum for Cemented Paste Backfill

Abstract

:1. Introduction

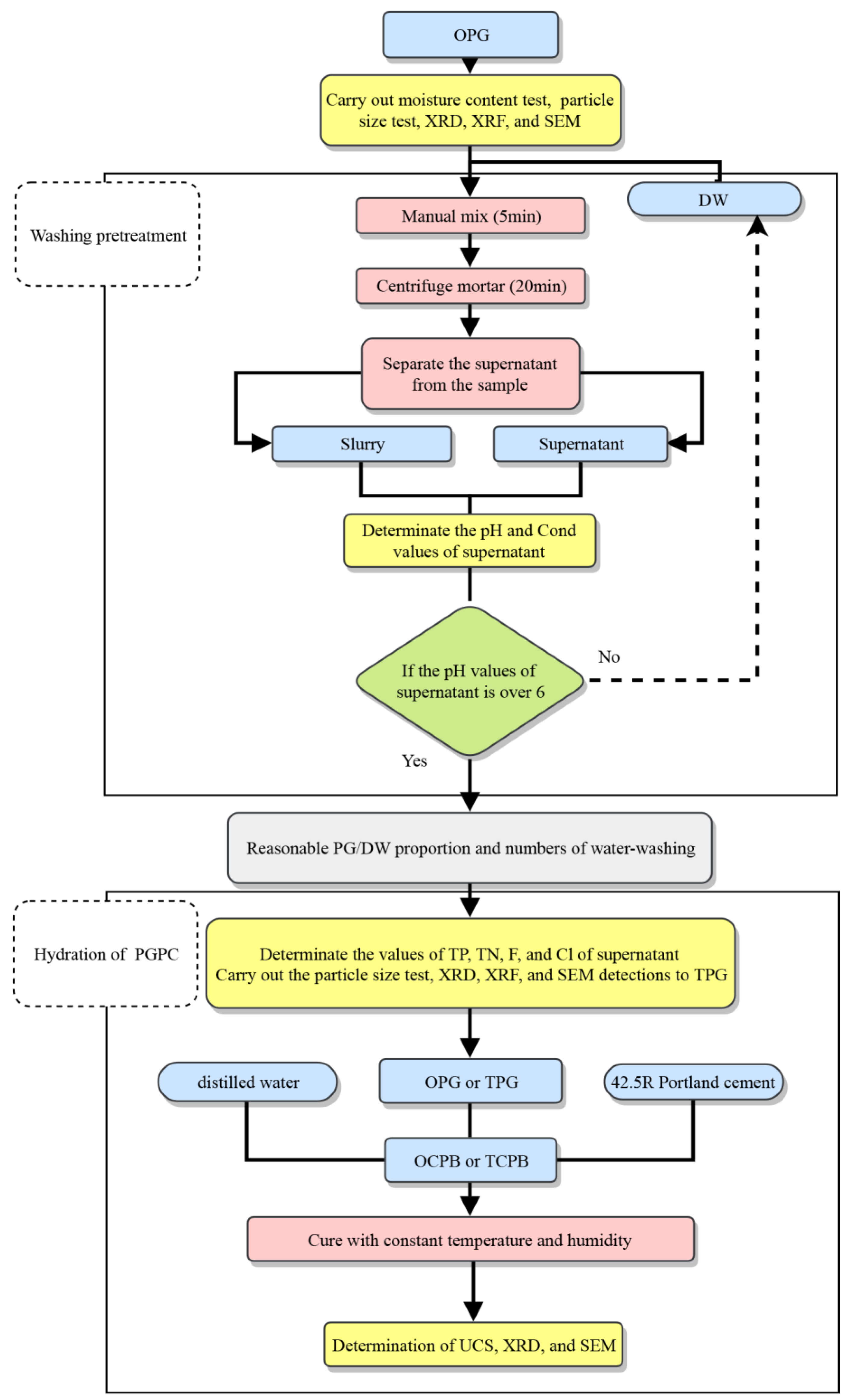

2. Materials and Methods

2.1. Raw Materials and Water-Washing Pre-Treatment

2.2. Mix Proportions and Cemented Paste Backfill (CPB) Preparation Process

2.3. Test Methods

2.3.1. Test of X-ray Fluorescence (XRF)

2.3.2. Test of Abrams Cone

2.3.3. Test of Uniaxial Compressive Strength (UCS)

2.3.4. Microstructural Analysis

3. Results and Discussion

3.1. Effect of Washing Pre-Treatment on Phosphogypsum (PG)

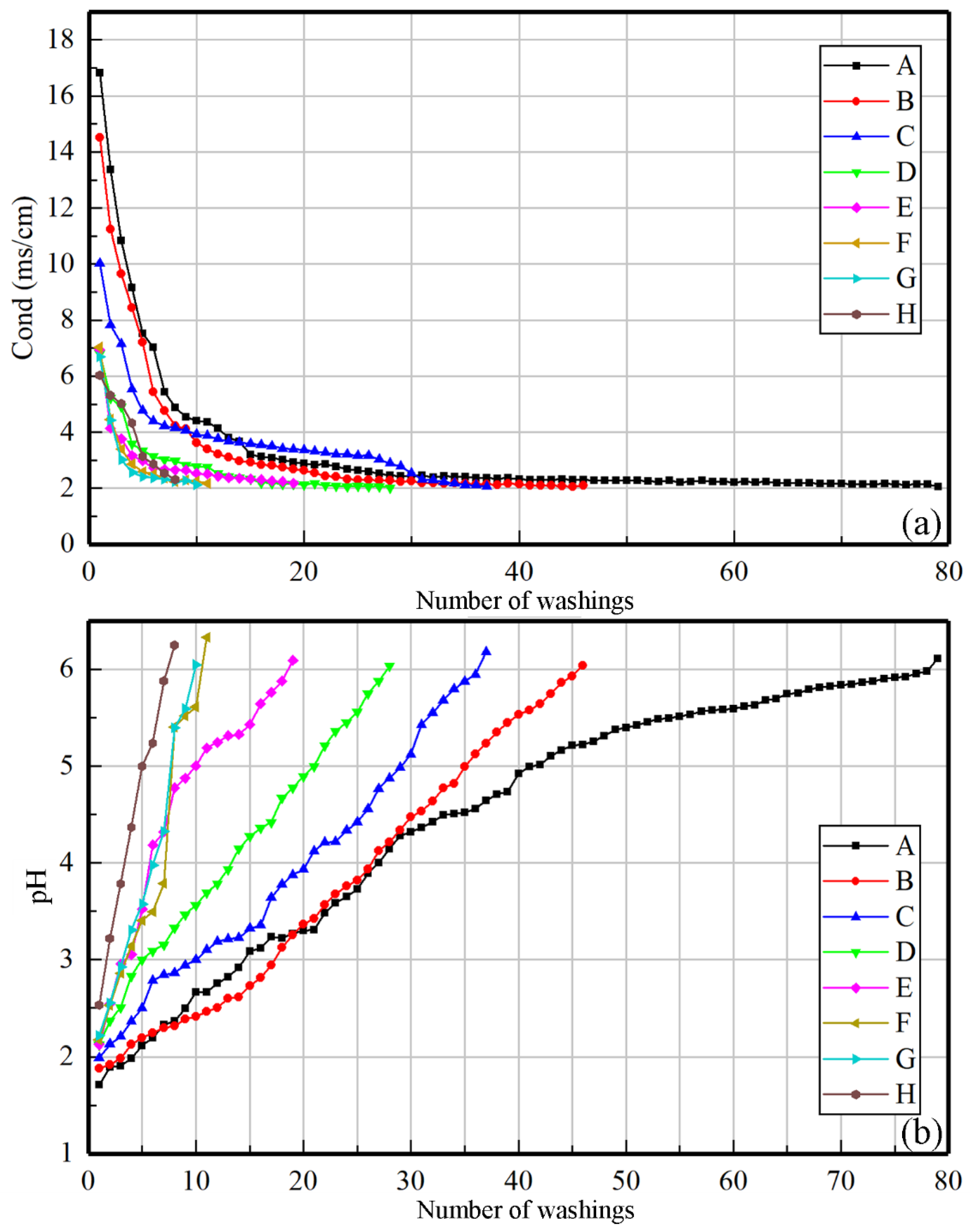

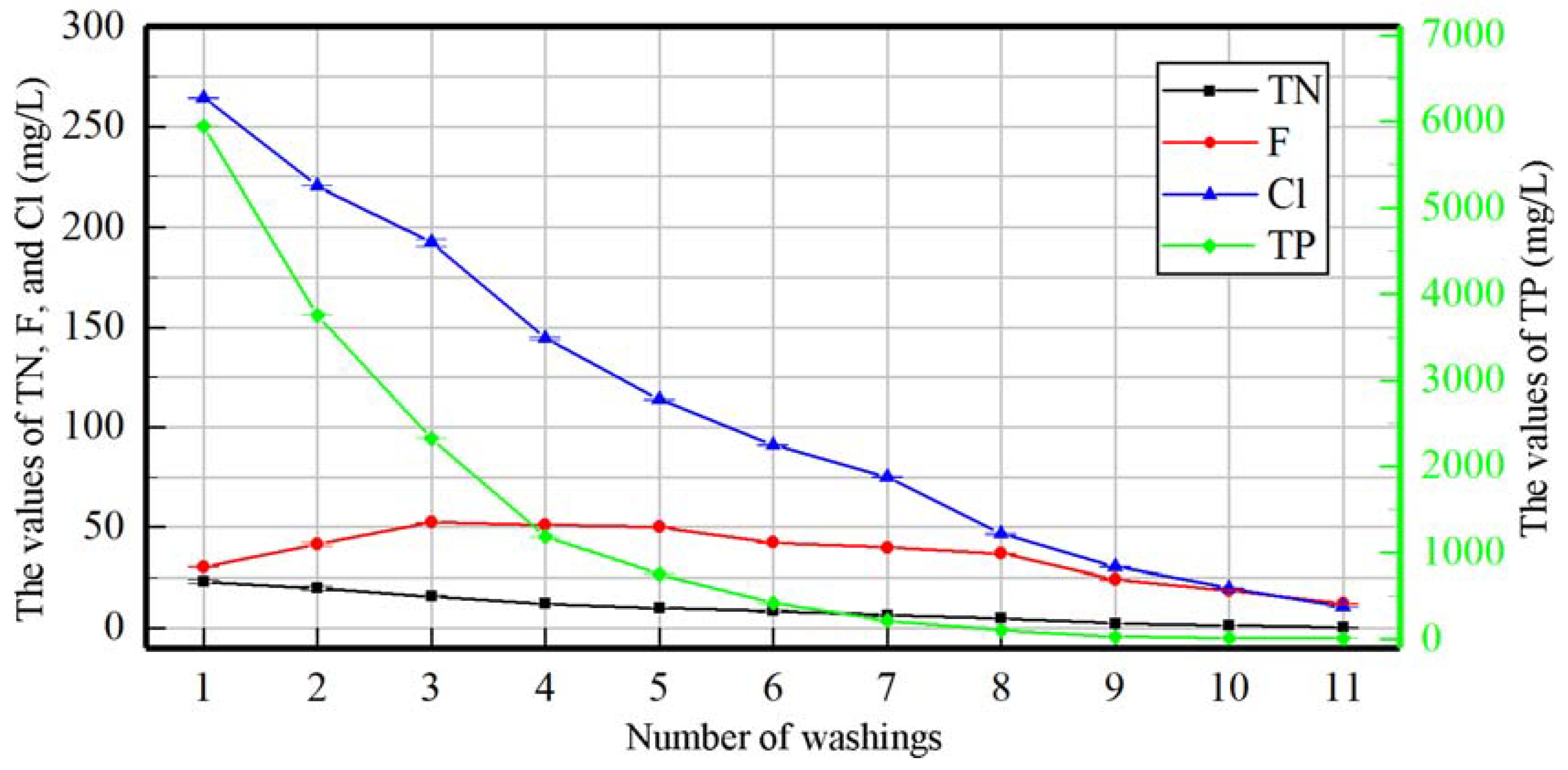

3.1.1. Changes of pH, Conductivity and Values of the Ions in the Supernatant

3.1.2. Analysis of XRF

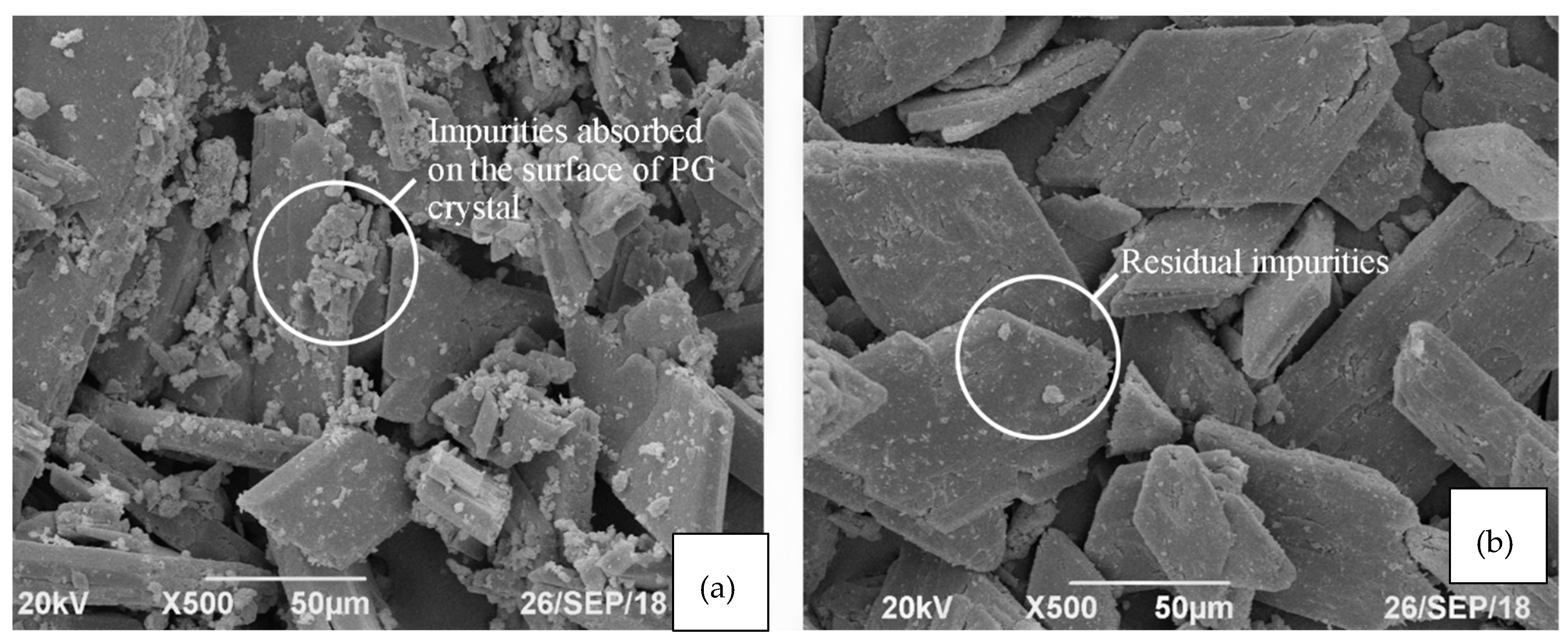

3.1.3. Analysis of Scanning Electron Microscopy (SEM)

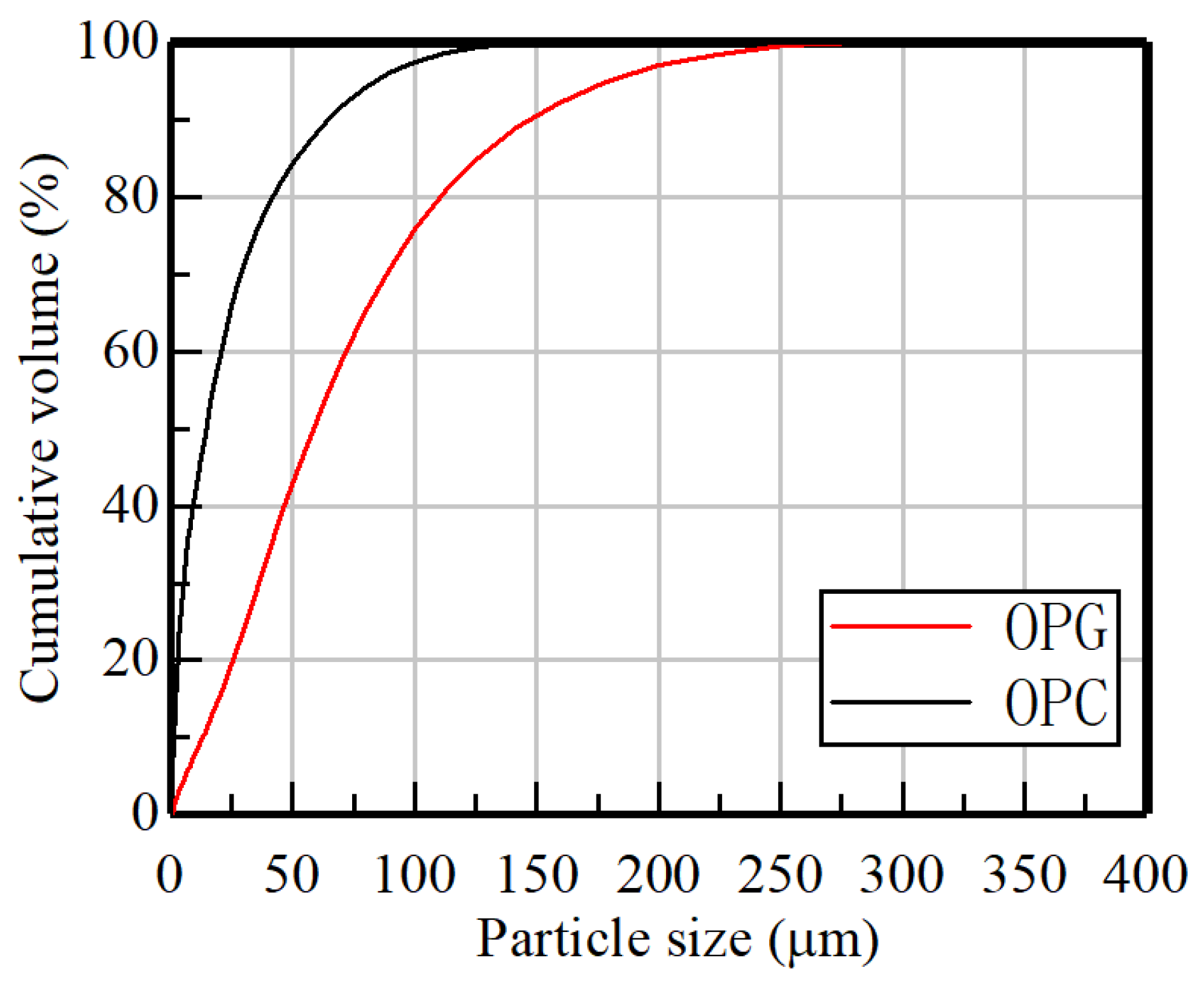

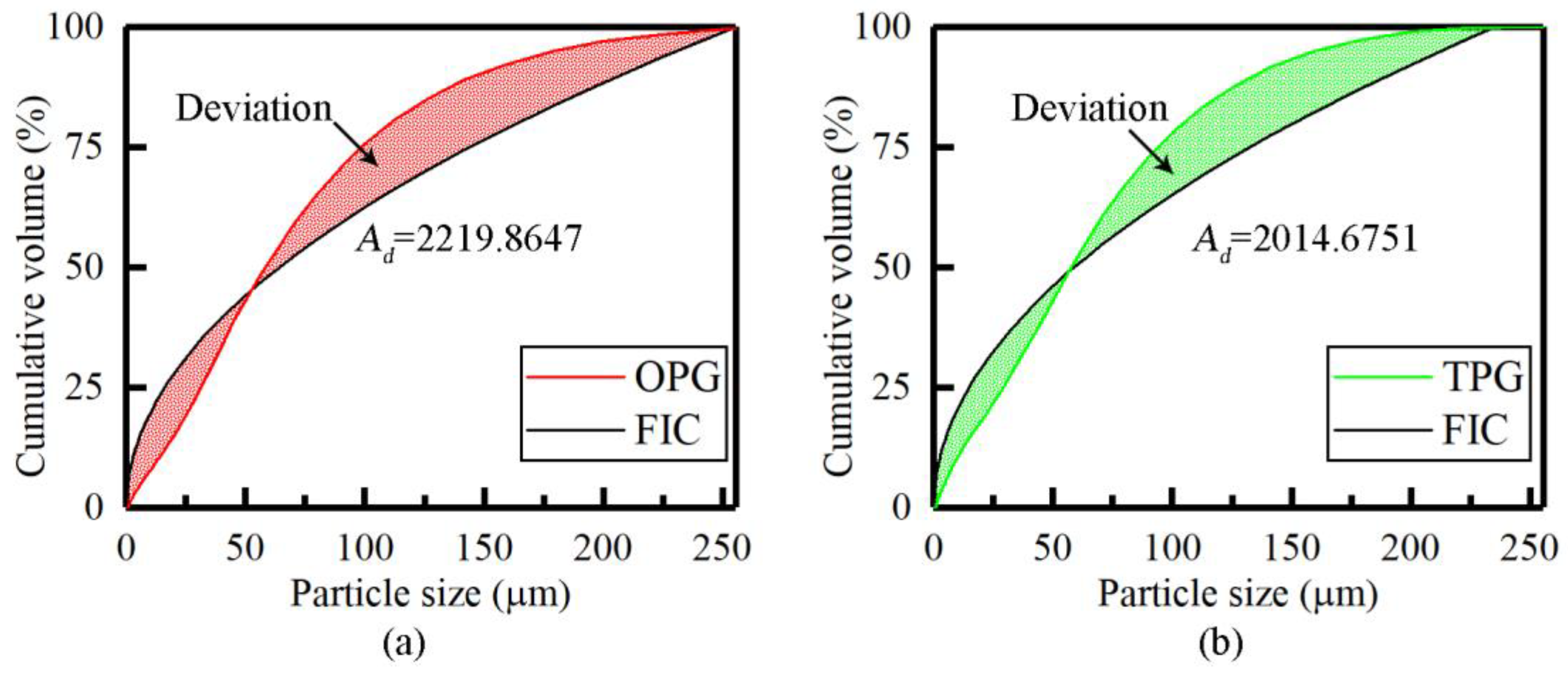

3.1.4. Analysis of the Particle Size

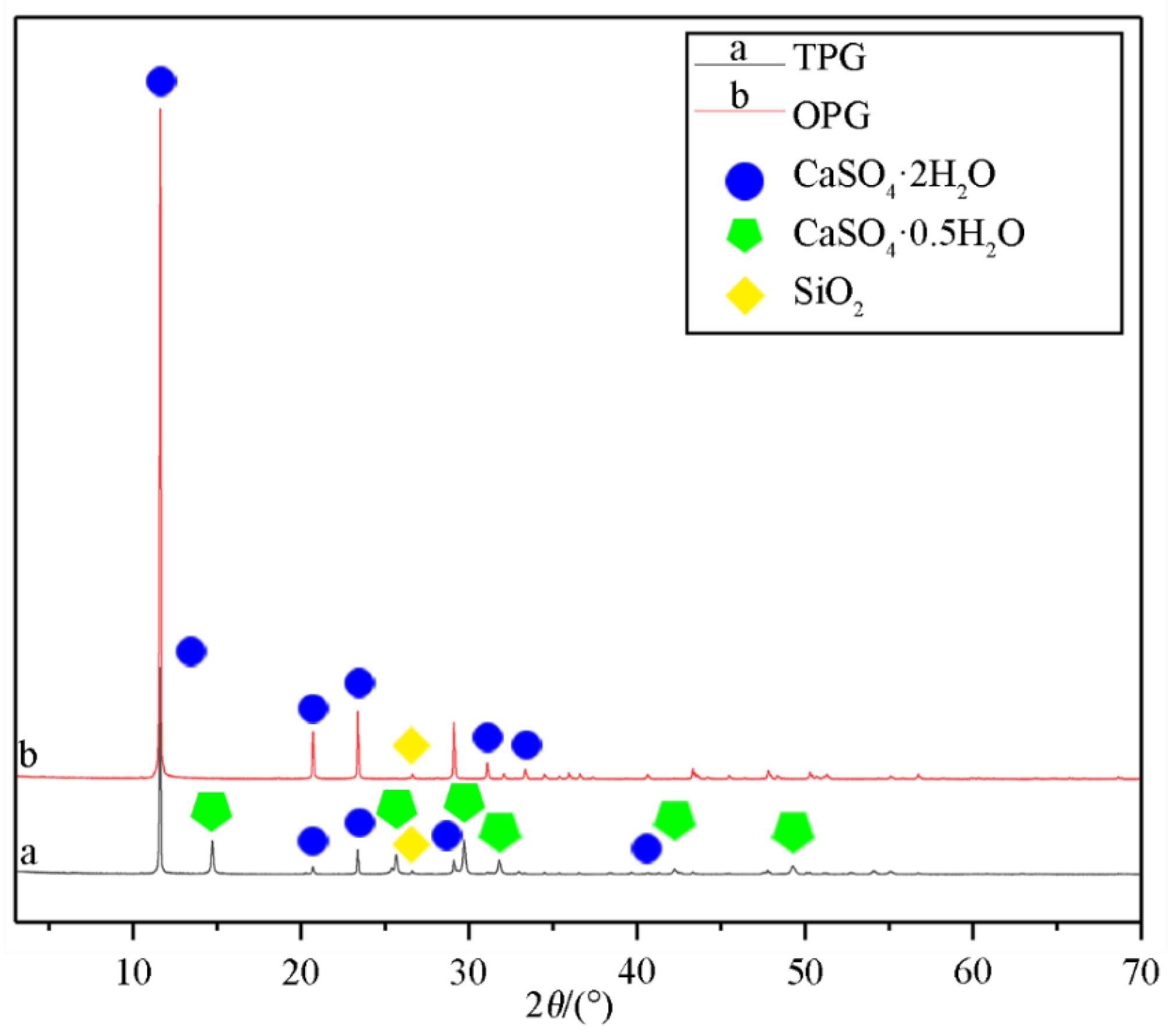

3.1.5. Analysis of X-ray Diffraction (XRD)

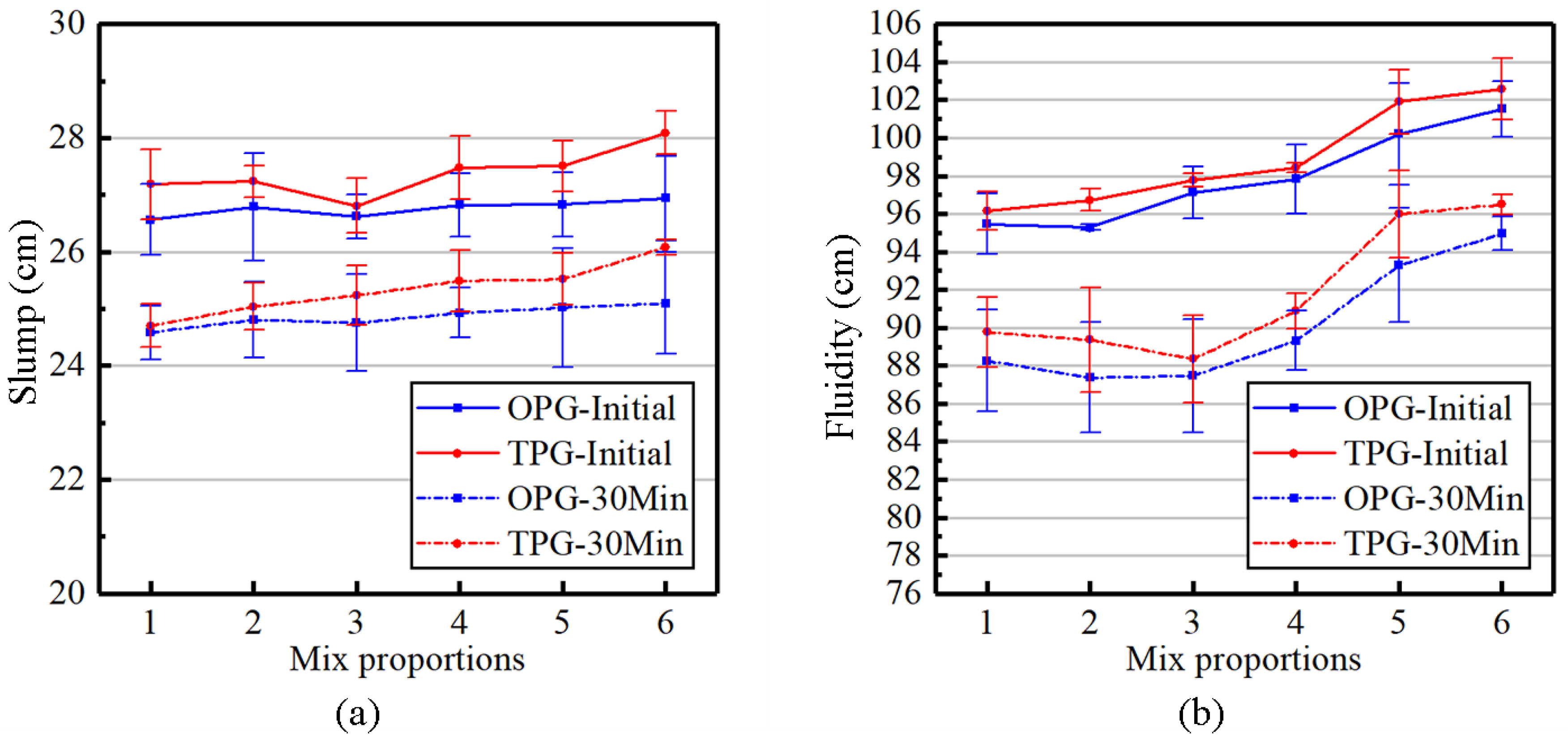

3.2. The Workability of PG-Based CPB

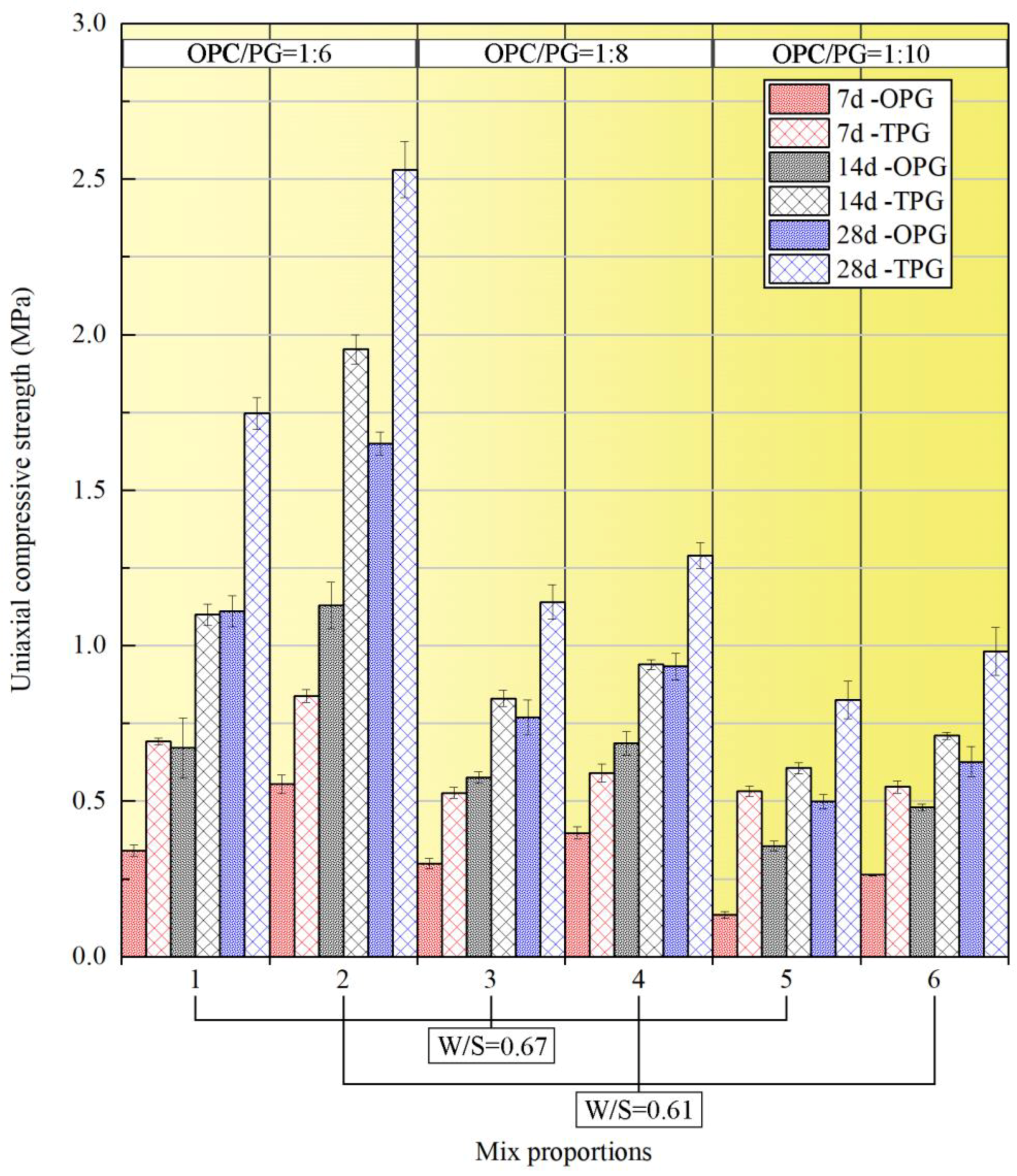

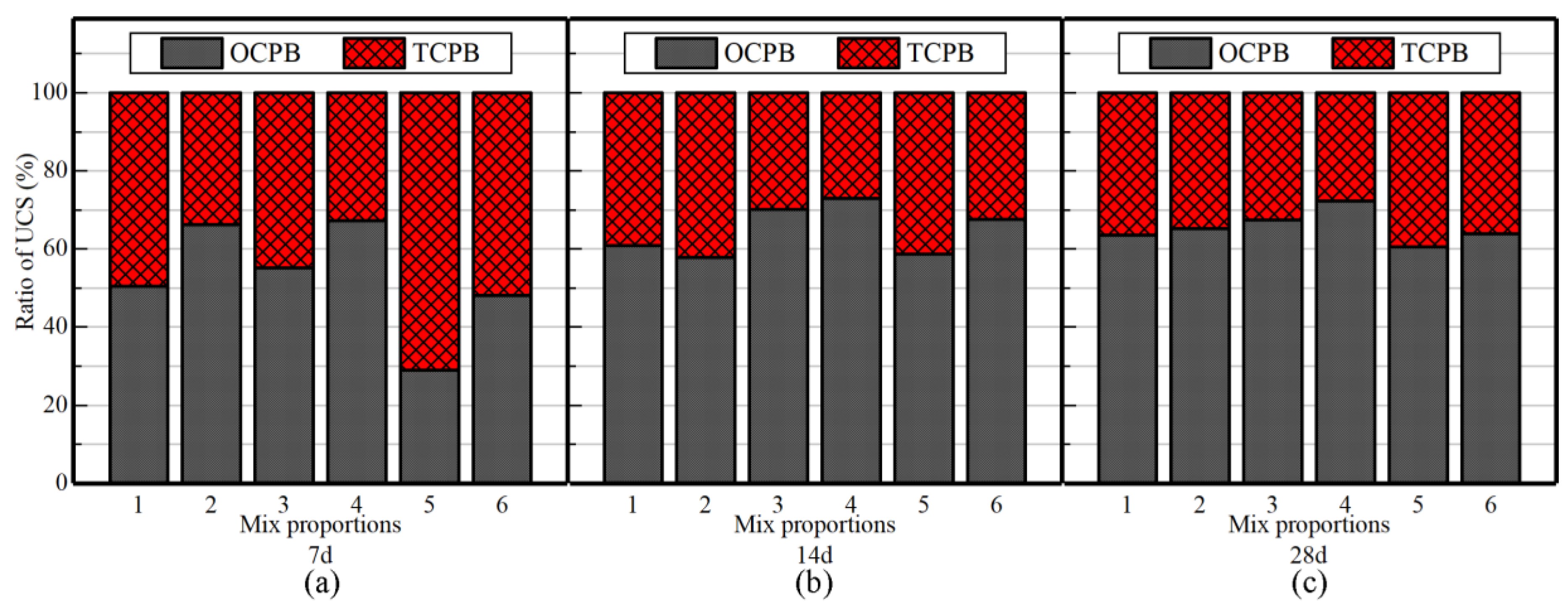

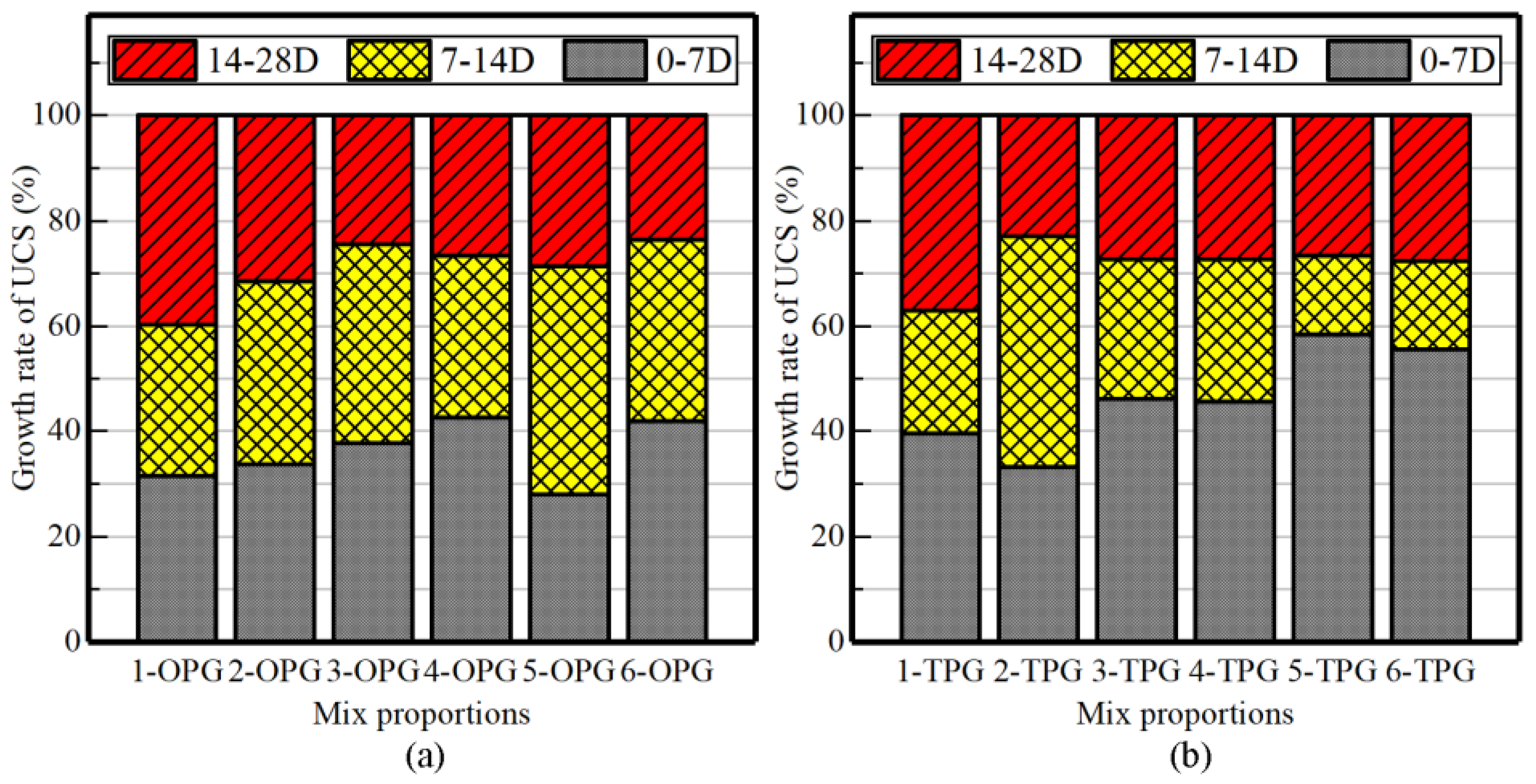

3.3. The UCS of PG-Based CPB

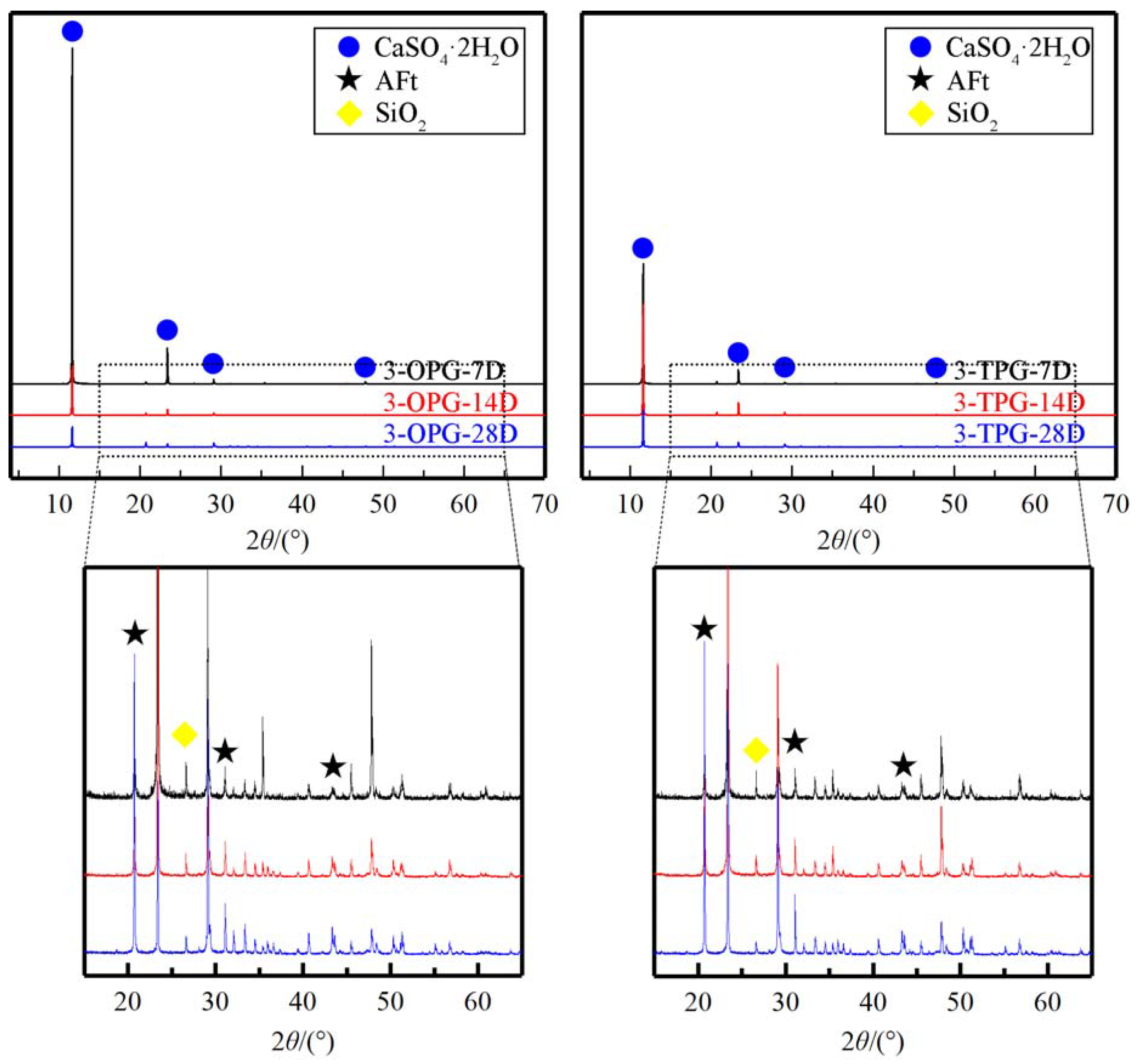

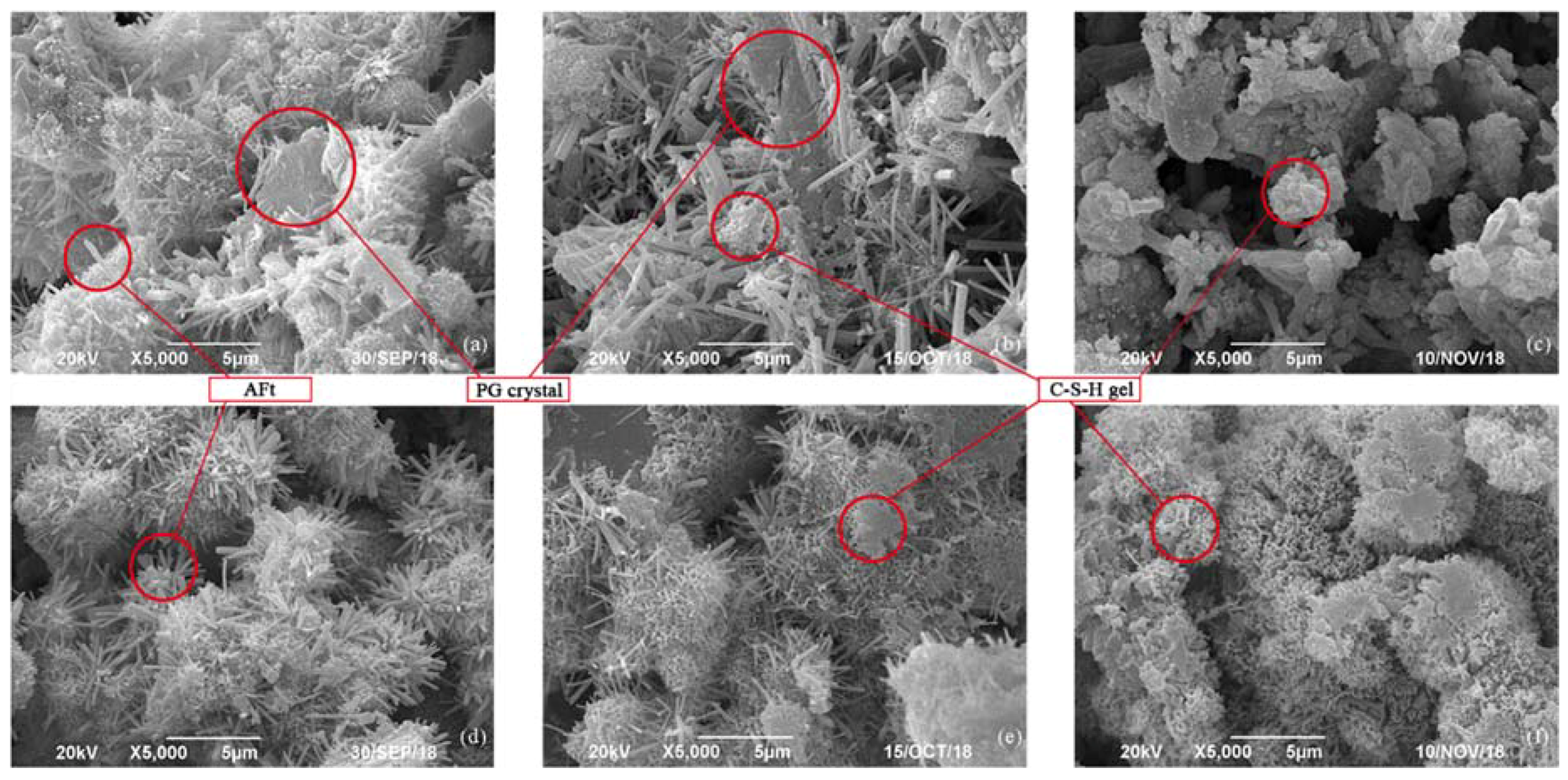

3.4. Microstructures of CPB

4. Conclusions

- During the water-washing pretreatment, a certain number of soluble impurities on the surface of PG crystals could be removed by water-washing, and the morphology and size of the PG crystals were slightly optimized for CPB.

- The water-washing pretreatment effectively improved the transport mobility and efficiency of the TCPB mixtures. The workability of the TCPB mixtures were greater than that of OCPB, which is beneficial to transport the TCPB to the stopes underground.

- Moreover, because of the purification by water-washing, the impurities, which greatly hamper the hydration process, were separated from the OPG. The UCS value of TCPB was up to 2.45 times higher than that of OCPB samples. It can be concluded that the figures for TCPB increase significantly from stages of 0 to 7 days, and the purification capacity of water-washing by enhance the early UCS growth rate.

- With the water-washing pretreatment, the diffraction peaks of AFt in the hydration system were also enhanced, although the diffraction peaks of some other hydration products were not found in the mineral phase due to the high PG content.

Author Contributions

Funding

Conflicts of Interest

References

- Howard, S.F.a.B.J. IAEA Technical Reports Series No. 475, Guidelines for Remediation Strategies to Reduce the Radiological Consequences of Environmental Contamination IAEA Safety Reports Series No. 78, Radiation Protection and Management of NORM Residues in the Phosphate Industry. J. Radiol. Prot. 2013, 33, 491–495. [Google Scholar] [CrossRef]

- Bisone, S.; Gautier, M.; Chatain, V.; Blanc, D. Spatial distribution and leaching behavior of pollutants from phosphogypsum stocked in a gypstack: Geochemical characterization and modeling. J. Environ. Manag. 2017, 193, 567–575. [Google Scholar] [CrossRef] [PubMed]

- Suárez, S.; Roca, X.; Gasso, S. Product-specific life cycle assessment of recycled gypsum as a replacement for natural gypsum in ordinary Portland cement: Application to the Spanish context. J. Clean. Prod. 2016, 117, 150–159. [Google Scholar] [CrossRef]

- Yang, J.; Liu, W.; Zhang, L.; Xiao, B. Preparation of load-bearing building materials from autoclaved phosphogypsum. Constr. Build. Mater. 2009, 23, 687–693. [Google Scholar] [CrossRef]

- Yang, L.; Yan, Y.; Hu, Z. Utilization of phosphogypsum for the preparation of non-autoclaved aerated concrete. Constr. Build. Mater. 2013, 44, 600–606. [Google Scholar] [CrossRef]

- Liang, H.; Zhang, P.; Jin, Z.; DePaoli, D. Rare Earth and Phosphorus Leaching from a Flotation Aggregate of Florida Phosphate Rock. Minerals 2018, 8, 416. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Q.; Fourie, A.; Xin, C. Utilization of phosphogypsum and phosphate aggregatefor cemented paste backfill. J. Environ. Manag. 2017, 201, 19–27. [Google Scholar] [CrossRef] [PubMed]

- Abril, J.M.; Garcia-Tenorio, R.; Perianez, R.; Enamorado, S.M.; Andreu, L.; Delgado, A. Occupational dosimetric assessment (inhalation pathway) from the application of phosphogypsum in agriculture in South West Spain. J. Environ. Radioactiv. 2009, 100, 29–34. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, Y.; Yan, Y. Utilization of original phosphogypsum as raw material for the preparation of self-leveling mortar. J. Clean. Prod. 2016, 127, 204–213. [Google Scholar] [CrossRef]

- Rajković, M.B.; Tošković, D.V. Phosphogypsum Surface Characterisation using Scanning Electron Microscopy. Acta Periodica Technol. 2003, 34, 61–70. [Google Scholar] [CrossRef]

- Ali, M.A.; Lee, C.H.; Kim, S.Y.; Kim, P.J. Effect of industrial by-products containing electron acceptors on mitigating methane emission during rice cultivation. Waste Manag. 2009, 29, 2759–2764. [Google Scholar] [CrossRef]

- Jiang, G.; Wu, A.; Wang, Y.; Lan, W. Low cost and high efficiency utilization of hemihydrate phosphogypsum: Used as binder to prepare filling material. Constr. Build. Mater. 2018, 167, 263–270. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Q.; Qi, C.; Fourie, A.; Xiao, C. Recycling phosphogypsum and construction demolition waste for cemented paste backfill and its environmental impact. J. Clean. Prod. 2018, 186, 418–429. [Google Scholar] [CrossRef]

- Shen, W.; Gan, G.; Dong, R.; Chen, H.; Tan, Y.; Zhou, M. Utilization of solidified phosphogypsum as Portland cement retarder. J. Mater. Cycles Waste 2012, 14, 228–233. [Google Scholar] [CrossRef]

- Yilmaz, E.; Belem, T.; Bussière, B.; Mbonimpa, M.; Benzaazoua, M. Curing time effect on consolidation behaviour of cemented paste backfill containing different cement types and contents. Constr. Build. Mater. 2015, 75, 99–111. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M.; Ouellet, S. Experimental characterization of the influence of aggregate fineness and density on the quality of cemented paste backfill. Miner. Eng. 2005, 18, 41–44. [Google Scholar] [CrossRef]

- Cihangir, F.; Akyol, Y. Mechanical, hydrological and microstructural assessment of the durability of cemented paste backfill containing alkali-activated slag. Int. J. Min. Reclam. Environ. 2018, 32, 123–143. [Google Scholar] [CrossRef]

- Ercikdi, B.; Cihangir, F.; Kesimal, A.; Deveci, H.; Alp, I. Utilization of water-reducing admixtures in cemented paste backfill of sulphide-rich mill Aggregate. J. Hazard. Mater. 2010, 179, 940–946. [Google Scholar] [CrossRef]

- Cihangir, F.; Ercikdi, B.; Kesimal, A.; Ocak, S.; Akyol, Y. Effect of sodium-silicate activated slag at different silicate modulus on the strength and microstructural properties of full and coarse sulphidic aggregate paste backfill. Constr. Build. Mater. 2018, 185, 555–566. [Google Scholar] [CrossRef]

- Dang, W.G.; Liu, Z.X.; He, X.Q.; Liu, Q.L.J.M.T. Mixture ratio of phosphogypsum in backfilling. Min. Technol. 2013, 122, 1–7. [Google Scholar] [CrossRef]

- Shen, W.; Zhou, M.; Zhao, Q. Study on lime–fly ash–phosphogypsum binder. Constr. Build. Mater. 2007, 21, 1480–1485. [Google Scholar] [CrossRef]

- Nizevičienė, D.; Vaičiukynienė, D.; Michalik, B.; Bonczyk, M.; Vaitkevičius, V.; Jusas, V.J.C.; Materials, B. The treatment of phosphogypsum with zeolite to use it in binding material. Constr. Build. Mater. 2018, 180, 134–142. [Google Scholar] [CrossRef]

- Shen, Y.; Qian, J.; Huang, Y.; Yang, D. Synthesis of belite sulfoaluminate-ternesite cements with phosphogypsum. Cem. Concr. Comp. 2015, 63, 67–75. [Google Scholar] [CrossRef]

- Li, X.; Du, J.; Gao, L.; He, S.; Gan, L.; Sun, C.; Shi, Y. Immobilization of phosphogypsum for cemented paste backfill and its environmental effect. J. Clean. Prod. 2017, 156, 137–146. [Google Scholar] [CrossRef]

- Romero-Hermida, M.I.; Borrero-López, A.M.; Alejandre, F.J.; Flores-Alés, V.; Santos, A.; Franco, J.M.; Esquivias, L. Phosphogypsum waste lime as a promising substitute of commercial limes: A rheological approach. Cem. Concr. Comp. 2019, 95, 205–216. [Google Scholar] [CrossRef]

- Taher, M.A. Influence of thermally treated phosphogypsum on the properties of Portland slag cement. Resour. Conserv. Recycl. 2007, 52, 28–38. [Google Scholar] [CrossRef]

- Singh, M. Treating waste phosphogypsum for cement and plaster manufacture. Cem. Concr. Res. 2002, 32, 1033–1038. [Google Scholar] [CrossRef]

- Mun, K.J.; Hyoung, W.K.; Lee, C.W.; So, S.Y.; Soh, Y.S. Basic properties of non-sintering cement using phosphogypsum and waste lime as activator. Constr. Build. Mater. 2007, 21, 1342–1350. [Google Scholar] [CrossRef]

- Potgieter, J.H.; Potgieter, S.S.; McCrindle, R.I.; Strydom, C.A. An investigation into the effect of various chemical and physical treatments of a South African phosphogypsum to render it suitable as a set retarder for cement. Cem. Concr. Res. 2003, 33, 1223–1227. [Google Scholar] [CrossRef]

- Kamimura, A.; Konno, E.; Yamamoto, S.; Watanabe, T.; Yamada, K.; Tomonaga, F. Improved method for the formation of recycled resins from depolymerized products of waste fiber-reinforced plastics: Simple and effective purification of recovered monomers by washing with water. J. Mater. Cycles Waste 2009, 11, 133–137. [Google Scholar] [CrossRef]

- Slavinskaya, G.V. Water pretreatment to remove organic impurities and desalination with ion exchangers. Russ. J. Appl. Chem. 2003, 76, 1089–1093. [Google Scholar] [CrossRef]

- Shuang, Y.; Hou, Y.; Zhang, B.; Yang, H.G. Impurity-Free Synthesis of Cube-Like Single-Crystal Anatase TiO2 for High Performance Dye-Sensitized Solar Cell. Ind. Eng. Chem. Res. 2013, 52, 4098–4102. [Google Scholar] [CrossRef]

- Ali, M.A.; Kim, P.J.; Inubushi, K. Mitigating yield-scaled greenhouse gas emissions through combined application of soil amendments: A comparative study between temperate and subtropical rice paddy soils. Sci. Total Environ. 2015, 529, 140–148. [Google Scholar] [CrossRef]

- Cárdenas-Escudero, C.; Morales-Flórez, V.; Pérez-López, R.; Santos, A.; Esquivias, L. Procedure to use phosphogypsum industrial waste for mineral CO2 sequestration. J. Hazard. Meter. 2011, 196, 431–435. [Google Scholar] [CrossRef]

- General Purpose Portland Cement; B175-2007; Standardization Administration of China: Beijing, China, 2007.

- Environmental Quality Standards for Surface Water; GB 3838-2002; Standardization Administration of China: Beijing, China, 2002.

- Integrated Wastewater Discharge Standard; GB 8978-1996; Standardization Administration of China: Beijing, China, 1996.

- Mould for Concrete Specimens; JG237-2008; Ministry of Housing and Urban-Rural Construction of the People’s Republic of China: Beijing, China, 2008.

- Wu, A.; Wang, Y.; Wang, H.; Yin, S.; Miao, X. Coupled effects of cement type and water quality on the properties of cemented paste backfill. Int. J. Min. Process. 2015, 143, 65–71. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.; Qi, C.; Zhang, B.; Guo, L.; Song, K.I.I.L. Numerical study on the pipe flow characteristics of the cemented paste backfill slurry considering hydration effects. Powder Technol. 2019, 343, 454–464. [Google Scholar] [CrossRef]

- Qi, C.; Chen, Q.; Fourie, A.; Zhao, J.; Zhang, Q. Pressure drop in pipe flow of cemented paste backfill: Experimental and modeling study. Powder Technol. 2018, 333, 9–18. [Google Scholar] [CrossRef]

- Standard Test Method for Slump of Hydraulic-Cement Concrete; C143/C143M-2015; American Society for Testing and Materials International (ASTM): West Conshohocken, PA, USA, 2015.

- Qi, C.; Chen, Q.; Fourie, A.; Tang, X.; Zhang, Q.; Dong, X.; Feng, Y. Constitutive modelling of cemented paste backfill: A data-mining approach. Constr. Build. Mater. 2019, 197, 262–270. [Google Scholar] [CrossRef]

- Standard Test Methods for Compressive Strength of Cylindrical Concrete Specimens; C39 C39M-2014a; American Society for Testing and Materials International (ASTM): West Conshohocken, PA, USA, 2015.

- Liu, T. Study on Pretreatment and Application of Phosphogypsum. Master’s Thesis, Wuhan University, Wuhan, China, 2010. [Google Scholar]

- Wang, A.Q.; Zhang, C.Z.; Zhang, N.S. The theoretic analysis of the influence of the particle size distribution of cement system on the property of cement. Cem. Concr. Res. 1999, 29, 1721–1726. [Google Scholar] [CrossRef]

- Sari, D.; Pasamehmetoglu, A.G. The effects of gradation and admixture on the pumice lightweight aggregate concrete. Cem. Concr. Res. 2005, 35, 936–942. [Google Scholar] [CrossRef]

- Yao, W. Research and Application of High Concentration Filling Theory of Coarse Aggregate in Mines. Ph.D. Thesis, Kunming University of Science and Technology, Kunming, China, 2011. [Google Scholar]

- Yang, J.-C.; Wu, H.-D.; Teng, N.-C.; Ji, D.-Y.; Lee, S.-Y. Novel attempts for the synthesis of calcium sulfate hydrates in calcium chloride solutions under atmospheric conditions. Ceram. Int. 2012, 38, 381–387. [Google Scholar] [CrossRef]

- Ma, B.; Lu, W.; Su, Y.; Li, Y.; Gao, C.; He, X. Synthesis of α-hemihydrate gypsum from cleaner phosphogypsum. J. Clean. Prod. 2018, 195, 396–405. [Google Scholar] [CrossRef]

- Belem, T.; Benzaazoua, M. Design and application of underground mine paste backfill technology. Geotech. Geol. Eng. 2008, 26, 147–174. [Google Scholar] [CrossRef]

- Li, M.; Moerman, A. Perspectives on the scientific and engineering principles underlying flow of mineral pastes. In Proceedings of the 34th Annual Meeting of CMP, Ottawa, ON, Canada, 22–24 January 2002; Paper No. 35. pp. 573–595. [Google Scholar]

- Akın Altun, İ.; Sert, Y. Utilization of weathered phosphogypsum as set retarder in Portland cement. Cem. Concr. Res. 2004, 34, 677–680. [Google Scholar] [CrossRef]

- Guo, C. Effect Mechanism of Fluorine and Phosphorus on Hydration Process of Cement Clinker. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2012. [Google Scholar]

- Chen, X.; Gao, J.; Liu, C.; Zhao, Y. Effect of neutralization on the setting and hardening characters of hemihydrate phosphogypsum plaster. Constr. Build. Mater. 2018, 190, 53–64. [Google Scholar] [CrossRef]

| Chemical Composition (%) | OPC | OPG |

|---|---|---|

| Na2O | 0.090 | 0.150 |

| MgO | 1.840 | 0.111 |

| Al2O3 | 4.420 | 0.782 |

| SiO2 | 17.94 | 5.730 |

| P2O5 | 0.215 | 1.224 |

| SO3 | 3.400 | 41.504 |

| Cl | 0.022 | - |

| K2O | 0.671 | 0.674 |

| CaO | 60.850 | 44.897 |

| TiO2 | 0.307 | 0.648 |

| V2O5 | 0.040 | - |

| Cr2O3 | 0.025 | - |

| MnO | 0.265 | - |

| Fe2O3 | 3.814 | 3.208 |

| CuO | 0.015 | - |

| ZnO | 0.043 | - |

| Rb2O | 0.003 | - |

| SrO | 0.067 | 0.142 |

| ZrO2 | 0.010 | - |

| BaO | 0.034 | 0.113 |

| F | - | 0.817 |

| Loss | 5.929 | - |

| Physical Properties | OPC | OPG |

|---|---|---|

| SSA (m2/g) | 1.690 | 0.324 |

| D [4,3] (μm) | 24.449 | 69.935 |

| D10 (μm) | 1.426 | 13.176 |

| D50 (μm) | 14.641 | 58.329 |

| D90 (μm) | 64.392 | 146.589 |

| Dd<20 μm (%) | 57.84 | 81.78 |

| Moisture content (%) | - | 18.26 |

| Natural density (g/cm3) | 2.94 | 1.62 |

| Dry density (g/cm3) | - | 0.86 |

| No. | Weight of OPG | DW (g) | PG:DW | Number of Washes | Total DW (g) | |

|---|---|---|---|---|---|---|

| Wet (g) | Dry (g) | |||||

| A | 1000.00 | 817.40 | 226.10 | 1:0.50 | 79 | 17,861.90 |

| B | 1000.00 | 817.40 | 430.45 | 1:0.75 | 46 | 19,800.70 |

| C | 1000.00 | 817.40 | 634.80 | 1:1.00 | 37 | 23,487.60 |

| D | 1000.00 | 817.40 | 839.15 | 1:1.25 | 28 | 23,496.20 |

| E | 1000.00 | 817.40 | 1043.50 | 1:1.50 | 19 | 19,826.50 |

| F | 1000.00 | 817.40 | 1247.85 | 1:1.75 | 11 | 13,726.35 |

| G | 1000.00 | 817.40 | 1452.20 | 1:2.00 | 10 | 14,522.00 |

| H | 1000.00 | 817.40 | 1860.90 | 1:2.50 | 8 | 14,887.20 |

| No. | OPC | OPG (Dry) | TPG (Dry) | Water | Water/Solid | Water/Cement |

|---|---|---|---|---|---|---|

| 1-OPG | 8.57% | 62.92% | - | 28.51% | 0.67 | 3.33 |

| 2-OPG | 8.86% | 65.01% | - | 26.13% | 0.61 | 2.95 |

| 3-OPG | 6.67% | 65.25% | - | 28.09% | 0.67 | 4.21 |

| 4-OPG | 6.89% | 67.42% | - | 25.69% | 0.61 | 3.73 |

| 5-OPG | 5.45% | 66.73% | - | 27.82% | 0.67 | 5.10 |

| 6-OPG | 5.64% | 68.95% | - | 25.41% | 0.61 | 4.51 |

| 1-TPG | 8.57% | - | 62.92% | 28.51% | 0.67 | 3.33 |

| 2-TPG | 8.86% | - | 65.01% | 26.13% | 0.61 | 2.95 |

| 3-TPG | 6.67% | - | 65.25% | 28.09% | 0.67 | 4.21 |

| 4-TPG | 6.89% | - | 67.42% | 25.69% | 0.61 | 3.73 |

| 5-TPG | 5.45% | - | 66.73% | 27.82% | 0.67 | 5.10 |

| 6-TPG | 5.64% | - | 68.95% | 25.41% | 0.61 | 4.51 |

| Chemical Composition (%) | Na2O | MgO | Al2O3 | SiO2 | P2O5 | SO3 | K2O |

| TPG | 0.065 | 0.005 | 0.300 | 5.194 | 0.714 | 45.014 | 0.298 |

| Chemical Composition (%) | CaO | TiO2 | Fe2O3 | SrO | BaO | F | Loss |

| TPG | 46.526 | 0.526 | 0.663 | 0.067 | 0.096 | 0.532 | - |

| Physical Properties | SSA (m2/g) | D[4,3] (μm) | D10 (μm) | D50 (μm) | D90 (μm) | Dd<20 μm (%) |

|---|---|---|---|---|---|---|

| TPG | 0.277 | 66.801 | 9.265 | 57.593 | 133.816 | 84.91 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zhang, Q.; Chen, Q.; Qi, C.; Su, Z.; Huang, Z. Utilisation of Water-Washing Pre-Treated Phosphogypsum for Cemented Paste Backfill. Minerals 2019, 9, 175. https://doi.org/10.3390/min9030175

Liu Y, Zhang Q, Chen Q, Qi C, Su Z, Huang Z. Utilisation of Water-Washing Pre-Treated Phosphogypsum for Cemented Paste Backfill. Minerals. 2019; 9(3):175. https://doi.org/10.3390/min9030175

Chicago/Turabian StyleLiu, Yikai, Qinli Zhang, Qiusong Chen, Chongchong Qi, Zhu Su, and Zhaodong Huang. 2019. "Utilisation of Water-Washing Pre-Treated Phosphogypsum for Cemented Paste Backfill" Minerals 9, no. 3: 175. https://doi.org/10.3390/min9030175

APA StyleLiu, Y., Zhang, Q., Chen, Q., Qi, C., Su, Z., & Huang, Z. (2019). Utilisation of Water-Washing Pre-Treated Phosphogypsum for Cemented Paste Backfill. Minerals, 9(3), 175. https://doi.org/10.3390/min9030175